Patents

Literature

115results about How to "Reduce pumping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preventing flow through subterranean zones

InactiveUS6843841B2Avoid flowKeep for a long timeCosmetic preparationsToilet preparationsCross-linkPolymer science

The present invention provides methods of preventing the flow of water or gas or both through a subterranean zone having a high temperature and a depth such that a long pumping time is required to place a sealing composition therein. The methods basically comprise the steps of preparing a polymeric sealing composition comprised of water, a cross-linking agent and a selected water-soluble polymer which reacts with the cross-linking agent and forms a sealing gel which is stable for a desired period of time at the temperature of the zone and has a pumping time before gelation in the presence of the cross-linking agent whereby the composition can be pumped to the depth of the zone and placed therein. Thereafter, the sealing composition is pumped into the zone and allowed to form a sealing gel therein.

Owner:HALLIBURTON ENERGY SERVICES INC

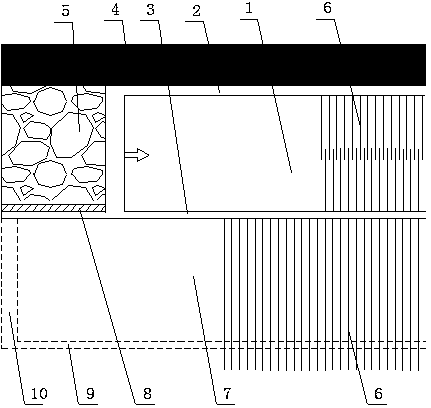

Gob-side entry retaining and sectional coal seam gas pre-extracting method for single low-permeability outburst coal seam

InactiveCN103670496AEmission reductionAchieve miningUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to the field of mine support and gas extraction, in particular to a gob-side entry retaining and sectional coal seam gas pre-extracting method for a single low-permeability outburst coal seam. A plurality of bedding drill holes are drilled in an air inlet crossheading and an air return crossheading of a working surface towards the working surface in the inclined direction of the coal seal in a parallel mode, and a pneumatic gas extraction device is used for carrying out gas extraction; gas of an adjacent working surface is extracted along the inclined bedding drill holes of the coal seam in the downstream direction of a transportation crossheading of the working surface, and an extraction pipeline is communicated for extracting gas of the coal seam of the adjacent working surface; after extraction, robbing is carried out on the coal seal of the working surface; extraction is not stopped until finish, and the steps are repeated until extraction of the coal seam is finished. According to the method, coal mining without pillars is achieved, the recovery rate of coal is improved, the total gas extraction time is saved, the gas extraction effect is improved, and coal mining and gas extracting are achieved at the same time.

Owner:CHINA UNIV OF MINING & TECH

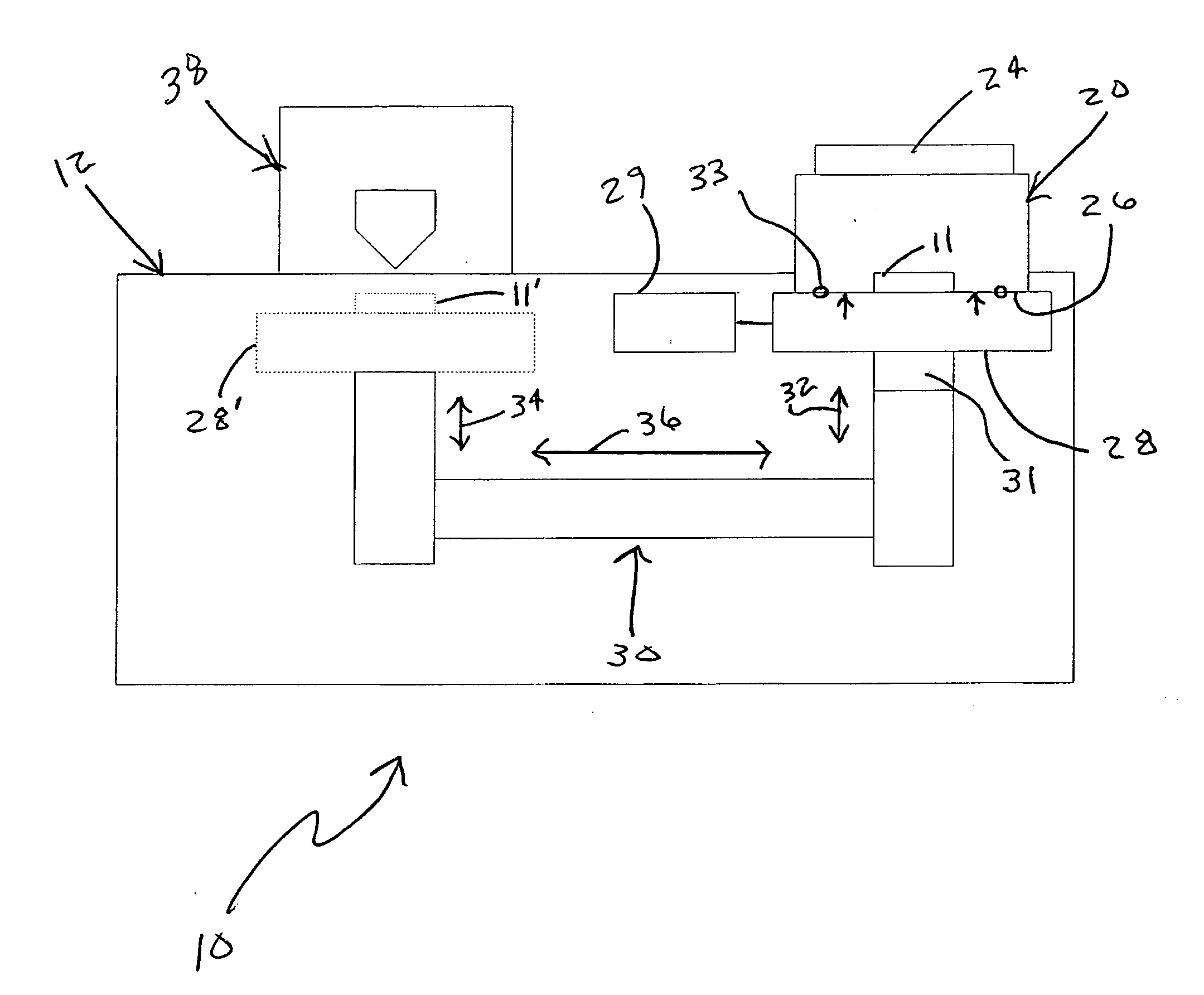

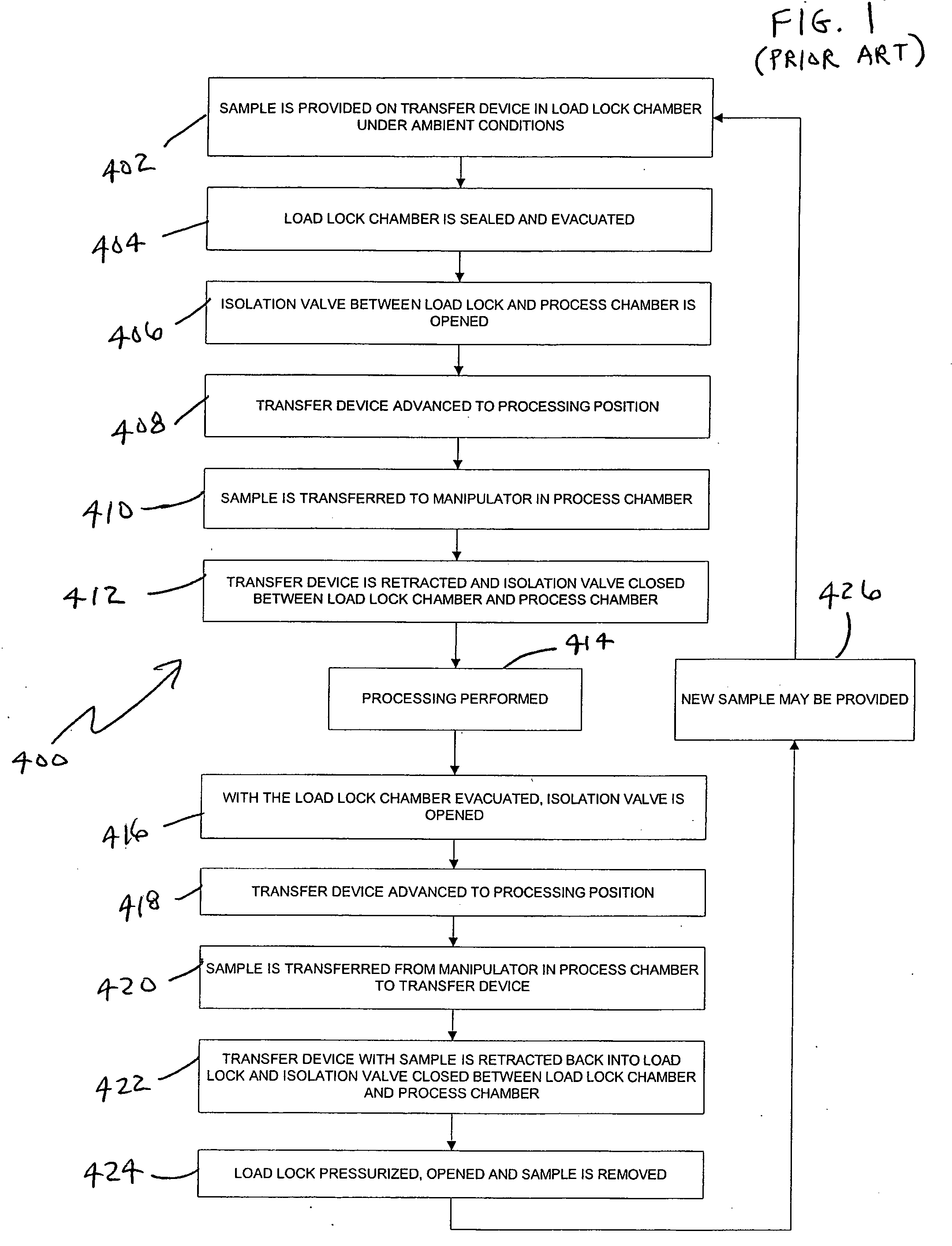

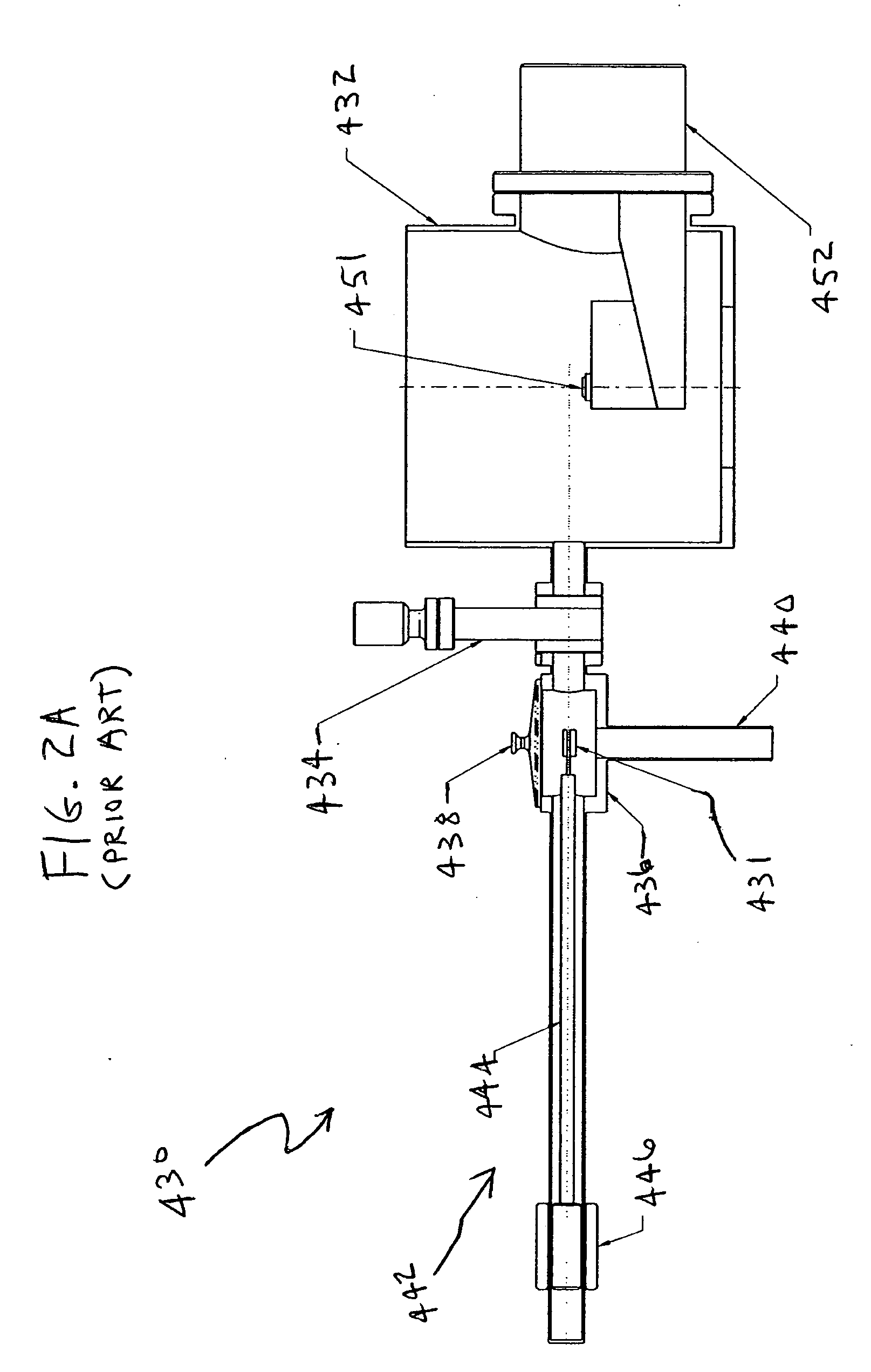

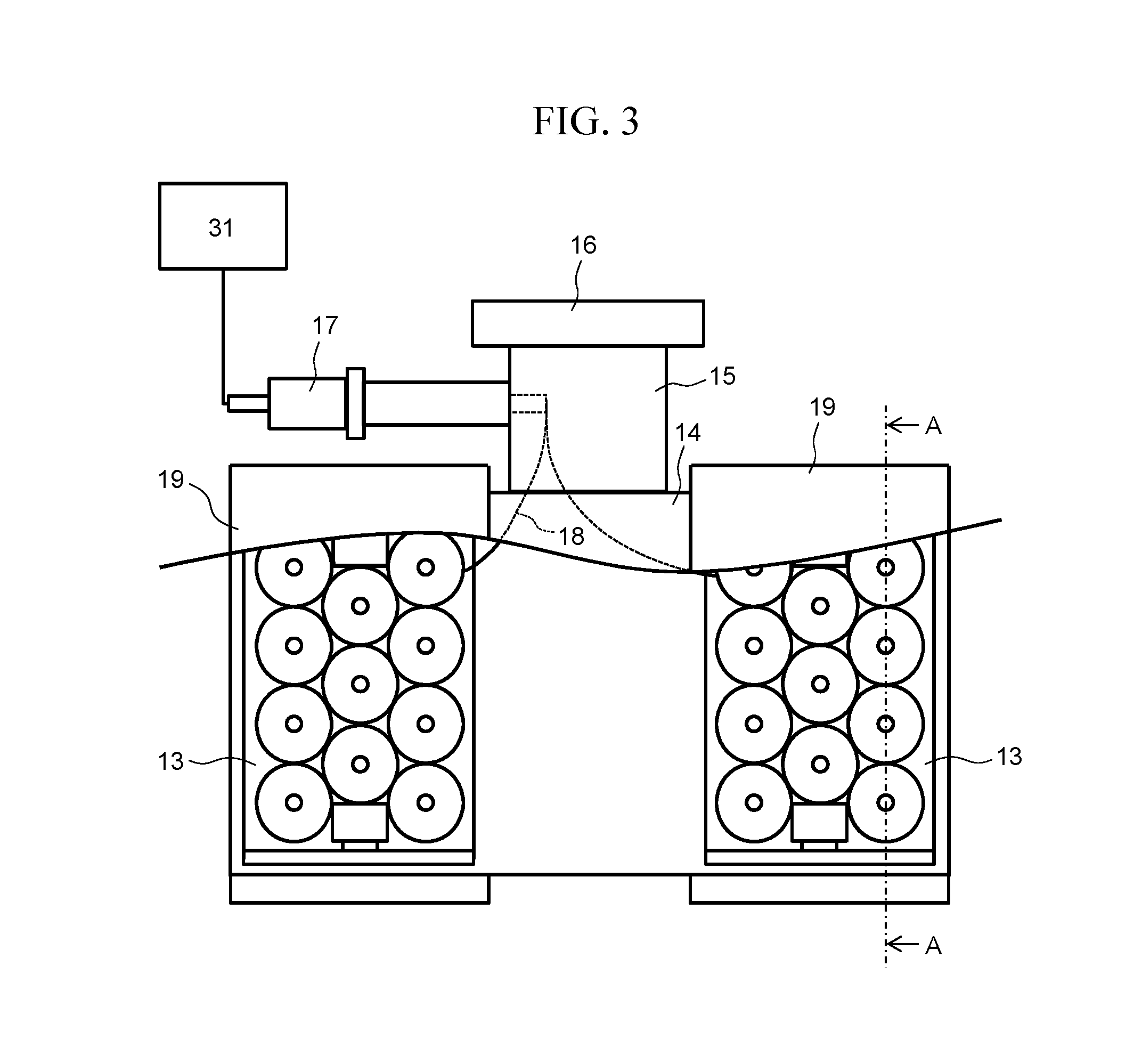

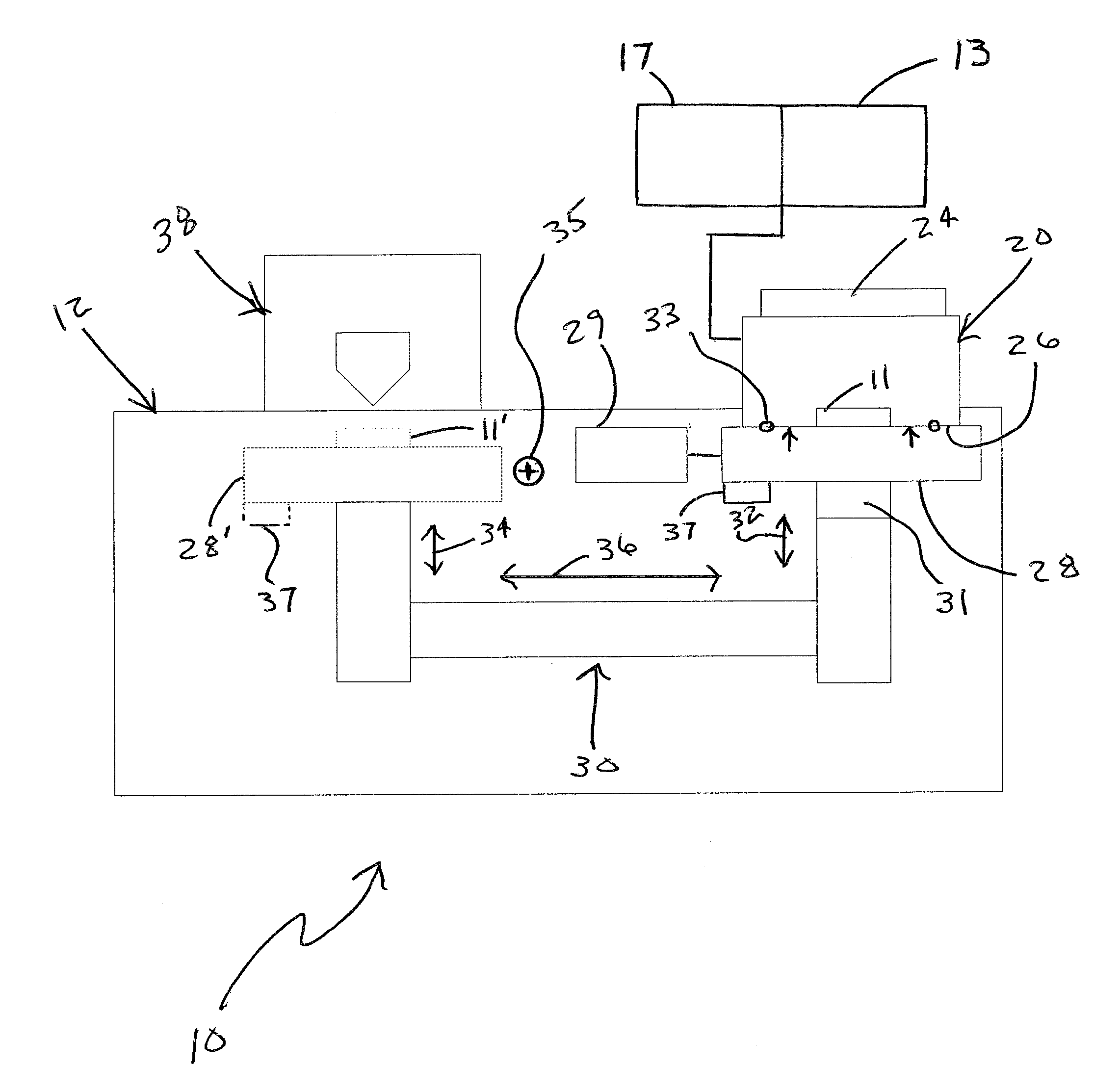

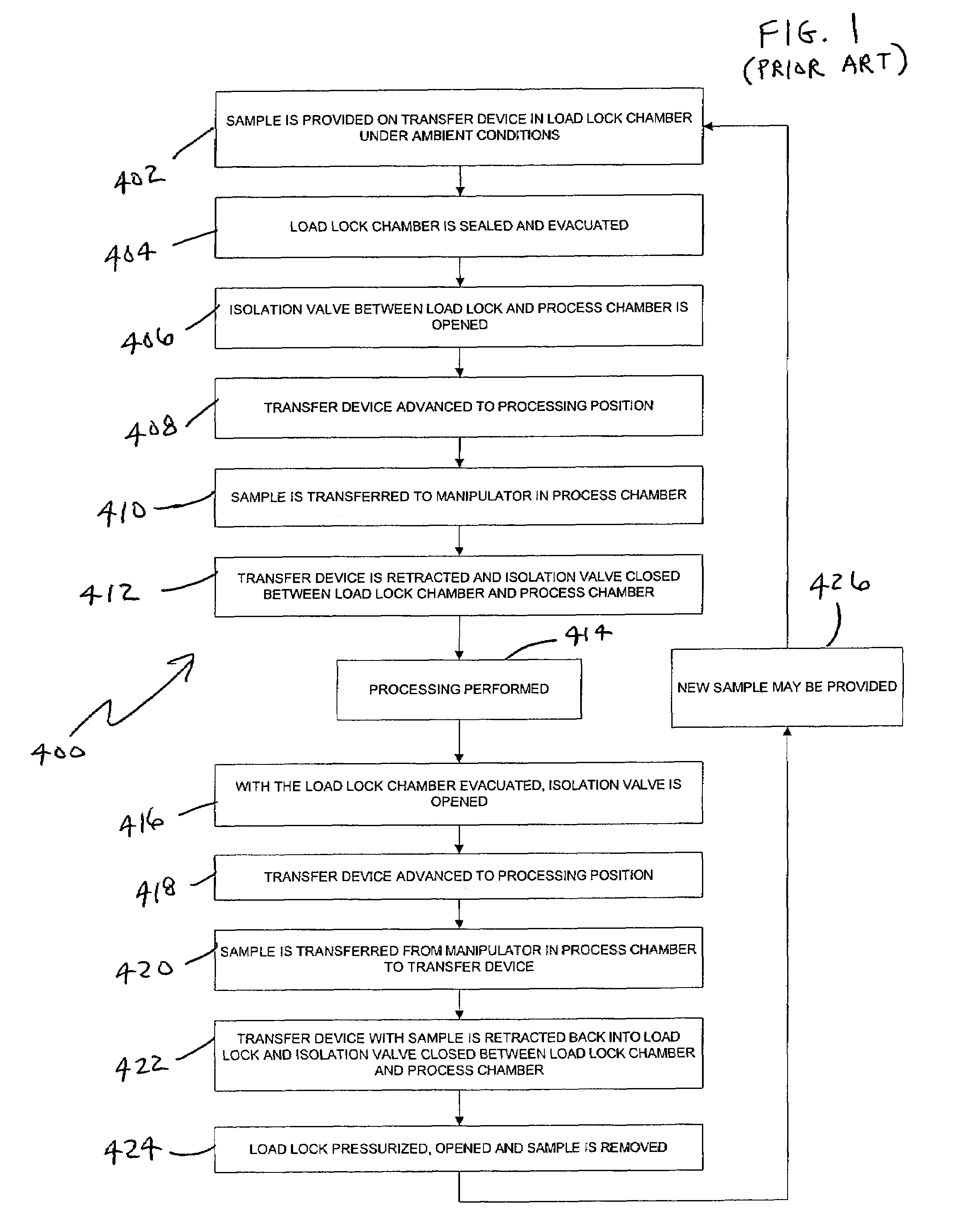

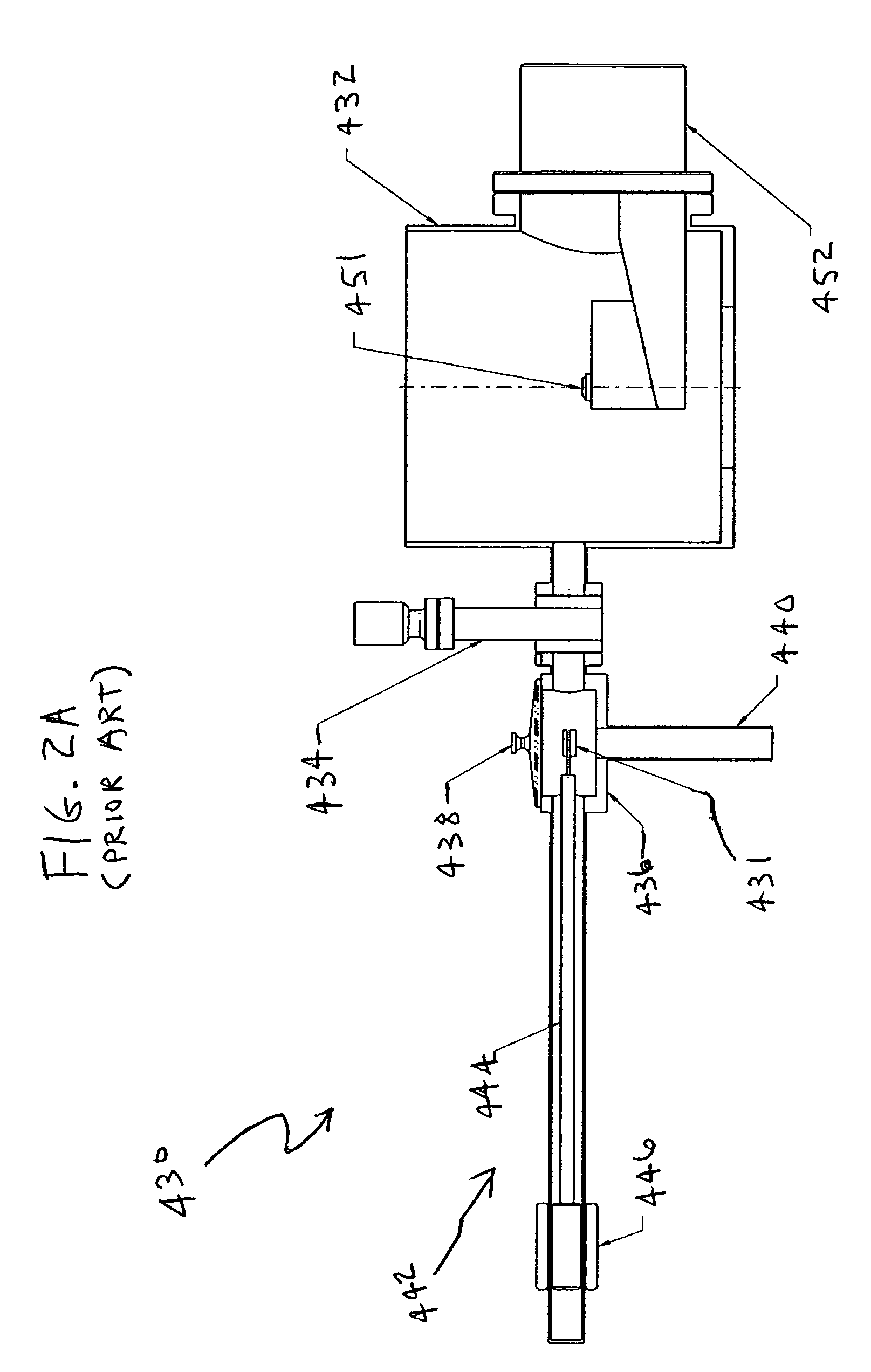

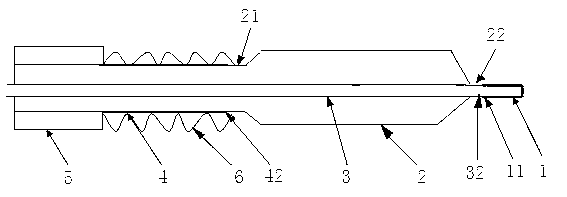

Sample introduction and transfer system and method

InactiveUS20080014056A1Improve simplicityLow costElectric discharge tubesPreparing sample for investigationTransfer systemEngineering

A method and system that provides a processing chamber associated with a load lock chamber. A sample receiving stage coupled to a sample positioning apparatus is configured to move between an introduction position and a processing analysis position within the process chamber. The sample receiving stage is used to result in a sealed barrier between the process chamber and the associated load lock chamber when in the introduction position.

