Patents

Literature

38results about How to "Constrained degrees of freedom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

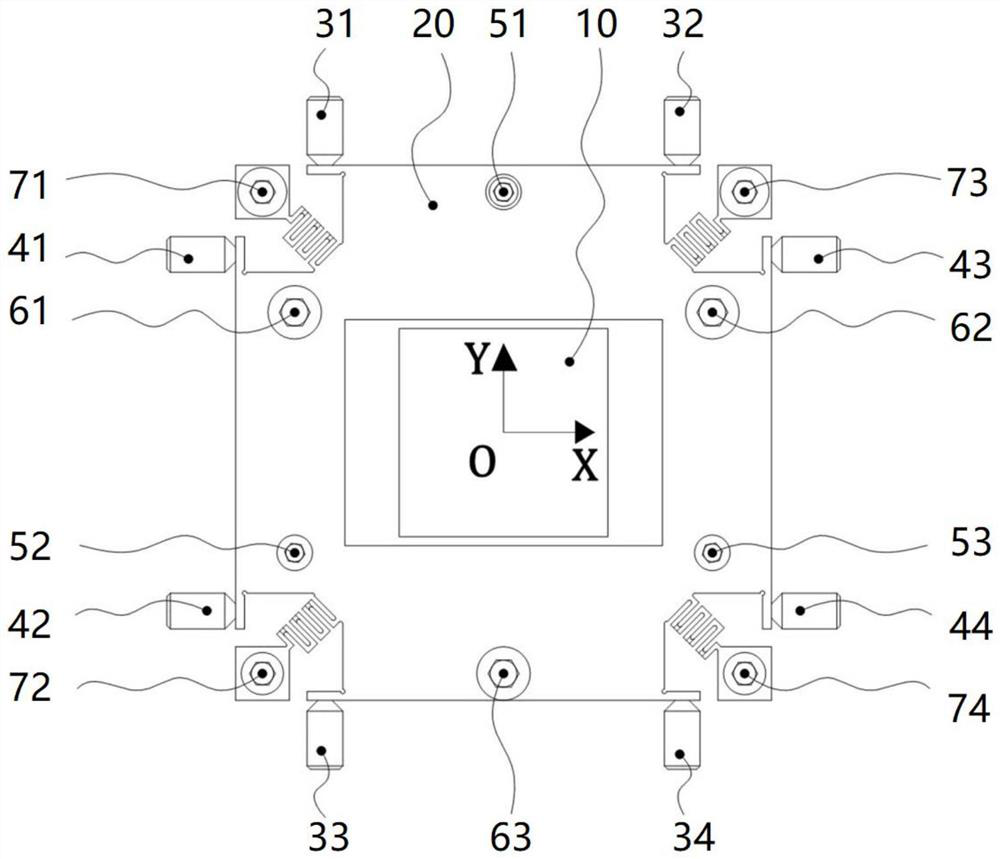

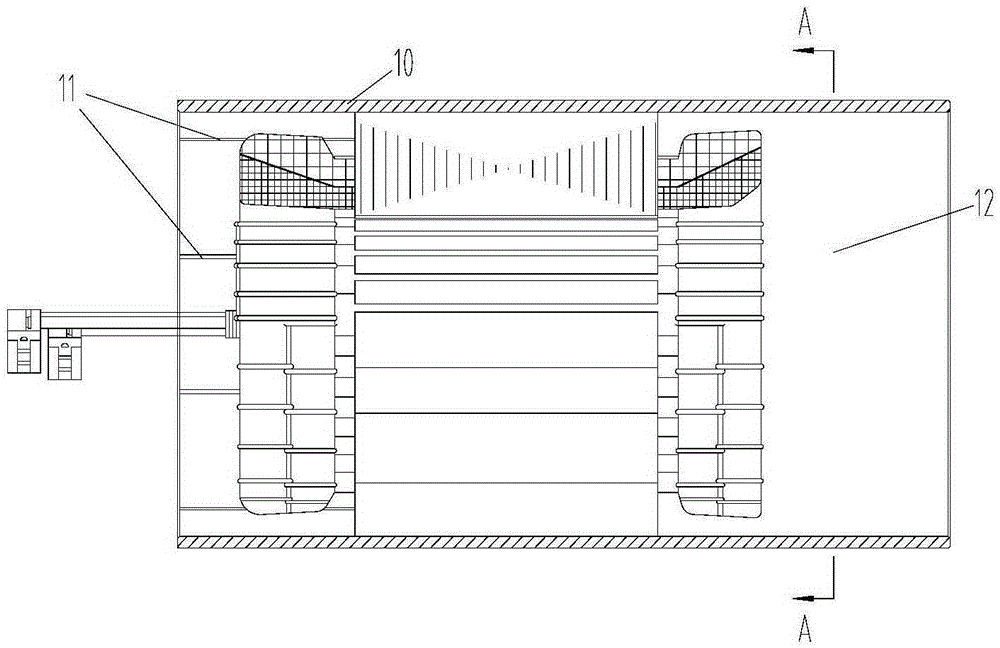

Active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection

ActiveCN106321719AHigh static stiffnessRaise the natural frequencyMagnetic springsGas based dampersAir springNegative stiffness

