Vacuum-pumping system

A technology of vacuum pumping system and vacuum pump, applied in the field of vacuum pumping system, can solve the problems of lower qualification rate of brazing products and de-soldering of heat exchangers, and achieve the effect of shortening pumping time, reducing internal and external leakage rate, and improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The invention provides a vacuum pumping system for vacuuming a vacuum heat processor (such as a vacuum brazing furnace) connected thereto. The vacuum pumping system includes a vacuum pump and a cold trap. To obtain a vacuum degree, the cold trap is arranged between the vacuum heat processor and the vacuum pump for removing water vapor and return oil of the vacuum heat processor.

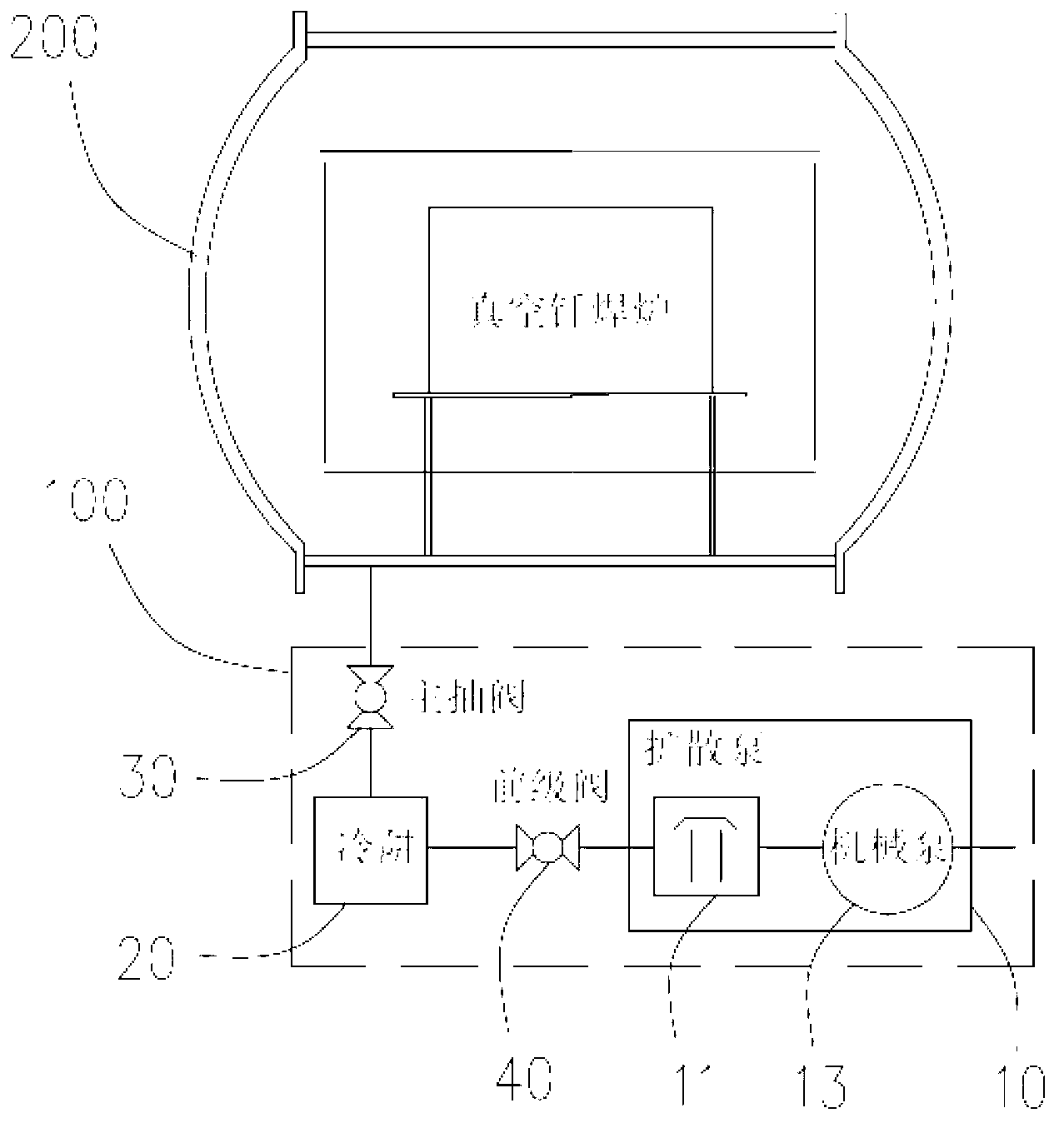

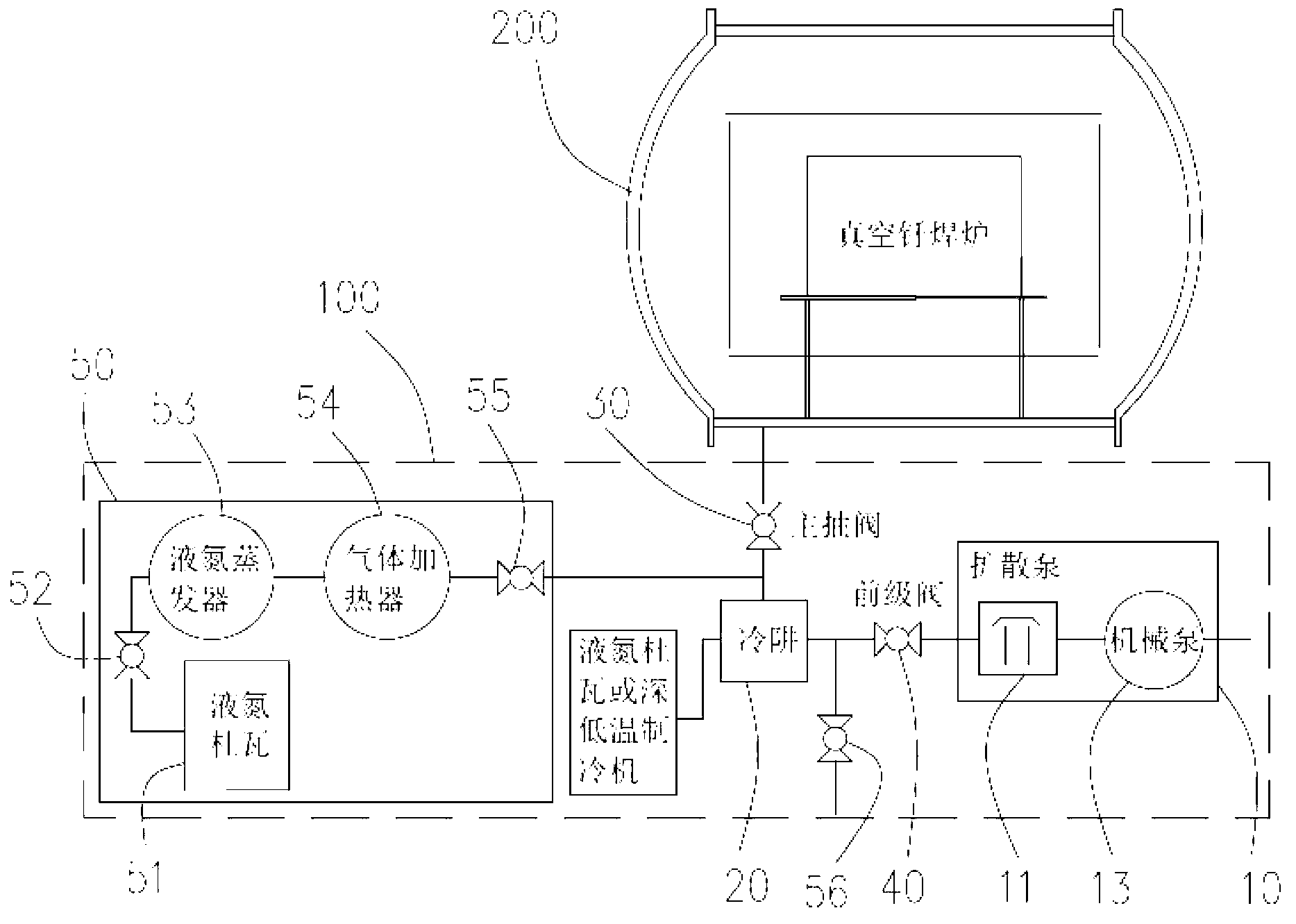

[0023] see figure 1 , the present invention takes the vacuum brazing furnace 200 as a vacuum heat processor as an example to illustrate a vacuum pumping system 100 provided by the first embodiment of the present invention. The vacuum system 100 is used for vacuuming the vacuum brazing furnace 200 connected thereto. The vacuum system 100 includes a vacuum pump 10 and a cold trap 20 . The vacuum pump 10 evacuates the vacuum brazing furnace 200 to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com