Owner:ULVAC PHI INC

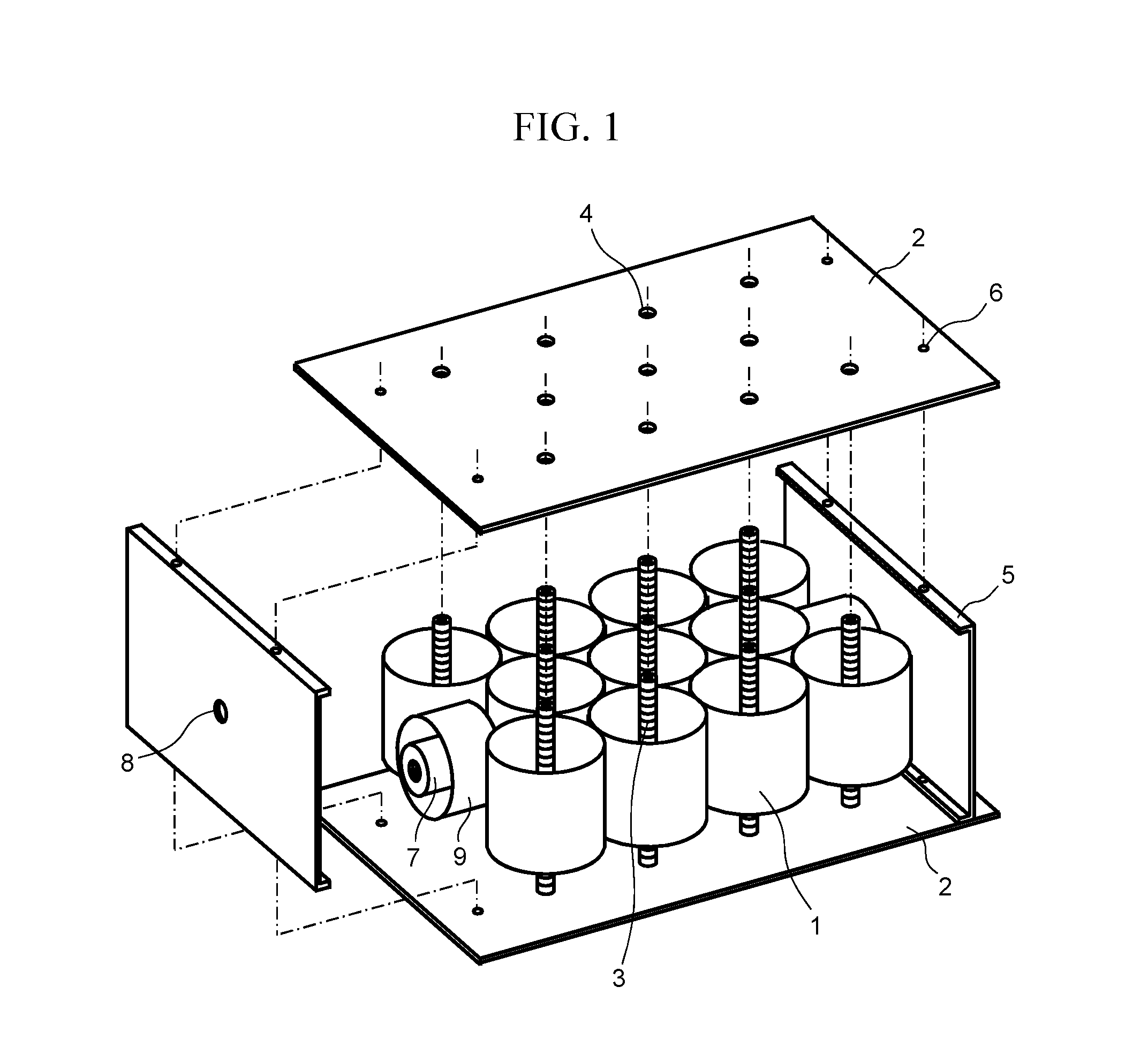

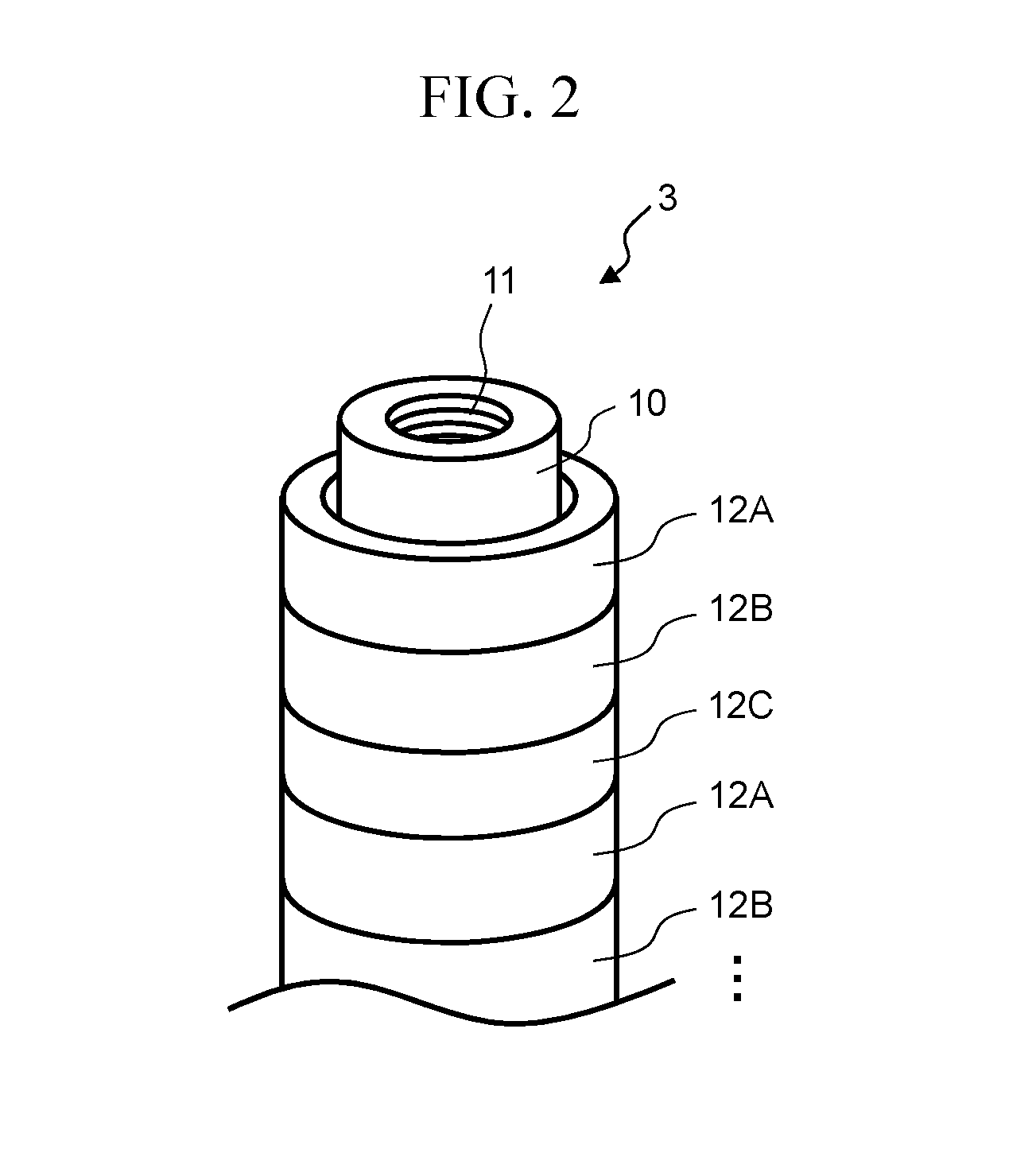

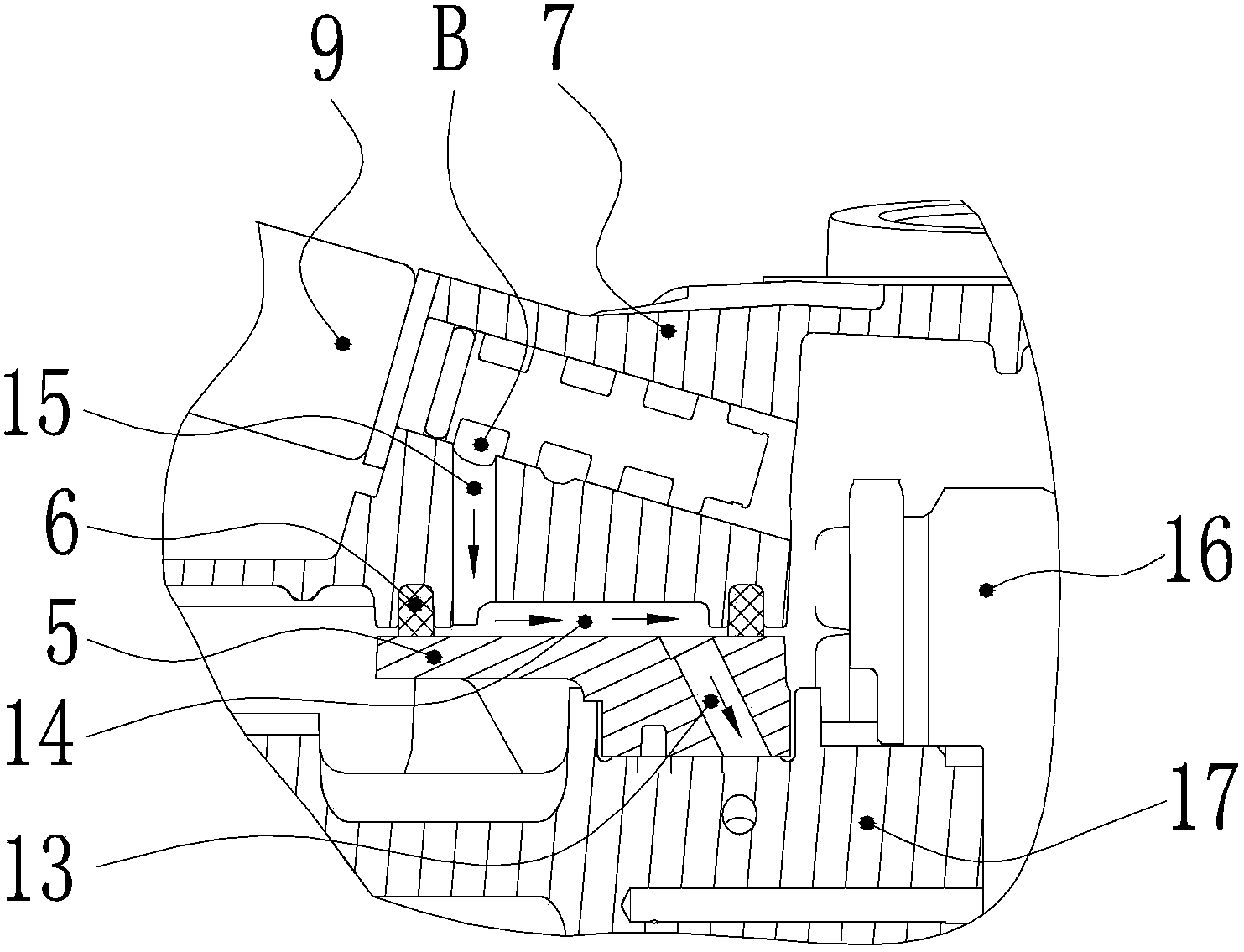

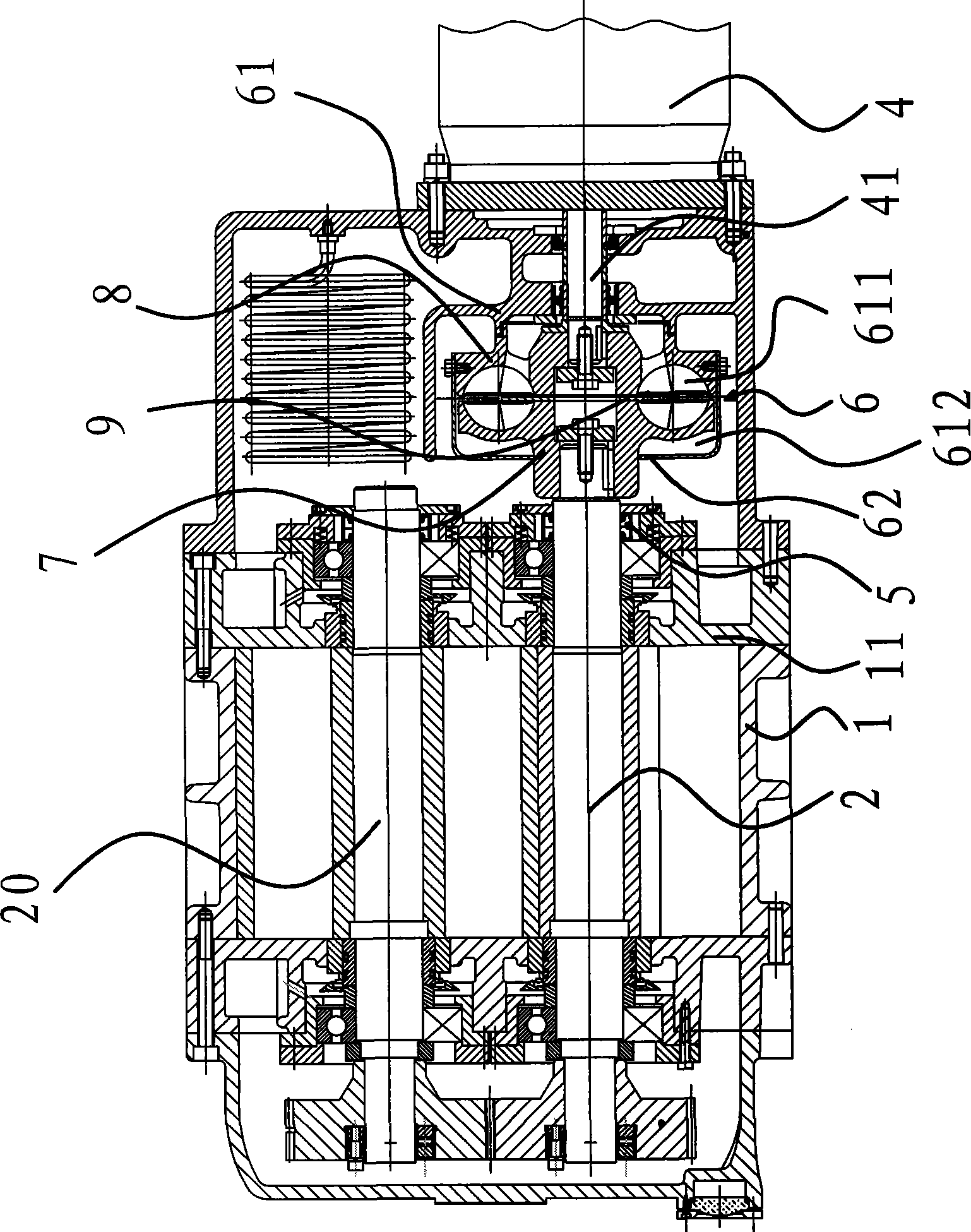

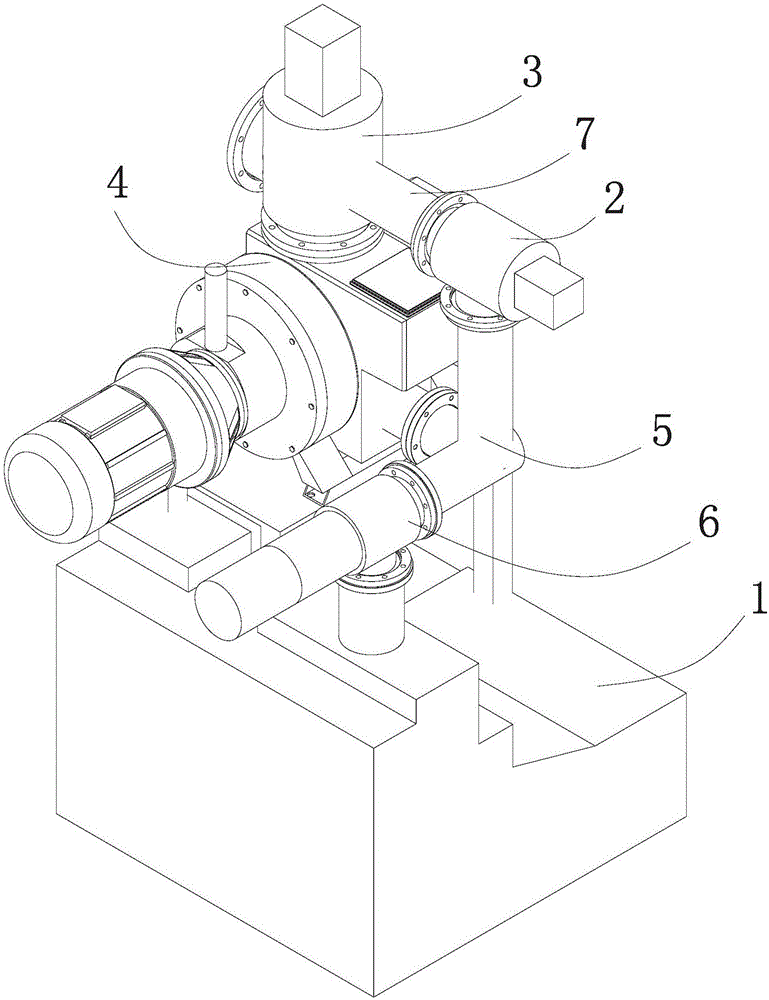

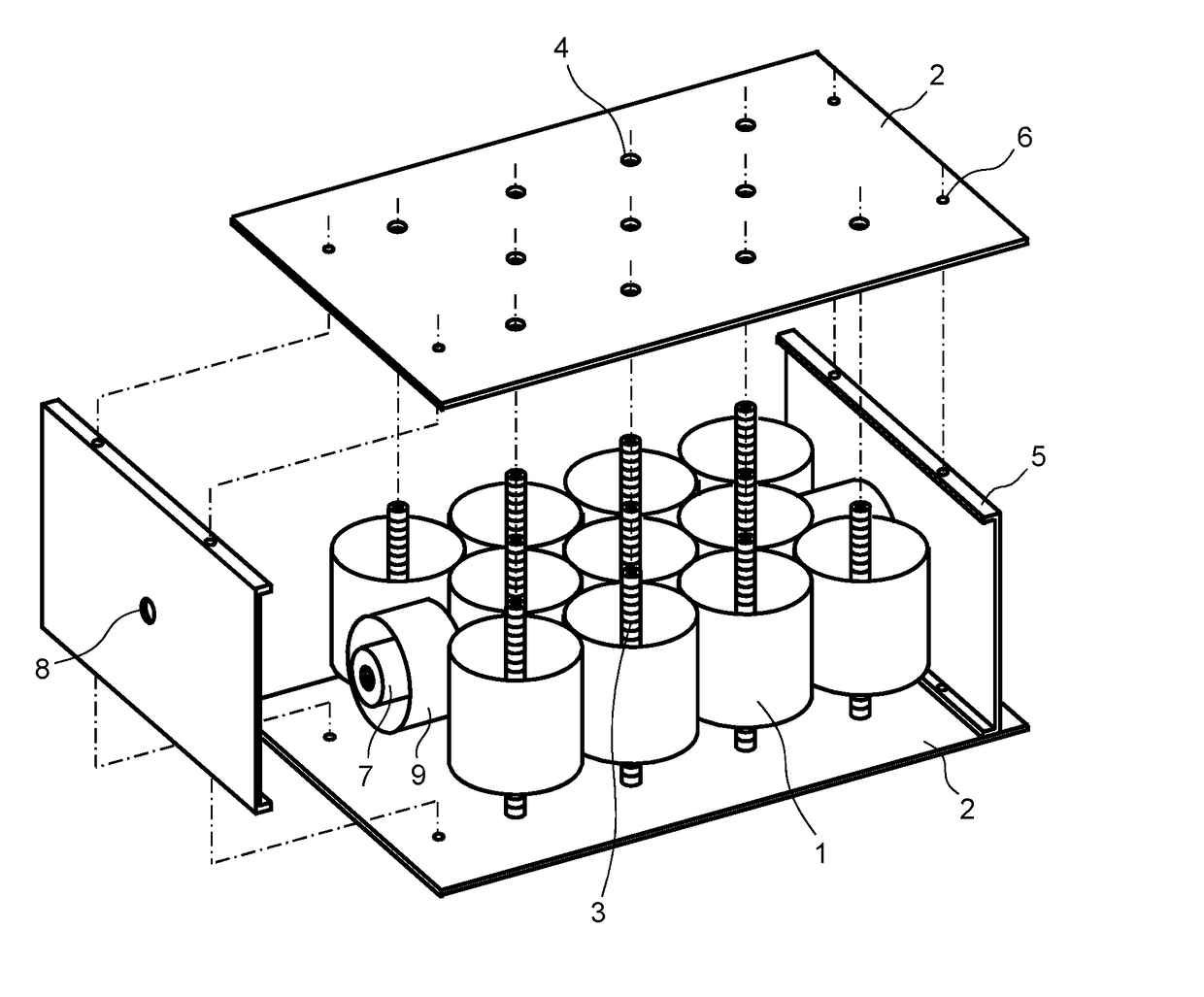

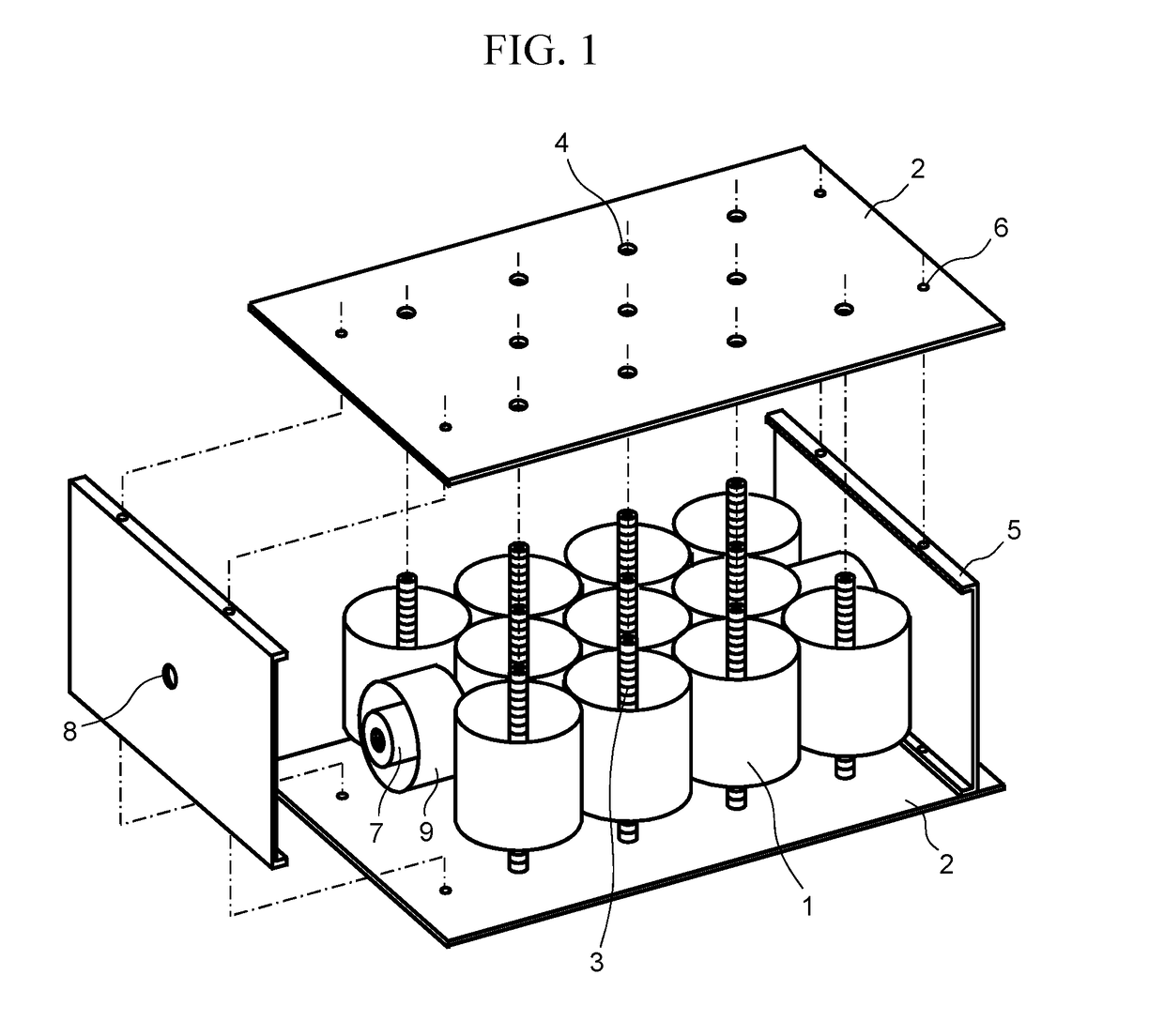

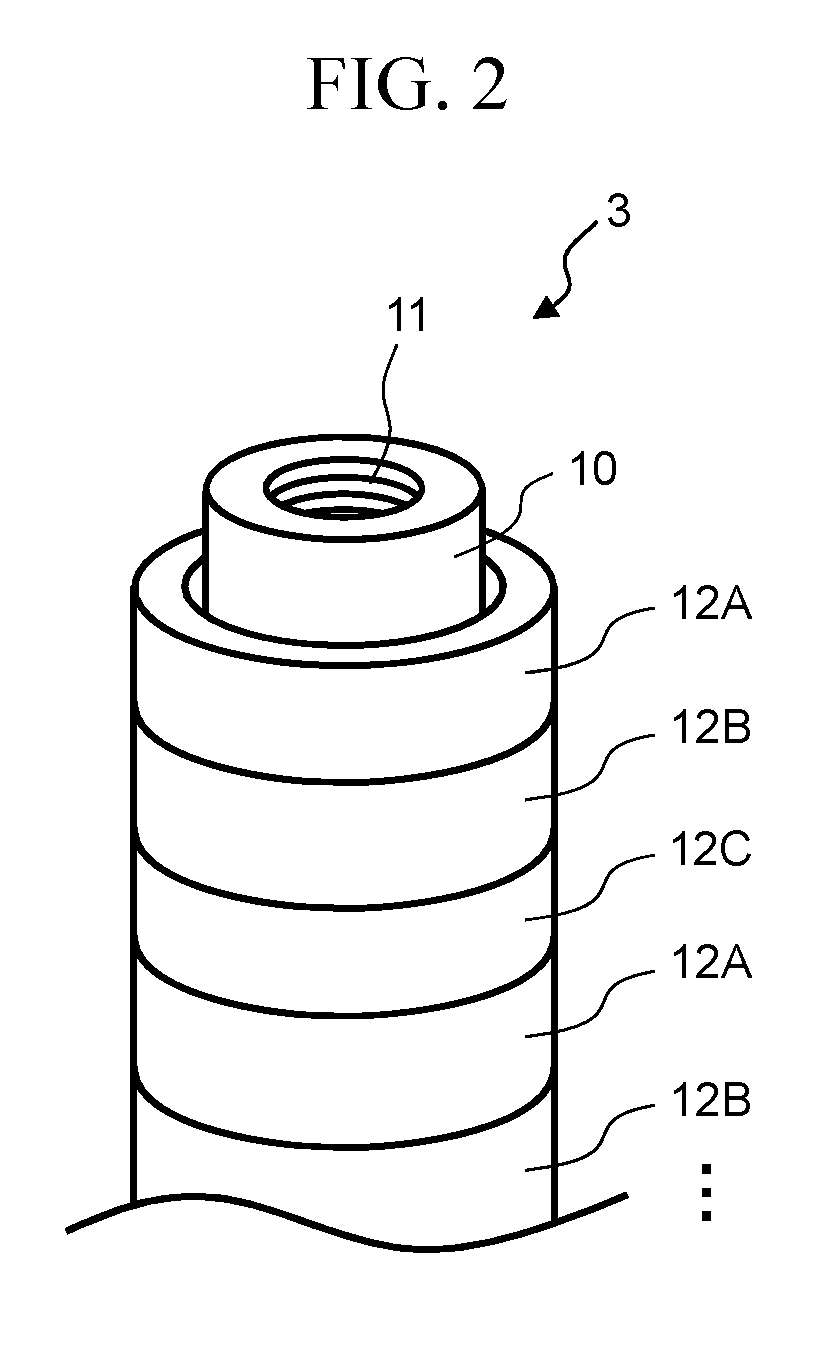

Ion pump and charged particle beam device using the same

An ion pump and a charged particle beam device each includes two opposite flat-plate cathodes, an anode with a cylindrical shape having openings that face the respective flat-plate cathodes, a voltage application unit configured to apply a potential higher than potentials of the flat-plate cathodes to the anode, a magnetic field application unit configured to apply a magnetic field along an axial direction of the cylindrical shape of the anode, and a cathode bar arranged within the anode. The surface of the cathode bar is formed with a material that forms a non-evaporative getter alloy film on the anode or the flat-plate cathodes.