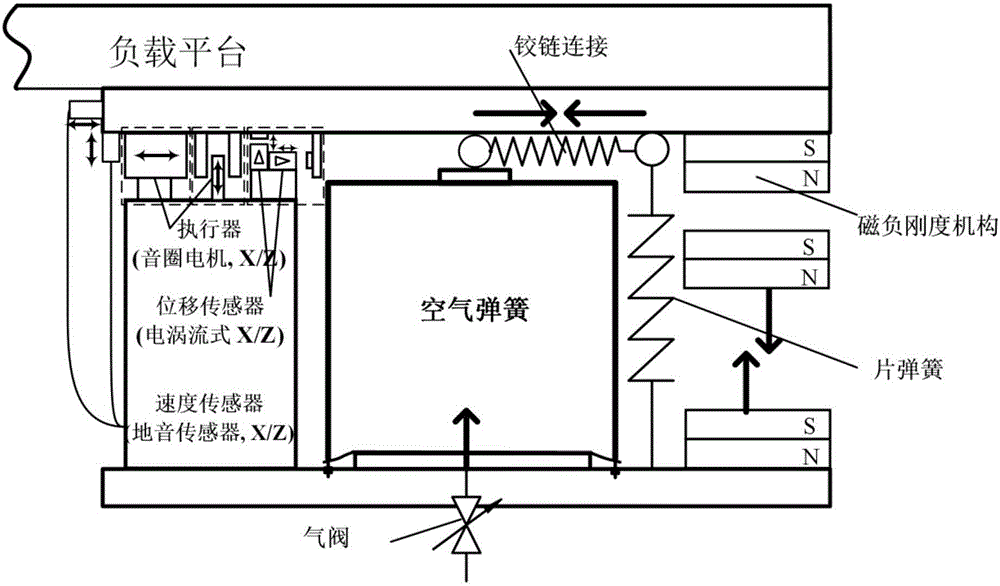

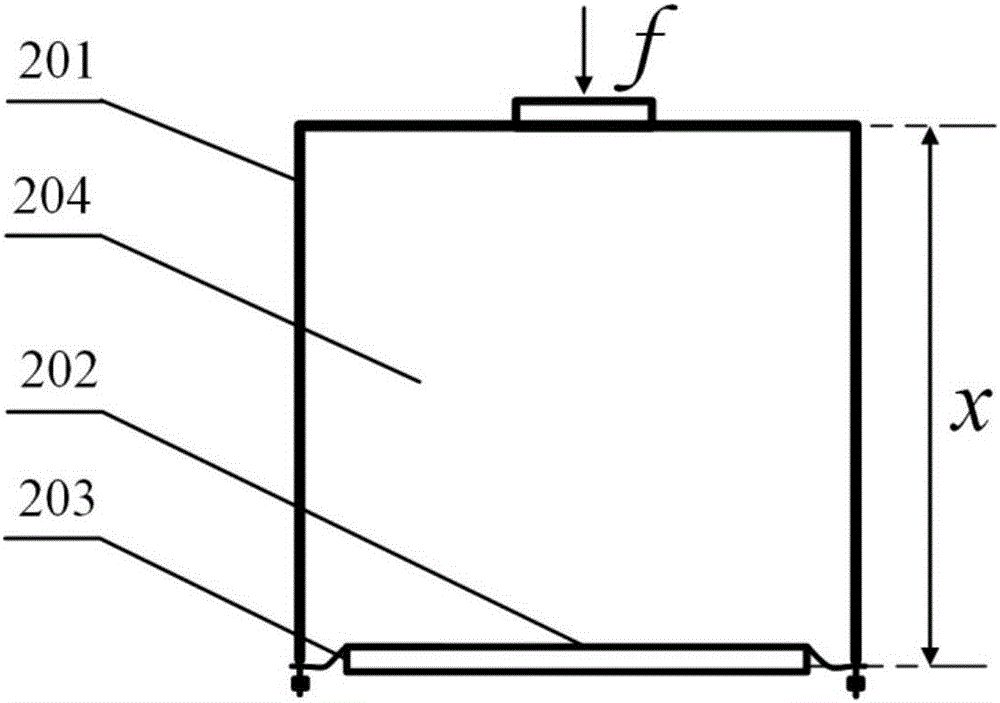

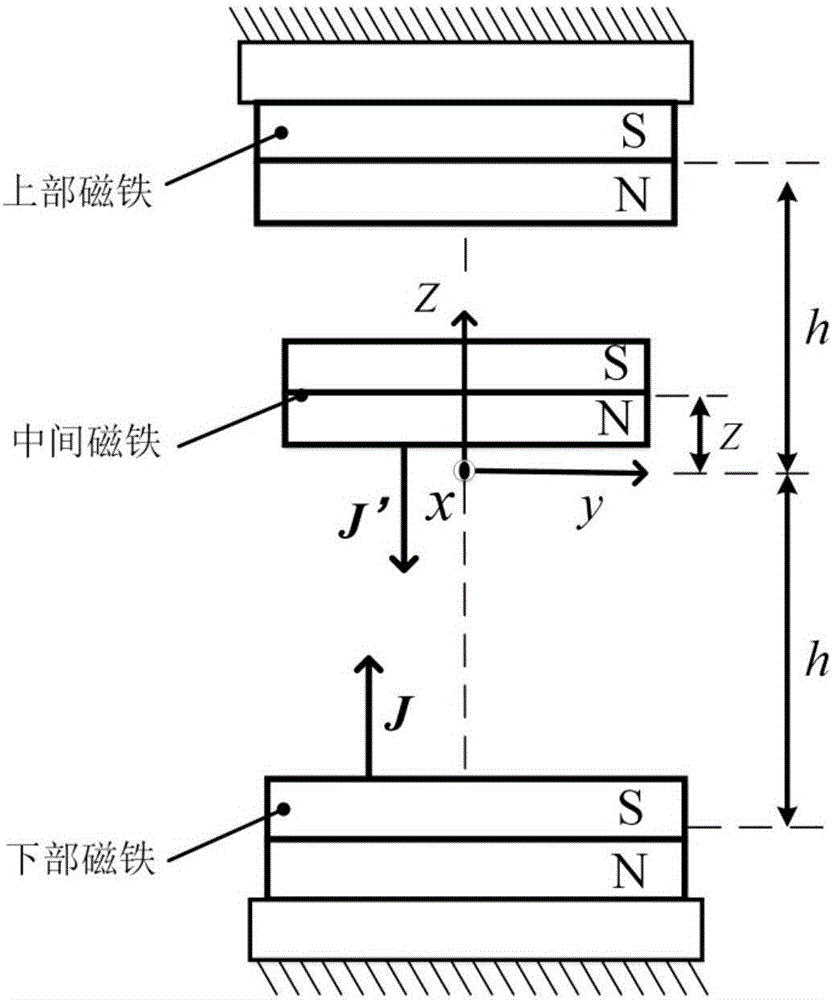

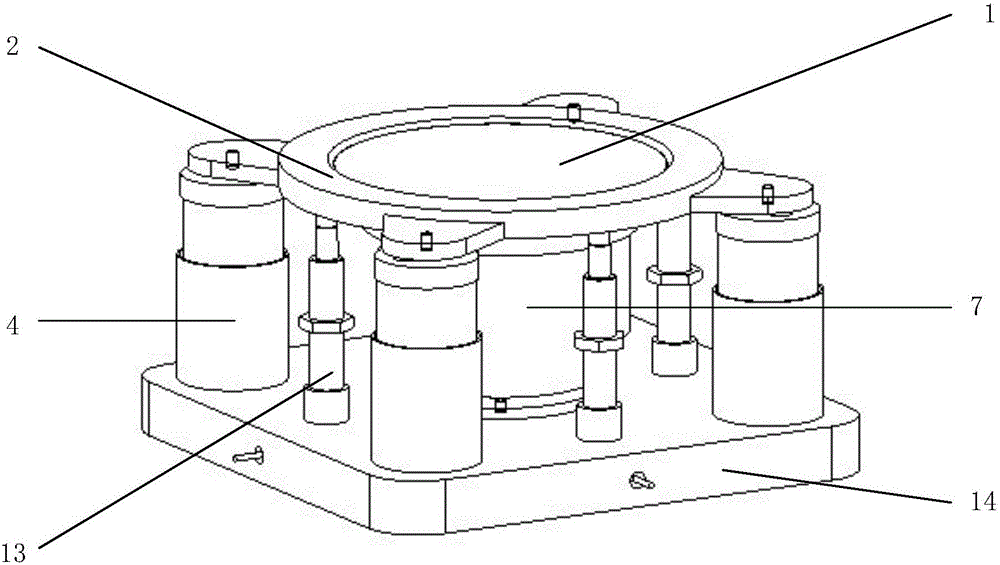

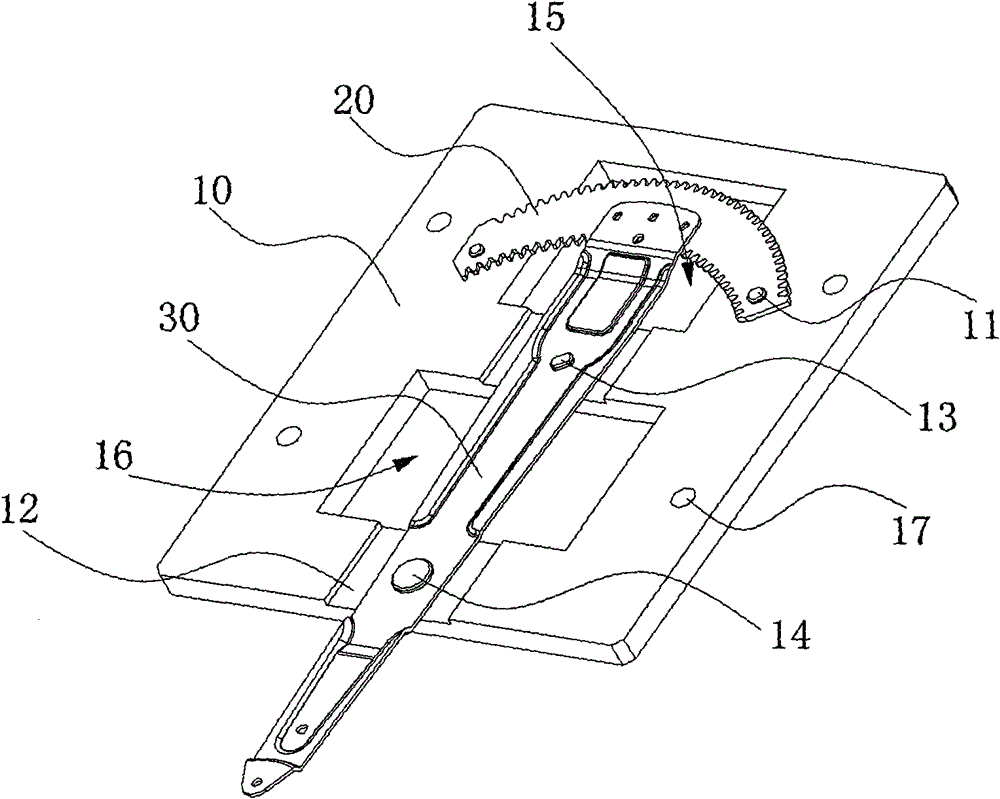

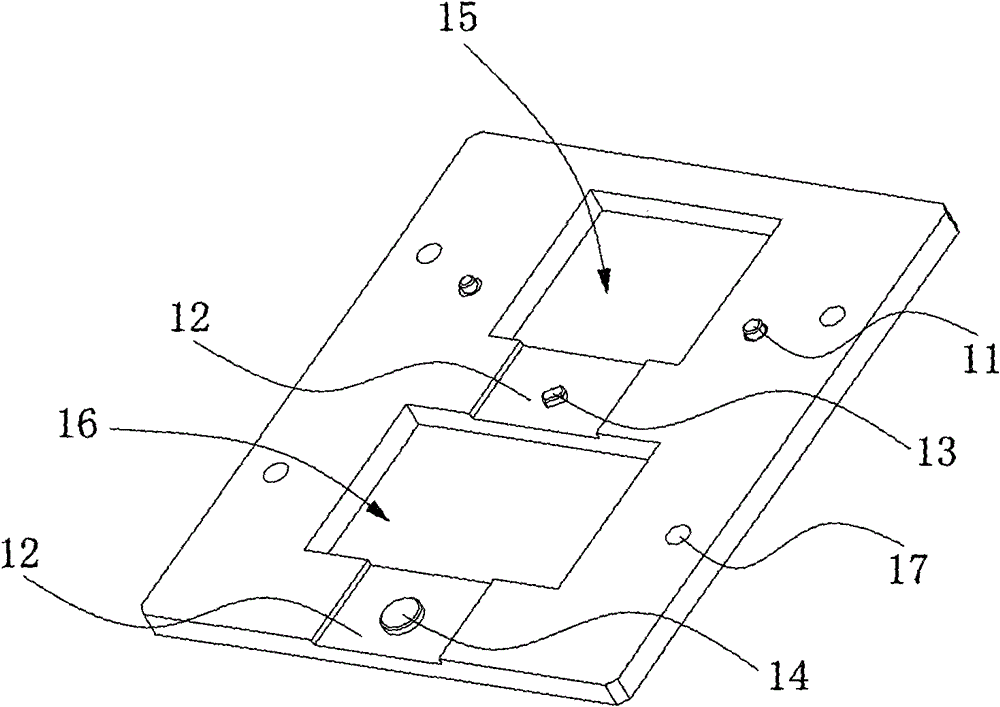

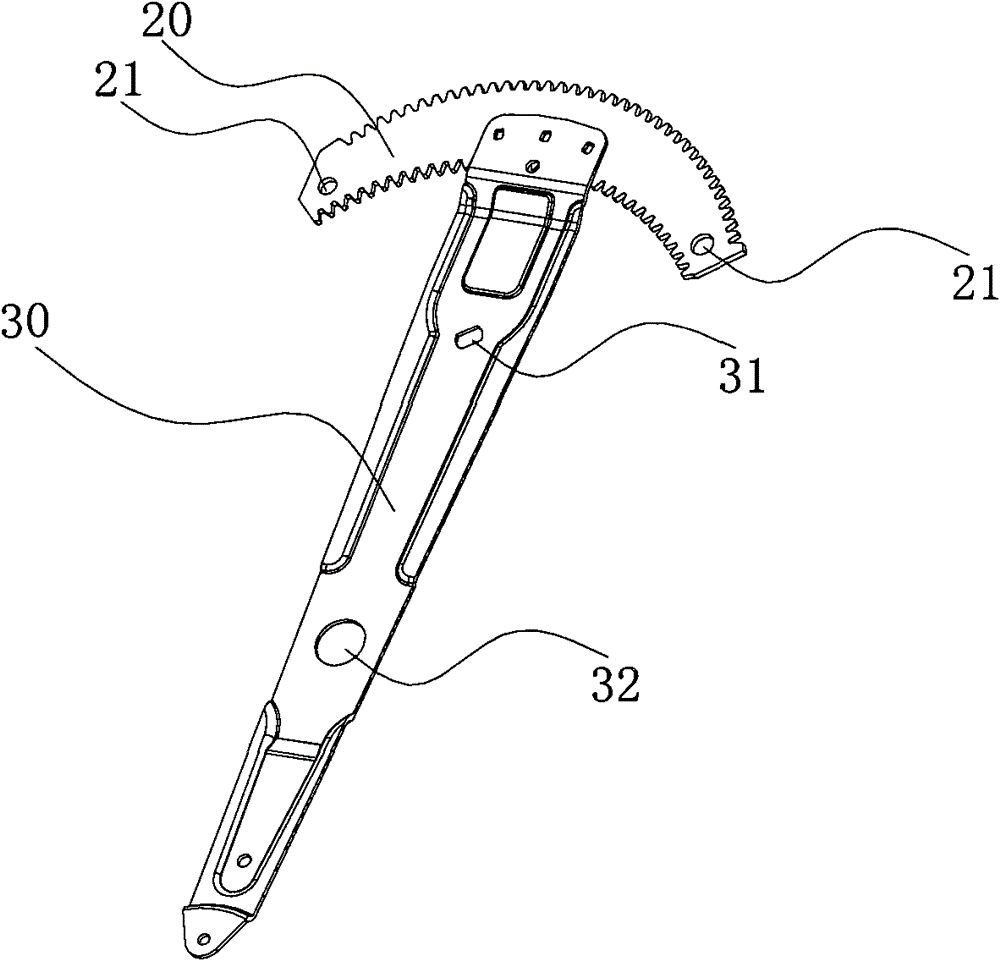

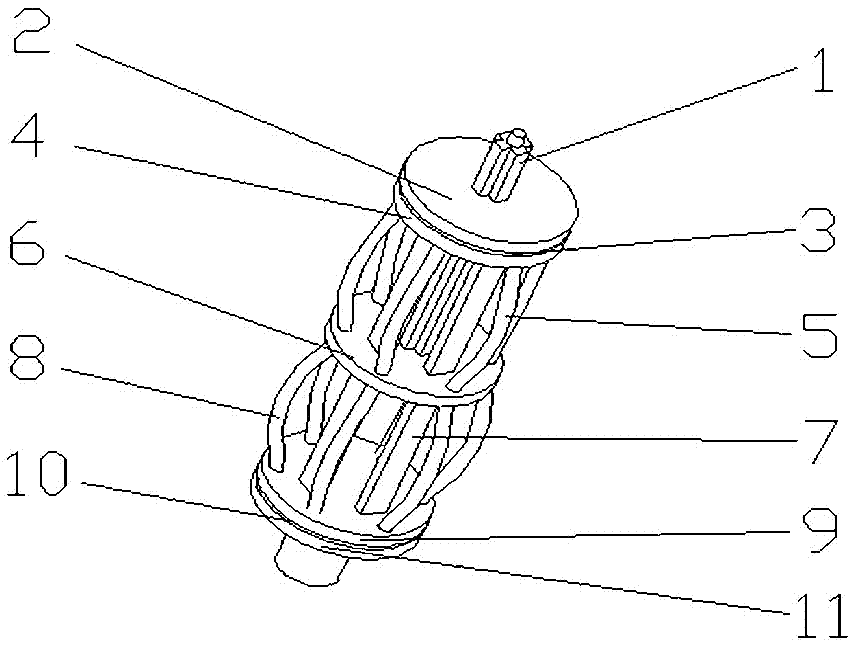

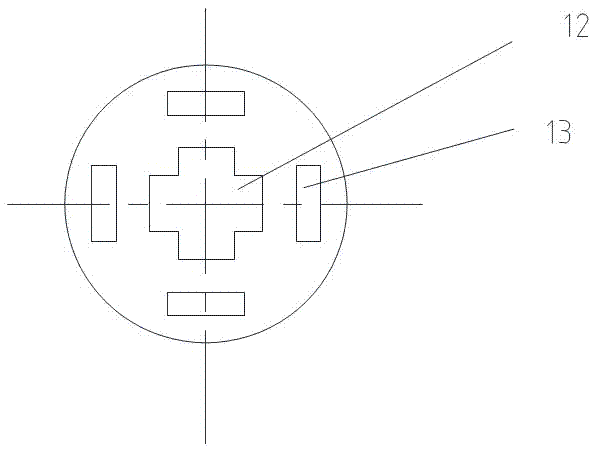

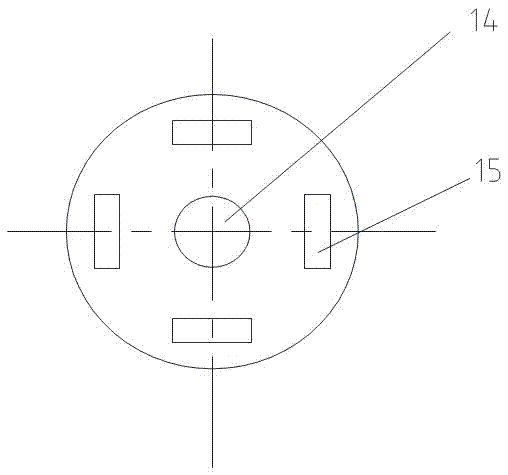

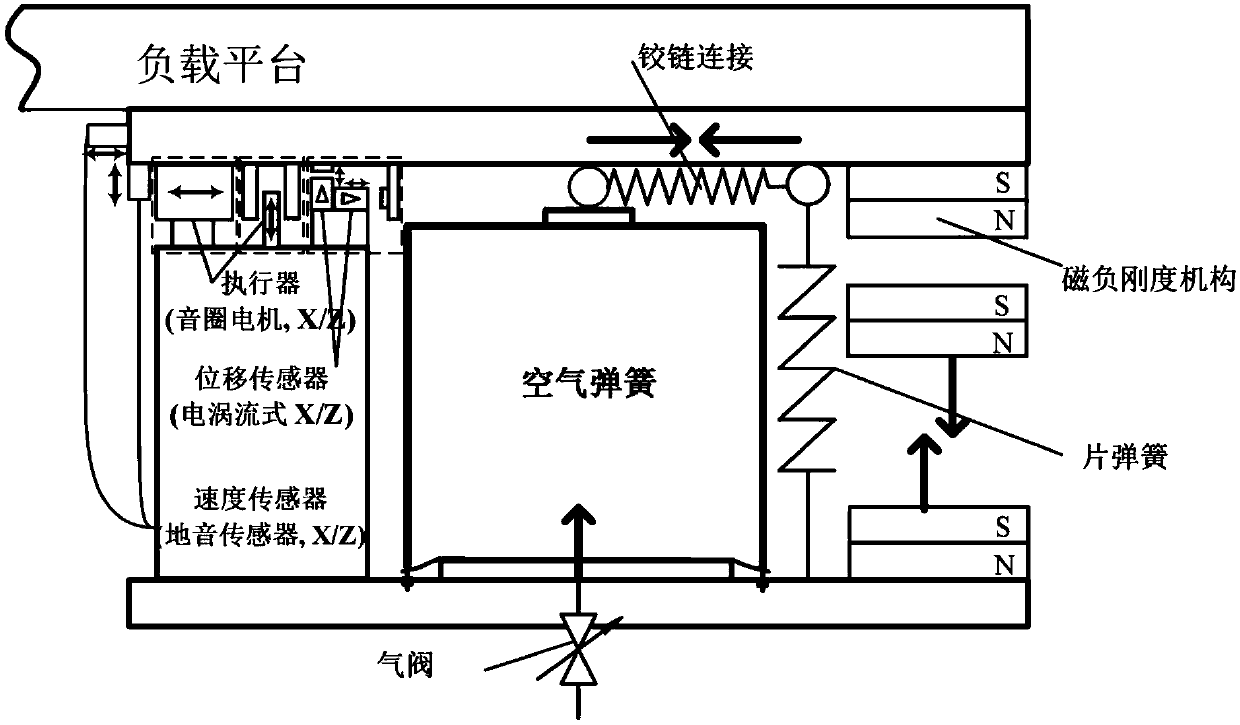

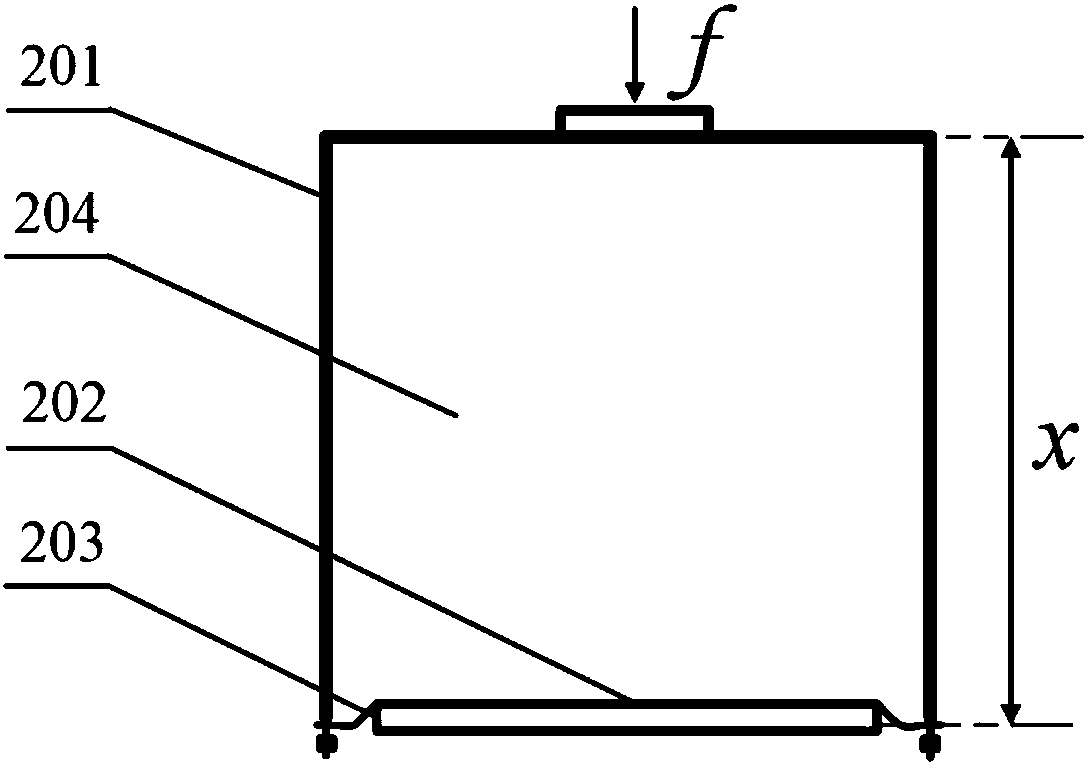

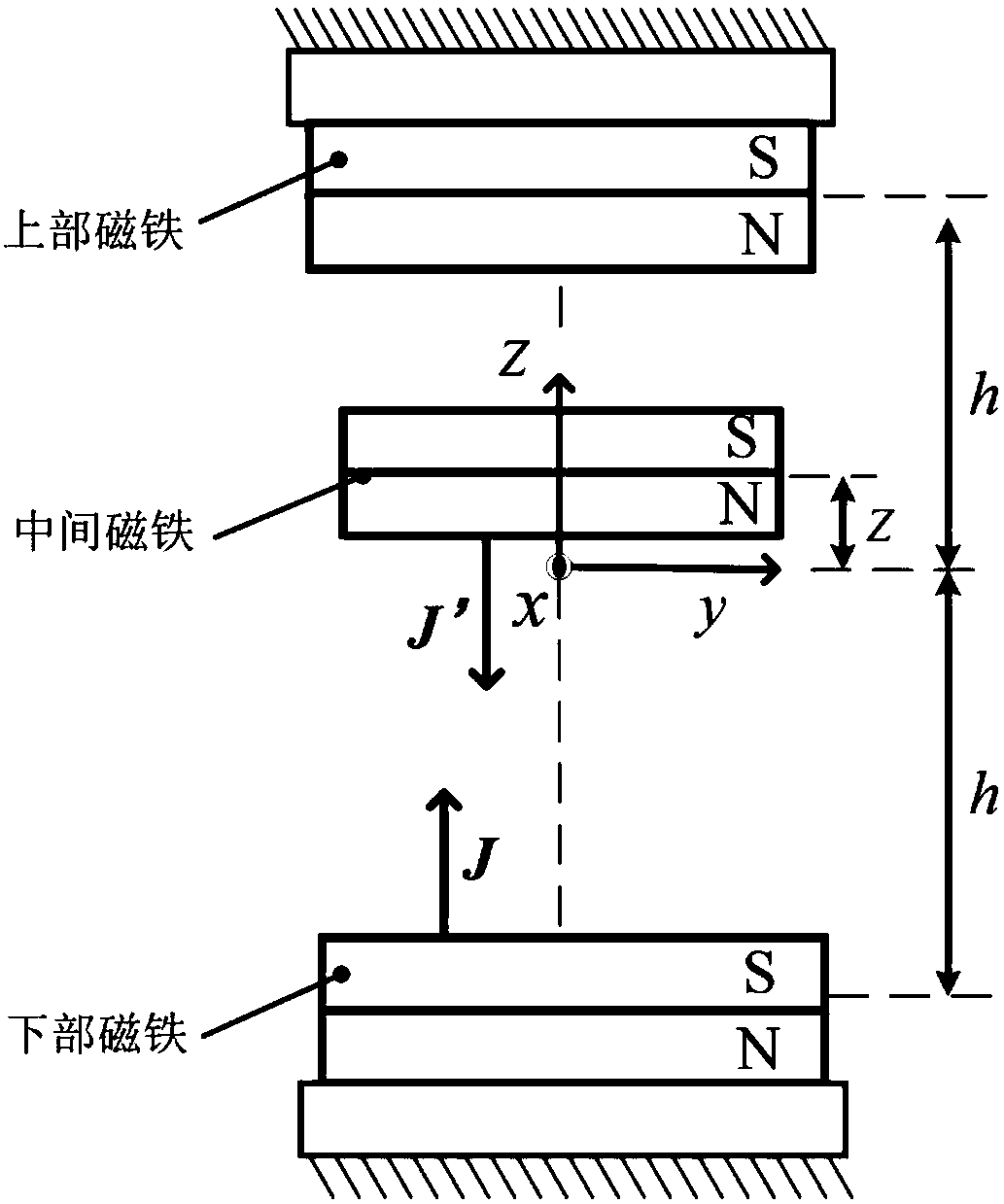

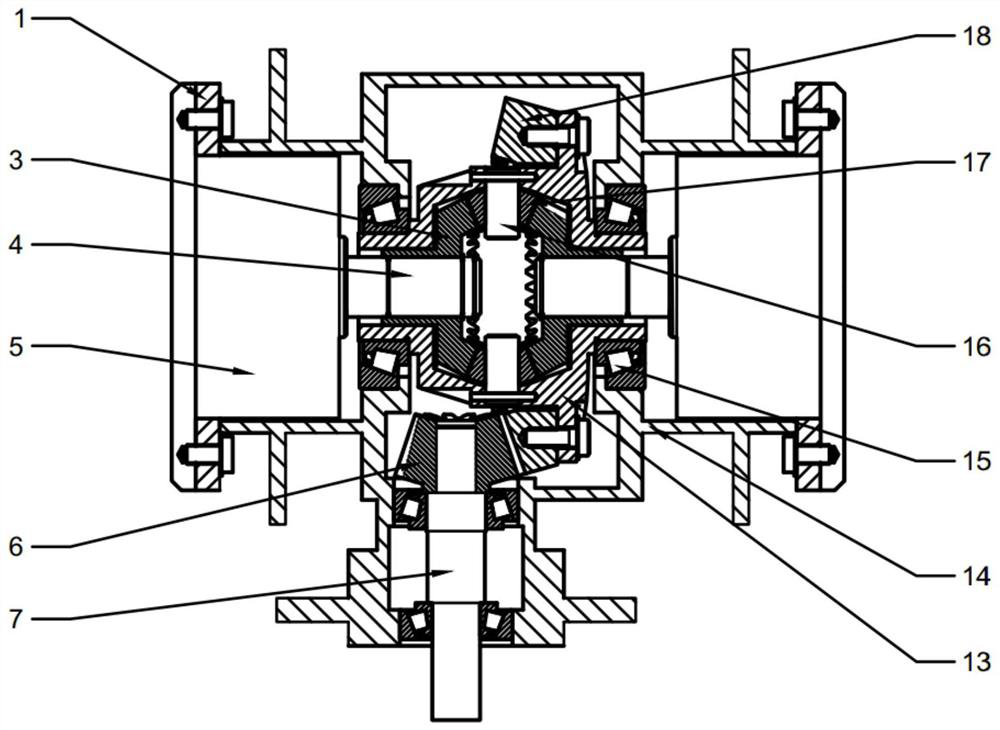

The invention discloses an active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection. The active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection comprises a basic platform (10), a load-bearing platform (30), a passive vibration isolation unit and an active vibration isolation unit, wherein the passive vibration isolation unit is provided with a positive-stiffness air spring (20) and a magnetic negative-stiffness mechanism (28) with adjustable negative stiffness in the first direction, so that the inherent frequency in the first direction is decreased, and the passive vibration isolation unit is provided with a stiffness-adjustable positive-stiffness leaf spring and a negative-stiffness inverted pendulum in the second direction, so that the inherent frequency in the second direction is decreased; the active vibration isolation unit is arranged at the outer side of the passive vibration isolation unit, the upper end of the active vibration isolation unit is linked with the load-bearing platform (30), and the lower end of the active vibration isolation unit is linked with the basic platform (10); and the active vibration isolation unit comprises displacement sensors, speed sensors, a proportional pressure valve and a voice coil motor, and the voice coil motor is used for fine adjustment of the load-bearing platform, so that vibration is further isolated. The active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection has high bearing capacity, and active and passive vibration isolation of two degrees of freedom is achieved at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

Serial-connected load carrying type rapid reflector structure

The invention provides a serial-connected load carrying type rapid reflector structure. A flexible support is taken as a structure directly contacted with a reflector frame to constraint the free degree of a rapid reflector. A ball is arranged in the tail hole at the bottom end of the center fixing column of the flexible support, a rigid support formed by a ball seat and a compression spring adjusts the gap between the flexible support structure and the reflector frame, and the gap between the reflector during the motion and the reflector frame can be reduced, so that the rough adjustment of the deflection position of the reflector is realized. A position sensitive device receives the position signal of the reflector and feeds the signal back to a control system, a voice coil motor receives the instruction signal from the control system, so that the fine adjustment of the position of the reflector can be realized. The reflector frame is directly pushed by four voice coil motors that are staggered with the position sensitive device, so that the whole structure is compact.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

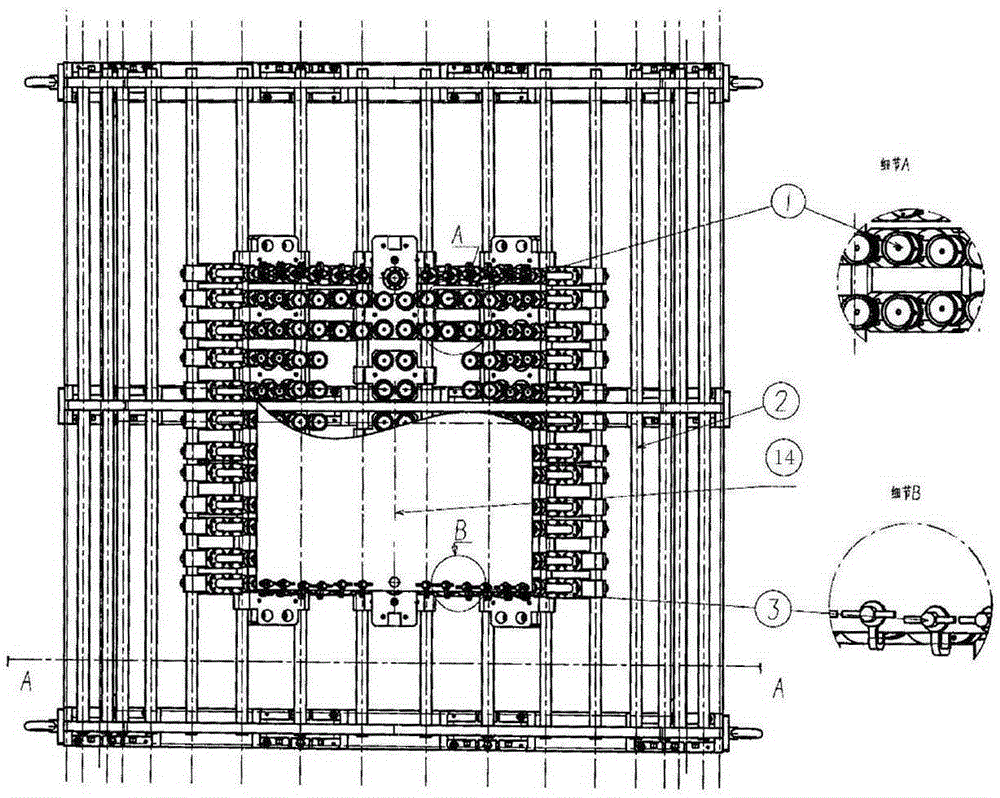

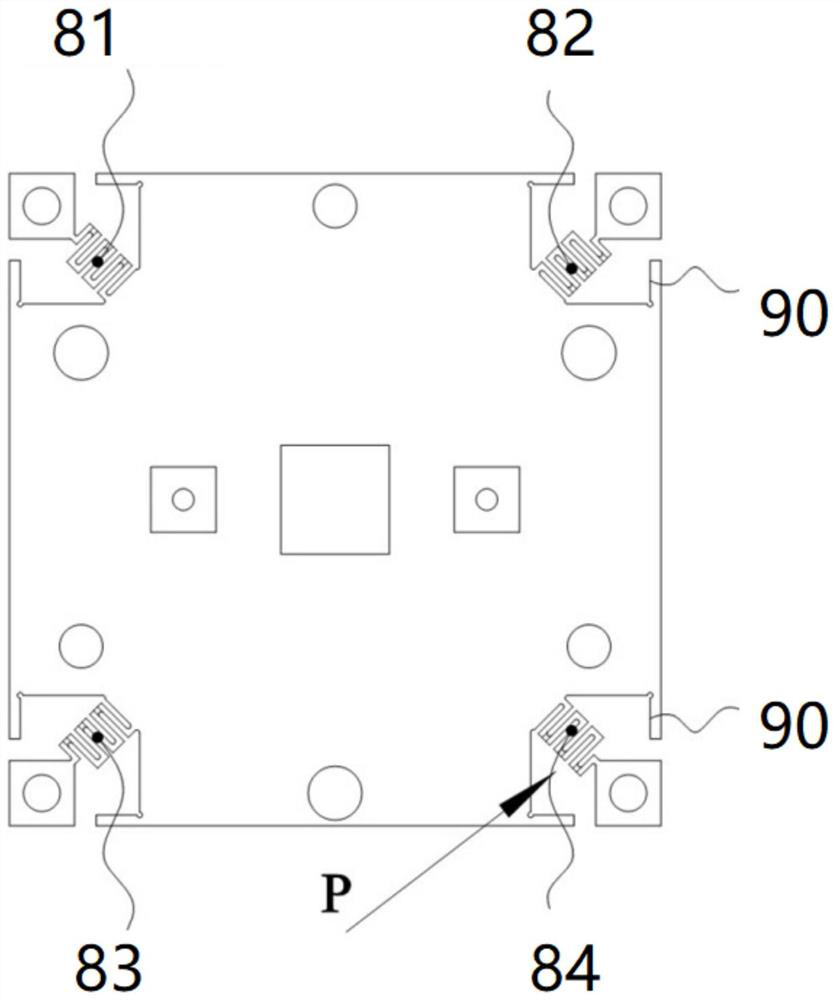

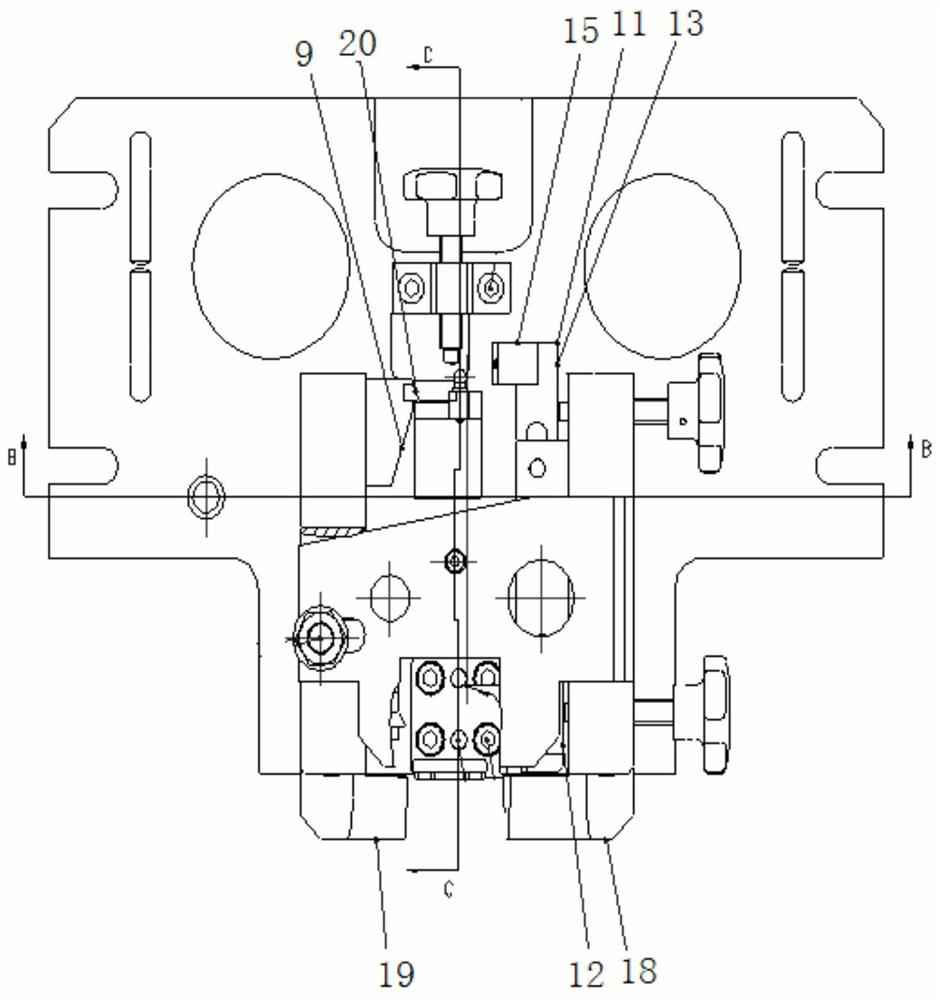

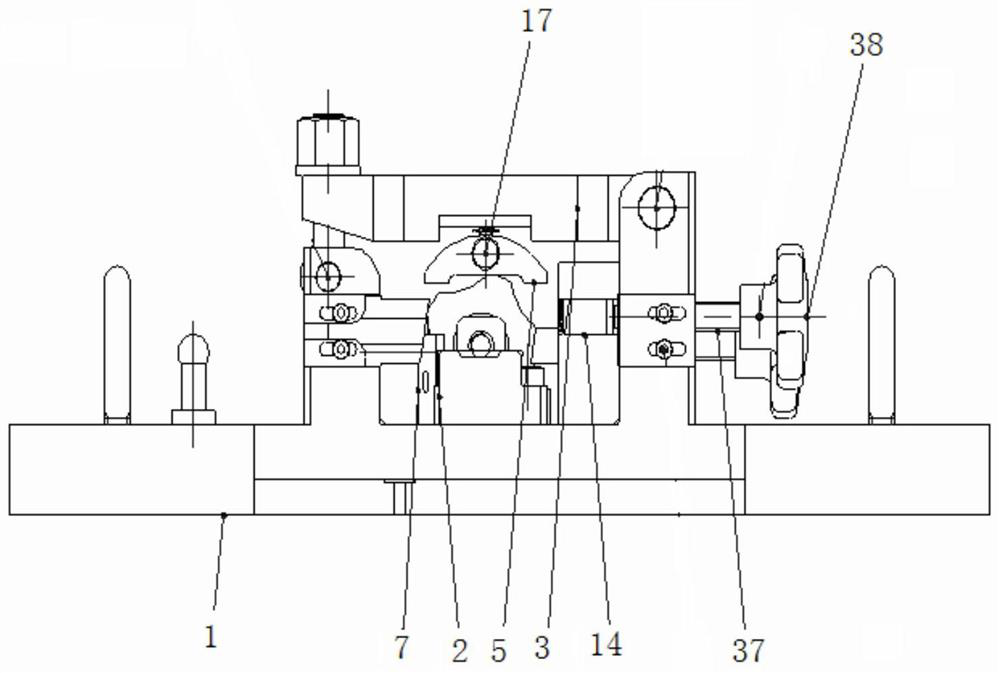

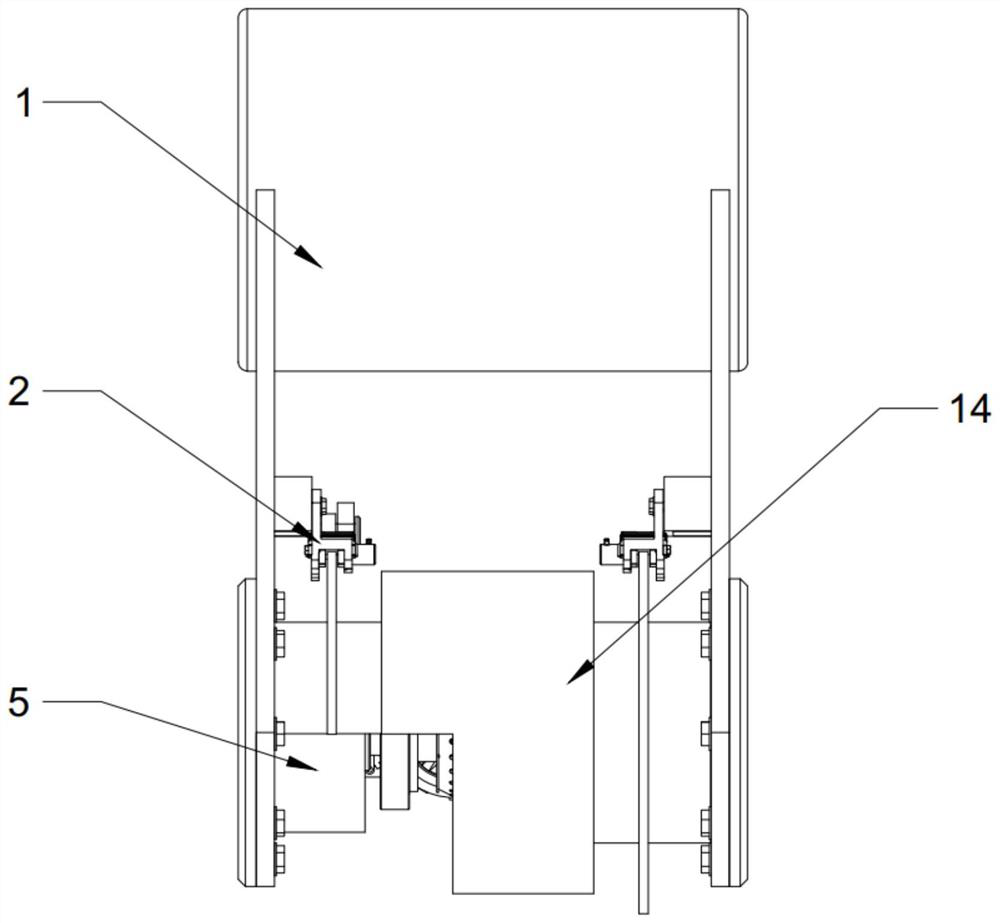

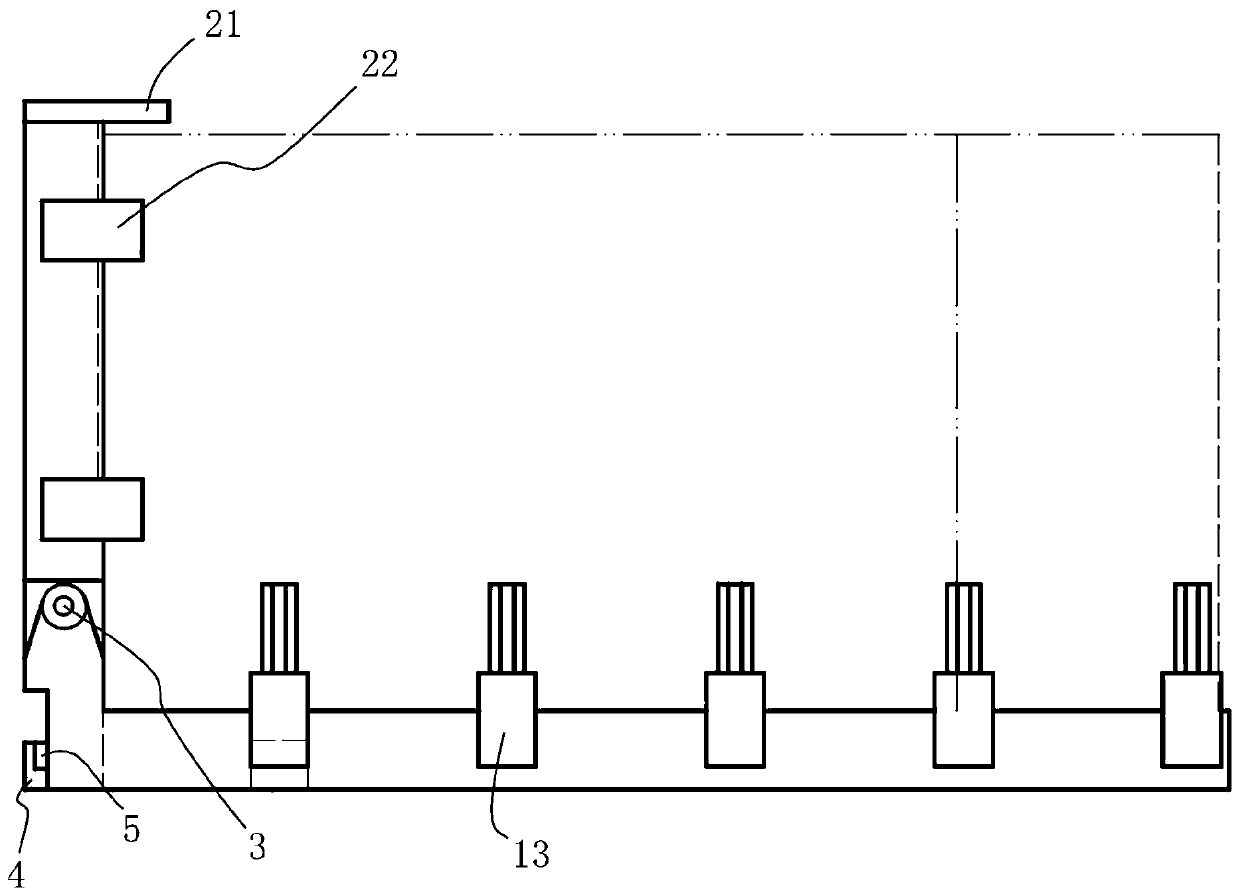

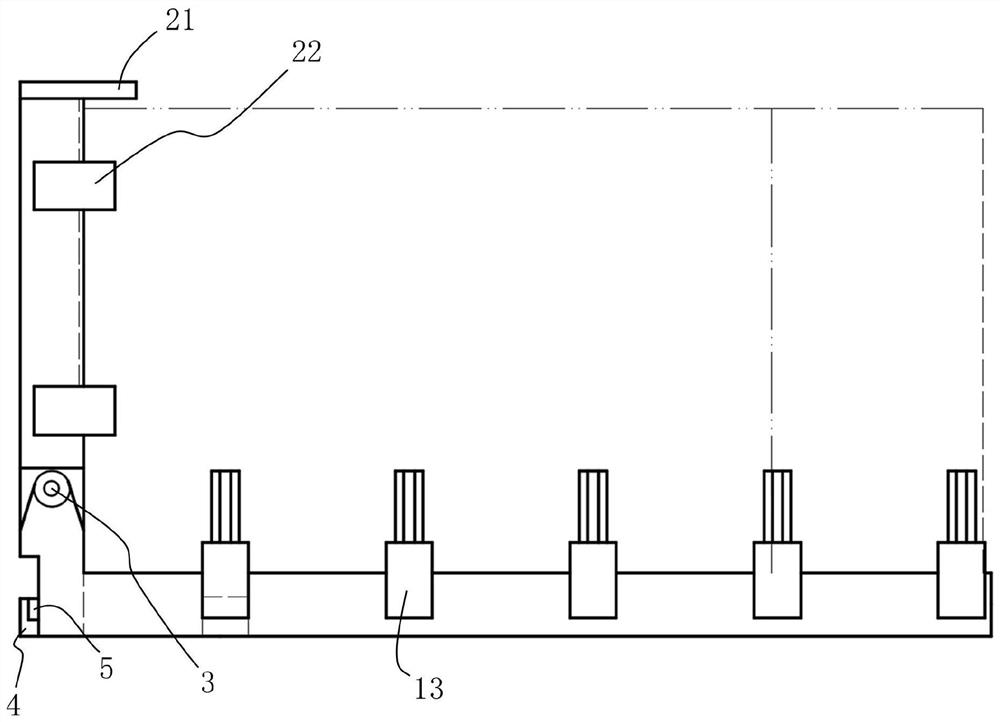

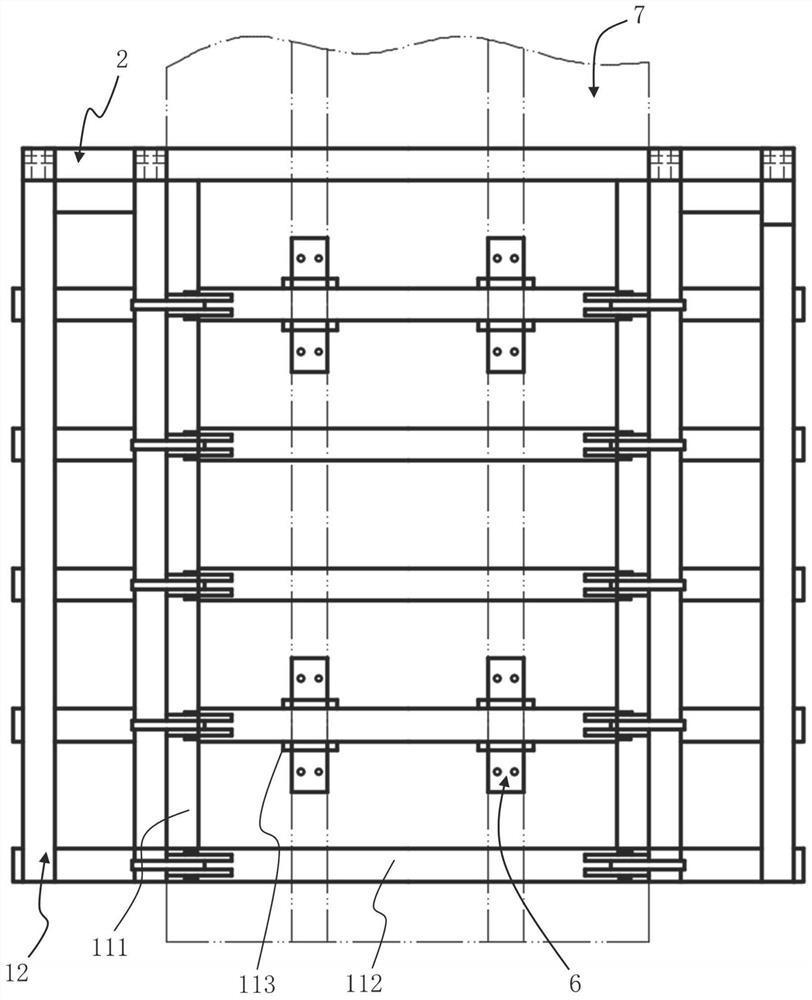

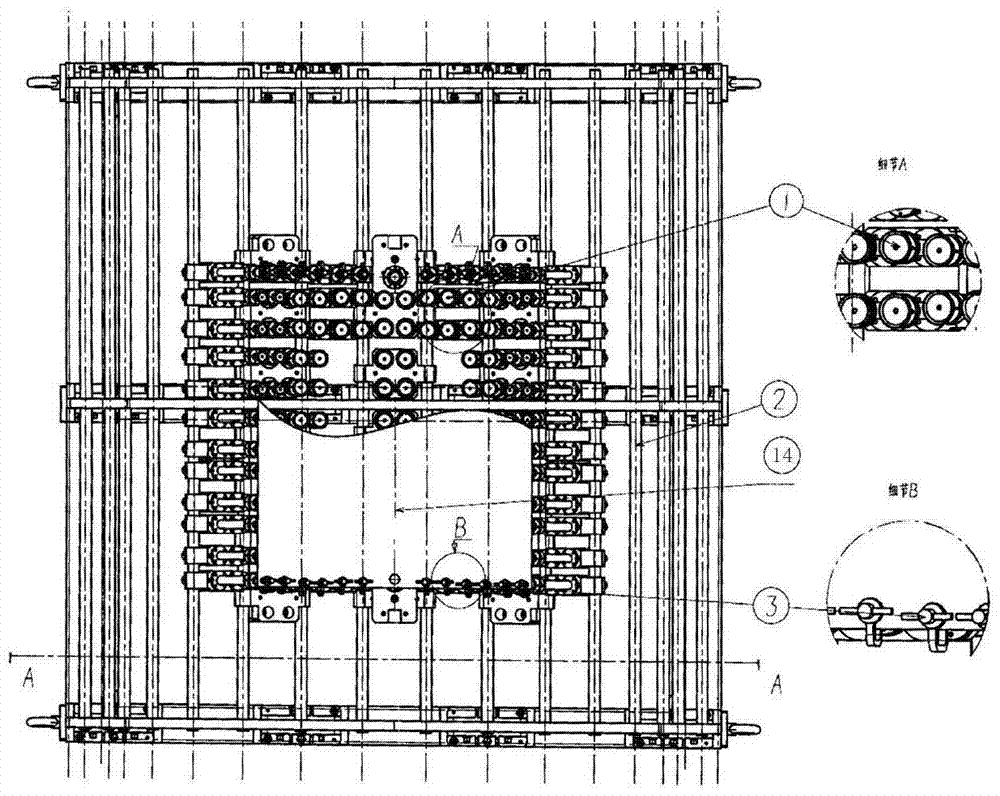

Aircraft skin no-allowance milling flexible tool and application method thereof

ActiveCN105290841ASimple structureLow costWorkpiecesMilling equipment detailsExtensibilityLocking mechanism

The invention discloses an aircraft skin no-allowance milling flexible tool. Multiple double-rod support units, multiple four-rod support units and multiple reference support units are arranged on a tool frame; bulb locking mechanisms are mounted on the double-rod support units and the four-rod support units; suckers or edge clampers are mounted on the bulb locking mechanisms; machining zero adaptors and assembly hole adaptors are arranged on the reference support units; the tool frame has a base; a connecting bracket is arranged on the base; a random support plate is arranged on the connecting bracket; multiple mounting holes are formed in the random support plate; expansion sleeves are mounted in the mounting holes; connecting rods are inserted in the coaxial mounting holes, and are locked through the expansion sleeves, so that the connecting rods and the random support plate are fastened; and the double-rod support units, the four-rod support units or the reference support units are mounted on the connecting rods. The aircraft skin no-allowance milling flexible tool has the advantages of simple structure, low cost, extensibility of modular structure, high clamping rigidity of thin-wall skin and convenience for application and promotion.

