Patents

Literature

33results about How to "Avoid localization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

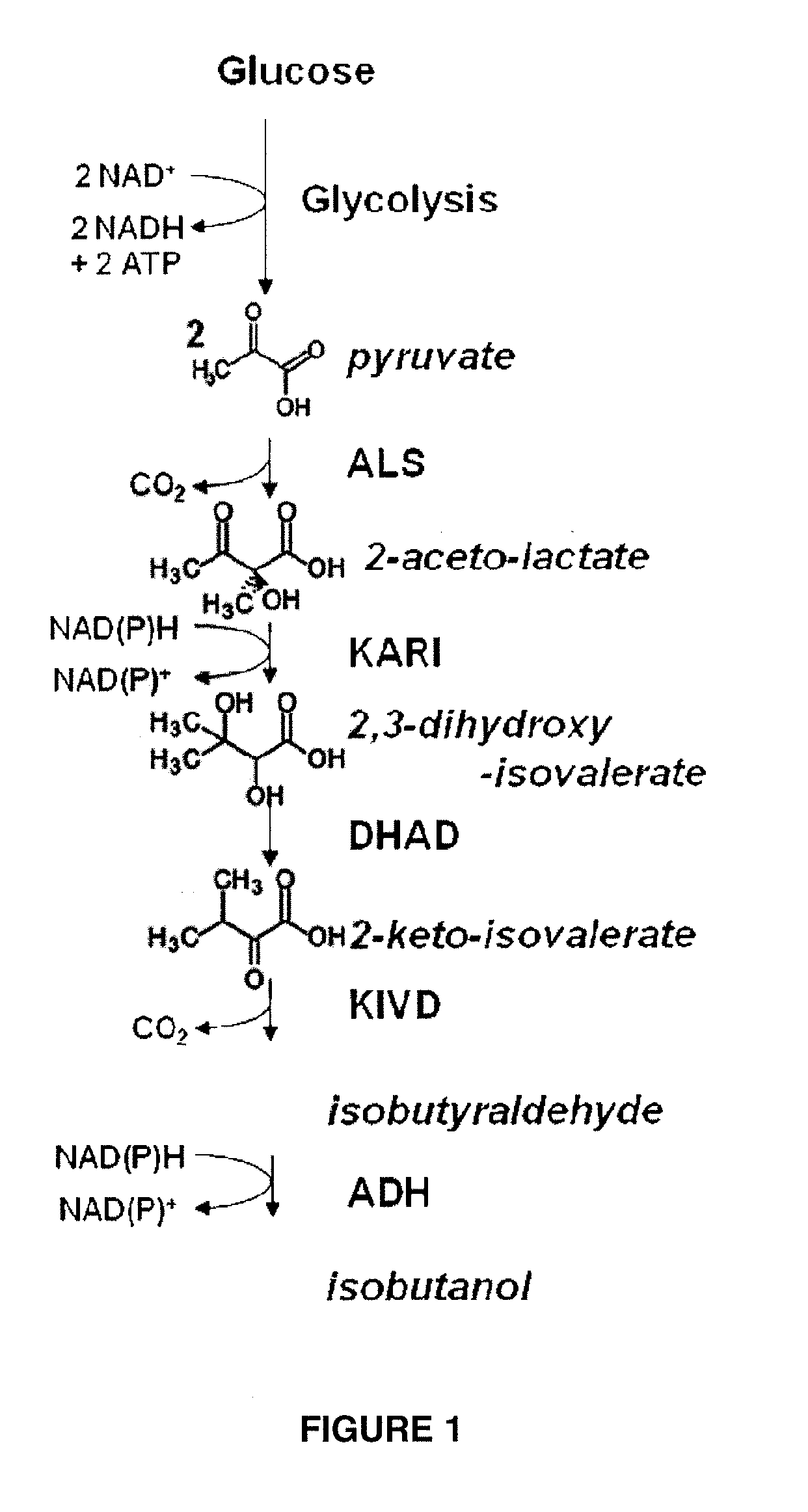

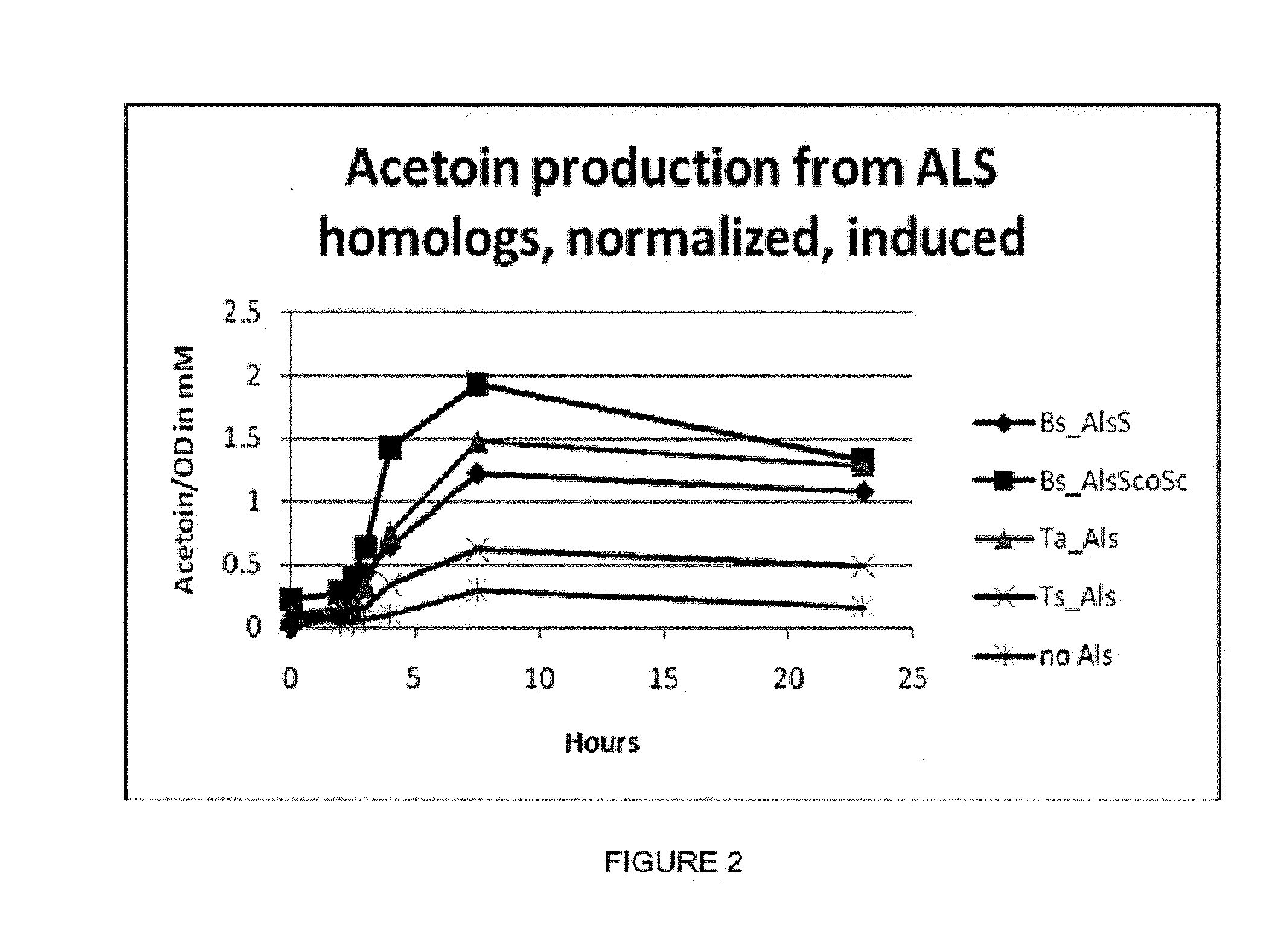

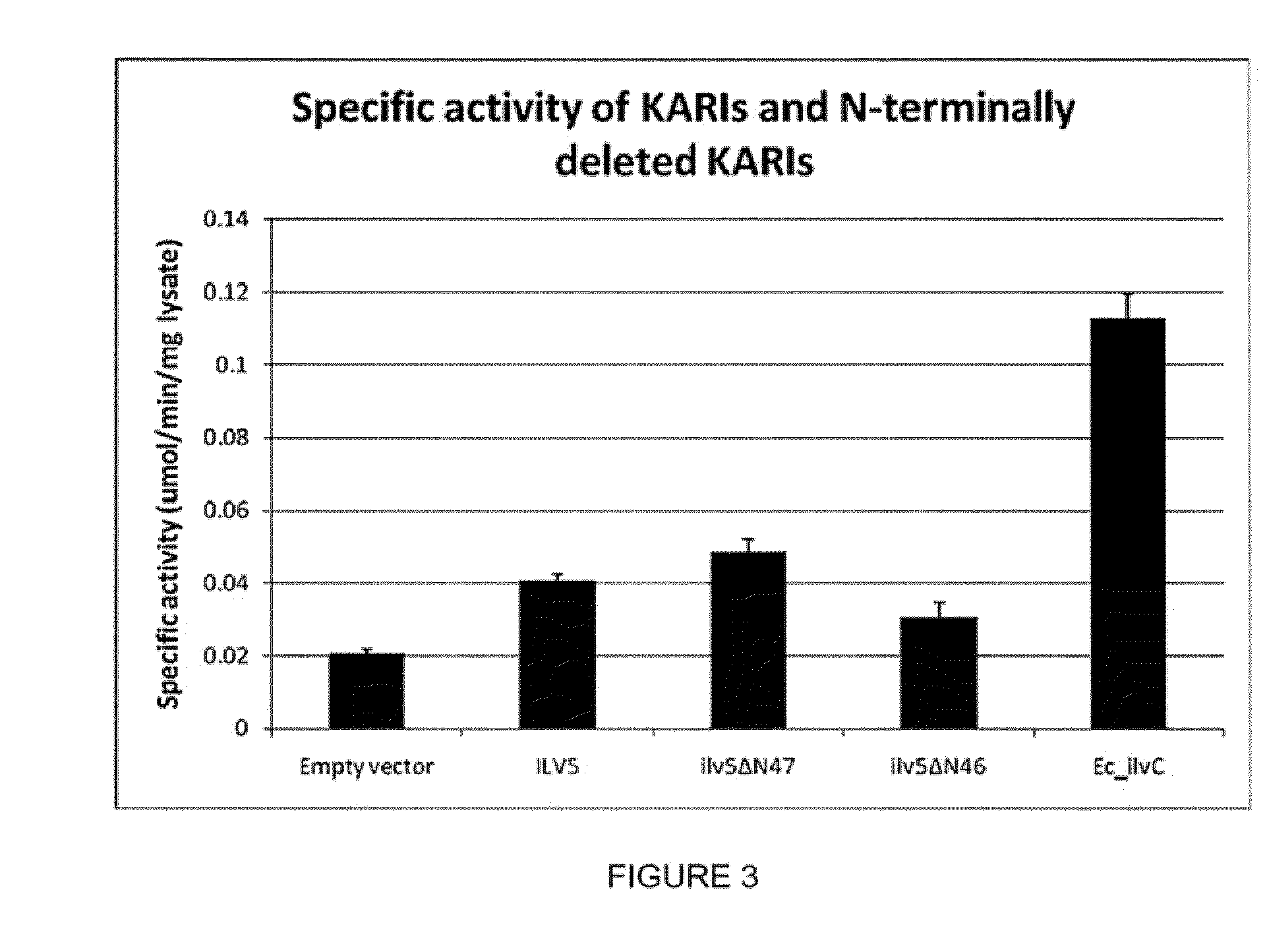

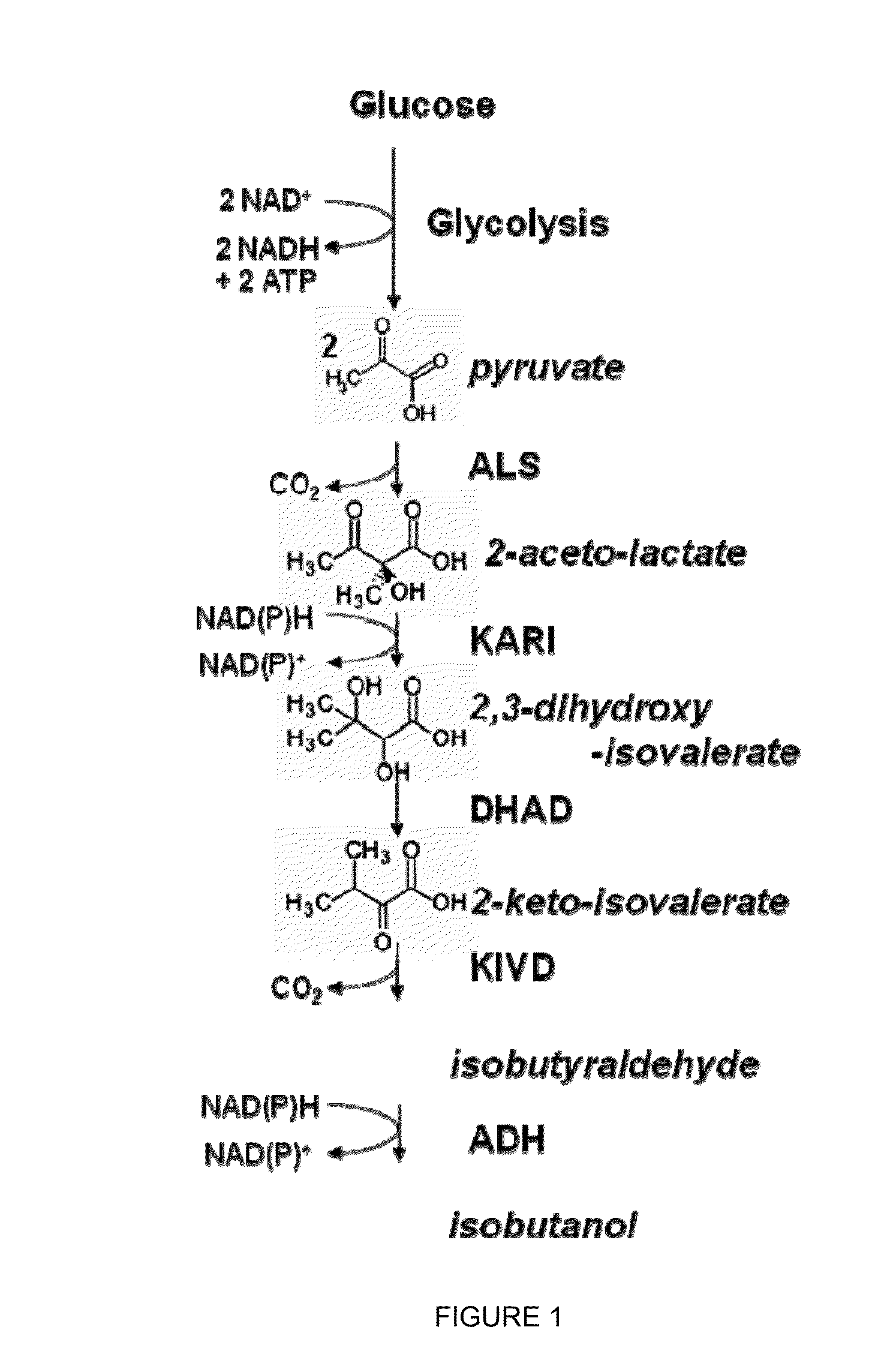

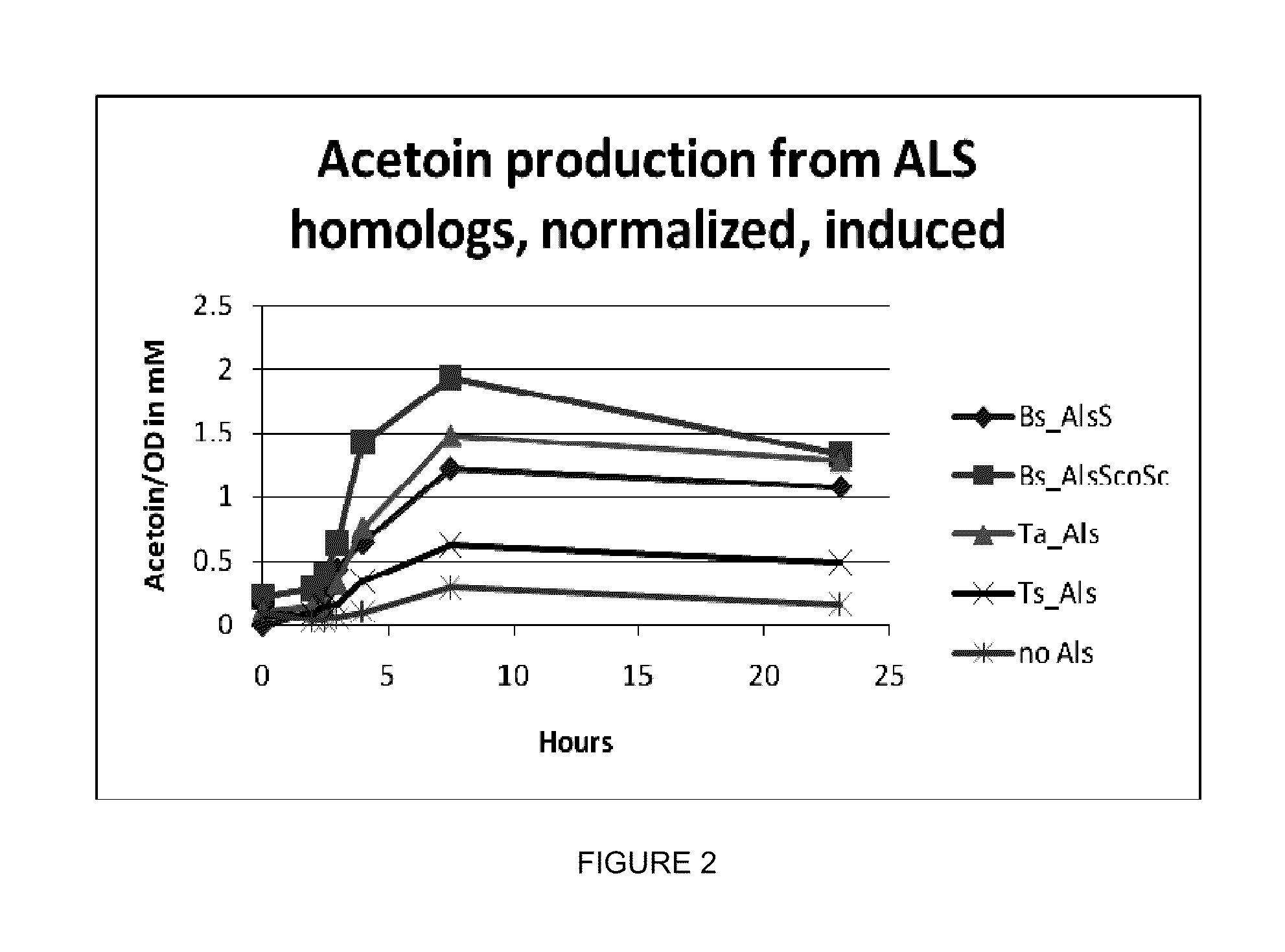

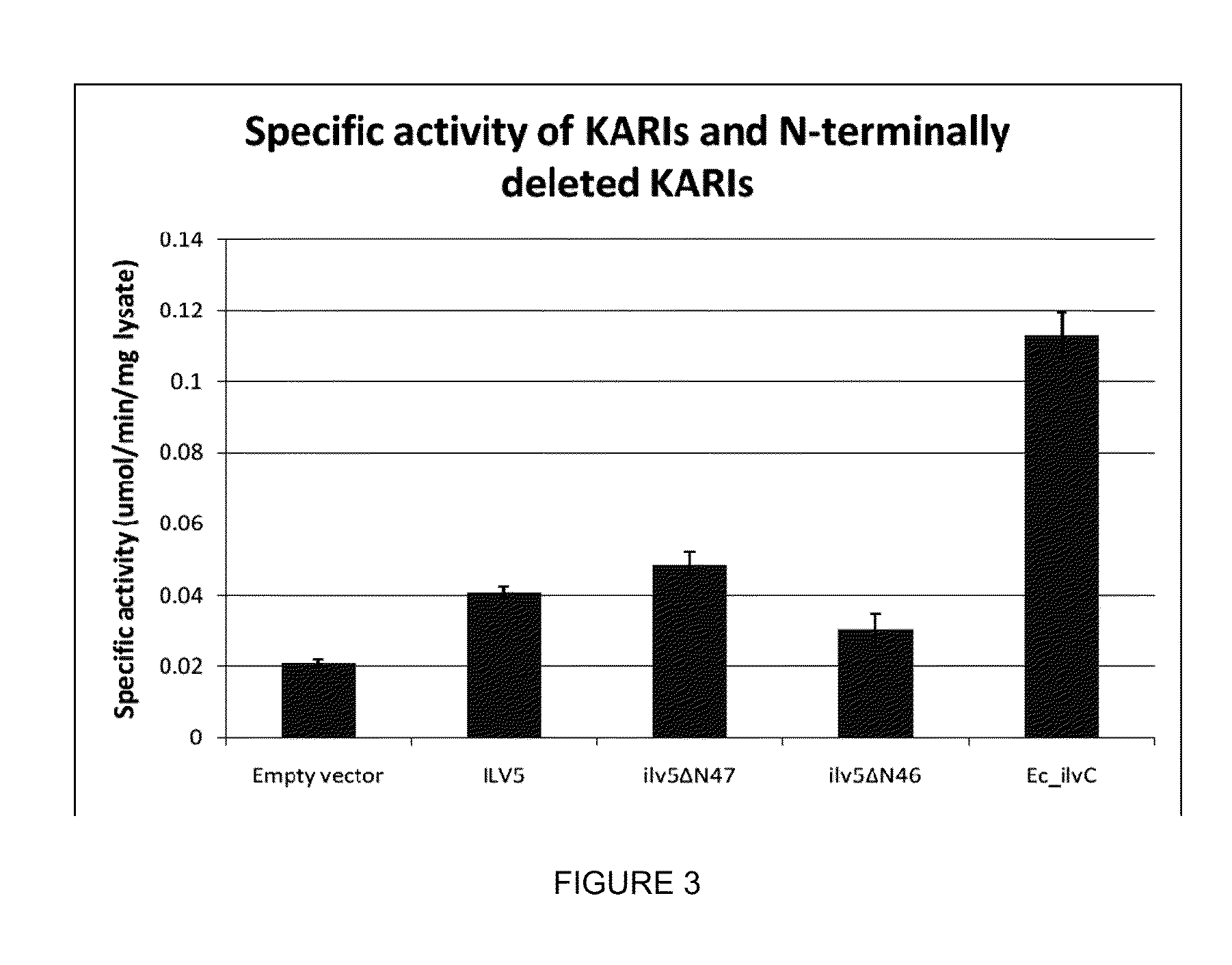

Cytosolic isobutanol pathway localization for the production of isobutanol

ActiveUS20110076733A1Increase cytosolic localizationIncrease cytosolic activityFungiBacteriaYeastIsobutanol

The present invention provides recombinant microorganisms comprising isobutanol producing metabolic pathway with at least one isobutanol pathway enzyme localized in the cytosol, wherein said recombinant microorganism is selected to produce isobutanol from a carbon source. Methods of using said recombinant microorganisms to produce isobutanol are also provided. In various aspects of the invention, the recombinant microorganisms may comprise a cytosolically active isobutanol pathway enzymes. In some embodiments, the invention provides mutated, modified, and / or chimeric isobutanol pathway enzymes with cytosolic activity. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:GEVO INC