Owner:HITACHI LTD

Method for surface modification and transmission increase of coal reservoirs by using chlorine dioxide

InactiveCN102168544AReduced methanotropic abilityImprove permeabilityFluid removalGas removalChlorine dioxideDesorption

The invention relates to a method for surface modification and transmission increase of coal reservoirs by using chlorine dioxide. The method sequentially comprises the following steps of: (1) selecting the proportioning concentration of the chlorine dioxide according to a coal step and a laboratory experiment; (2) selecting a ground coalbed methane well or an underground drill hole for hydraulic fracturing reservoir modification; (3) pumping chlorine dioxide with selected concentration by stages in the hydraulic fracturing process, wherein the pumping amount in the prepad fluid stage is not less than 70 percent; (4) closing the well for more than 3 hours, and starting to return discharge of a fracturing fluid; and (5) inspecting effects, wherein main indexes comprise critical desorption pressure, daily gas yield and ultimate recovery ratio of the coalbed methane wells or the pumping amount of the underground drill hole. By the method, the daily gas yield and the recovery rate of a single well can be improved, the underground drilling and extraction capability is improved, the extraction efficiency is improved, and the pumping time is shortened.

Owner:HENAN POLYTECHNIC UNIV

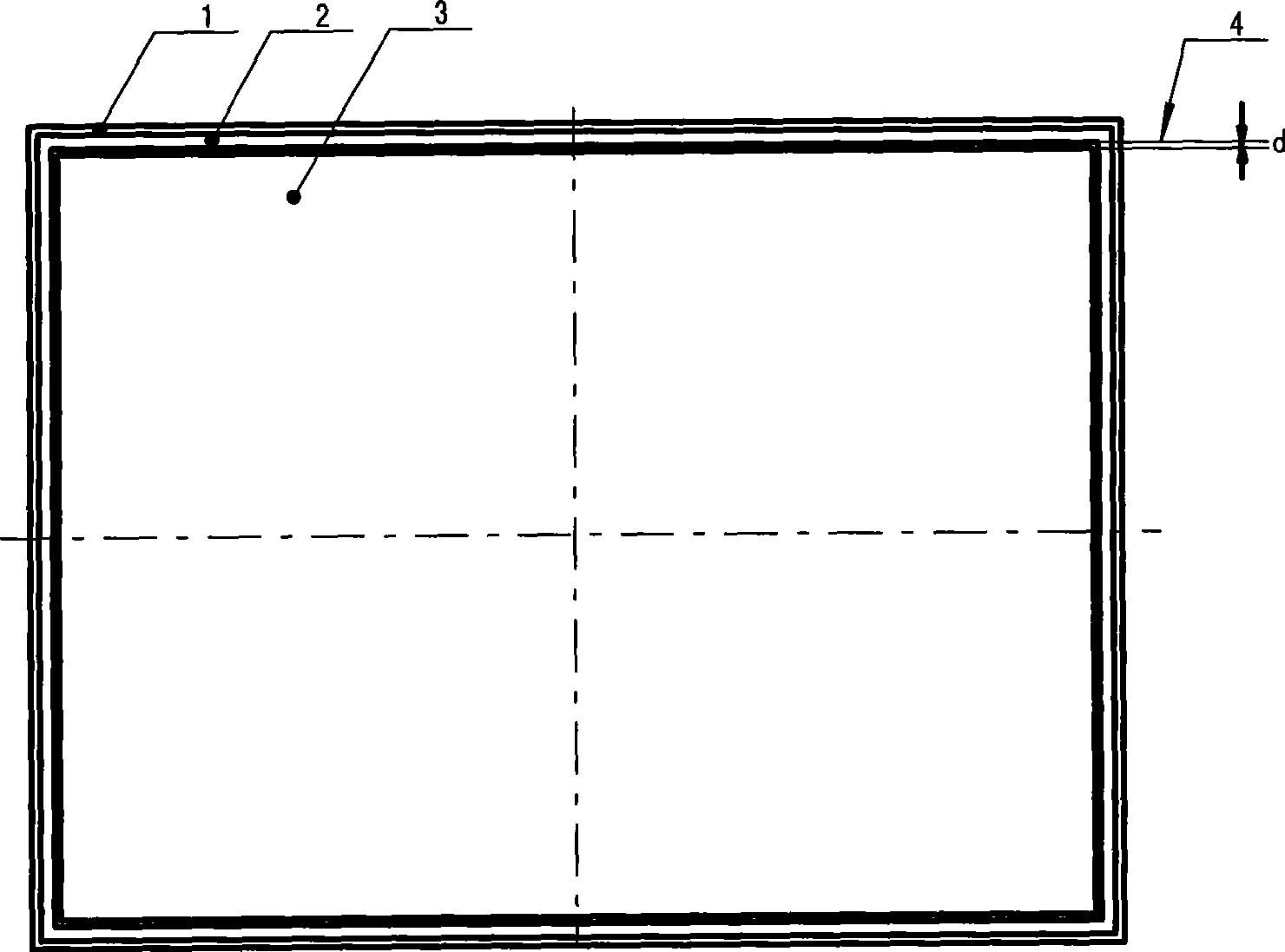

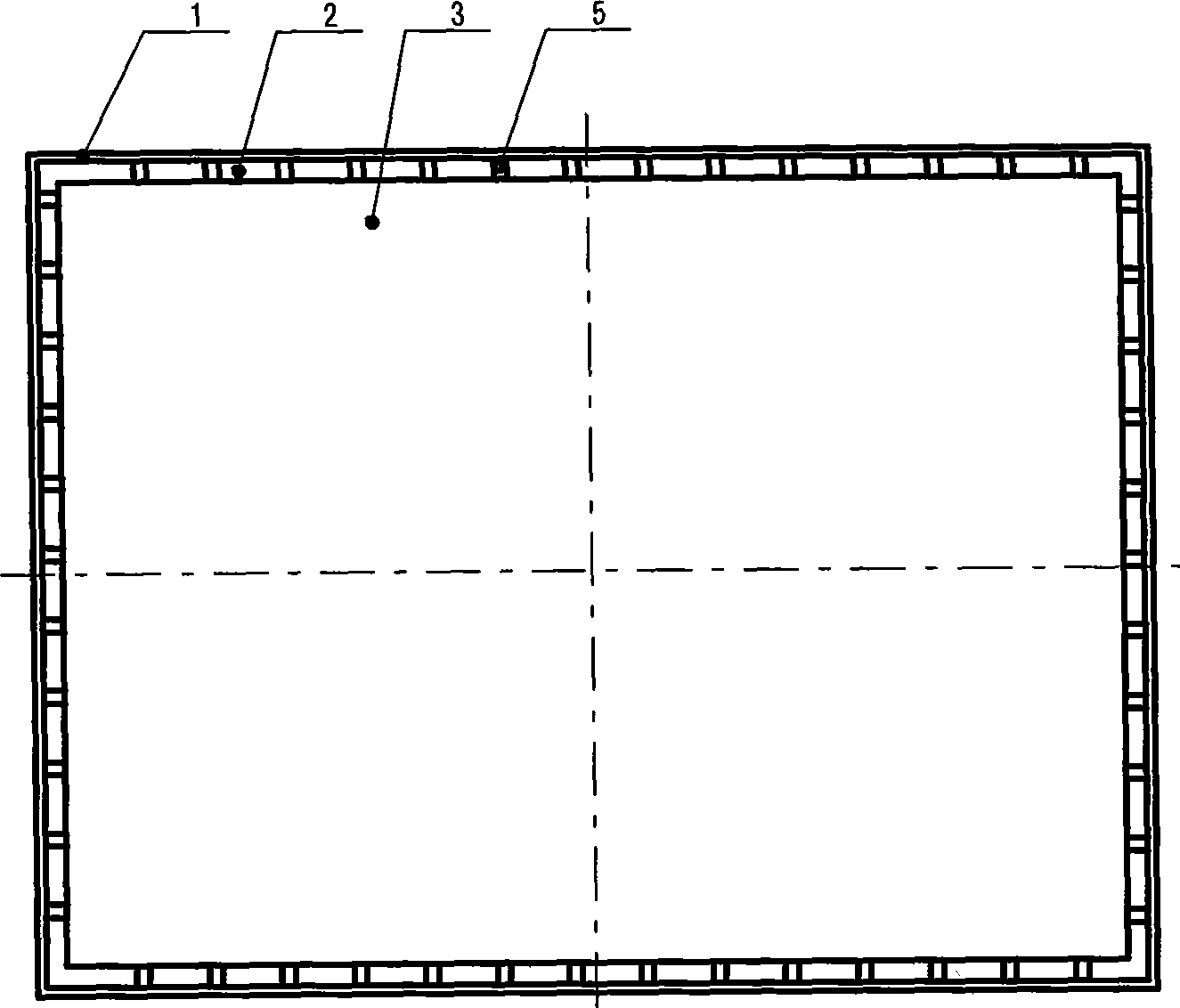

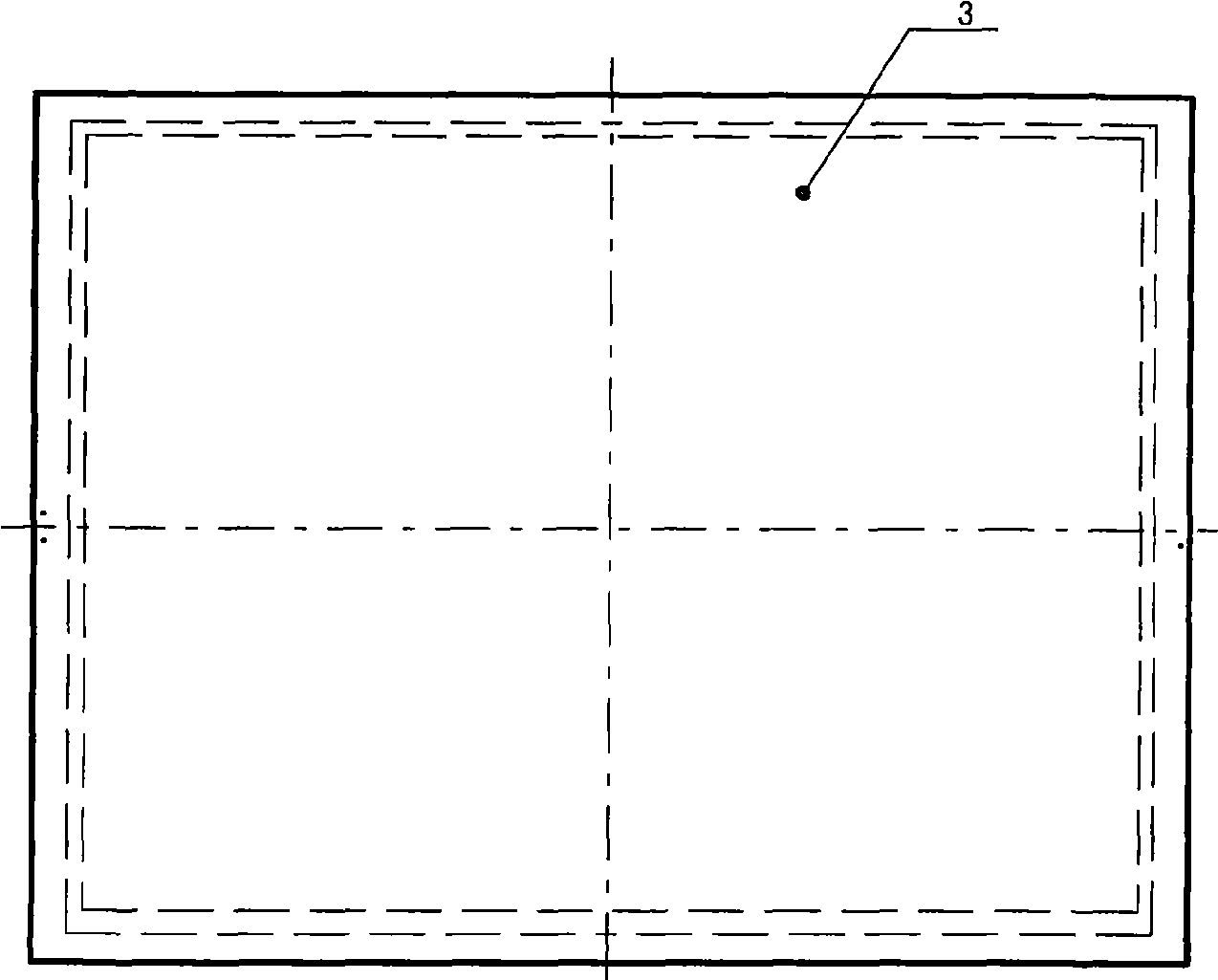

Automatic edge sealing process for vacuum glass

InactiveCN101481205AImprove the effect of edge bandingBeautiful edge bandingGlass reforming apparatusHeating furnaceAir tightness

The invention relates to an automatic edge sealing technology for vacuum glass, which comprises the following steps of arranging supporters on basal board glass, arranging upper plate glass on the basal board glass, using low melting-point glass powder between the upper plate glass and the basal board glass for sealing edges, placing the upper plate glass and the basal board glass into a vacuum heating furnace to be heated and taking out upper plate glass and the basal board glass to get a finished vacuum glass, wherein in the step of using the low melting-point glass powder for sealing the edge, a section bar of low melting-point glass powder or the low melting-point glass powder is arranged on the basal board glass, and a gap of air escaping in the evacuation in the heating furnace is left in a chamber formed between the basal board glass and the upper plate glass. The invention has simple integrated structure, greatly shortens the evacuation time, increases the work efficiency, has reliable automatic evacuation and sealed package, good air tightness, little air leakage hazard, attractive appearance and production technology simplification, greatly promotes the development of the vacuum glass industry, and is particularly suitable for the industrialized, the scale and the standardized production of the vacuum glass.

Owner:左树森

Vacuum deposition equipment

InactiveCN1594650ASimple structureImprove medium vacuum pumping speedVacuum evaporation coatingSputtering coatingEngineeringVacuum pump

The invention discloses a vacuum plating equipment, which comprises filming chamber, backing vacuum pump, high vacuum valve, soft vacuum valve, high vacuum gage, vacuometer and film source, and molecular drag pump. Molecular drag pump air admission port is connected with filming chamber, air exhaust opening is connected with backing pump, and air flow dust arrester is installed between molecular drag pump bearing and bleed-off passage. The inventive vacuum film coating equipment has a simple structure, low energy consumption, high production efficiency, short air exhaust time, and promote the vacuum filming product quality, specificly apply to vacuum filming field sensitive to oil steam contamination.

Owner:储继国

Sample introduction and transfer system and method

InactiveUS7581916B2Improve simplicityLow costSamplingElectric discharge tubesTransfer systemEmbedded system

A method and system that provides a processing chamber associated with a load lock chamber. A sample receiving stage coupled to a sample positioning apparatus is configured to move between an introduction position and a processing analysis position within the process chamber. The sample receiving stage is used to result in a sealed barrier between the process chamber and the associated load lock chamber when in the introduction position.

Owner:ULVAC PHI INC

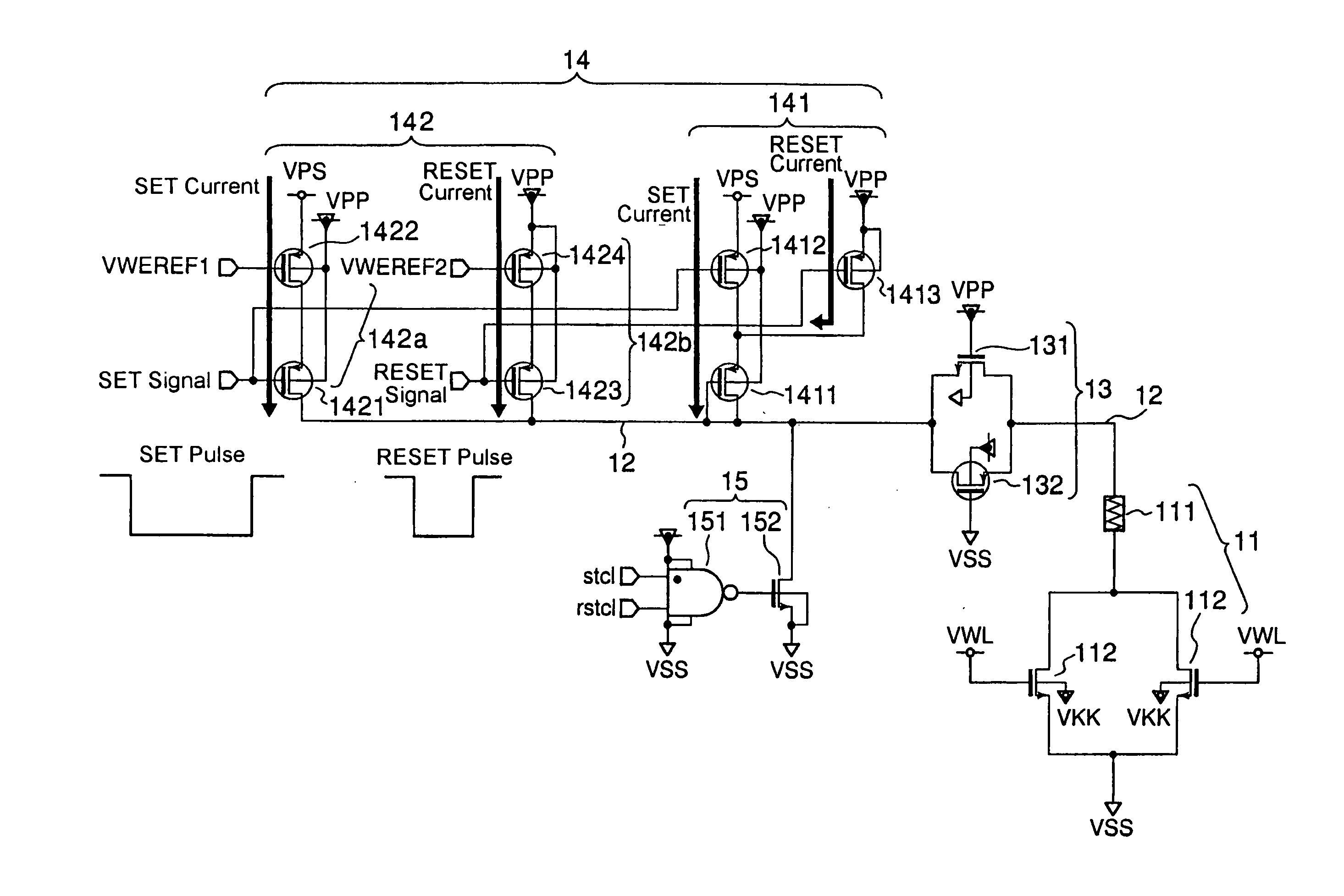

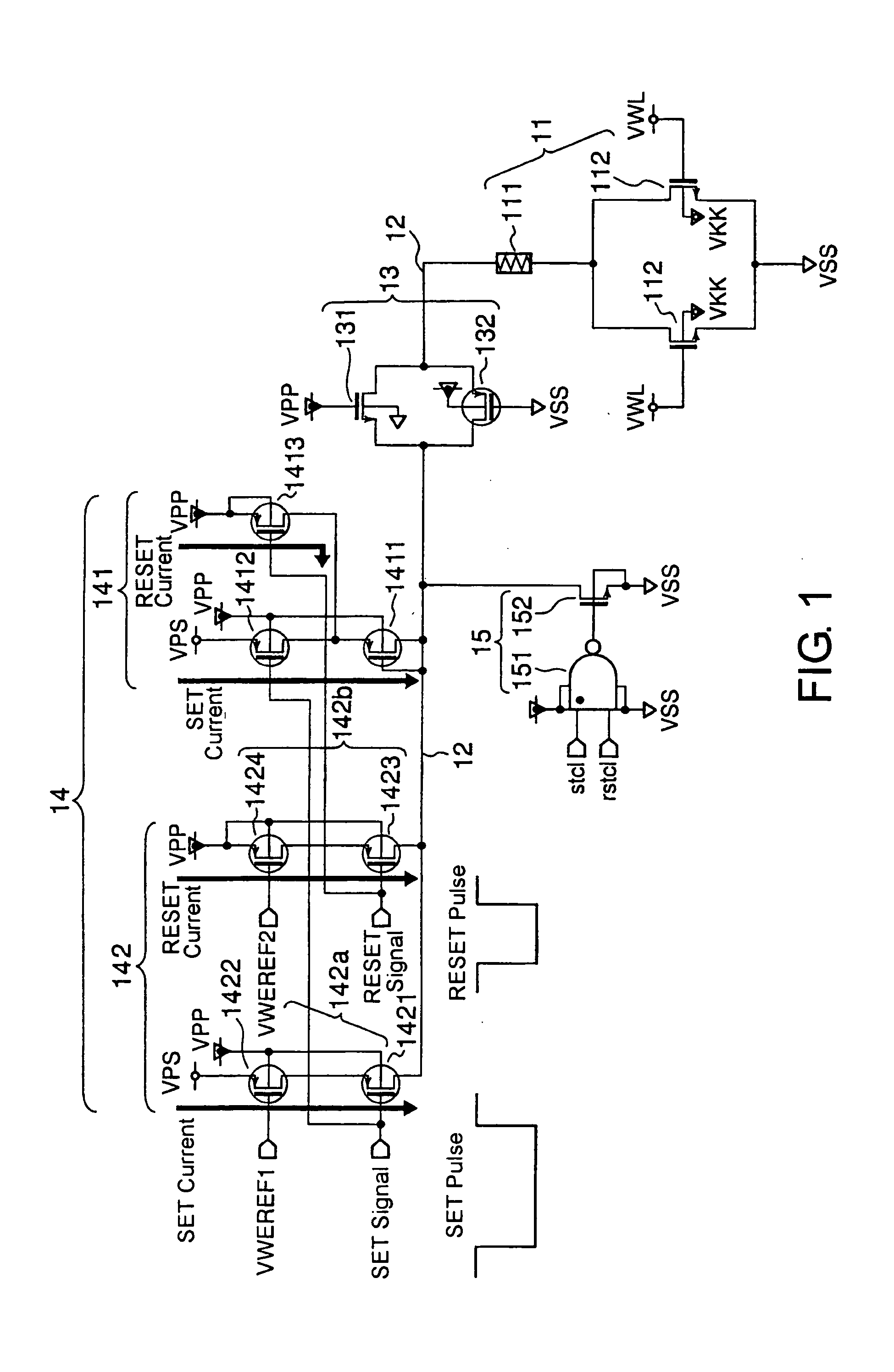

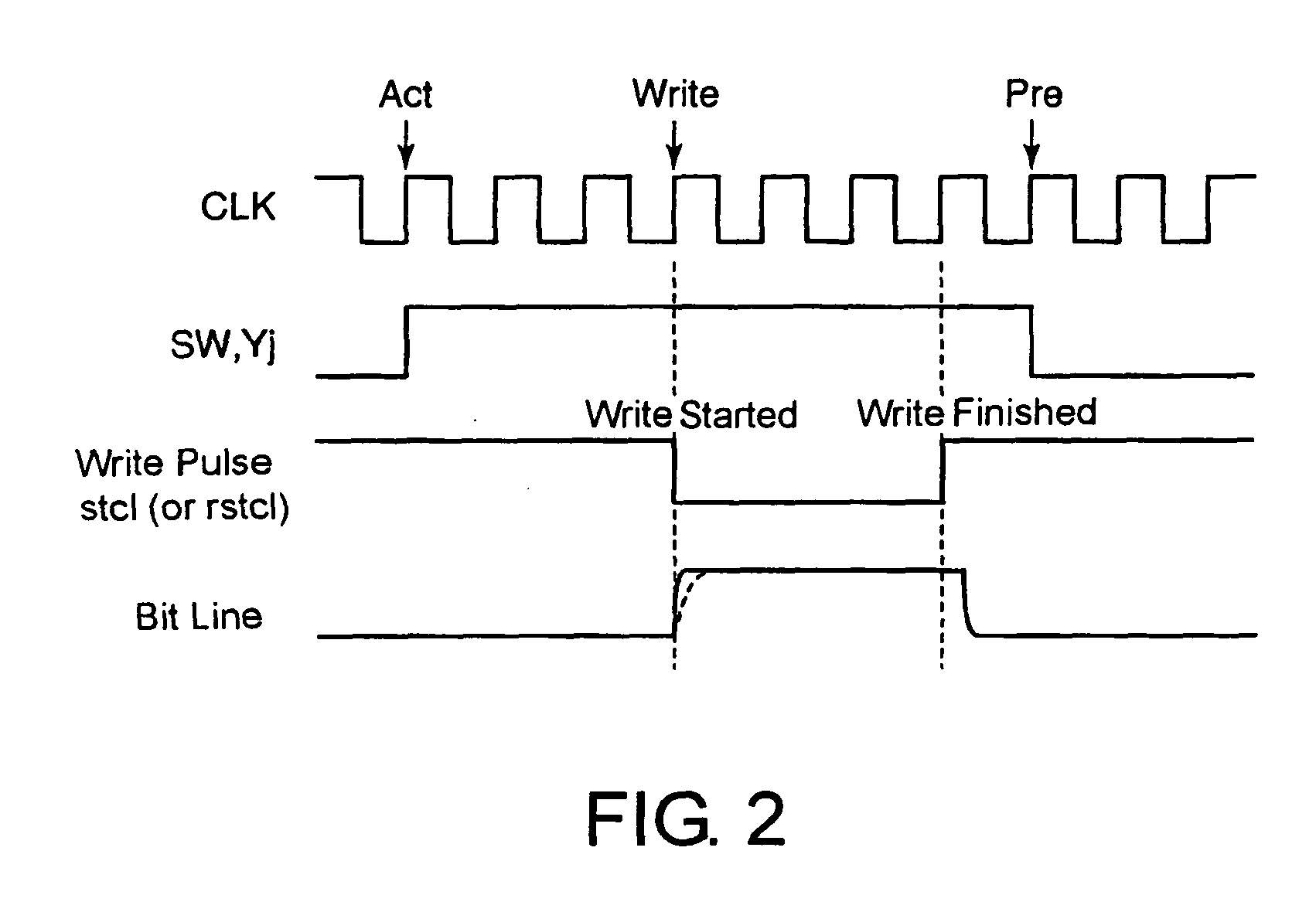

Memory device and writing method thereof

InactiveUS20100124104A1Shorten write timeReduce pumping timeDigital storageBit lineAudio power amplifier

A write amplifier for driving a bit line connected to a selected phase change memory cell drives the bit line with a first current driving capability and then drives the bit line with a second current driving capability lower than the first current driving capability.