Owner:SHENYANG AIRCRAFT CORP

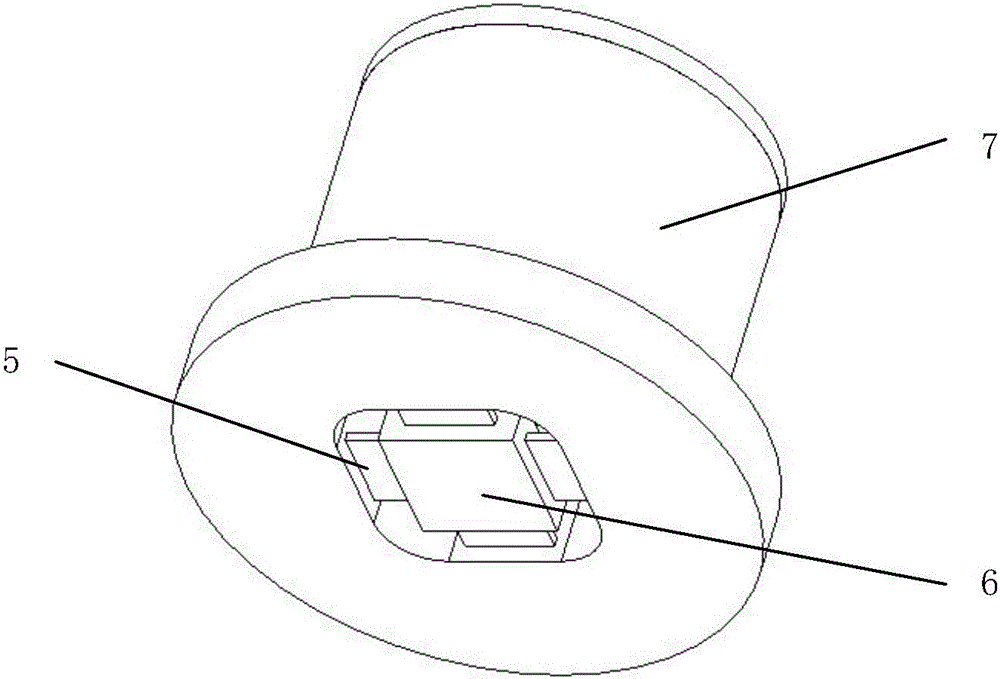

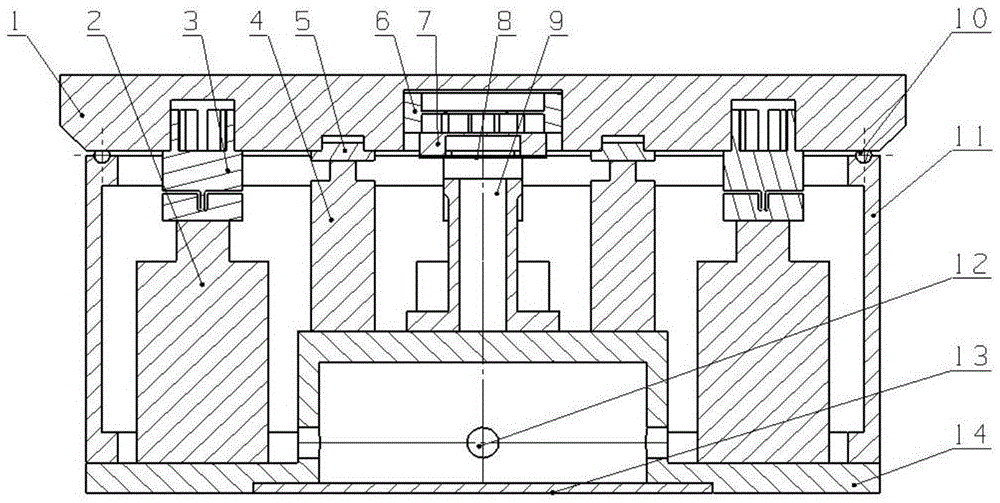

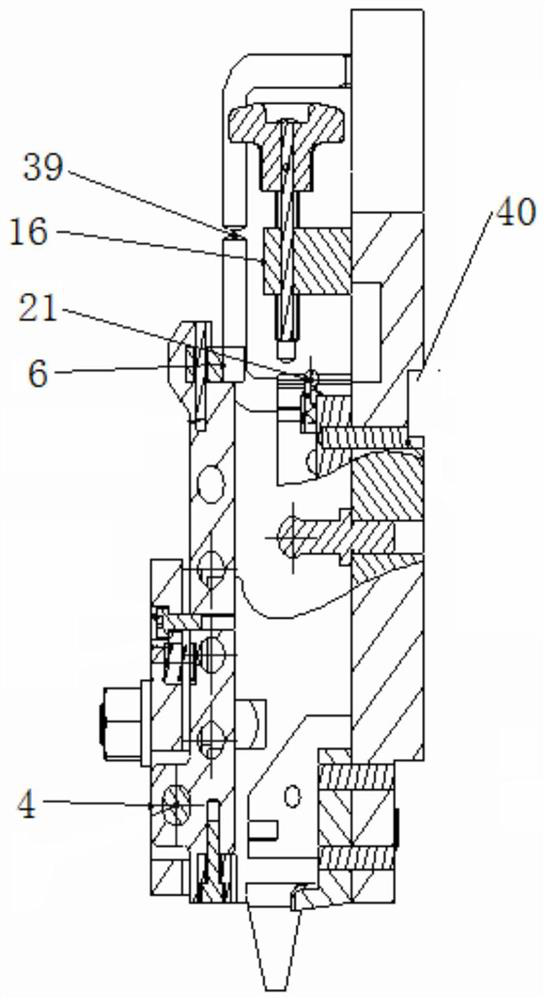

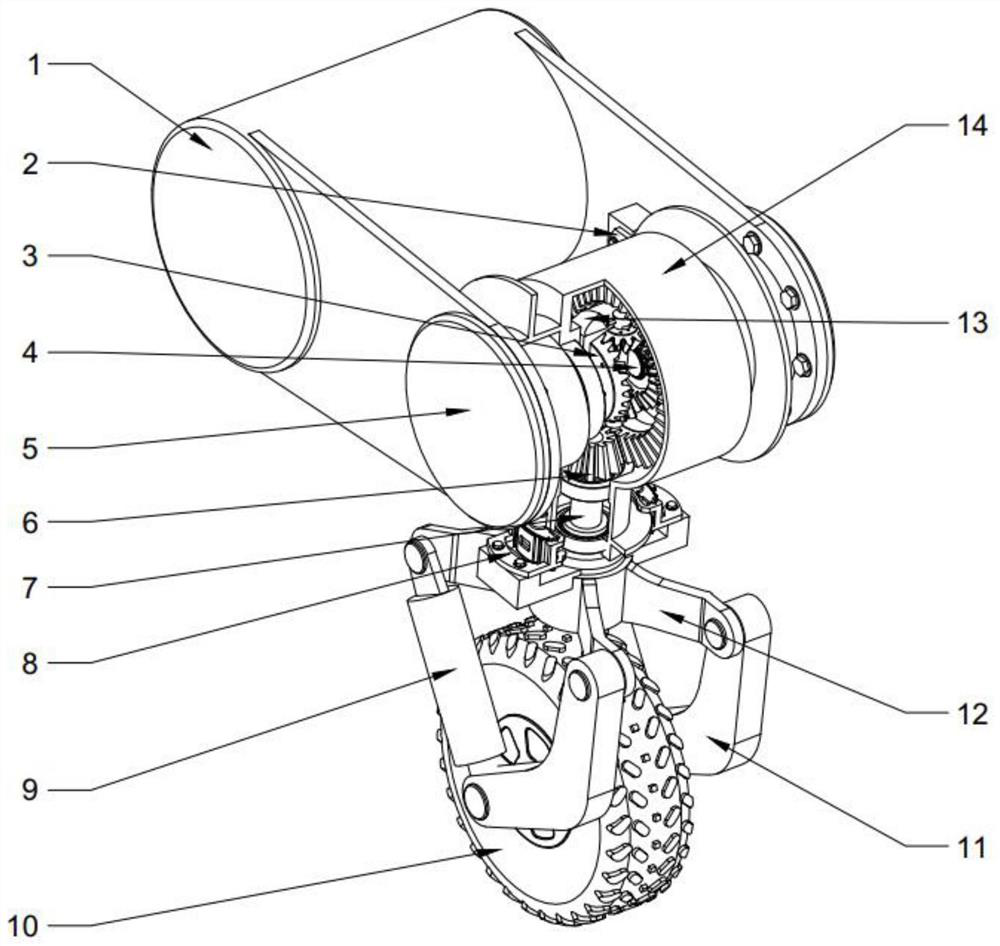

Optical-mechanical integrated rapid control reflector

ActiveCN105572862ARaise the resonant frequencyConstrained degrees of freedomMountingsEngineeringElectric control

The invention discloses an optical-mechanical integrated rapid control reflector, relating to the precision optical-mechanical structure technology field. The optical-mechanical integrated rapid control reflector is aimed to improve the control bandwidth while increasing the caliber of the present reflector and comprises an actuator, an elastic sleeve, a sensor, a sensor induction pad, an elastic revolving center ring, a first axial elastic sheet, a second axial elastic sheet, a center support base, a protective ring, an outer housing, an electric control base plate and a pedestal; the sensor induction pad is fixed on the reflector which is fixedly connected to the actuator through the elastic sleeve; the elastic revolving center is connected to the center hole of the reflector in the axial direction and is connected to the first axial elastic sheet, the second axial elastic sheet and the center support seat in series in the axial direction; the actuator, the sensor, the center support seat and the housing are fixed on the pedestal; a wiring hole is formed in the pedestal; a protective ring is fixed on the housing; the wires of actuator and the sensor are collected on the related circuit board; and the electric control base plate is used for sealing the related circuit board. The invention is applicable to rapid reflectors of various kinds.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

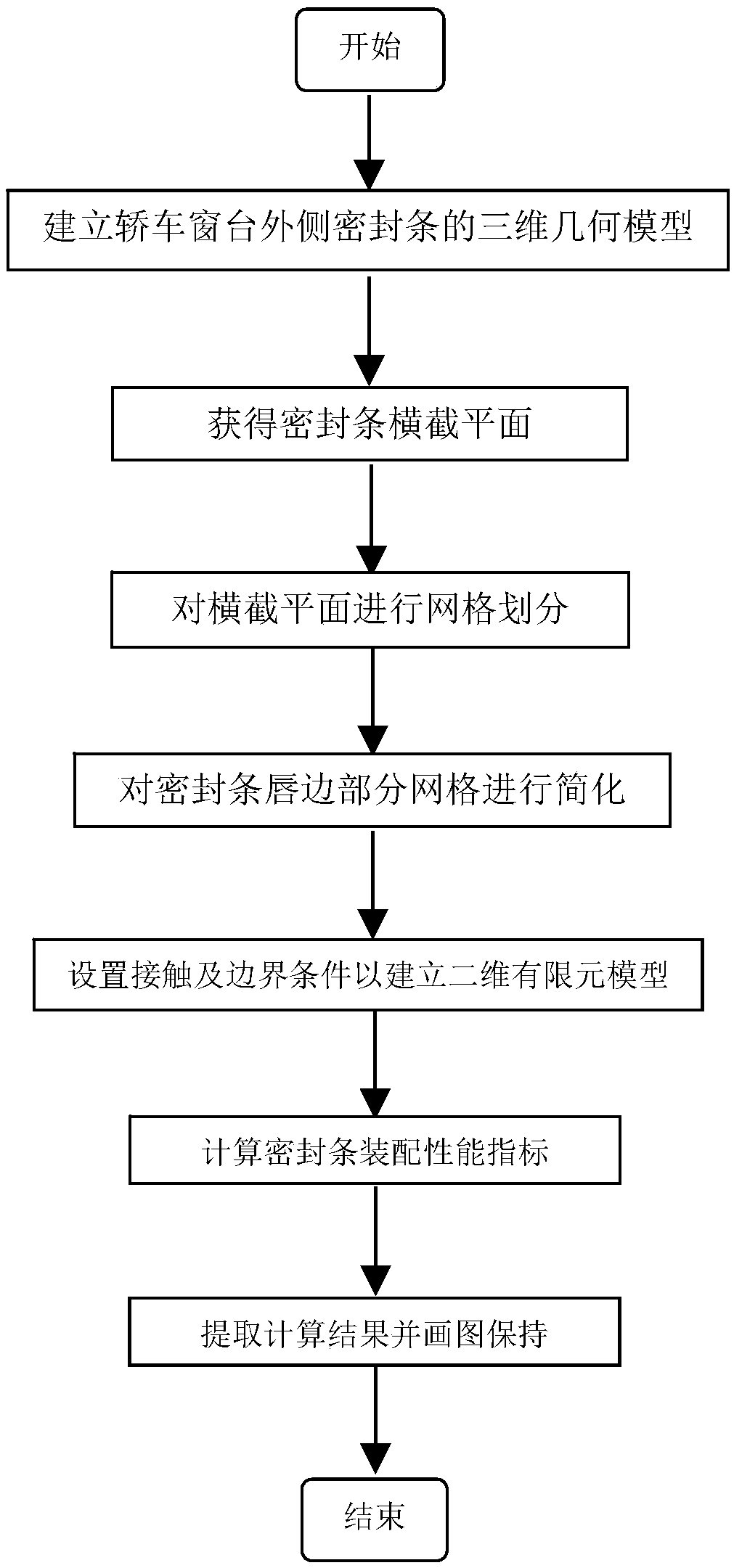

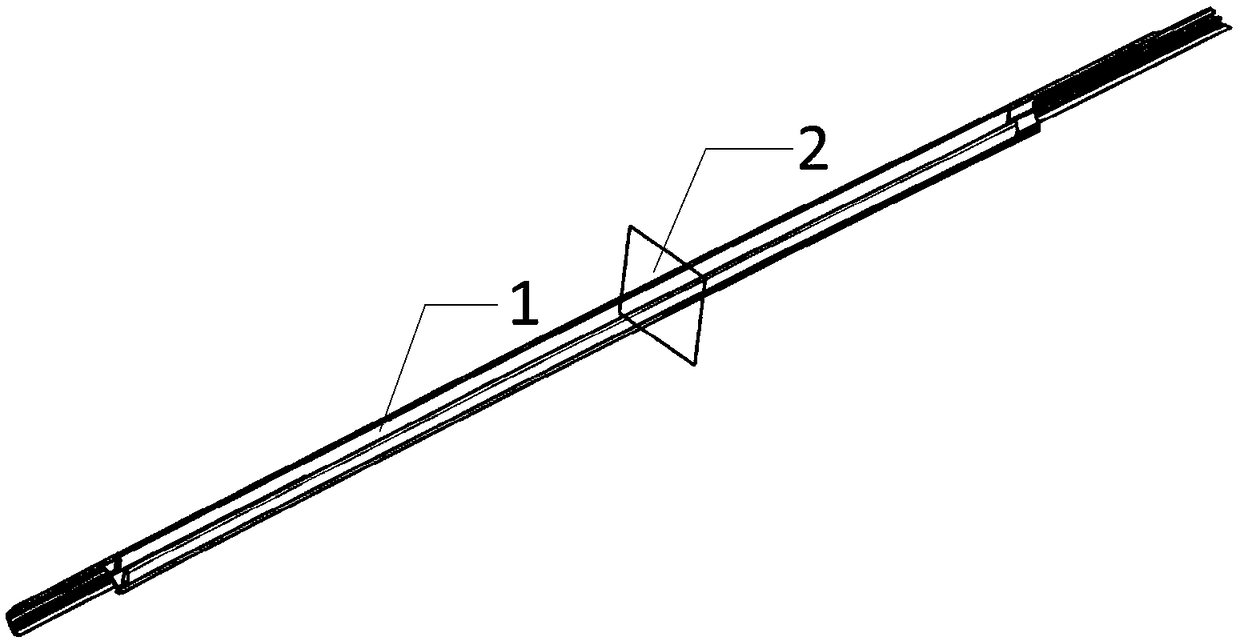

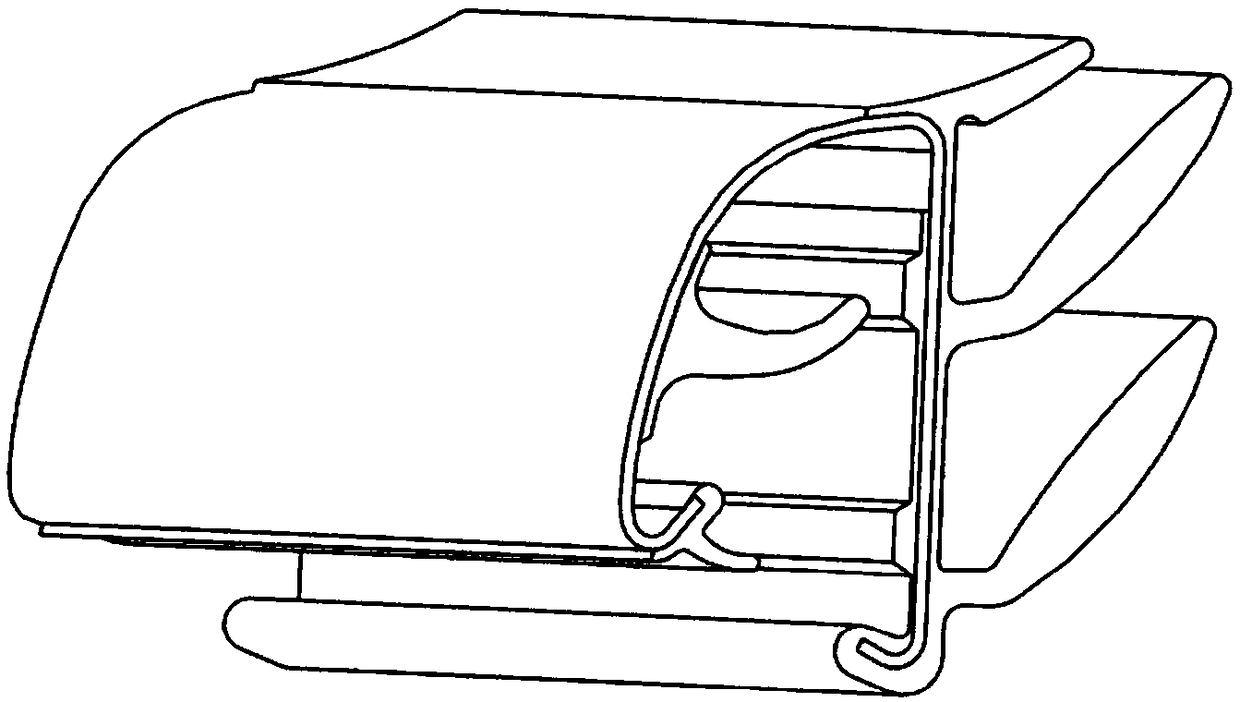

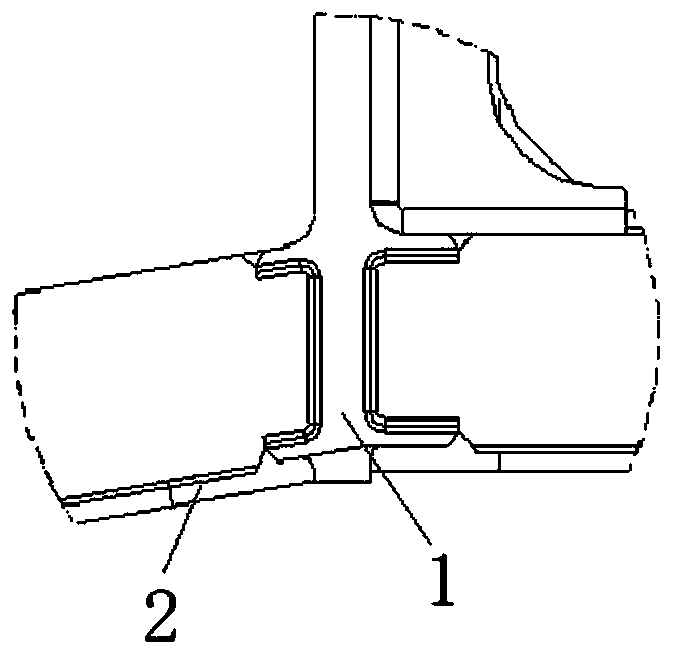

A calculation method for assembling performance of outer sealing strip of car windowsill

PendingCN109308372APredicted Insertion ForcePredicted Gripping ForceGeometric CADDesign optimisation/simulationElement modelWindow sill

The invention discloses a calculation method for assembling performance of outer sealing strip of car window sill, which comprises the following steps: 1) establishing a three-dimensional geometric model and carrying out volume splitting; 2) generating a cross-sectional plane of the sealing strip by using the split three-dimensional geometric model; 3) establish a material constitutive model of that sealing strip accord to the material test; 4) divide that transverse plane into finite element mesh and setting element type; 5) Create a rigid body plane and ignore the deformation of the door sheet metal and define its outer contour curve as a rigid body plane. 6) establish a two-dimensional finite element model for that assembly performance analysis of the sealing strip, and generate an input file which can be recognized by the solver; 7) submit that input file to the solver to obtain the simulation result file, and utilize the post-processing module to process and extract the relevant data and save the drawing. The invention greatly improves the calculation efficiency, more accurately simulate the actual loading situation of the outer sealing strip of the car window sill, and the structure type of the analyzable sealing strip is more than the existing calculation method.

