Mounting structure of clutch separation shifting fork and supporting mechanism

A technology for separating shift forks and supporting mechanisms, which is applied in the direction of clutches, mechanical drive clutches, couplings, etc., can solve the problems of clutch pedal vibration, abnormal noise of separation shift forks, etc., and achieve the effects of avoiding shaking, convenient installation, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

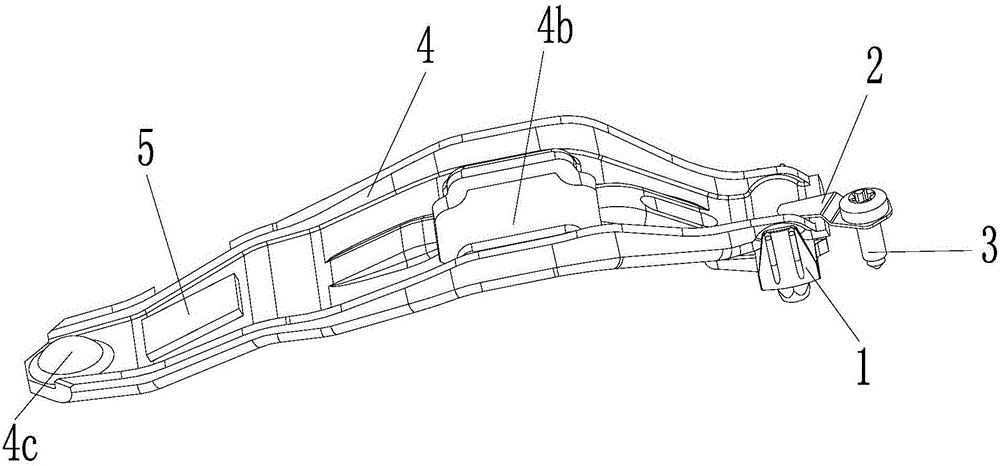

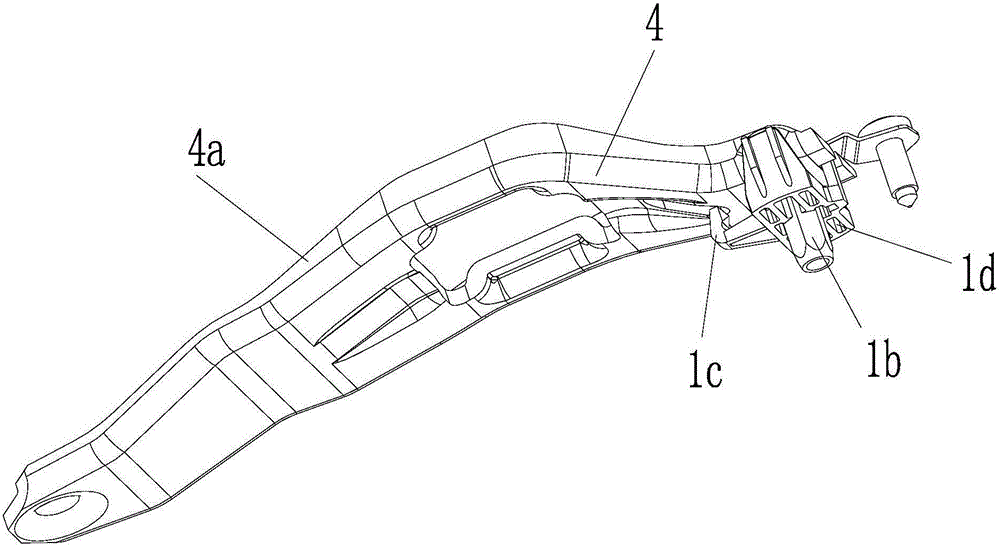

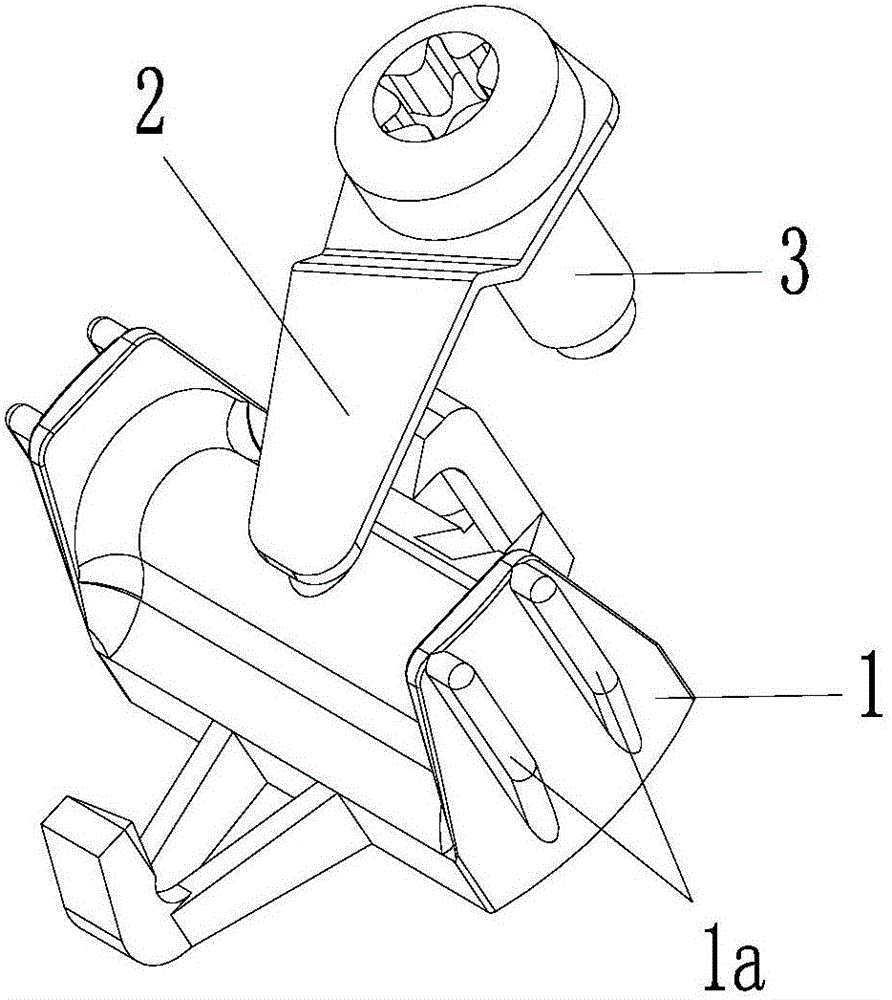

[0015] to combine figure 1 — image 3 As shown, an installation structure of a clutch release fork and a support mechanism is mainly composed of a clutch release fork 4 and a support mechanism.

[0016] The clutch release shift fork 4 is an integrally formed plate-shaped metal sheet. Preferably, the metal sheet is symmetrical left and right as a whole. The middle part of the metal sheet is wide, and the width towards the front and rear ends gradually decreases. Flanged 4a for added strength. The rear end of the metal sheet is provided with an upwardly arched circular pit 4c as the contact point of the clutch actuator, and the middle part of the metal sheet is provided with a rectangular hole 4b for installing the release bearing.

[0017] A mass block 5 is welded on the top surface of the clutch release shift fork 4, and the mass block 5 is welded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com