Owner:LONGITUDE SEMICON S A R L

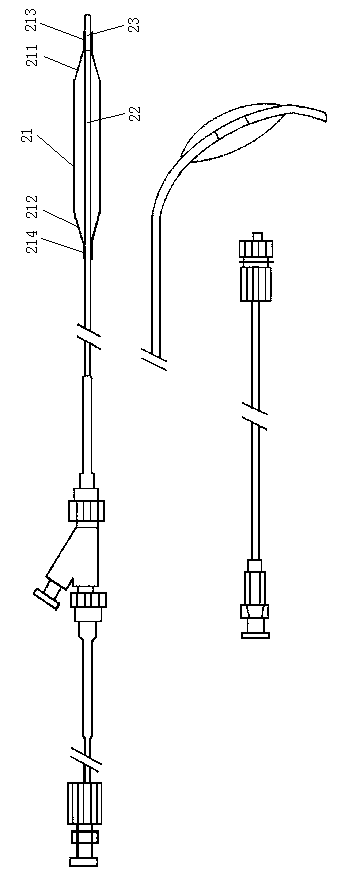

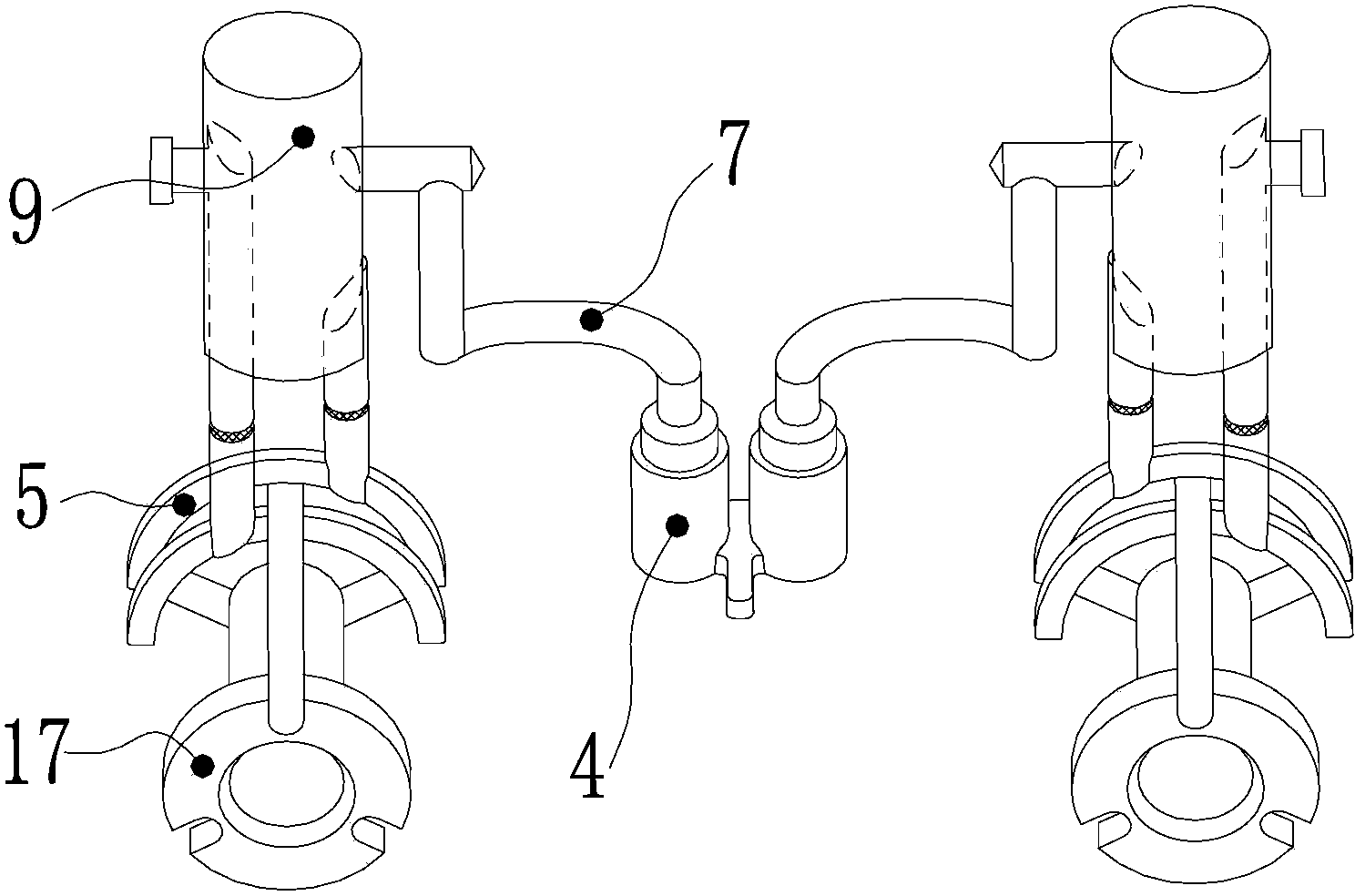

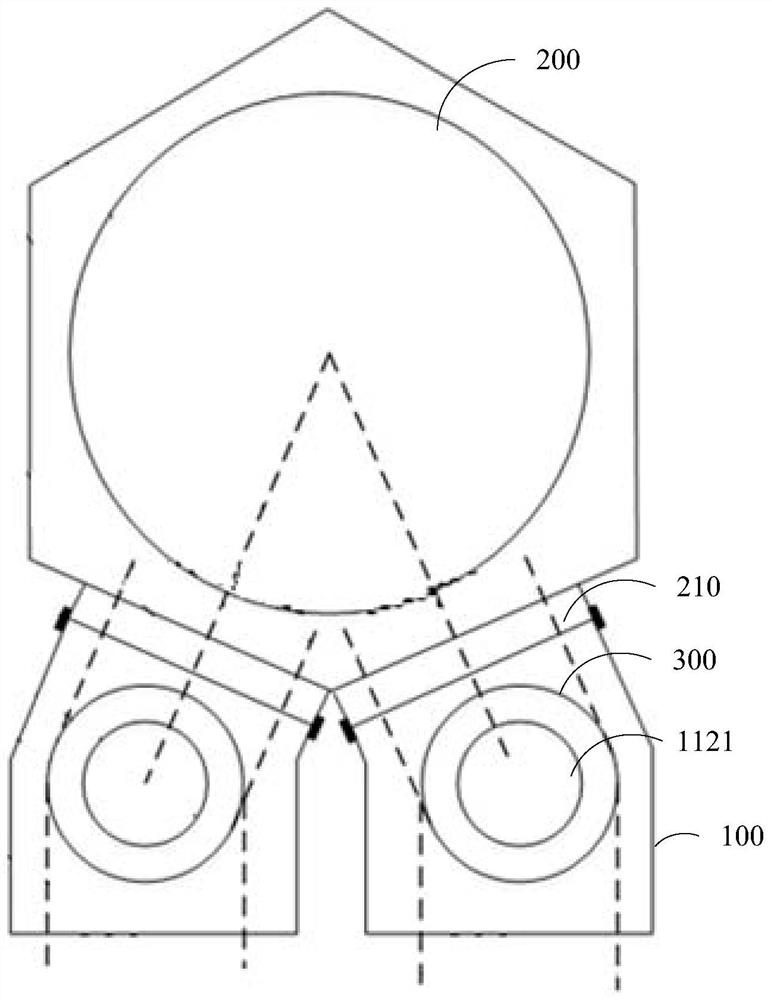

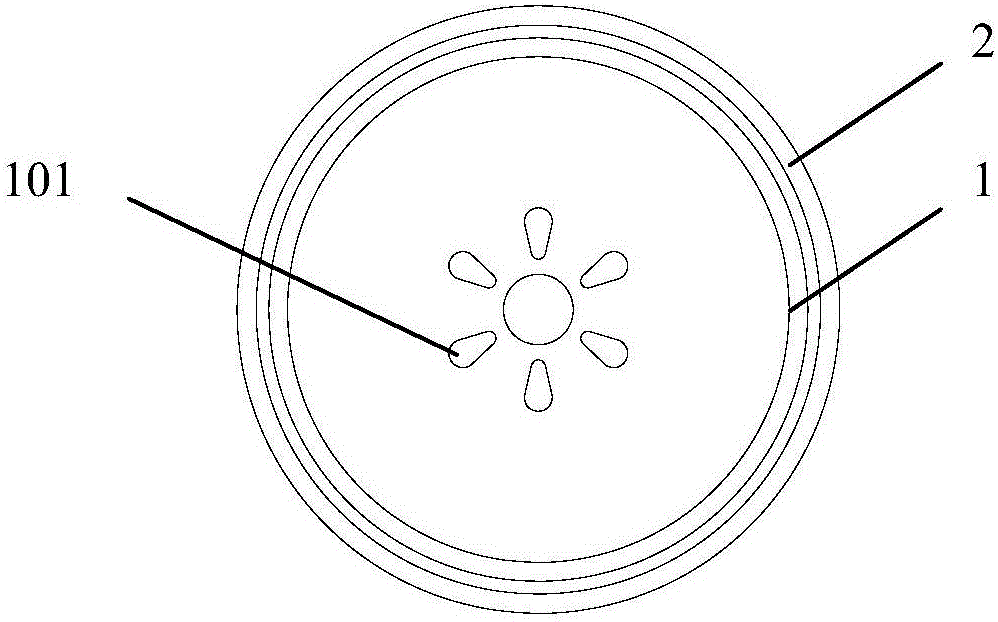

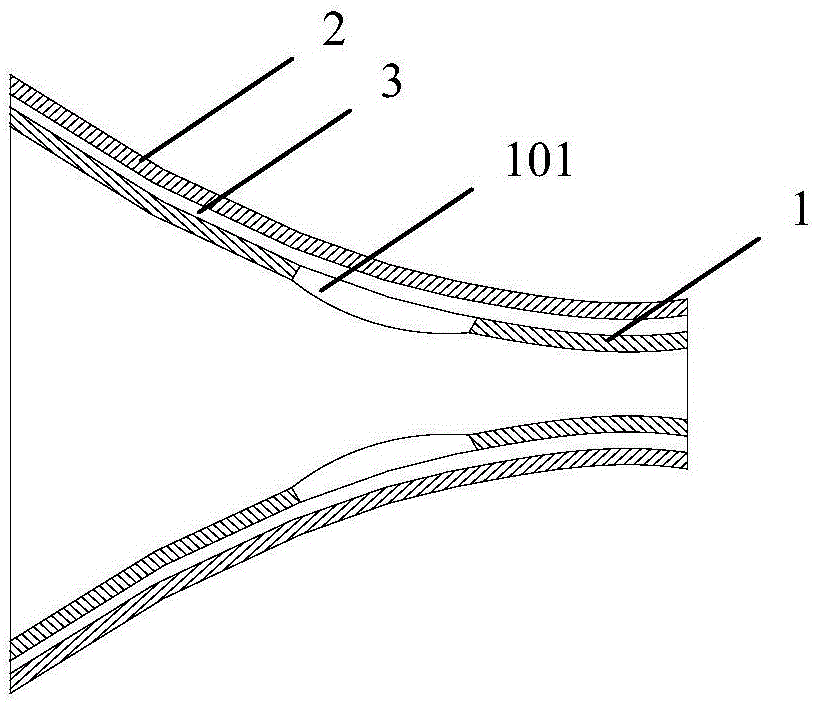

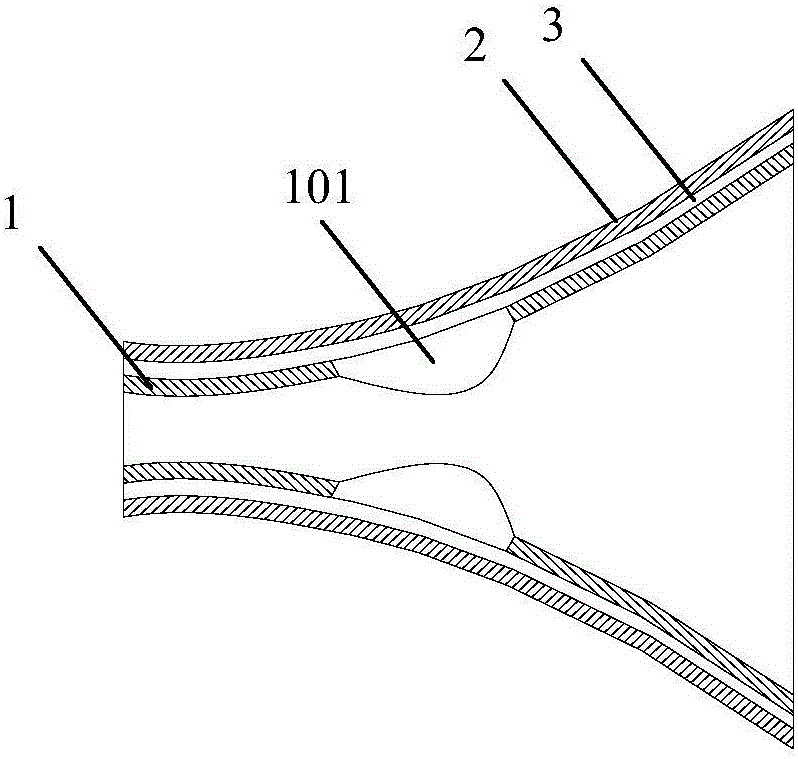

Novel balloon expandable stent conveying system

ActiveCN102793598ASimple structureImprove handlingSurgeryProsthesisBiomedical engineeringBlood vessel

The invention discloses a novel balloon expandable stent conveying system which comprises a balloon, an inner tube, a far-end outer tube, a corrugated tube, a soft head and a stent pushing tube. The inner tube runs through an inner cavity of the far-end outer tube and an inner cavity of the balloon; a combination body of the soft head and the inner tube is placed and connected into the neck part of the far end of the balloon; the farthest end of the far-end outer tube is placed into the neck part of the near end of the balloon and is connected with the neck part of the near end of the balloon; the balloon is of a one-layer or multilayer structure; and at least one layer of the balloon is made of a material with a micropore structure. The stent conveying system disclosed by the invention has a simple structure, also has the functions of pre-expanding a narrow tube cavity and conveying a stent, has good operation and control performance and strong passing performance, is rapid and convenient to operate and is cost-saving. When adopting the ePTFE (expanded polytetrafluoroethylene) material with the micropore structure, the balloon does not need to be folded and is simple to process; and time of sucking liquid in the balloon is short, the blood supply of far-end blood vessels is high in recovery speed, the balloon is changed into a cylinder shape with a small diameter after the liquid is pumped out, and the blood vessels cannot be damaged or the stent shifting cannot be caused in the retracting process. The balloon with the double-layer structure has higher pressure resistance capacity.

Owner:吕文峰

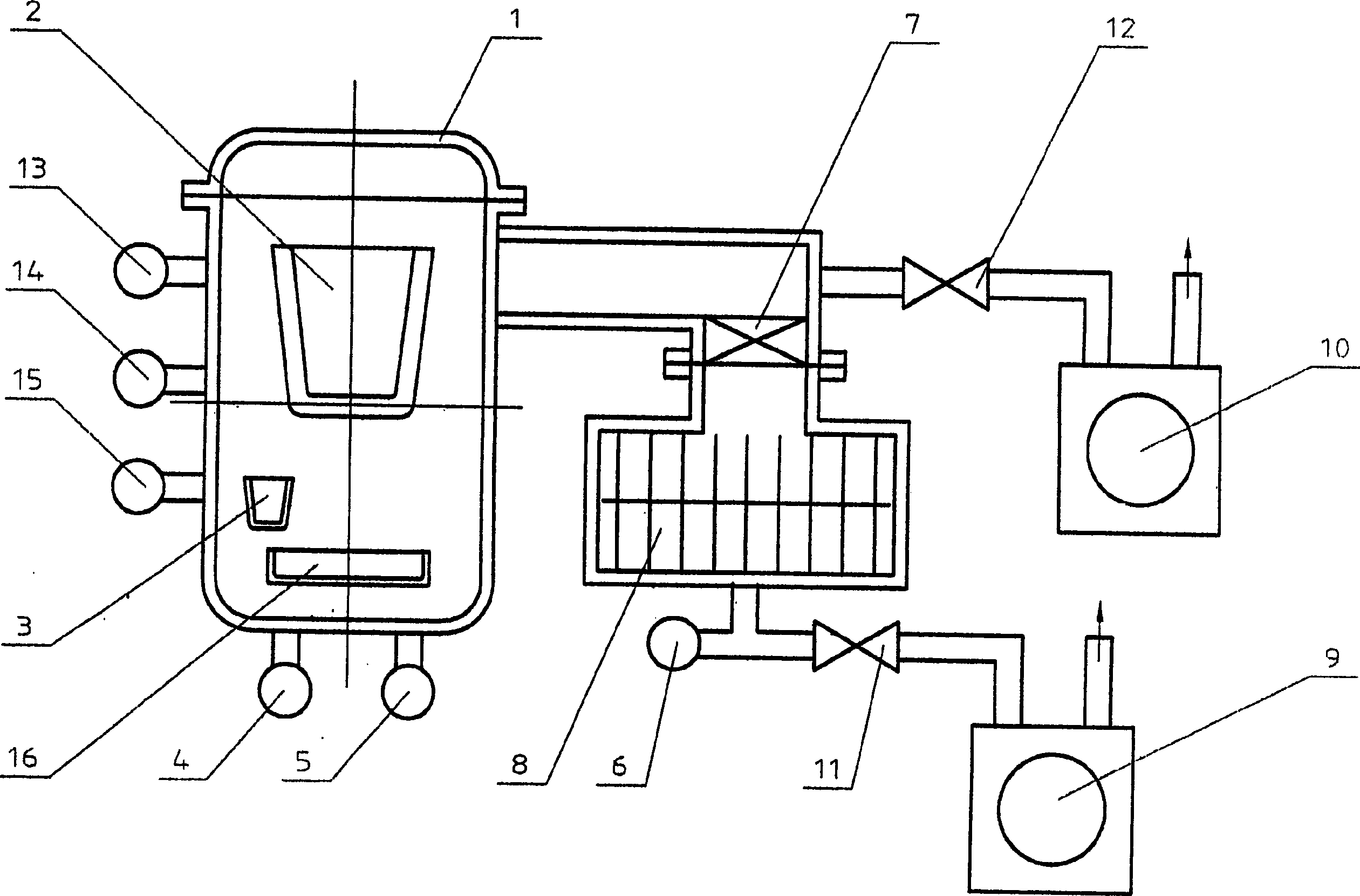

Vacuum smelting furnace

Disclosed is a vacuum smelting furnace, comprising smelting chamber, bush, cavity, middle vacuum gauge, low vacuum gauge, high vacuum valve, vacuum pump, low vacuum valve, protective gas source and heat electric power source, and molecular drag pump whose are inlet is connected to the high vacuum valve, the low vacuum gauge and low vacuum valve are separately connected to air exhausting mouth of the molecular drag pump, besides, dust arrester, partial pressure monitoring meter and auxiliary evaporation source with active getter material are added between of the and air extracting channel. The vacuum smelting furnace is suitable for smelting of oxidable metal material and alloy, especially for permanent magnet alloy of rubidium-iron- boron. The invention has simple structure can reduce air extracting time and save energy, increase production efficiency and production quality.

Owner:SHENZHEN UNIV

Method for eliminating coal mine gas explosion, burst and exceeding

Provided is a coal mine gas prevention method for eliminating coal mine gas explosion, burst and exceeding by injecting nitrogen from the ground to discharge and mine coal bed gas. The method comprises the steps that wells are drilled from the ground, the high pressure nitrogen is injected into one or more coal beds from the multiple nitrogen injection wells, desorbing of the coal bed gas is reinforced, the desorbed gas is driven to be transported to the production wells from the nitrogen injection wells, the gas or mixed gas of the gas and the nitrogen is obtained from the multiple production wells, the coal bed gas content is decreased, the risks of coal mine gas explosion, burst and exceeding are eliminated, the utilization rate of the coal mine gas is increased, the gas discharged to the atmosphere during coal mine mining is reduced, and the atmosphere environment is protected. By adoption of the method, the coal bed gas content can be effectively decreased to be lower than the residual gas content set according to the coal mining safety requirements, and the gas produced by the production wells through the method can be fully utilized basically.

Owner:湖州优研知识产权服务有限公司

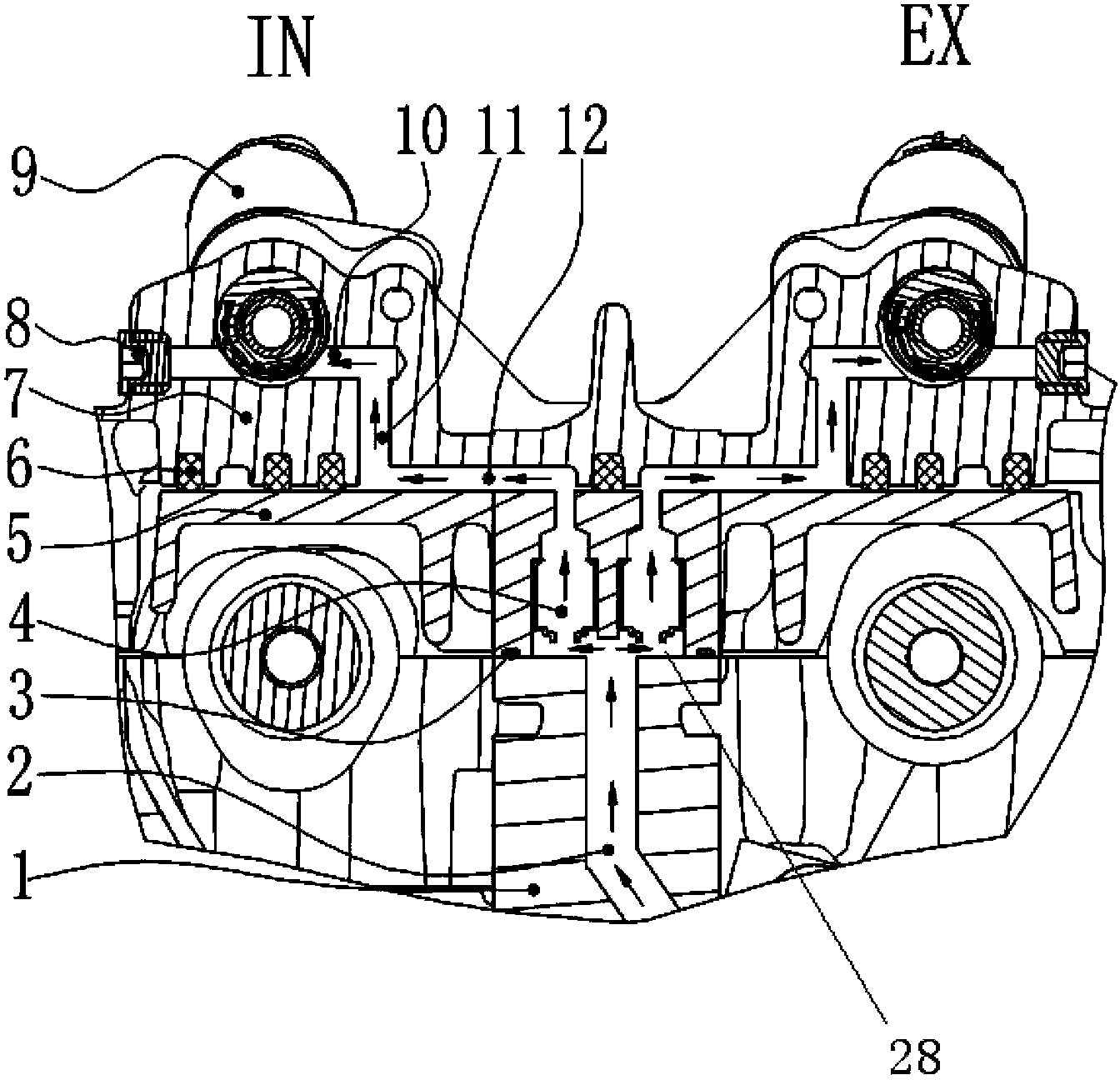

Control oil line of variable valve timing system

ActiveCN103775155AReduce distanceSmall pressure lossMachines/enginesNon-mechanical valveExhaust valveVariable valve timing

The invention discloses a control oil line of a variable valve timing system. The control oil line of the variable valve timing system comprises an intake valve variable timing oil line and an exhaust valve variable timing oil line. An inlet of the intake valve variable timing oil line and an inlet of the exhaust valve variable timing oil line are communicated with an outlet of a main oil gallery arranged in a cylinder head. The intake valve variable timing oil line and the exhaust valve variable timing oil line are distributed on a camshaft bearing cap, a camshaft and a cylinder head cover in a bilateral symmetry mode. Engine oil enters the control oil line through an oil gallery one-way valve, flows through the cylinder head cover and then reaches an engine oil control valve. When the engine oil flows out of an oil port A of the engine oil control valve, the engine oil flows through the cylinder head cover, the camshaft bearing cap and the camshaft in sequence and reaches a front oil cavity of a phaser finally. At this time, the engine oil in a rear oil cavity of the phaser flows out, flows through the camshaft, the camshaft bearing cap and the cylinder head cover in sequence, reaches an oil port B of the engine oil control valve finally and then is discharged through an oil port T of the engine oil control valve. According to the control oil line of the variable valve timing system, the oil line is shortened, so that loss of oil line pressure is reduced, and the performance of an engine is improved; moreover, the structure is simple and reasonable, so that the spatial arrangement of the engine is compact.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