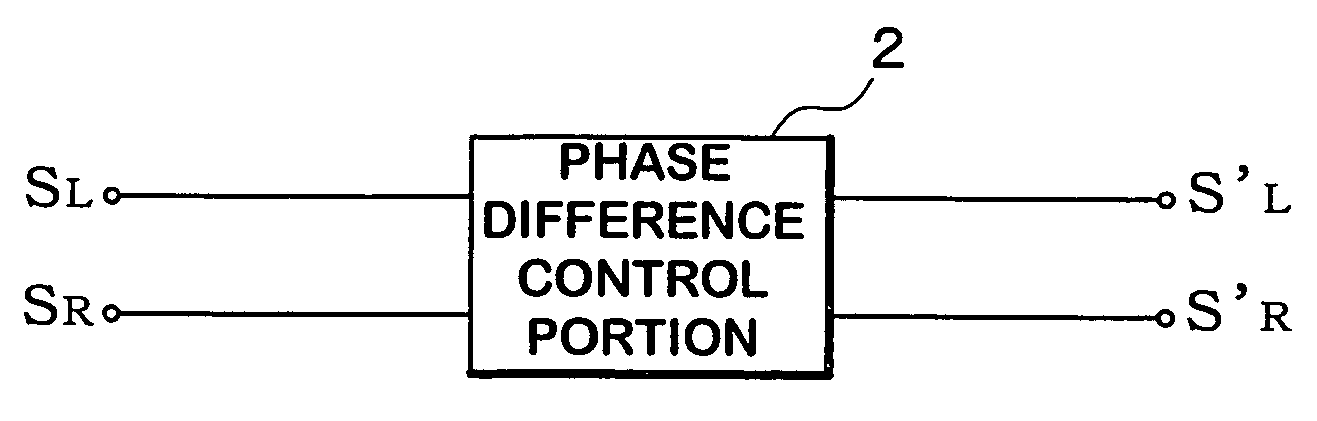

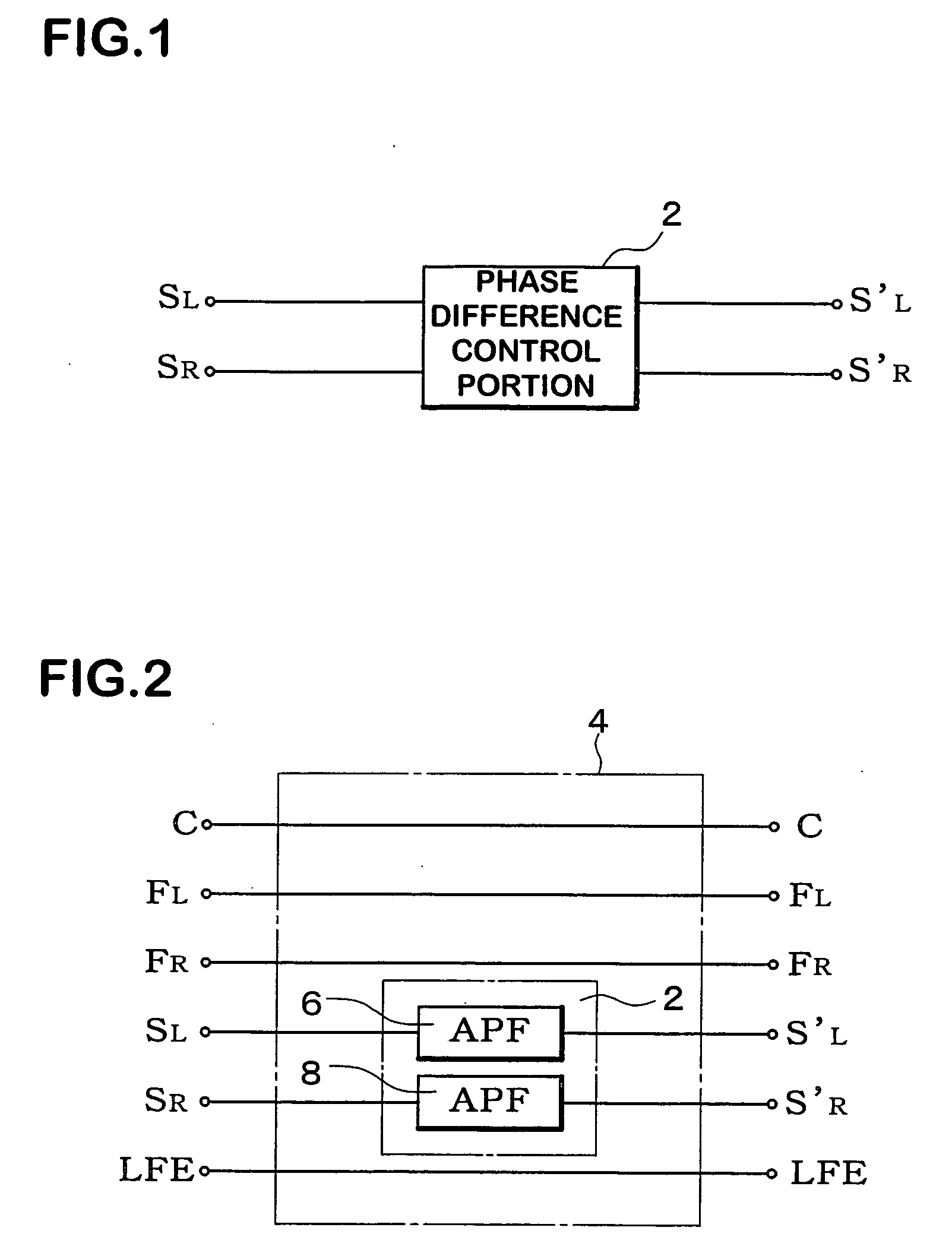

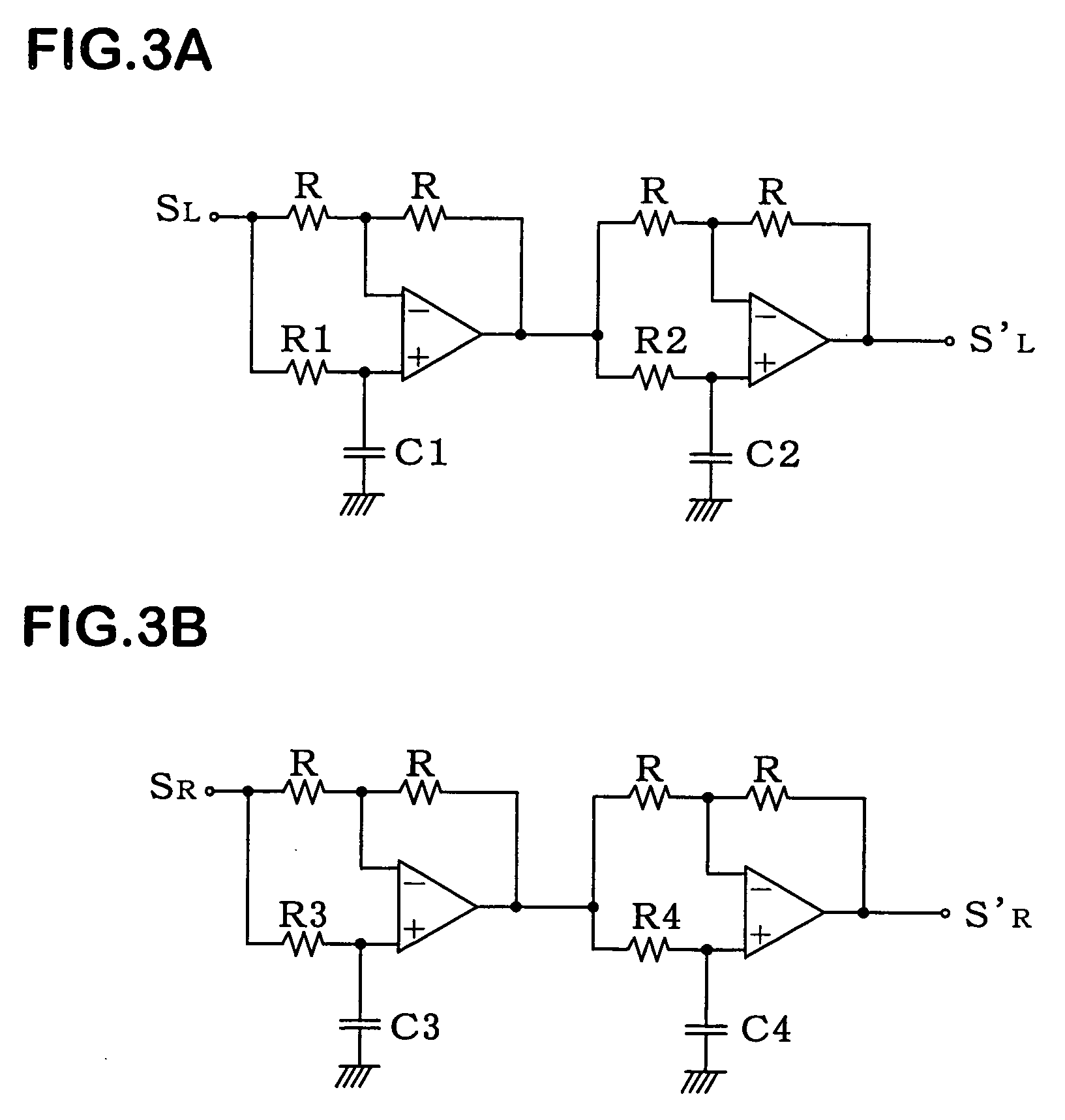

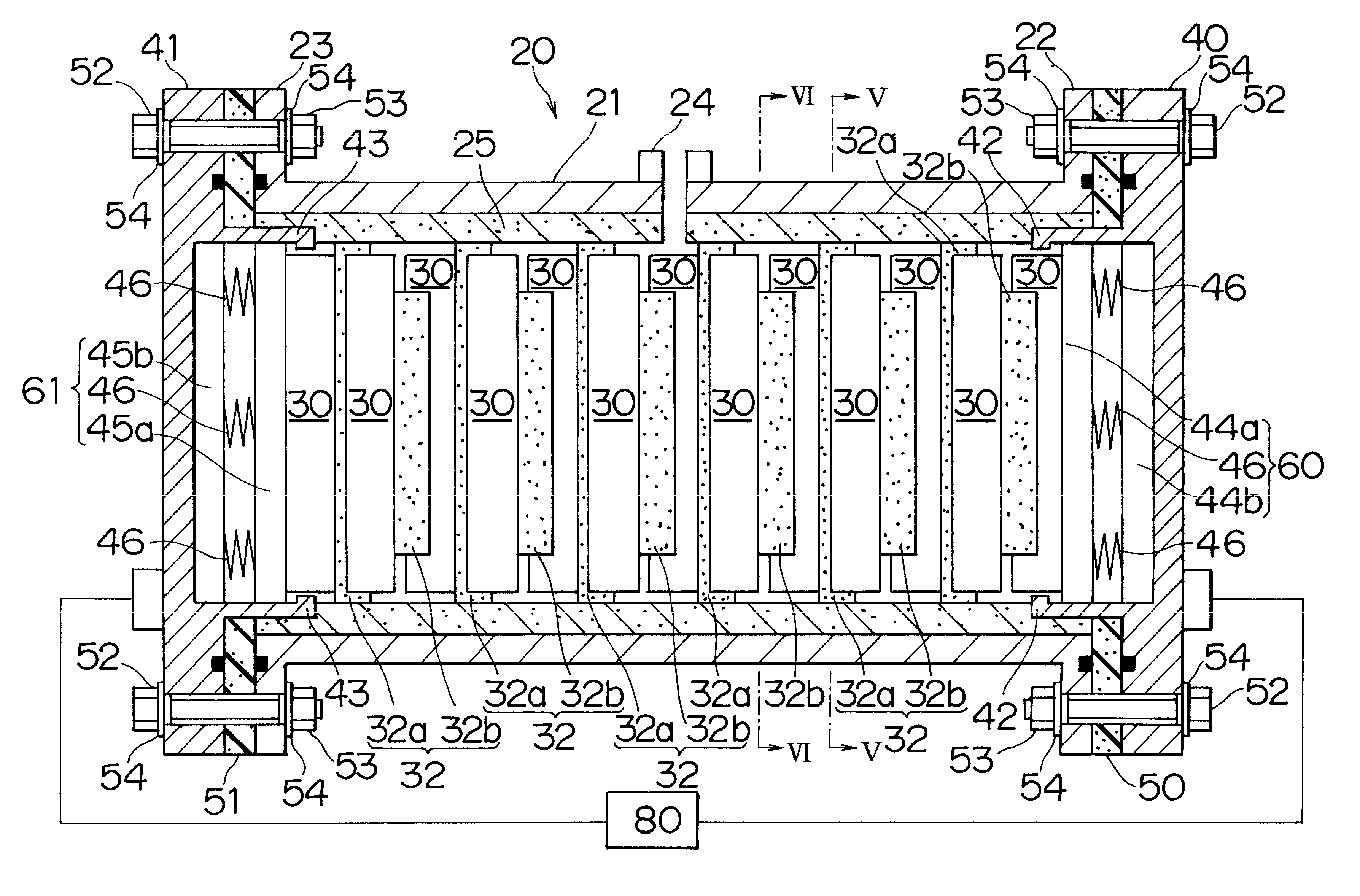

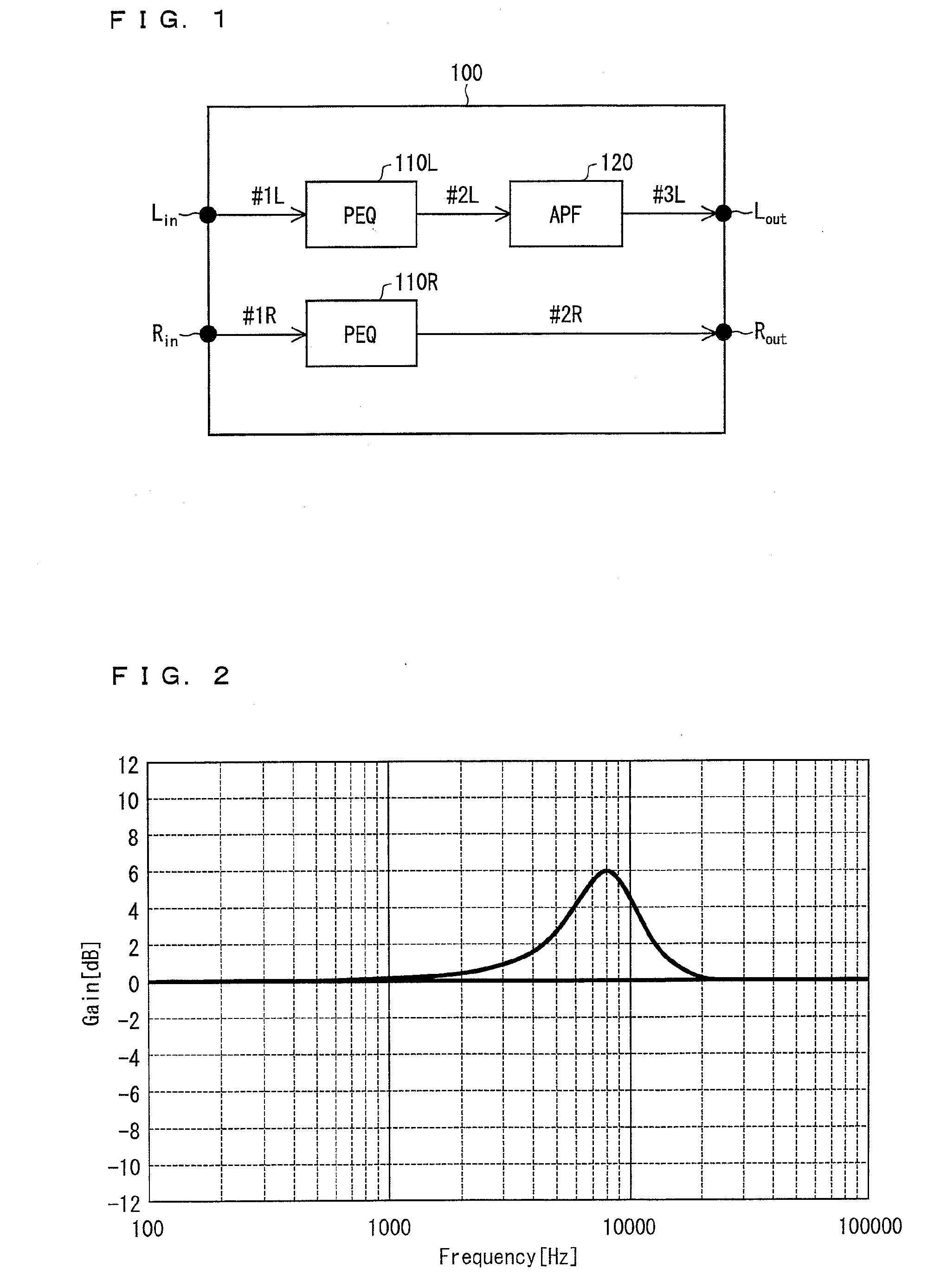

Audio signal processing circuit

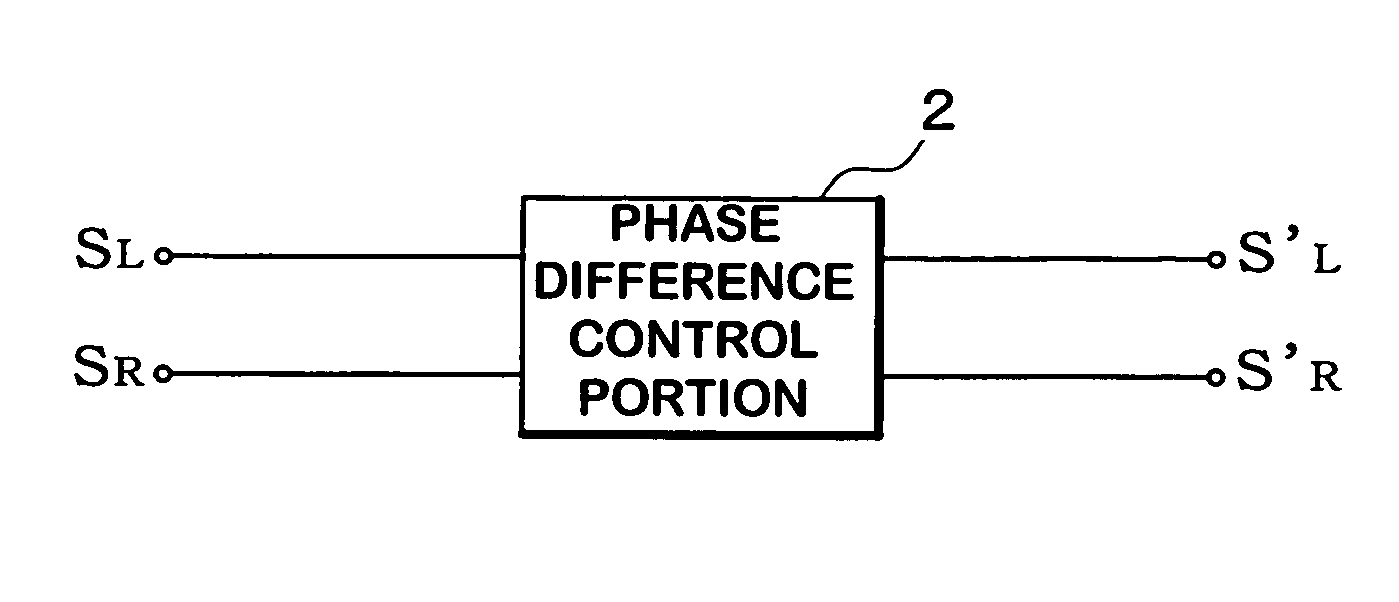

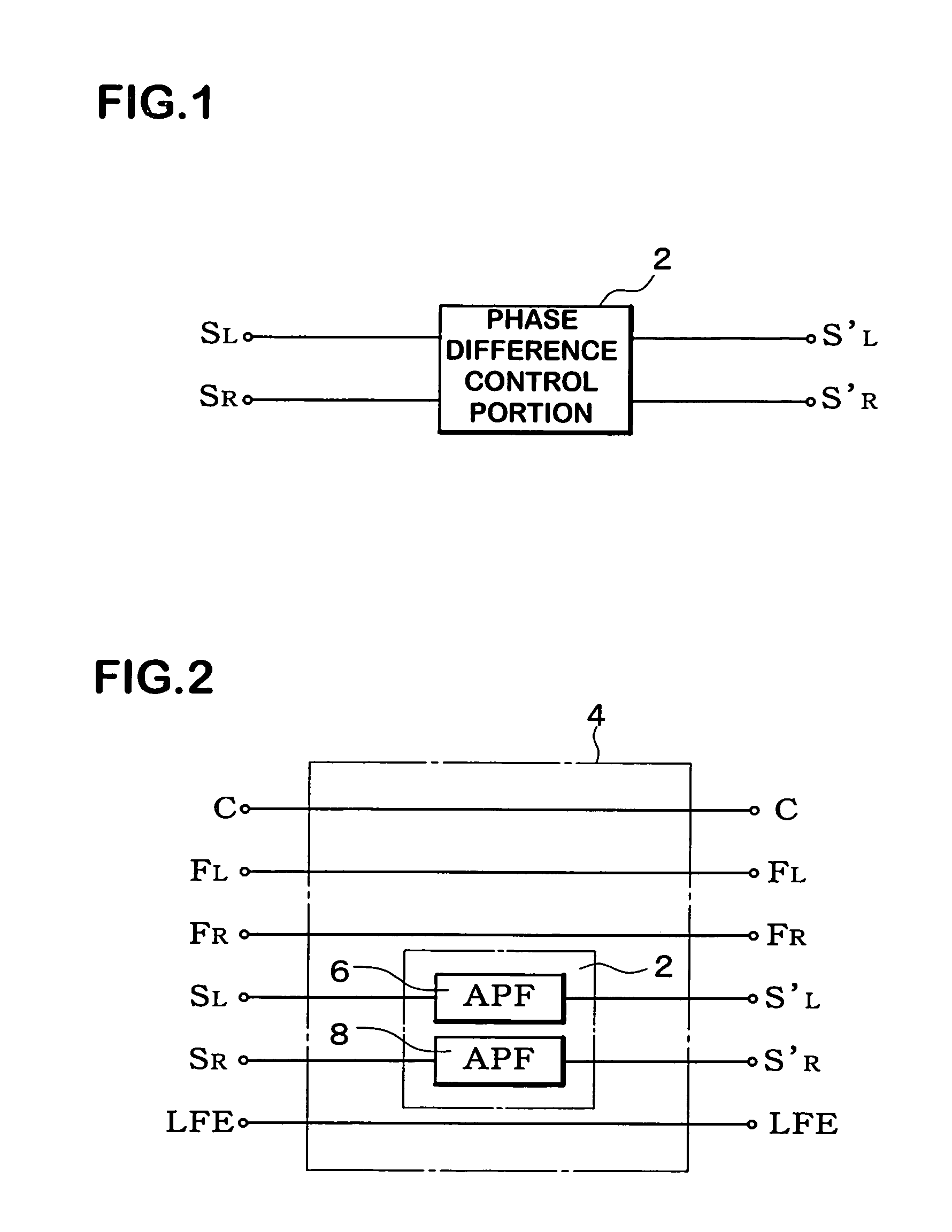

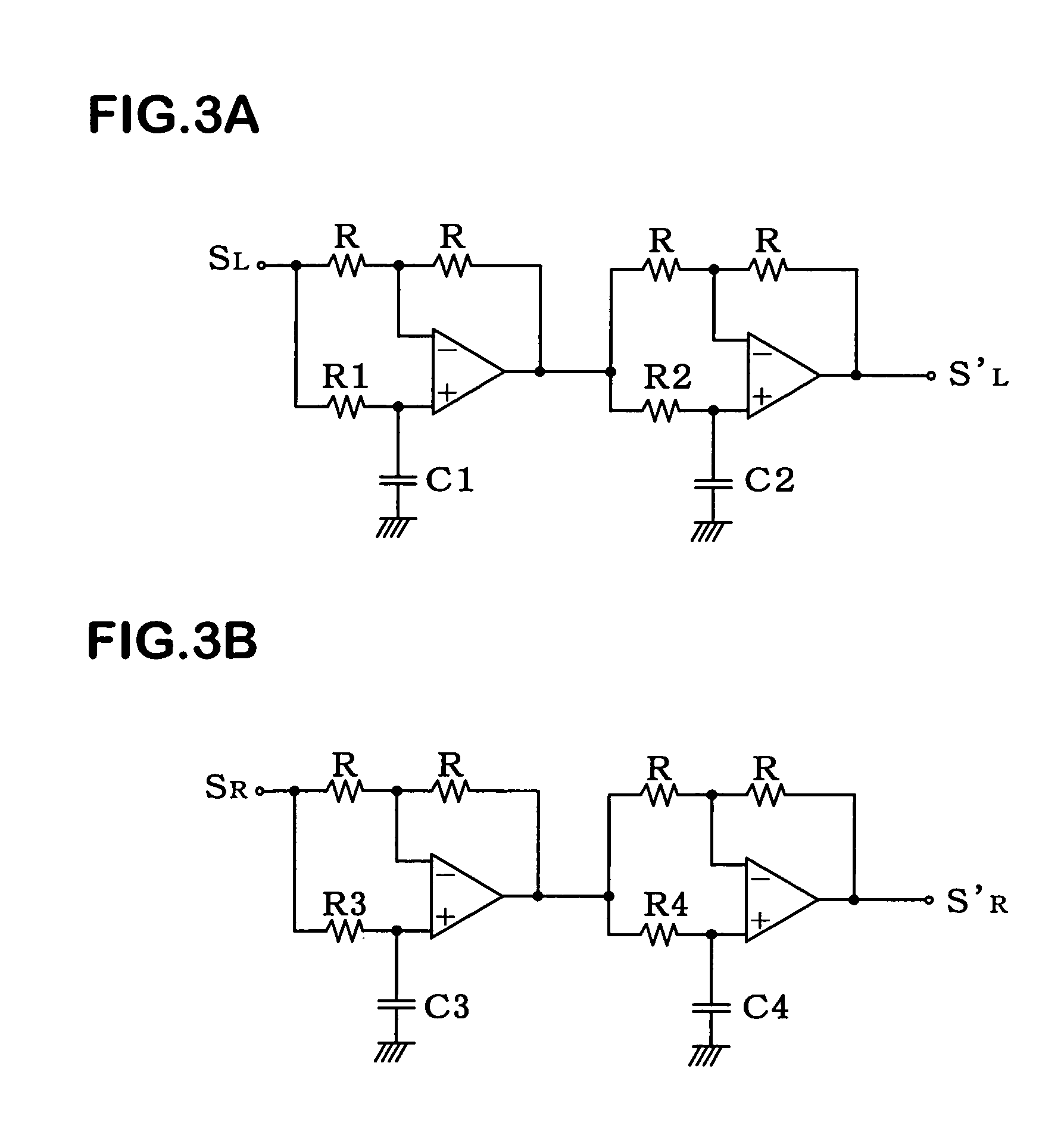

InactiveUS20050220312A1Avoid localizationQuality improvementTwo-channel systemsFrequency/directions obtaining arrangementsSound sourcesSignal processing circuits

An audio signal processing circuit for an audio reproduction apparatus at least having sound source located substantially at left and right sides to a listener, is provided. The audio signal processing circuit includes a phase difference control portion. The phase difference control portion receives a left channel signal for the left sound source and a right channel signal for the right sound source, controls a phase difference between the left and right channel signals so as to produce a relative phase difference in the range of 140 degrees to 160 degrees, and outputs the phase difference controlled left and right channel signals for the left and right sound source, respectively.

