Improved low-temperature vacuum drying oven

A low-temperature vacuum drying and vacuum tube technology, which is used in dryers for static materials, drying solid materials, drying chambers/containers, etc. Improve drying efficiency, reduce drying energy loss, and avoid dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

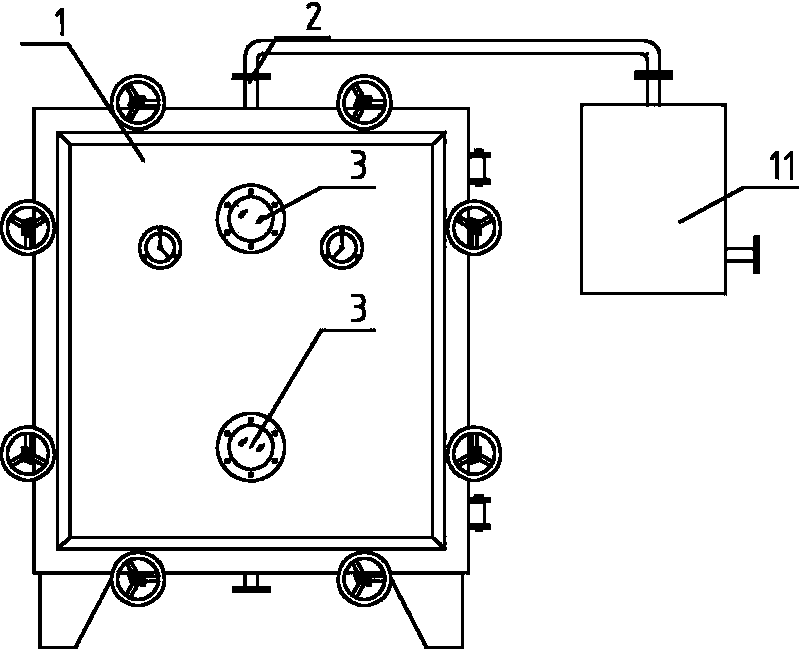

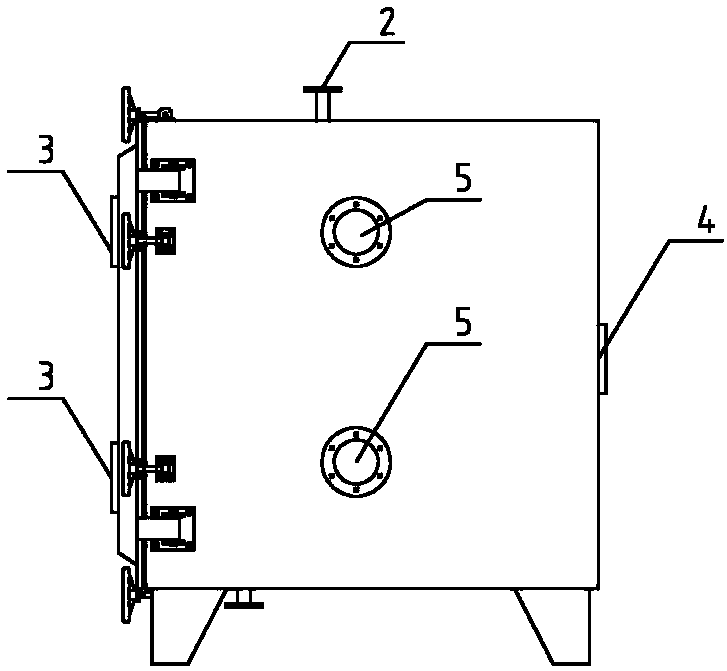

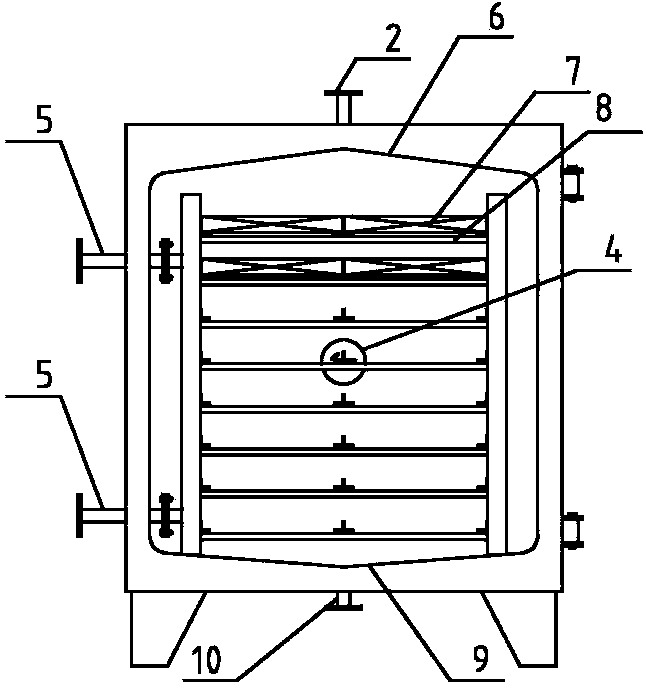

[0017] Example: Low-temperature vacuum drying oven of the present invention, its structure schematic diagram is as figure 1 As shown, the side view is as figure 2 As shown, the cross-sectional view is as image 3 As shown, it includes a casing 1, a drying rack 8 and a baking tray 7.

[0018] The size of the box body 1 is 1.5m×1.5m×1.5m. The front-view mirror 3 is arranged at the upper middle and lower parts of the front of the box body 1, and the rear-view mirror 4 is arranged at the center of the back of the box body 1. The inner wall of the box body 1 is in line with the An insulation layer is arranged in the middle of the outer wall. The thickness of the insulation layer is 80mm. The insulation material is filled with aluminum silicate refractory fiber cotton. The top of the top 6 is connected to the vacuum tube 2, the vacuum tube 2 is connected to the buffer tank 11, and the inner bottom 9 at the bottom of the vacuum operation is concave, and the concave bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com