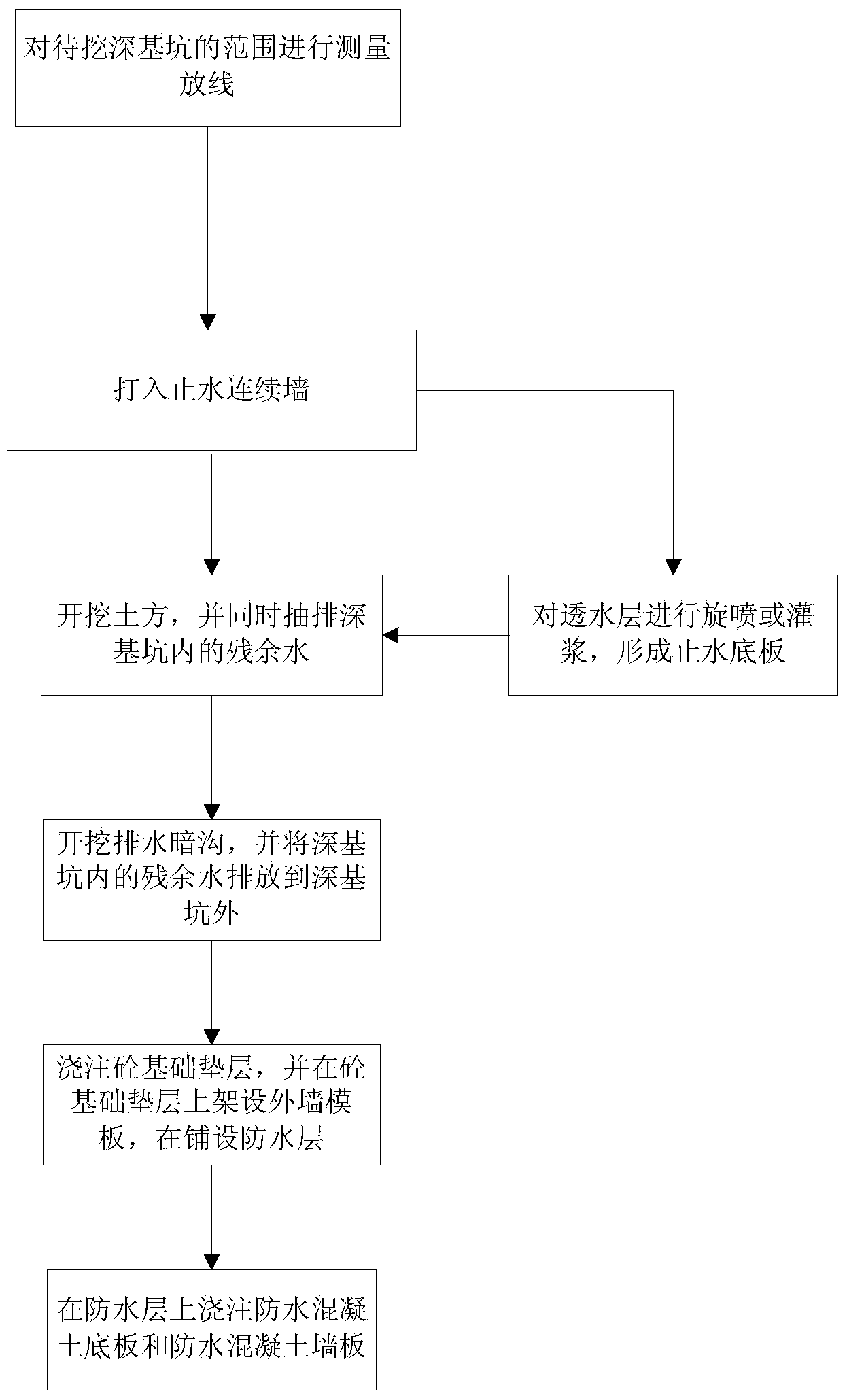

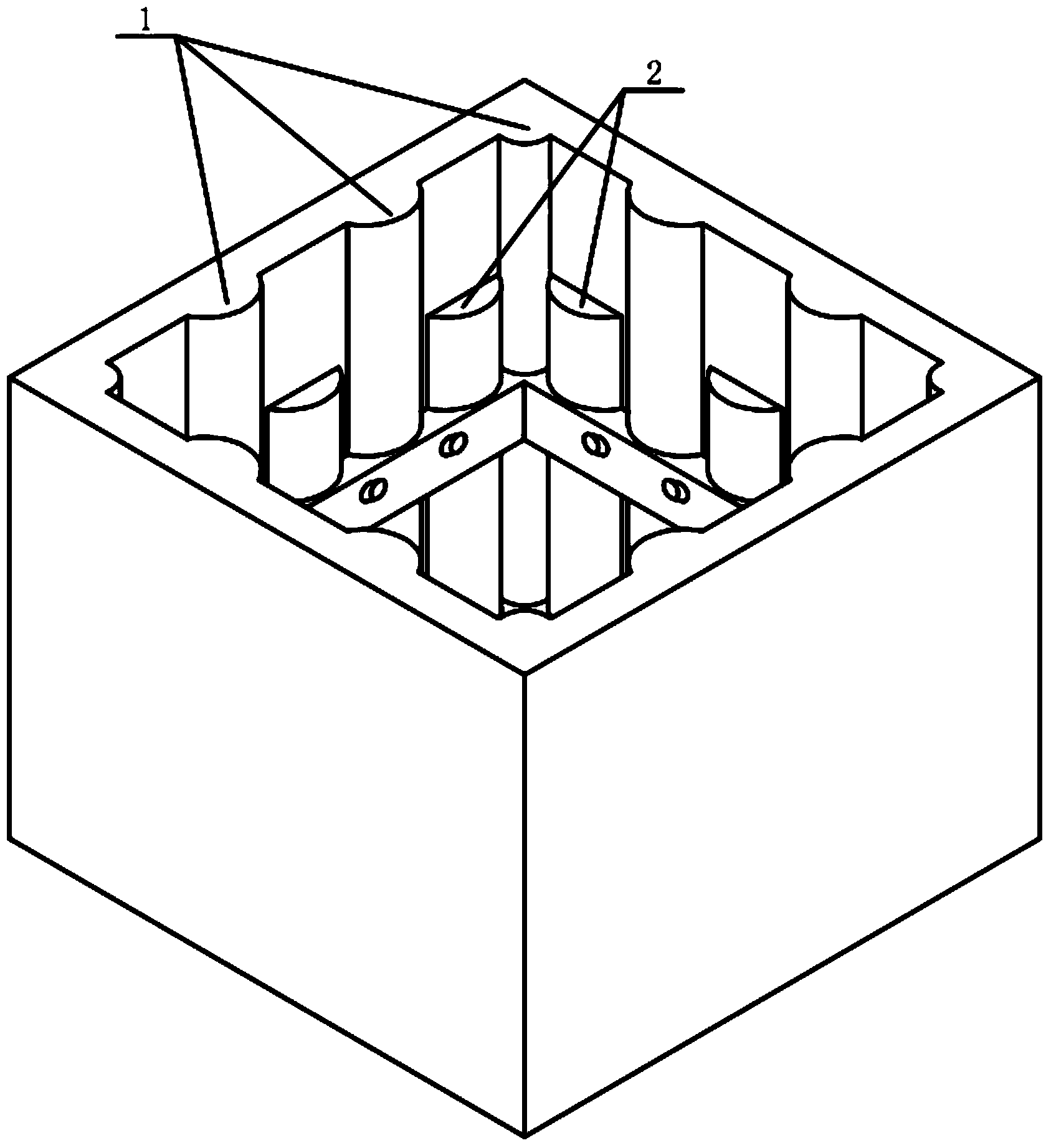

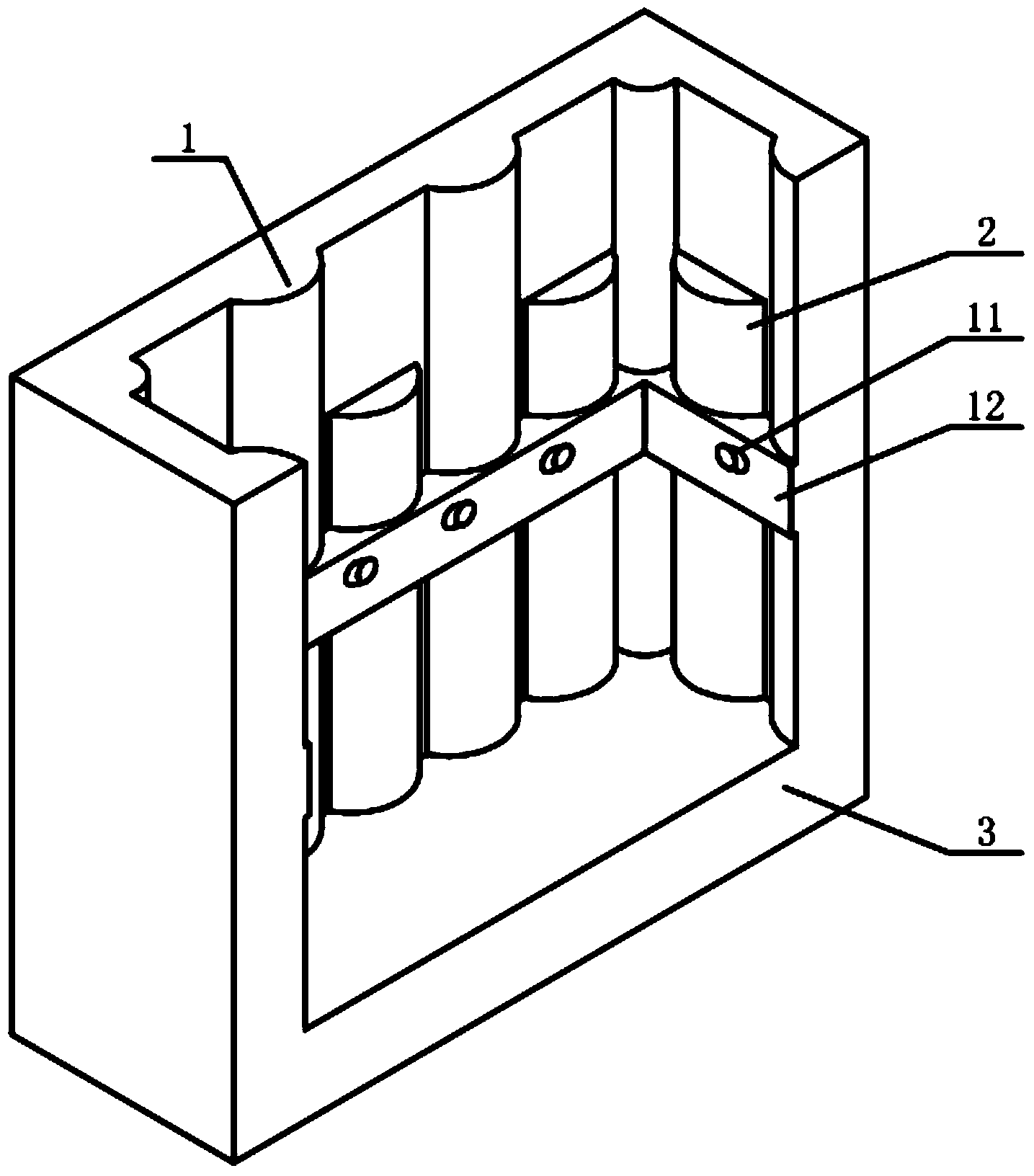

Water-stopping deep foundation pit excavation method and structure thereof

InactiveCN103967015AEnsure balanceAchieve sustainable developmentExcavationsStructure of the EarthWater resources

The invention provides a water-stopping deep foundation pit excavation method. The water-stopping deep foundation pit excavation method comprises the following steps that (1) surveying and setting out are carried on in the range of a deep foundation pit to be excavated; (2) retaining piles are driven downwards along side walls of the deep foundation pit to be excavated, jet grouting piles are driven into gaps between the retaining piles after the adjacent retaining piles are driven at intervals, so that a water-stopping continuous wall is formed, and the water-stopping continuous wall extends into a bearing layer below a basic design elevation; (3) the bearing layer below the basic design elevation is a permeable layer, mortar grouting or jet grouting is conducted on the bearing layer below the basic design elevation, so that a water-stopping bottom plate is formed at the top of the bearing layer, and the retaining piles and the jet grouting piles extend into the water-stopping bottom plate. According to the water-stopping deep foundation pit excavation method, underground water outside the deep foundation pit can be isolated from a working plane inside the deep foundation pit in the construction process, as a result, a large area of underground water surrounding the deep foundation pit does not need to be drained when the deep foundation pit is excavated, and water resources are protected.