Owner:ONKYO TECH KK

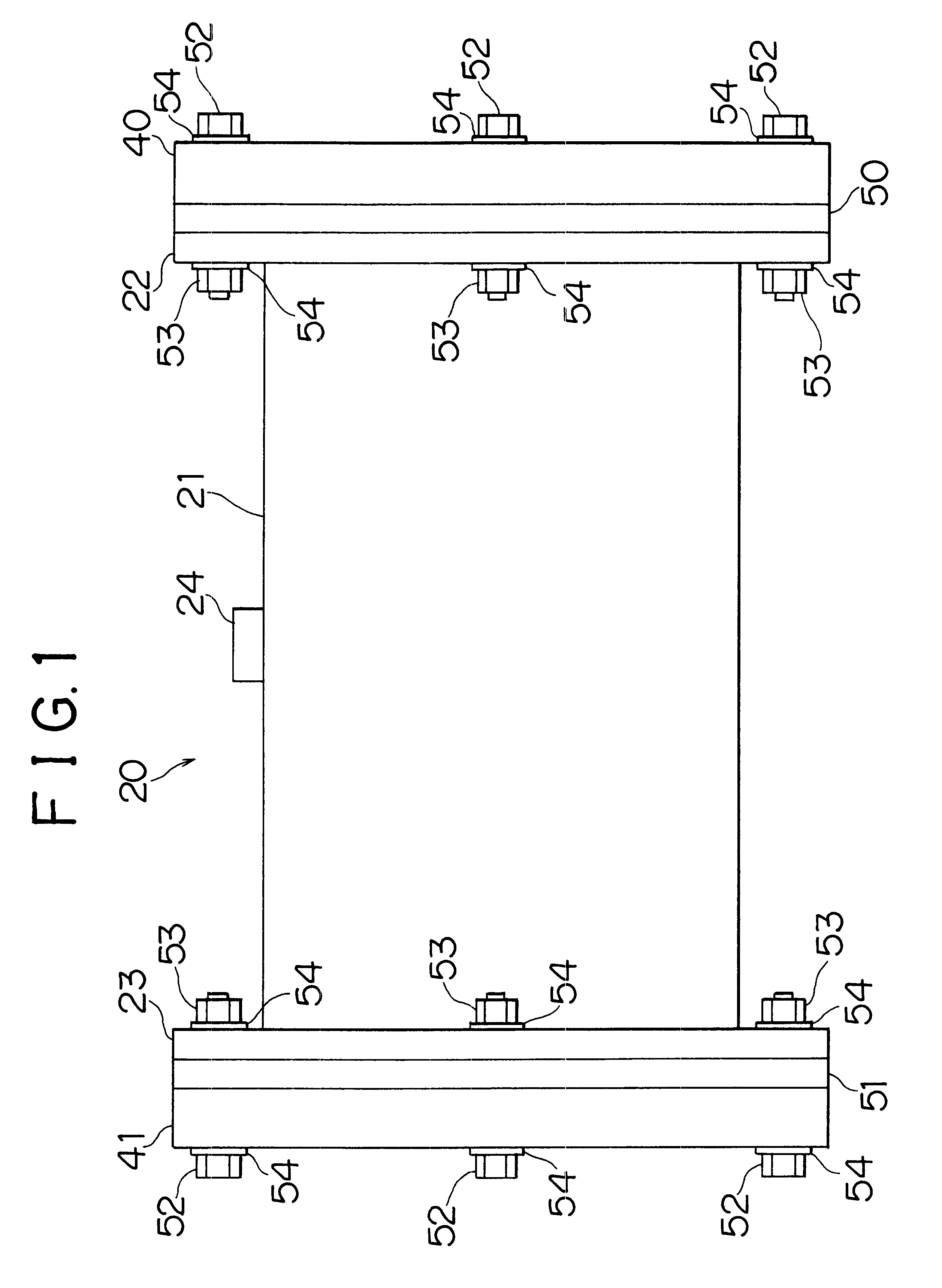

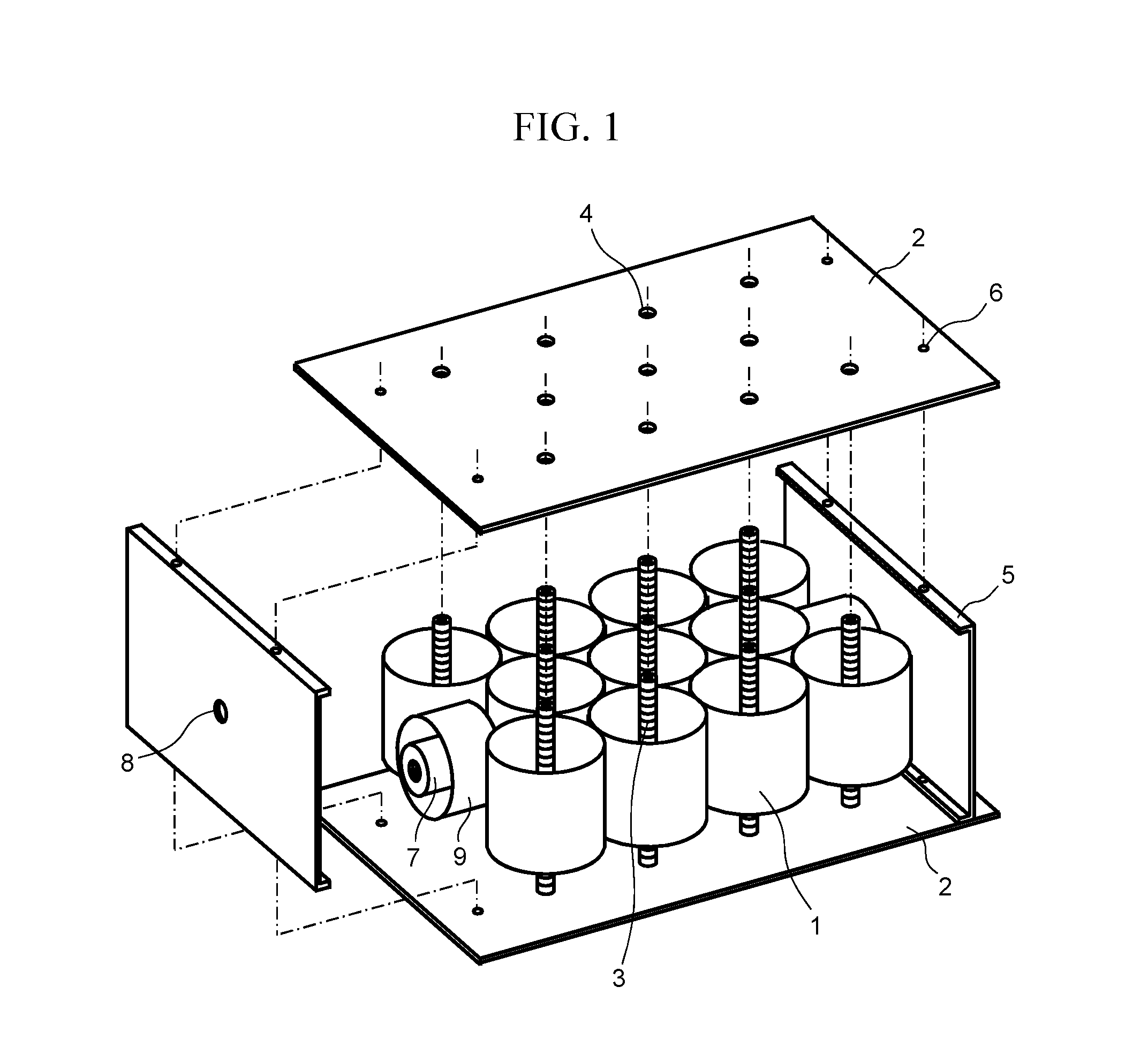

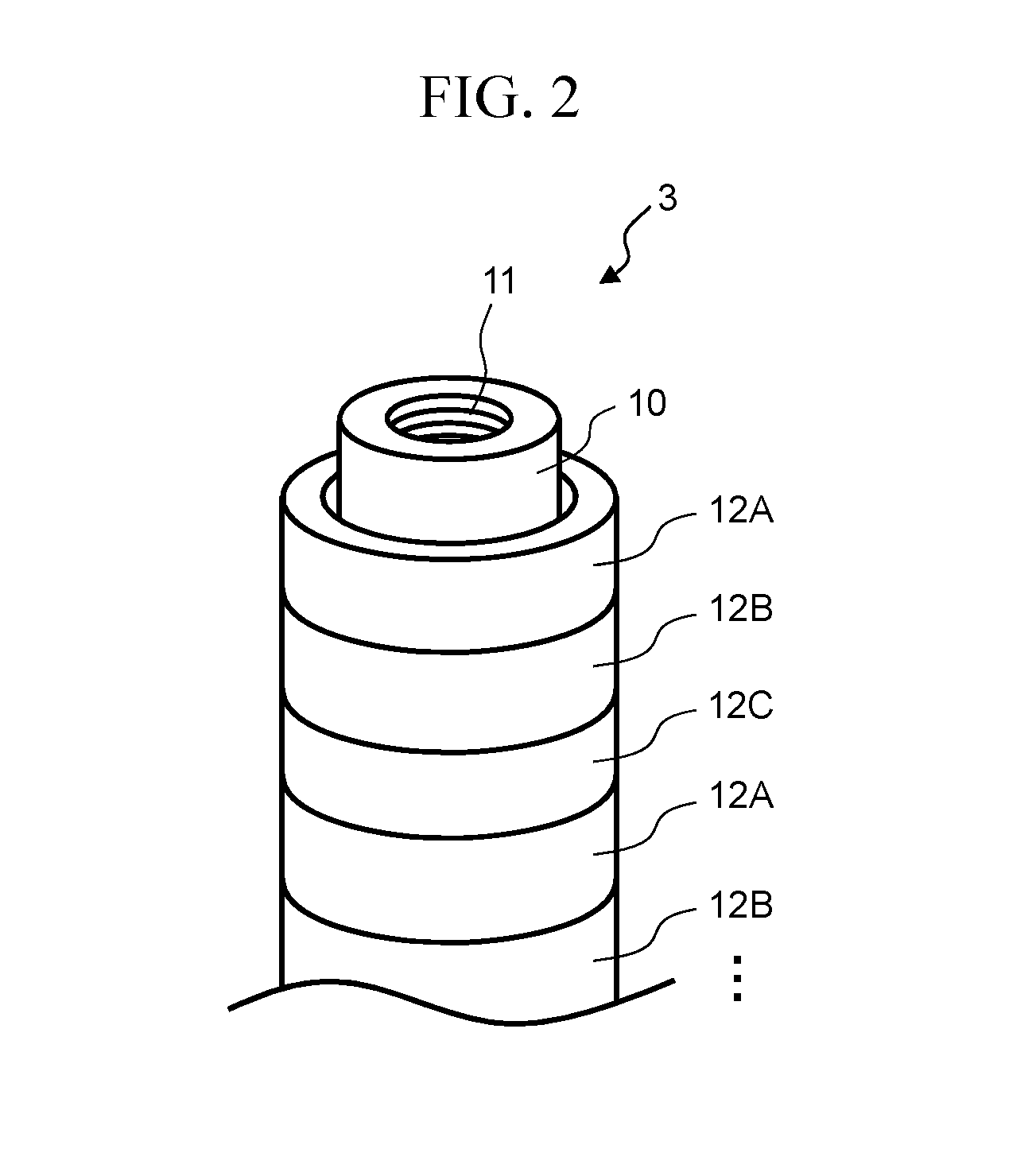

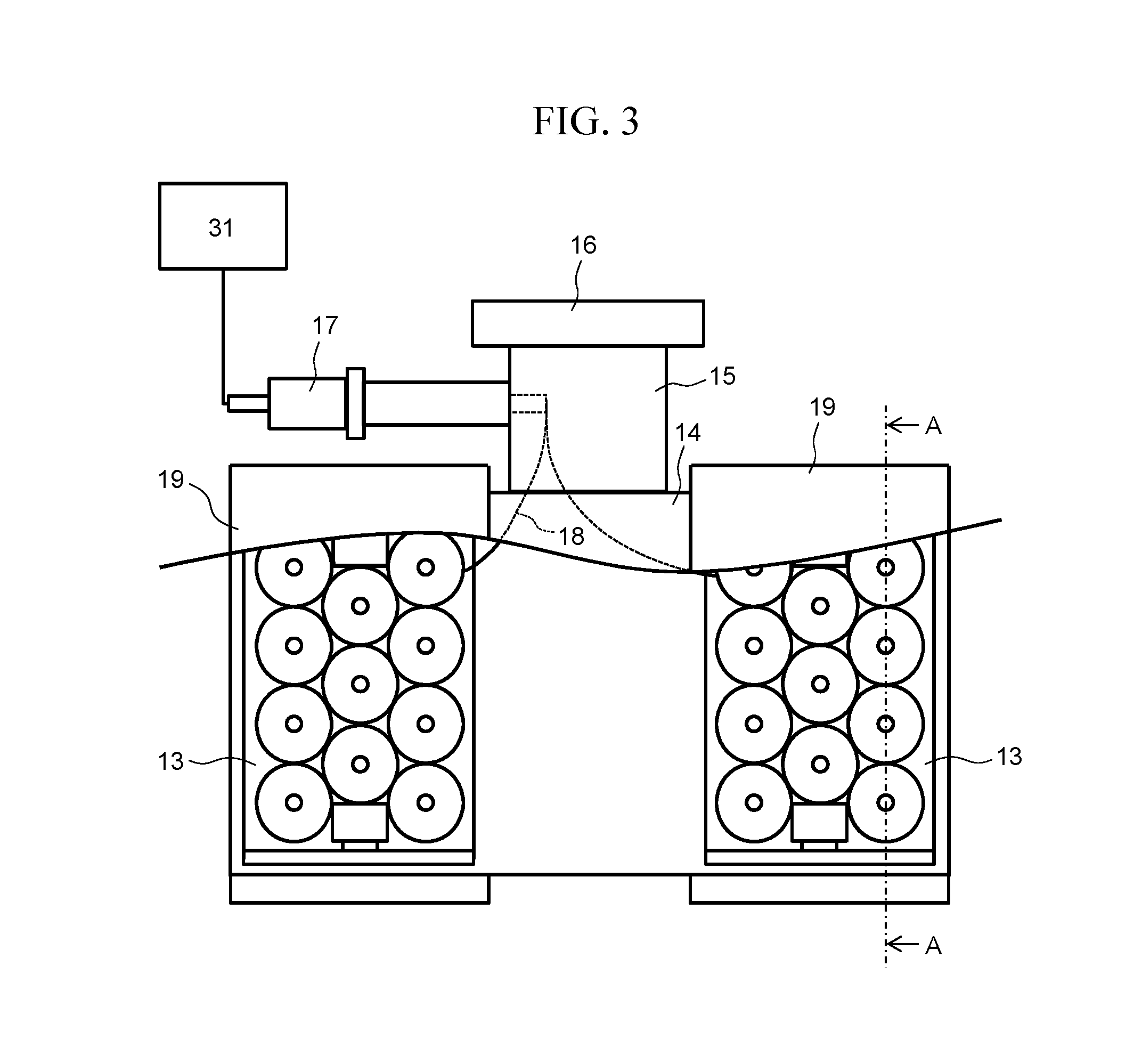

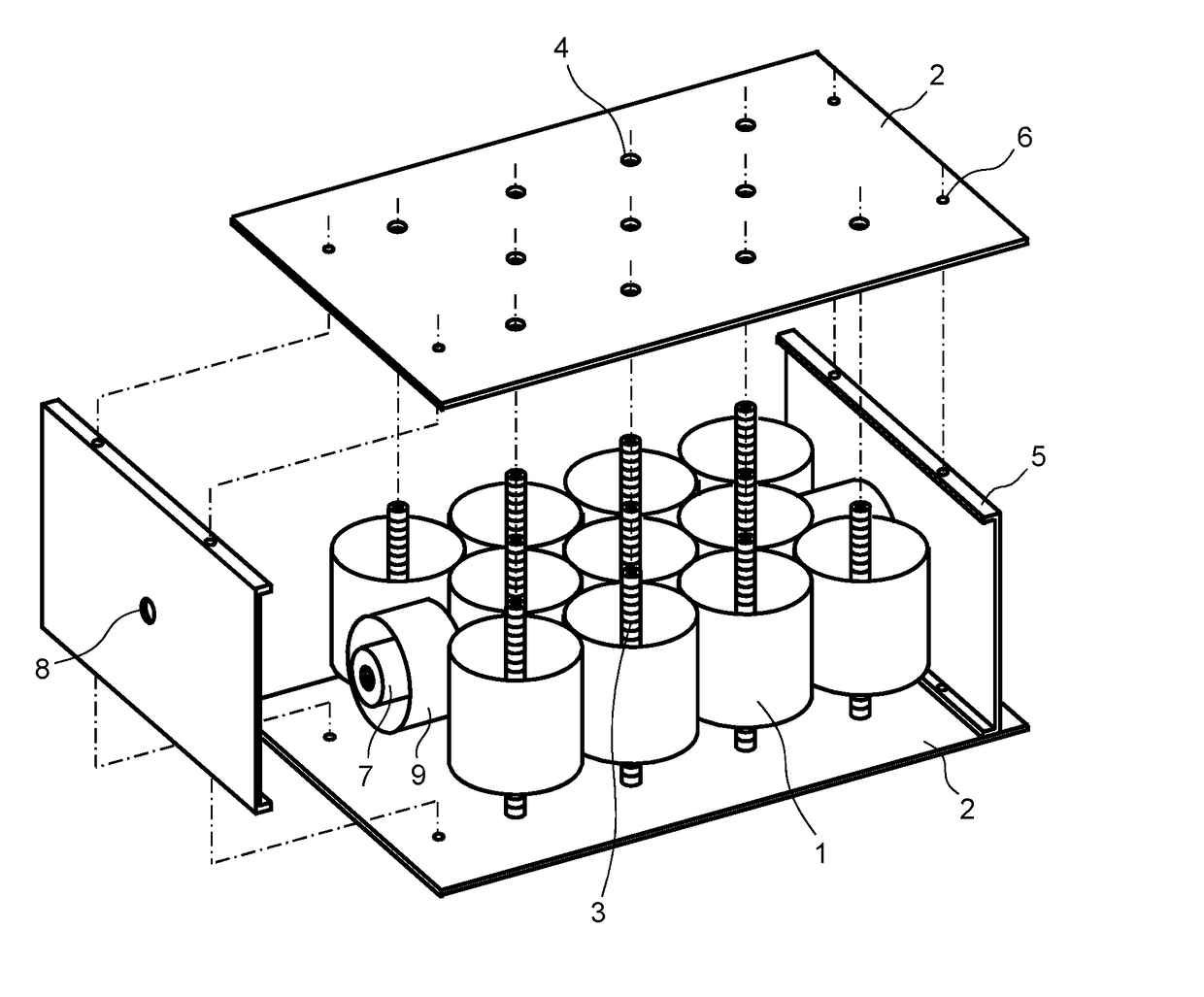

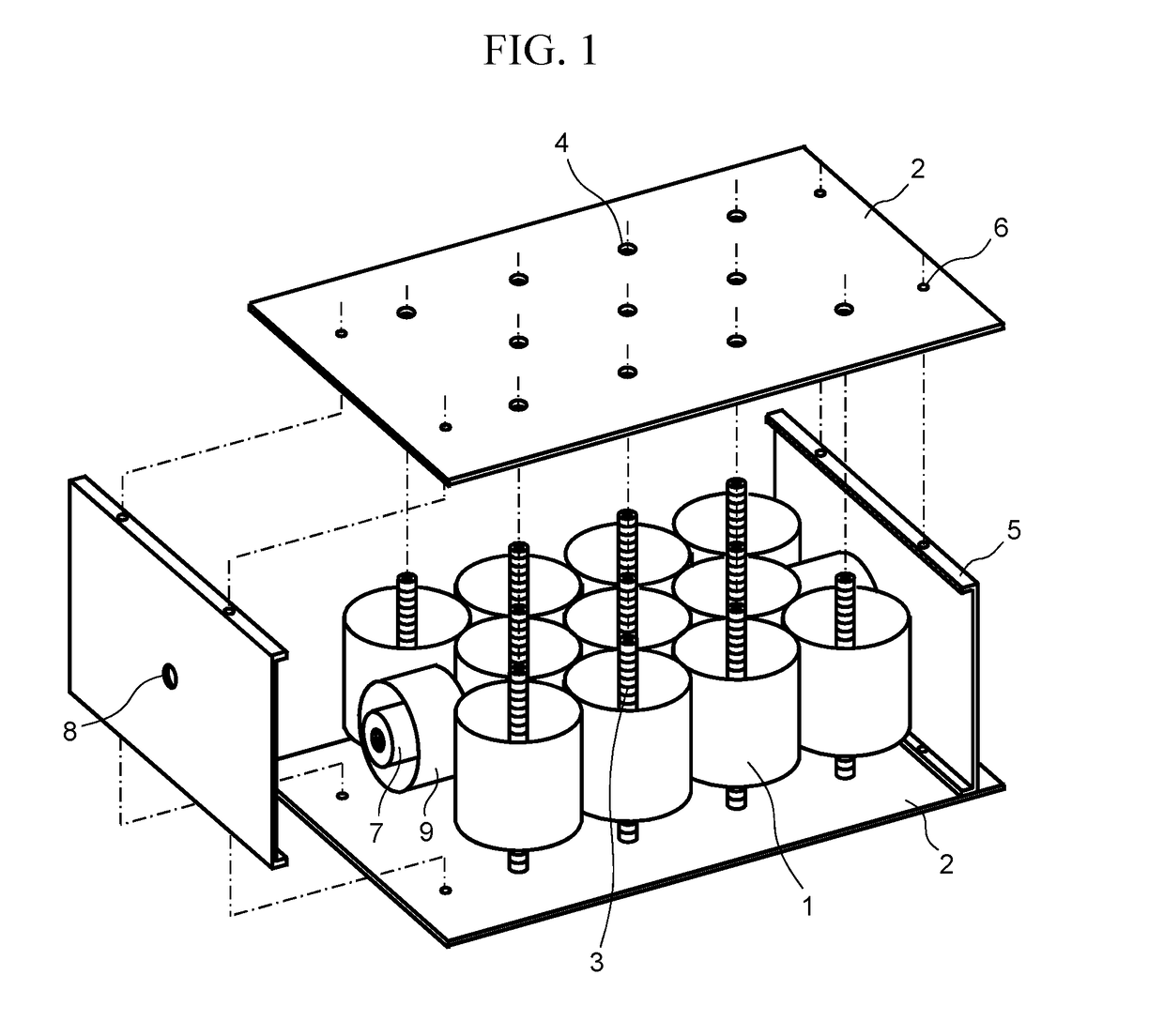

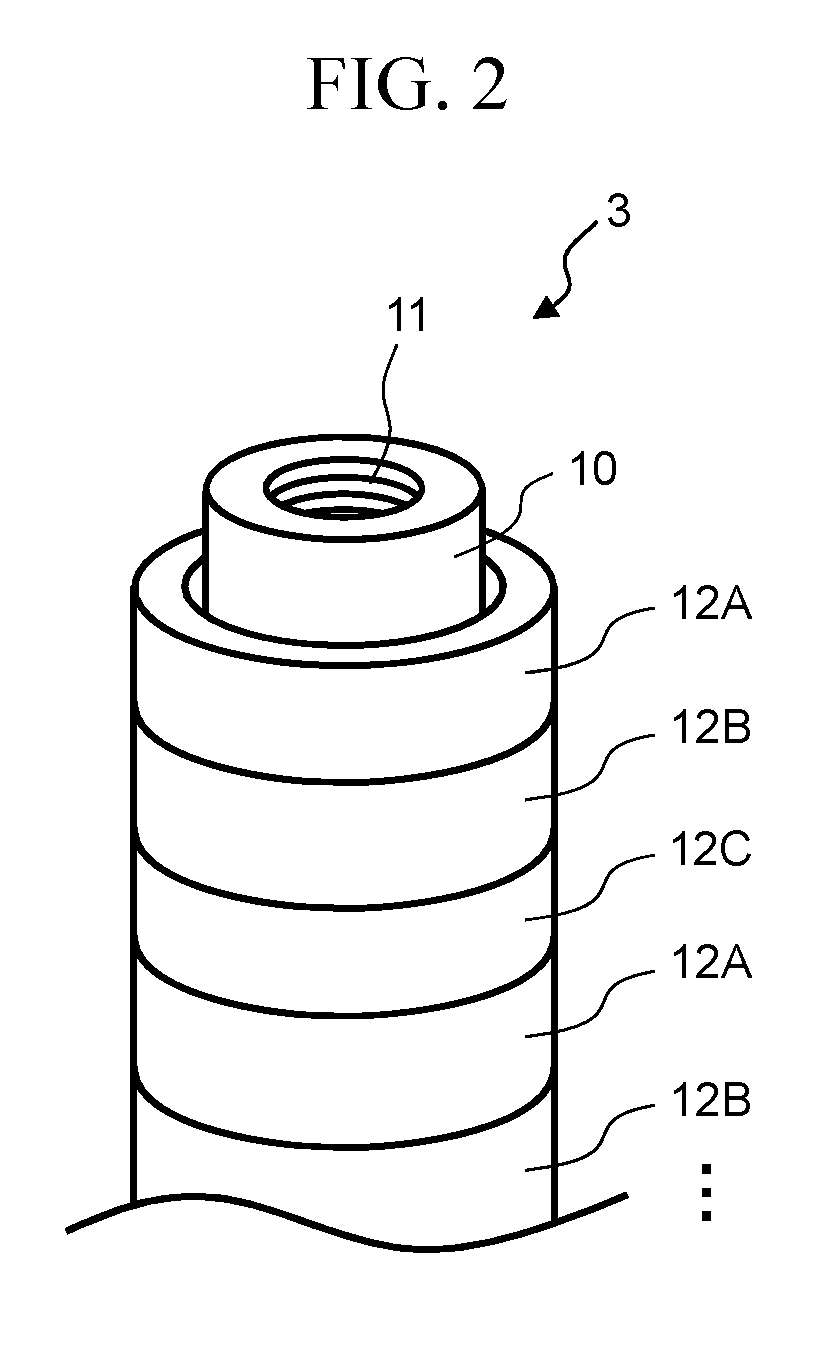

Hydrogen storage device and hydrogen storage system

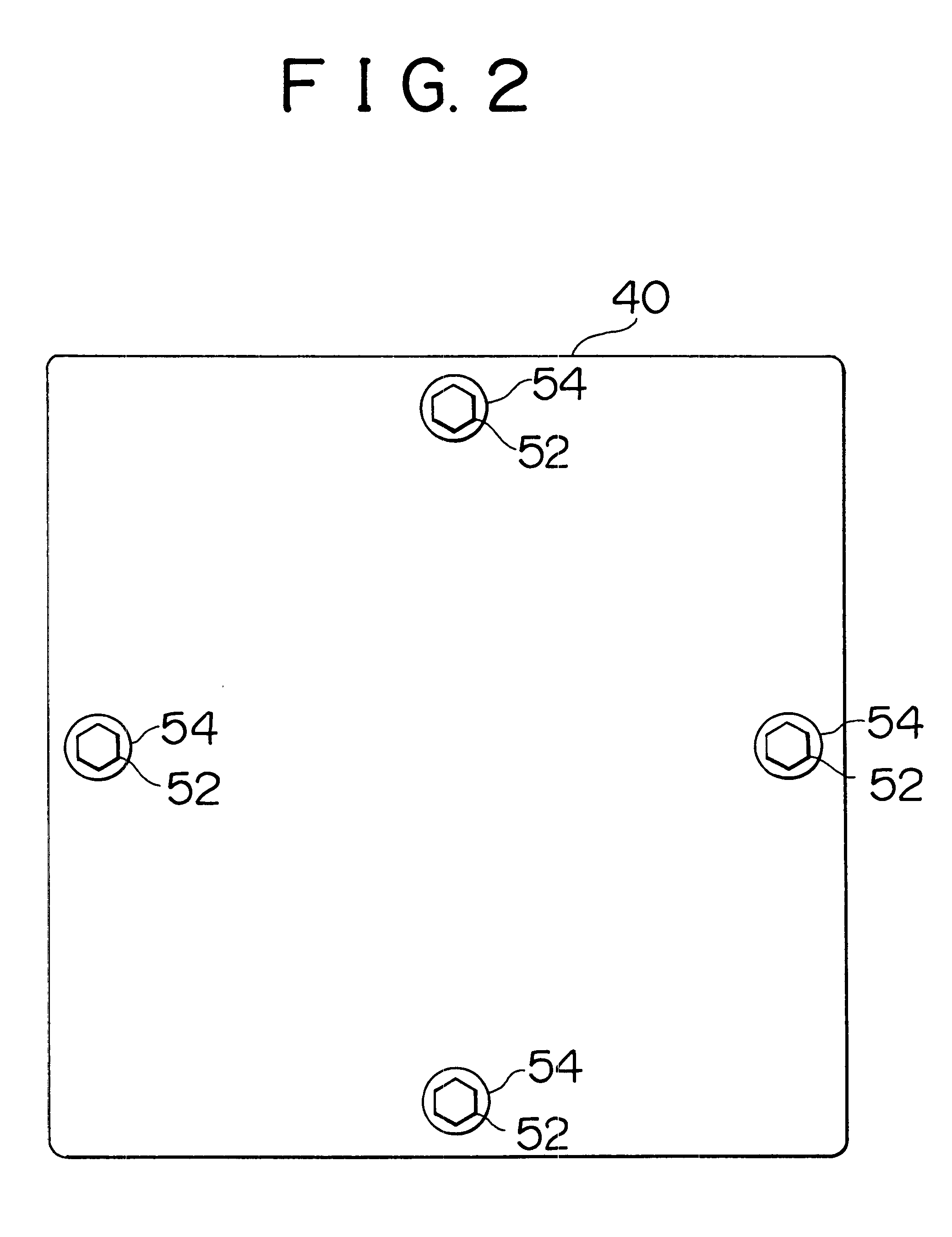

InactiveUS6530233B1Avoid localizationEasy dischargeReversible hydrogen uptakeIndirect heat exchangersCushioningOptoelectronics

A hydrogen storage device prevents localization of hydrogen occlusion alloy and ensures rapid discharge of hydrogen. The hydrogen storage device has a plurality of porous molded pieces arranged longitudinally at predetermined intervals. Conductive cushioning materials are inserted between the molded pieces and between the molded pieces and an adiabatic insulation material. The conductive cushioning materials include first conductive cushioning materials inserted between the adiabatic insulation material and upper and lower end surfaces of the molded pieces and second conductive cushioning materials inserted between left and right end surfaces of the adiabatic insulation material. Disposed at opposed ends of a row of the molded pieces are movable urging electrodes which can move in response to dimensional changes of the molded pieces resulting from their volume changes and which urge the molded pieces to constantly maintain physical contact between the molded pieces and lids.

Owner:TOYOTA JIDOSHA KK

Audio signal processing circuit

InactiveUS7242782B1Avoid localizationQuality improvementTwo-channel systemsFrequency/directions obtaining arrangementsSound sourcesPhase difference

An audio signal processing circuit for an audio reproduction apparatus at least having sound source located substantially at left and right sides to a listener, is provided. The audio signal processing circuit includes a phase difference control portion. The phase difference control portion receives a left channel signal for the left sound source and a right channel signal for the right sound source, controls a phase difference between the left and right channel signals so as to produce a relative phase difference in the range of 140 degrees to 160 degrees, and outputs the phase difference controlled left and right channel signals for the left and right sound source, respectively.

Owner:ONKYO KK

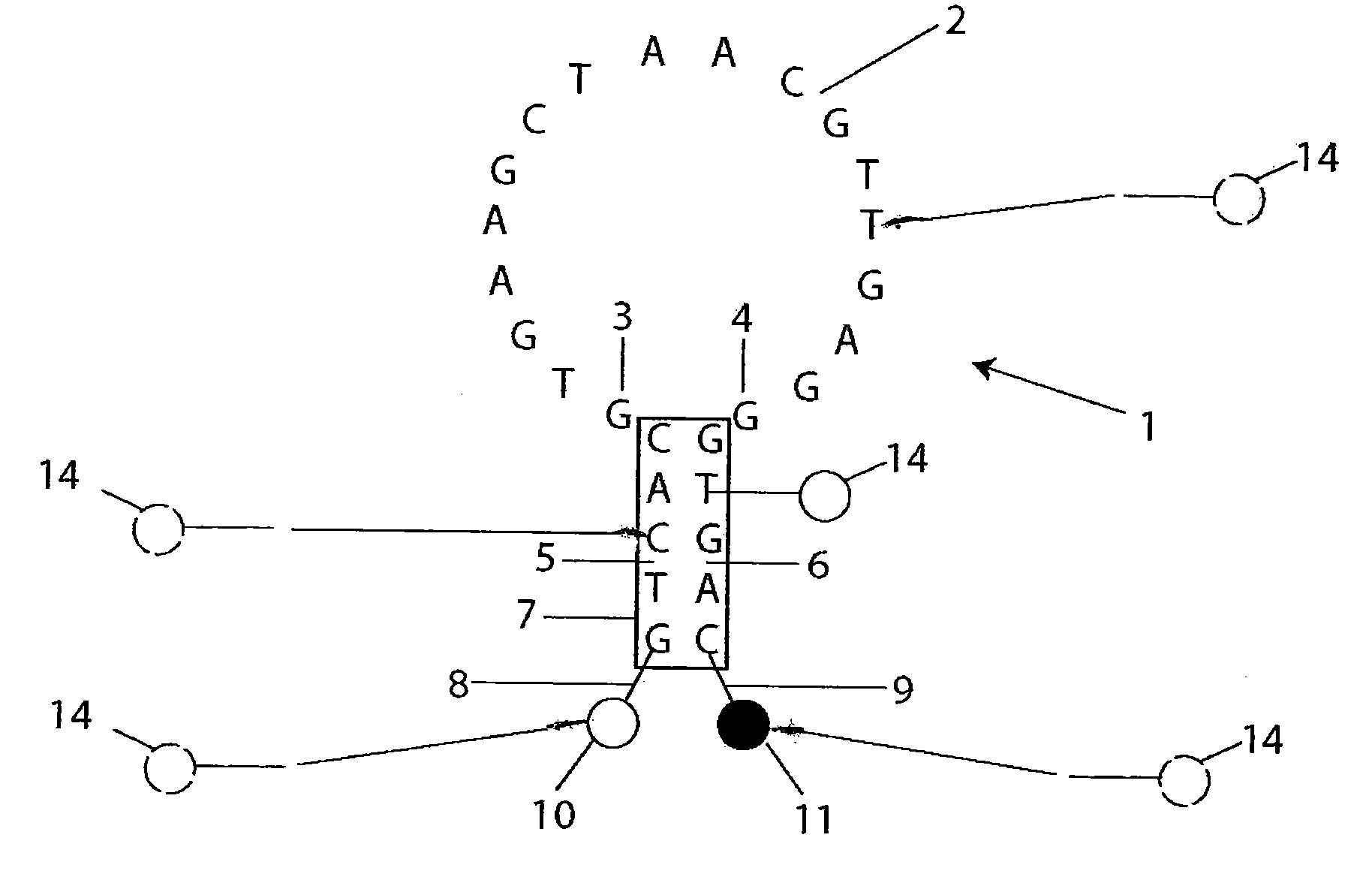

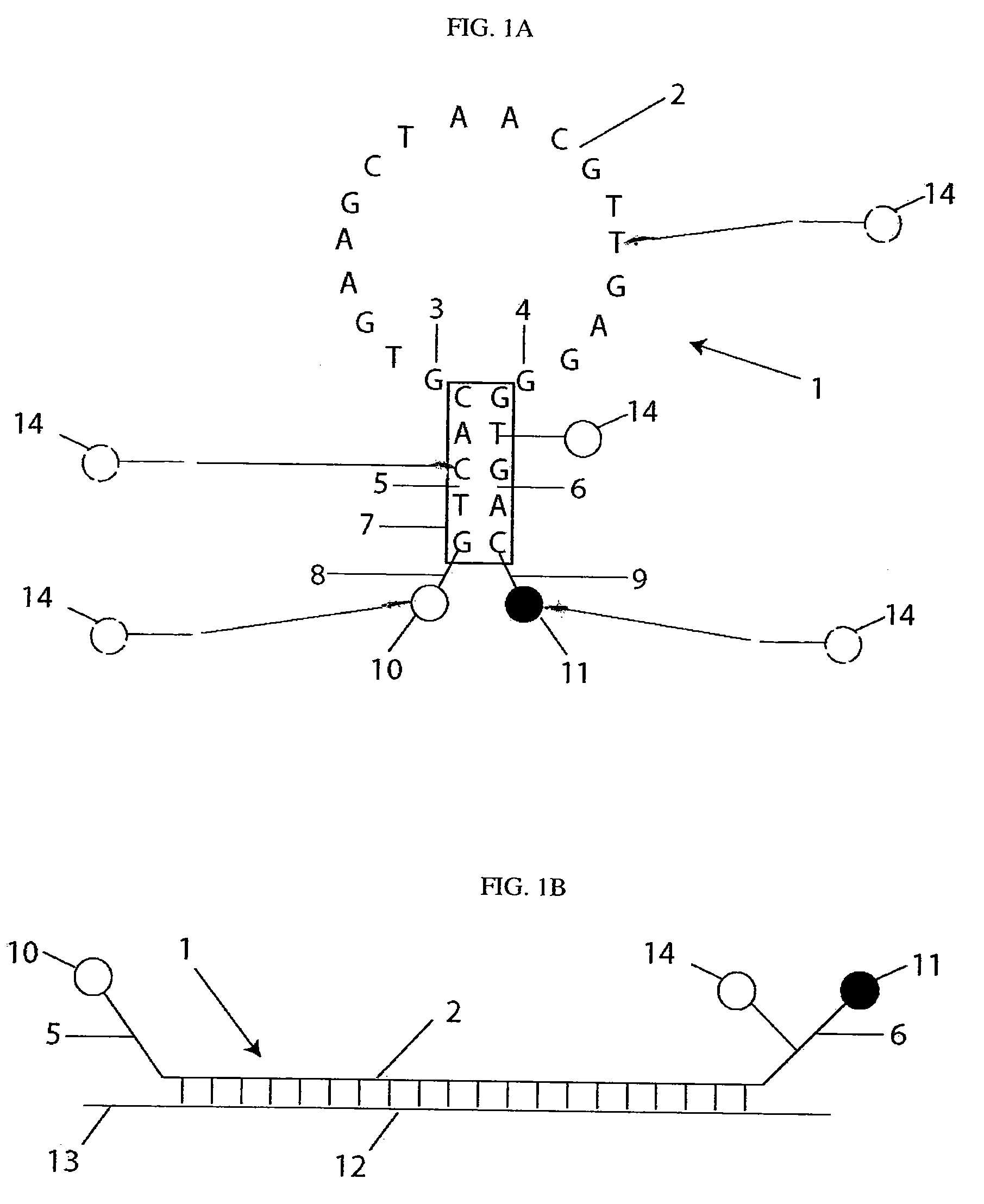

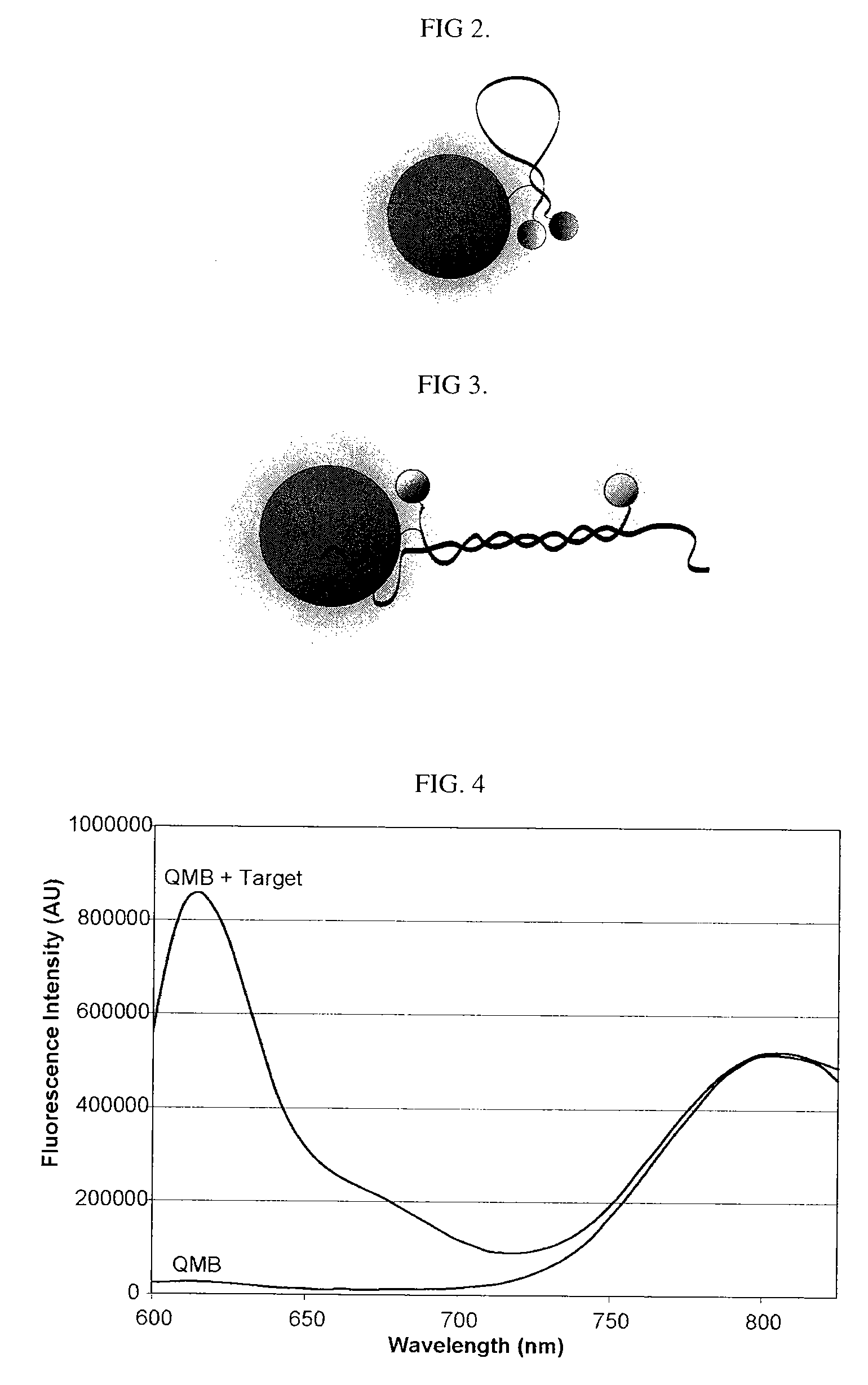

Quantitative molecular probes

InactiveUS20090104614A1Improved spatial quantificationEasy to quantifySugar derivativesMicrobiological testing/measurementQuantum dotFluorophore

In accordance with this invention, a molecular probe for detection of a nucleic acid target containing a preselected target sequence is constructed and has at least two sources of a signal: a conventional reporter source and a reference source in a form of a luminescent material, e.g., a fluorophore, quantum dot, fluorescent nanoparticle, or other fluorescent reference dye / nanoparticle / microparticle conjugated to the molecular probe.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Ion pump and charged particle beam device using the same

An ion pump and a charged particle beam device each includes two opposite flat-plate cathodes, an anode with a cylindrical shape having openings that face the respective flat-plate cathodes, a voltage application unit configured to apply a potential higher than potentials of the flat-plate cathodes to the anode, a magnetic field application unit configured to apply a magnetic field along an axial direction of the cylindrical shape of the anode, and a cathode bar arranged within the anode. The surface of the cathode bar is formed with a material that forms a non-evaporative getter alloy film on the anode or the flat-plate cathodes.

Owner:HITACHI LTD

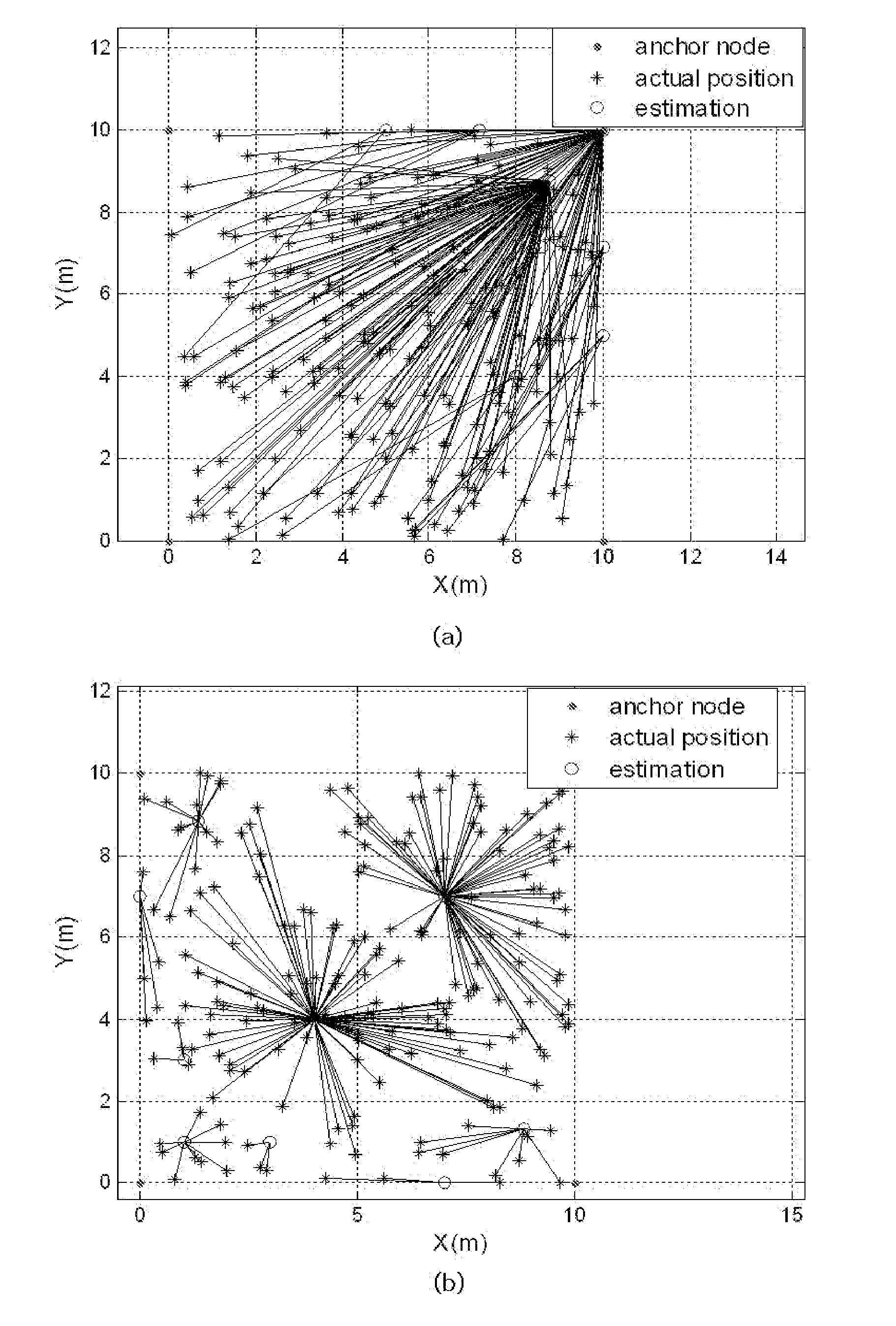

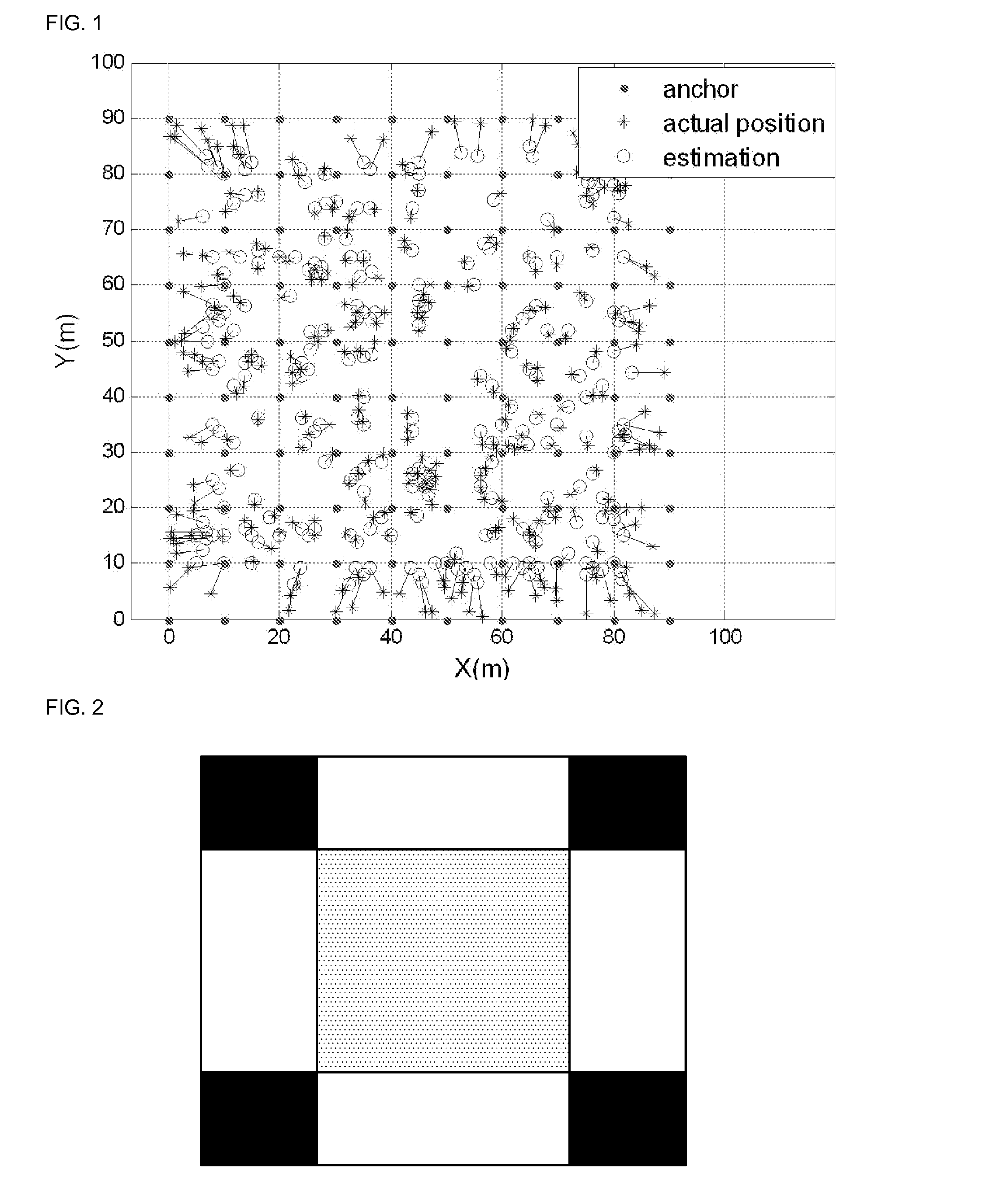

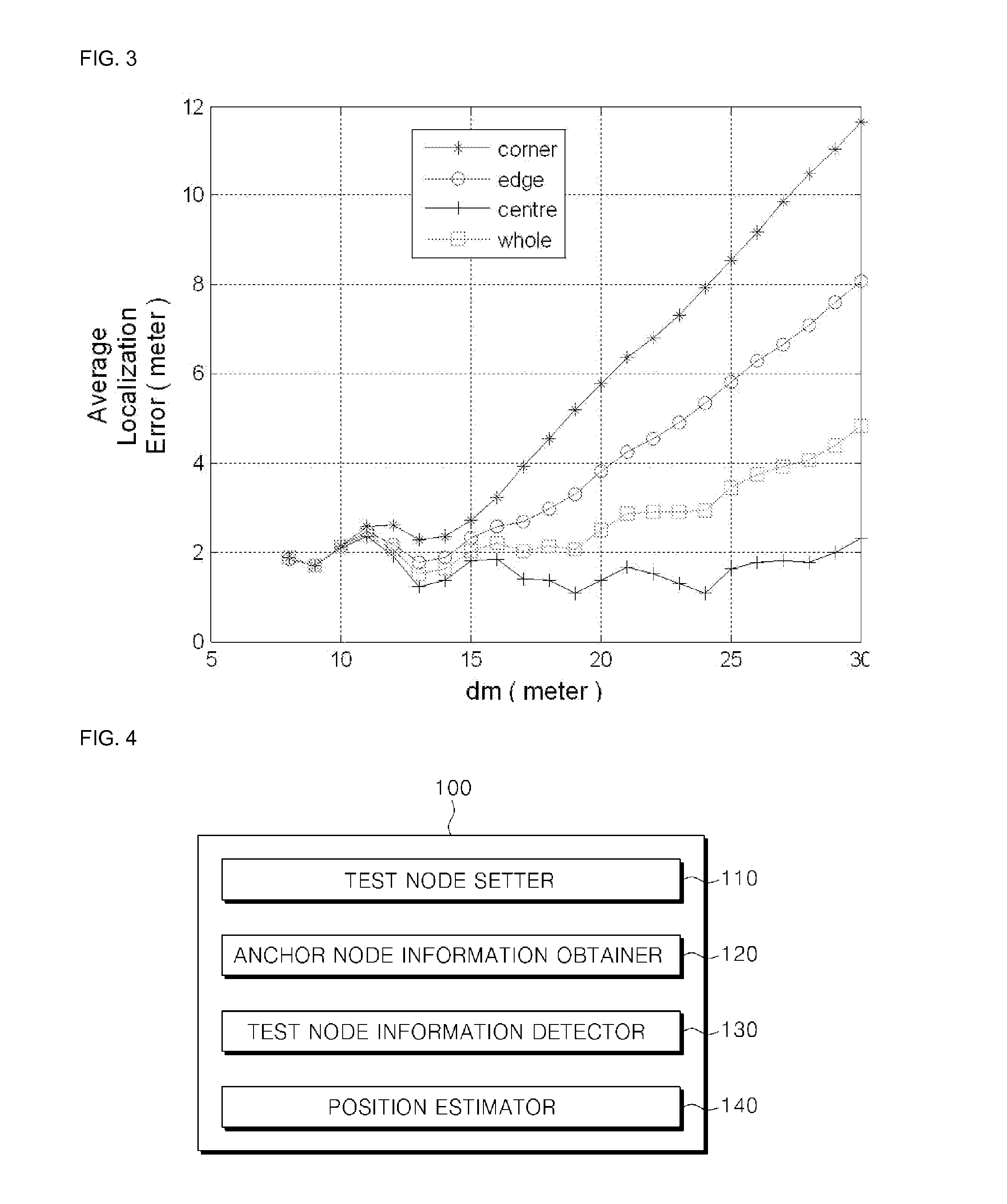

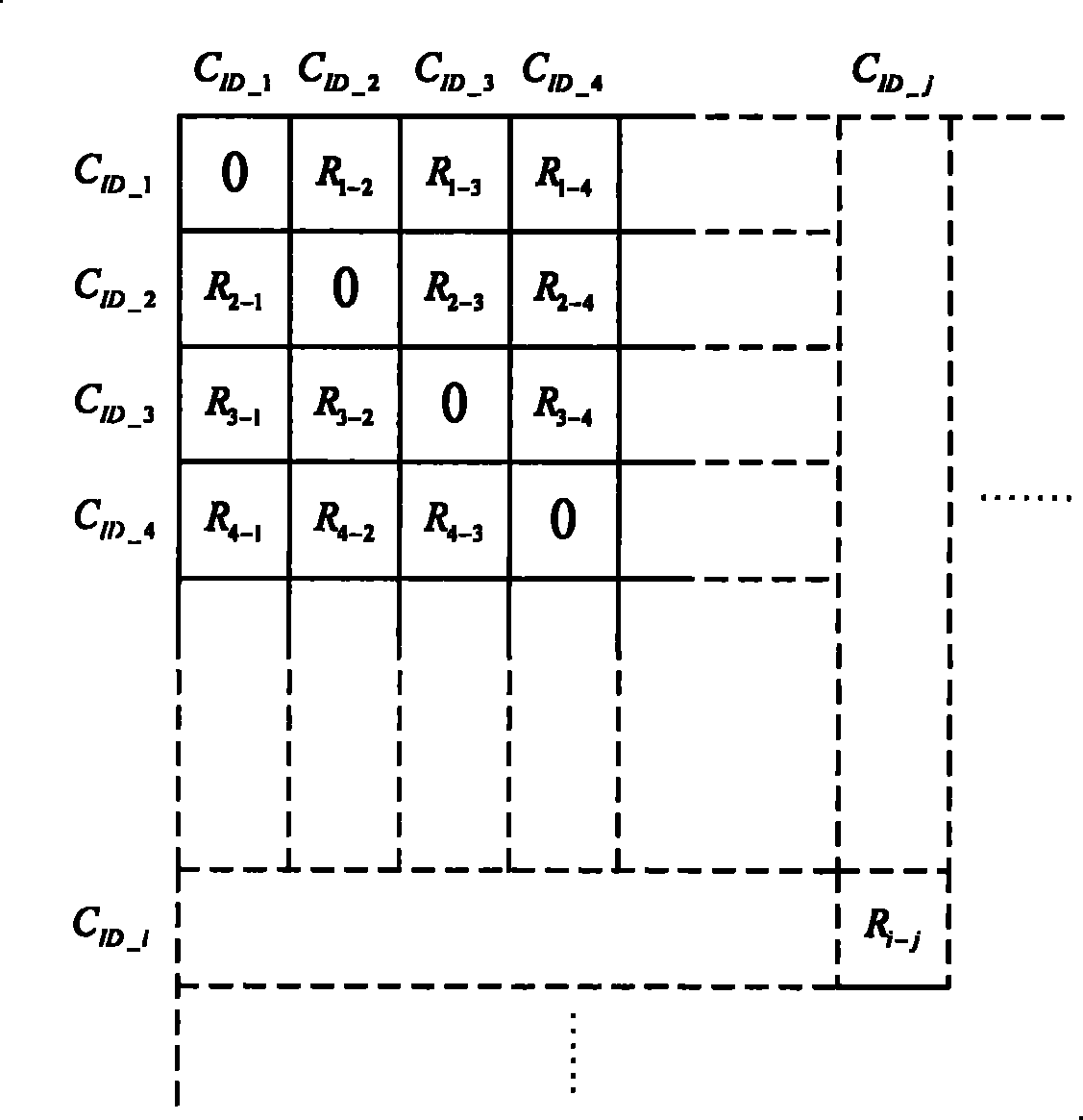

Wireless positioning method and apparatus using wireless sensor network

ActiveUS20140153424A1Prevent errorAvoid localizationError preventionFrequency-division multiplex detailsReal-time computingWireless sensor networking

Provided is a wireless positioning method using a wireless sensor network, for estimating a position of an unknown node that is a positioning target by using a plurality of anchor nodes arranged at regular intervals, the wireless positioning method including: setting a plurality of test nodes at regular intervals on a space formed by some of the plurality of anchor nodes; obtaining a number and position information of anchor nodes within a predetermined distance from the unknown node; detecting at least one test node matching the obtained number and position information; and estimating a position of the unknown node by calculating an average coordinate value of the detected at least one test node.

