Interlayer vacuumizing method for cryogenic vessel and special device thereof

A technology of vacuuming and vacuuming systems, applied in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve problems such as adverse effects, and achieve the goal of improving qualified indicators, improving container pumping quality, and shortening pumping time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

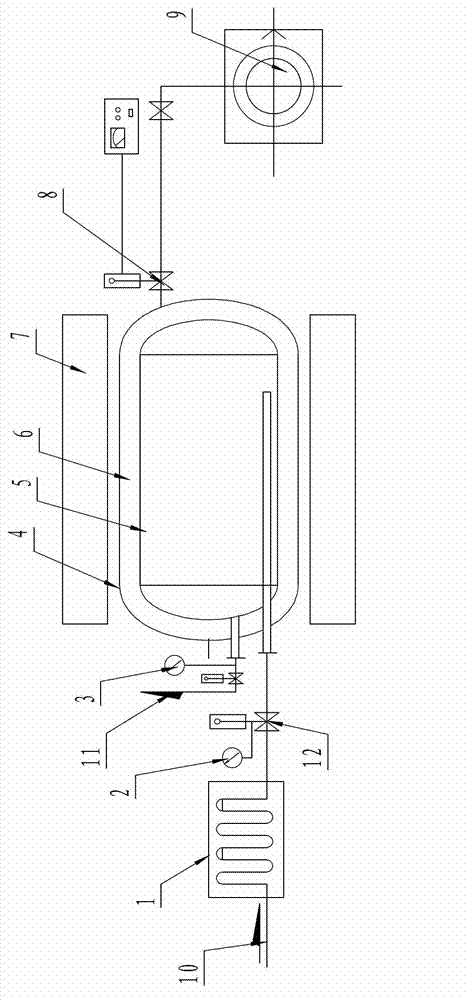

[0013] Embodiment 1, a method for vacuuming the interlayer of a cryogenic container, is characterized in that: use heating equipment to heat the outer cylinder of the cryogenic container, and continuously fill N2 heated to 350-370°C into the inner tank of the cryogenic container, Control the inlet pressure at 0.4Mpa; the outlet pressure at 0.2Mpa, and use a vacuum pump to heat the interlayer 6 between the outer cylinder and the inner tank of the cryogenic vessel while heating the outer cylinder 4 and the inner tank 5 of the cryogenic vessel at the same time. Do a vacuum.

Embodiment 2

[0014] Embodiment 2, the special device used in the method of vacuuming the interlayer of cryogenic containers, is characterized in that: it includes an inner tank heating system, an outer cylinder heating device and an interlayer vacuuming system,

[0015] The inner tank heating system includes a nitrogen heating furnace 1, a hot nitrogen temperature measuring and pressure measuring device 2 installed between the nitrogen heating furnace and the nitrogen inlet pipe of the inner tank, and a nitrogen outlet temperature measuring and pressure measuring device installed on the nitrogen outlet pipe device 3,

[0016] The outer cylinder heating device 7 is a heating furnace capable of heating the entire outer cylinder,

[0017] The interlayer vacuum pumping system includes a vacuum pump 9, a vacuum valve and a vacuum measuring device 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com