Owner:刘绍国

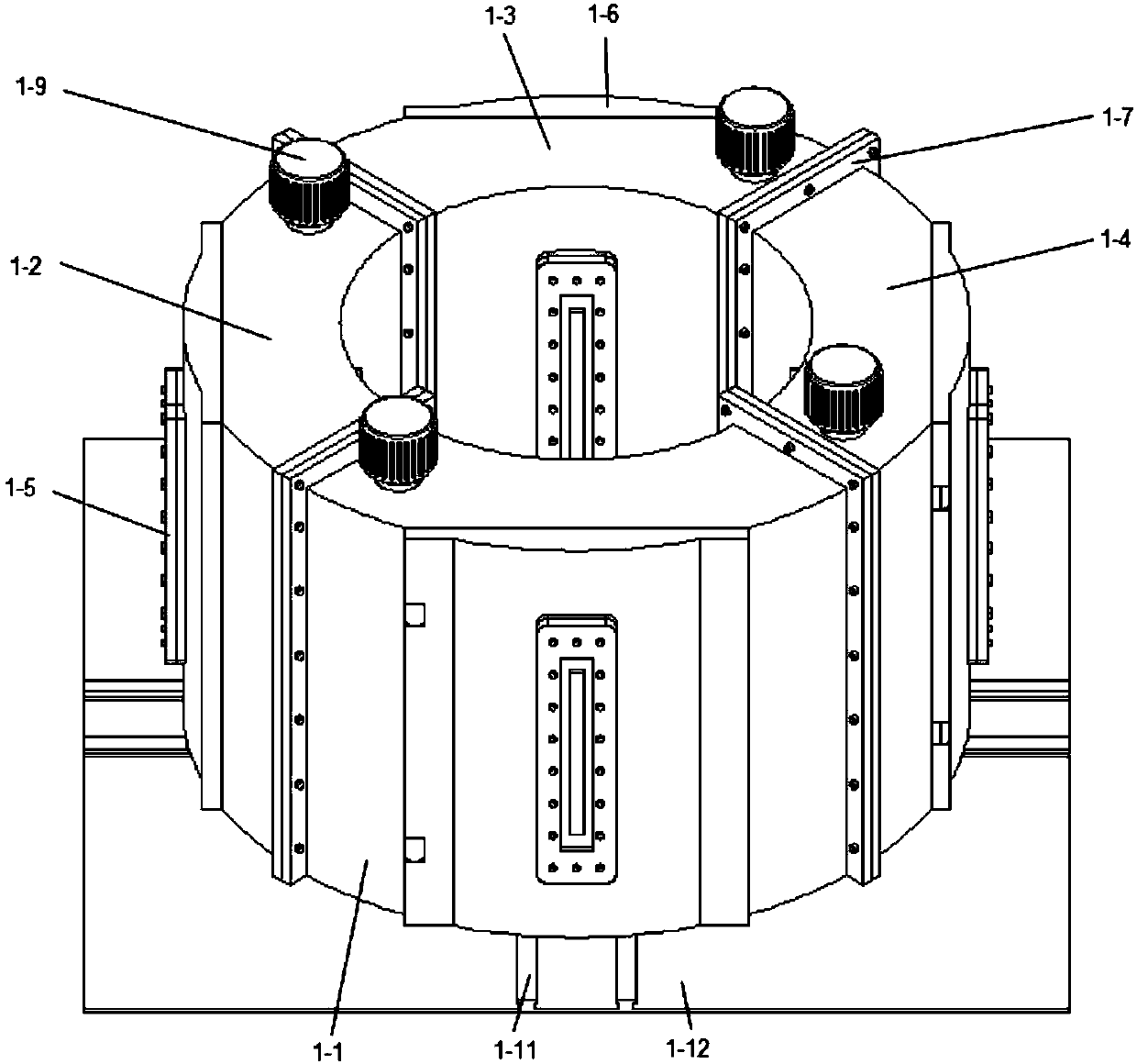

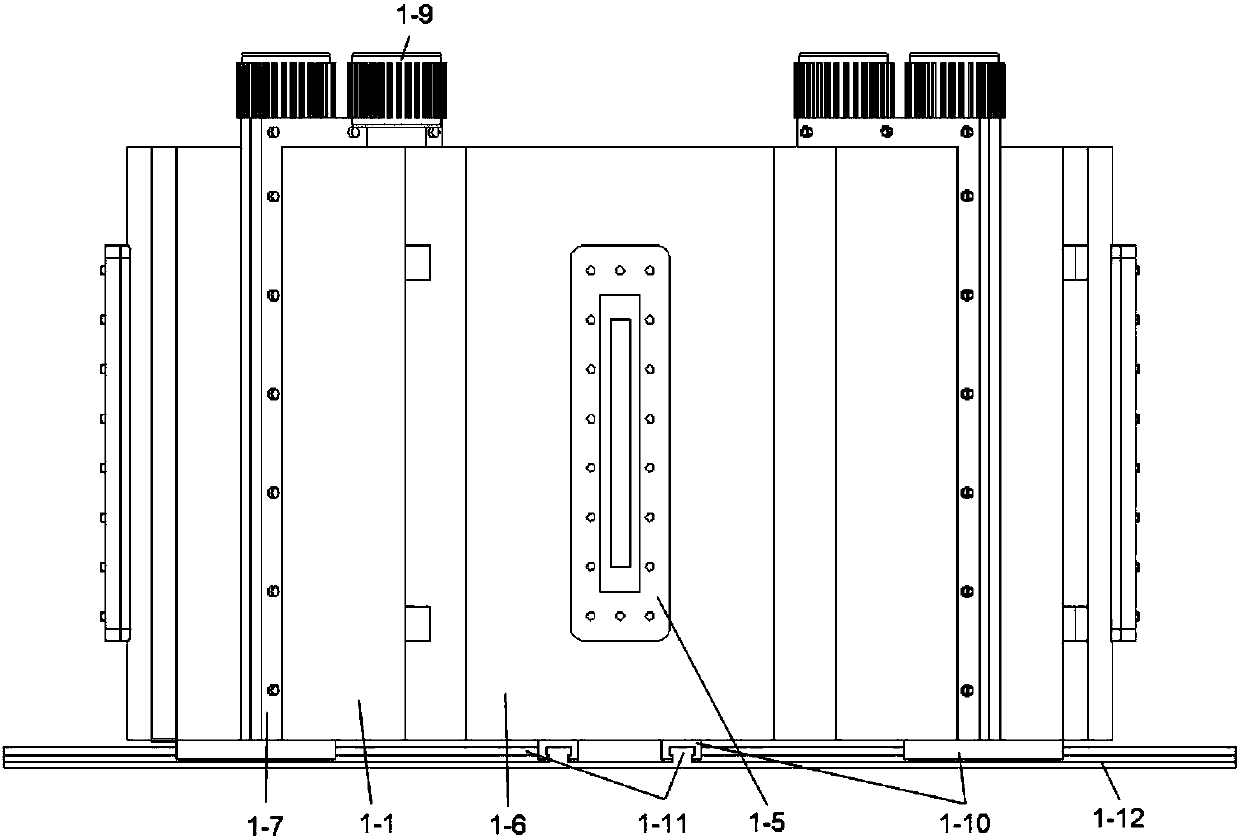

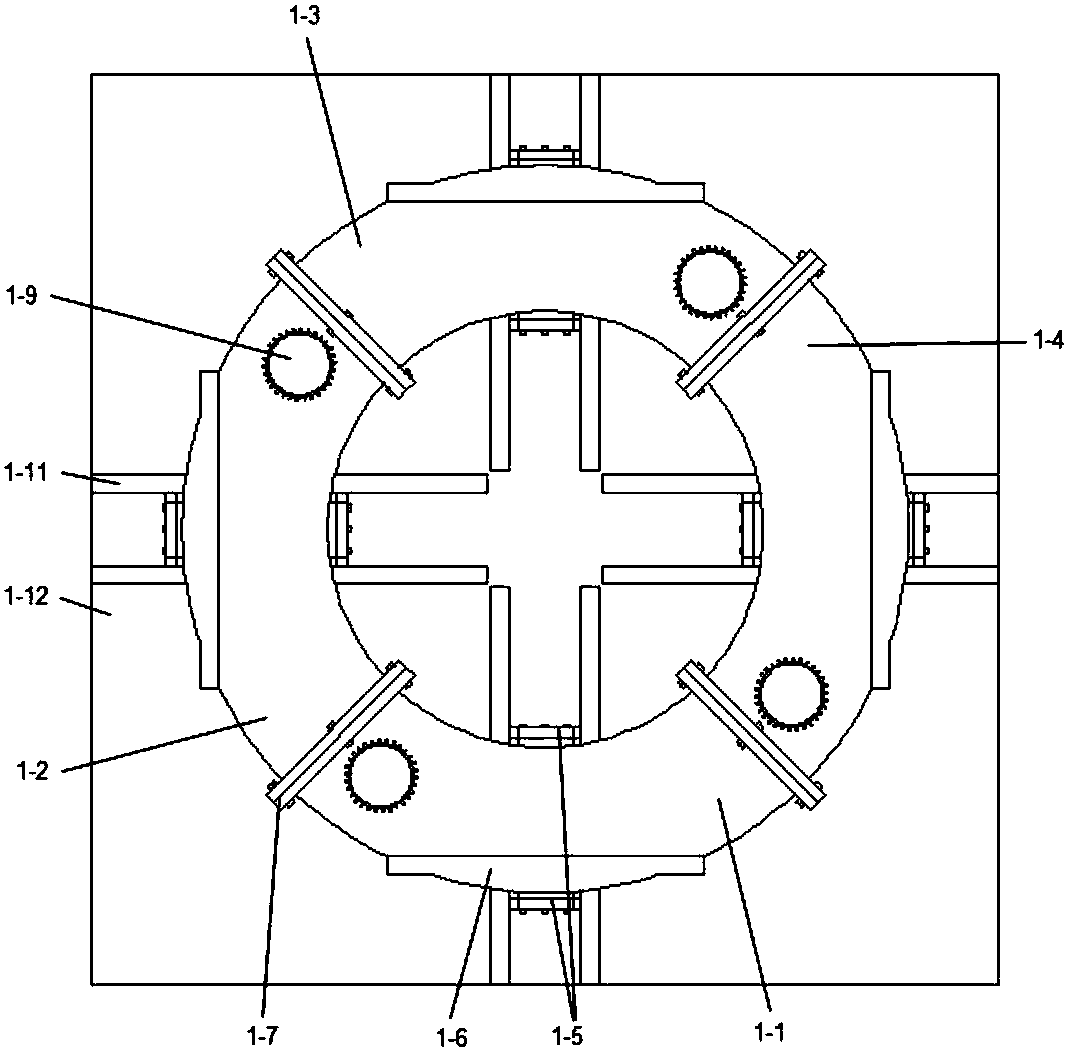

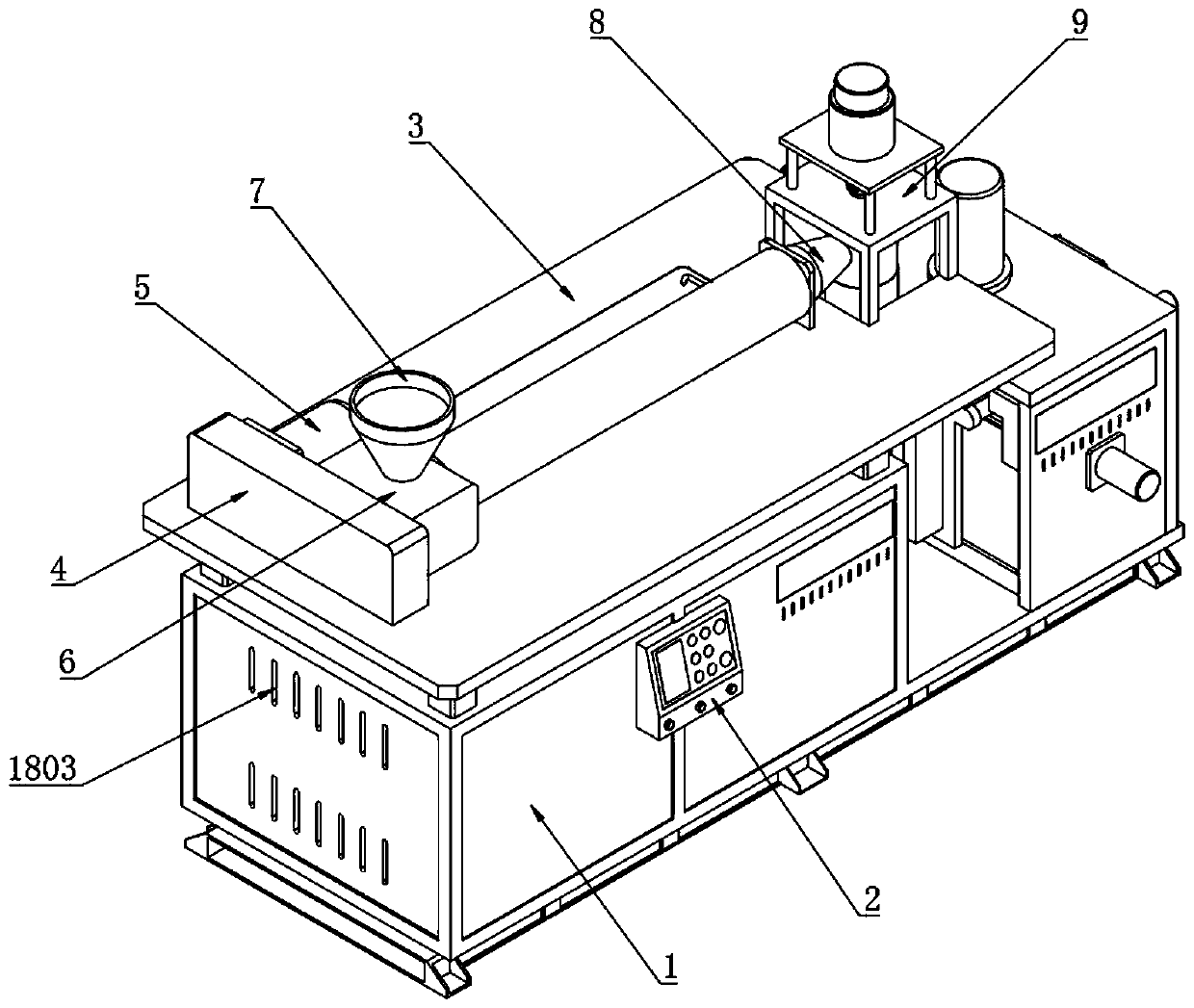

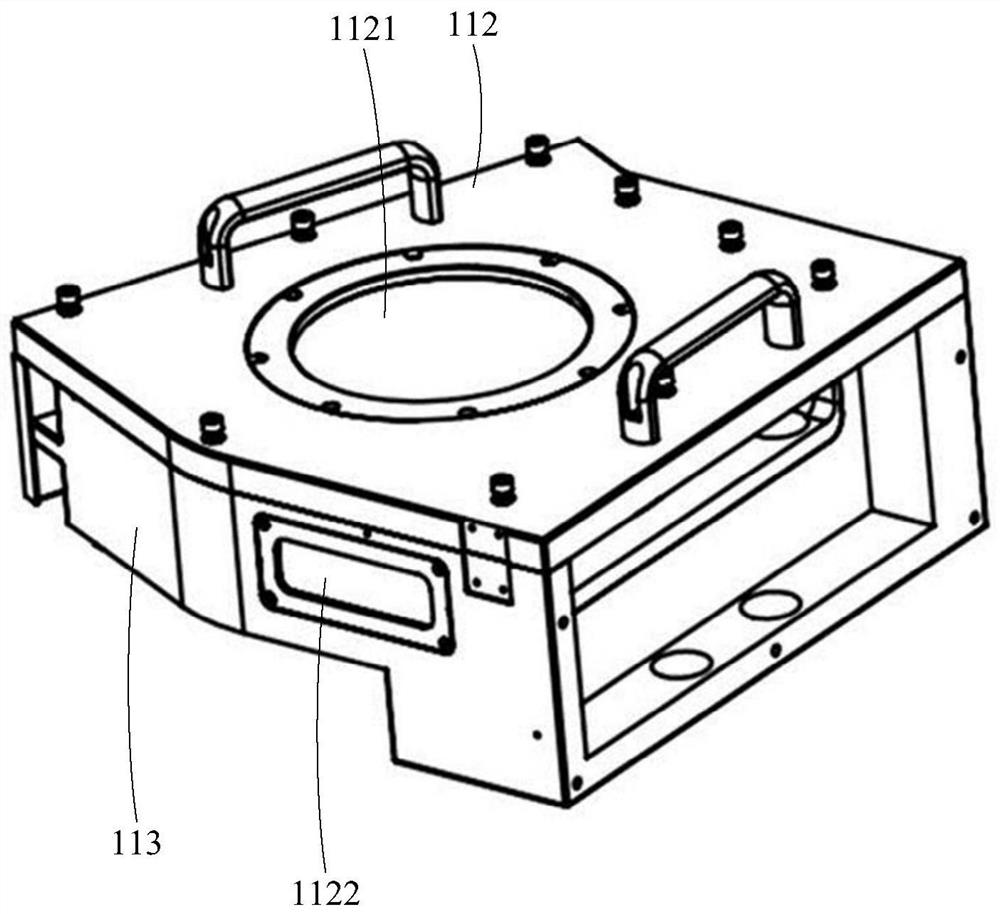

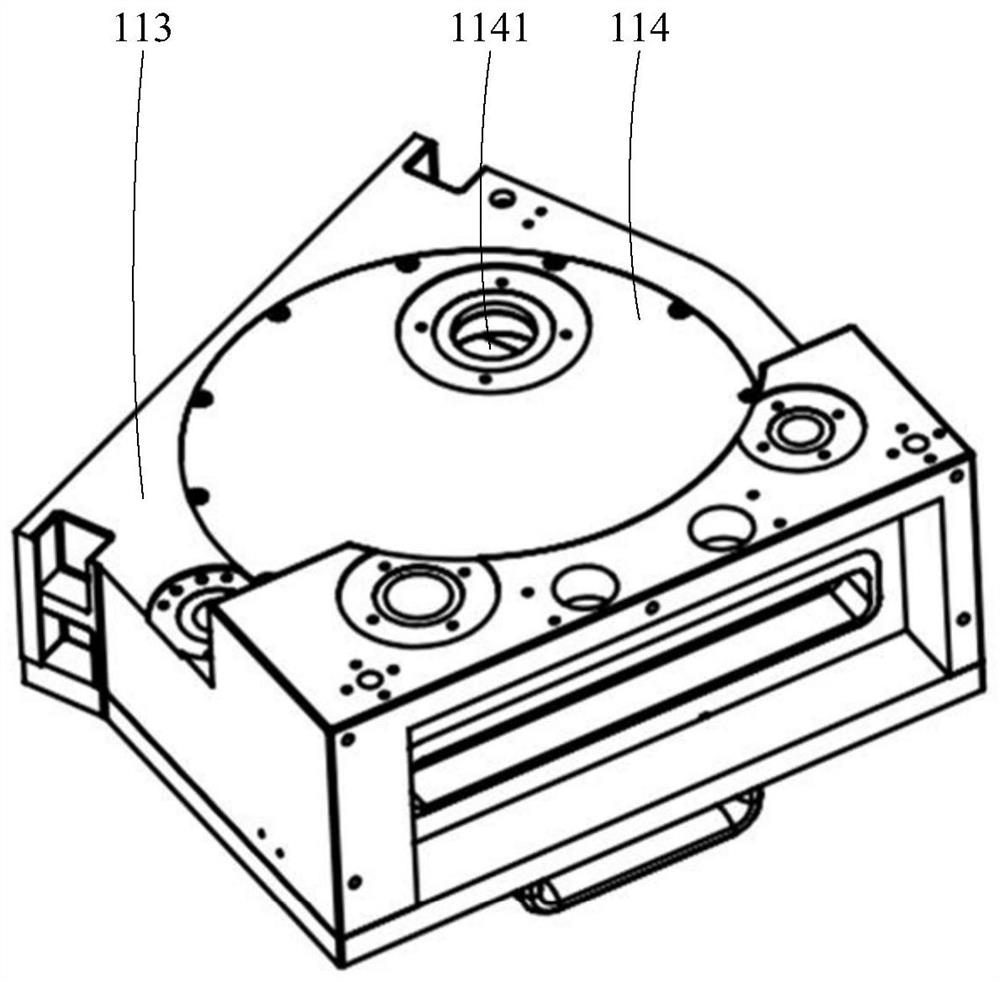

Efficient annular vacuum coating device for fuel cell metal bipolar plate

ActiveCN107604328AIncrease the effective volume ratioReduce pumping timeVacuum evaporation coatingSputtering coatingFilm baseEngineering

The invention relates to an efficient annular vacuum coating device for a fuel cell metal bipolar plate. The efficient annular vacuum coating device comprises a vacuum chamber, an ion source, target materials, a workpiece frame, a workpiece frame transmission system, a vacuum system, an isolating system and an electronic control system. According to the efficient annular magnetron sputtering device, compared with an original circular cavity, the areas, irrelevant to coating, in the center of the chamber are omitted, the effective use volume ratio of coating is increased, the air pumping time is shortened, and the coating efficiency is improved; secondly, the opposite-target sputtering mode is adopted, a substrate does not rotate, the constant target-substrate distance is kept, and uniformity of coating is facilitated; at the same time, the distance between two targets is shortened, the round larger chamber can better form a closed magnetic field, and enhancement of film base binding force is facilitated; and at the same time, the annular chamber can be divided into a plurality of branch chamber bodies, the pair of target materials of the same type is mounted in each branch chamberbody, and multilayer composite coatings can be deposited on the substrate surface. Compared with the prior art, the coating efficiency is high, the film layer quality is good, the yield is high, and the great significance is achieved on industrialization of the fuel cell metal bipolar plate coatings.

Owner:SHANGHAI JIAO TONG UNIV

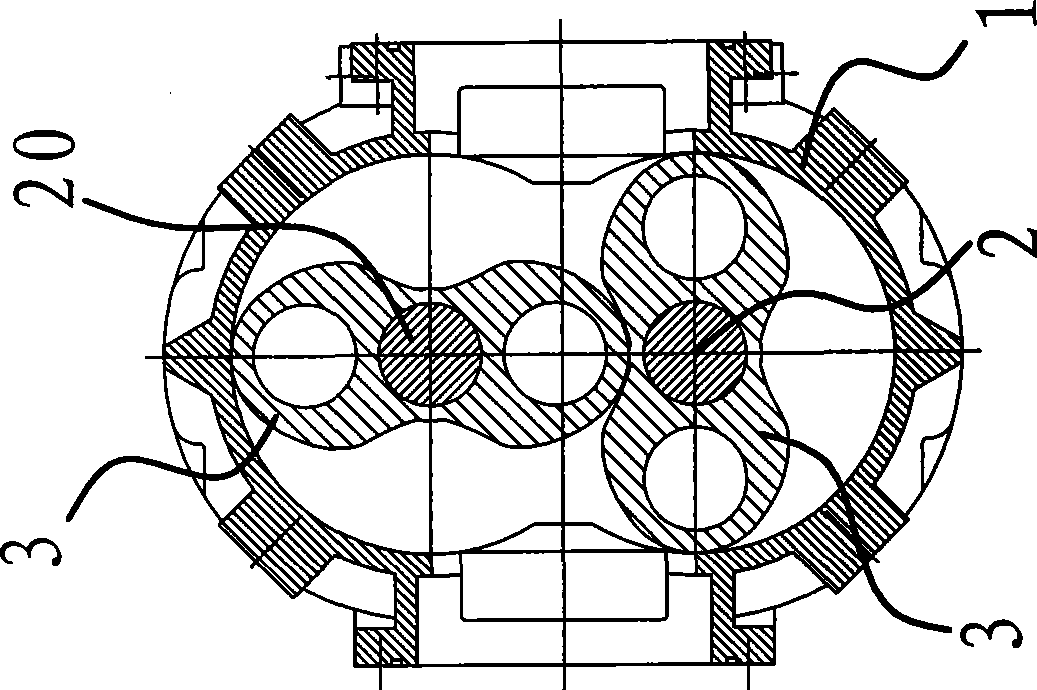

Roots vacuum pump

InactiveCN101463816ALow ultimate pressureReduce pumping timeRotary piston pumpsRotary piston liquid enginesPower gridEngineering

The invention provides a Roots vacuum pump, which belongs to the technical field of machinery and solves the technical problems of hard load start, high starting current, high impact on an electricity grid, high bearing impact, and the like of the existing Roots vacuum pump. The Roots vacuum pump comprises a pump body and a long pump shaft and a short pump shaft arranged in the pump body, wherein, rotors are respectively connected on the long pump shaft and the short pump shaft, the long pump shaft and the short pump shaft are connected with each other by a pair of engaged driver gears, one end of the long pump shaft extends out of the pump body on which an electric motor is arranged, and a rotating shaft of the electric motor and the pump shafts are connected by hydraulic driving mechanisms. The Roots vacuum pump has the advantages of favorable overload protection, low starting current, easy load start, short air suction time, etc.

Owner:ZHEJIANG VACUUM EQUIP GROUP

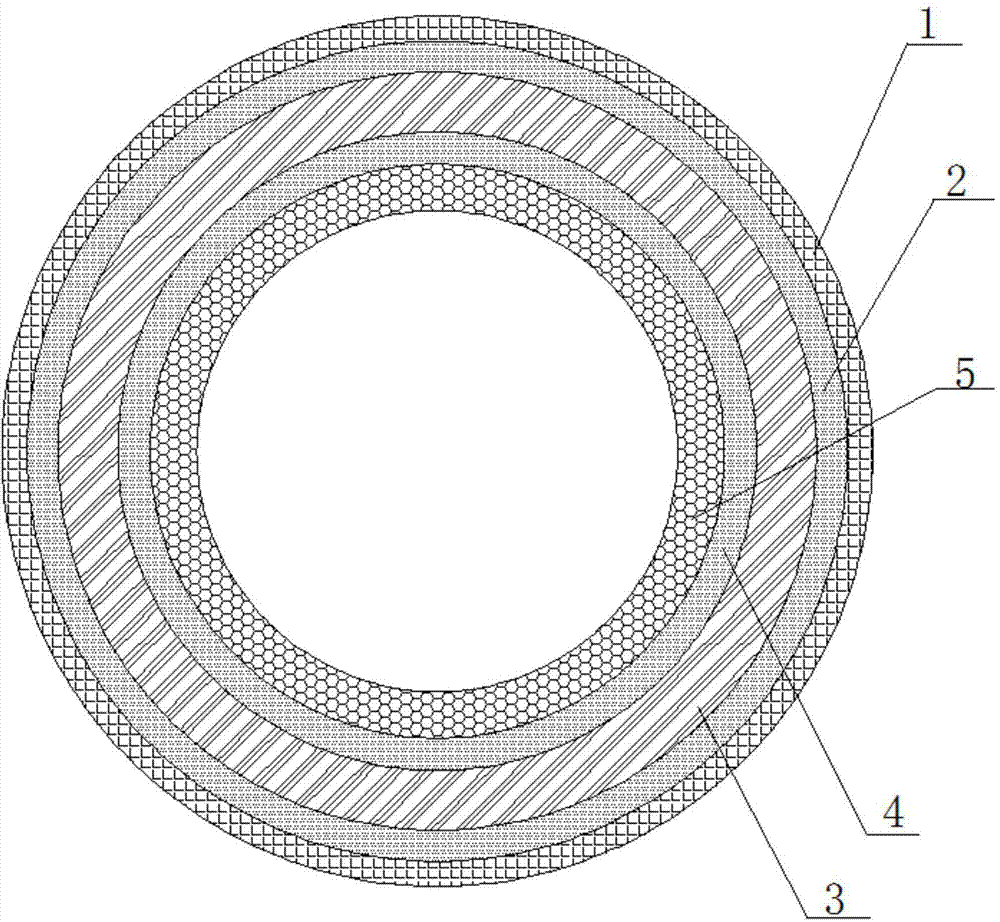

Glass fiber-reinforced plastic polyurethane TPU composite tube and manufacturing process thereof

InactiveCN104847977AExtended service lifeReduced operating and maintenance costsThermal insulationFlexible pipesPolyesterCorrosion resistant

The invention discloses a glass fiber-reinforced plastic polyurethane TPU composite tube. The glass fiber-reinforced plastic polyurethane TPU composite tube comprises an outer protective layer, an outer reinforcing layer, a sand inclusion structure layer, an inner reinforcing layer and a lining layer which are sequentially arranged from outside to inside, wherein the outer protective layer is a composite layer with quartz sand and unsaturated polyester resin, the outer reinforcing layer is a composite layer with glass fibers and unsaturated polyester resin, the sand inclusion structure layer is a composite layer with quartz sand, glass fibers and unsaturated polyester resin, the inner reinforcing layer is a composite layer with glass fibers and unsaturated polyester resin, and the lining layer is a low free nanometer polyester layer. The invention further discloses a manufacturing process of the glass fiber-reinforced plastic polyurethane TPU composite tube. The glass fiber-reinforced plastic polyurethane TPU composite tube has reliability, safety and economy, is mainly used for pulp conveying, bittern conveying, sea water desalination and corrosion-resistant and abrasion-resistant process pipelines, has the advantages of being light, high in strength, resistant to corrosion, high in abrasion resistance, long in service life, low in operation and maintenance cost and the like, and saves a large number of expenses for construction engineering.

Owner:张俊达 +1

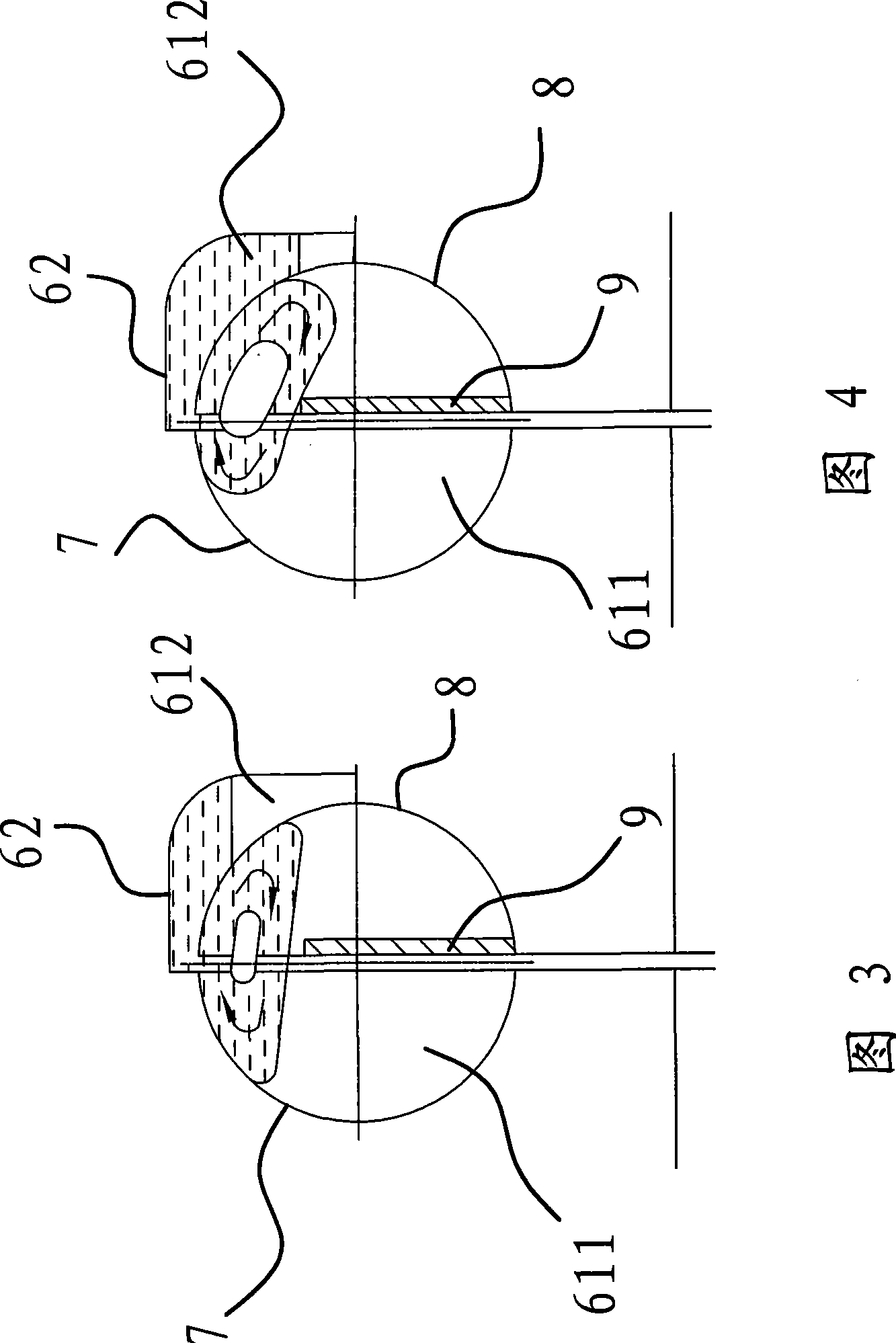

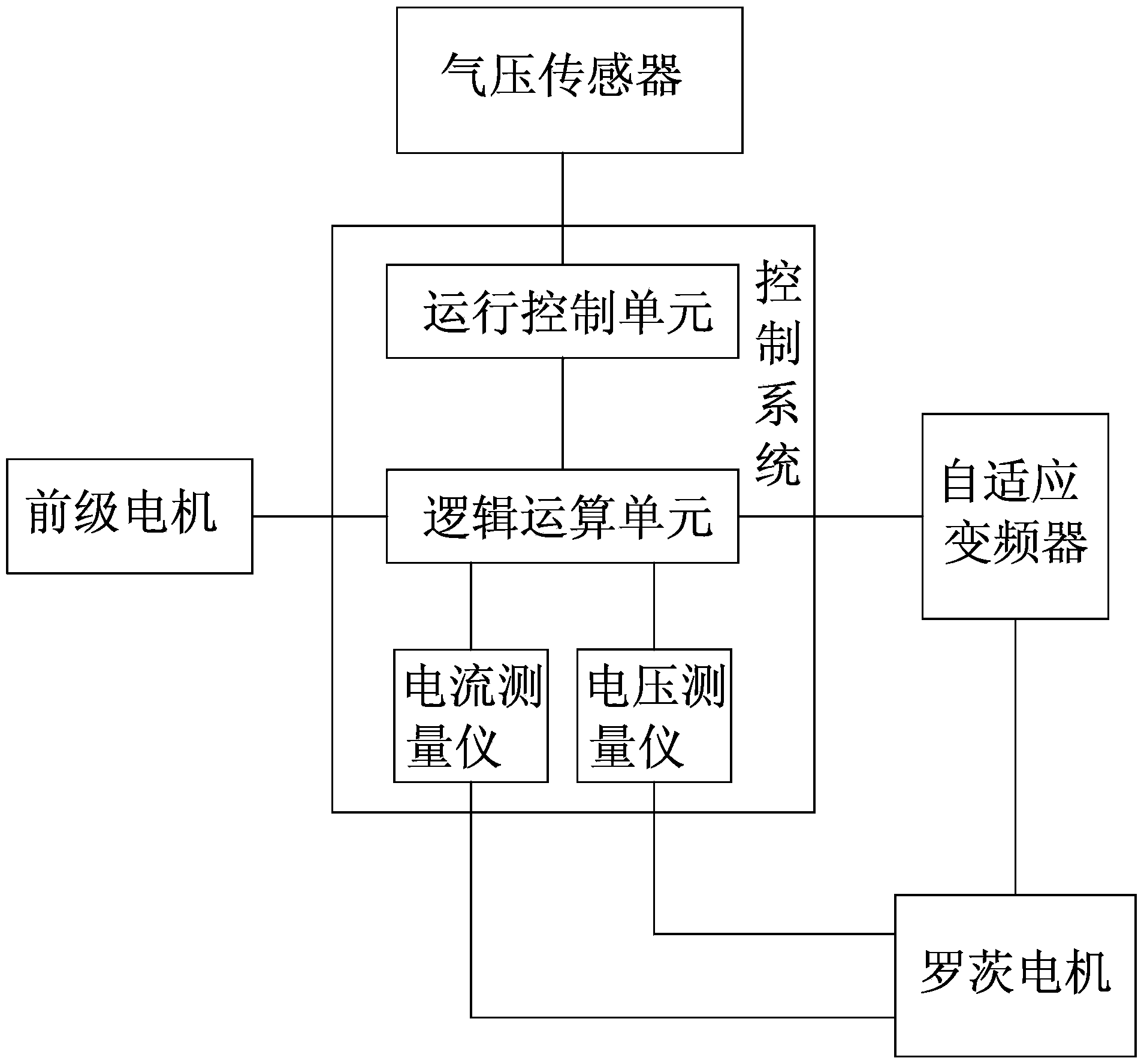

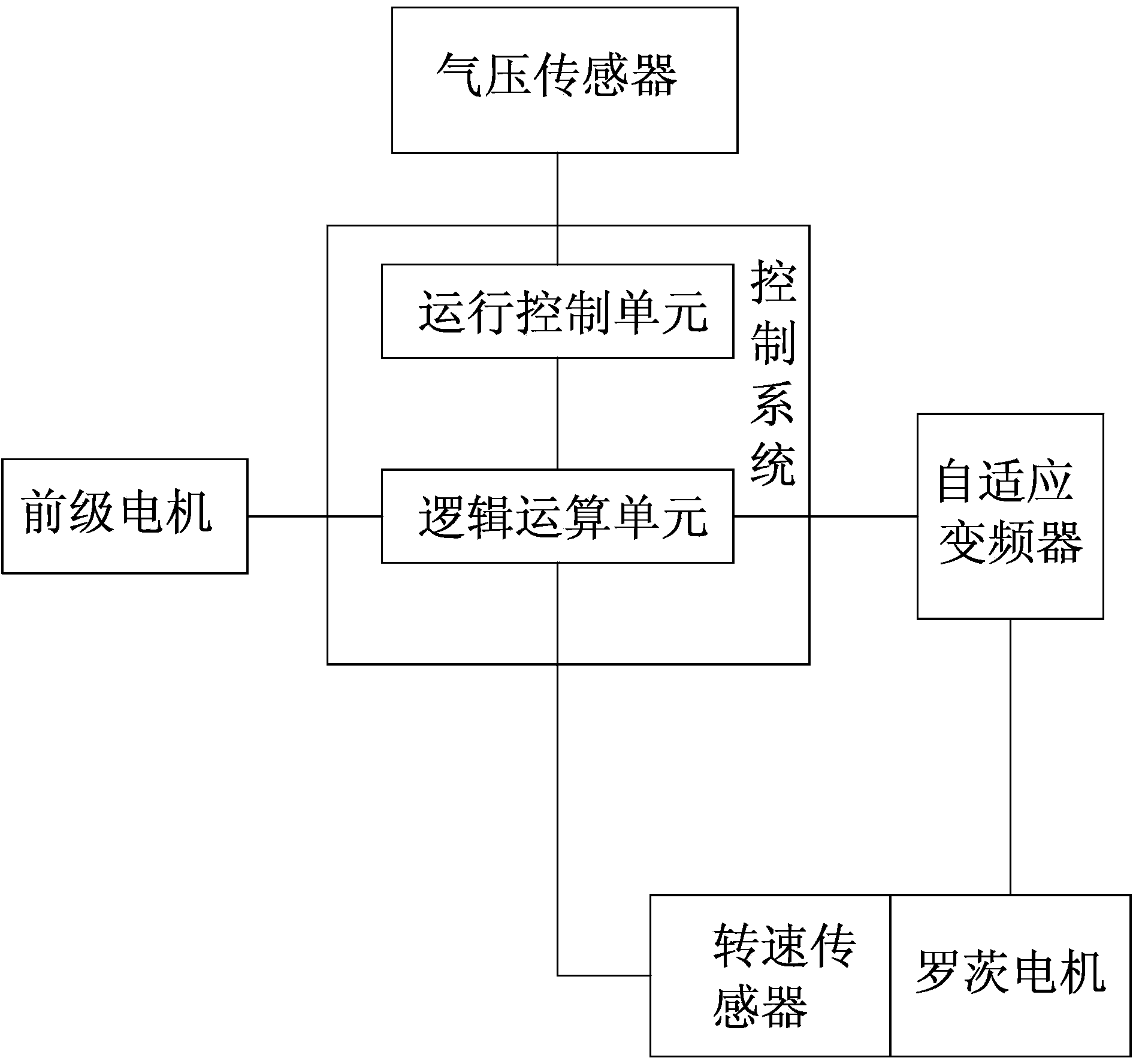

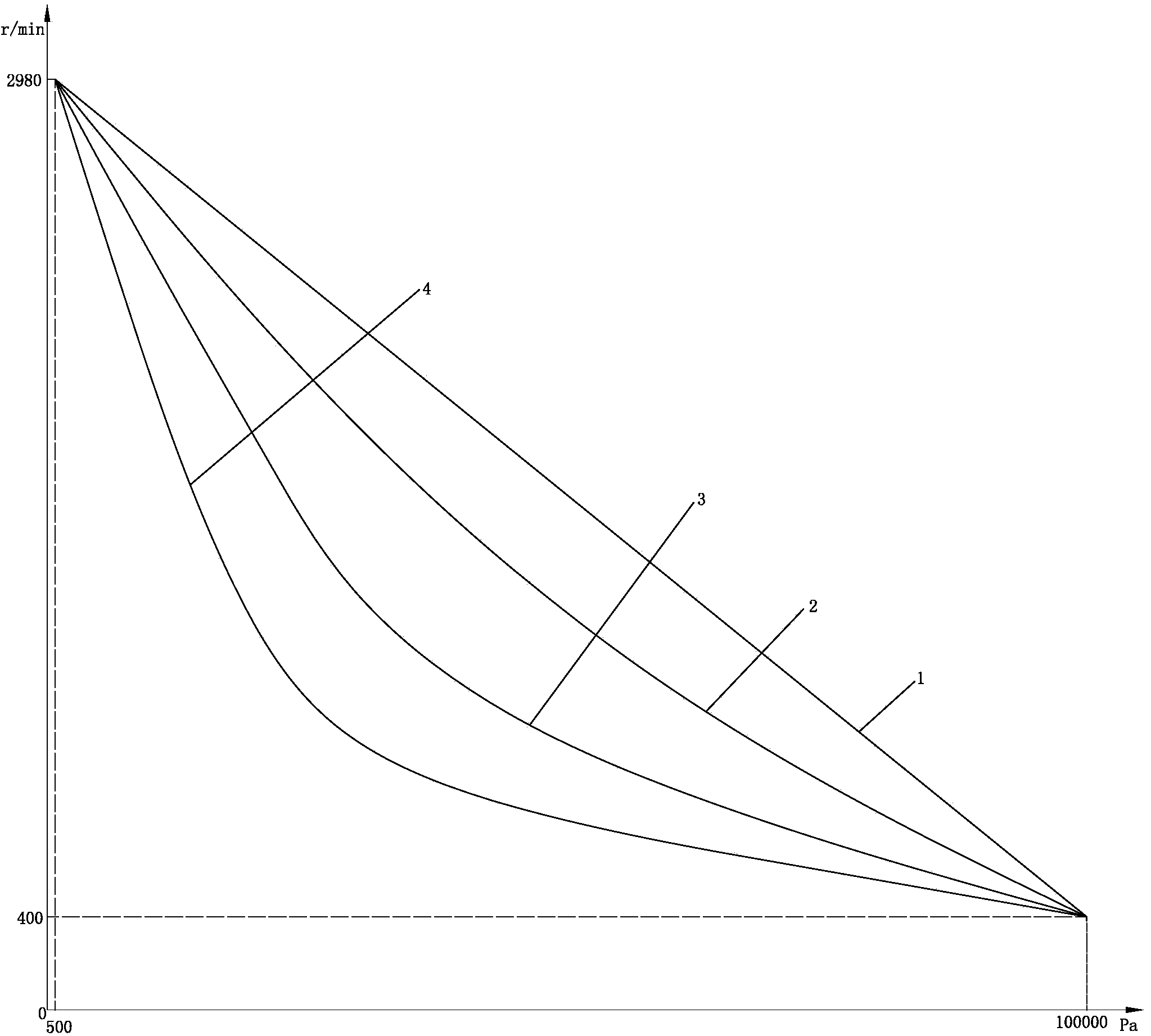

Roots atmosphere direct-exhausting smart machine unit

ActiveCN104047858AIncrease speedImprove work efficiencyRotary/oscillating piston combinations for elastic fluidsPump controlFrequency changerAtmospheric air

The invention provides a Roots atmosphere direct-exhausting smart machine unit, belongs to the technical field of vacuum devices and solves the problem that an existing Roots vacuum machine unit is long in vacuumizing and large in electric power consumption. The smart machine unit comprises a Roots vacuum pump, a backing pump, a negative pressure sensor and a control system, wherein the control system is provided with a monitoring unit for monitoring the running speed of a Roots motor; the Roots vacuum pump comprises a pump body and the Roots motor; the backing pump comprises a backing motor; the negative pressure sensor is arranged in a pump body of the Roots vacuum pump and is electrically connected with the control system; the Roots motor is electrically connected with the control system through a self-adaptive frequency transformer; the backing motor is electrically connected with the control system. The Roots vacuum pump of the smart machine unit is started in advance, the pumping speed of the machine unit is increased; the air pumping time is extremely shortened and the work efficiency of the overall machine is improved; the smart machine unit also has the advantage of being capable of prolonging the service life of the Roots vacuum pump and reducing the impact to a power grid.