Owner:SOUTH CHINA UNIV OF TECH

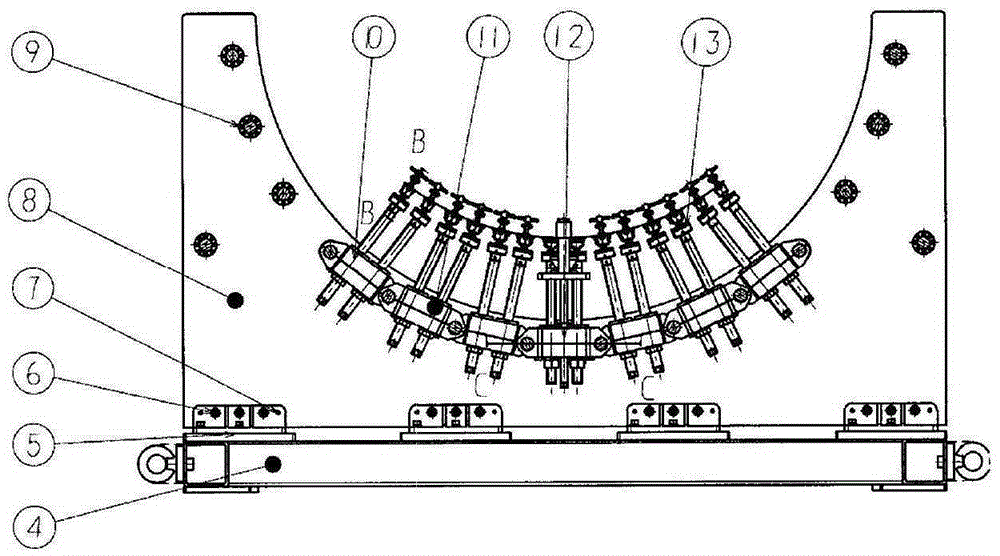

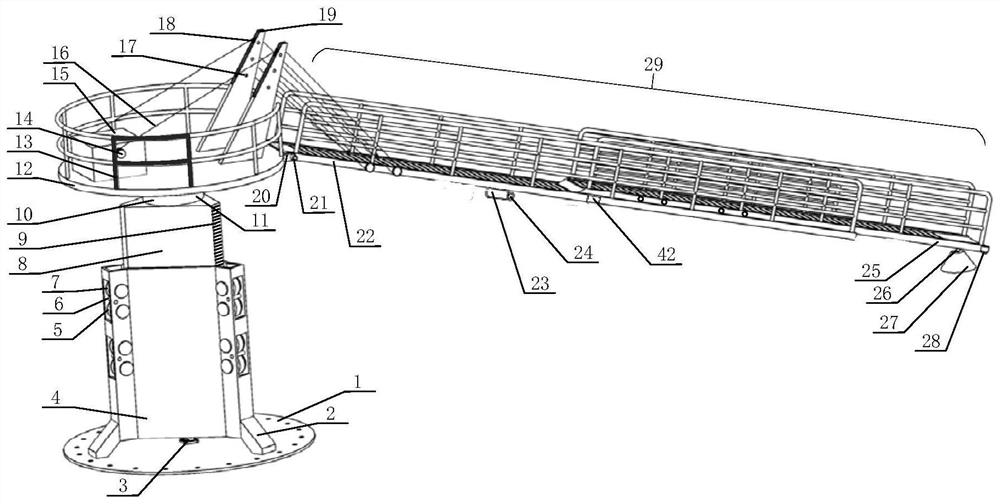

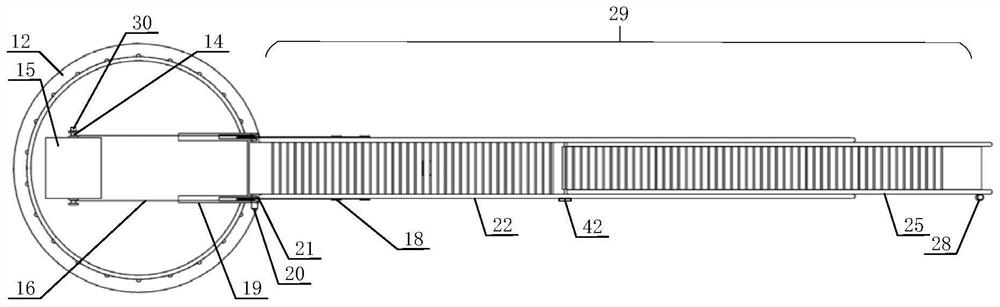

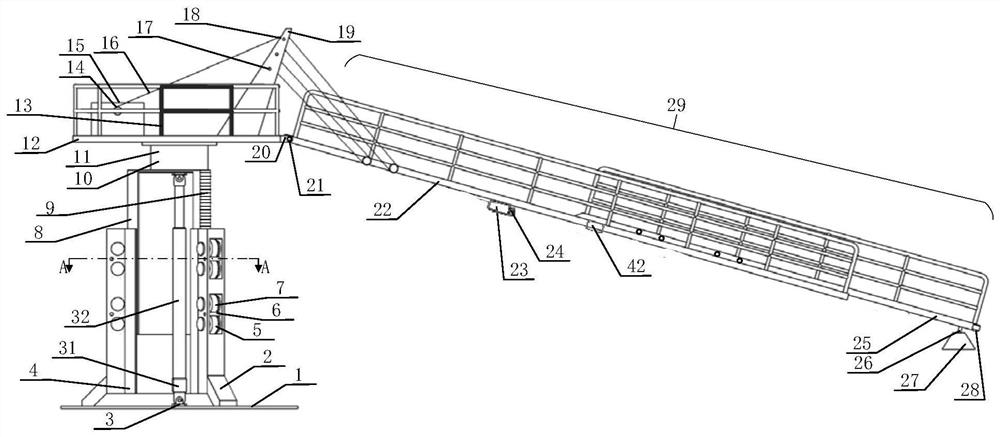

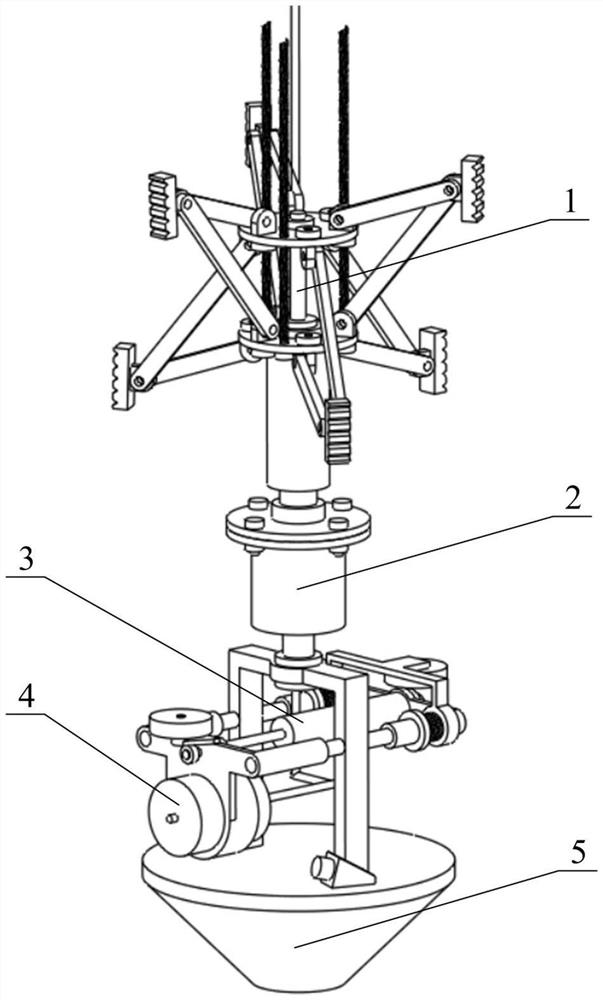

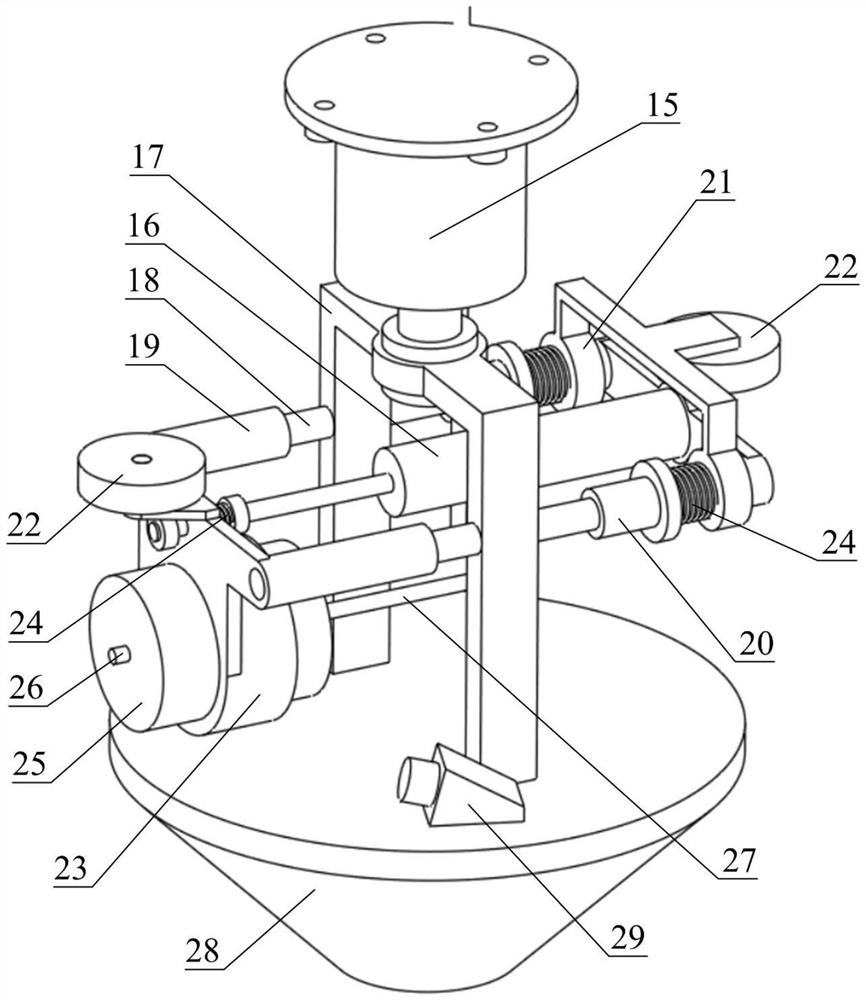

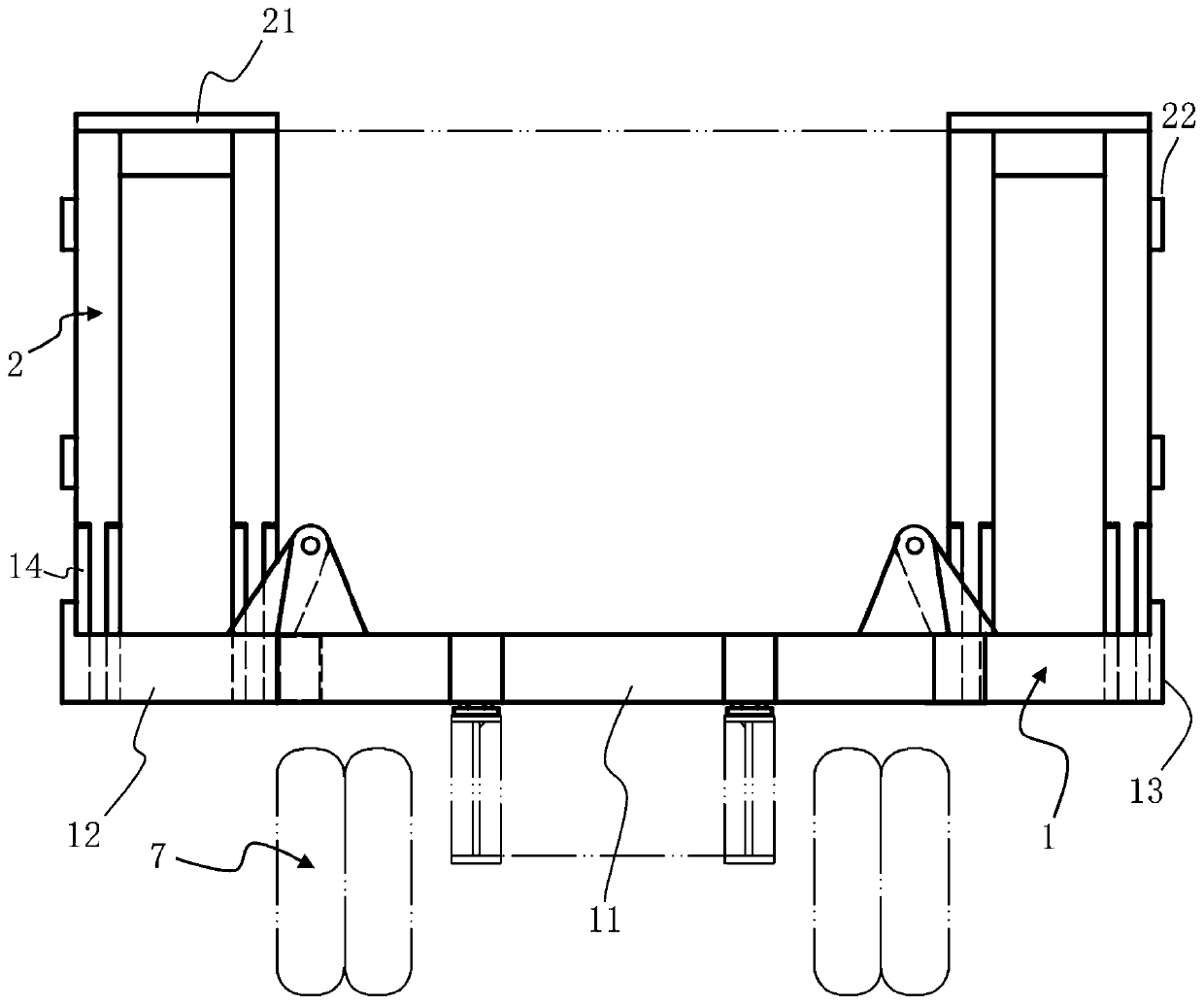

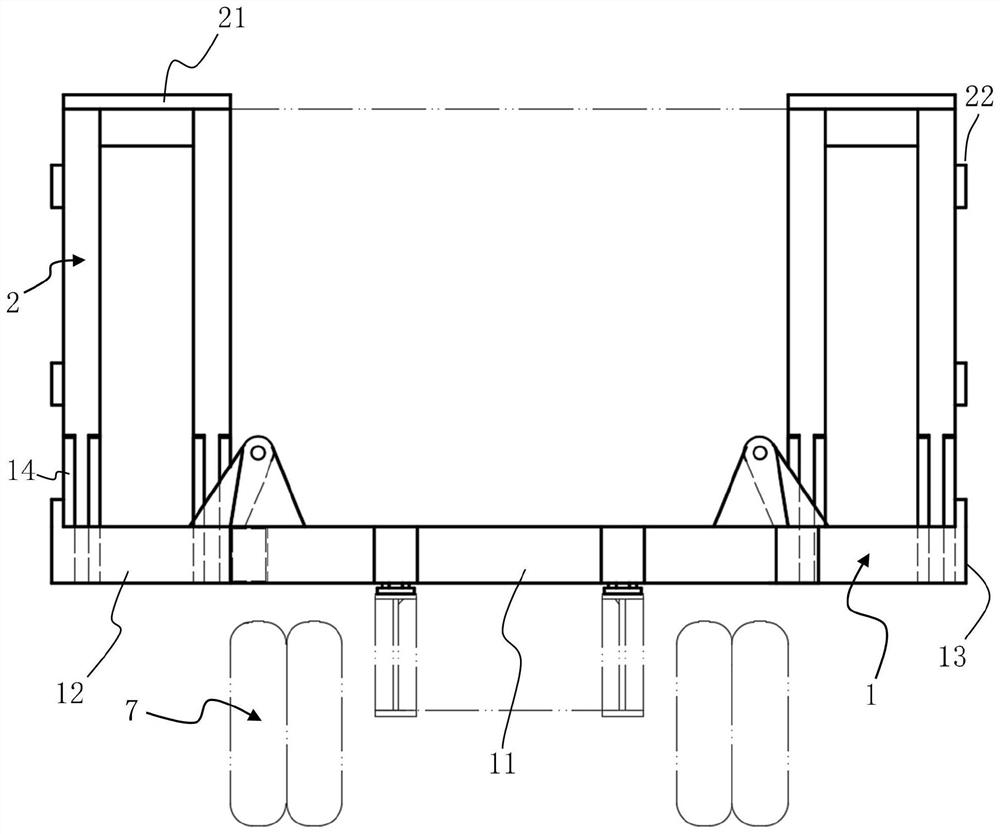

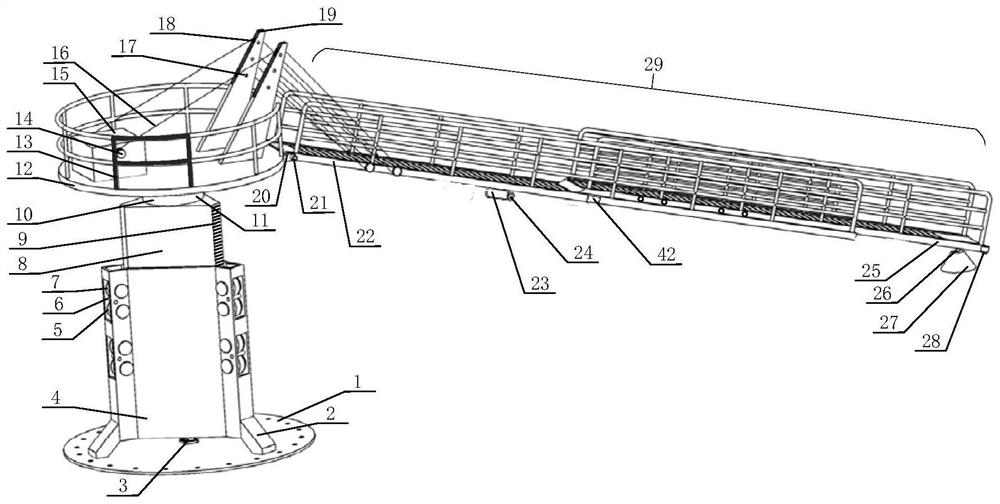

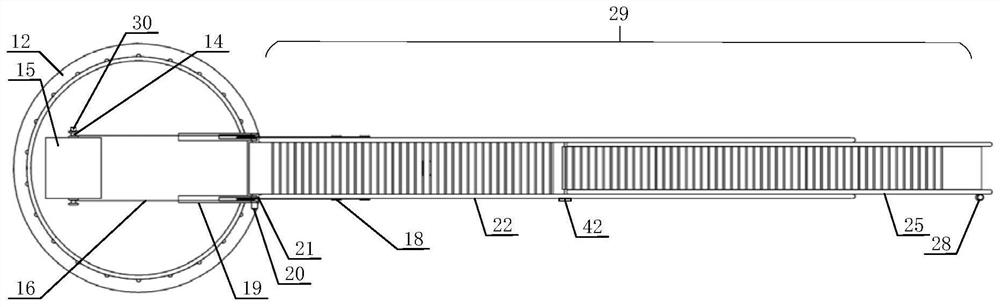

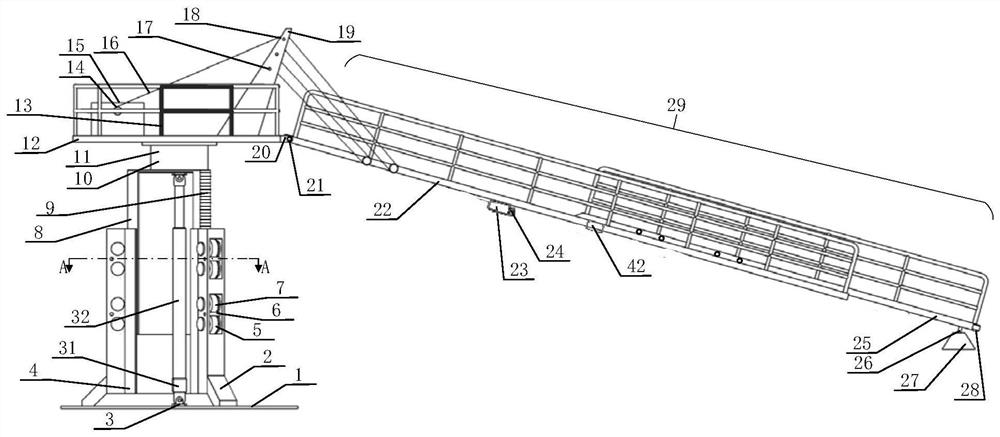

Offshore transfer trestle with wave compensation function and working method thereof

ActiveCN113232768AImprove securityImprove comfortCargo handling apparatusVessel partsFreeboardMarine engineering

The invention discloses an offshore transfer trestle with a wave compensation function and a working method thereof. The offshore transfer trestle comprises a heaving mechanism, a trestle system and an active wave compensation control system. According to the invention, the disturbance to the transfer trestle caused by the swaying motion of the two ships can be compensated, even if a freeboard difference exists between the host ship and the target ship, the safe angle between the trestle body and the horizontal plane can still be kept unchanged in the personnel transfer process of the transfer trestle, and the safety and comfort of personnel transfer between the two ships on the sea are improved. After lap joint of the transfer trestle is completed, the front end of the trestle body is fixedly connected with a transfer point, and in the personnel transfer process, the safe angle between the trestle body and the horizontal plane is kept unchanged only by controlling the heaving mechanism. The front end of the trestle body and the transfer point are fixedly connected through the electromagnetic landing cones, an additional mechanical device is not needed for fixing, the trestle body can be rapidly separated from the transfer point in an emergency, emergency lifting is achieved, and safety is improved.

Owner:DALIAN MARITIME UNIVERSITY

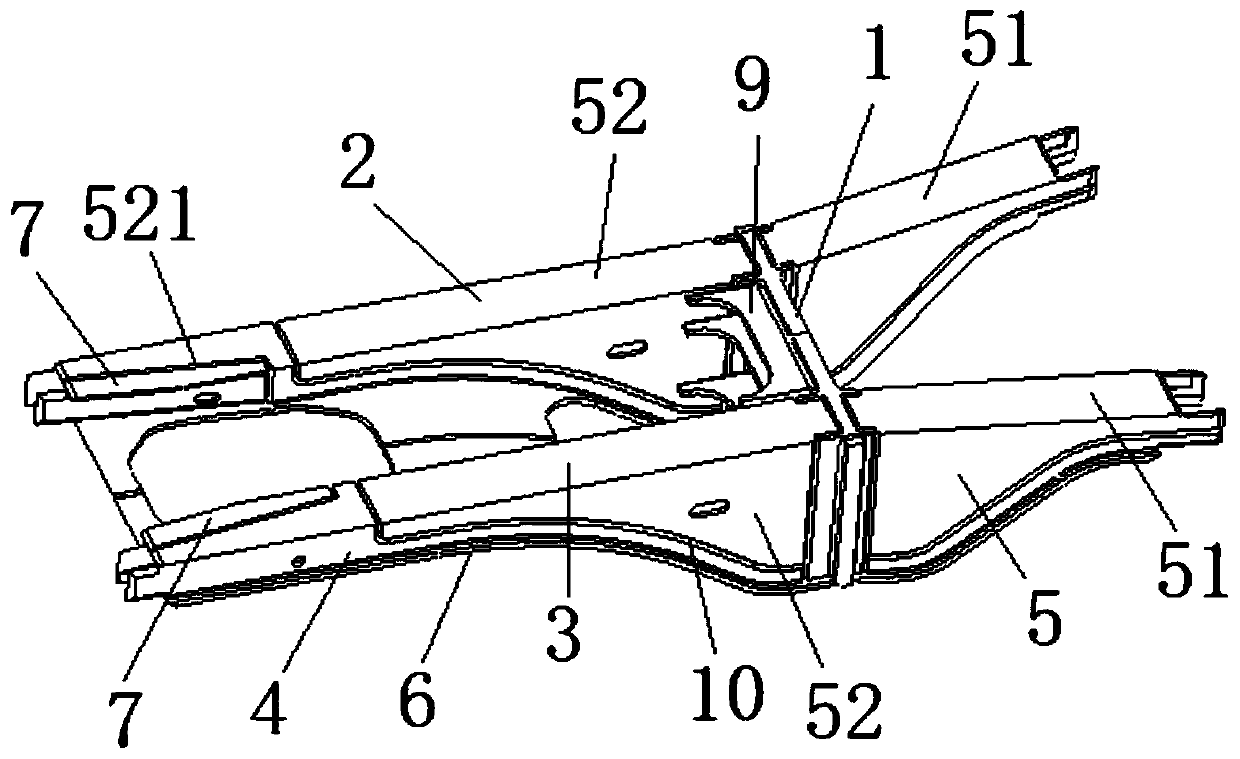

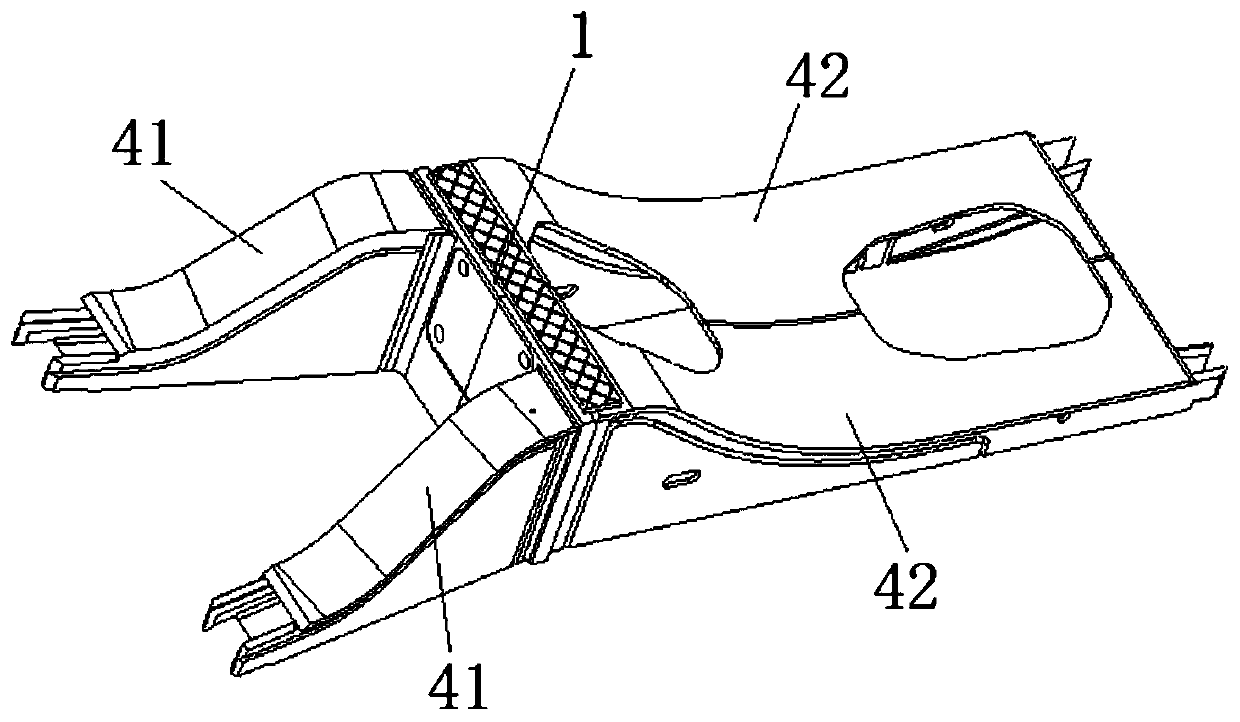

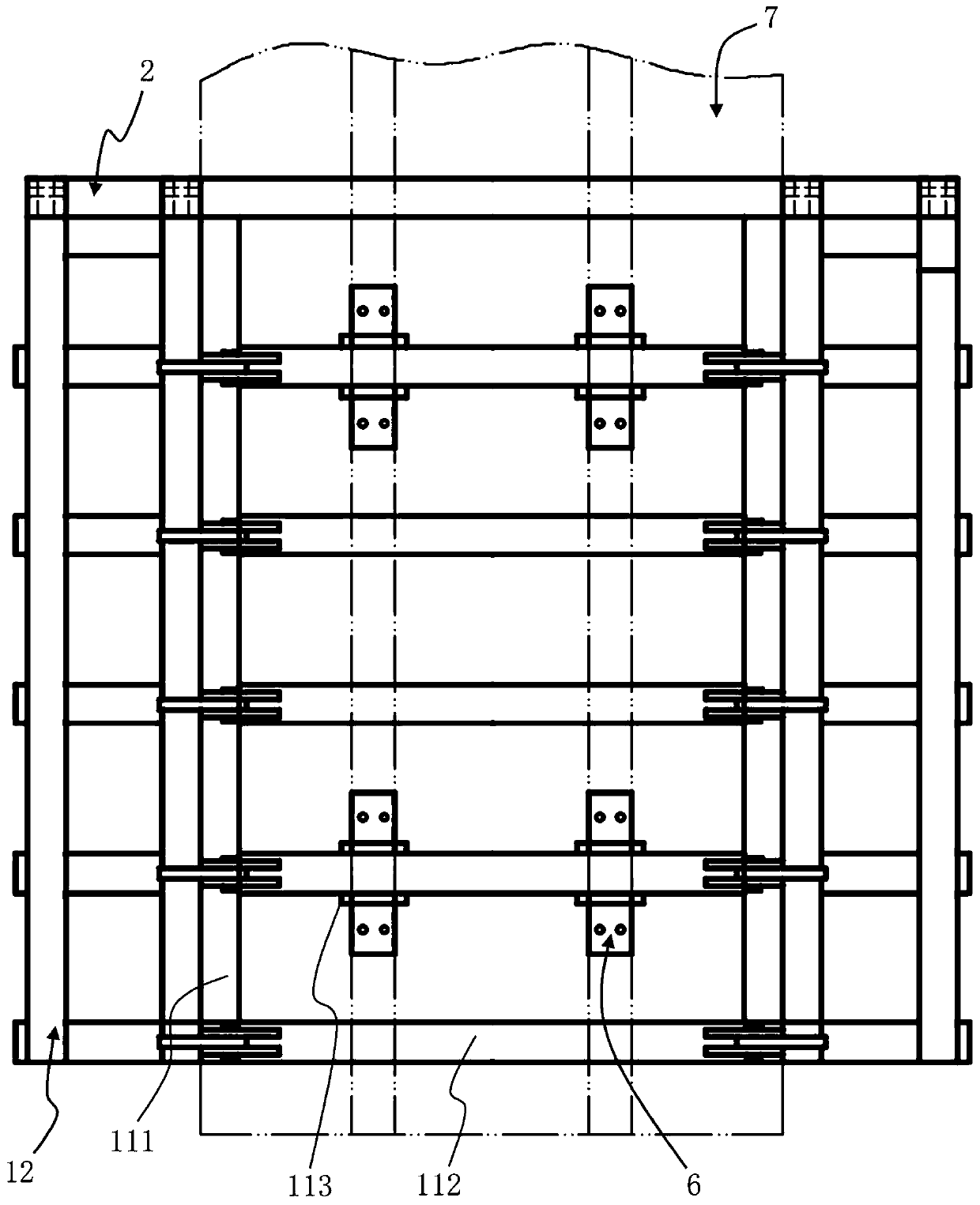

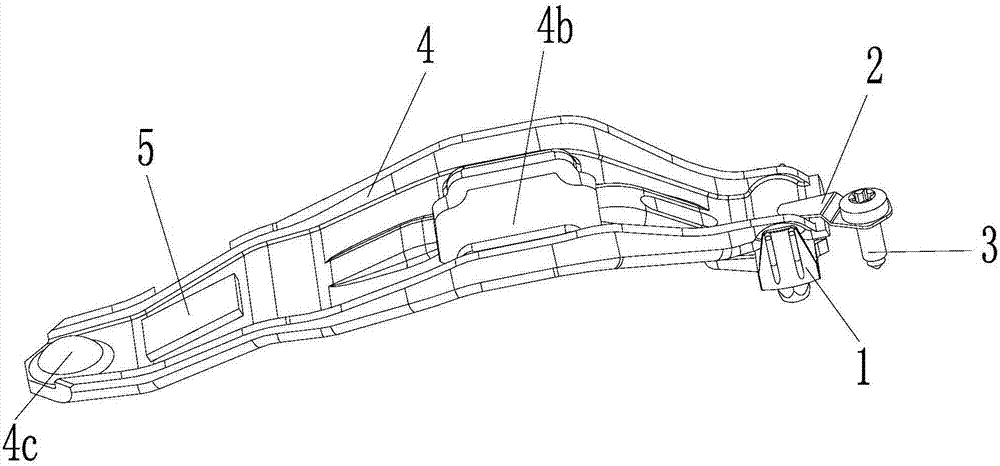

Traction beam structure, end chassis with traction beam structure and rail vehicle

ActiveCN110155097AConstrained degrees of freedomRealize automatic weldingUnderframesEngineeringWelding

The invention relates to the technical field of rail vehicles, and discloses a traction beam structure, an end chassis with the traction beam structure and a rail vehicle. The traction beam structurecomprises a coupler mounting seat, a first traction beam body and a second traction beam body, wherein the first traction beam body and the second traction beam body are oppositely arranged and are arranged on the two sides of the coupler mounting seat correspondingly, the first traction beam body and the second traction beam body both comprise lower cover plates and traction beam web plates whichare arranged at the upper ends of the lower cover plates and are in butt joint with the lower cover plates, V-shaped grooves are formed in the butt joint positions of the lower cover plates and the traction beam web plates, and the edges of the traction beam web plates protrude out of the edges of the lower cover plates to form mounting parts. The traction beam structure has the advantages of being capable of realizing automatic welding, good in welding quality and small in deformation after welding.