Owner:FOUND OF SOONGSIL UNIV IND COOP

Cytosolic isobutanol pathway localization for the production of isobutanol

The present invention provides recombinant microorganisms comprising isobutanol producing metabolic pathway with at least one isobutanol pathway enzyme localized in the cytosol, wherein said recombinant microorganism is selected to produce isobutanol from a carbon source. Methods of using said recombinant microorganisms to produce isobutanol are also provided. In various aspects of the invention, the recombinant microorganisms may comprise a cytosolically active isobutanol pathway enzymes. In some embodiments, the invention provides mutated, modified, and / or chimeric isobutanol pathway enzymes with cytosolic activity. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:GEVO INC

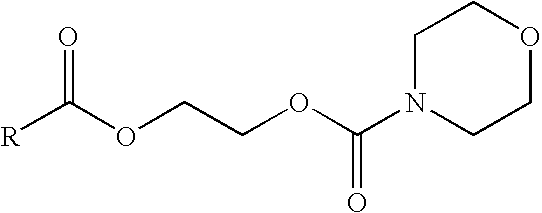

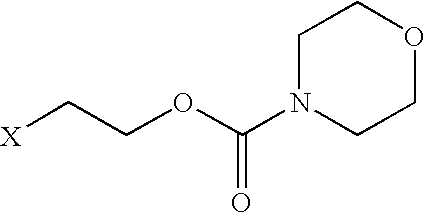

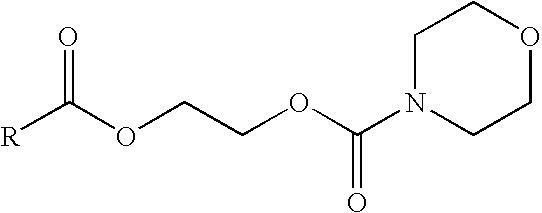

Prodrugs of non-steroidal anti-inflammatory and carboxylic acid containing compounds

InactiveUS20050004118A1Minimize gastrointestinal tract side effectAvoid localizationOrganic active ingredientsOrganic chemistryArylActive agent

Compounds of the formula: RC(O)O-spacer-OC(O)R′, wherein (i) RC(O)— is the acyl residue of an NSAID or other pharmaceutically active agent bearing a carboxylic acid function, (ii) spacer is Cn alkyl, (iii) n is from 1 to 6, and (iv) R′ is substituted or unsubstituted heteroaryl or heterocycle, and pharmaceutical compositions thereof.

Owner:JILANI JAMAL A

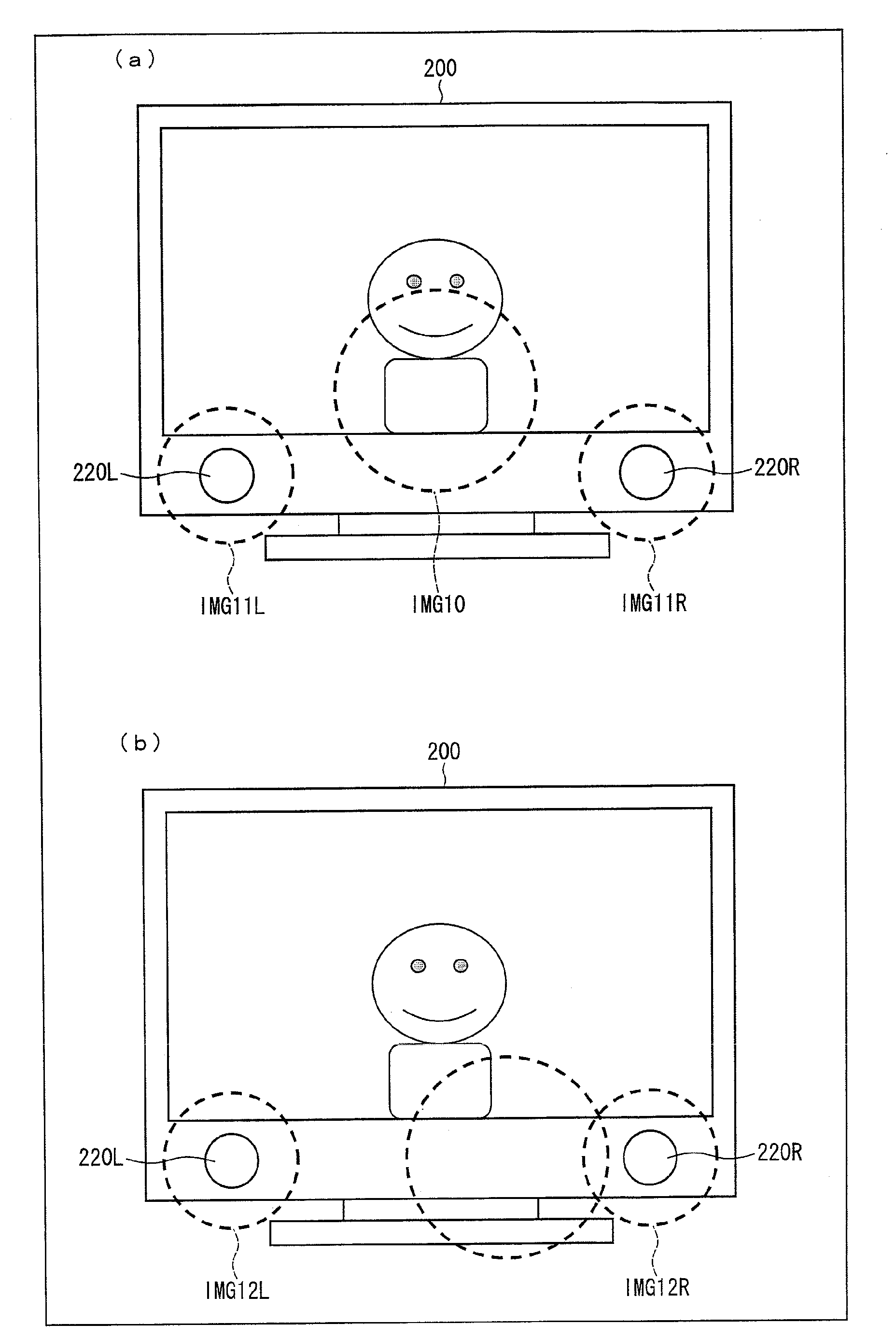

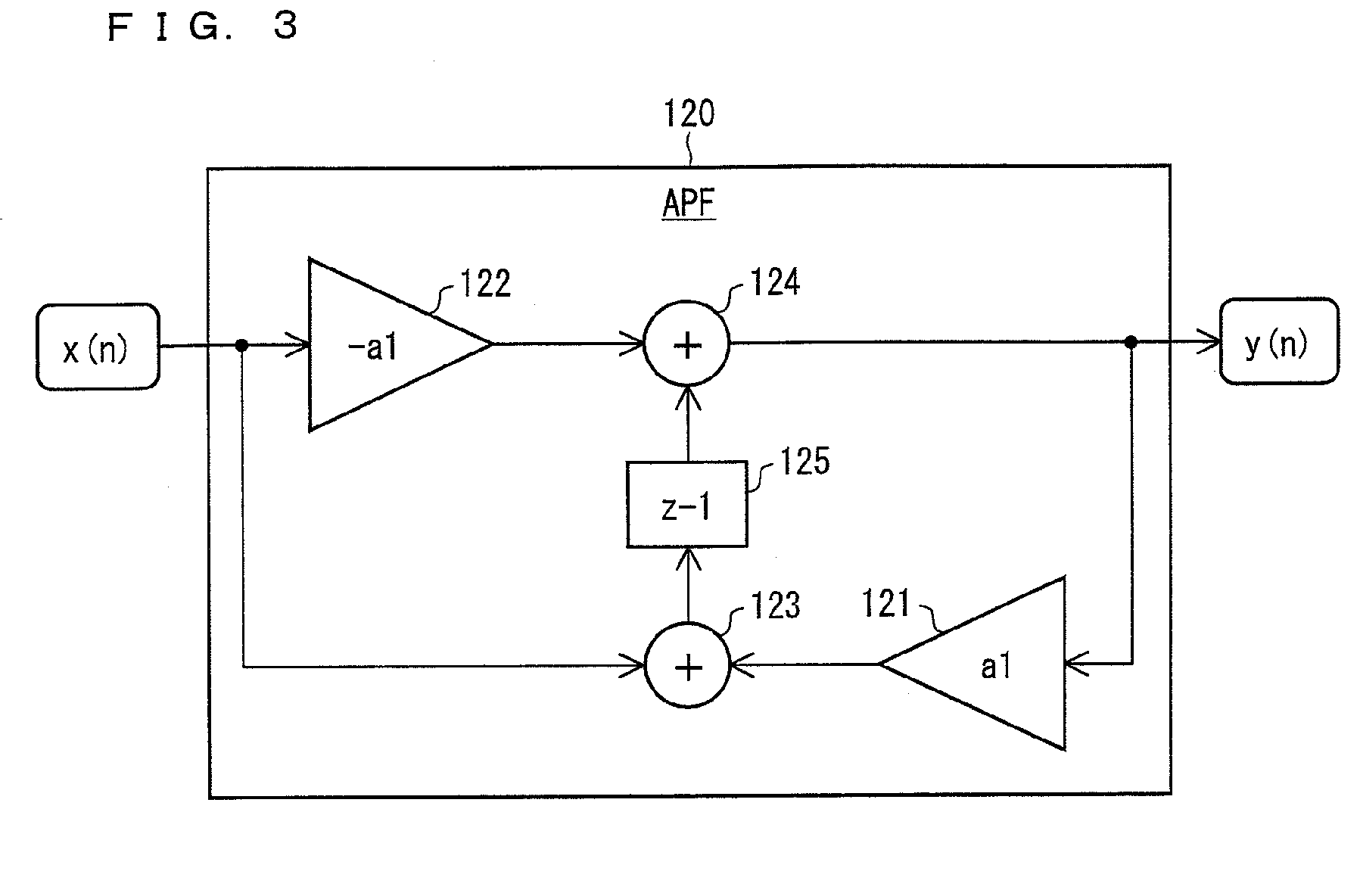

Sound signal processing apparatus, sound signal processing method, display apparatus, rack, program, and storage medium

InactiveUS20110115987A1High bandwidthEnhances respective bandwidthTelevision system detailsSignal processingSound imageComputer science

A sound signal processing apparatus (100) includes: an equalizer (110L) for enhancing an 8 kHz band of a sound signal (#1L); an equalizer (110R) for enhancing an 8 kHz band of a sound signal (#1R); and a filter (120) for delaying a phase of a sound signal (#2L). The filter (120) decreases correlation between the sound signals (#3L) and (#2R). This sufficiently moves a sound image upward, without use of a technique of pseudo surround.

Owner:SHARP KK

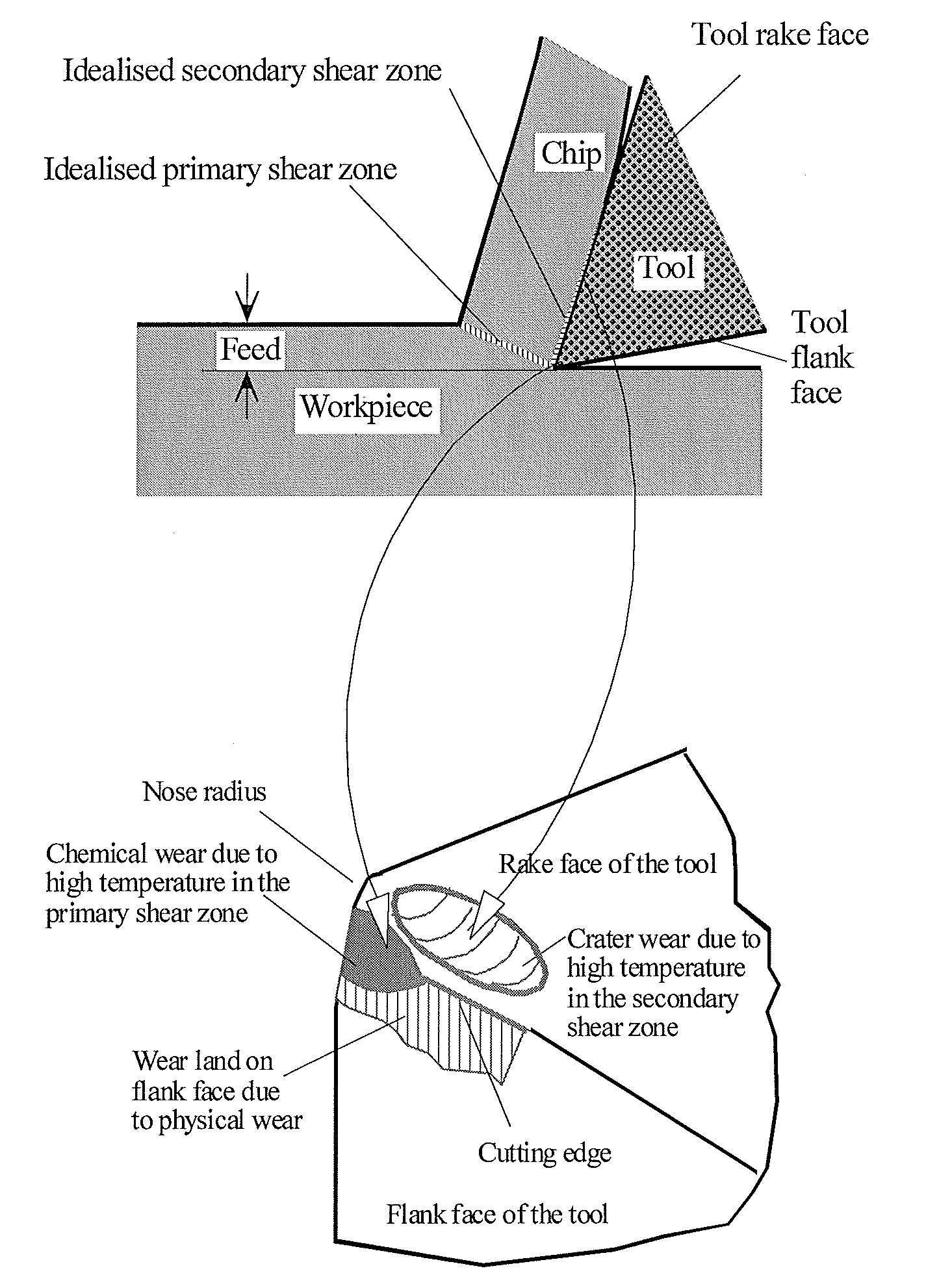

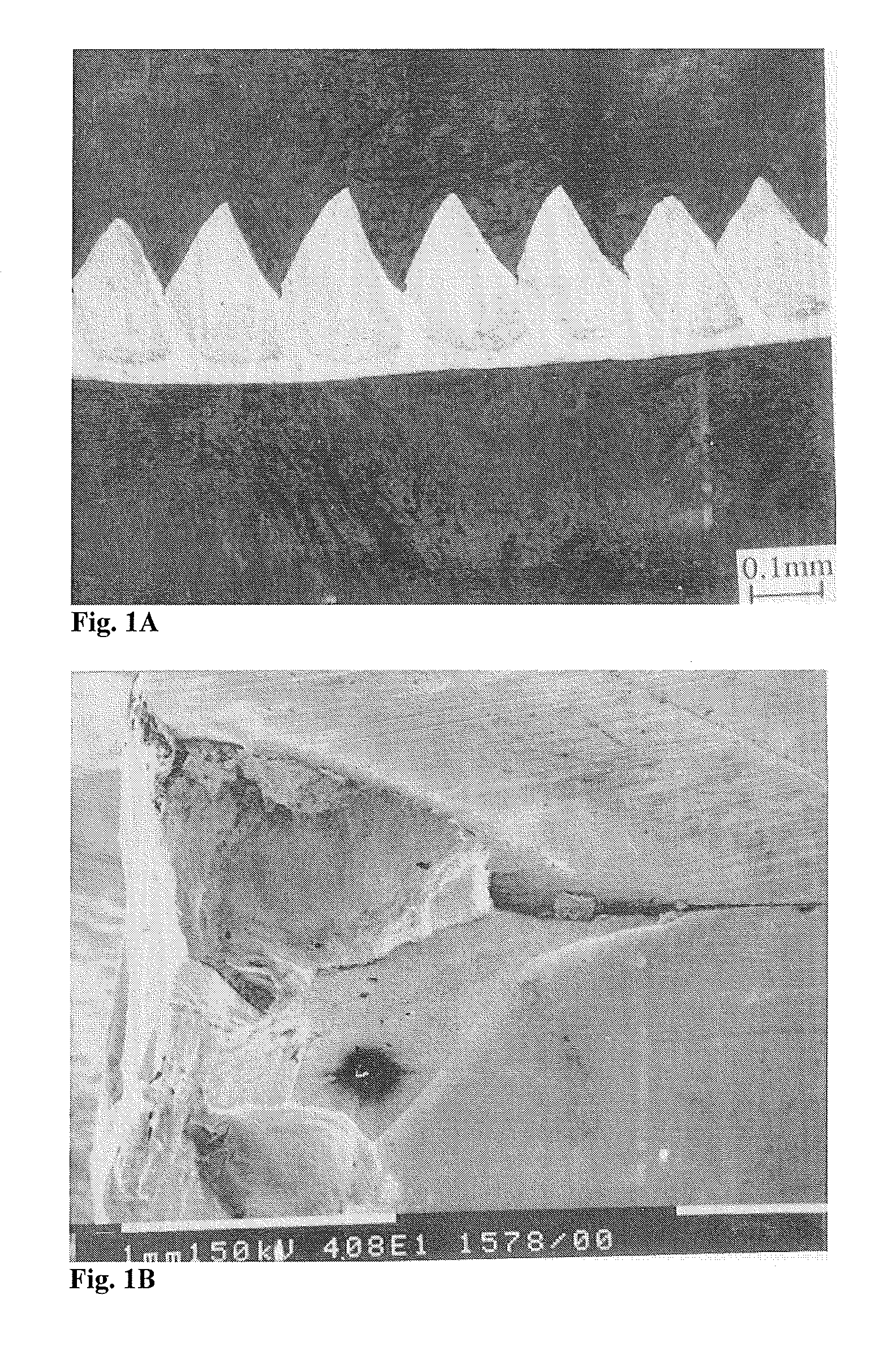

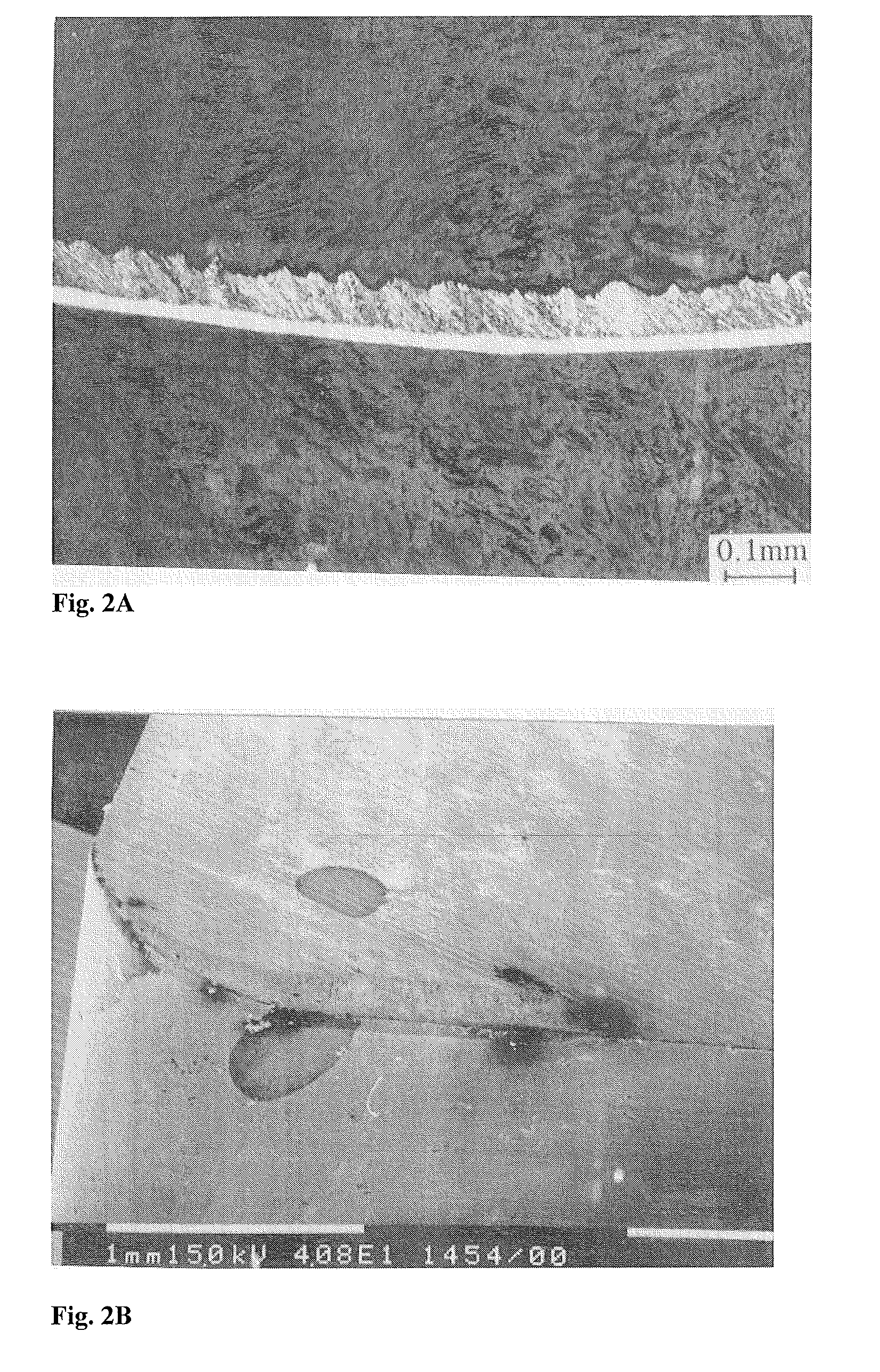

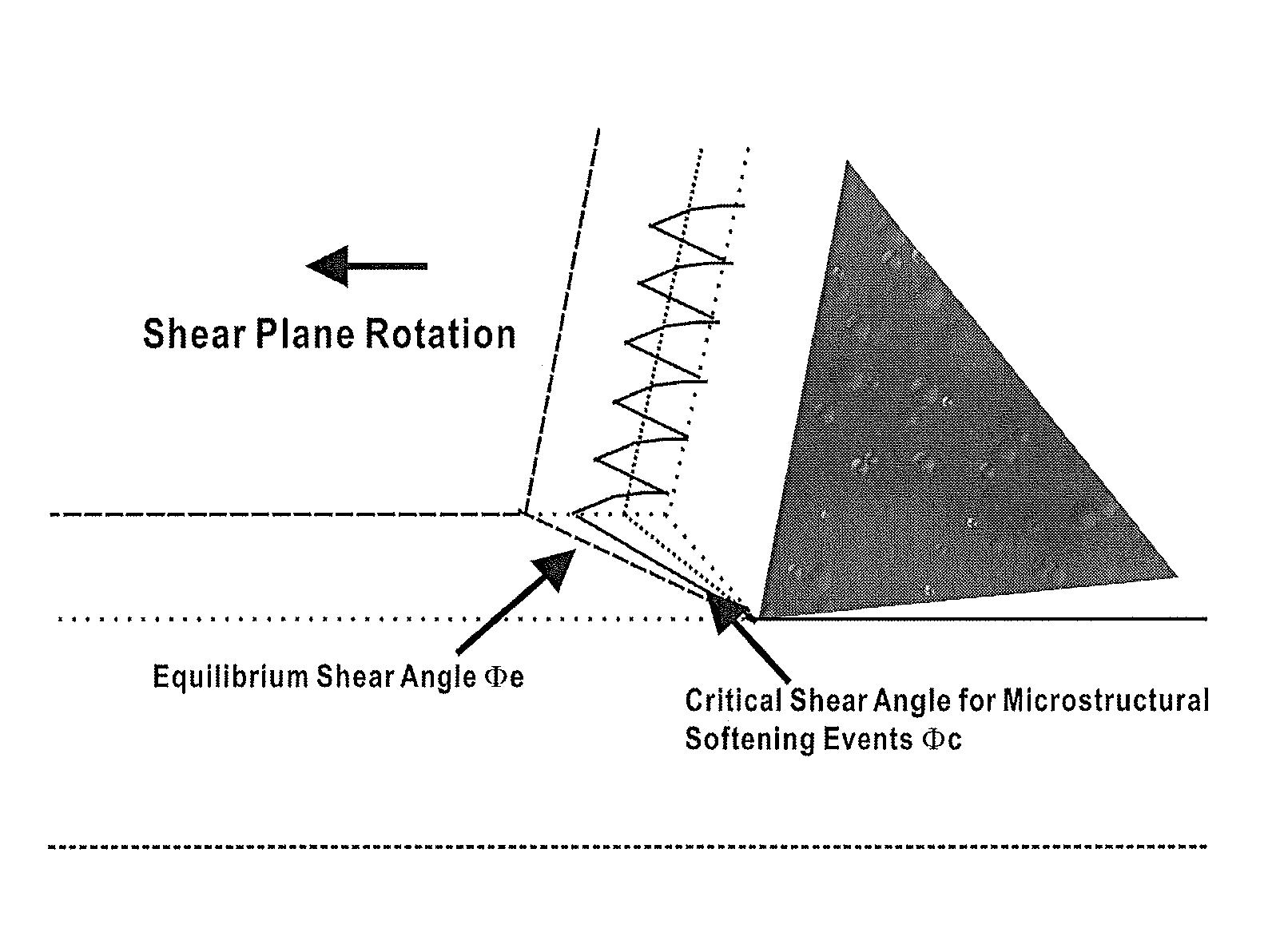

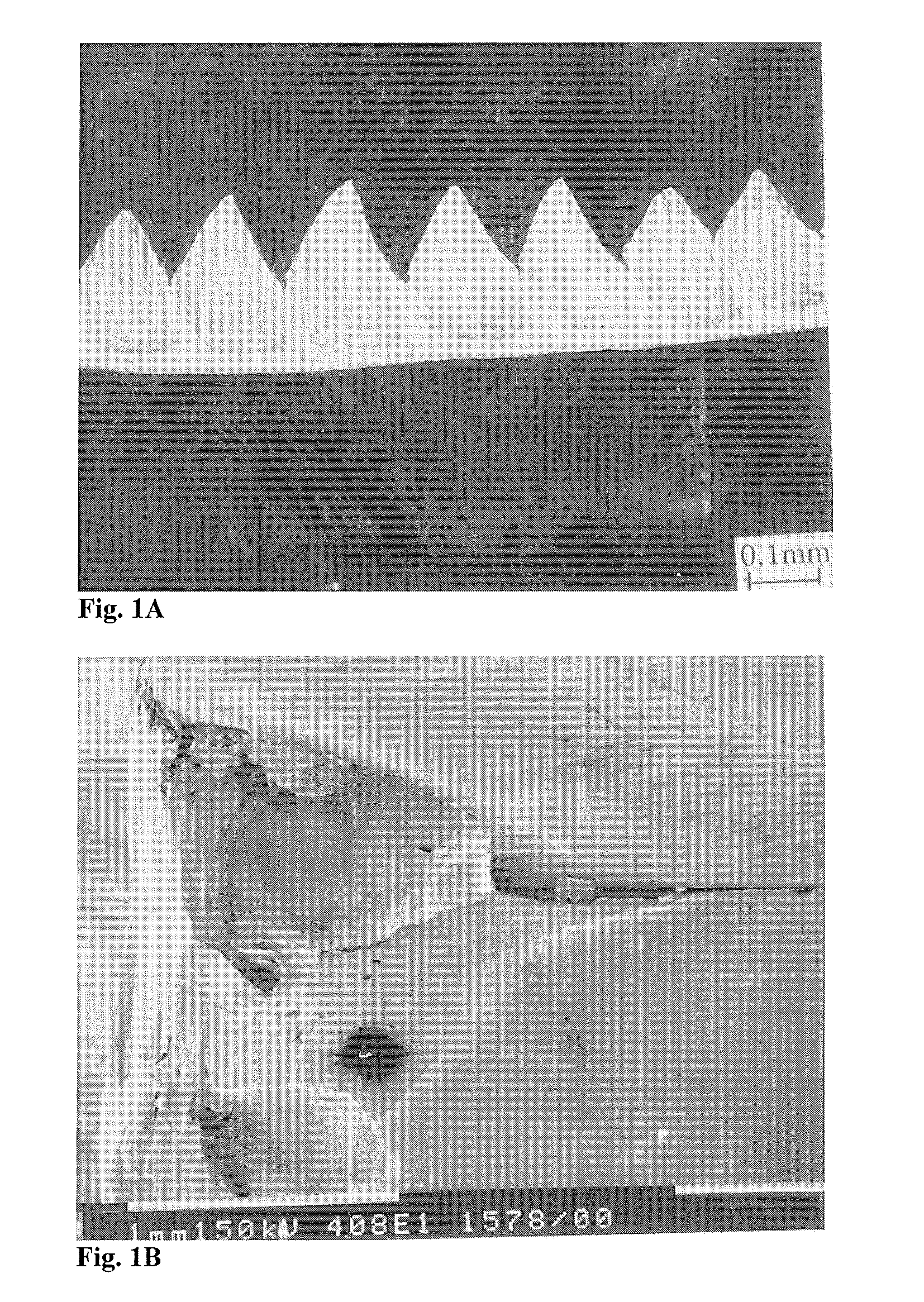

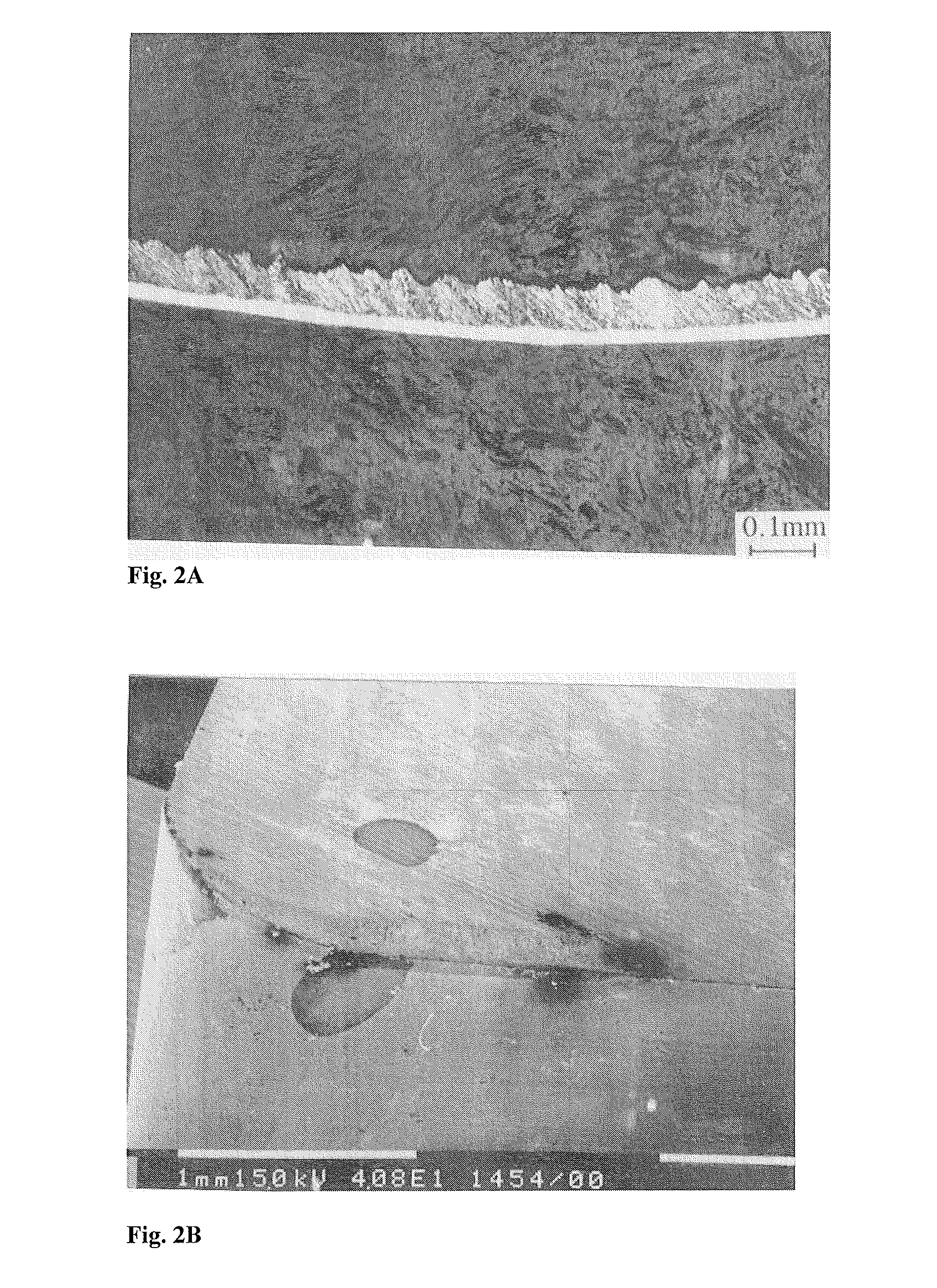

Processes for improving tool life and surface finish in high speed machining

InactiveUS20100086369A1Enhanced grain boundary diffusionReduce wearLathesAutomatic/semiautomatic turning machinesPerformance toolEngineering

Processes for high speed machining of workpiece materials using high performance tools with prolonged tool life and improved surface finish are provided by vibrating the tool and / or the workpiece at a frequency greater than the frequency of shear localization in the primary shear zone or chip segmentation occurring in the absence of tool vibration, with an amplitude sufficient to break up the tool-chip atomic contact, thereby decreasing the tool-chip contact length through decreasing the tool-chip contact time, thereby suppressing accelerated chemical tool wear caused by dissolution of the tool into the workpiece by nanocrystalline grain boundary diffusion and grain boundary sliding mechanisms by preventing shear localization associated with nanocrystalline grain formation in the primary shear zone of the chip, and suppressing oxidation wear of the tool by preventing segmentation of the chip.