Owner:项敏 +1

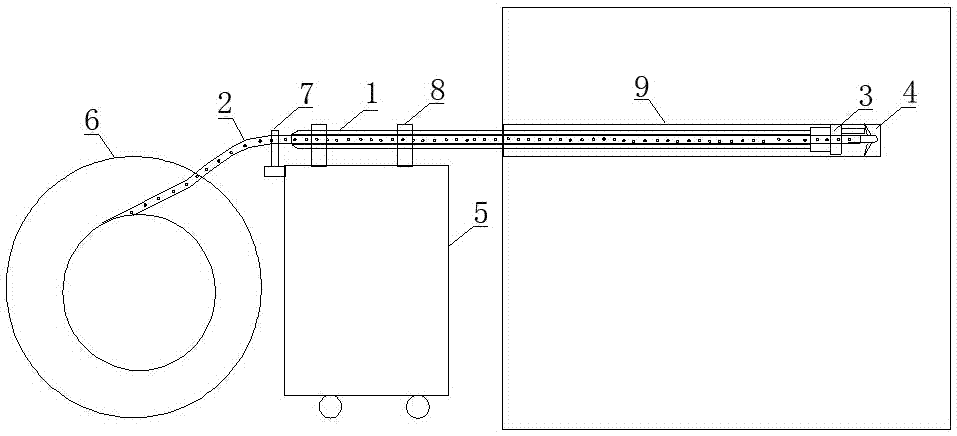

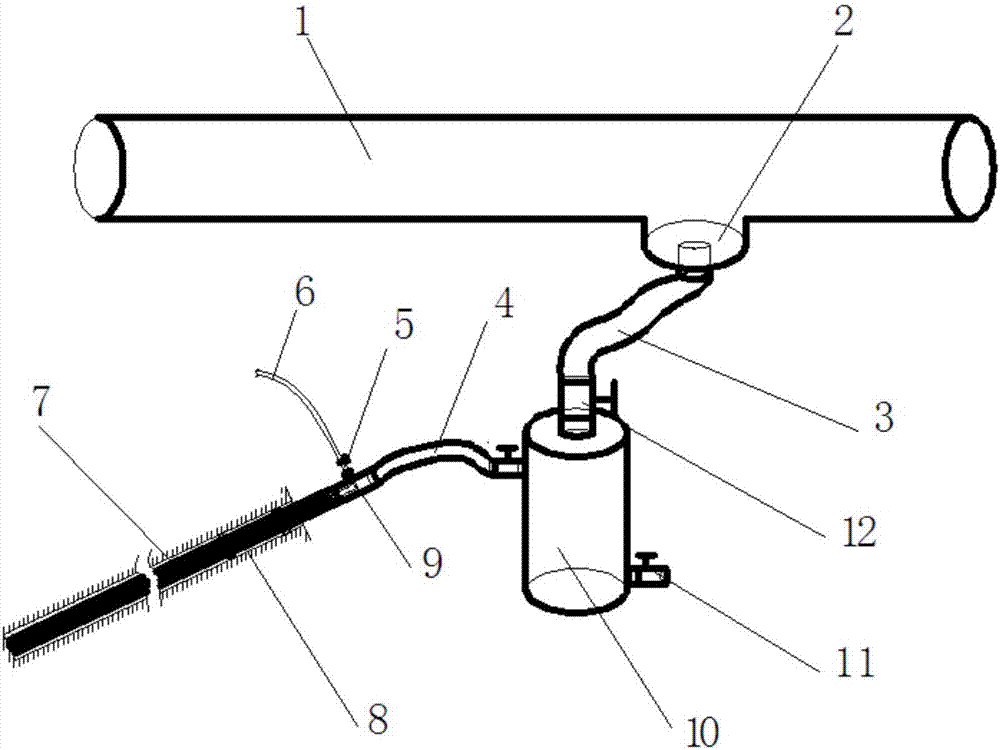

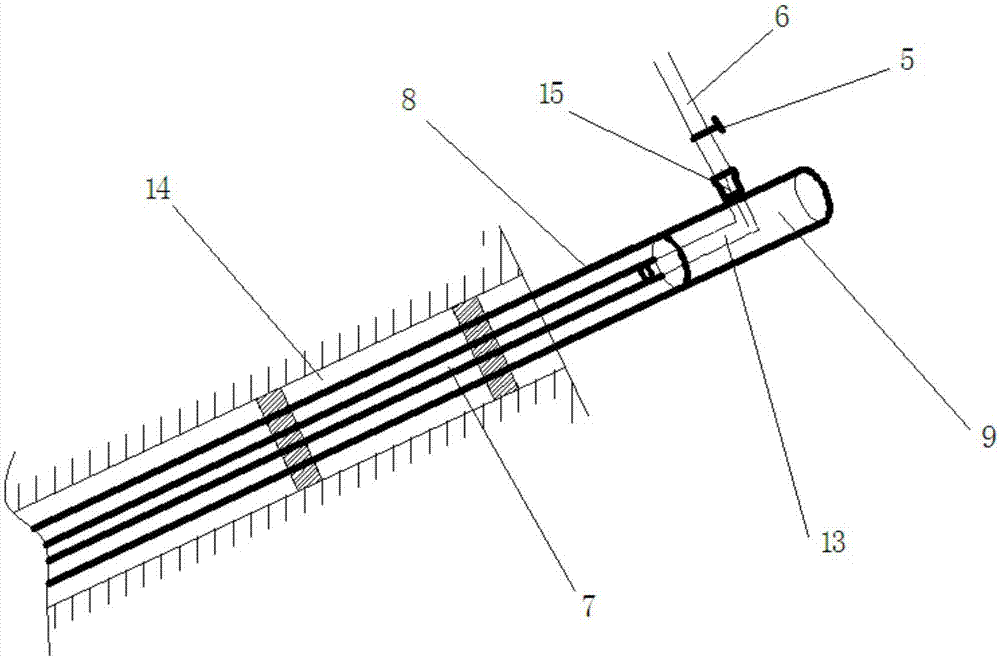

Down hole continuous screen pipe hole protection method for coal mine

InactiveCN106869989AIncrease the effective inner diameterImprove efficiencyFluid removalGas removalDischarge efficiencyCompressive strength

The invention belongs to the technical field of coal mine safe production and particularly provides a down hole continuous screen pipe hole protection method for a coal mine. The method comprise the following steps that testing devices such as a drilling machine and a screen pipe conveying device and materials are transferred to a drilling construction site, a cylindrical reeling disc is reeled with a continuous screen pipe, and a hole clamping device is installed at the end of the screen pipe conveying device; drilling is conducted on a soft coal construction consequent layer or penetrating layer; after drilling is conducted to the position of a designed depth, drilling is stopped, and the screen pipe conveying device is installed on the drilling machine; the continuous screen pipe and the hole clamping device are inserted into the screen pipe conveying device, and the continuous screen pipe is conveyed into a drilling rod through the conveying device; a lower screen pipe drill bit is ejected away through the hole clamping device at the end of the continuous screen pipe, and the screen pipe is fixed to the wall of a drill hole; the continuous screen pipe is cut off at a hole mouth, and the drilling rod is withdrawn; and hole sealing continuous pumping is conducted through a large-diameter sleeve pipe. According to the down hole continuous screen pipe hole protection method for the coal mine, in soft coal drilling, the screen pipe putting in time is short, efficiency is high, the compression strength of the screen pipe is high, drill hole gas extraction efficiency is high, drill hole pumping and discharging efficiency are sufficiently improved, the gas pre-pumping time is shortened, and gas disasters are eliminated to the utmost extent.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

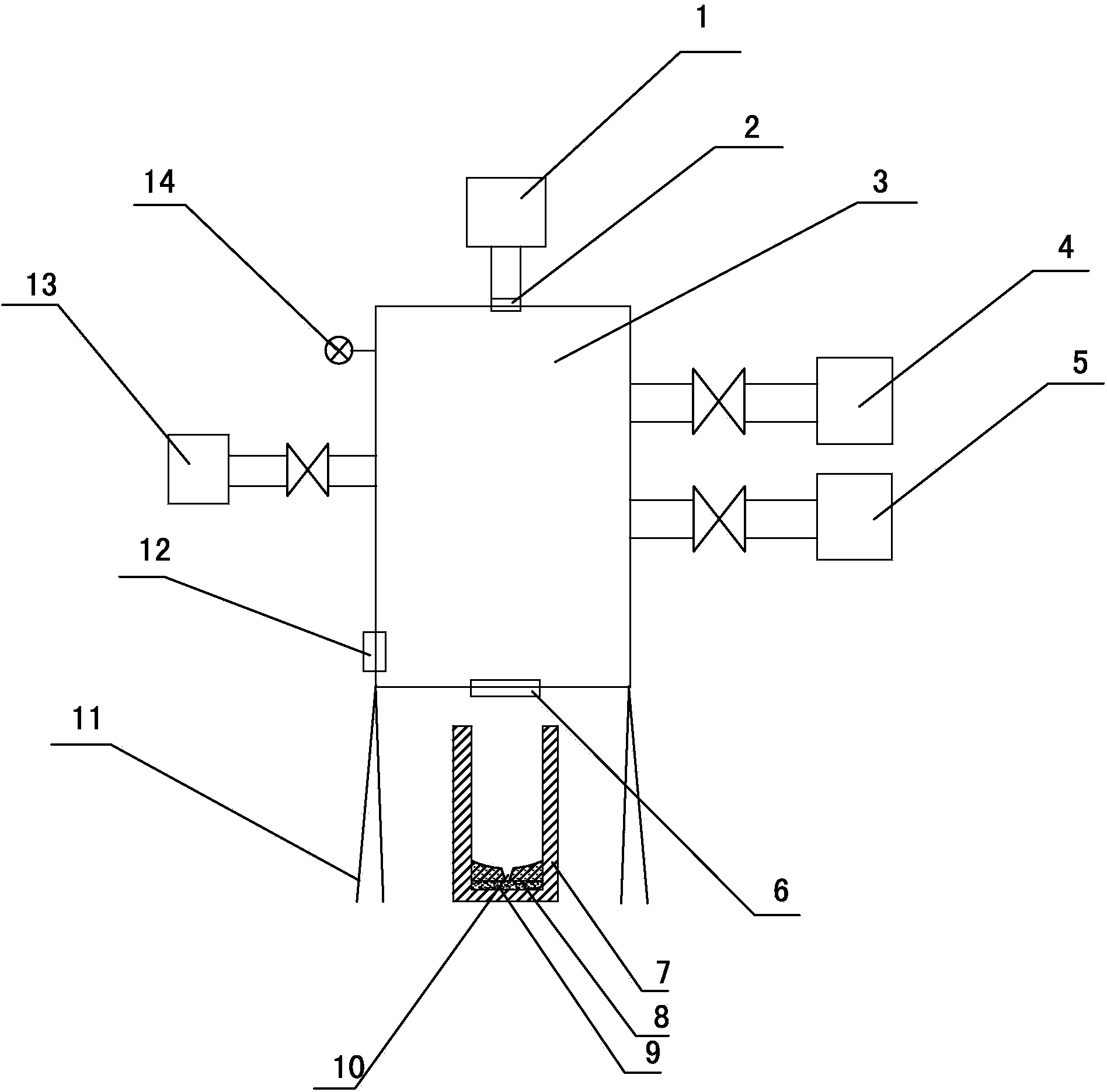

Titanium manganese alloy smelting device

The invention belongs to the field of metal smelting, and in particular relates to a titanium manganese alloy smelting device. The titanium manganese alloy smelting device comprises a smelting furnace, wherein a feeding device is arranged above the smelting furnace and is connected with a feeding hole in the top of the smelting furnace through a pipeline; a vacuum pump, a molecular drag pump and an air distribution device are connected with the smelting furnace through pipelines respectively; valves are arranged on the pipelines among the vacuum pump, the molecular drag pump, the air distribution device and the smelting furnace respectively; a vacuum meter and a heating device are arranged on one side of the smelting furnace; brackets are arranged on two sides of the bottom of the smelting furnace; a discharging hole is formed in the middle of the bottom of the smelting furnace; a pouring mold with an upward opening is arranged at a position, corresponding to the discharging hole, below the smelting furnace; a cast ingot base pad and a heat-preserving base pad are sequentially arranged at the lower part of the inner cavity of the pouring mold from bottom to top; a through hole is formed in the middle of the heat-preserving base pad; a circular arc of 80 to 100 degrees is formed between the upper end surface of the heat-preserving base pad and the horizontal plane. The titanium manganese alloy smelting device is simple in structure, the air exhaust time is shortened, the air exhaust energy consumption is reduced, and the quality of a cast ingot is effectively improved.

Owner:SHANDONG ROITIE NEW MATERIAL SCI & TECH

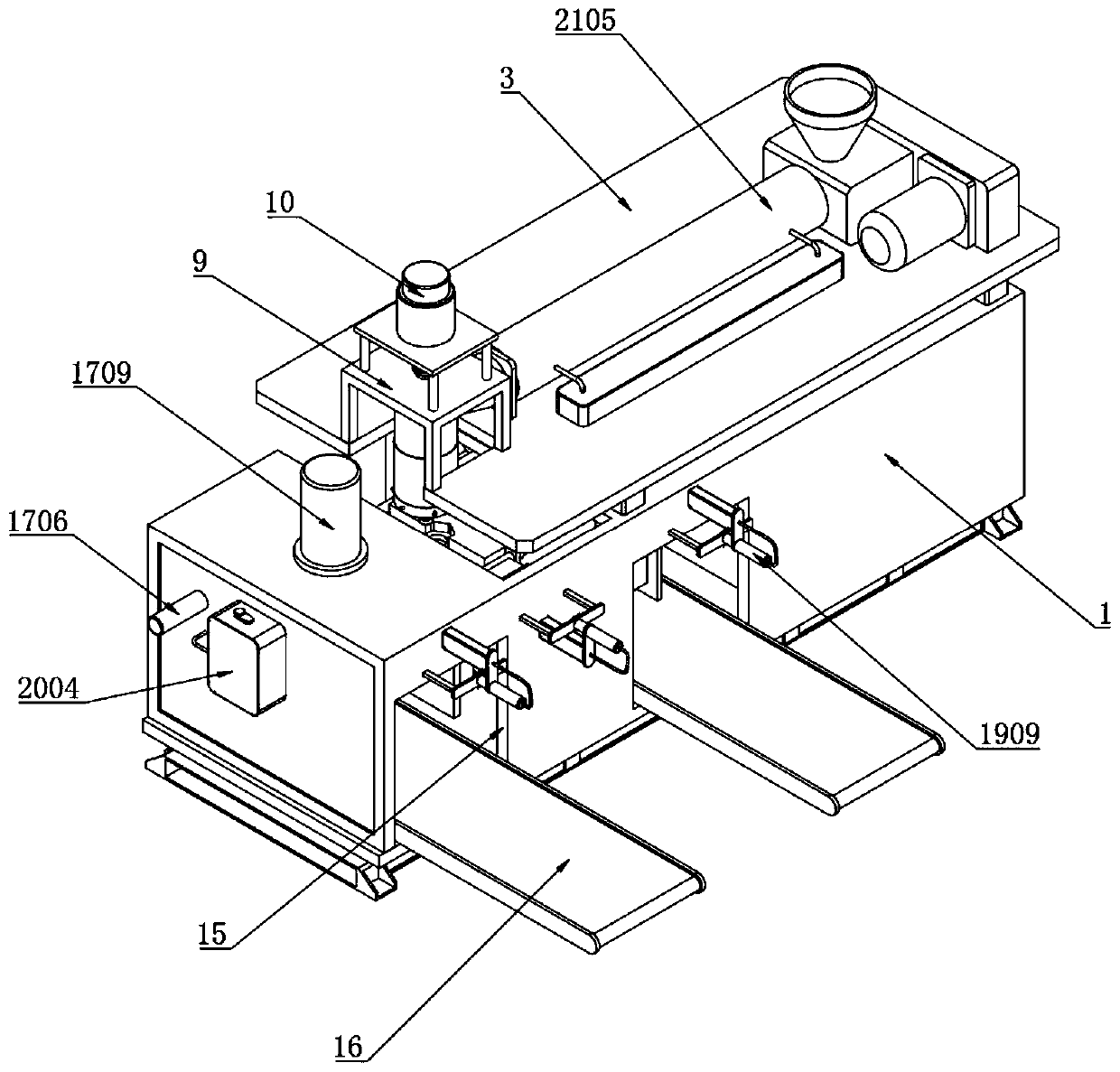

Automatic blow molding machine adopting artificialized feeding and discharging

The invention discloses an automatic blow molding machine adopting artificialized feeding and discharging. The automatic blow molding machine adopting artificialized feeding and discharging comprisesa blow molding machine box. One end of the blow molding machine box is provided with a control switch. The top end of the blow molding machine box is provided with an top plate through connection columns. The top end of the top plate is fixedly connected with a transmission bin, and the end, corresponding to the transmission bin, of the top end of the top plate is connected with an injection molding motor. The side, corresponding to the injection molding motor, of one end of the transmission bin is provided with a hot melting bin. The automatic blow molding machine adopting artificialized feeding and discharging is scientific and reasonable in structure and safe and convenient to use. By arranging a first hydraulic lever, a first side mold, a shifting side mold and a second side mold, theefficiency of the blow molding process is improved, through combination with arrangement of a six-edge seal ring and a six-edge seal groove, the seal performance during blow molding can be improved, and the air pumping time required during blow molding is shortened; by arranging a draw-off pump, an absorption bin, a transfer pipe, a dispersion plate, activated carbon plates and a desiccant plate,absorption of harmful gas in air is convenient during blow molding of raw materials, and the safety guarantee during blow molding production is improved.