Owner:CRRC QINGDAO SIFANG CO LTD

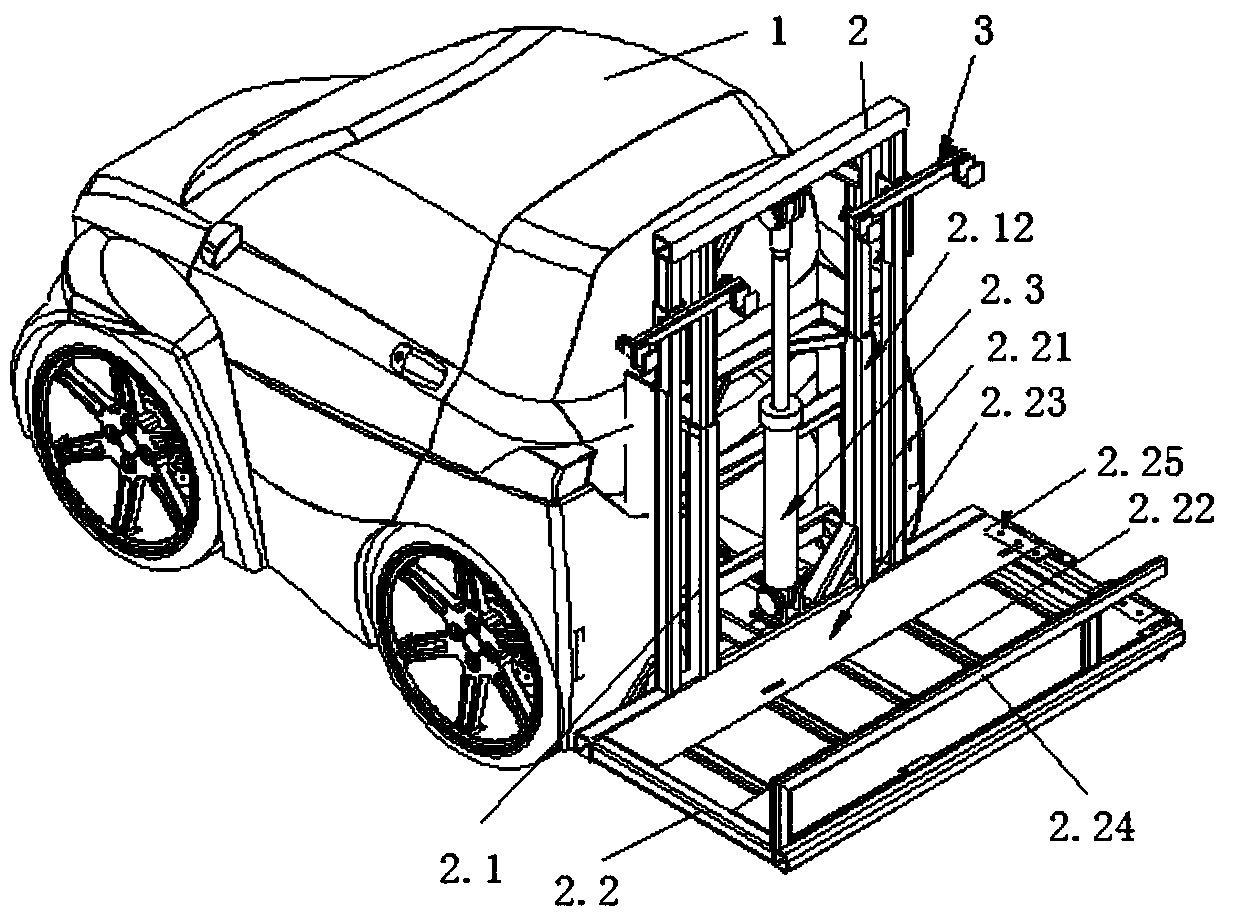

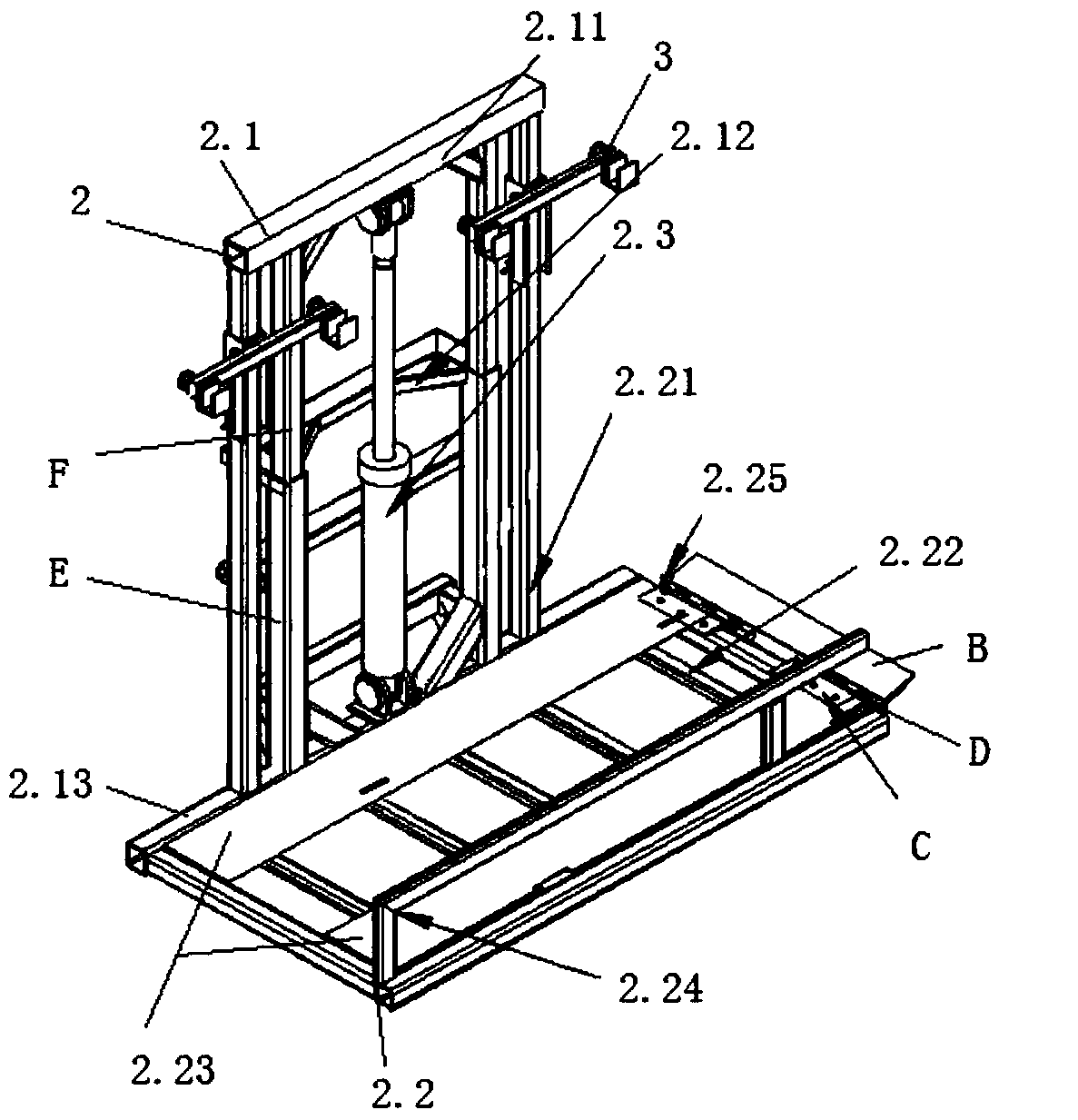

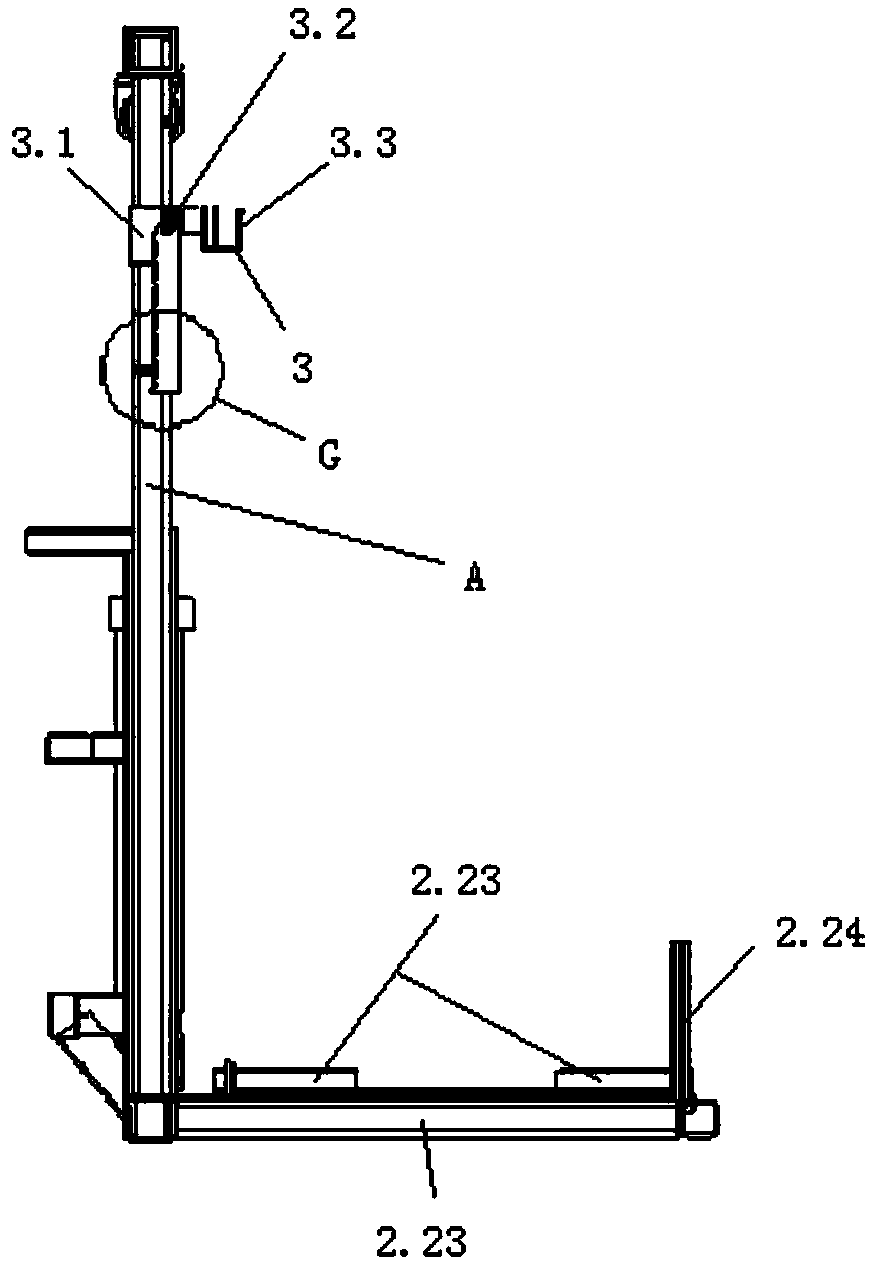

Garbage can transfer trolley for narrow road

PendingCN109368103AReduce vibrationSimple structureRefuse vehiclesWaste collection and transferModular designIndustrial engineering

The invention provides a garbage can transfer trolley for a narrow road. The garbage can transfer trolley comprises an electric trolley, a lifting device and a locking device, wherein the lifting device comprises a guide rail, a lifting rack and a telescopic part; the guide rail comprises an upper supporting seat, a guide rail rack and a lower supporting seat; the lifting rack comprises a verticalrack and a horizontal rack; the upper end of the telescopic part is arranged on the upper supporting seat; and the lower end of the telescopic part is arranged on the lower supporting seat. Accordingto the garbage can transfer trolley, the integral structure is simple, and mounting, disassembly and maintenance are convenient through modular design of the electric trolley, the lifting device andthe locking device; the electric trolley can be purchased from the market, and the tail part of the electric trolley is correspondingly changed to fix the lifting device and the locking device; the lifting device has the main function of rising the lifting rack to be flush with a road shoulder, so that a garbage can is placed from the side, and the lifting device has a function of fixing the locking device; the telescopic part provides driving force for up-down moving of the lifting rack; and the locking device has the main function of fixing the garbage can, so that vibration of the garbage can during transportation is reduced, and stability of the transportation process is improved.

Owner:HUNAN UNIV

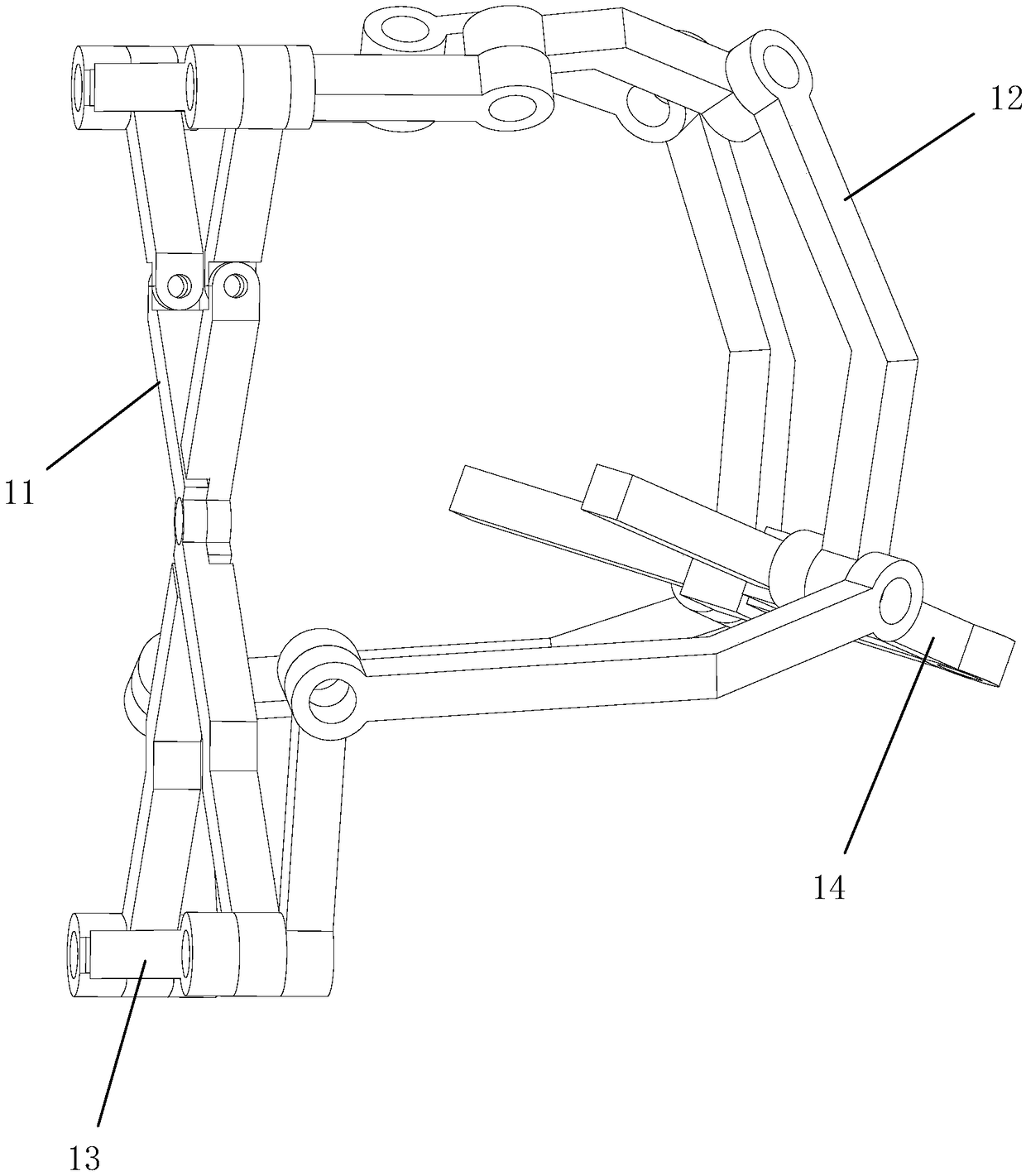

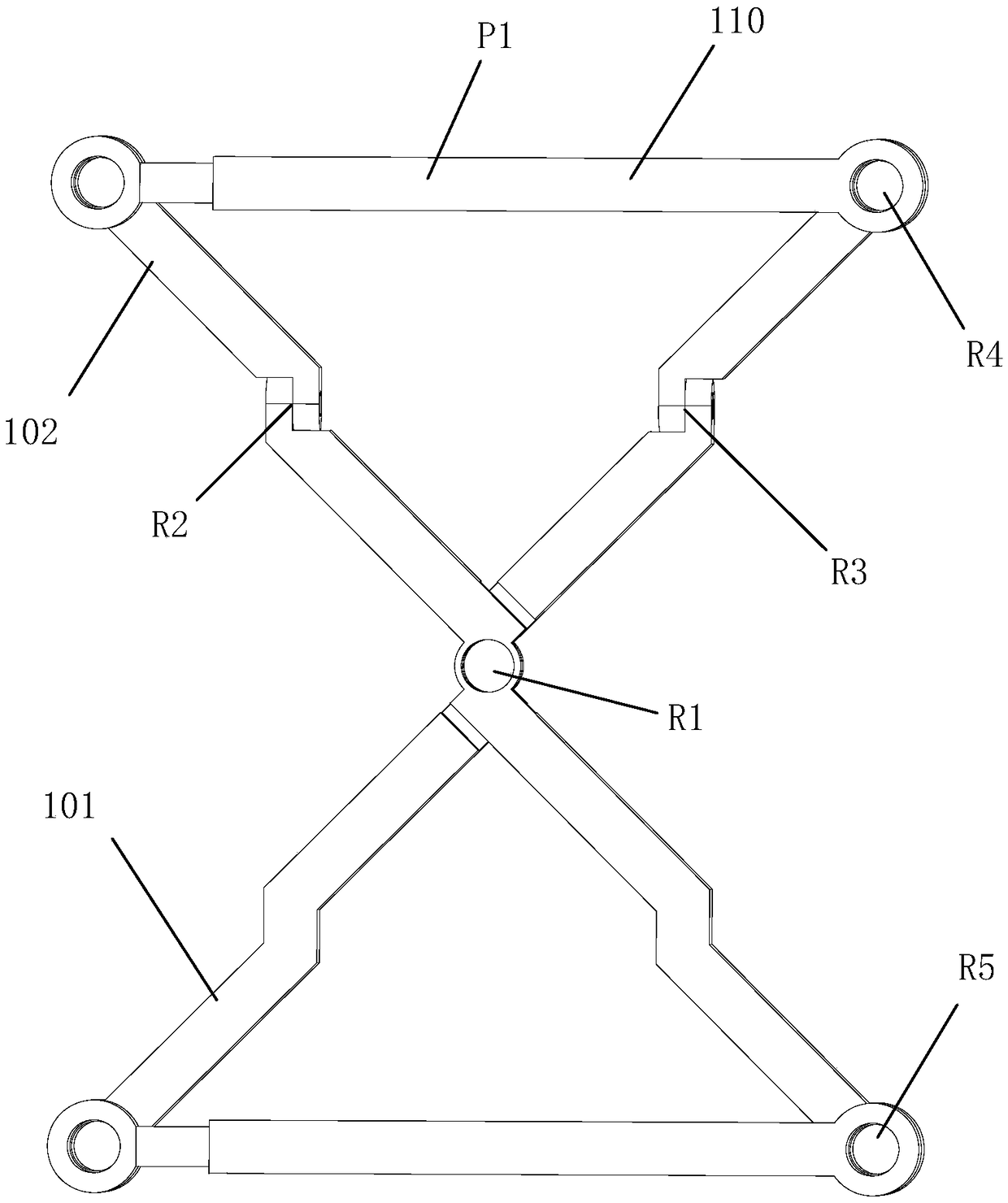

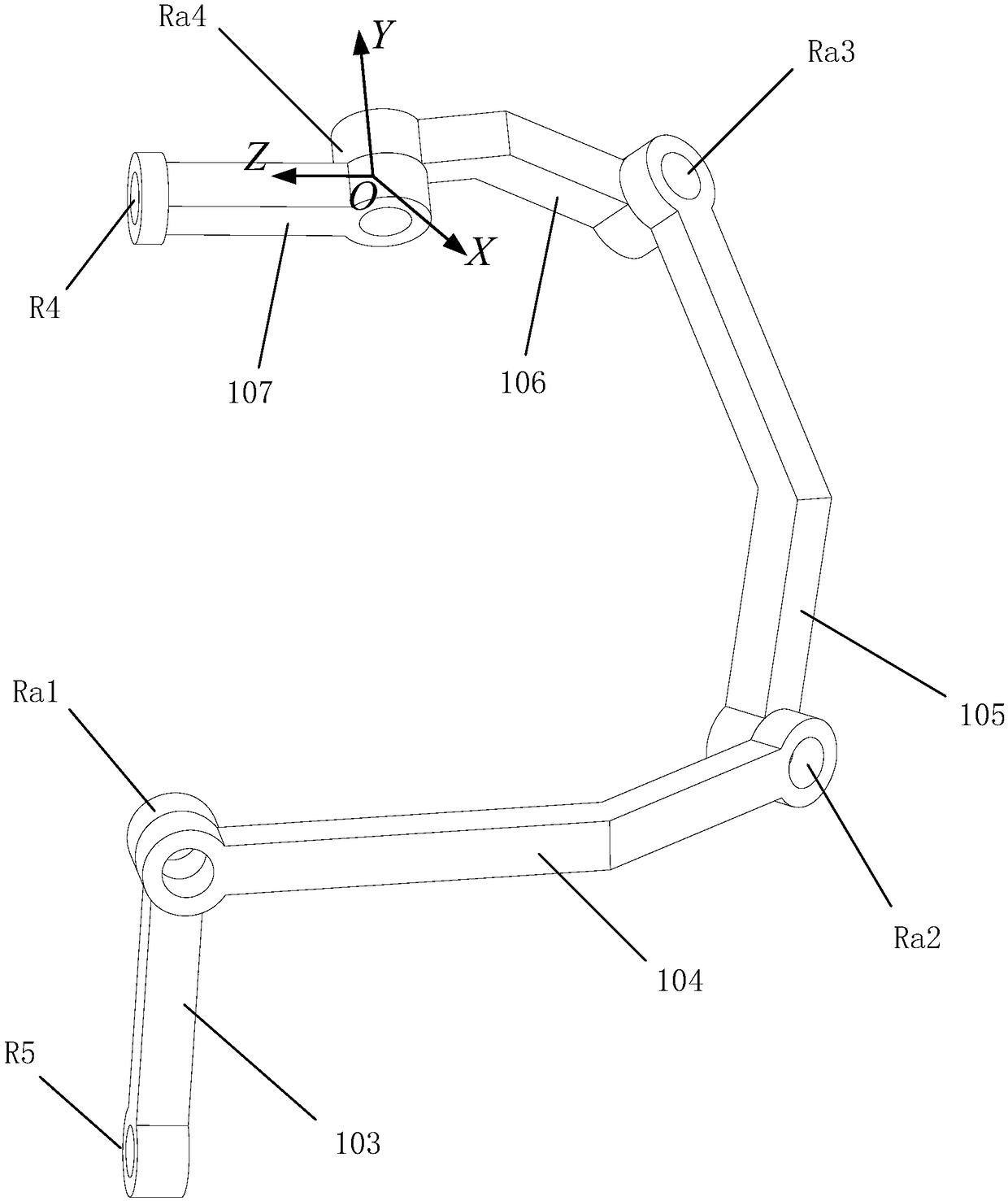

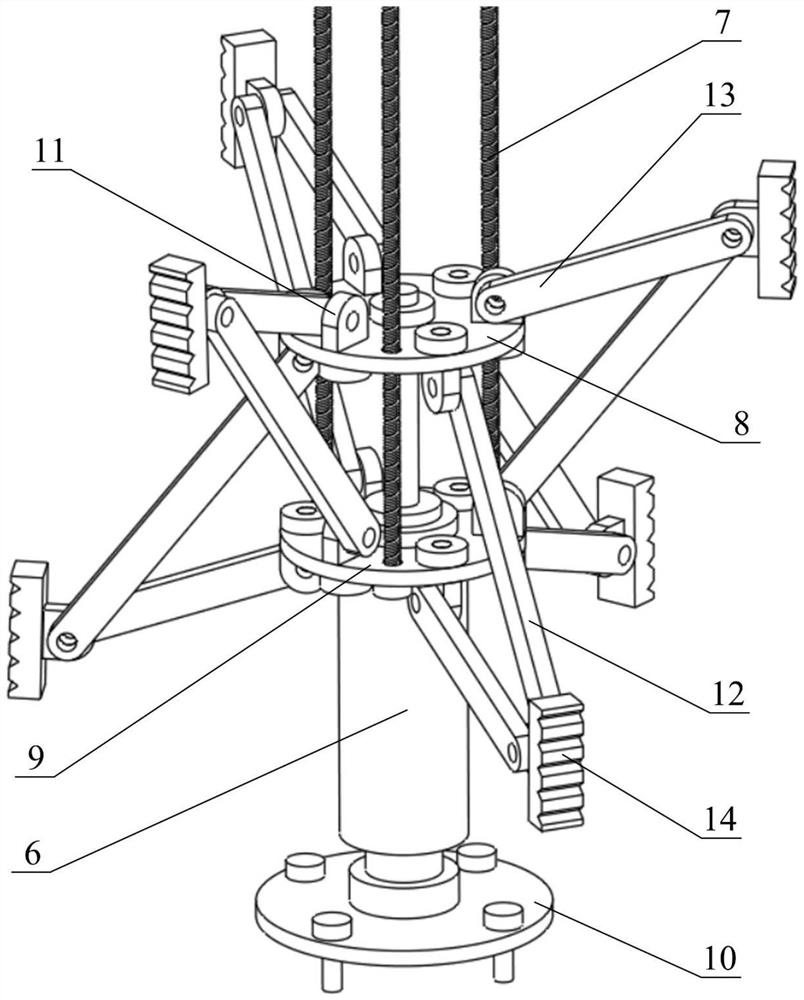

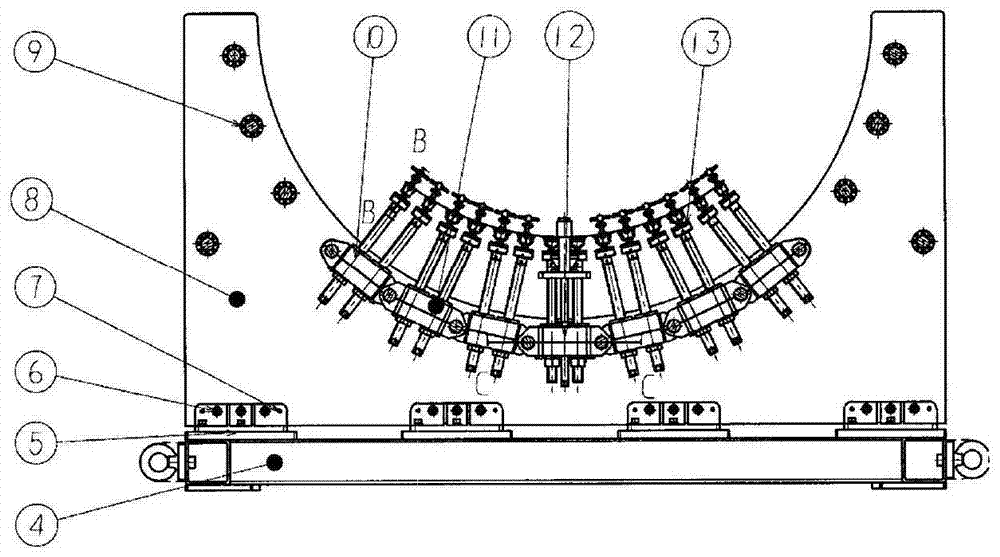

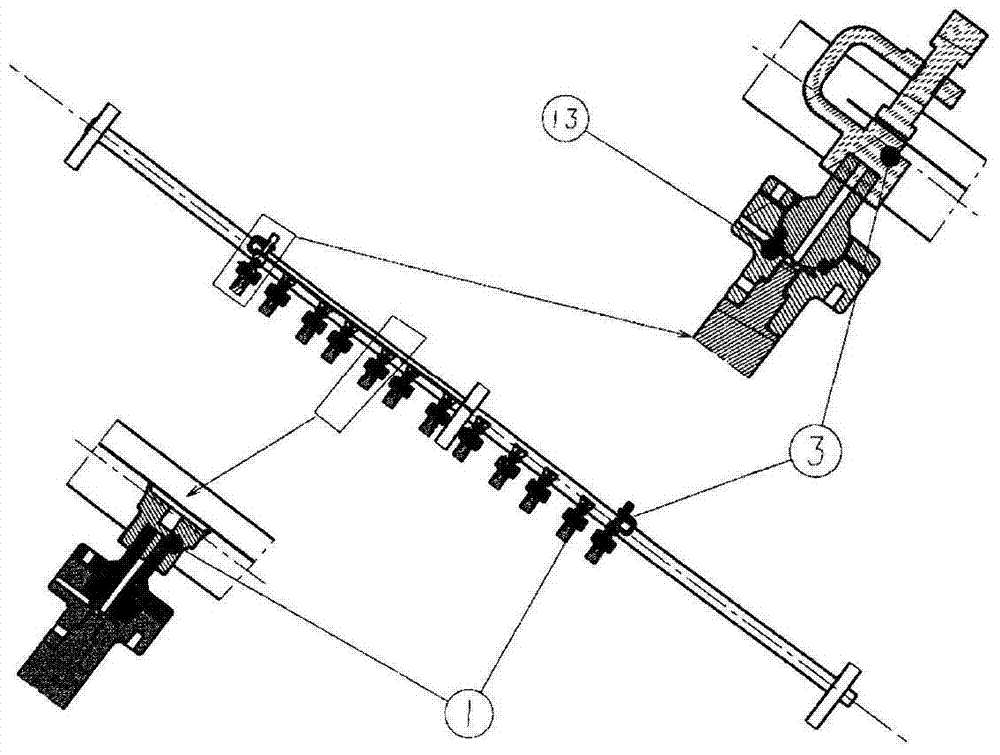

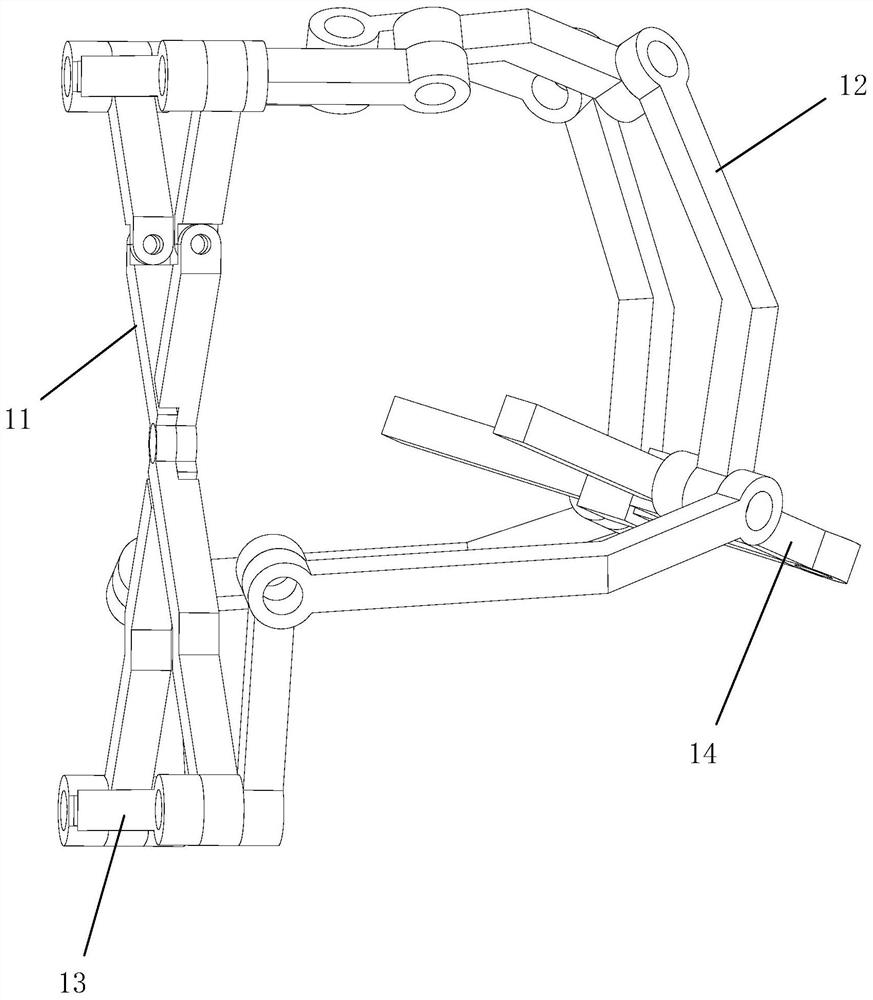

Foldable catching metamorphic mechanism based on constraint screw.