Owner:SUBRAMANIAN SUNDARESA V

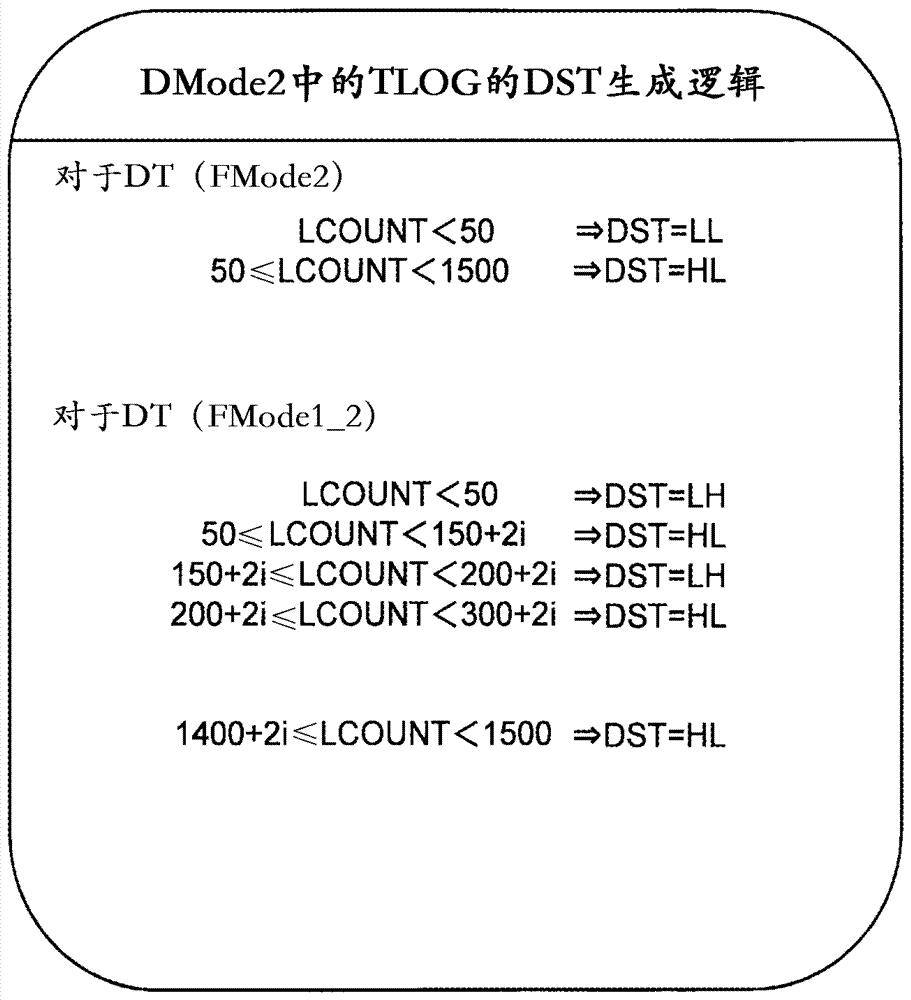

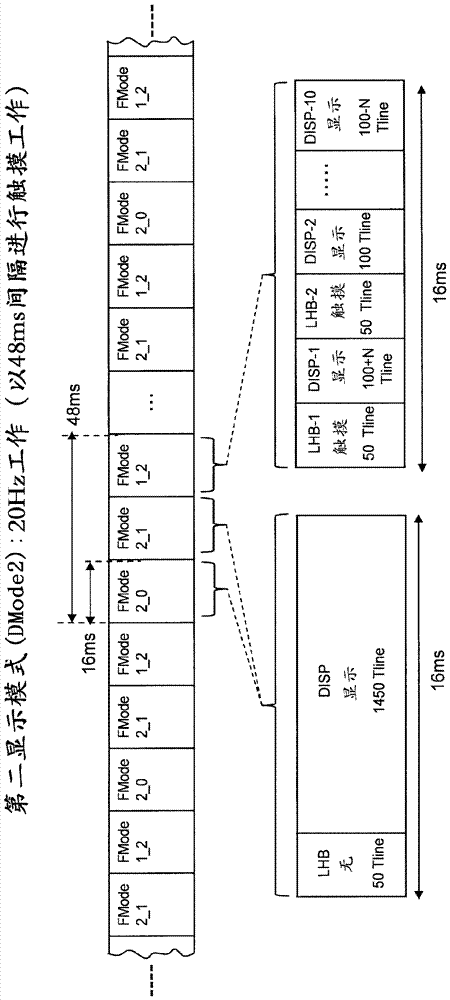

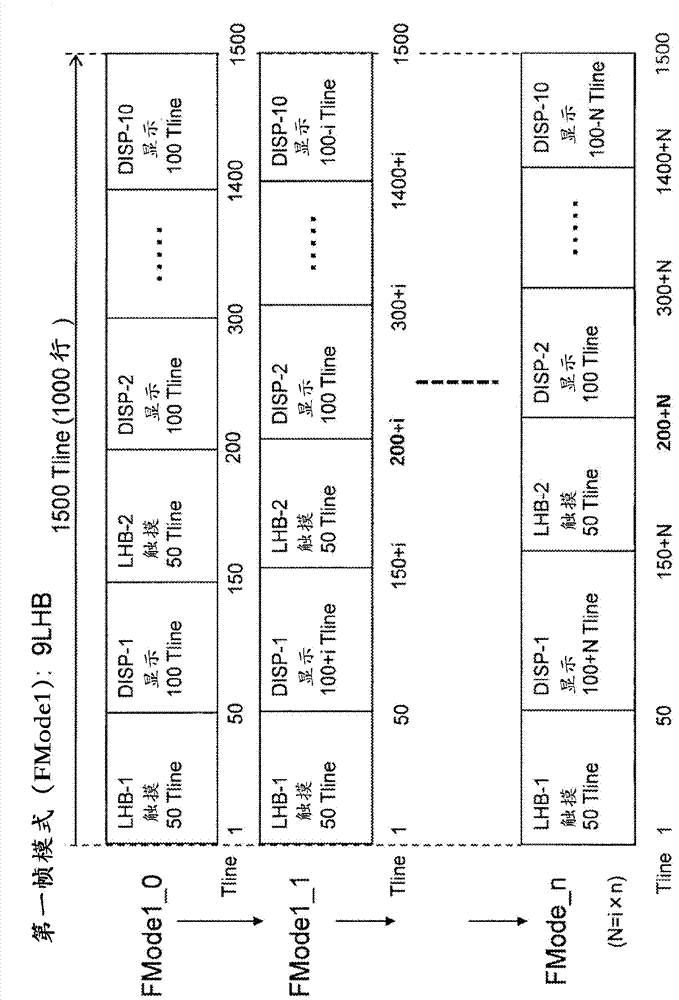

Drive control device and electronic equipment

ActiveCN107340907AAvoid localizationEasy to controlCathode-ray tube indicatorsInput/output processes for data processingSwitching cycleLine switching

The present disclosure relates to a drive control device and electronic equipment, thereby totally simplifying the control of non-display and display drive terms in each display frame period, which a drive control device performs for the purpose of preventing display lines subjected to the degradation in display performance from being localized, or display lines with flicker arising thereon from being unevenly distributed in adopting the control arranged. Start timing of the display drive term and start timing of the non-display drive term are changed for each display frame period in a first frame mode. A second frame mode has a display drive term, and the display drive term is not interrupted by a non-display drive term halfway. The second frame mode is arranged so that the cycle of the display line clock signal in synchronization with the display line switching cycle is made longer than that in the first frame mode.

Owner:OMNIVISION TDDI ONTARIO LLP

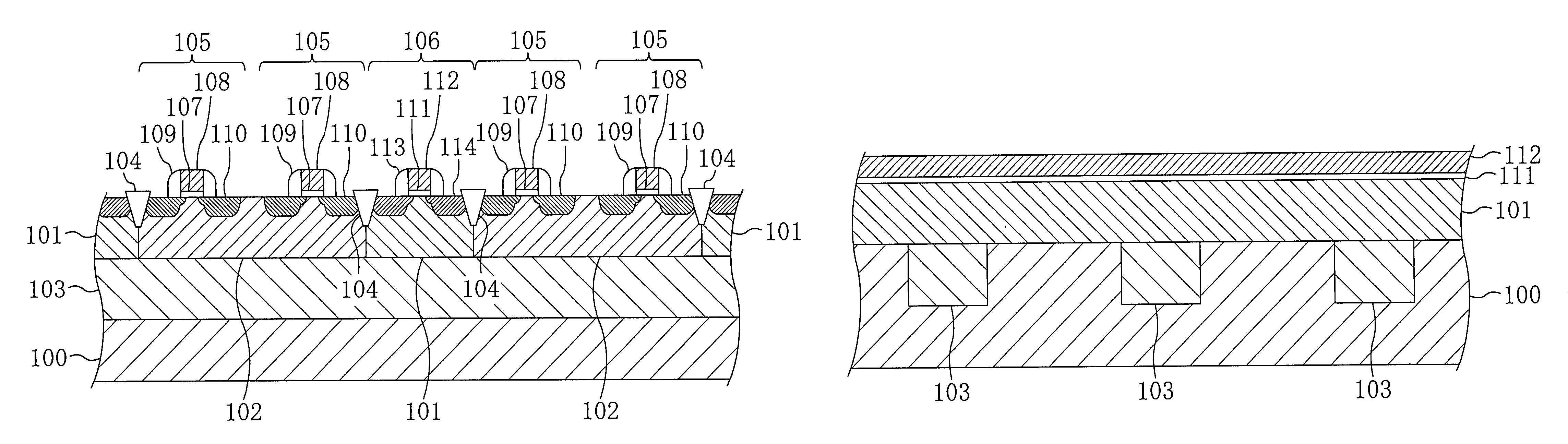

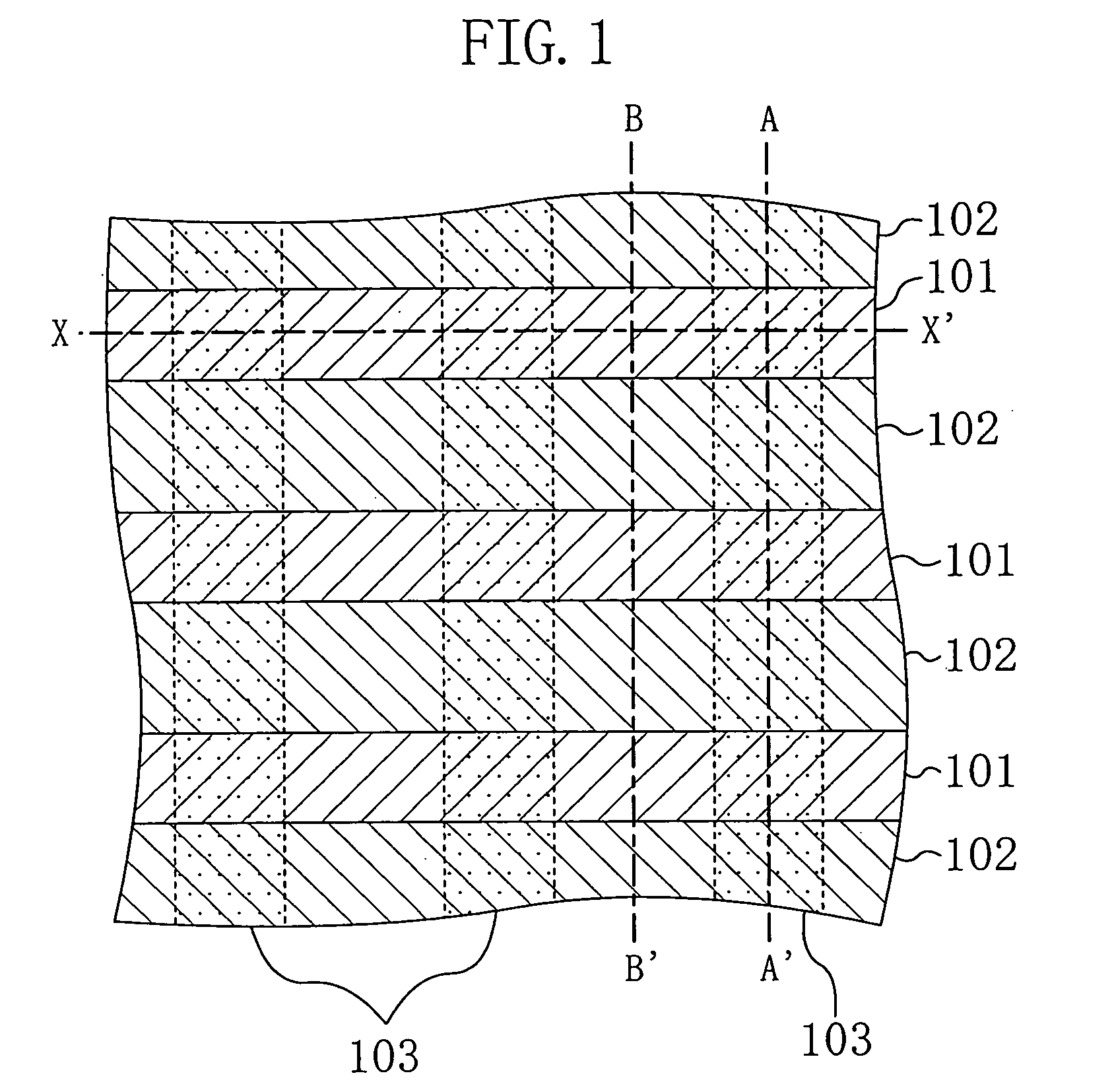

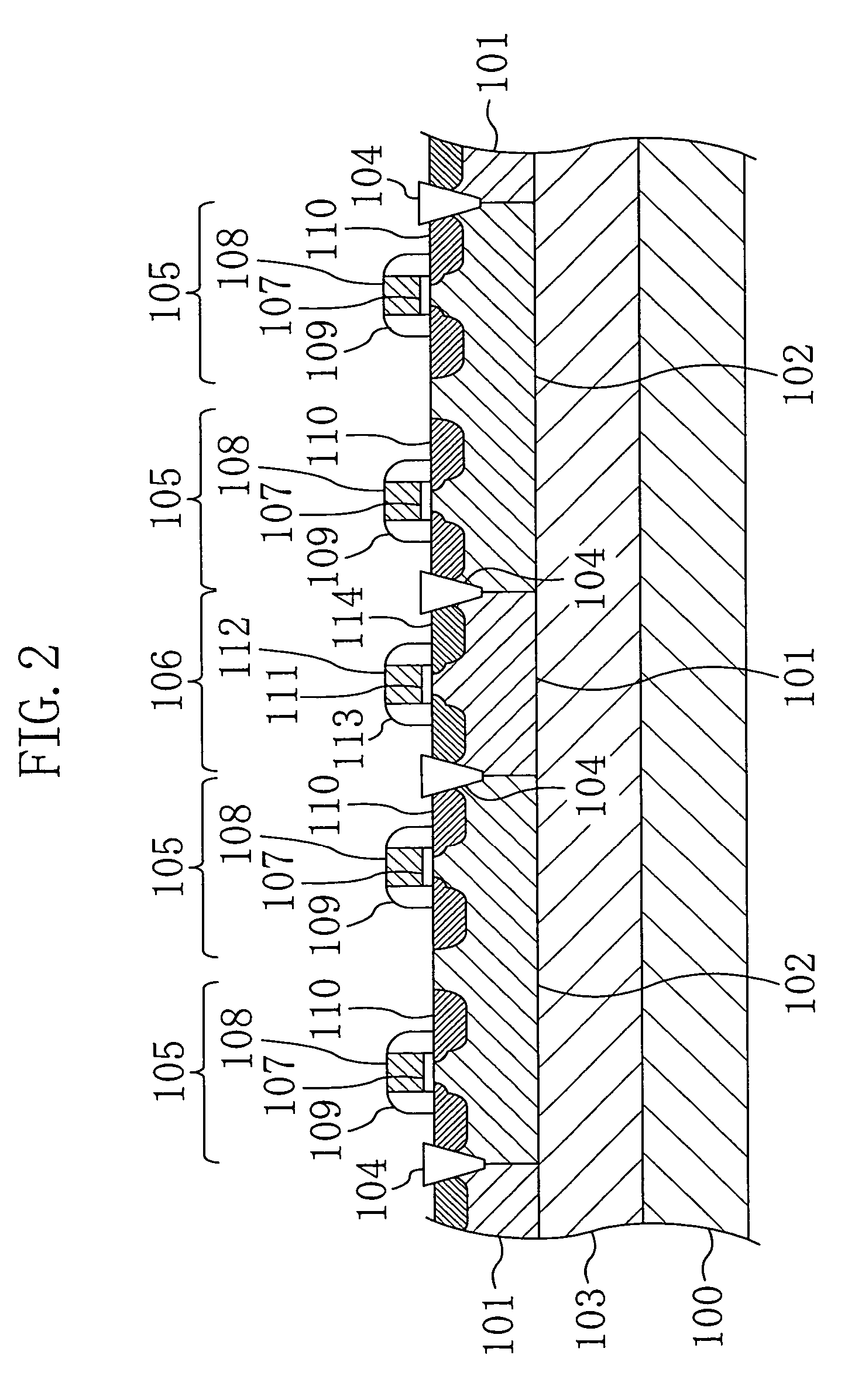

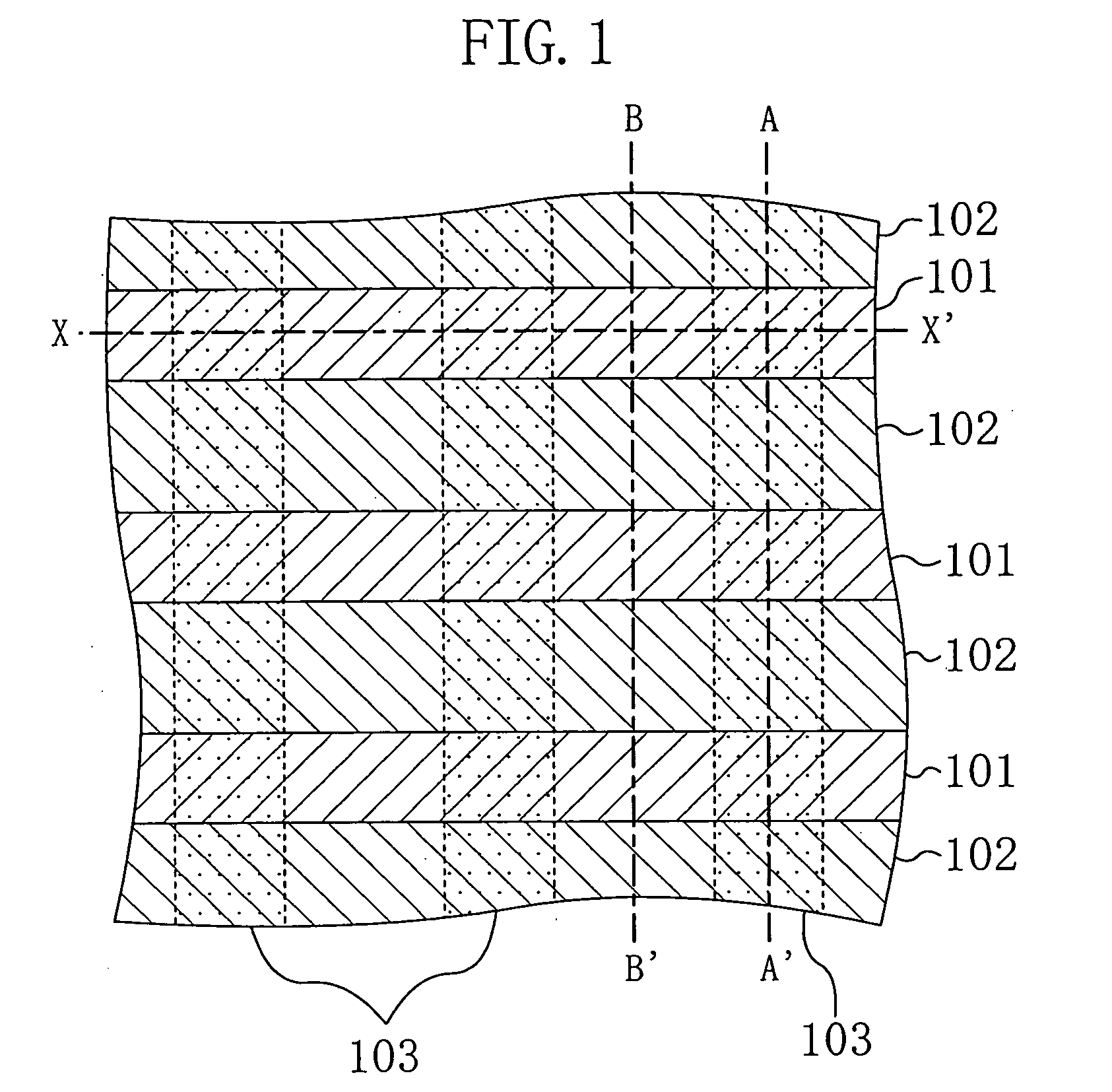

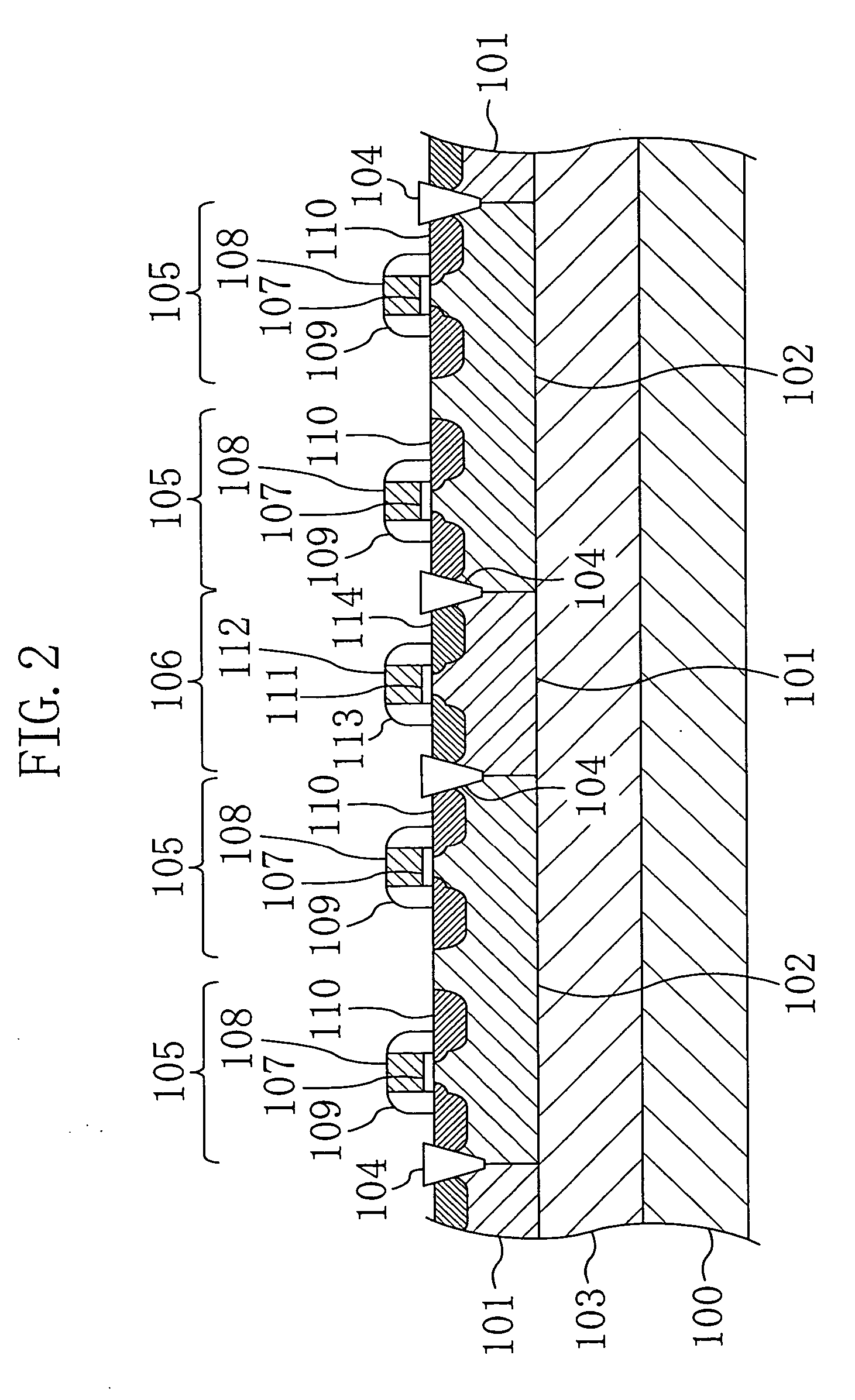

Semiconductor device having triple-well structure

ActiveUS7271449B2Reduce N-well resistanceImprove breakdown voltageTransistorSolid-state devicesSemiconductorSemiconductor device

A semiconductor device has a semiconductor substrate of a first conductivity type, a first well region of the first conductivity type which is formed to extend from the surface of the semiconductor substrate toward the inside thereof, a pair of second well regions of a second conductivity which are formed to extend from the surface of the semiconductor substrate toward the inside thereof in such as manner as to sandwich the first well region therebetween, and a third well region of the second conductivity type which is formed under each of the first well region and the pair of second well regions in the semiconductor substrate. The third well region electrically connects the pair of second well regions to each other. The first well region has at least a portion thereof connected to the region of the semiconductor substrate in which the third well region is not formed.

Owner:GK BRIDGE 1

Processes for improving tool life and surface finish in high speed machining

InactiveUS8205530B2Enhanced grain boundary diffusionReduce wearLathesAutomatic/semiautomatic turning machinesPerformance toolEngineering

Processes for high speed machining of workpiece materials using high performance tools with prolonged tool life and improved surface finish are provided by vibrating the tool and / or the workpiece at a frequency greater than the frequency of shear localization in the primary shear zone or chip segmentation occurring in the absence of tool vibration, with an amplitude sufficient to break up the tool-chip atomic contact, thereby decreasing the tool-chip contact length through decreasing the tool-chip contact time, thereby suppressing accelerated chemical tool wear caused by dissolution of the tool into the workpiece by nanocrystalline grain boundary diffusion and grain boundary sliding mechanisms by preventing shear localization associated with nanocrystalline grain formation in the primary shear zone of the chip, and suppressing oxidation wear of the tool by preventing segmentation of the chip.

Owner:SUBRAMANIAN SUNDARESA V

Semiconductor device and fabrication method therefor

ActiveUS20060086990A1Improve the immunityIncrease latch-up breakdown voltageTransistorSolid-state devicesDevice materialSemiconductor

A semiconductor device has a semiconductor substrate of a first conductivity type, a first well region of the first conductivity type which is formed to extend from the surface of the semiconductor substrate toward the inside thereof, a pair of second well regions of a second conductivity which are formed to extend from the surface of the semiconductor substrate toward the inside thereof in such as manner as to sandwich the first well region therebetween, and a third well region of the second conductivity type which is formed under each of the first well region and the pair of second well regions in the semiconductor substrate. The third well region electrically connects the pair of second well regions to each other. The first well region has at least a portion thereof connected to the region of the semiconductor substrate in which the third well region is not formed.