Owner:张周钦

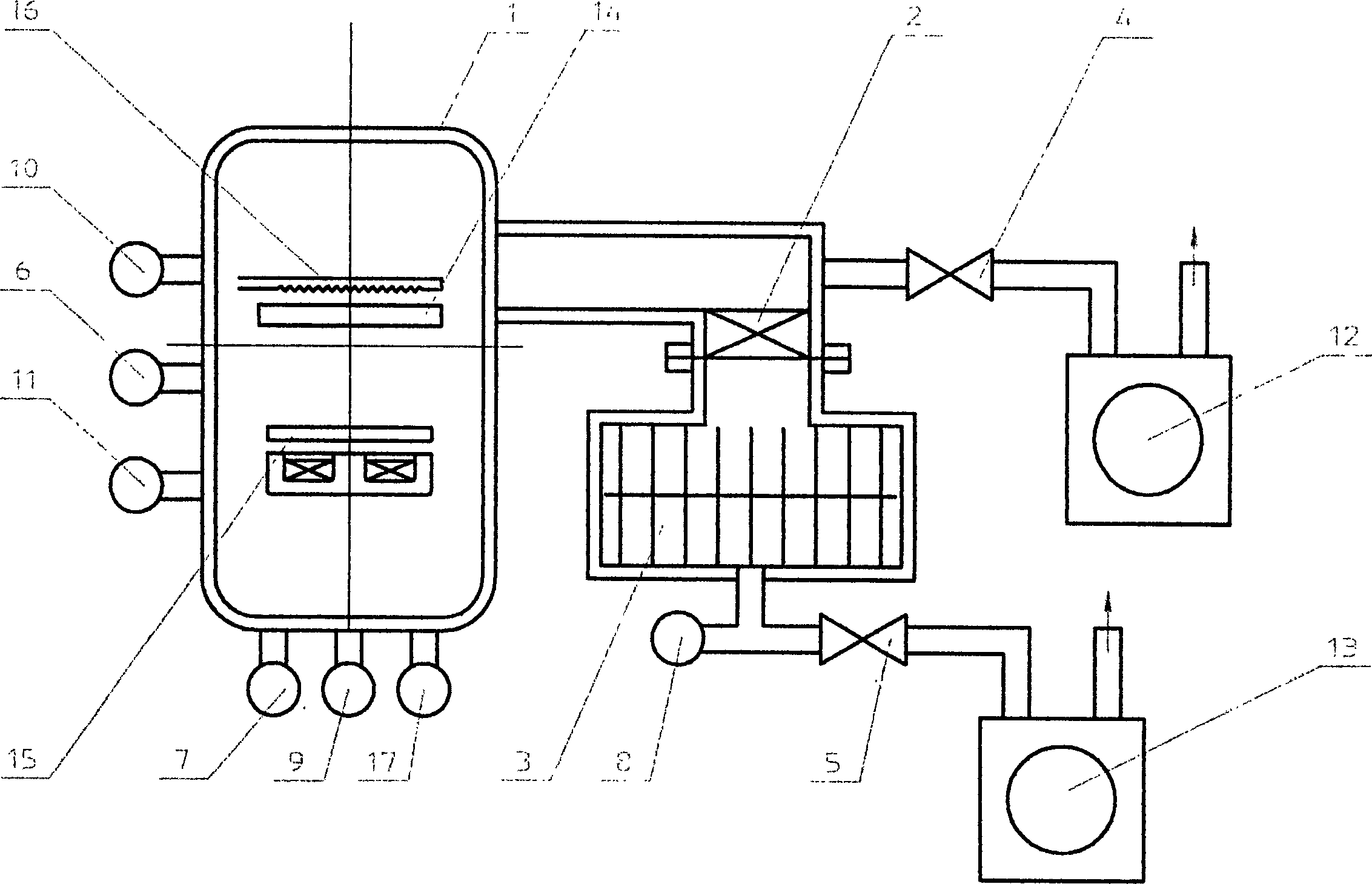

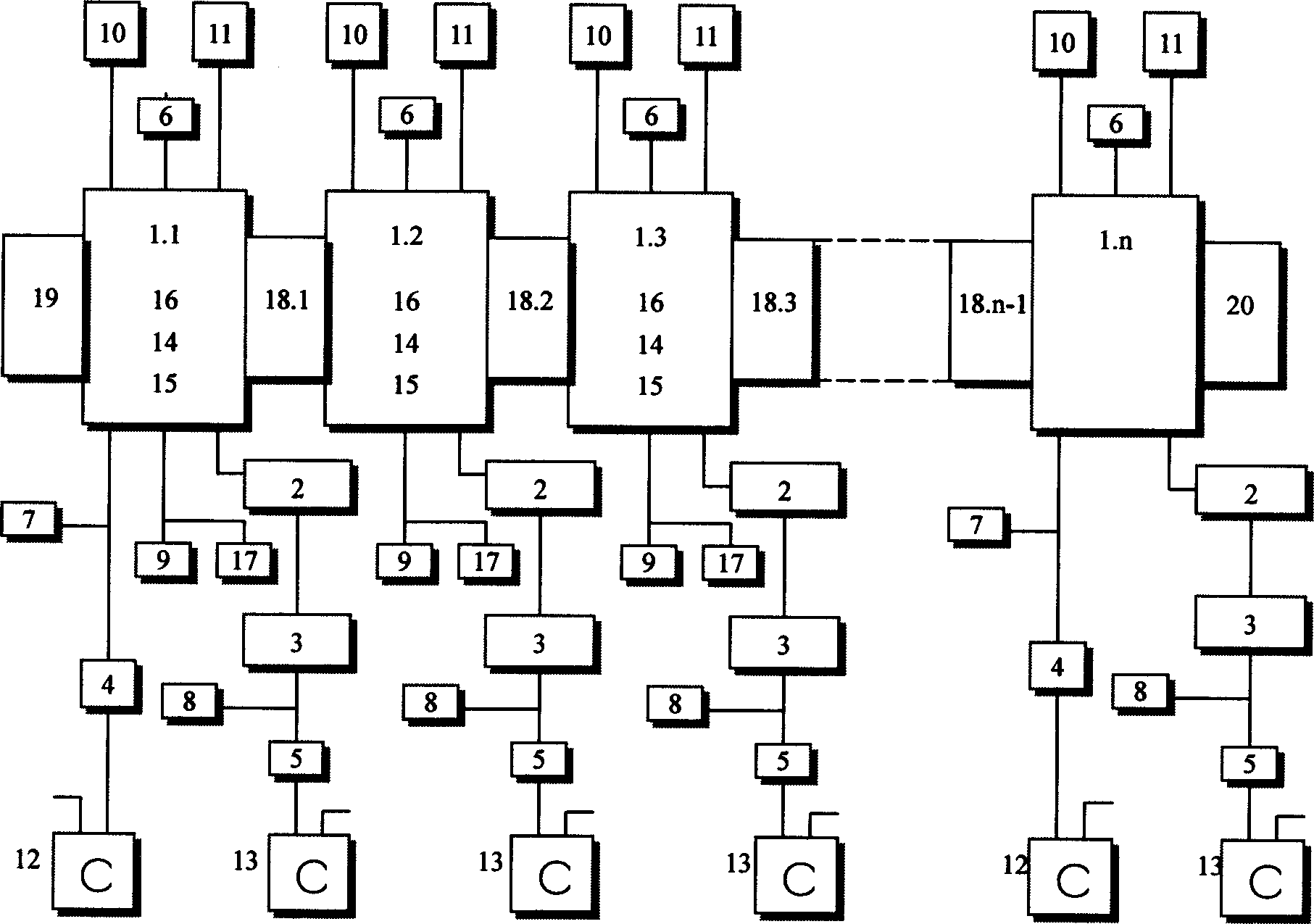

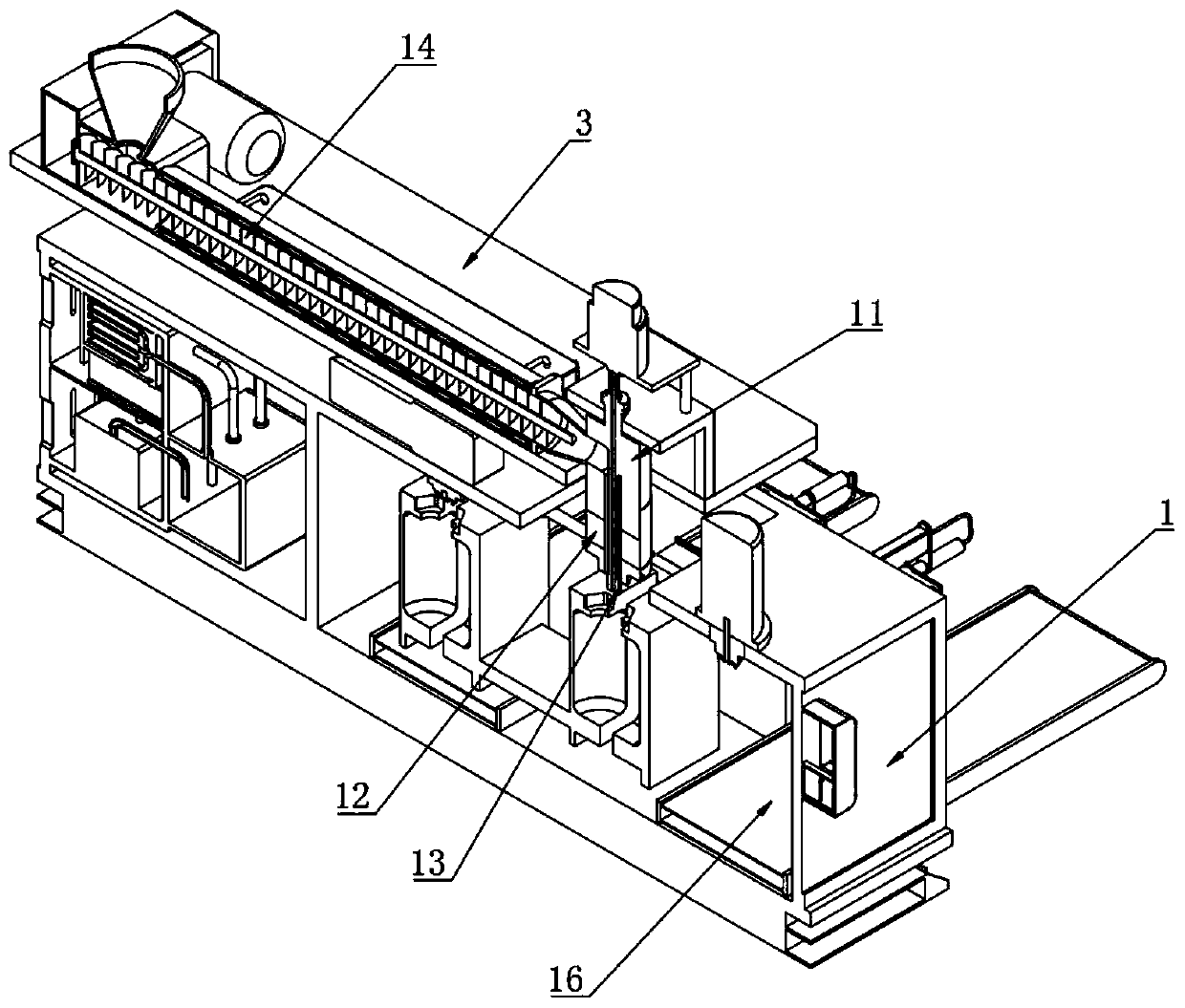

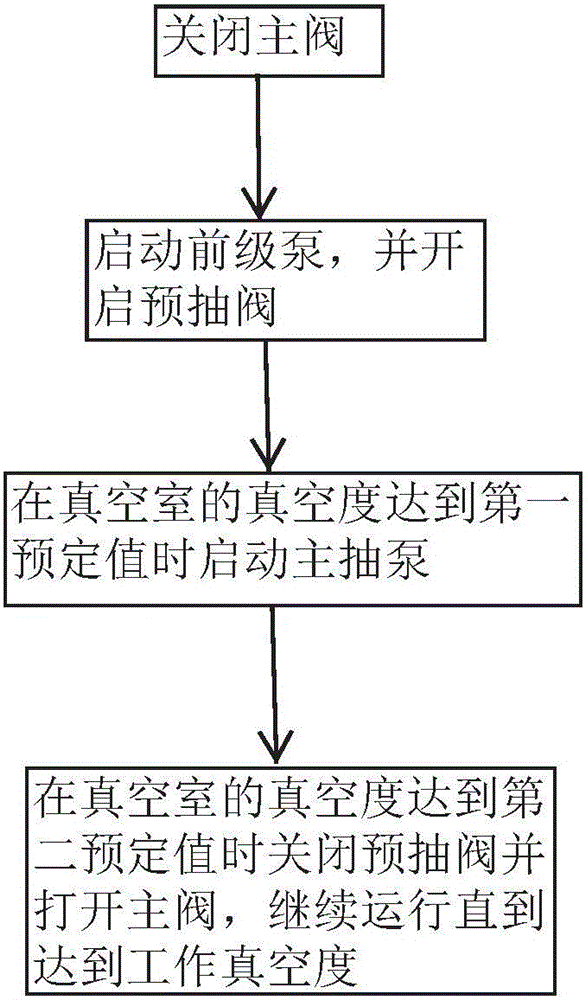

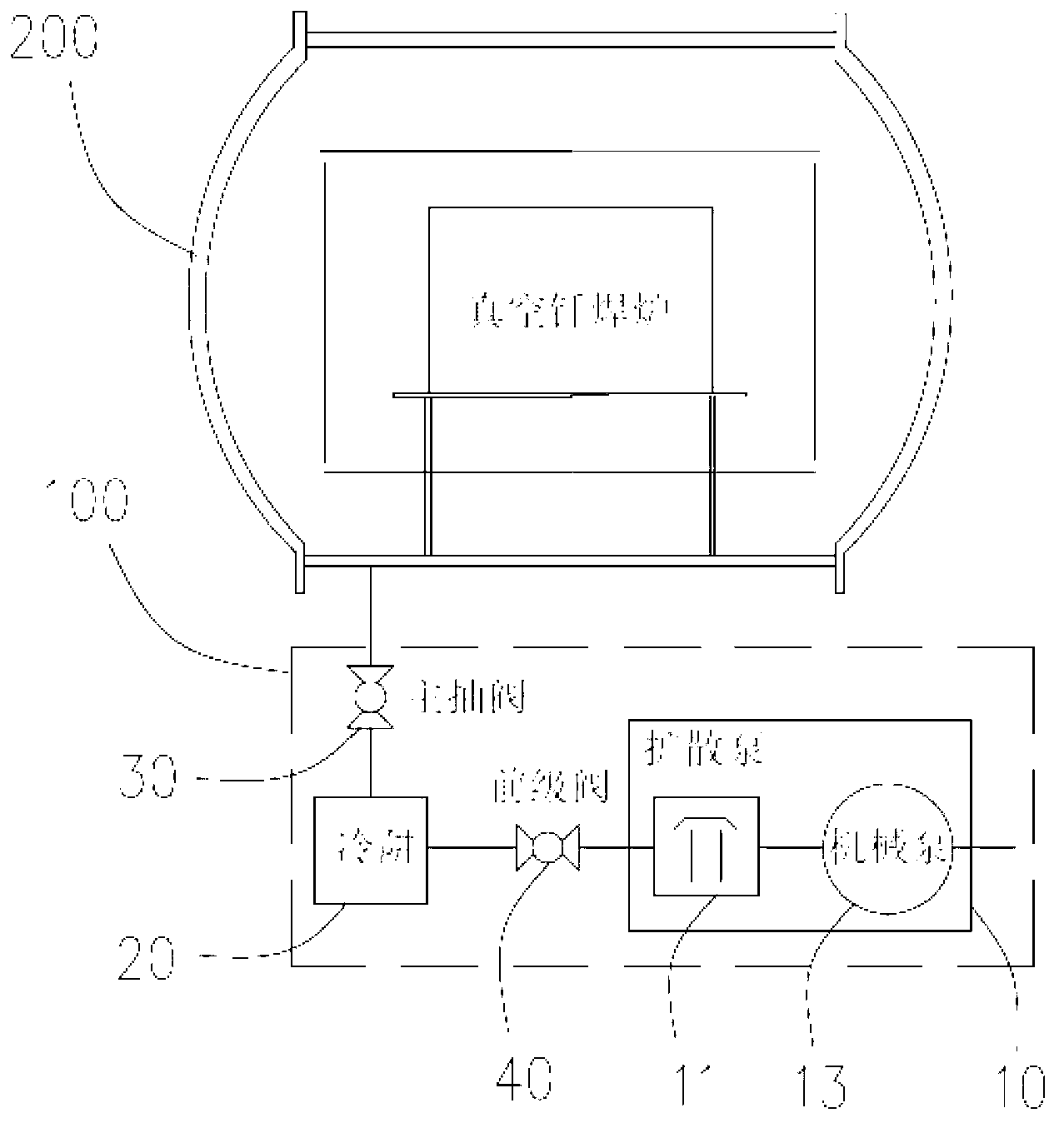

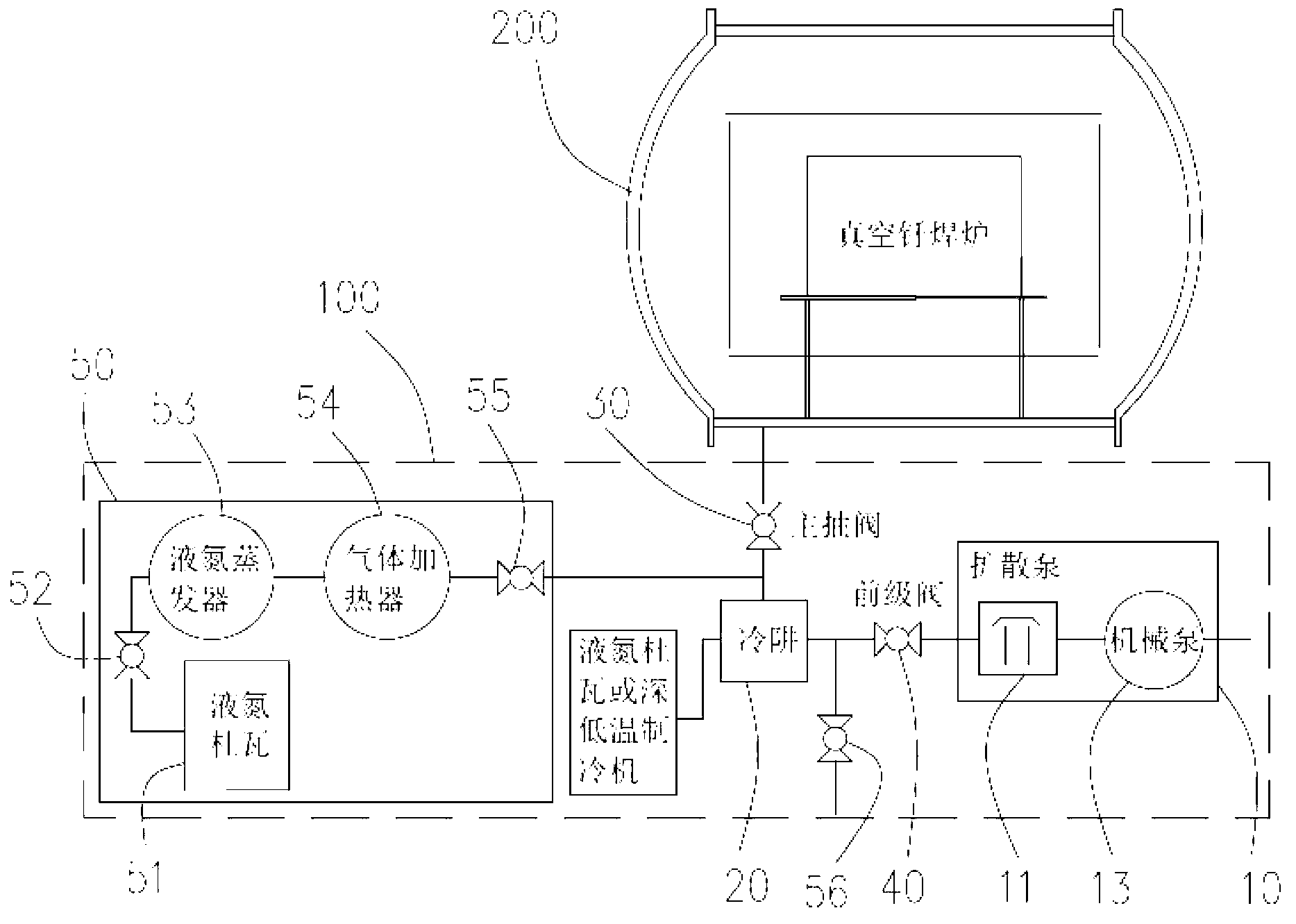

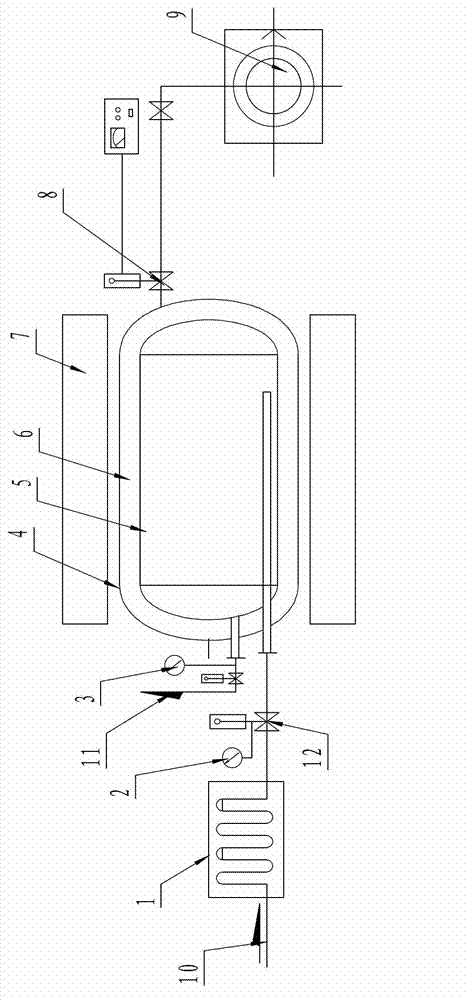

Vacuumizing system and method

InactiveCN106762537AShort vacuum timeReduce pumping timePositive displacement pump componentsPump installationsCouplingEngineering

The invention discloses a vacuumizing system. The vacuumizing system is used for vacuumizing a vacuum chamber and comprises a backing pump, a main pump, a pre-pumping valve and a main valve, wherein the main valve is provided with an inlet, a pre-pumping port and an outlet; the inlet of the main valve communicates with a vacuumizing port of the vacuum chamber; the pre-pumping port of the main valve communicated with an inlet of the pre-pumping valve; the outlet of the main valve communicates with an extraction opening of the main pump; and an extraction opening of the backing pump simultaneously and directly communicates with an exhaust port of the main pump and an outlet of the pre-pumping valve through a tee coupling. Through the vacuumizing system, the vacuum chamber can reach the required vacuum degree in a quite short time.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

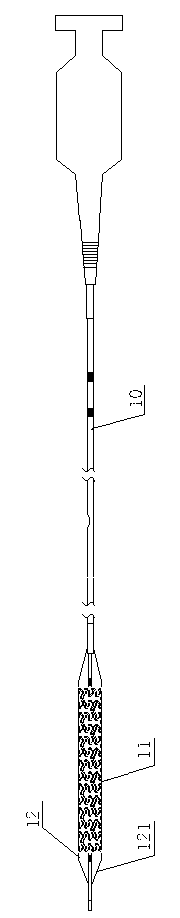

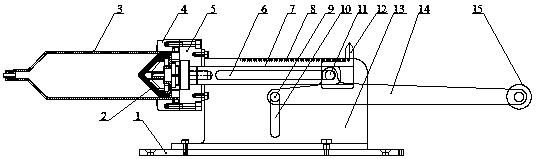

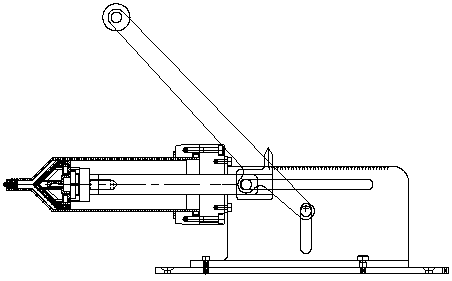

Liquid extractor for high-pressure radiography injector

InactiveCN108568005AGuaranteed efficiencyReduce work intensityAutomatic syringesIntravenous devicesEngineeringHigh pressure

The invention belongs to the field of medical equipment and apparatuses, and particularly relates to a liquid extractor for a high-pressure radiography injector. The liquid extractor comprises a high-pressure radiography injector needle cylinder, a piston arranged in the high-pressure radiography injector needle cylinder, an injector installation fixing seat, a connecting component, a rack, a rackfixing seat and a pushing rod, the injector installation fixing seat fixedly sleeves the tail end of the high-pressure radiography injector needle cylinder, and the high-pressure radiography injectorneedle cylinder is installed at and fixed to the left side of the rack through the injector installation fixing seat and the connecting component; a first sliding rail is transversely and horizontally arranged above the front side face of the rack, a sliding rail is longitudinally and vertically arranged on the position, below the first sliding rail, of the rack, one end of the pushing rod is inclamping connection with the piston mutually and cooperatively, and the other end of the pushing rod is fixed to the middle of the connecting rod through a first pin column. Through the structure design of the liquid extractor, a handle can be rotated manually to complete the liquid extracting operation, the efficiency of the liquid extracting operation is ensured, working intensity of medical workers is reduced, and the operation is convenient, safe and reliable.

Owner:迈德旺(苏州)医疗设备有限公司

Vacuum-pumping system

ActiveCN103264204AImprove applicabilityIncrease production capacityMetal working apparatusSoldering auxillary devicesVacuum pumpingWater vapor

The invention provides a vacuum-pumping system used for vacuum pumping of a vacuum heater treater connected with the vacuum-pumping system. The vacuum-pumping system comprises a vacuum pump obtaining the vacuum degree for the vacuum heater treater. The vacuum-pumping system further comprises a cold trap which is arranged between the vacuum heater treater and the vacuum pump. The vacuum-pumping system can quickly absorb water vapor and oil vapor by means of the cold trap, the pump-down time is shortened, the vacuum heater treater can quickly achieve a vacuumized state, quality of heat treatment products can be effectively guaranteed, production capacity of the vacuum heater treater is improved, in terms of vacuum brazing, quality of the vacuum brazing can be effectively improved, the leakage rates of the inside and the outside of a brazing heat exchanger are reduced, the rate of finished products of the heat exchanger is thereby improved, and additionally, the vacuum-pumping system is strong in adaptability, is not limited to be used for a vacuum brazing furnace and is suitable for other vacuum heater treaters.

Owner:北京中科富海低温科技有限公司

Water blowing structure for coal mine underground gas extraction and construction method thereof

PendingCN107882586AReasonable structureIncrease the concentration of pumpingMining devicesDrainageDrill holeWater pipe

The invention discloses a water blowing structure for coal mine underground gas extraction and a construction method thereof. The water blowing structure for coal mine underground gas extraction comprises an extraction system and an air compressing system. A gas suction port is formed in the upper portion of a gas-water separator; a first valve is arranged on the gas suction port and connected with a three-way joint of the extraction system through a first hose; the bottom of the gas-water separator is connected with a drainage device; the side edge of the upper portion of the gas-water separator is connected with a second hose, and the second hose is connected with a water blowing device; the side edge of the water blowing device is connected with the air compressing system through a second valve, and the other end of the water blowing device is connected with a hole-sealing screen pipe; and a water blowing pipe is arranged inside the hole-sealing screen pipe ad connected with the second valve. After a pipeline is connected, the second valve with a high-pressure pipe rapid connector is opened to supply air into a drilled hole when accumulated water exists in the drilled hole, so that the accumulated water is blown out, then enters the gas-water separator and is drained from the drainage device. The accumulated water in the drilled hole is discharged timely through air-compressing water blowing, hole collapse of the drilled hole due to soaking of the accumulated water is prevented, long-term efficient extraction of the gas extraction drilled hole is kept, and the great effect is achieved.

Owner:GUIZHOU PANJIANG REFINED COAL

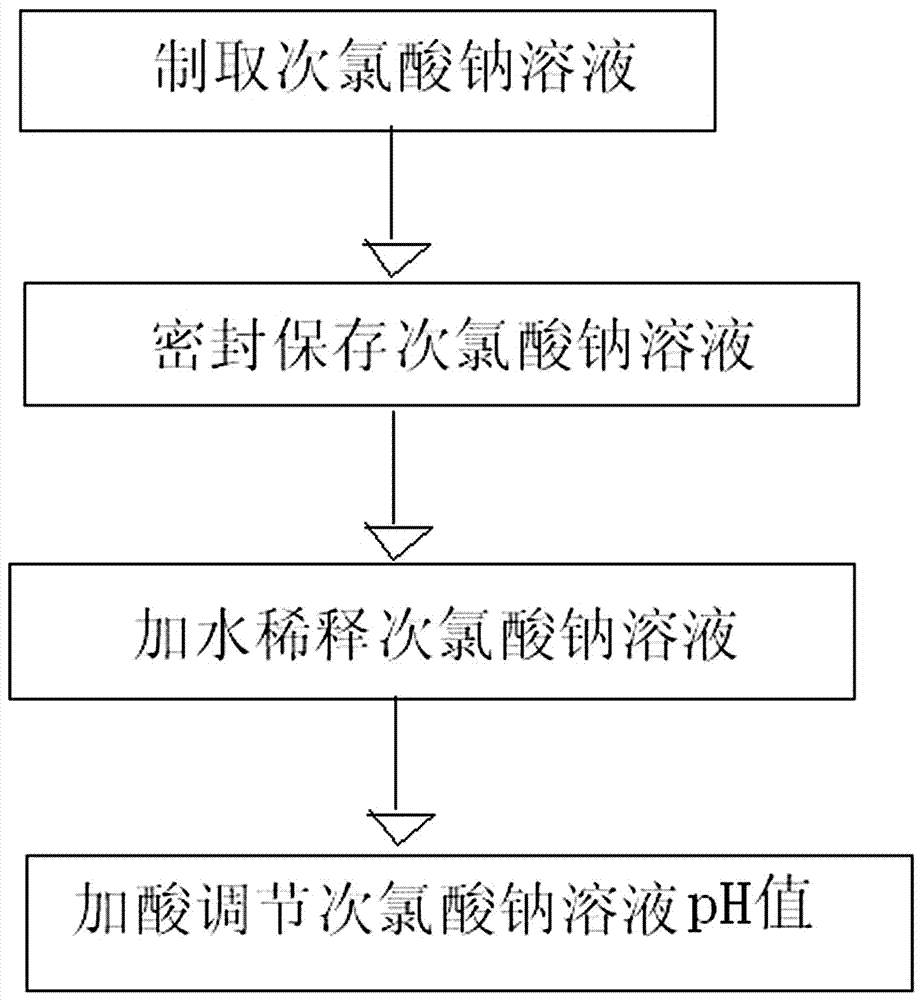

Coal reservoir permeability increasing agent based on aqueous solution of sodium hypochlorite

InactiveCN106867501AIncrease coal seam permeabilitySave manpower and material resourcesFluid removalDrilling compositionCalcium hypochloriteRADIUS

The invention belongs to the technical field of coal mine safety production. In order to solve the problems of difficulty in field large-scale popularization and application, ultralow oxidation rate on coal at the normal temperature of an existing permeability increasing agent, the invention provides a coal reservoir permeability increasing agent based on aqueous solution of sodium hypochlorite. The coal reservoir permeability increasing agent consists of a component A, a component B and water; the component A is sodium hypochlorite solid or sodium hypochlorite solution; the component B is a pH regulator and is hydrochloric acid or sulfuric acid of which concentration is smaller than 10%; concentration of effective chloridion in the coal reservoir permeability increasing agent based on the aqueous solution of sodium hypochlorite is 1% to 6%; a pH value of the coal reservoir permeability increasing agent based on the aqueous solution of sodium hypochlorite is 9 to 13. Gas permeability of a coal seam is improved, and an actual working surface is subjected to pre-drainage rapidly and regionally. When the coal reservoir permeability increasing agent is adopted to carry out permeability increasing on coal, gas drainage time is greatly shortened; a drilling work amount is reduced; high-gas low-gas-permeability coal seam permeability increasing and efficient gas drainage are implemented, regional gas pre-drainage efficiency of a coalface and a coal road strip is improved, drainage time is shortened, a drainage radius is enlarged, the drilling work amount is reduced, and gas disasters are eliminated to the greatest extent.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Ion pump and charged particle beam device using the same

Owner:HITACHI LTD

Pre-loading chamber and semiconductor process platform

ActiveCN112151431AShorten inflation timeReduce pumping timeFinal product manufactureSemiconductor/solid-state device manufacturingWaferEngineering

The invention discloses a pre-loading cavity and a semiconductor process platform. The pre-loading cavity comprises a chamber body and a wafer supporting frame, the chamber body is provided with an accommodating cavity, the wafer supporting frame is located in the accommodating cavity, the wafer supporting frame comprises a first bearing platform and a second bearing platform, the first bearing platform and the second bearing platform are both used for bearing wafers, the first bearing platform is arranged above the second bearing platform. The first bearing table is provided with an avoidingpart, the second bearing table is provided with a connecting part, the avoiding part and the connecting part are oppositely arranged, a fixing piece can penetrate through the avoiding part to be assembled in the connecting part, and the second bearing table is connected with the chamber body through the fixing piece. According to the scheme, the problem that the transmission efficiency of the wafer is low can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Interlayer vacuumizing method for cryogenic vessel and special device thereof

InactiveCN103047535AImprove pumping qualityReduce pumping timePressure vesselsNitrogenInlet pressure

The invention discloses an interlayer vacuumizing method for a cryogenic vessel, which belongs to vessels used for accommodating or storing compressed, liquefied or cured gases, particularly a manufacturing method of a cryogenic vessel, which comprises insulation measures. The interlayer vacuumizing method for the cryogenic vessel is characterized in that the outer cylinder body of the cryogenic vessel is heated by heating equipment, N2 heated to 350-370 DEG C is continuously injected into the inner container of the cryogenic vessel, and the inlet pressure is controlled to be 0.4 Mpa; and the outlet pressure is 0.2 Mpa, and in the state of heating the outer cylinder body and the inner container of the cryogenic vessel, a vacuum pump is used to vacuumize an interlayer between the outer cylinder body and the inner container of the cryogenic vessel. According to the invention, hot nitrogen higher than 350 DEG C is adopted to heat the inner container, and a heating furnace is adopted to heat the outer cylinder body so as to heat the inner container and the outer cylinder body at the same time, so that the bleeding rate of a substance in the interlayer is increased in the heated state to facilitate decomposing remaining water molecules and other substances, the vacuumizing efficiency and the vacuity of the interlayer are both improved and the qualified index of the bleeding rate is improved.

Owner:SHANDONG HONGDA TECH GRP

Breast pad, bra body and breast pump

InactiveCN106075620AIncrease milk efficiencyIncrease intensityMilking pumpMedical devicesGynecologyLactiferous sinus

The invention discloses a breast pad and a bra body which are applied to a breast pump, and belongs to the technical field of pumping transfer of body fluid. Squeezing bodies for squeezing breast lactiferous sinuses are arranged on an inner wall of the breast pad. The arrangement of the squeezing bodies conforms to the physiological constructions of the breasts of a woman more. In the milk pumping process of the breast pump, the breast lactiferous sinuses are squeezed by the squeezing bodies, so that squeezing of breast milk is facilitated, the milk pumping efficiency of the breast pump is increased, the milk pumping time is shortened, and the probability of pain or stretching (deformation) of sore nipples in the milk pumping process is lowered. The breast pad is arranged in a milk pumping bra to construct the bra body, and gas is introduced from a through hole in the milk pumping bra in order that the squeezing bodies project, so that the breast lactiferous sinus squeezing strength is enhanced, and squeezing of the breast milk is further facilitated. A squeezing pump which is communicated with the through hole in the milk pumping bra is arranged on the breast pump, so that a power source is provided for filling of gas into the through hole, and the bra body and the breast pump are simple in structures and are convenient to operate on the premise of increasing the milk pumping efficiency.

Owner:DONGGUAN KIDSME IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com