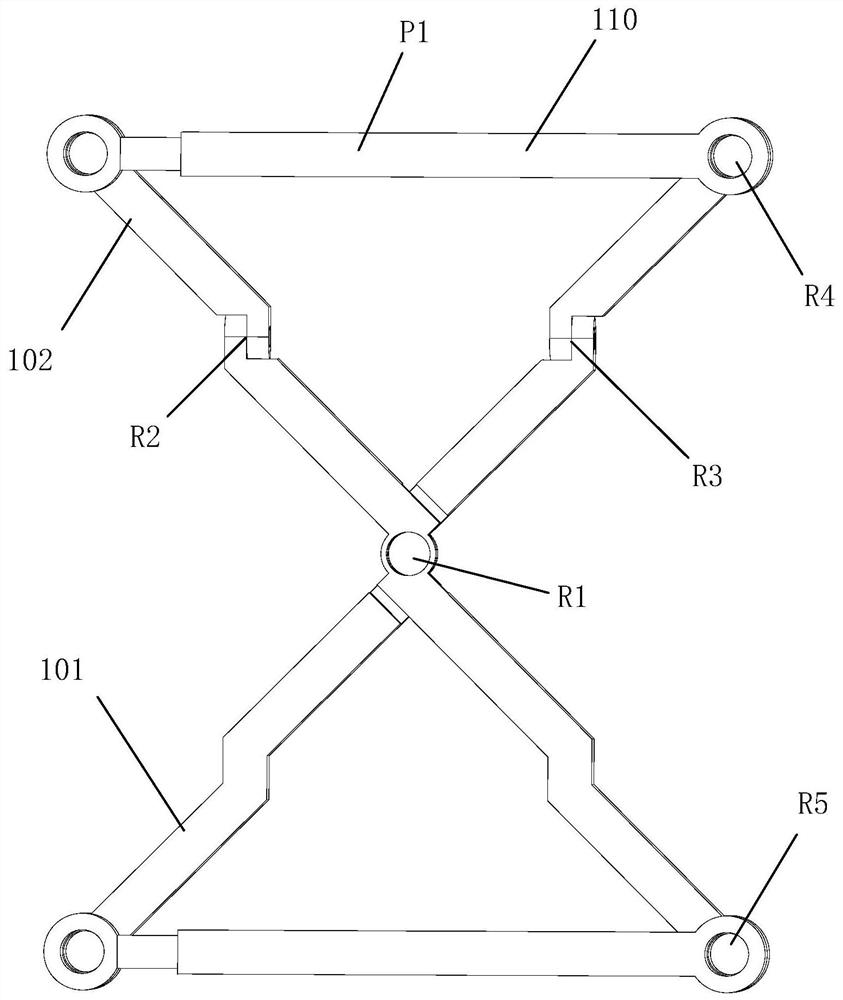

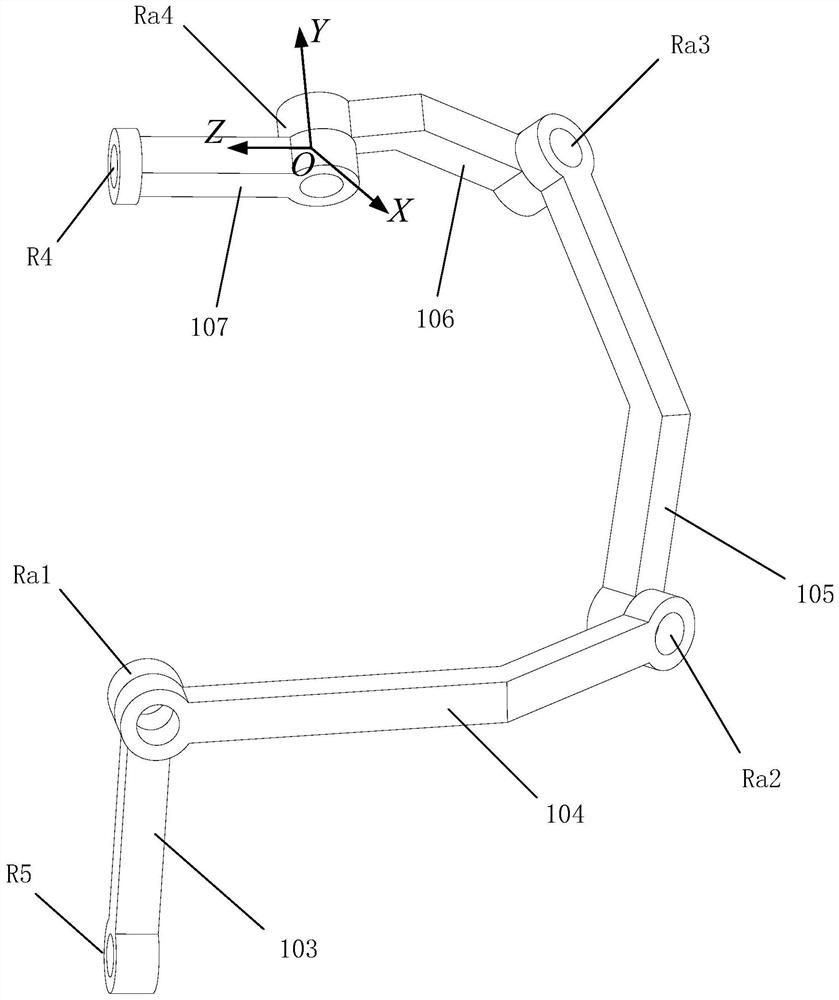

ActiveCN108657473AConstrained degrees of freedomGuaranteed stiffnessProgramme-controlled manipulatorToolsEngineeringDegrees of freedom

The invention provides a foldable catching metamorphic mechanism based on constraint screw. The foldable catching metamorphic mechanism based on constraint screw comprises a plurality of identical metamorphic units. Each of the metamorphic units comprises a catching mechanism, and the catching mechanism comprises two scissor-shaped rods, two connecting rods, and the two scissor-shaped rods are connected with each other through a rotating pair R1 to form a scissor-shaped mechanism. The bottom ends of the two connecting rods are connected to the top ends of the two scissor-shaped rods separatelythrough a rotating pair R2 and a rotating pair R3, and rotating branch mechanisms comprise first rotating rods, second rotating rods, third rotating rods, fourth rotating rods and fifth rotating rods, wherein the first rotating rods, the second rotating rods, the third rotating rods, the fourth rotating rods and the fifth rotating rods are rotatably connected in sequence. The fifth rotating rodsare connected to the top end of the connecting rods through a rotating pair R4, the first rotating rods are connected to the bottom end of the scissor-shaped rods through a rotating pair R5, and the two rotating branch mechanisms are connected to each other through a hinge mechanism. By controlling the redundant degrees of freedom and retaining the two degrees of freedom, that is the folding and catching, the foldable catching metamorphic mechanism reduces the number and types of degrees of freedom in order to simplify the structure.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

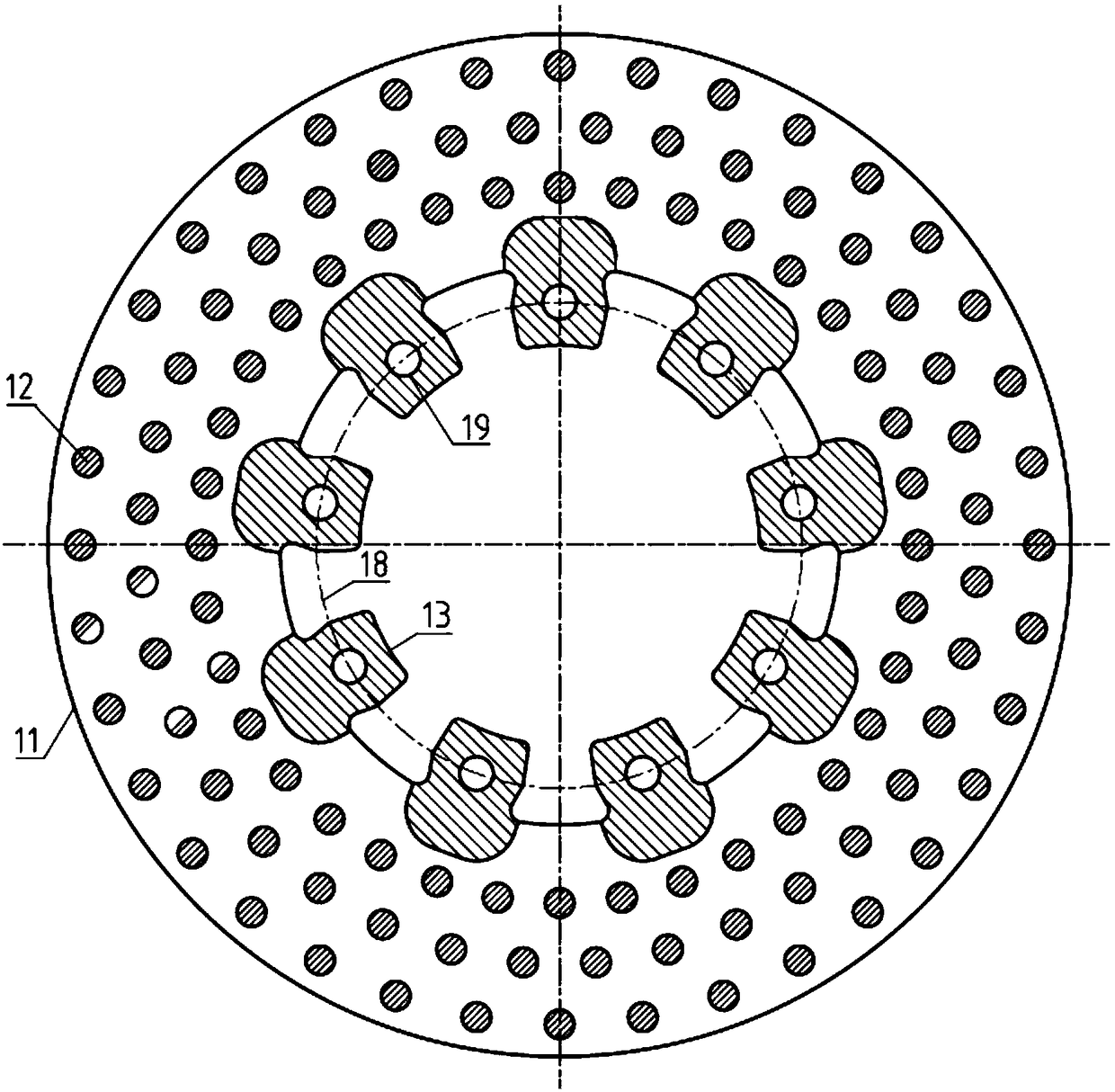

Focal plane assembly adjusting device and method

ActiveCN111766671ARealize six-dimensional adjustmentCooperate wellMountingsOptic systemMechanical engineering

The invention relates to a focal plane assembly adjusting device and method. The focal plane assembly is composed of a detector and a detector mounting plate, and an adjusting device comprises a fixing screw, a screw for adjusting and tightening and a locking screw. Four mounting corners of the detector mounting plate are designed into flexible structures, the flexible design ensures that the detector is provided with six-dimensional degree of freedom and has necessary strength, and the adjustment of different dimensions of the detector mounting plate can be realized through the adjusting andtightening screws at different positions, so that an optical system is ensured to meet a certain precision requirement, and the detector mounting plate is locked through the locking screws after the adjustment is completed. The device is simple in structure and convenient to adjust, high-precision adjustment of the focal plane can be achieved, and six-dimensional adjustment of the focal plane assembly is achieved.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

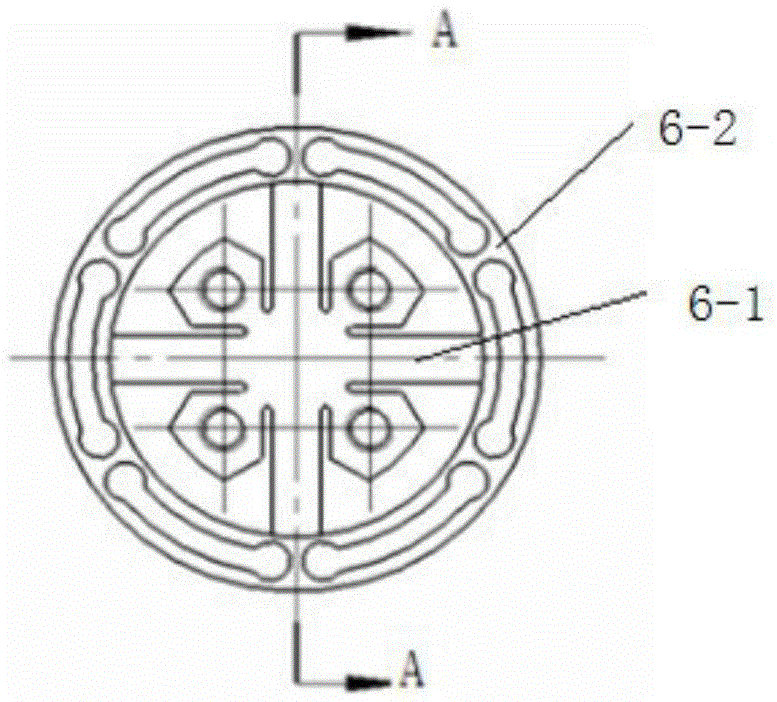

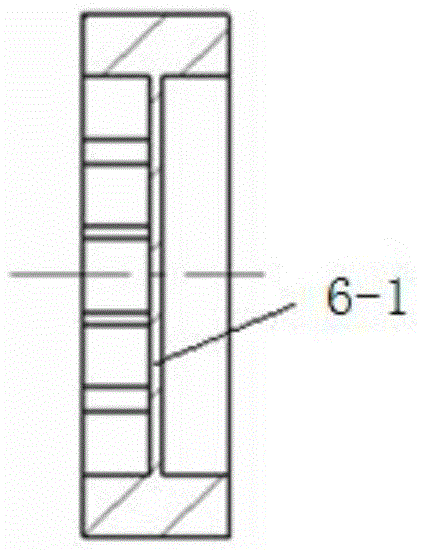

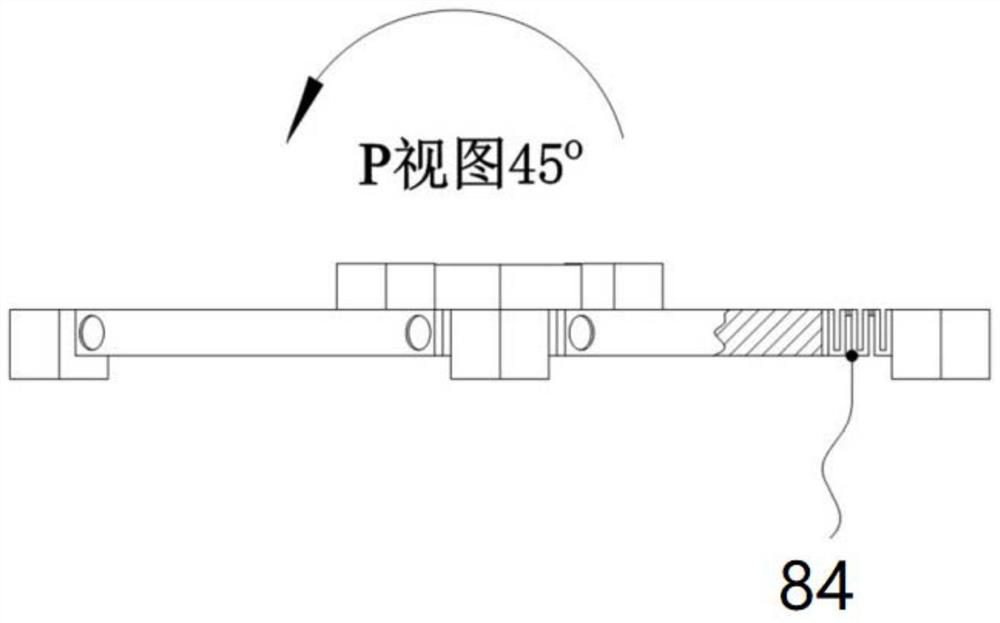

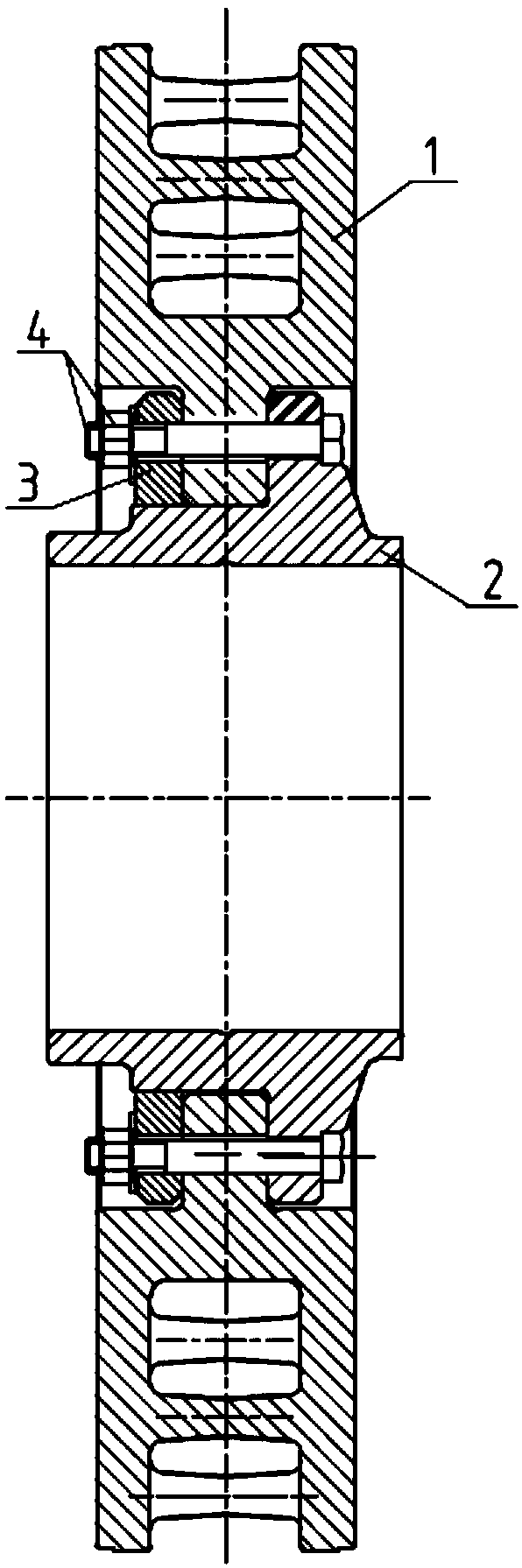

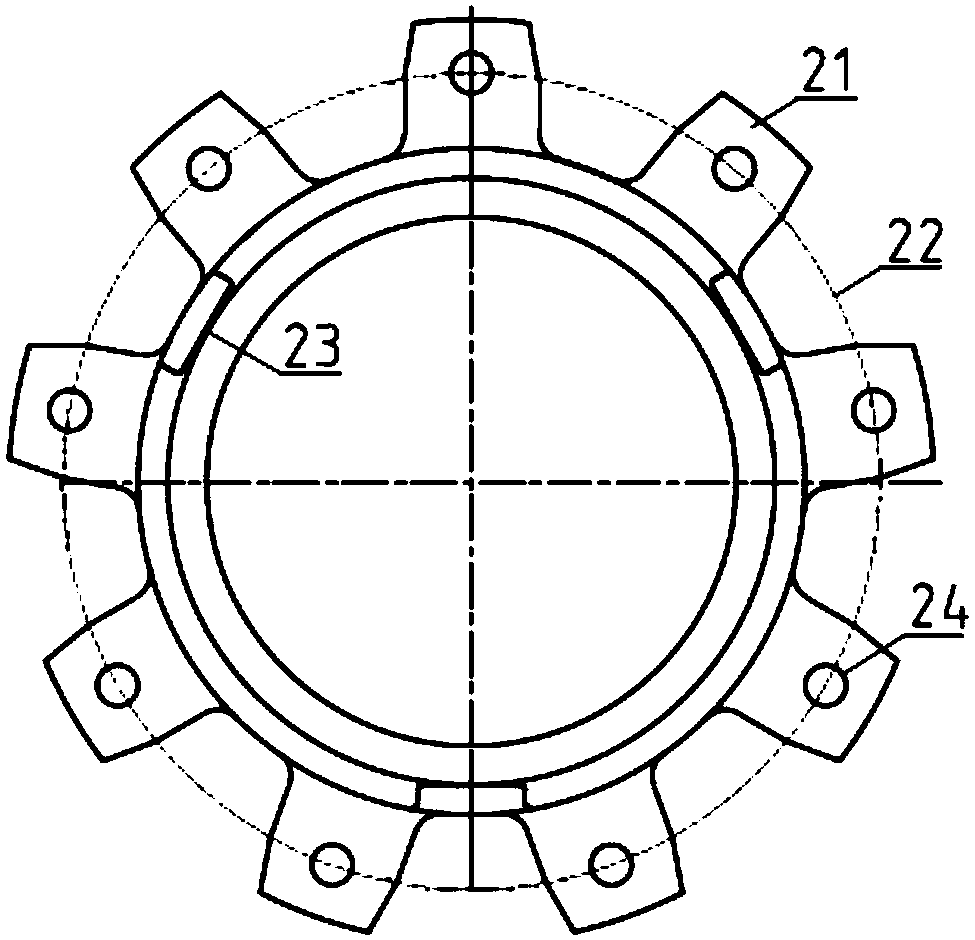

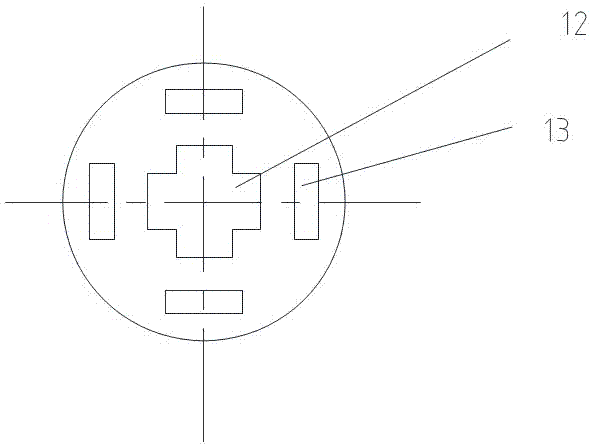

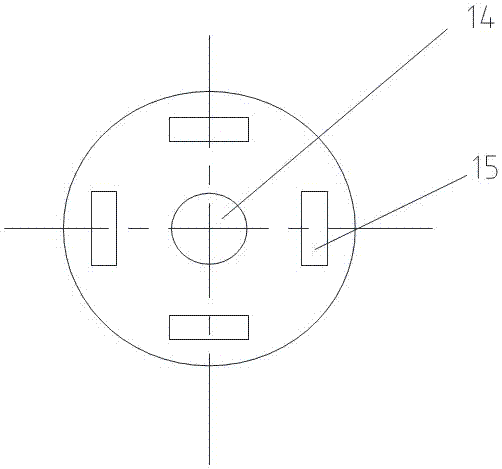

High-speed train shaft-mounted brake disc

The invention belongs to the technical field of train brake devices, and particularly relates to a high-speed train shaft-mounted brake disc which comprises a disc body, a disc hub, a pressing ring and a fastening piece. The disc body is the integral type welding disc body with radiating ribs; the disc hub is provided with nine disc hub flange teeth distributed in an equal circumference way and provided with bolt holes in the middles; three tooth grooves distributed in an equal circumference way are arranged on the surface matched with the pressing ring; and nine bolt holes distributed in an equal circumference way and three pressing ring flange teeth adaptive to the tooth grooves distributed in an equal circumference way are arranged on the pressing ring. According to the high-speed trainshaft-mounted brake disc provided by the invention, a processing method of an original high-speed train shaft-mounted brake disc body is changed, and a forging and welding method replaces an existingcasting method, so that the yield of products is improved, the production cost of the products is reduced, and the delivery period of the products is shortened; and meanwhile, the structures of an original shaft-mounted brake disc hub and an original pressing ring are further improved, all degrees of freedom of the pressing ring except for the longitudinal direction are restrained, and the bending moment stressed on bolts is reduced, so that the service life of the brake disc is effectively prolonged, and the core competitiveness of the products is improved.

Owner:南京中盛铁路车辆配件有限公司

Sector welding tool

InactiveCN102717222AConstrained six degrees of freedomConstrained degrees of freedomWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to a sector welding tool which can enable the welding positions between a sector and a master arm to be accurate, avoid the abnormal sound which is generated during the operation process of a lifter, and prolong the service life of the lifter. The sector welding tool comprises a plate body, wherein first location pins which are symmetrical to each other are arranged on the surface of the plate body, a groove which extends from the outer parts of the location pins to the edge of one side of the plate body is arranged on a central axis between the two first location pins, and a second location pin and a third location pin are respectively arranged in the groove along the length direction of the groove. Through the technical scheme, the tool adopts a double-point positioning mode, so the six freedom degrees of the sector can be effectively restrained, the sector is accurately positioned, the welding positions between the sector and the master arm are enabled to be accurate during the welding process, the abnormal sound which is generated during the operation process of the lifter is avoided, and meanwhile, the service life of the lifter is prolonged.

Owner:WUHU MOTIONTEC AUTOMOTIVE

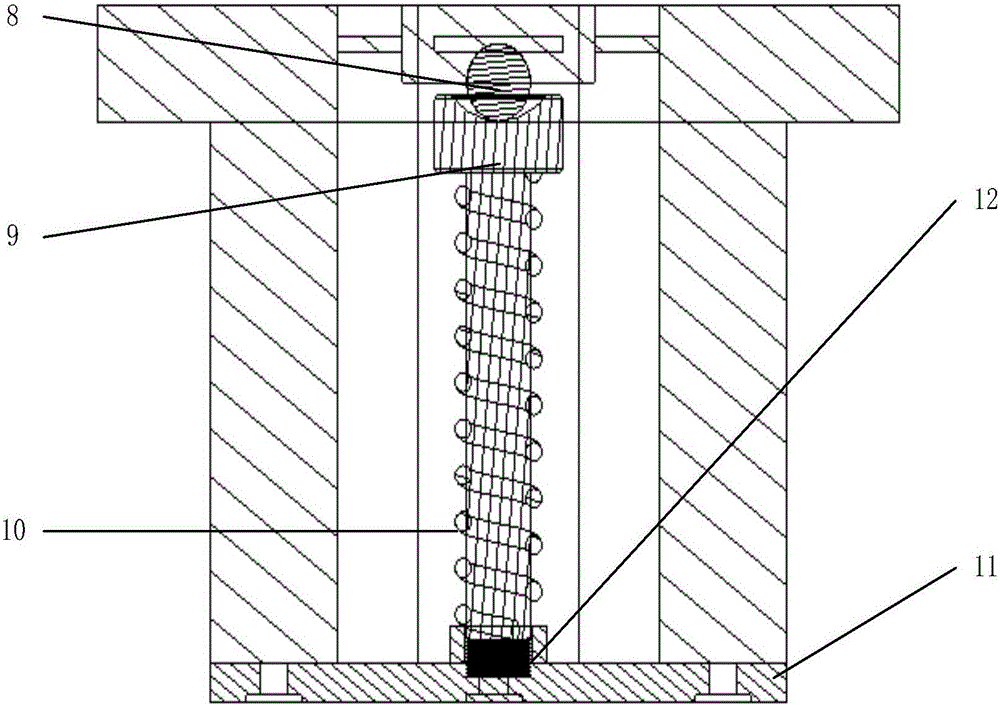

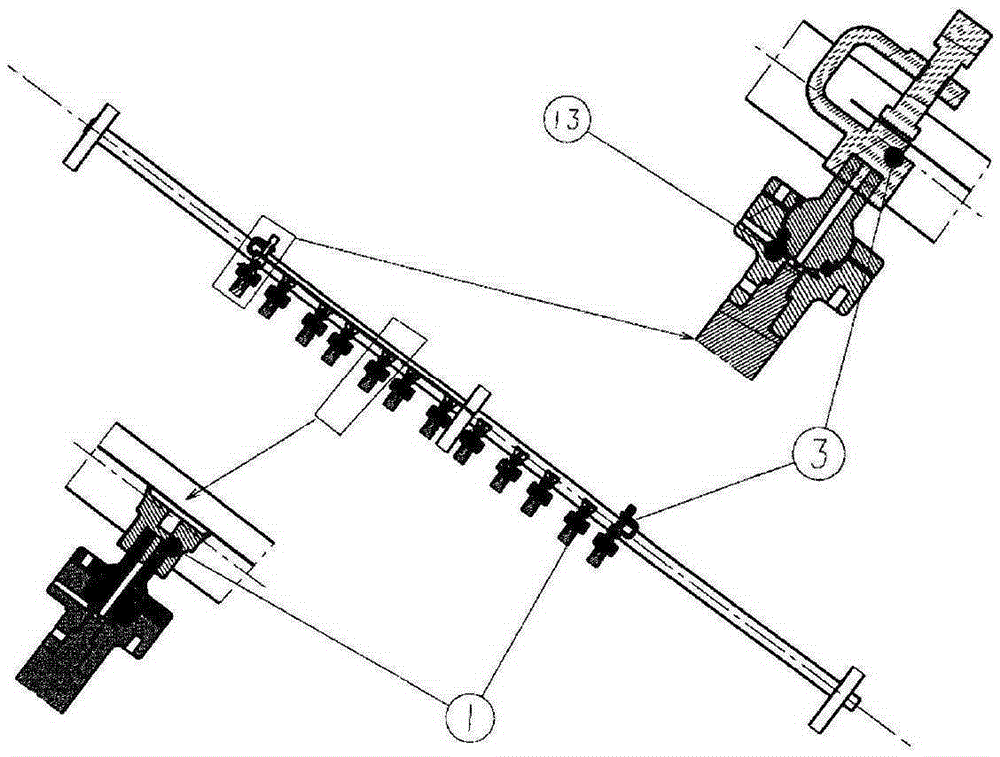

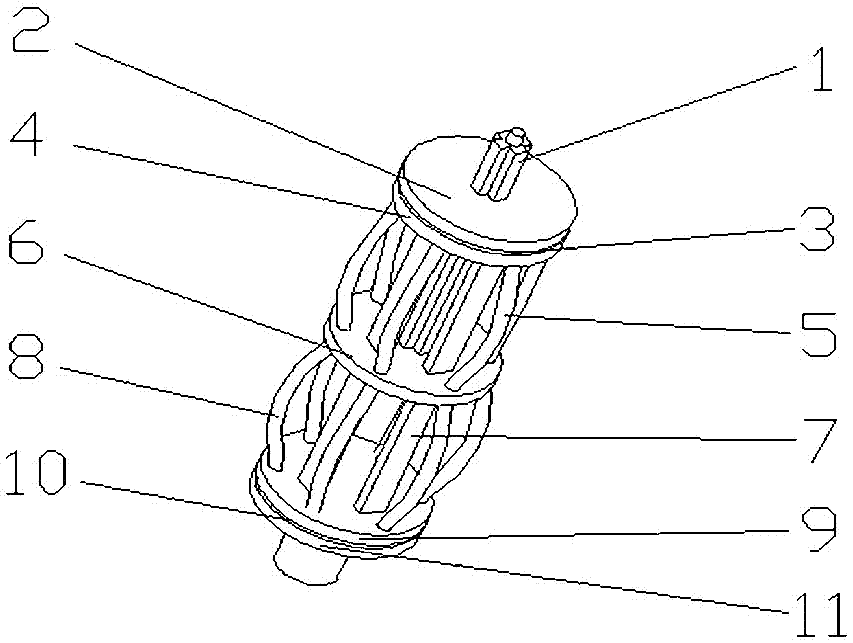

Stretching and compressing both-way steel wire rope vibration isolator

ActiveCN105443633AConstrained degrees of freedomNo bendingShock absorbersClassical mechanicsVibration isolation

The invention provides a stretching and compressing both-way steel wire rope vibration isolator to overcome the defects of an existing vibration isolator. The stretching and compressing both-way steel wire rope vibration isolator comprises a cross guide rod, an upper outer side limiting block, an upper inner side limiting block, upper vibration isolation steel wire ropes, a sliding block, plate-shaped connecting pieces, lower vibration isolation steel wire ropes, a lower inner side limiting block and a lower outer side limiting block. The stretching and compressing both-way steel wire rope vibration isolator has the technical beneficial effects that the freedom degree of axial rotation of the vibration isolator is completely restrained, meanwhile, it is guaranteed that the vibration isolator cannot be bent, and the performance of the vibration isolator is guaranteed.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST +1

An Active-Passive Composite Vibration Isolator Using Parallel Connection of Positive and Negative Stiffnesses

ActiveCN106321719BAchieving positive stiffness properties in the vertical directionAchieve magnetic negative stiffness characteristicsMagnetic springsGas based dampersAir springNegative stiffness

The invention discloses an active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection. The active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection comprises a basic platform (10), a load-bearing platform (30), a passive vibration isolation unit and an active vibration isolation unit, wherein the passive vibration isolation unit is provided with a positive-stiffness air spring (20) and a magnetic negative-stiffness mechanism (28) with adjustable negative stiffness in the first direction, so that the inherent frequency in the first direction is decreased, and the passive vibration isolation unit is provided with a stiffness-adjustable positive-stiffness leaf spring and a negative-stiffness inverted pendulum in the second direction, so that the inherent frequency in the second direction is decreased; the active vibration isolation unit is arranged at the outer side of the passive vibration isolation unit, the upper end of the active vibration isolation unit is linked with the load-bearing platform (30), and the lower end of the active vibration isolation unit is linked with the basic platform (10); and the active vibration isolation unit comprises displacement sensors, speed sensors, a proportional pressure valve and a voice coil motor, and the voice coil motor is used for fine adjustment of the load-bearing platform, so that vibration is further isolated. The active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection has high bearing capacity, and active and passive vibration isolation of two degrees of freedom is achieved at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

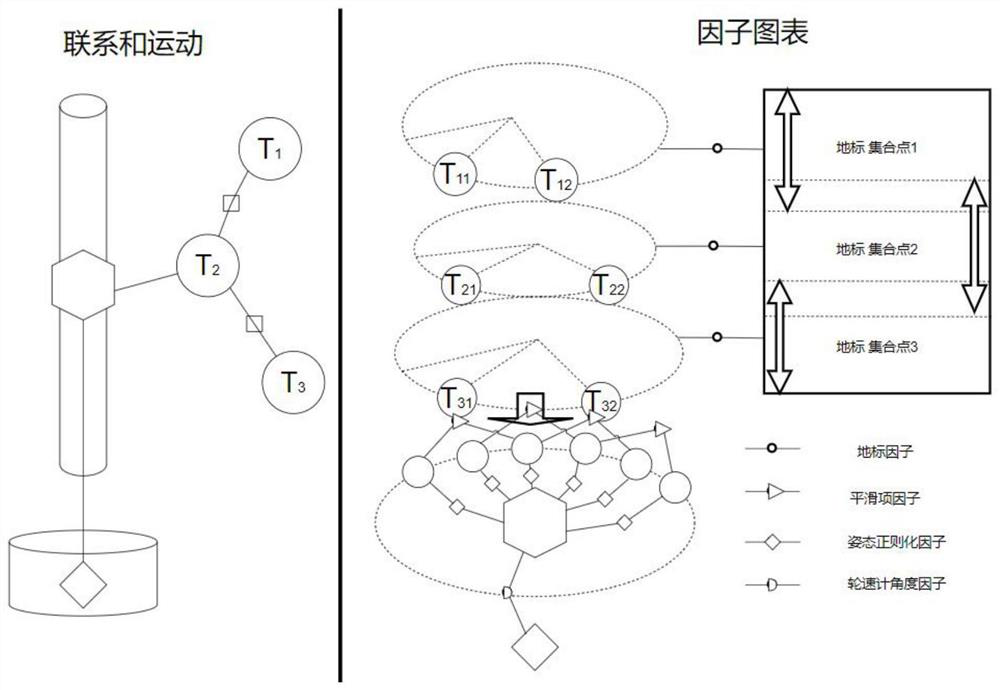

Three-dimensional reconstruction device and method based on multi-view structure

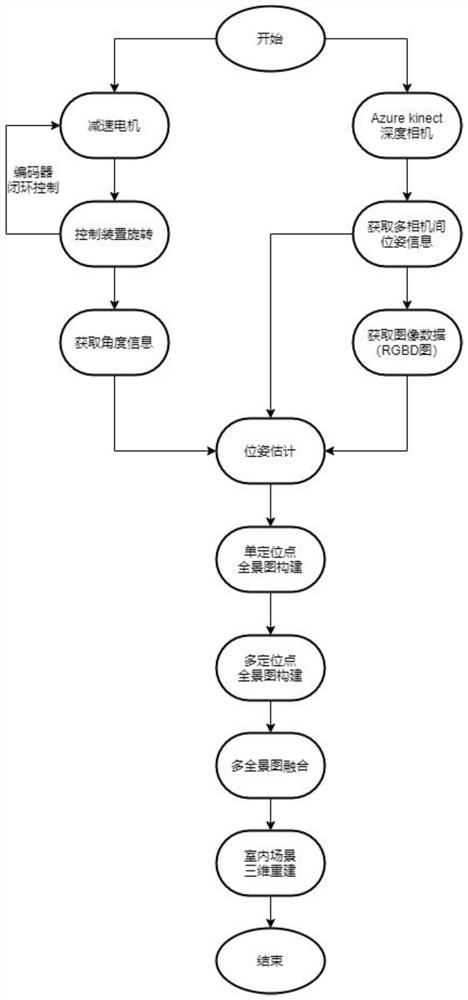

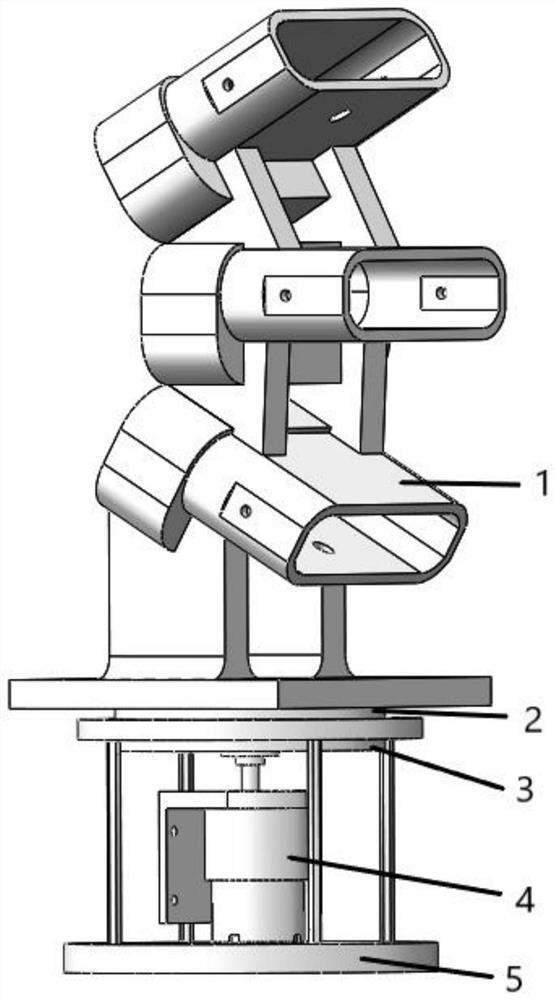

PendingCN114092633AConstrained degrees of freedomAccurate estimateImage enhancementDetails involving processing stepsPattern recognitionComputer graphics (images)

The invention discloses a three-dimensional reconstruction device and method based on a multi-view structure. Firstly, required data are obtained through an independently designed three-dimensional reconstruction device based on a multi-view structure, and panoramic scanning and pose estimation among multiple cameras are achieved so that subsequent indoor three-dimensional scene reconstruction or panoramic image generation can be carried out. In addition, a vision-wheel speed meter tight coupling frame is provided by fusing information of a plurality of sensors and utilizing a factor graph optimization mode so as to realize high-precision and robust state estimation and reconstruction. According to the method, the consistency of partial motion of the camera is limited through the three-dimensional reconstruction device so as to restrain the degree of freedom of the camera, and the motion of the camera is more accurately estimated through the provided tight coupling frame in a factor graph optimization mode, so that the reconstruction result is more accurate.