Owner:GK BRIDGE 1

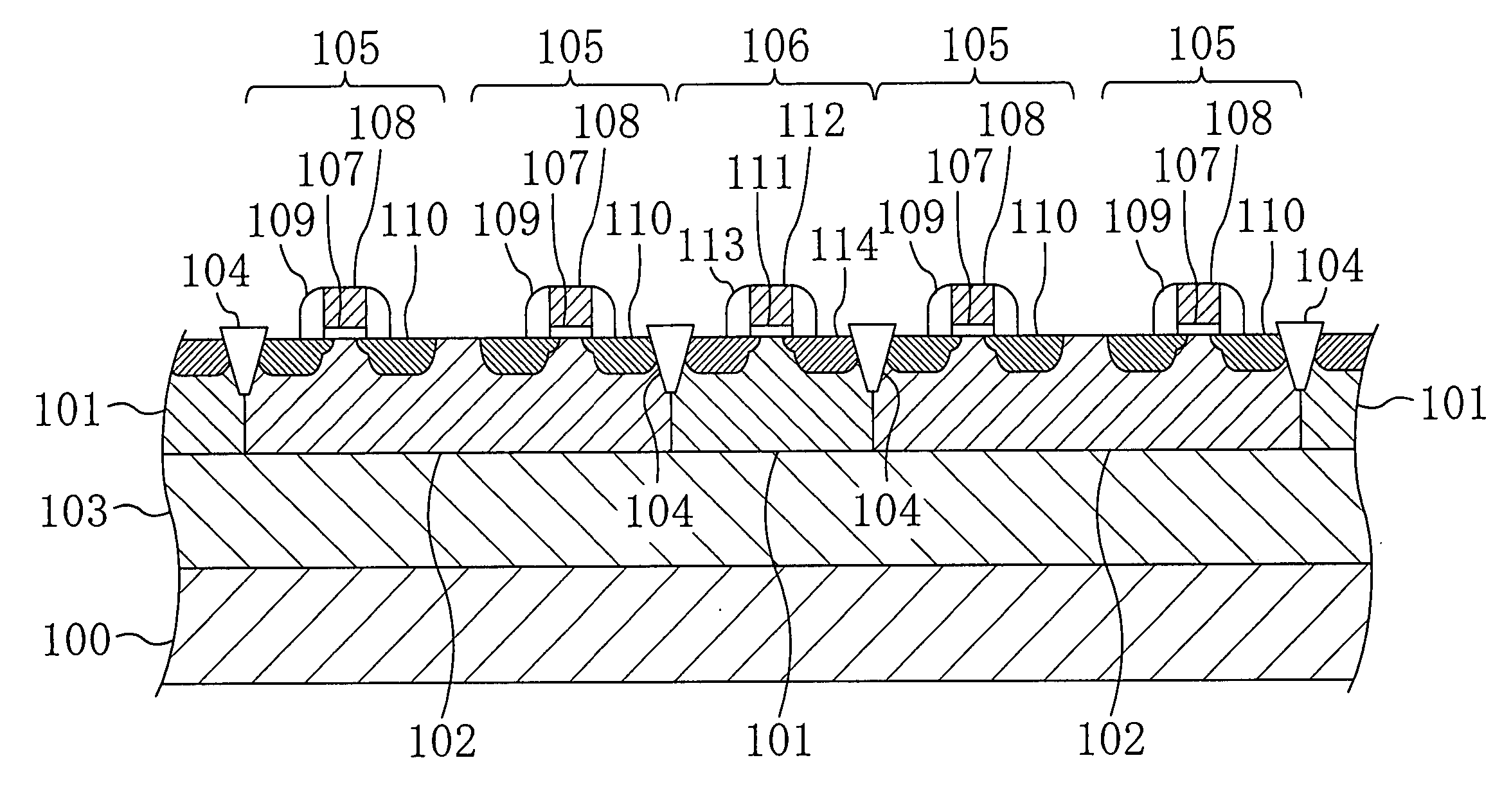

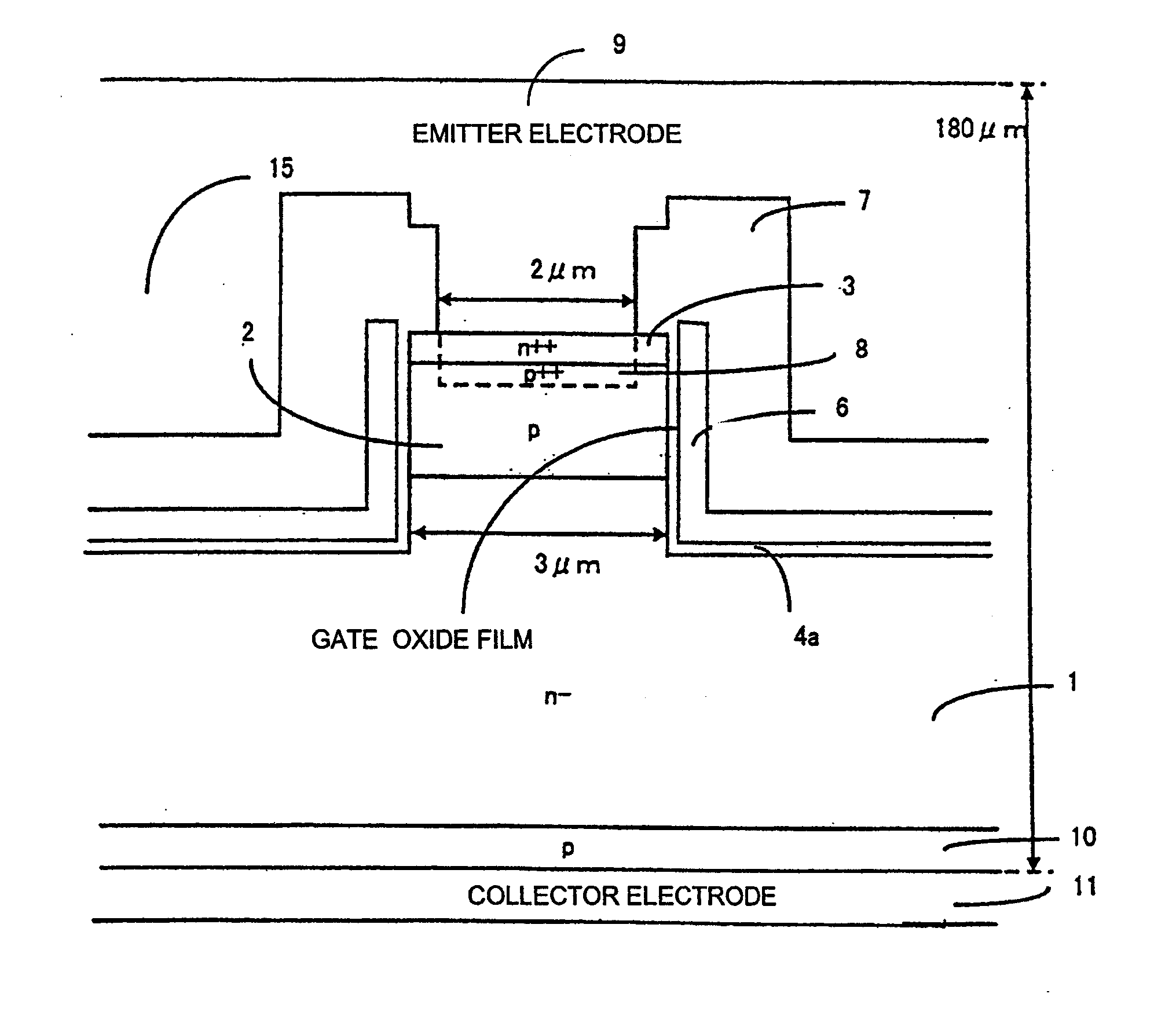

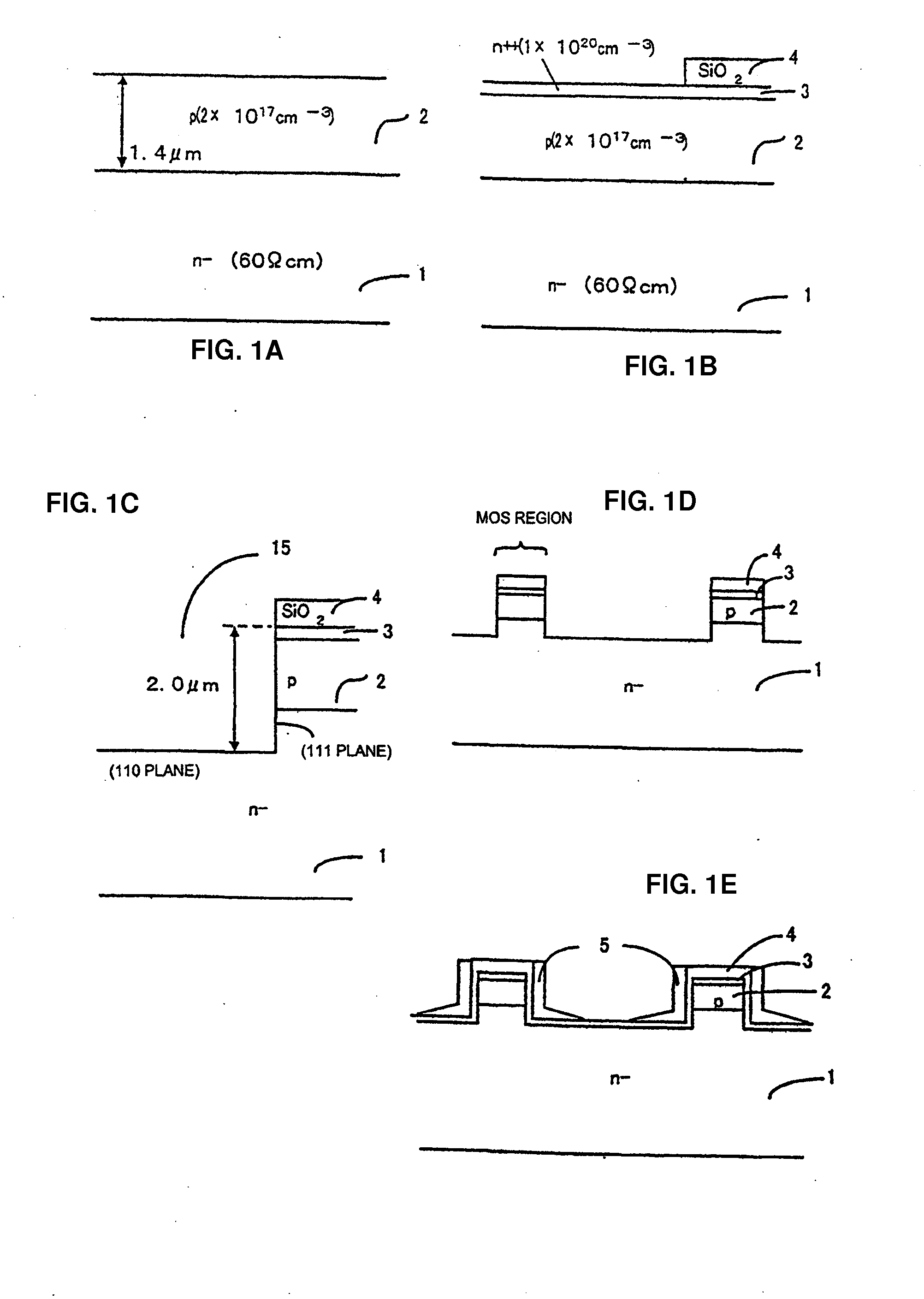

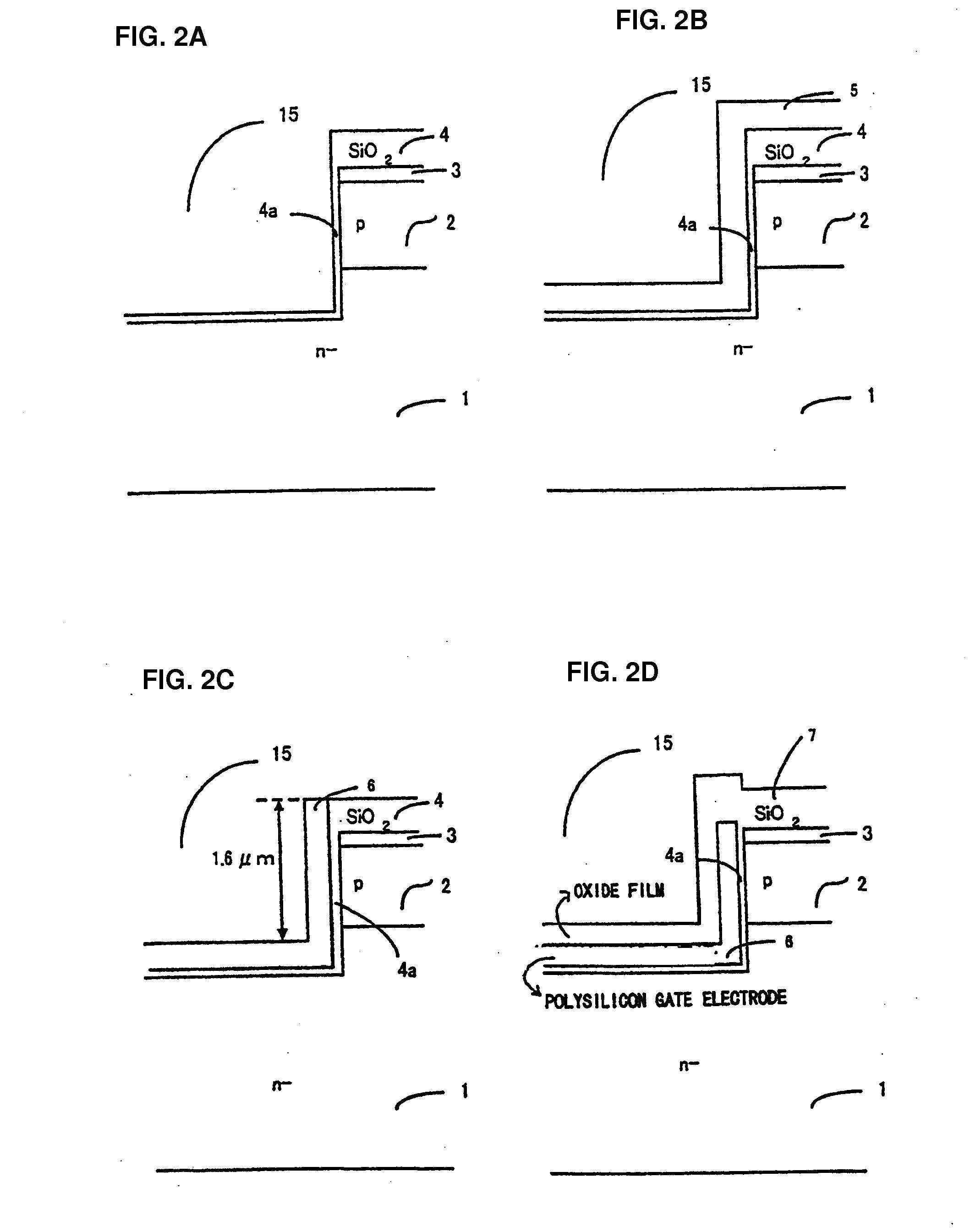

Power semiconductor device and the method of manufacturing the same

ActiveUS20100140657A1Reduce manufacturing costImprove throughputSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A semiconductor device according to the invention includes n-type semiconductor substrate 1; trenches 15 formed in the surface portion of semiconductor substrate 1; a protruding semiconductor region between trenches 15; p-type base layer 2 in the protruding semiconductor region, p-type base layer 2 being positioned as deep as or shallower than trench 15; an n++-type emitter region or a source region in the surface portion of p-type base layer 2; gate insulator film 4a on the first side wall of the protruding semiconductor region; and gate electrode 6 on gate insulator film 4a. Trench 15 is from 0.5 μm to 3.0 μm deep and the short side of trench 15 is 1.0 μm or longer. The short side of the protruding semiconductor region is from 0.5 μm to 3.0 μm long. Gate electrode 6 contains electrically conductive polycrystalline silicon as its main component. Gate electrode 6 is from 0.2 μm to 1.0 μm thick. The semiconductor device according to the invention is manufactured with very low manufacturing costs and with a high throughput of non-defective products. The semiconductor device according to the invention facilitates exhibiting a high IE effects, exhibiting a low ON-state voltage, preventing electric field localization from causing and realizing a high breakdown voltage.

Owner:FUJI ELECTRIC CO LTD

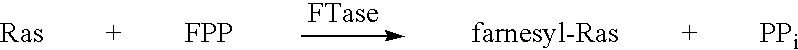

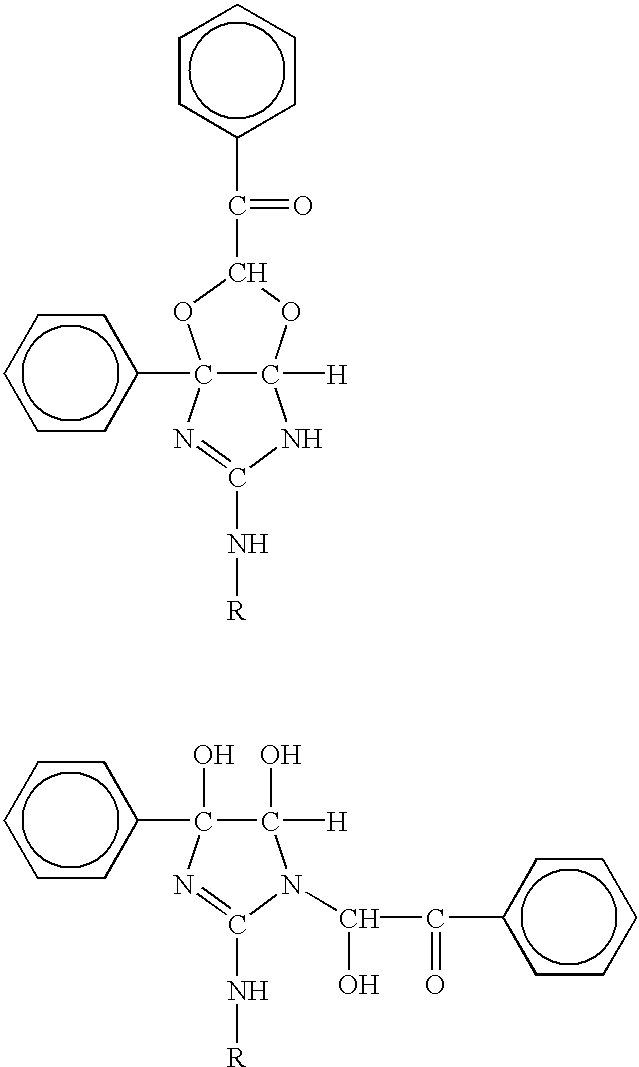

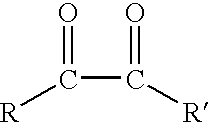

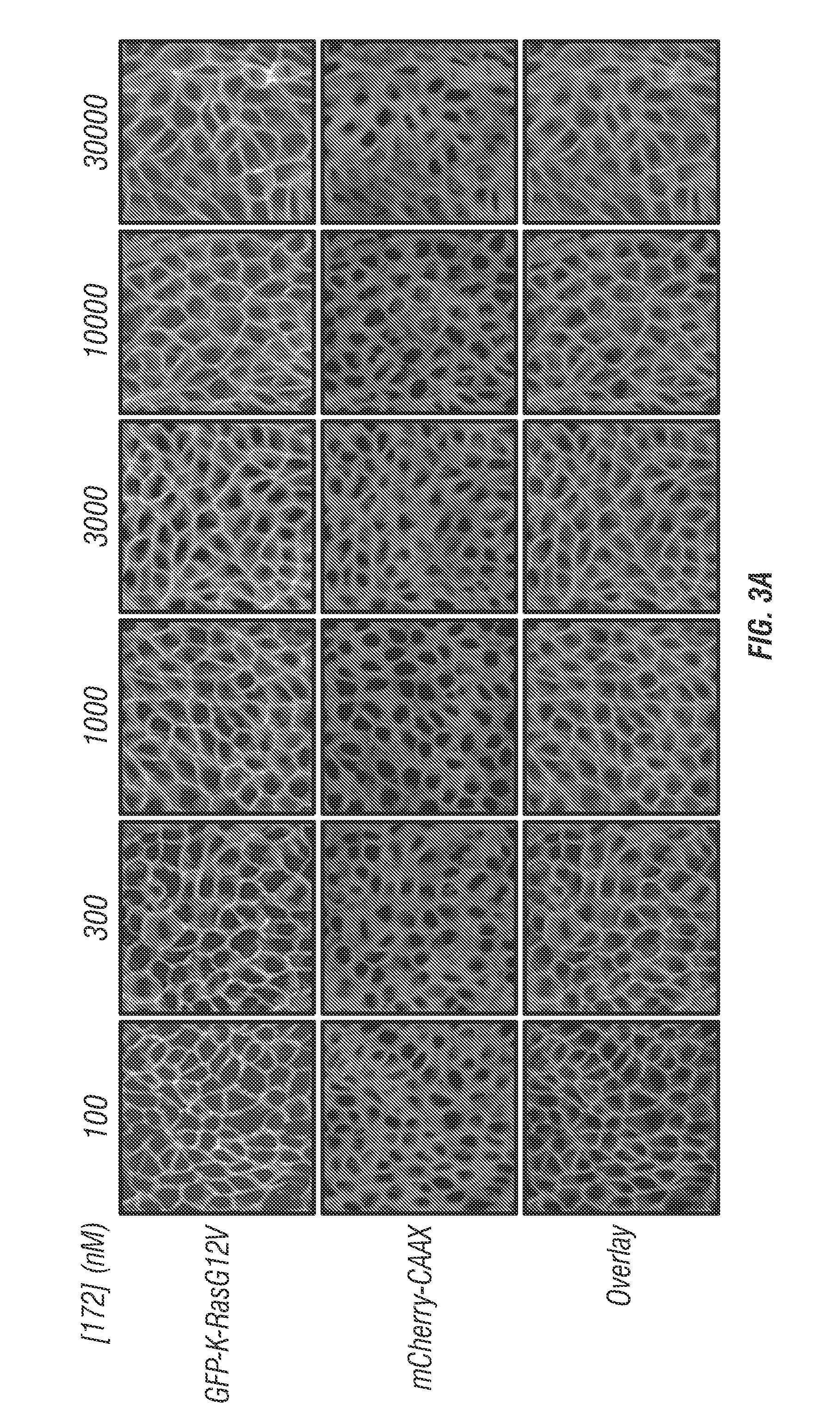

Anticancer agents based on prevention of protein prenylation

InactiveUS6576436B1Hampering and preventing proliferationShrink tumorBiocideCompound screeningAnticarcinogenProtein Geranylgeranylation

Prenylating enzymes are involved in modifying oncoproteins, such as RAS, so that growth of neoplastic cells becomes uncontrolled. Inactivation of such enzymes can prevent uncontrolled growth. alpha-Dicarbonyl compounds can be used to covalently modify and thereby inactivate prenylating enzymes such as protein farnesyltransferase and protein geranylgeranyltransferase. The compounds can be designed to enhance affinity and / or specificity for a particular protein substrate.

Owner:ARIZONA BIOMEDICAL RES COMMISSION

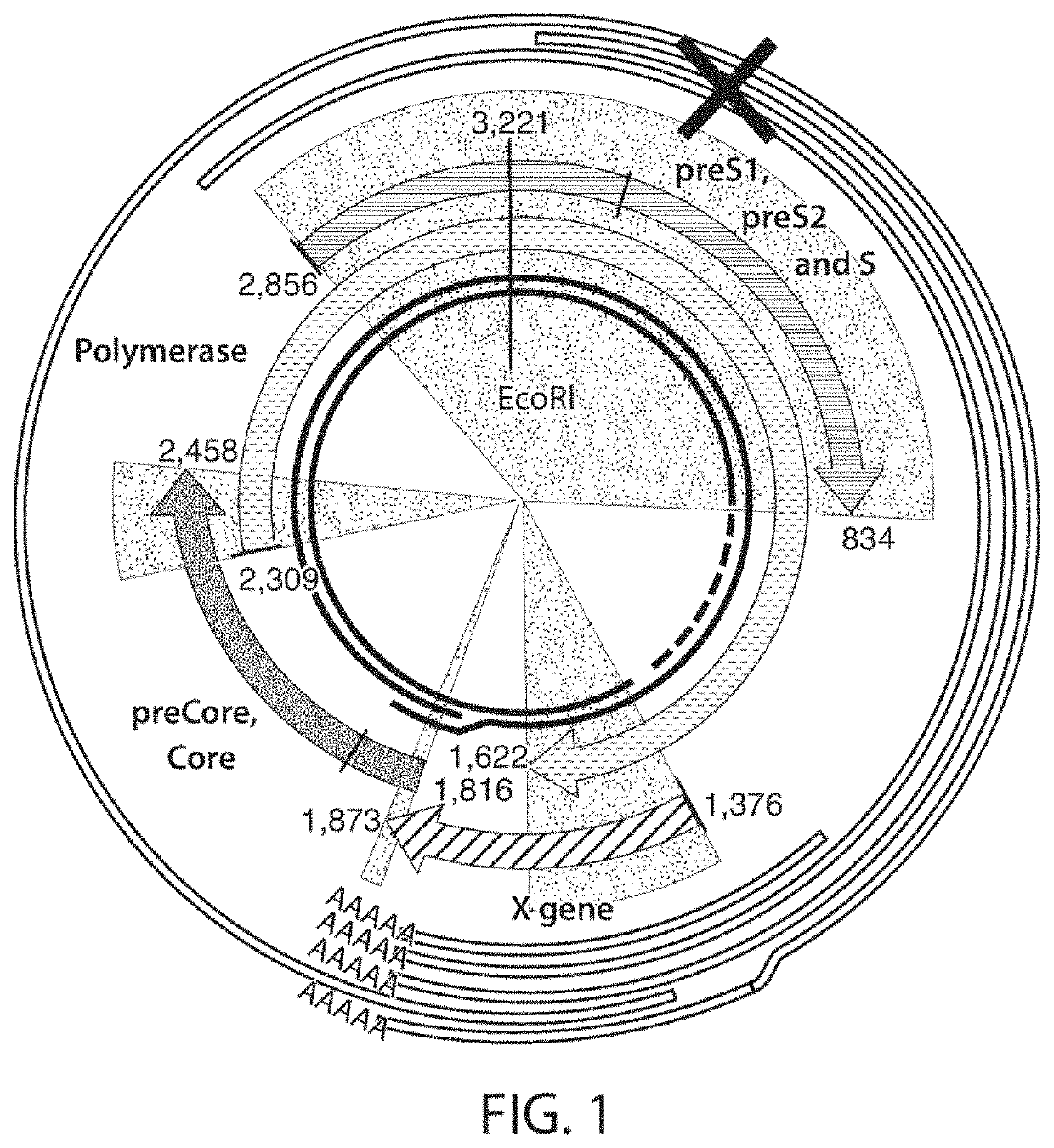

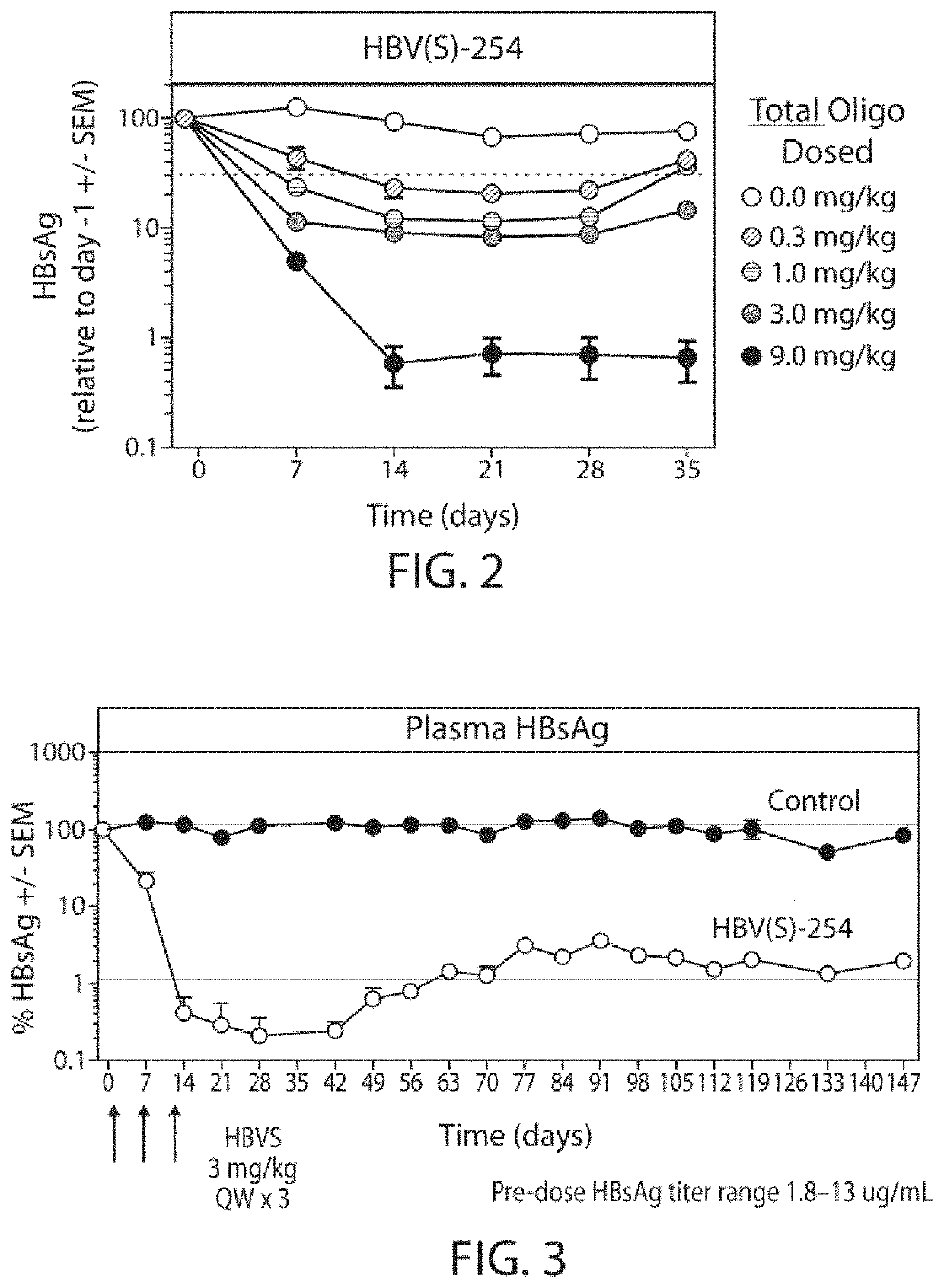

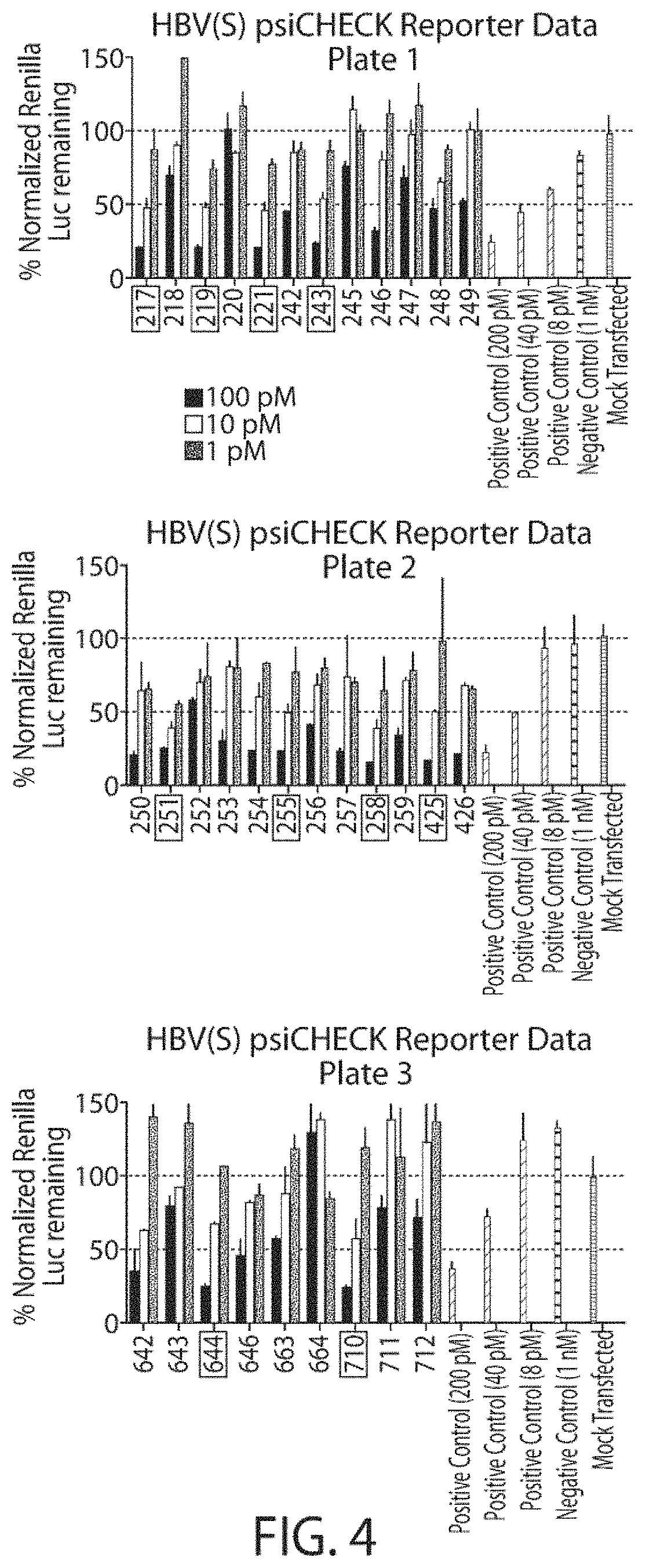

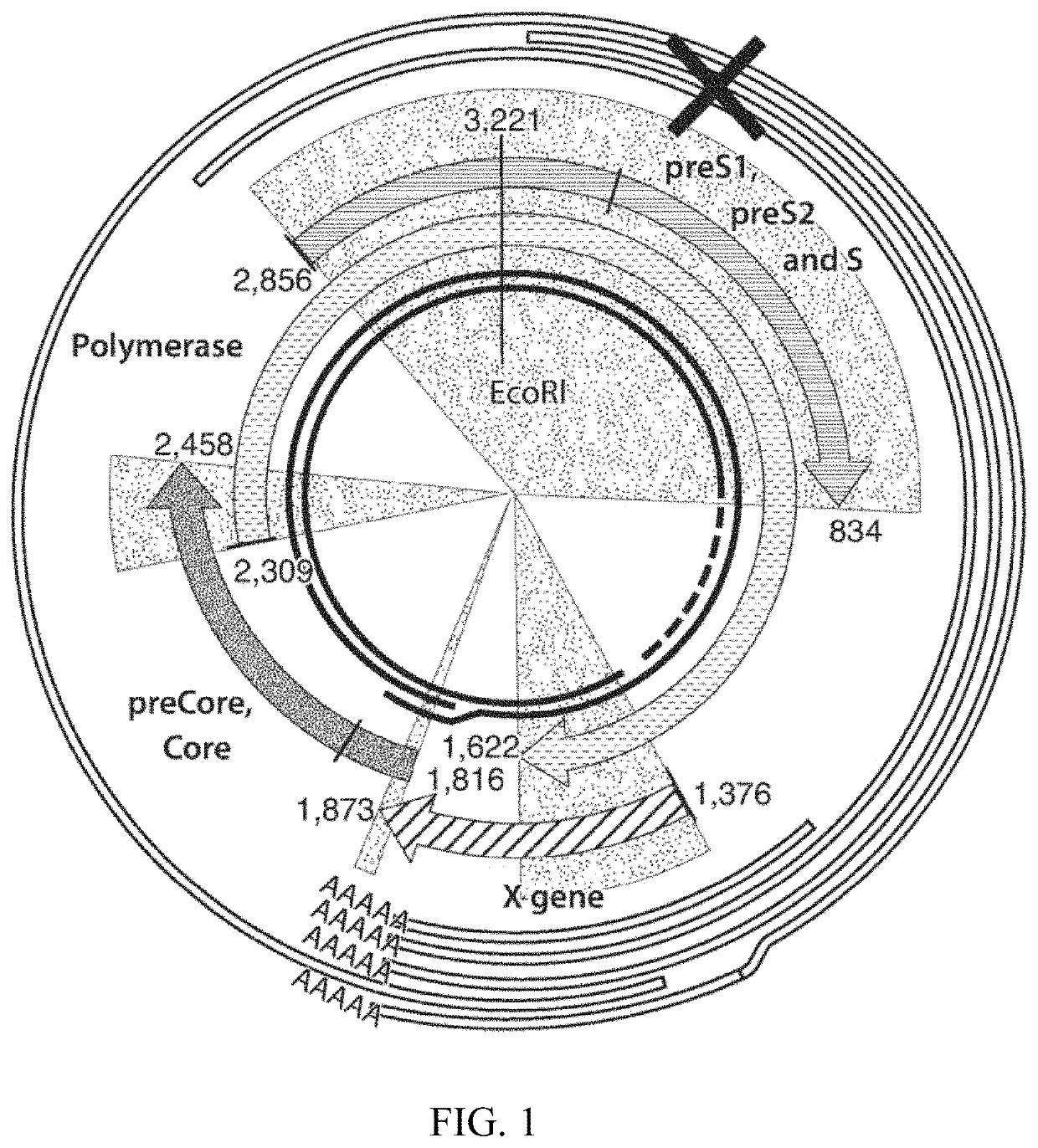

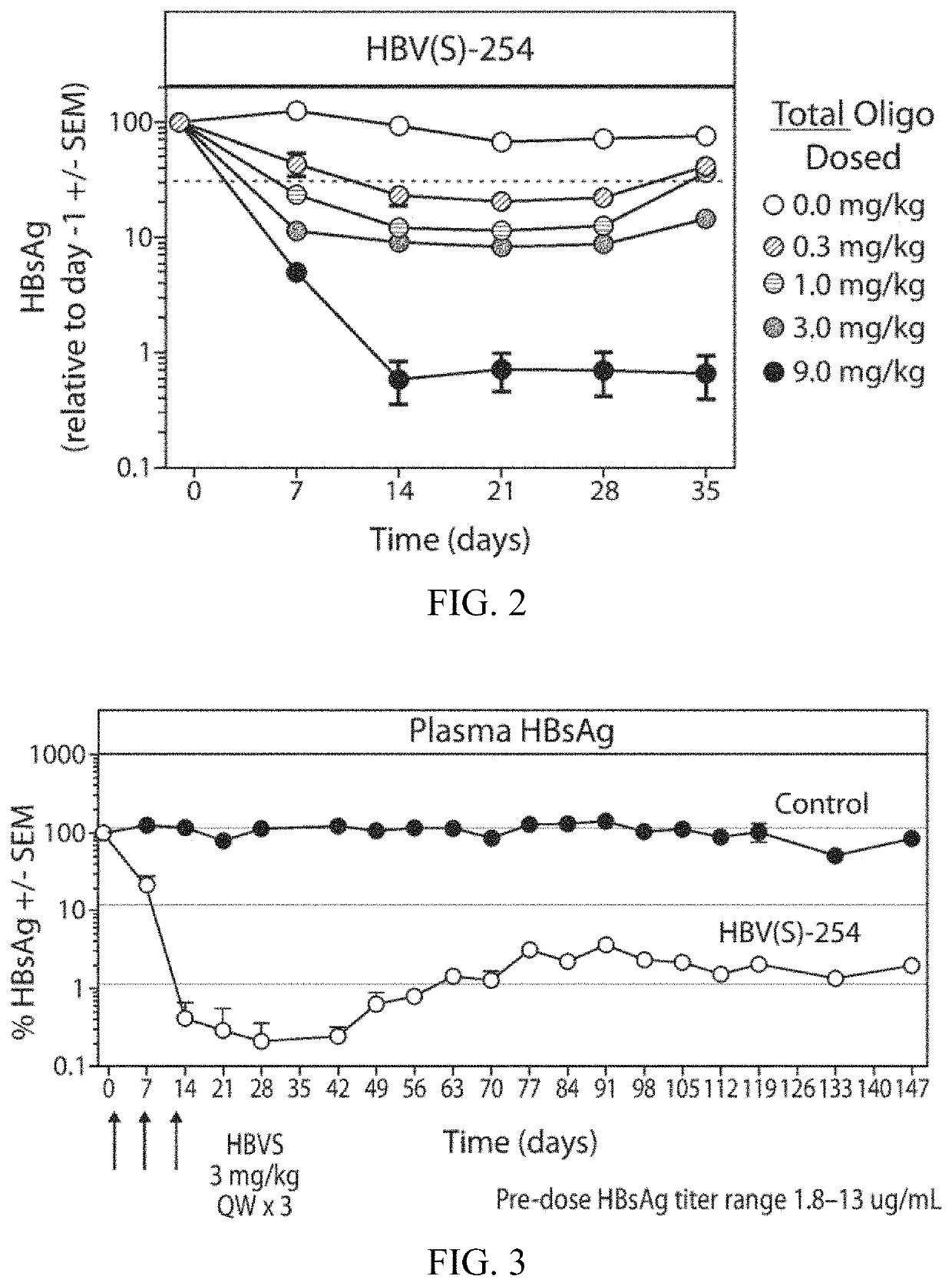

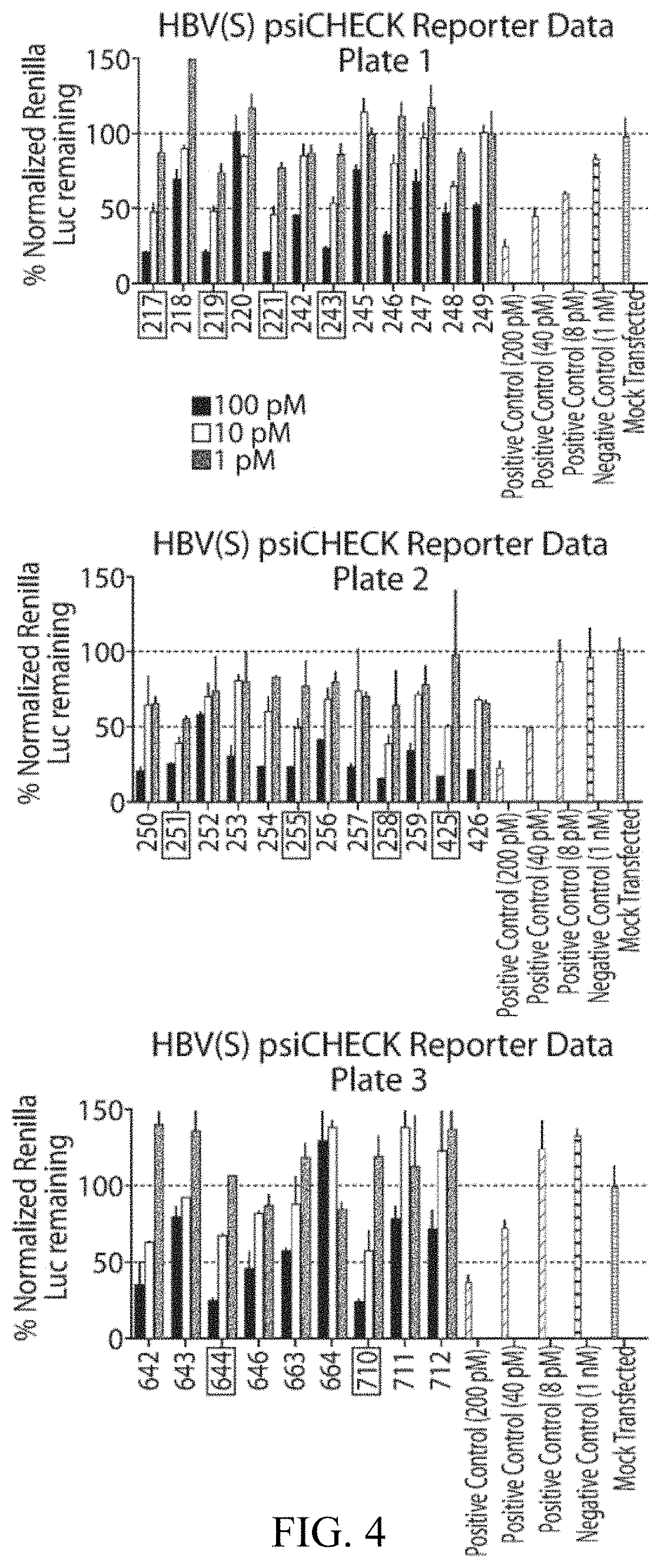

Methods for treating hepatitis b infection

ActiveUS20200171069A1Easy to optimizeStable reductionOrganic active ingredientsGenetic material ingredientsHepatitis B immunizationOligonucleotide

This application relates to potent oligonucleotides useful for reducing HBsAg expression and treating HBV infections.

Owner:DICERNA PHARM INC

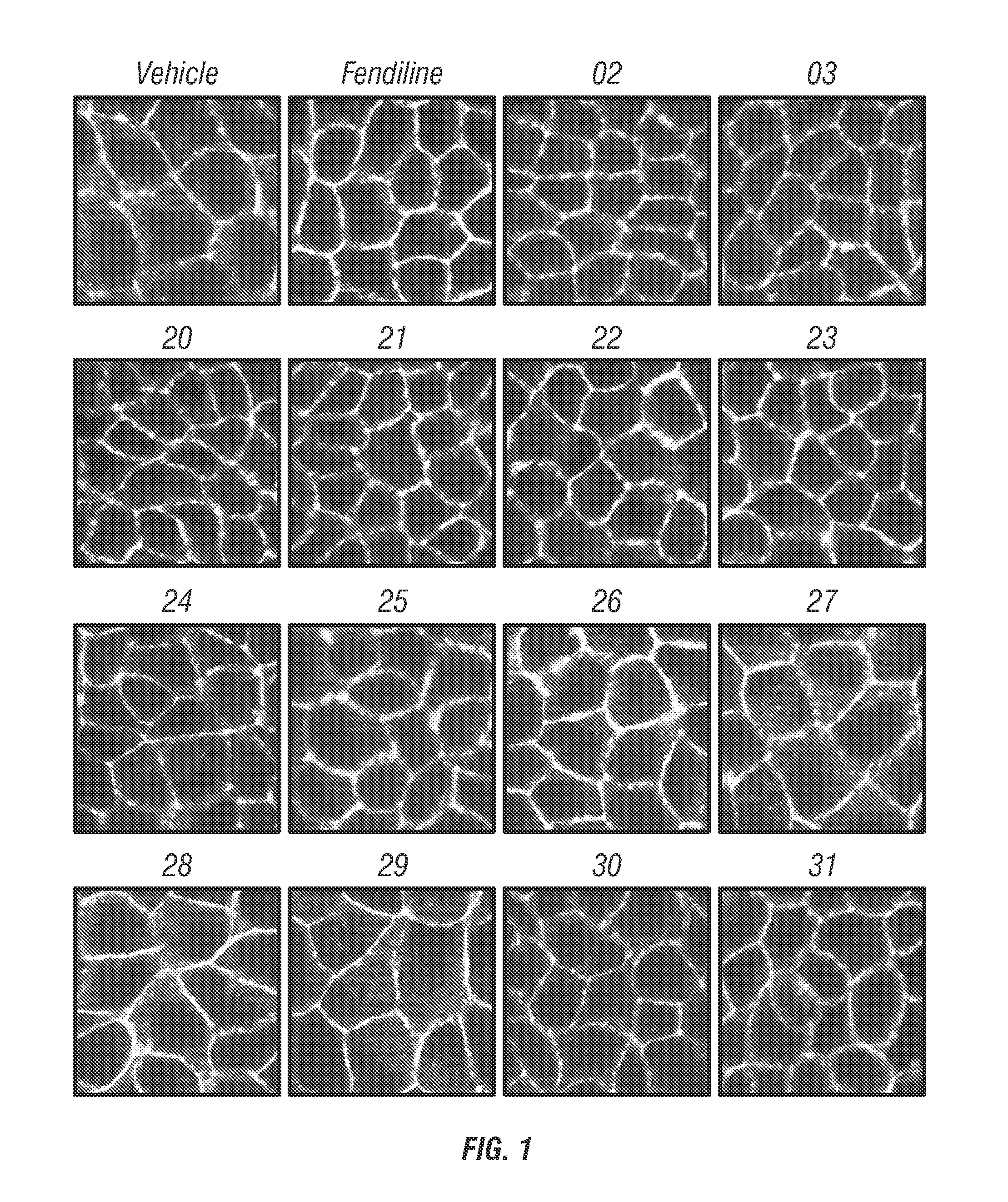

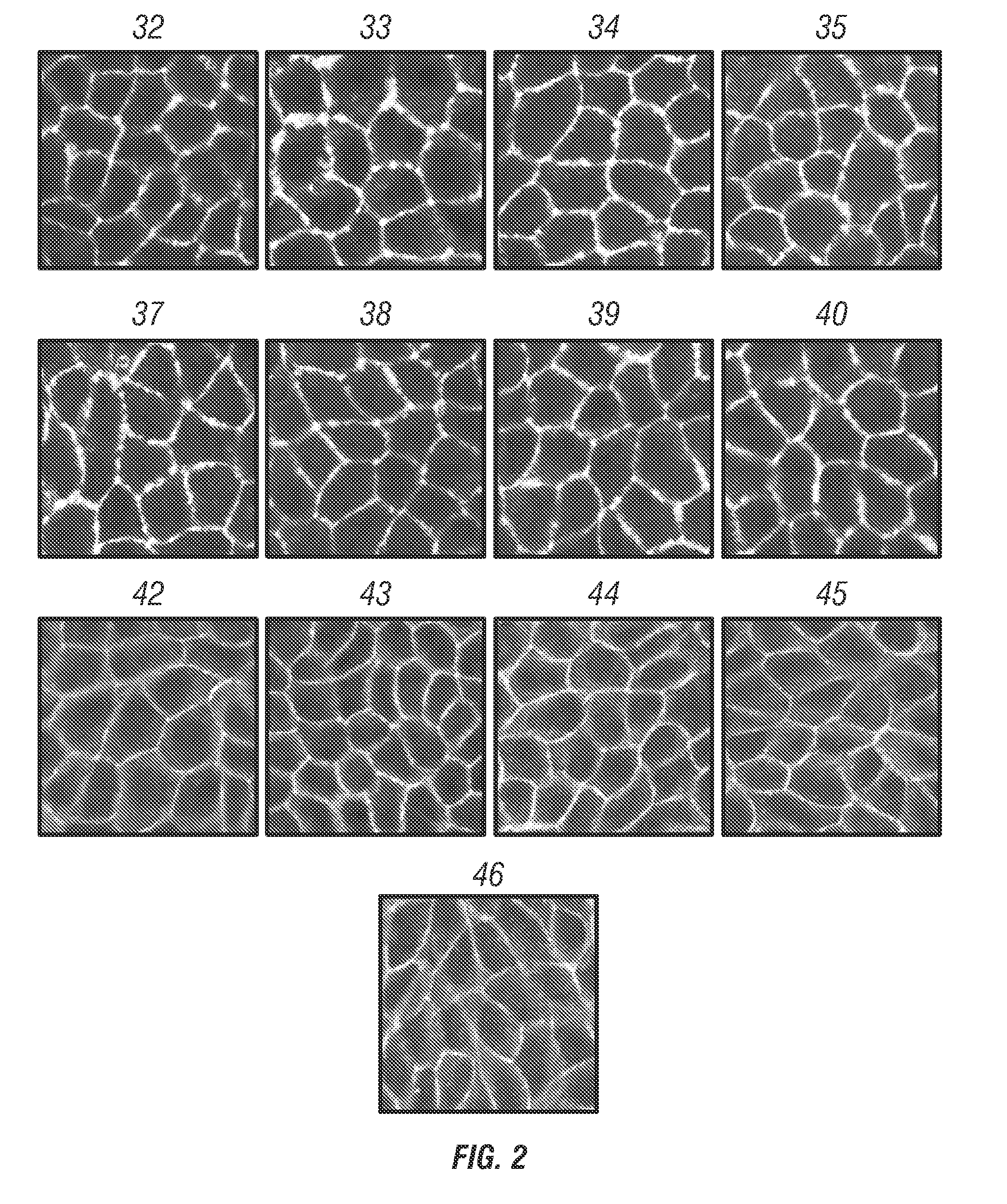

Fendiline derivatives and methods of use thereof

InactiveUS20150344407A1Avoid localizationBiocideOrganic compound preparationStereochemistryPerylene derivatives

Disclosed herein are novel derivatives of fendiline, including compounds of the formula: wherein the variables are defined herein. Also provided are pharmaceutical compositions, kits and articles of manufacture comprising these derivative compounds. Methods and intermediates useful for making the derivatives, and methods of using the derivatives, for example, for the inhibition of K-Ras plasma membrane localization, and compositions thereof, including for the treatment of cancer, are also provided.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Ion pump and charged particle beam device using the same

Owner:HITACHI LTD

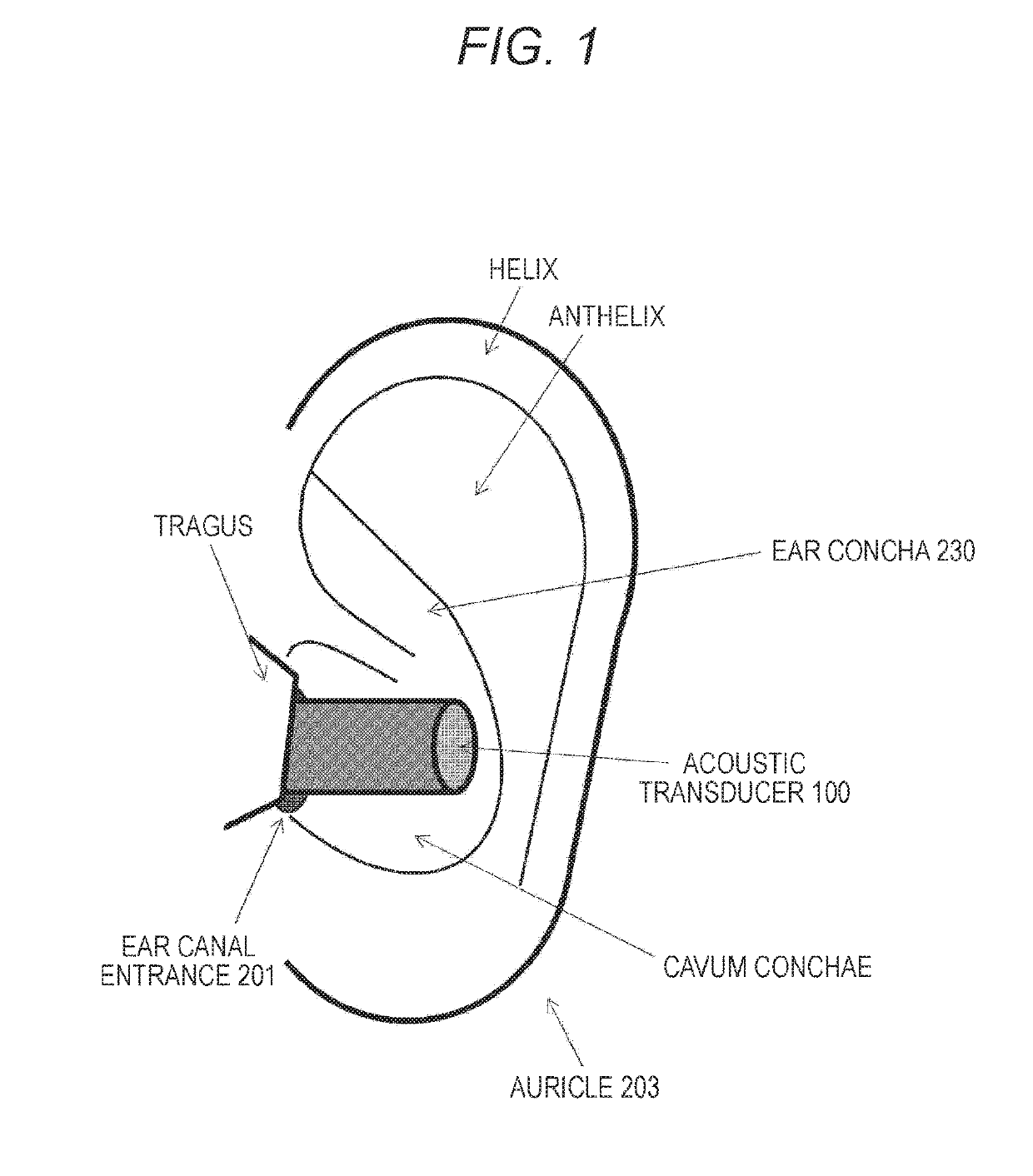

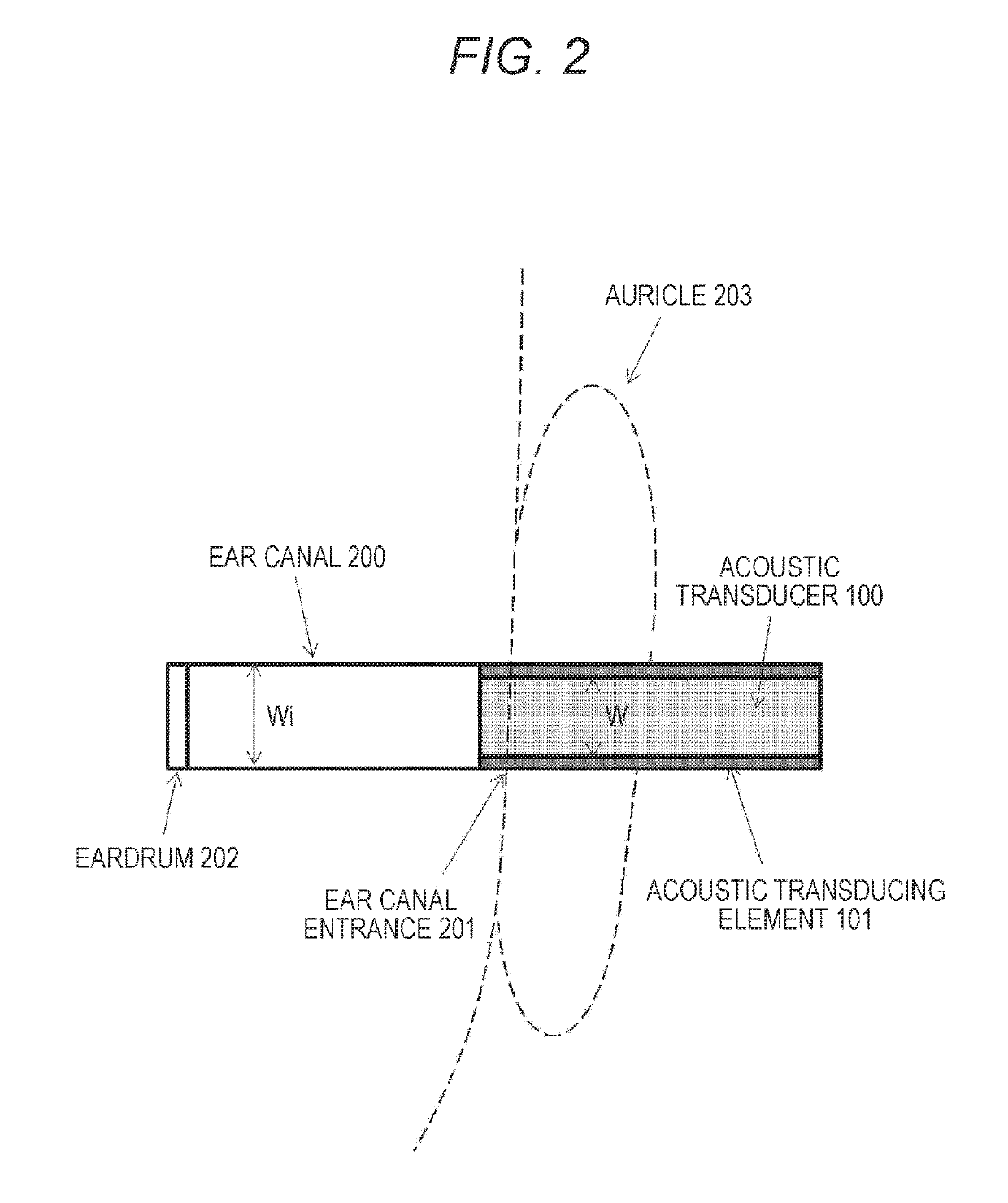

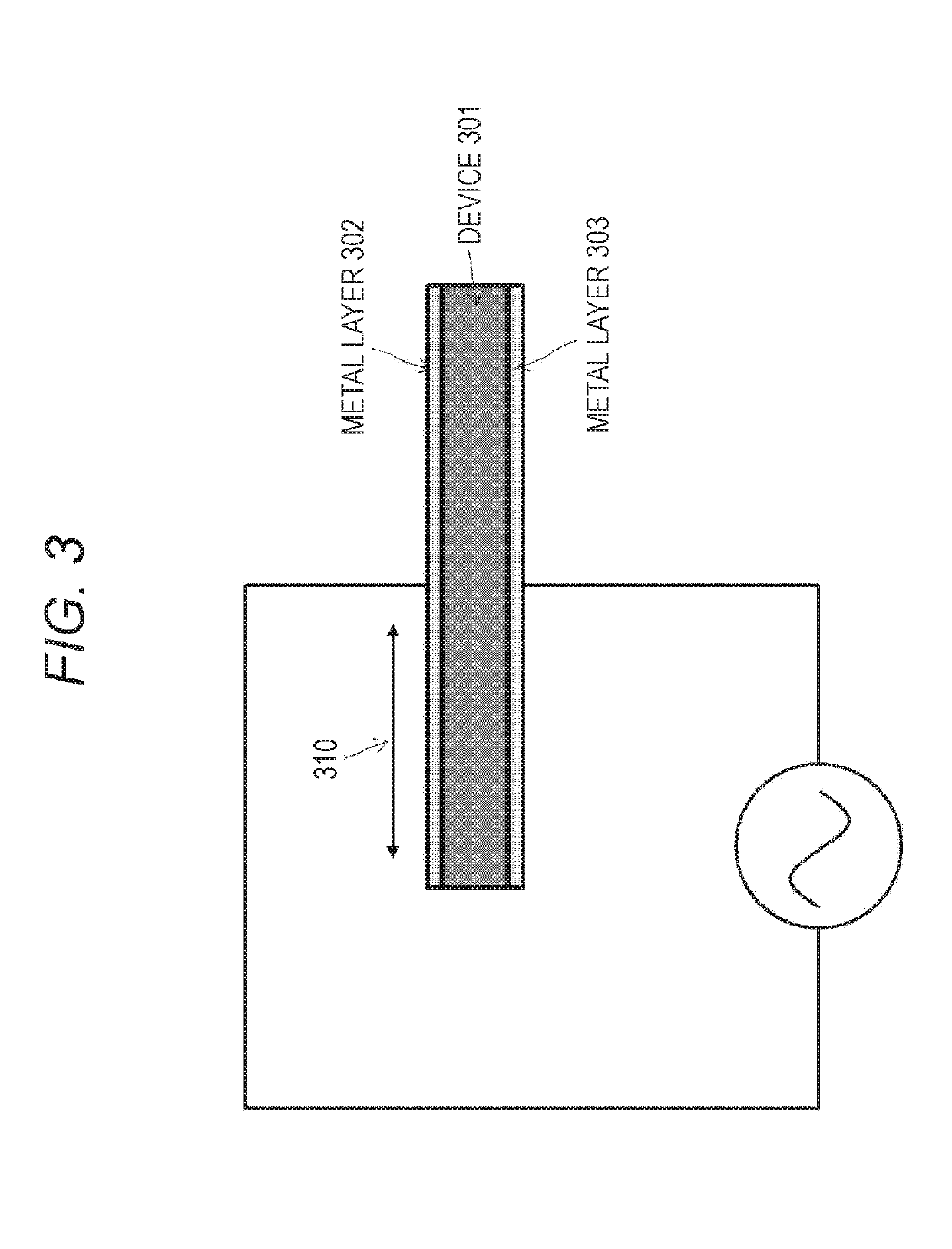

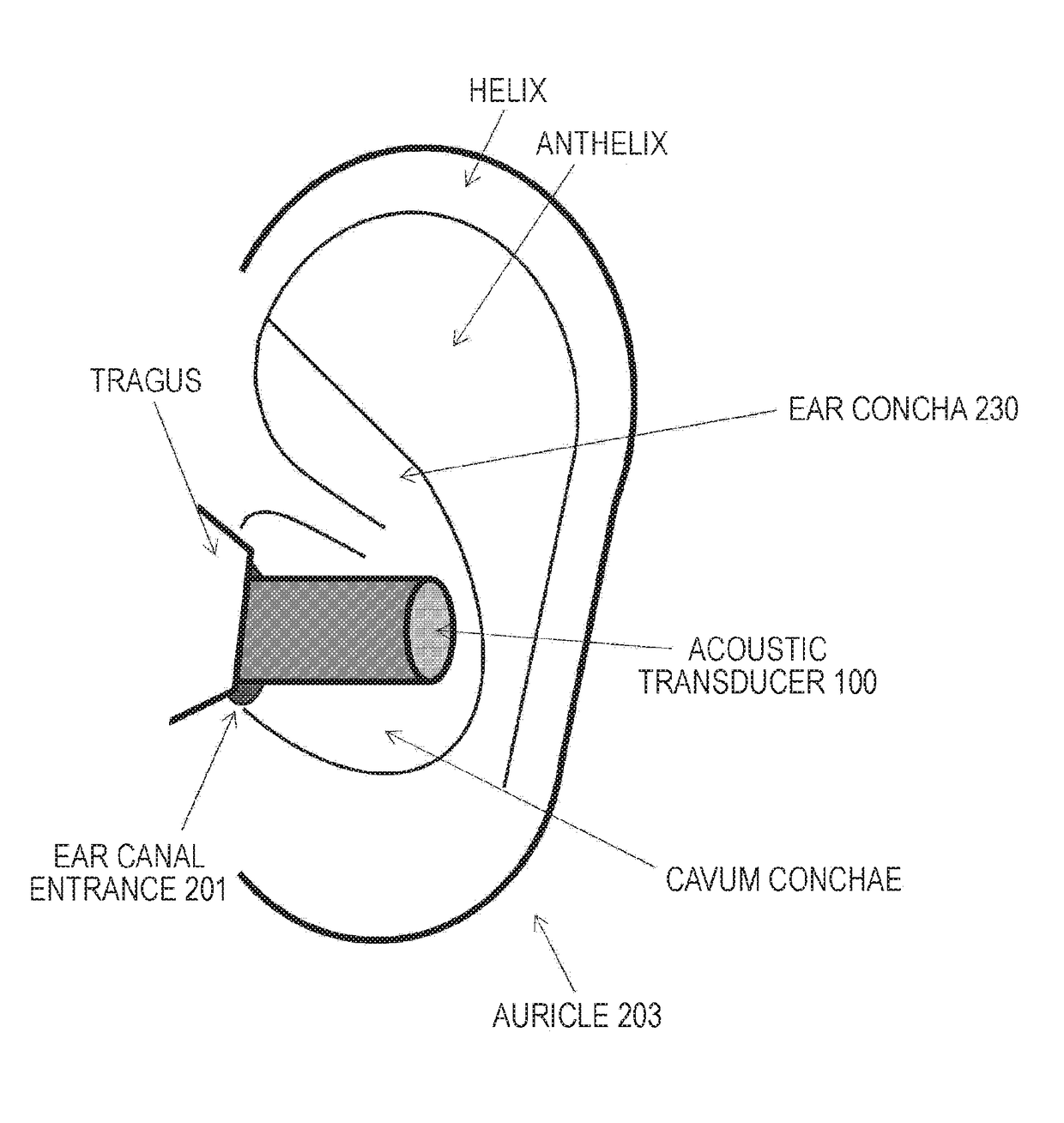

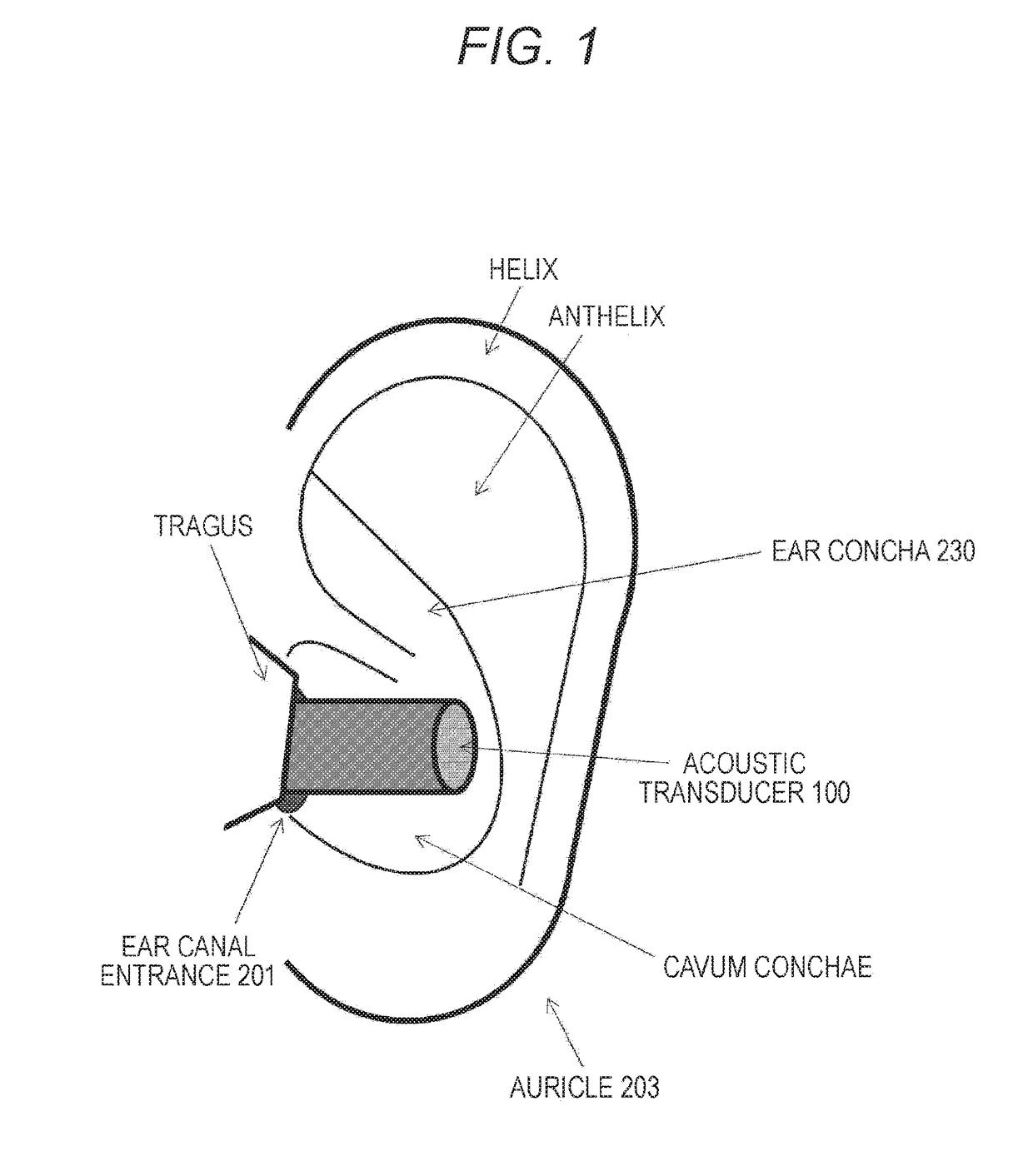

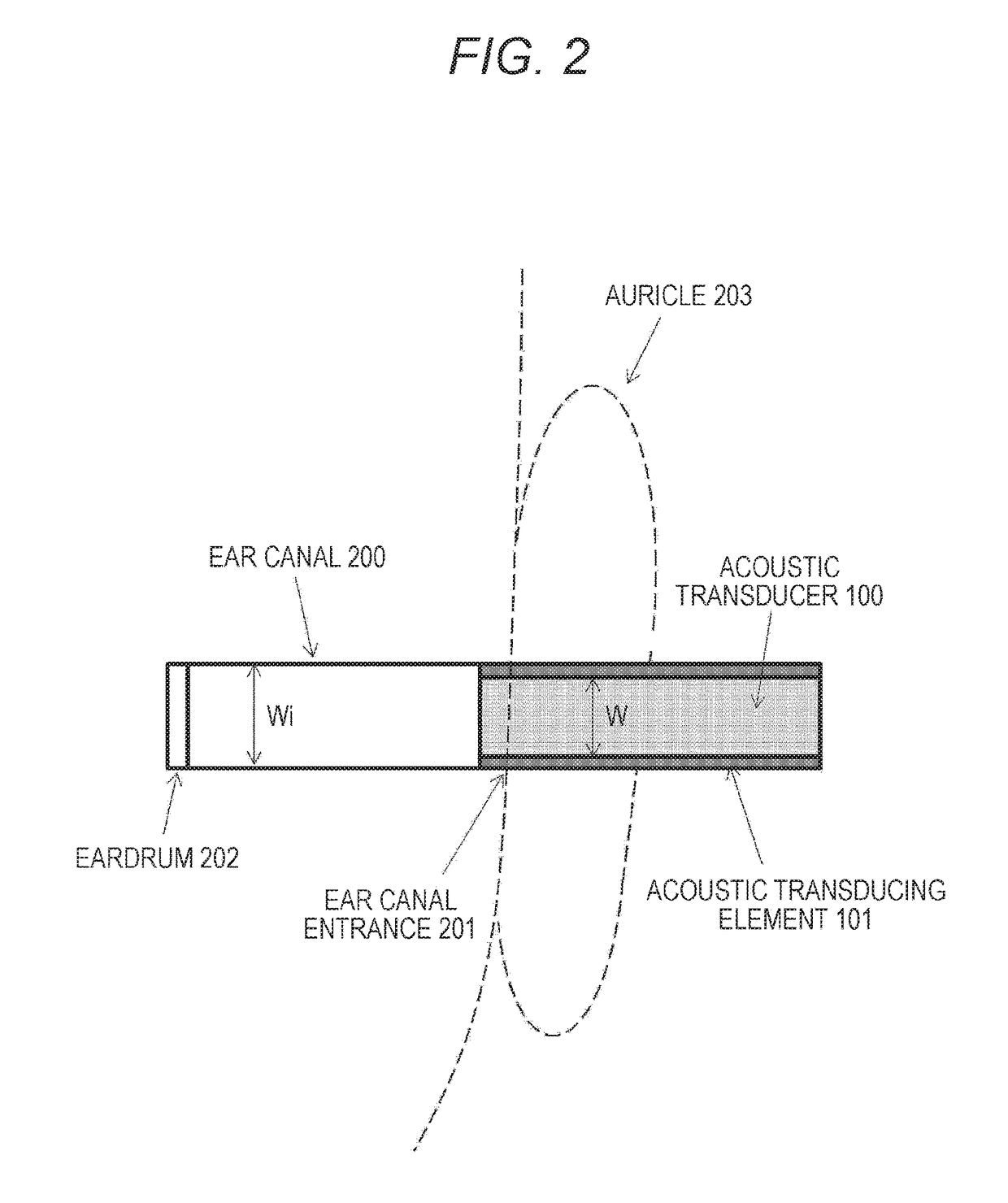

Acoustic transducer

ActiveUS10511902B2Promote reproductionRe-reflection of the sound wave reflected by the eardrum can be preventedPiezoelectric/electrostrictive microphonesLoudspeakersAuditory senseTransducer

Provided is an acoustic transducer which is used by being fitted into an ear of a listener, is formed in a compact and lightweight shape, and preferably prevents re-reflection of a sound wave. An acoustic transducer 100 is formed of a film-shaped material having an expanding and contracting action and includes a cylindrical acoustic transducing element 101. The cylindrical acoustic transducing element 101 also functions as a sound guide tube. The acoustic transducing element 101 prevents re-reflection of the sound wave reflected by an eardrum when the sound wave has been generated and prevents localization phenomenon and a feeling of pressure in auditory sense. Also, since the acoustic transducing element 101 is formed in a compact and lightweight shape, the acoustic transducing element 101 generates the sound wave for directly reaching the eardrum or collects the sound at a place near the eardrum without a feeling of foreign materials in a case where a person wears the acoustic transducing element 101 the an ear.

Owner:SONY CORP

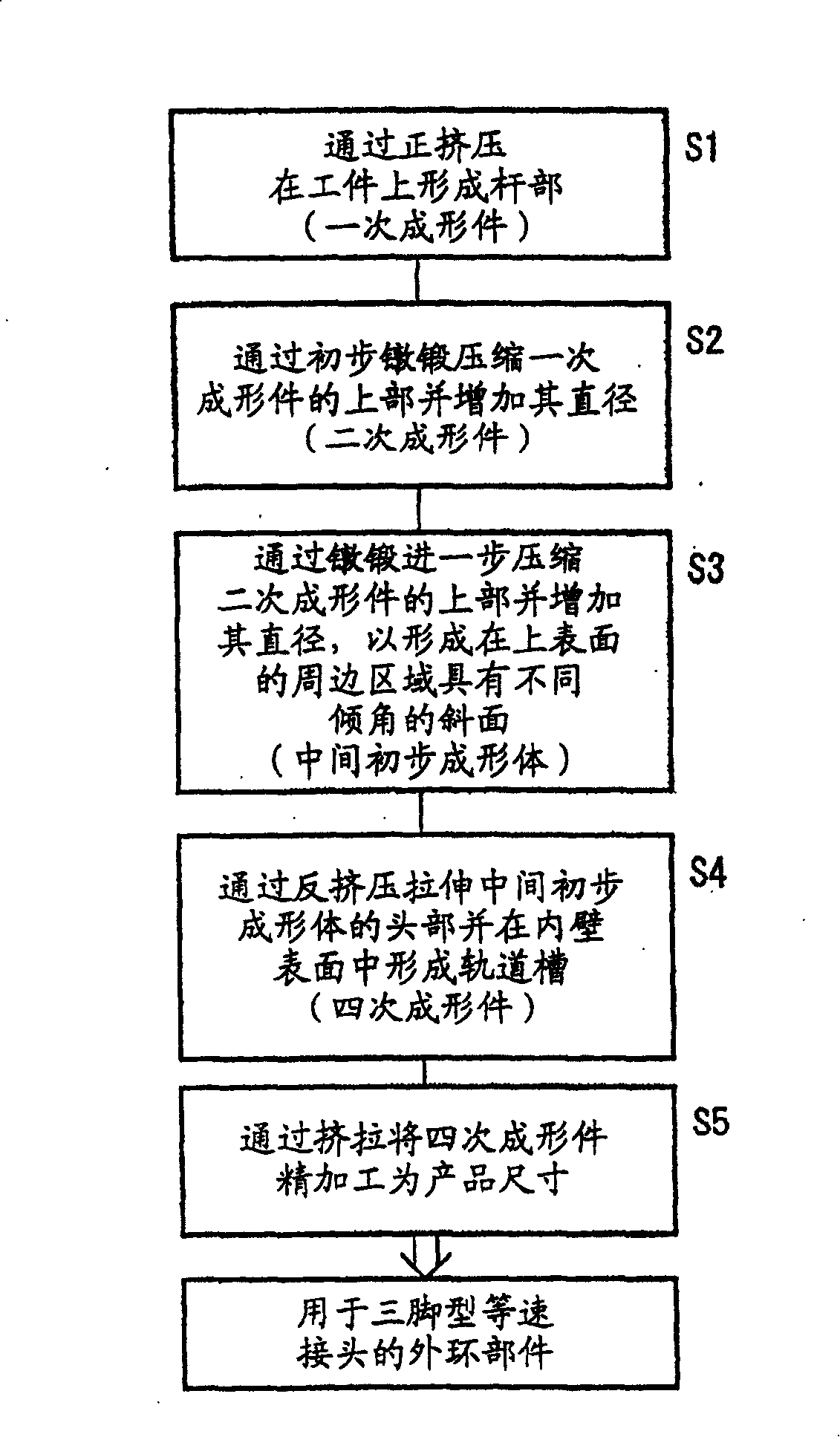

Method of manufacturing outer ring member for constant velocity joint

InactiveCN100409971CSpeed up the flowAxial Dimension HomogenizationYielding couplingMetal-working apparatusEngineeringExtrusion

A method of manufacturing an outer ring member for a constant velocity joint, comprising the steps of forming a secondary molding (20) by applying a preliminary upsetting to a work (10) after applying a forward extrusion-molding (S1) to the work (10) (S2), forming intermediate pre-molded bodies (24, 24a) having annular sloped surfaces (36, 36a) formed thereon to have a difference in flow resistance between large diameter parts (28a to 28c) and small diameter parts (30a to 30c) by applying the upsetting to the upper part (22) of the secondary molding (20) (S3, S3a), forming a quaternary molding (58) having a cup part (62) with track grooves (60a to 60c) by applying a backward extrusion-molding to the intermediate pre-molded bodies (24, 24a)(S4), and applying an ironing to the cup part (62) of the quaternary molding (58) to finish the quaternary molding (58) to product dimensions (S5).