Owner:HANGZHOU DIANZI UNIV

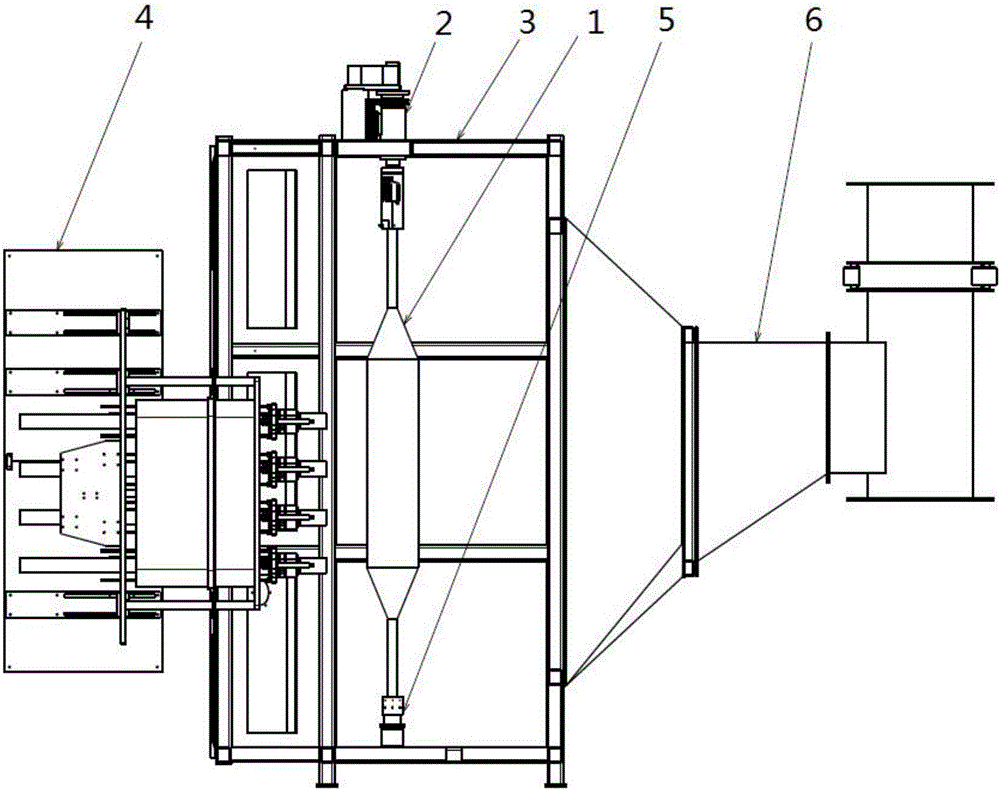

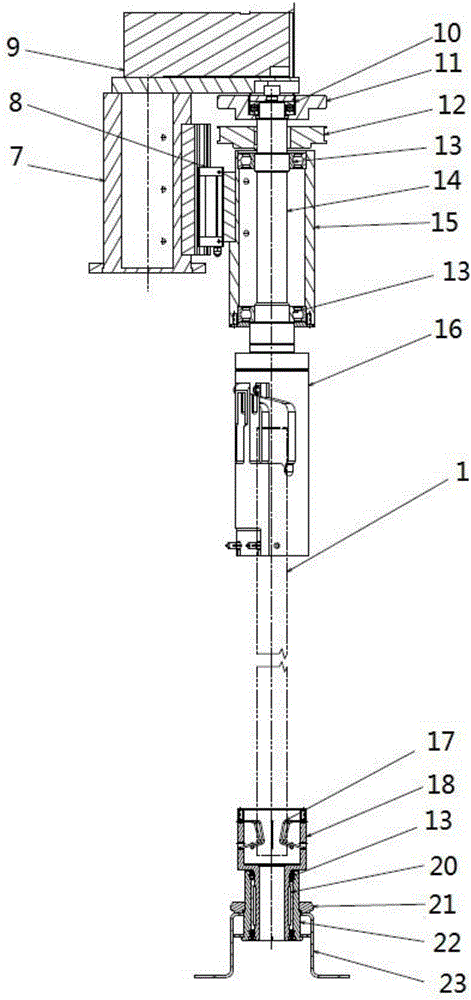

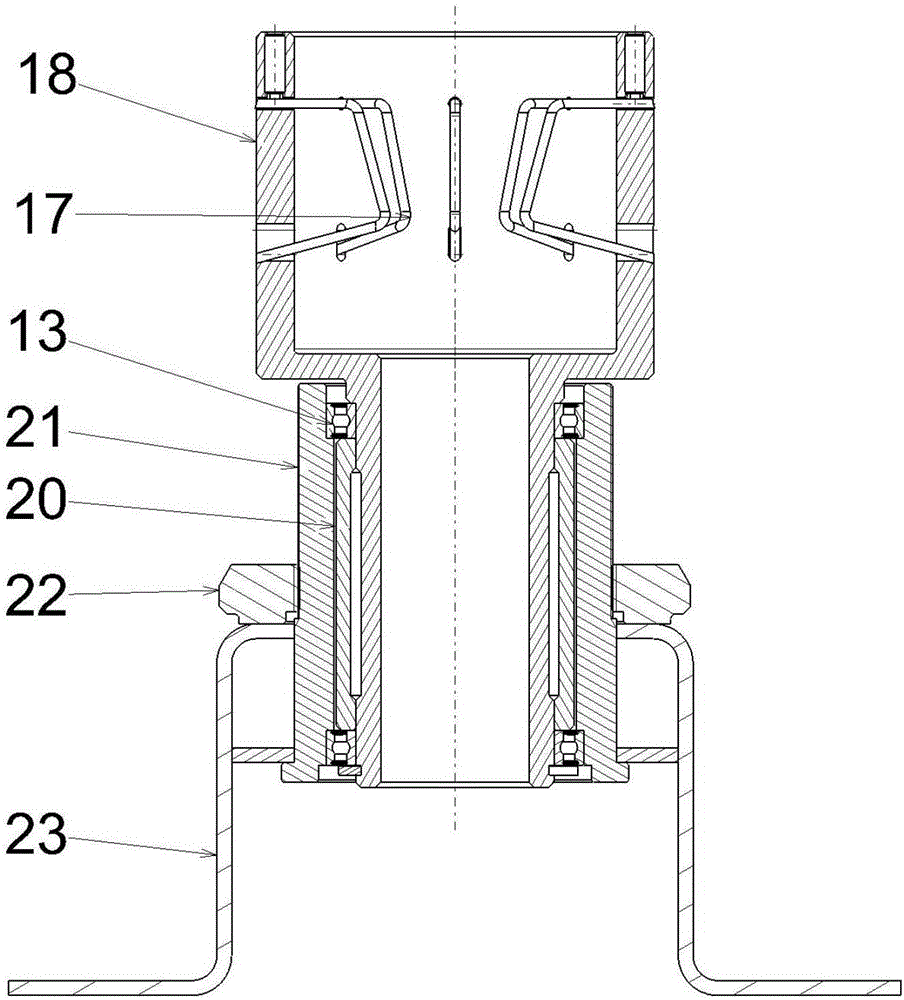

Online weighing system being suitable for OVD process

ActiveCN106242263AHigh rotation accuracyAccurate measurementGlass making apparatusWeighing apparatus for materials with special property/formAgricultural engineeringGrippers

The invention discloses an online weighing system being suitable for an OVD process, which includes an upper gripper mechanism, a lower support mechanism, and a weighing unit. The upper gripper mechanism includes a pedestal, a linear slide rail, and an upper rod-holding gripper which is connected to upper end of a powder rod and is connected to the lower end of a rotary shaft; the upper end of the rotary shaft is connected to the weighing unit through a horizontal bearing and a horizontal bearing base; a rotary outer sleeve tube is arranged outside the rotary shaft and is connected to the pedestal through the linear slide rail; the pedestal is connected to a chamber wall of a deposition chamber; the lower support mechanism includes a lower gripper pedestal which is connected to a bottom board of the deposition chamber, and a lower gripper elastic member arranged around the lower end of the powder rod; and the lower gripper elastic member is connected to the lower gripper pedestal through a connection mechanism. The system is free of interference between weighing function and self-rotational movement, so that high rotation precision of the powder rod is maintained and the weight of the rotating powder rod can be accurately measured in real time.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Fixture mechanism for creep feed grinding of tenon teeth of turbine blade

PendingCN112496469APrecise positioningEasy clampingGrinding work supportsGear-cutting machinesGrindingTurbine blade

The invention discloses a fixture mechanism for creep feed grinding of tenon teeth of a turbine blade. According to the fixture mechanism, a supporting block, a blade body locating block, a side locating block and an axial locating pin are all locating points, are fixed to a main body and are used for locating the bottom face, the side face and the axial direction of the blade; a pressing rod is connected to a cover plate through a pin shaft; a front pressing head and a rear pressing head are connected to the two ends of the pressing rod through pin shafts; the cover plate, the pressing rod, the front pressing head and the rear pressing head form a whole and are arranged on the main body; a front pressing rod and a rear pressing rod are connected with a pressing rod body through pin shafts; a side pressing head is connected with the front pressing rod, a tail pressing head is connected with the rear pressing rod, and a side pressing plate assembly of a lever structure is formed; a leftguide plate and a right guide plate are fixed into grooves in the front ends of two bosses of the main body respectively; and a rapid locating clamping groove is formed in the bottom end of the mainbody and is used for being connected with a machining tool. The tool achieves a very good effect through on-site application. The fixture structure has the advantages of clamping convenience, accuracyand stability, thereby having important significance in optimizing and improving a process route.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Marine abandoned wellhead cutting device based on plasma arc cutting

ActiveCN112253027AFast cutting speedShorten working timeBorehole/well accessoriesWellheadCutting force

The invention relates to a marine abandoned wellhead cutting device based on plasma arc cutting and application of the marine abandoned wellhead cutting device. The marine abandoned wellhead cutting device comprises a supporting mechanism, a rotating mechanism, a feeding mechanism, a cutting mechanism and a guiding mechanism. The supporting mechanism is used for providing underground support for the whole device and guaranteeing that the lower rotating mechanism of the supporting mechanism is located in the center of a casing pipe; the rotating mechanism is used for driving the feeding mechanism and the cutting mechanism to rotate so as to achieve the purpose of casing pipe girdling; the feeding mechanism is used for adjusting the distance between the cutting mechanism and the inner wall of the casing pipe; the cutting mechanism is used for generating high-temperature plasma arcs to realize cutting operation; and the guiding mechanism provides guiding for the whole device, and it is guaranteed that the device can be smoothly lowered in the axial direction of the casing pipe. The marine abandoned wellhead cutting device is simple and compact in structure, good in stability, low in equipment manufacturing cost and large in application range; by by using plasma arcs for cutting, the marine abandoned wellhead cutting device is small in cutting force, free of vibration, efficient incutting, free of pollution and capable of greatly reducing the operation cost so as to be good in economic benefit and market value and worthy of application and popularization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Foot joint structure of wheel type walking vehicle steering drive axle

ActiveCN112550509AGuaranteed steering functionReduce volumeMotor depositionVehiclesElectric machineryControl theory

The invention discloses a foot joint structure of a wheel type walking type vehicle steering drive axle. An upper mechanical leg is fixedly connected with a motor assembly; the motor assembly comprises two gear motors which are coaxial in output shaft and oppositely arranged, and the two gear motors serve as power sources and provide torque for wheel steering and foot joint movement; a transmission mechanism assembly can convert the single-direction output of the motor into two different-direction outputs, namely the rotation of wheels around a main pin and the rotation of the foot joint around the axis of the motor; a foot joint rotation locking mechanism is used for locking the rotation movement of the foot joint and positioning the position of the foot joint in a wheel steering mode, and a wheel steering locking mechanism is used for locking the steering of the wheels and positioning the position of the wheels in a foot joint rotation mode. The foot joint structure has two transmission routes, well decomposes the rotation motion of the foot joint around the wheel main pin and the rotation motion around a motor rotating shaft, switches the working modes by means of the two locking mechanisms, is reliable and effective, and has good application potential.

Owner:WUHAN UNIV OF TECH

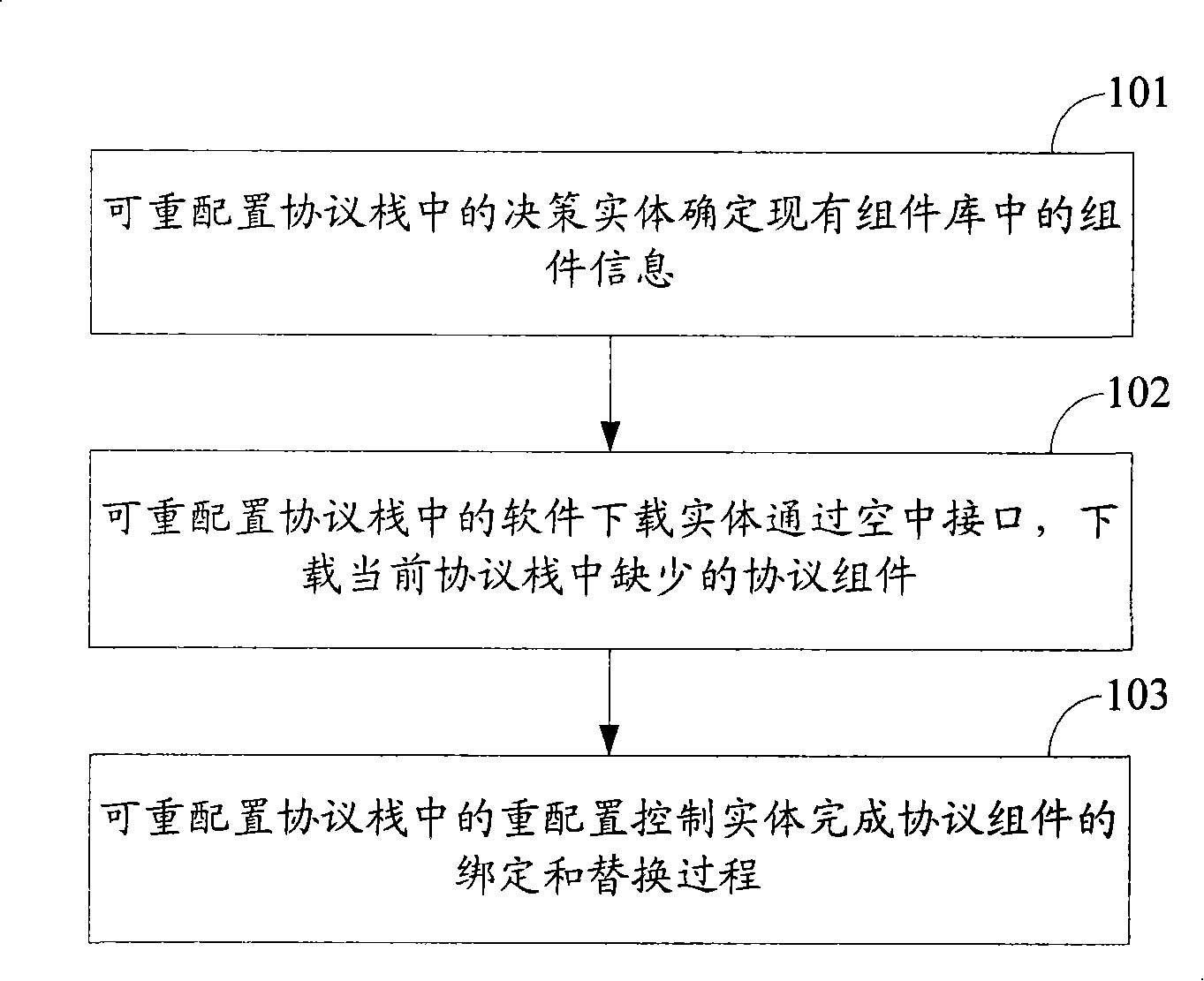

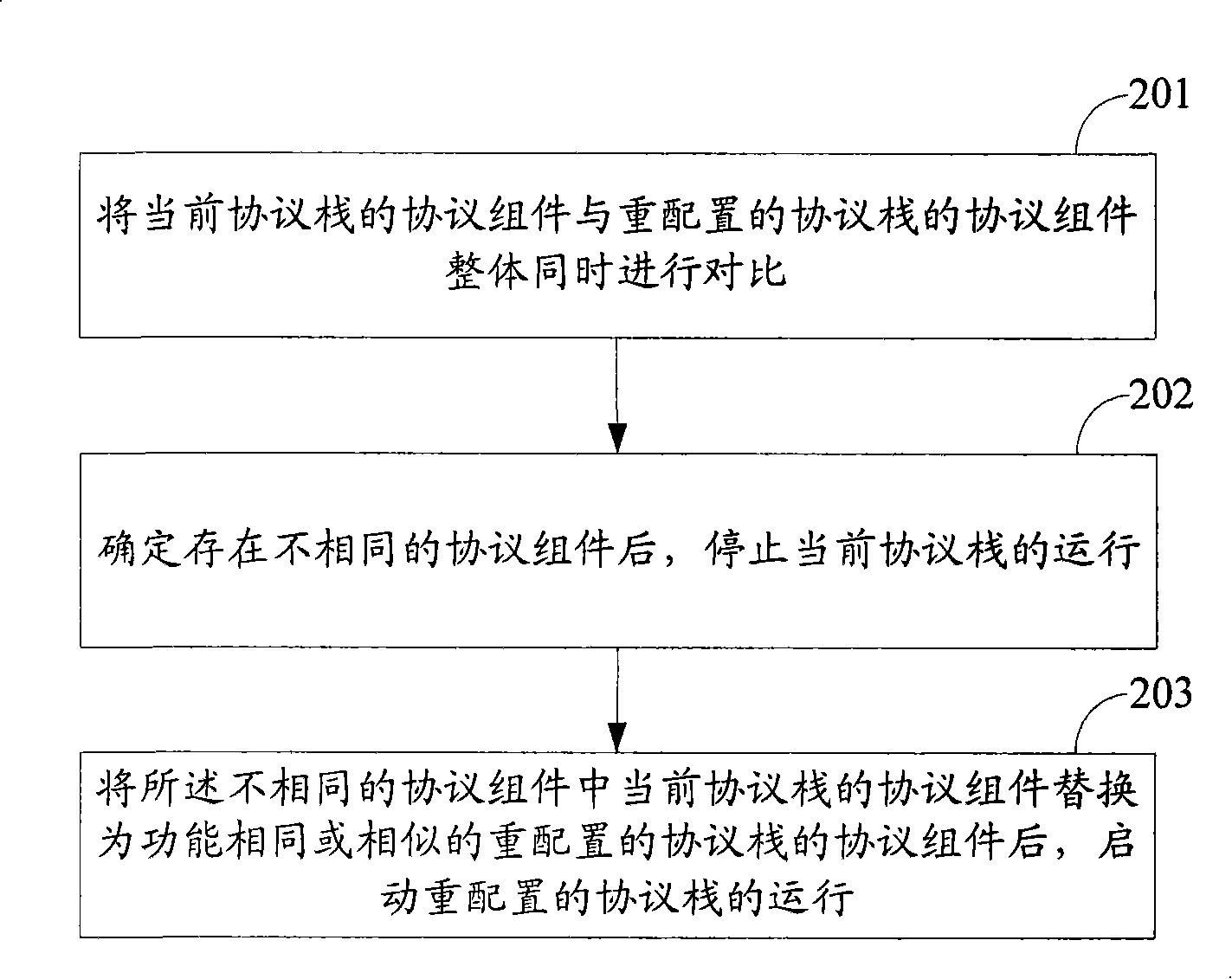

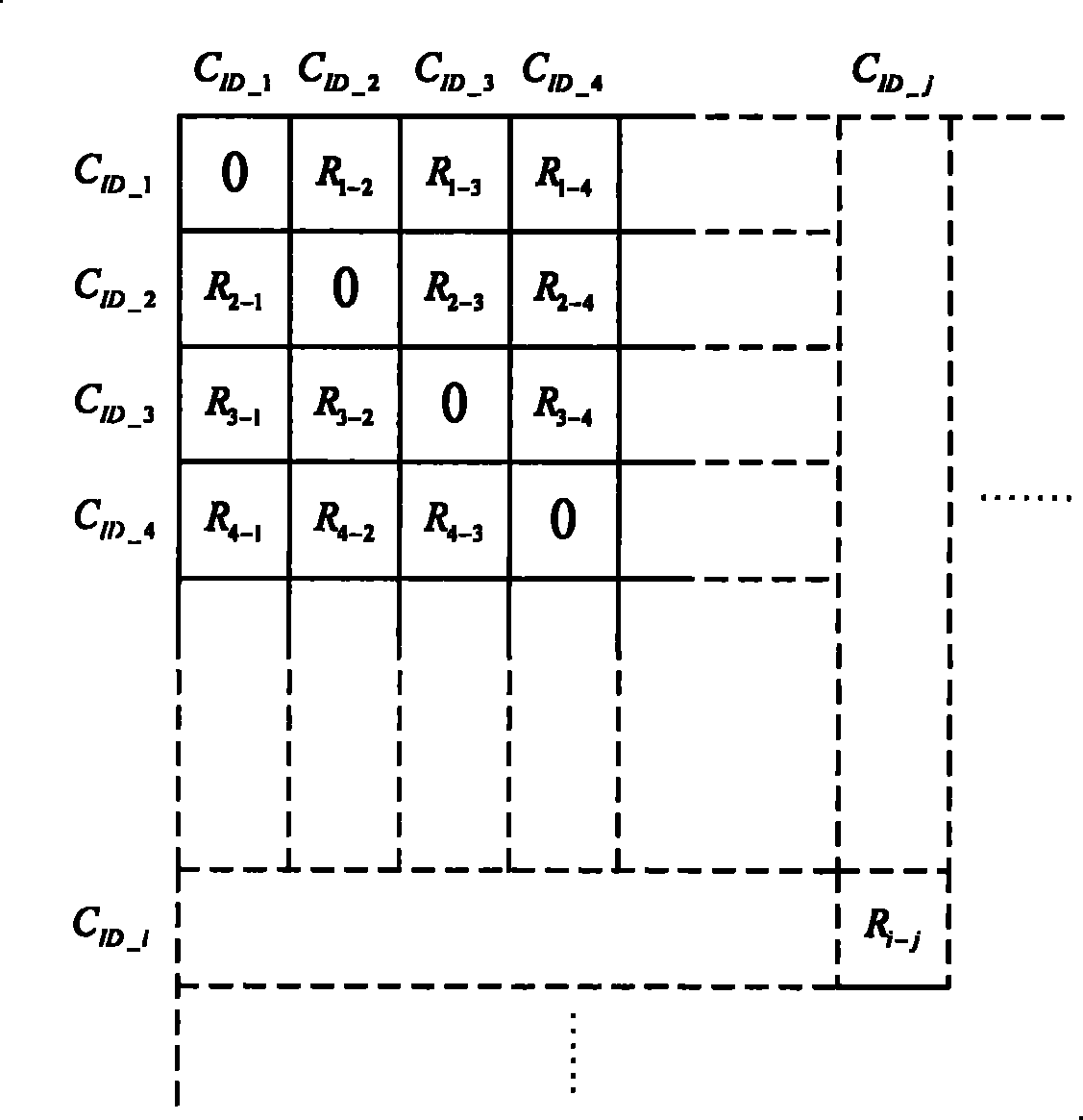

Method, equipment and system for reconfiguring protocol stack based on assembly

ActiveCN101599854BAvoid localizationConstrained degrees of freedomData switching networksTime delaysProtocol stack

The invention discloses a method for reconfiguring a protocol stack based on an assembly. The method comprises the following steps: simultaneously comparing a protocol assembly of the current protocol stack with the whole of a protocol assembly of the reconfigured protocol stack; confirming that different protocol assemblies exist, and then stopping running the current protocol stack; replacing the protocol assembly of the current protocol stack in the different protocol assemblies with the protocol assembly of the reconfigured protocol stack with same or similar function, and then starting up the running of the protocol assembly of the current protocol stack. The invention also discloses equipment and a system for reconfiguring a protocol stack based on an assembly. The invention can improve the success ratio of reconfiguration and effectively lower the time delay of the reconfiguration.

Owner:CHINA MOBILE COMM GRP CO LTD

Box culvert carrying auxiliary support

ActiveCN110654289APrevent damage to edges and cornersEasy to storeVehicle to carry long loadsLoading/unloading vehicle arrangmentArchitectural engineeringCivil engineering

The invention relates to a box culvert carrying auxiliary support. The auxiliary support comprises a frame, wherein the frame comprises a first supporting plate and a second supporting plate, and thelength of the first supporting plate is greater than the length of the second supporting plate; the second supporting plate is rotationally connected to one end of the first supporting plate in the length direction through a hinge shaft, and the second supporting plate can rotate from a folded position to an unfolded position around the hinge shaft; a plurality of first baffles are arranged on theside wall, perpendicular to the hinge shaft, of the first supporting plate, and a plurality of second baffles are arranged on the side wall, away from the first supporting plate, of the second supporting plate; and when the second supporting plate is in the unfolded position, the first supporting plate and the second supporting plate are perpendicular to each other to form a containing area, andthe first baffles and the second baffles are arranged in a protruding mode towards the containing area. According to the box culvert carrying auxiliary support, a box culvert can be turned over 90 degrees before loading, and corners of the box culvert can be prevented from being damaged in the turning over process.

Owner:INNER MONGOLIA ROAD & BRIDGE +1

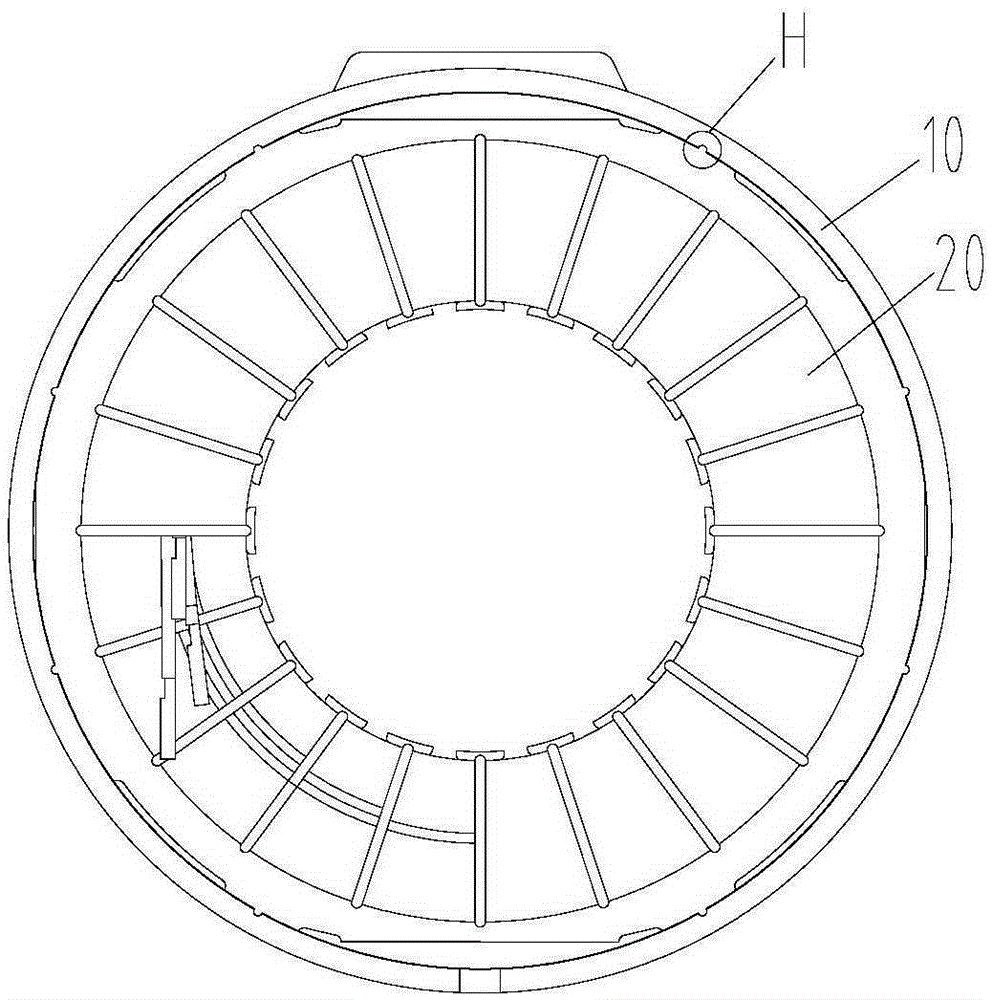

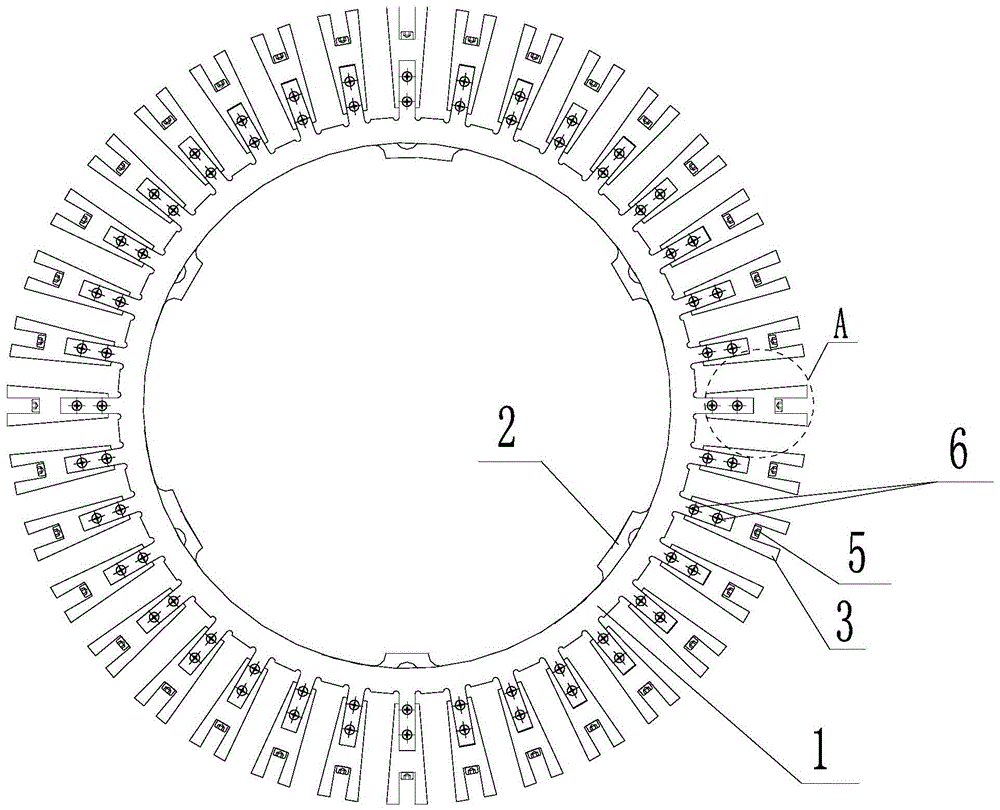

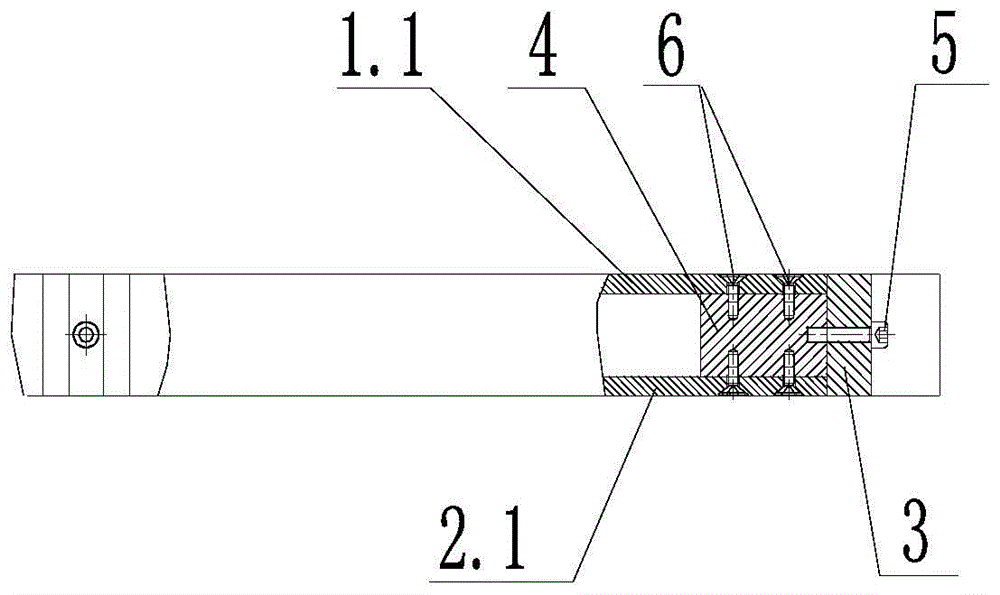

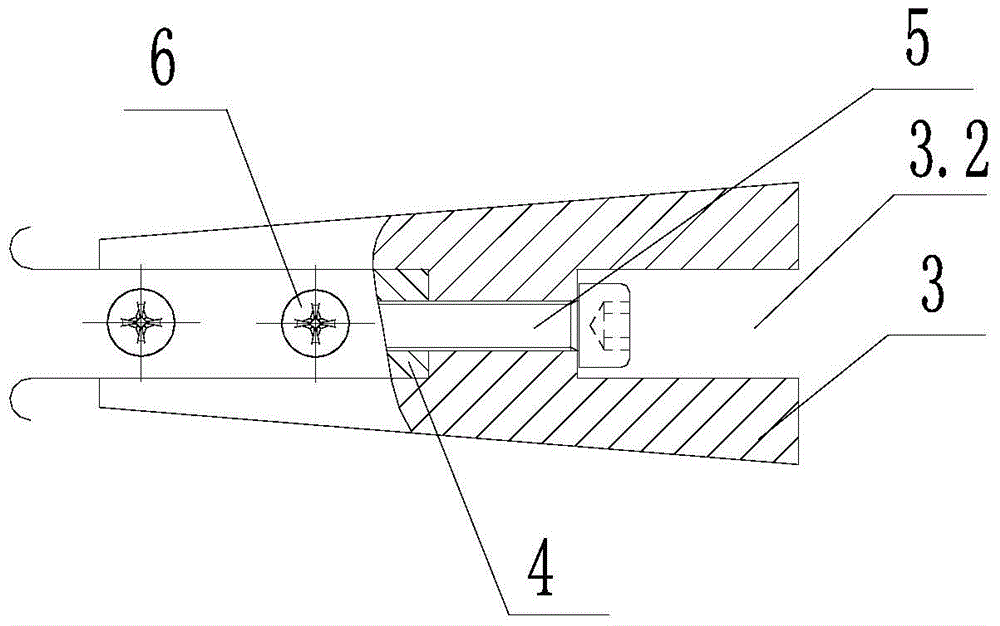

Compressor and heat exchanging device

InactiveCN105351201AConstrained degrees of freedom for circumferential rotationConstrained degrees of freedomRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringAssembly structure

The invention provides a compressor and a heat exchanging device. The compressor comprises a housing and a stator, wherein the housing is provided with a chamber, and a first assembling structure is arranged on the inner wall of the housing; the stator is embedded into the chamber, and a second assembling structure which is in match with the first assembling structure is arranged at one side, toward the housing, of the stator; after the housing and the stator are assembled in place, the stator can circumferentially stop rotating relative to the housing under the effects of the first assembling structure and the second assembling structure; the housing is in clearance fit with the stator. With the adoption of the compressor, the problem of complex assembling and disassembling processes of the housing and the stator of the compressor in the prior art can be solved.

Owner:ZHUHAI LANDA COMPRESSOR +1

Box culvert handling auxiliary support

ActiveCN110654289BConstrained degrees of freedomPrevent back and forth, left and right movementVehicle to carry long loadsLoading/unloading vehicle arrangmentArchitectural engineeringEngineering

The invention relates to a box culvert carrying auxiliary support. The auxiliary support comprises a frame, wherein the frame comprises a first supporting plate and a second supporting plate, and thelength of the first supporting plate is greater than the length of the second supporting plate; the second supporting plate is rotationally connected to one end of the first supporting plate in the length direction through a hinge shaft, and the second supporting plate can rotate from a folded position to an unfolded position around the hinge shaft; a plurality of first baffles are arranged on theside wall, perpendicular to the hinge shaft, of the first supporting plate, and a plurality of second baffles are arranged on the side wall, away from the first supporting plate, of the second supporting plate; and when the second supporting plate is in the unfolded position, the first supporting plate and the second supporting plate are perpendicular to each other to form a containing area, andthe first baffles and the second baffles are arranged in a protruding mode towards the containing area. According to the box culvert carrying auxiliary support, a box culvert can be turned over 90 degrees before loading, and corners of the box culvert can be prevented from being damaged in the turning over process.

Owner:INNER MONGOLIA ROAD & BRIDGE +1

An offshore transfer trestle with wave compensation function and its working method

ActiveCN113232768BImprove securityImprove comfortCargo handling apparatusVessel partsFreeboardMarine engineering

The invention discloses a sea transfer trestle with wave compensation function and a working method thereof. The sea transfer trestle includes a heave mechanism, a trestle system and an active wave compensation control system. The invention can compensate the disturbance of the transfer trestle due to the swaying motion of the two ships, even if there is a difference in freeboard between the host ship and the target ship, it can still ensure that the safe angle between the trestle bridge body and the horizontal plane remains unchanged during the personnel transfer process of the transfer trestle bridge. Improve the safety and comfort of personnel transfer between two ships at sea. After the transfer trestle bridge of the present invention is lapped, the front end of the trestle bridge body is fixedly connected to the transfer point, and the personnel transfer process only needs to control the heave mechanism to ensure that the trestle bridge body and the horizontal plane maintain a safe angle. The front end of the trestle bridge body of the present invention and the transfer point are fixedly connected by electromagnetic landing cones, without additional mechanical devices for fixing, so that the trestle bridge body can be quickly separated from the transfer point in an emergency, and can be lifted urgently to improve safety sex.

Owner:DALIAN MARITIME UNIVERSITY

A flexible tooling for milling and cutting aircraft skin without margin and its use method

ActiveCN105290841BSimple structureLow costWorkpiecesMilling equipment detailsExtensibilityLocking mechanism

The invention discloses an aircraft skin no-allowance milling flexible tool. Multiple double-rod support units, multiple four-rod support units and multiple reference support units are arranged on a tool frame; bulb locking mechanisms are mounted on the double-rod support units and the four-rod support units; suckers or edge clampers are mounted on the bulb locking mechanisms; machining zero adaptors and assembly hole adaptors are arranged on the reference support units; the tool frame has a base; a connecting bracket is arranged on the base; a random support plate is arranged on the connecting bracket; multiple mounting holes are formed in the random support plate; expansion sleeves are mounted in the mounting holes; connecting rods are inserted in the coaxial mounting holes, and are locked through the expansion sleeves, so that the connecting rods and the random support plate are fastened; and the double-rod support units, the four-rod support units or the reference support units are mounted on the connecting rods. The aircraft skin no-allowance milling flexible tool has the advantages of simple structure, low cost, extensibility of modular structure, high clamping rigidity of thin-wall skin and convenience for application and promotion.

Owner:SHENYANG AIRCRAFT CORP

A Foldable Capturing Metamorphic Mechanism Based on Constrained Helix

ActiveCN108657473BConstrained degrees of freedomGuaranteed stiffnessProgramme-controlled manipulatorToolsTwo degrees of freedomMetamorphosis

The invention provides a constrained helix-based foldable catch-and-change mechanism, which includes a plurality of identical change-and-change units. The two scissor rods are connected to each other through the rotating pair R1 to form a scissor mechanism; the bottom ends of the two connecting rods are respectively connected to the top ends of the two scissor rods through the rotating pair R2 and R3; The first rotating rod, the second rotating rod, the third rotating rod, the fourth rotating rod, and the fifth rotating rod; the fifth rotating rod is connected to the top of the connecting rod through the rotating pair R4, and the first rotating rod is connected to the connecting rod through the rotating pair R5 The bottom end of the scissor bar; the two rotating branches are connected to each other through a hinge mechanism. The present invention realizes reducing the number and types of degrees of freedom by controlling the redundant degrees of freedom and retaining the two degrees of freedom of folding and catching. Realize the simplification of the structure.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

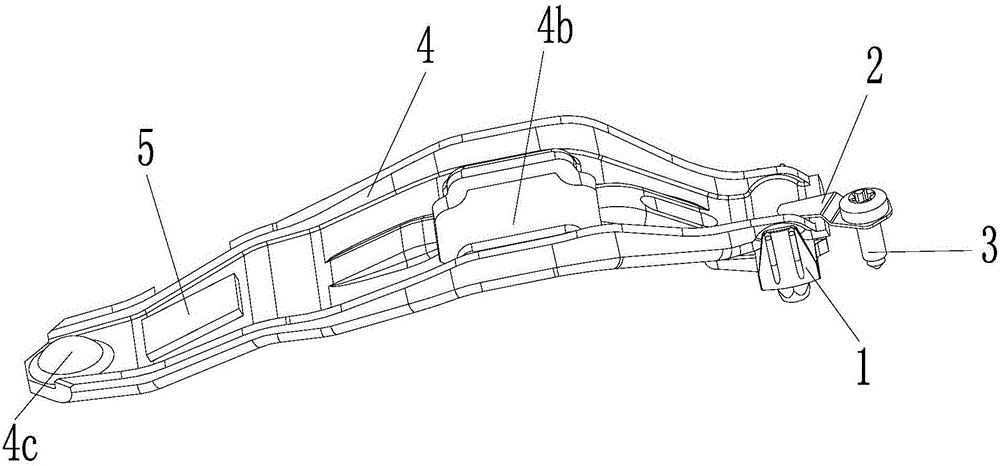

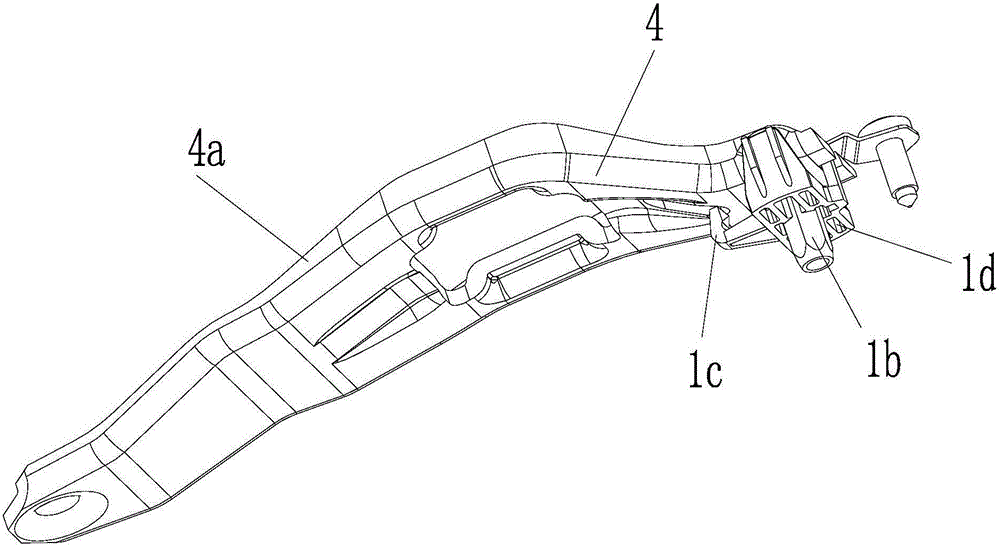

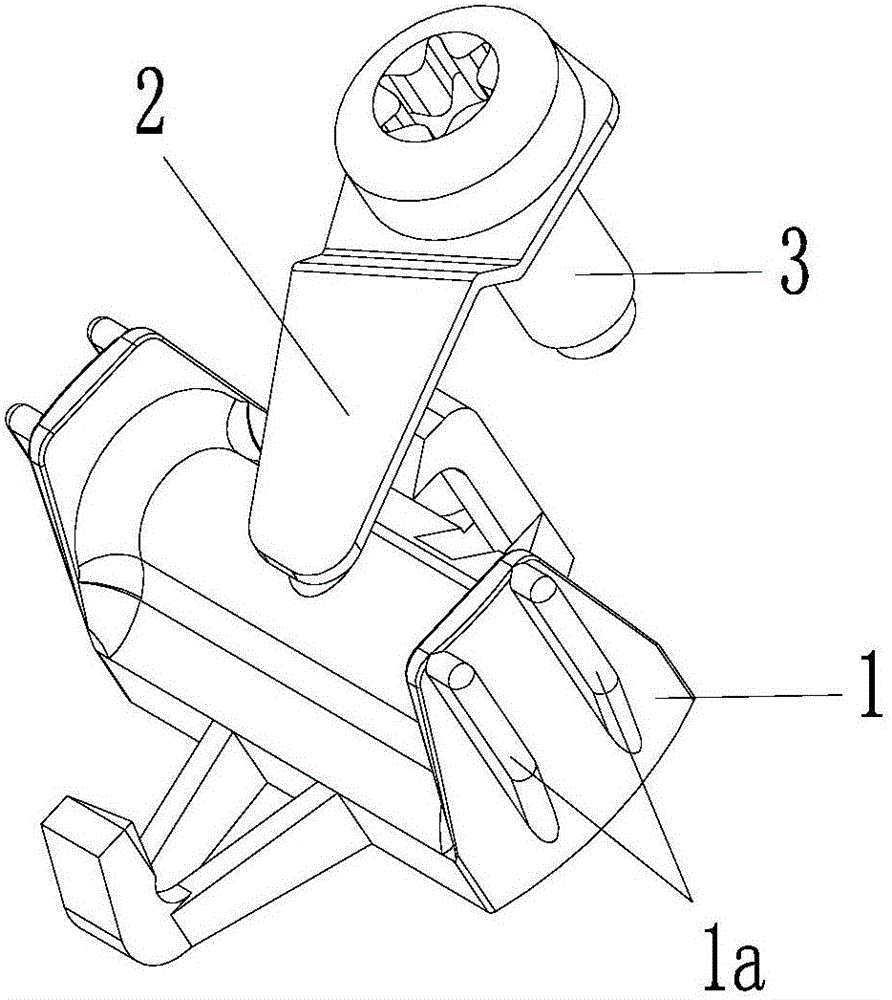

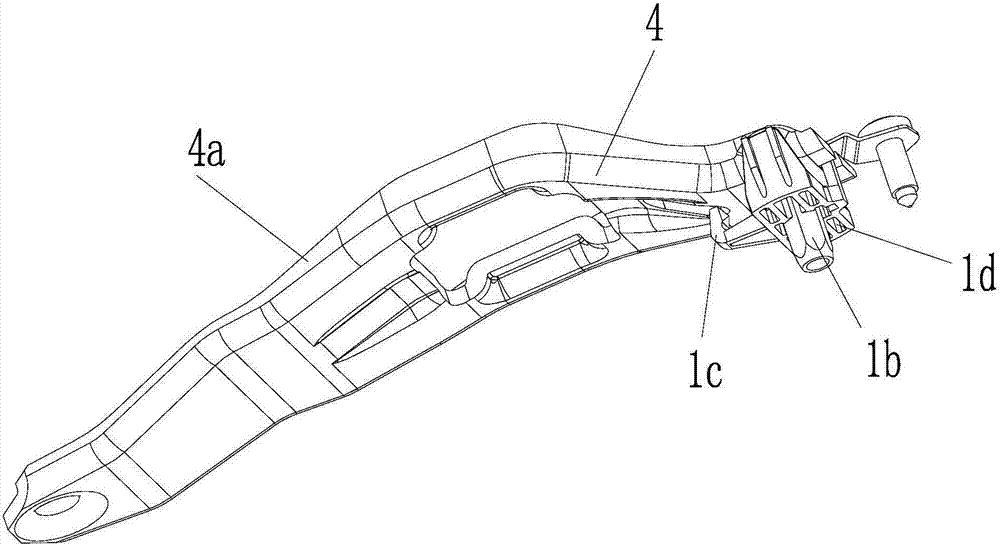

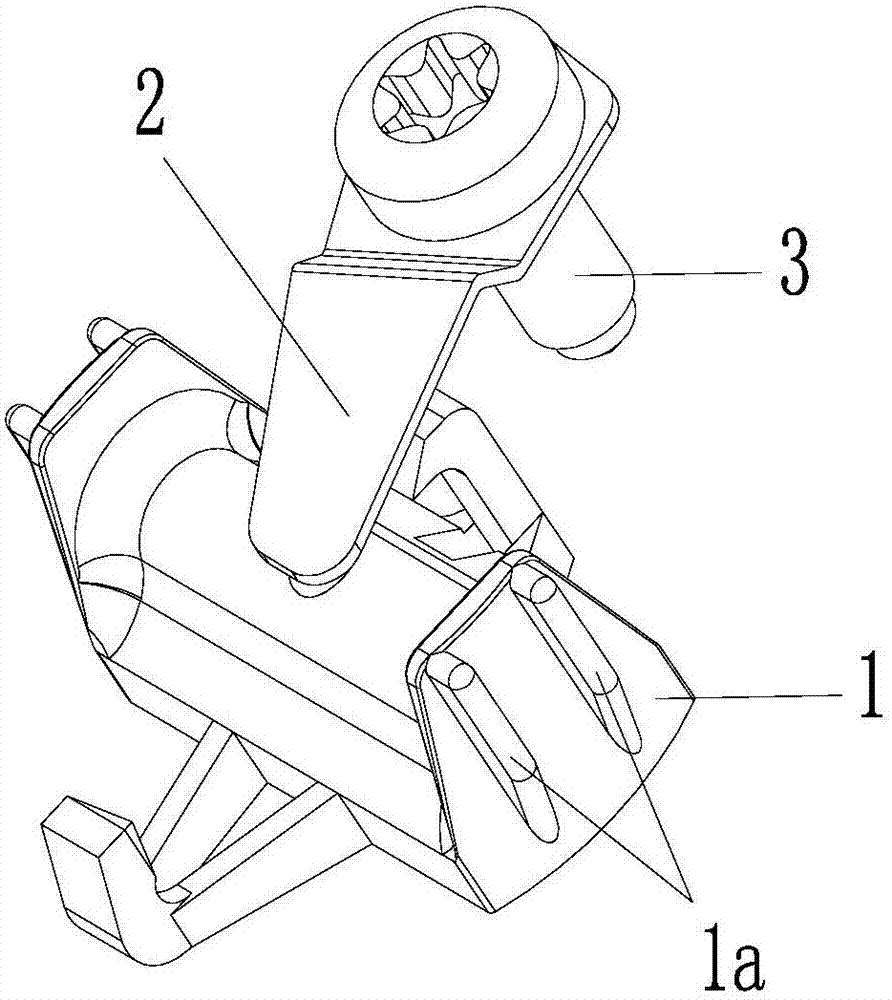

Mounting structure of clutch separation shifting fork and supporting mechanism

InactiveCN105840688AConstrained degrees of freedomLimit swingInertia force compensationVibration dampersResonanceEngineering

The invention discloses a mounting structure of a clutch separation shifting fork and a supporting mechanism. A mass block is welded to the top face of the separation shifting fork. The supporting mechanism comprises a rubber mounting base, an elastic press piece and a locking bolt. A U-shaped base serves as a body of the rubber mounting base. An inserting column extending downwards is arranged at the bottom of the U-shaped base. A sheet metal part with the middle portion bent and the front portion and the rear portion parallel serves as the elastic press piece, and the locking bolt is sleeved with the front portion of the elastic press piece. The front end of the clutch separation shifting fork is clamped in a U-shaped opening of the rubber mounting base from top to bottom. A hook head of the rubber mounting base is hooked in a via hole correspondingly formed in the clutch separation shifting fork. The rear portion of the elastic press piece is pressed on the front end of the clutch separation shifting fork. The radial movement and rotation freedom degree of the shifting fork can be restrained, and pedal shaking and separation shifting fork abnormal sounds brought by clutch excitation can be absorbed well; and modals are increased to change the inherent frequency of the separation shifting fork, and the situation that resonance is caused by inherent frequency coincidence of engines is avoided.

Owner:CHONGQING KAITE POWER SCI & TECH

A tension-compression two-way wire rope vibration isolator

ActiveCN105443633BConstrained degrees of freedomNo bendingShock absorbersClassical mechanicsEngineering

Aiming at the deficiencies of the existing vibration isolators, the invention provides a tension-compression two-way steel wire rope vibration isolator. Including cross guide rod, upper outer limit block, upper inner limit block, upper vibration isolation wire rope, sliding block, plate connector, lower vibration isolation wire rope, lower inner limit block, lower outer limit block. Beneficial technical effect: the present invention not only completely constrains the degree of freedom of the vibration isolator in axial rotation, but also ensures that the vibration isolator will not be bent, thereby ensuring the performance of the vibration isolator.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST +1

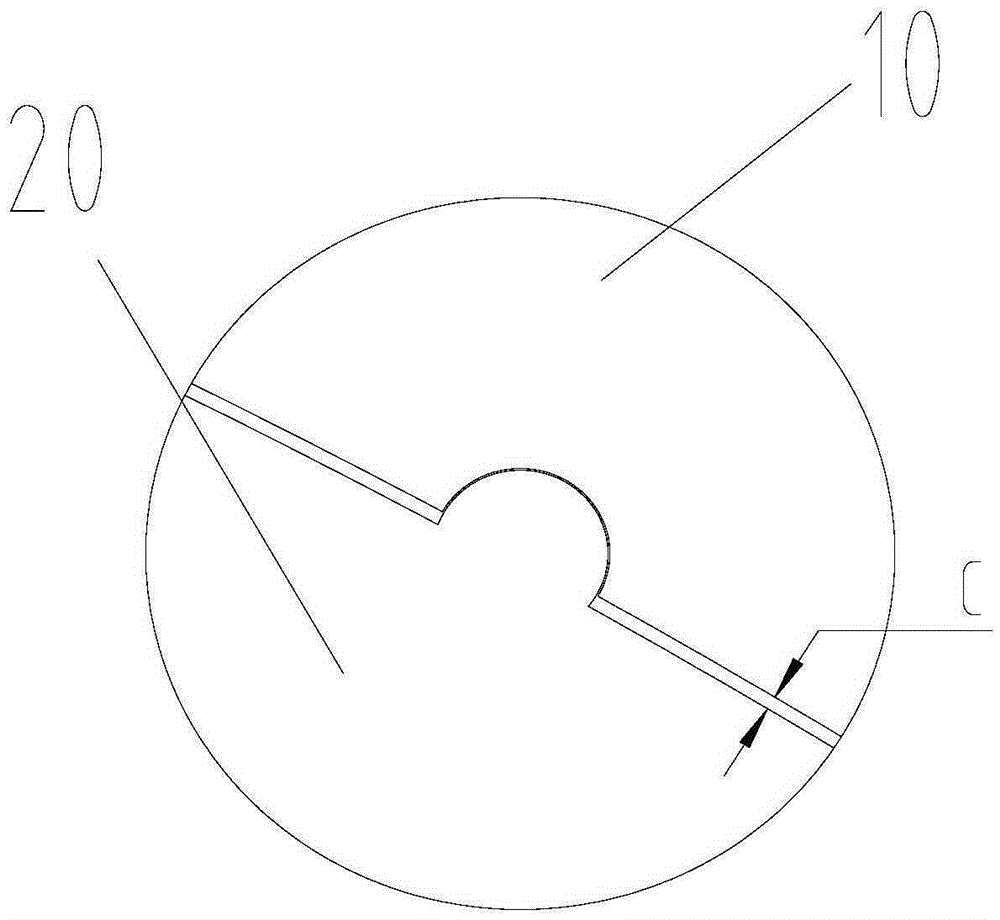

Cigarette Hard Packing Machine Drying Wheel

ActiveCN105000227BConstrained degrees of freedomEasy to replacePackagingIsosceles trapezoidEngineering

The invention discloses a drying wheel of a cigarette hard packet packer. The drying wheel comprises an upper rotating frame and a lower rotating frame which are coaxially arranged. An upper fixing rod and a lower fixing rod are arranged at corresponding positions of the edge of the upper rotating frame and the edge of the lower rotating frame respectively. A nylon module is fixed between the upper fixing rod and the lower fixing rod. The drying wheel is characterized in that the nylon module is an isosceles trapezoid column; the middles of the upper bottom face and the lower bottom face, parallel to each other, of the nylon module are each provided with two through grooves; every two corresponding through grooves are communicated through a through hole; a connecting block is placed in each through groove at the smaller end; the position, corresponding to the corresponding through hole, of each connecting block is provided with a threaded hole; locking screws penetrate the through holes and are connected with the threaded holes in the connecting blocks; and the connecting blocks are fixed between the upper fixing rod and the lower fixing rod. The drying wheel has the beneficial effect that the nylon module can be fast replaced.

Owner:HUBEI CHINA TOBACCO IND

An installation structure for a clutch release fork and a support mechanism

InactiveCN105840688BConstrained degrees of freedomLimit swingInertia force compensationVibration dampersResonanceEngineering

The invention discloses a mounting structure of a clutch separation shifting fork and a supporting mechanism. A mass block is welded to the top face of the separation shifting fork. The supporting mechanism comprises a rubber mounting base, an elastic press piece and a locking bolt. A U-shaped base serves as a body of the rubber mounting base. An inserting column extending downwards is arranged at the bottom of the U-shaped base. A sheet metal part with the middle portion bent and the front portion and the rear portion parallel serves as the elastic press piece, and the locking bolt is sleeved with the front portion of the elastic press piece. The front end of the clutch separation shifting fork is clamped in a U-shaped opening of the rubber mounting base from top to bottom. A hook head of the rubber mounting base is hooked in a via hole correspondingly formed in the clutch separation shifting fork. The rear portion of the elastic press piece is pressed on the front end of the clutch separation shifting fork. The radial movement and rotation freedom degree of the shifting fork can be restrained, and pedal shaking and separation shifting fork abnormal sounds brought by clutch excitation can be absorbed well; and modals are increased to change the inherent frequency of the separation shifting fork, and the situation that resonance is caused by inherent frequency coincidence of engines is avoided.

Owner:CHONGQING KAITE POWER SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com