Owner:HONDA MOTOR CO LTD

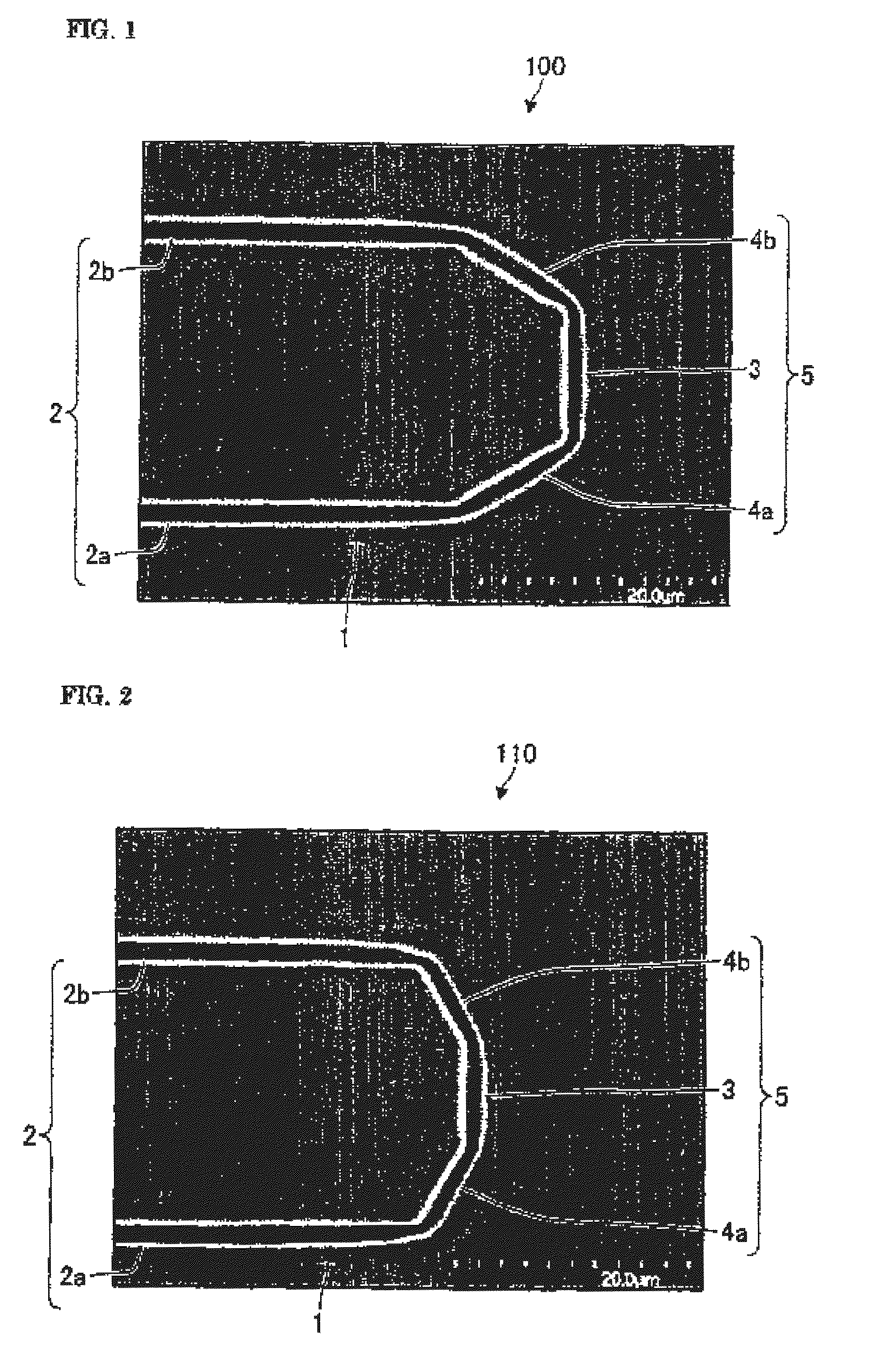

Method for manufacturing silicon carbide semiconductor device and the silicon carbide semiconductor device

ActiveUS8232184B2Easy to solveAvoid deformationSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

Silicon carbide semiconductor device includes trench, in which connecting trench section is connected to straight trench section. Straight trench section includes first straight trench and second straight trench extending in parallel to each other. Connecting trench section includes first connecting trench perpendicular to straight trench section, second connecting trench that connects first straight trench and first connecting trench to each other, and third connecting trench that connects second straight trench and first connecting trench to each other. Second connecting trench extends at 30 degrees of angle with the extension of first straight trench. Third connecting trench extends at 30 degrees of angle with the extension of second straight trench. A manufacturing method according to the invention for manufacturing a silicon carbide semiconductor device facilitates preventing defects from being causes in a silicon carbide semiconductor device during the manufacture thereof.

Owner:FUJI ELECTRIC CO LTD

Methods for treating hepatitis B infection

ActiveUS10799524B2Stable reductionSimple compositionOrganic active ingredientsGenetic material ingredientsHepatitis B immunizationOligonucleotide

Owner:DICERNA PHARM INC

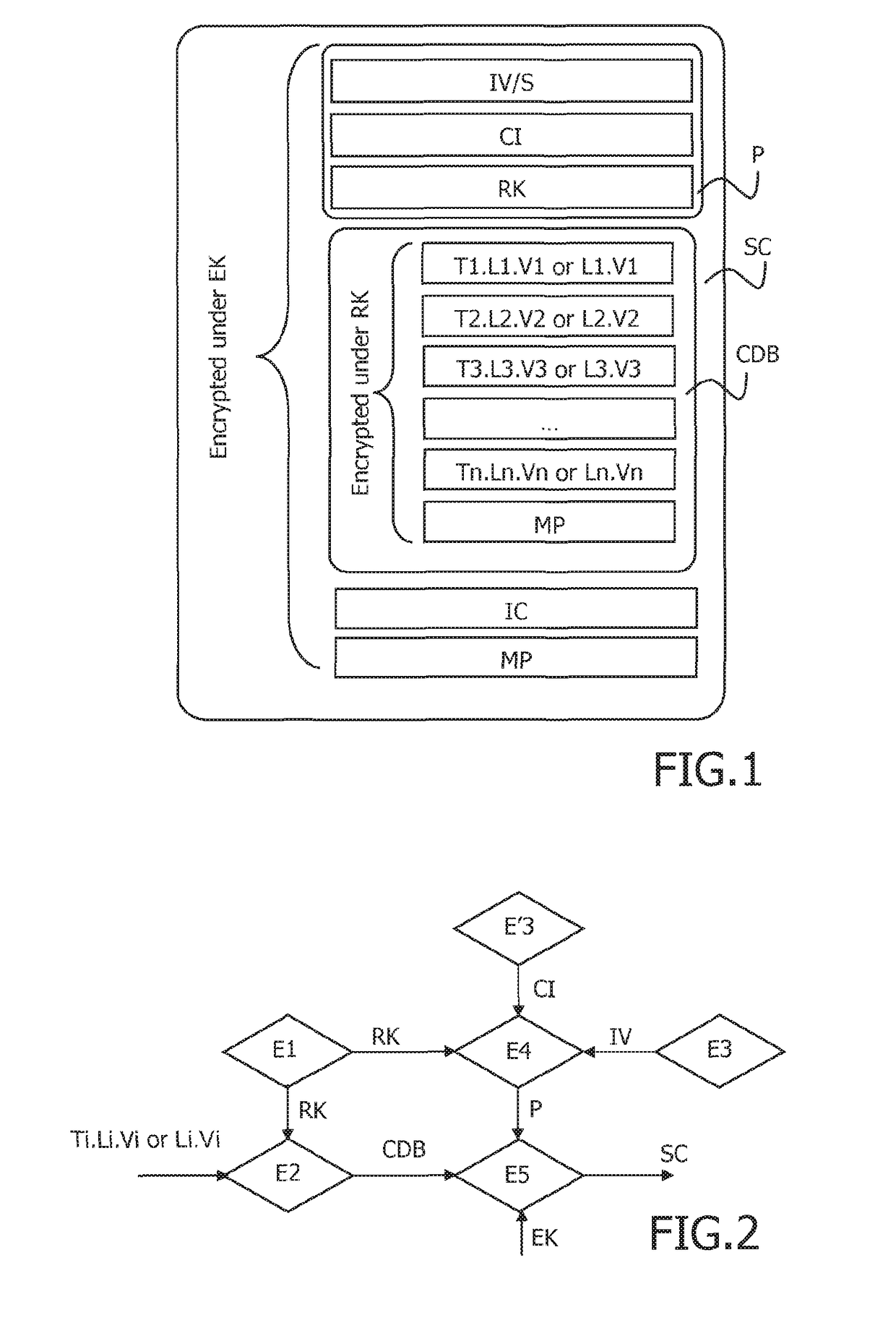

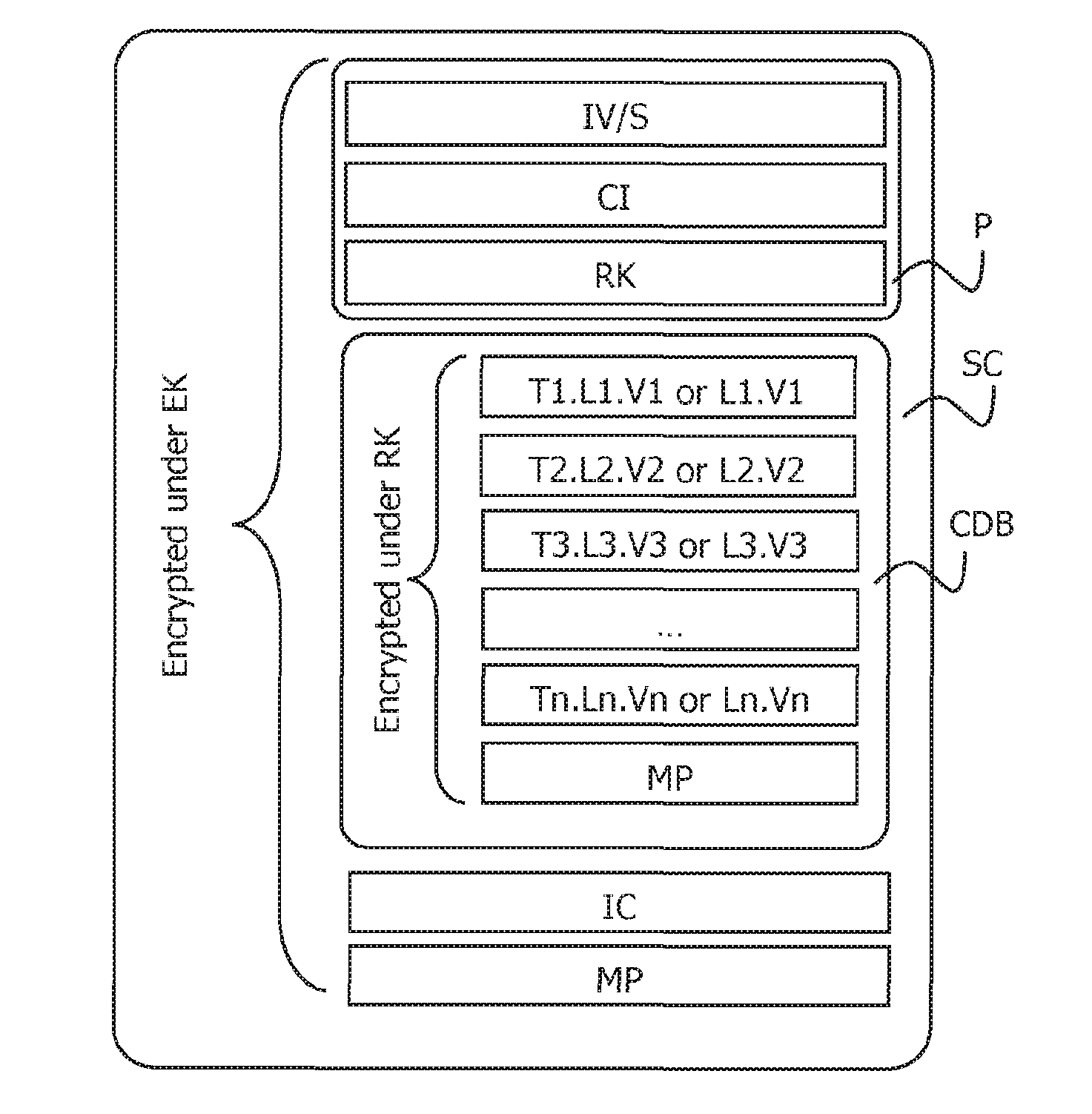

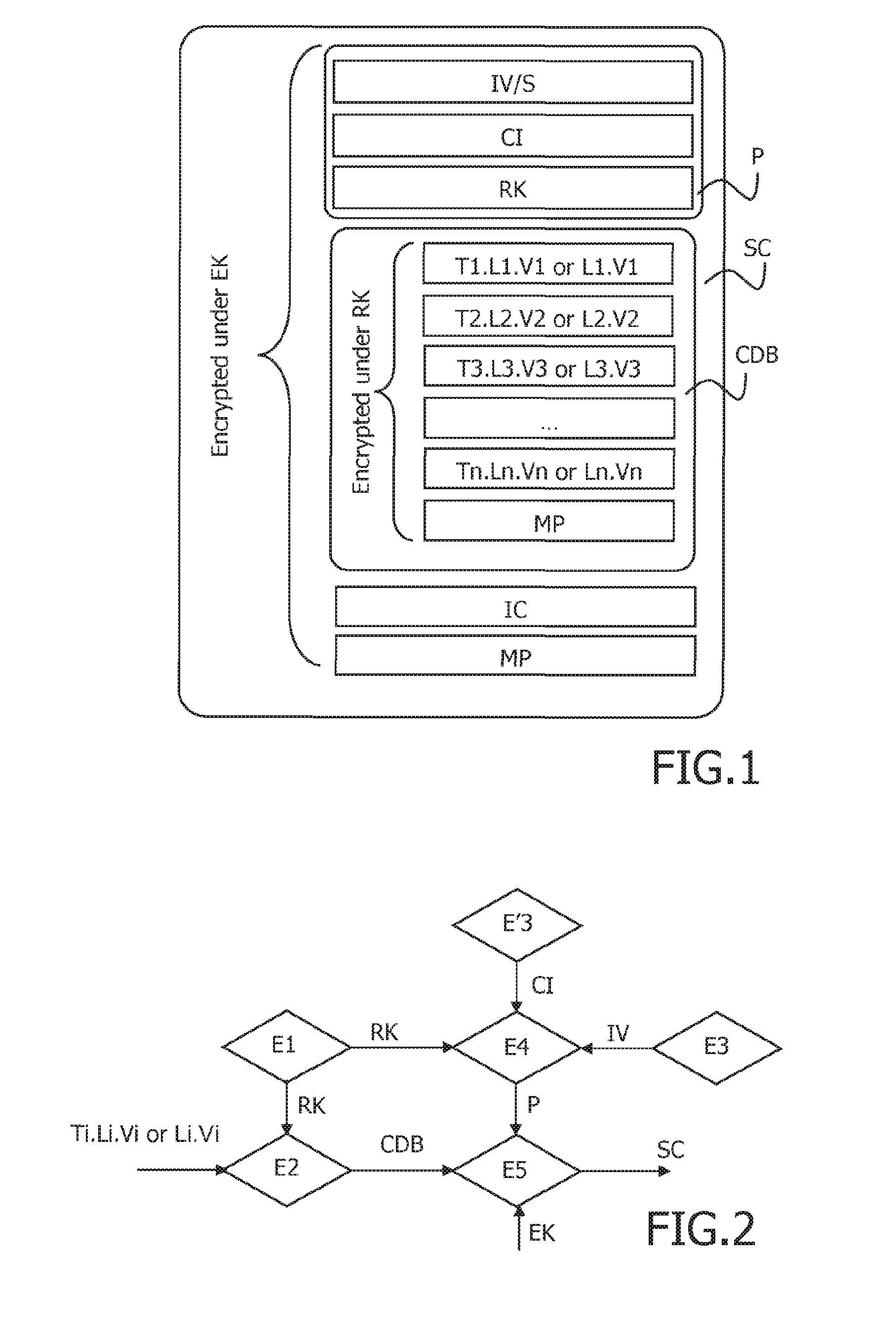

Method to protect a set of sensitive data associated to public data in a secured container

InactiveUS10225240B2Increased durabilityAvoid localizationMultiple keys/algorithms usageDigital data protectionData setEncryption

The present invention relates to a method to protect, in a secured container using an encryption key, a set of mixed sensitive and public data to be transferred to an entity. The method includes the steps of: generating a random key, ciphering the set of mixed sensitive and public data using said random key to obtain a ciphered set of data, generating an initialization value, and defining configuration information for the secured container. The initialization value, the configuration information and random key form a preamble. The preamble and the ciphered set of data are encrypted. The initialization value renders the resulting encrypted data variable from a secured container to another even in case of repetitive configuration information in the preamble.

Owner:GEMPLU

Method to protect a set of sensitive data associated to public data in a secured container

InactiveUS20160294791A1Prevent malicious attacksIncreased durabilityMultiple keys/algorithms usageDigital data protectionData setEncryption

The present invention relates to a method to protect, in a secured container using an encryption key, a set of mixed sensitive and public data to be transferred to an entity. The method includes the steps of: generating a random key, ciphering the set of mixed sensitive and public data using said random key to obtain a ciphered set of data, generating an initialization value, and defining configuration information for the secured container. The initialization value, the configuration information and random key form a preamble. The preamble and the ciphered set of data are encrypted. The initialization value renders the resulting encrypted data variable from a secured container to another even in case of repetitive configuration information in the preamble.

Owner:GEMPLU

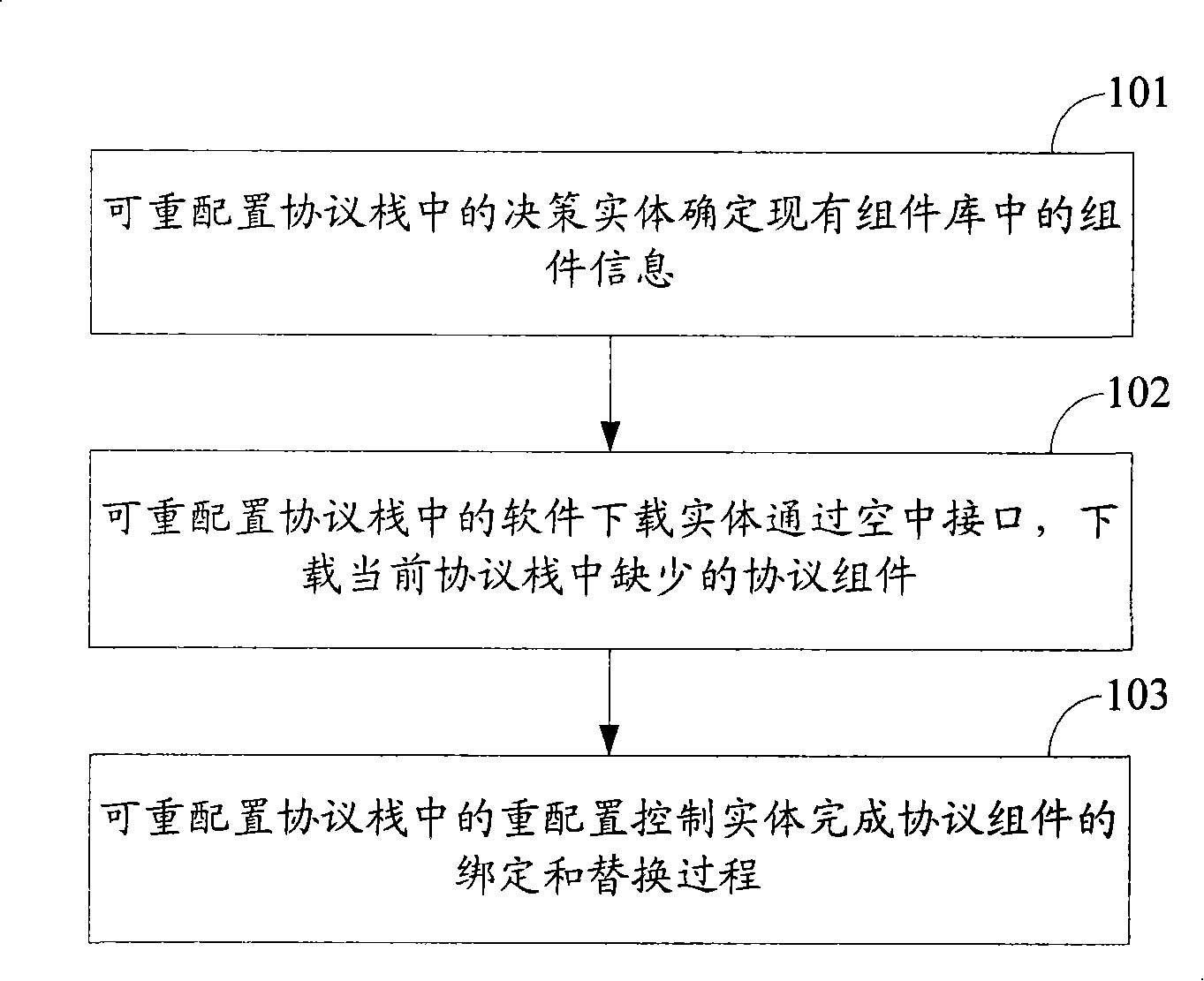

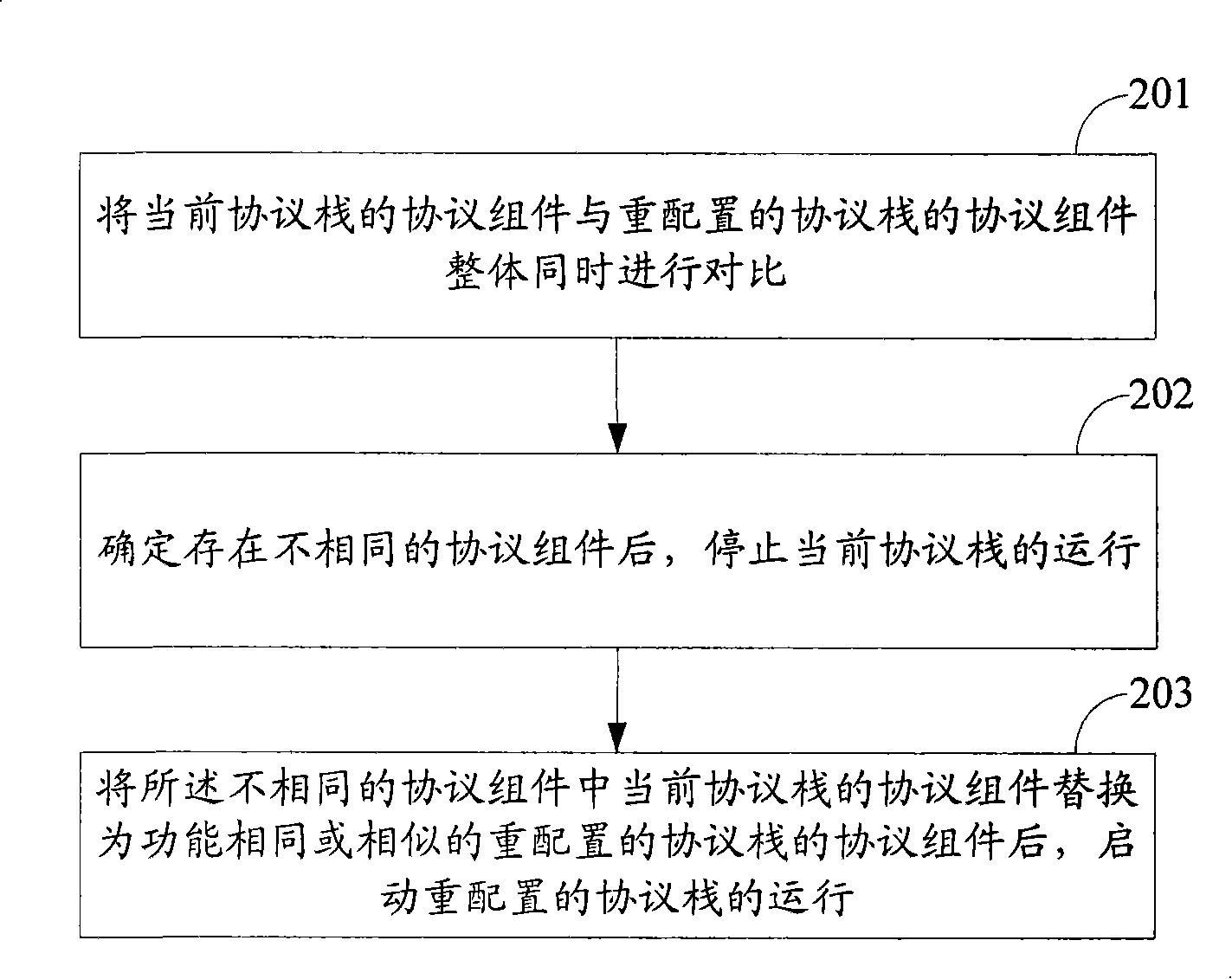

Method, equipment and system for reconfiguring protocol stack based on assembly

ActiveCN101599854BAvoid localizationConstrained degrees of freedomData switching networksTime delaysProtocol stack

The invention discloses a method for reconfiguring a protocol stack based on an assembly. The method comprises the following steps: simultaneously comparing a protocol assembly of the current protocol stack with the whole of a protocol assembly of the reconfigured protocol stack; confirming that different protocol assemblies exist, and then stopping running the current protocol stack; replacing the protocol assembly of the current protocol stack in the different protocol assemblies with the protocol assembly of the reconfigured protocol stack with same or similar function, and then starting up the running of the protocol assembly of the current protocol stack. The invention also discloses equipment and a system for reconfiguring a protocol stack based on an assembly. The invention can improve the success ratio of reconfiguration and effectively lower the time delay of the reconfiguration.

Owner:CHINA MOBILE COMM GRP CO LTD

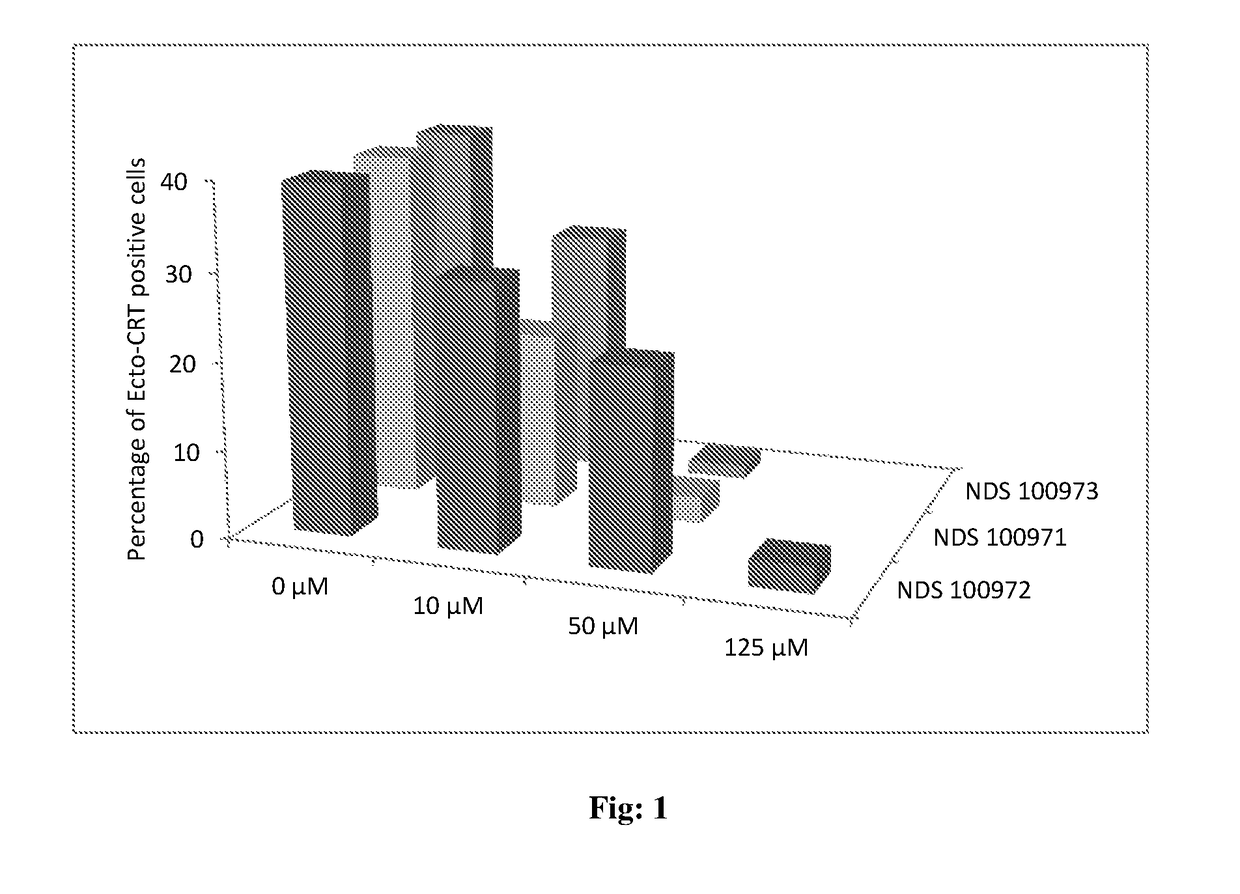

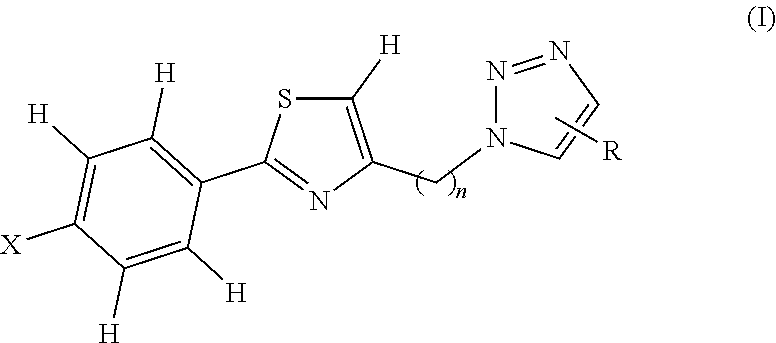

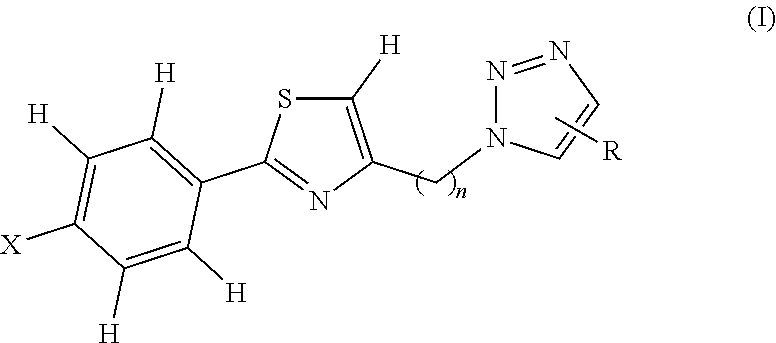

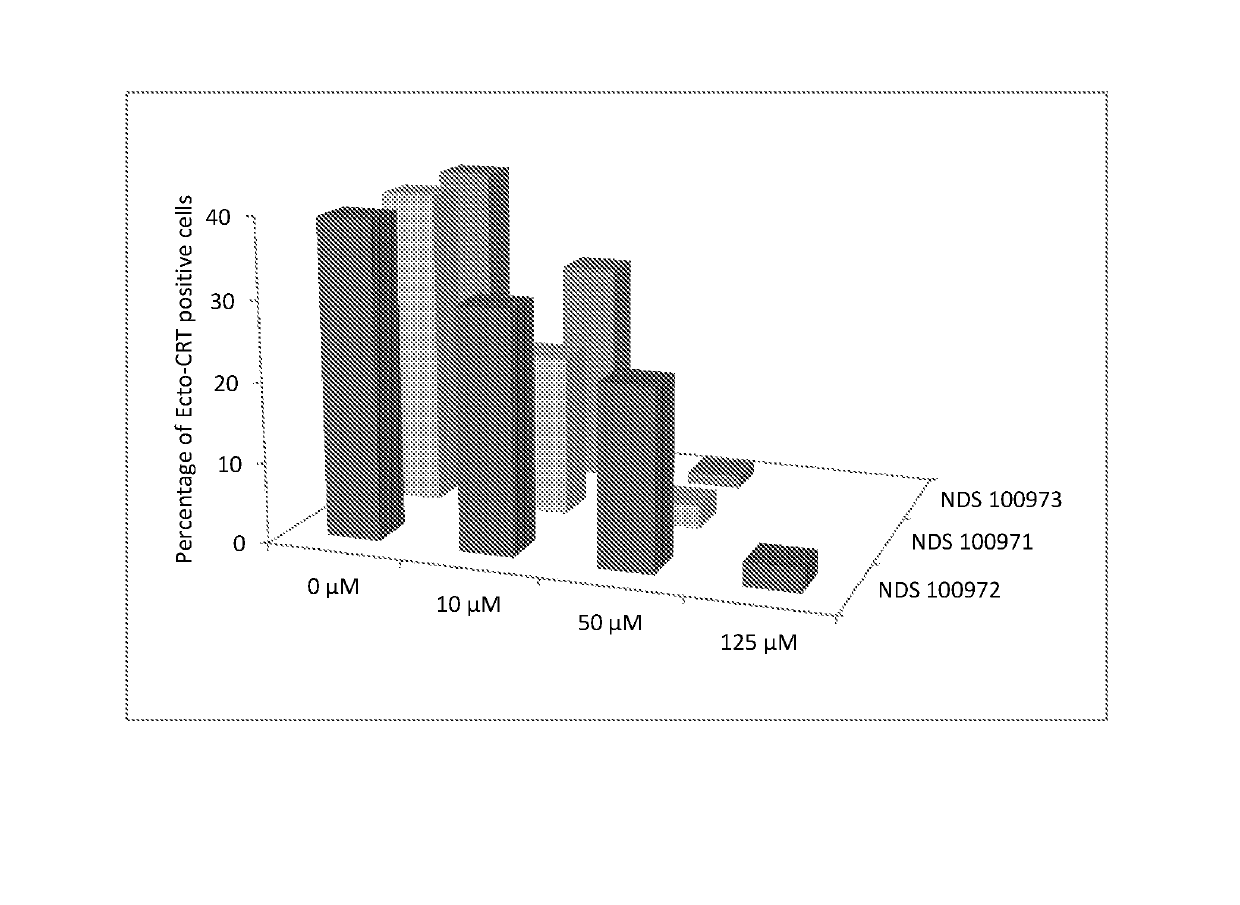

Novel 1,2,3 triazole-thiazole compounds, process for preparation and use thereof

InactiveUS20180370962A1Avoid spreadingAvoid cell deathOrganic active ingredientsOrganic chemistryThiazole1,2,3-Triazole

Owner:COUNCIL OF SCI & IND RES

1,2,3 triazole-thiazole compounds, process for preparation and use thereof

InactiveUS10246449B2Suppressing immunogenic cell deathAvoid spreadingOrganic active ingredientsOrganic chemistryThiazolePharmaceutical drug

Owner:COUNCIL OF SCI & IND RES

Acoustic transducer

ActiveUS20170318373A1Promote reproductionRelieve stressLoudspeakersBone conduction transducer hearing devicesAuditory senseTransducer

Provided is an acoustic transducer which is used by being fitted into an ear of a listener, is formed in a compact and lightweight shape, and preferably prevents re-reflection of a sound wave. An acoustic transducer 100 is formed of a film-shaped material having an expanding and contracting action and includes a cylindrical acoustic transducing element 101. The cylindrical acoustic transducing element 101 also functions as a sound guide tube. The acoustic transducing element 101 prevents re-reflection of the sound wave reflected by an eardrum when the sound wave has been generated and prevents localization phenomenon and a feeling of pressure in auditory sense. Also, since the acoustic transducing element 101 is formed in a compact and lightweight shape, the acoustic transducing element 101 generates the sound wave for directly reaching the eardrum or collects the sound at a place near the eardrum without a feeling of foreign materials in a case where a person wears the acoustic transducing element 101 the an ear.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com