Cigarette Hard Packing Machine Drying Wheel

A packaging machine and drying wheel technology, which is applied in the field of tobacco processing, can solve the problems of inconvenient replacement work and narrow replacement space, and achieve the effect of saving nylon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

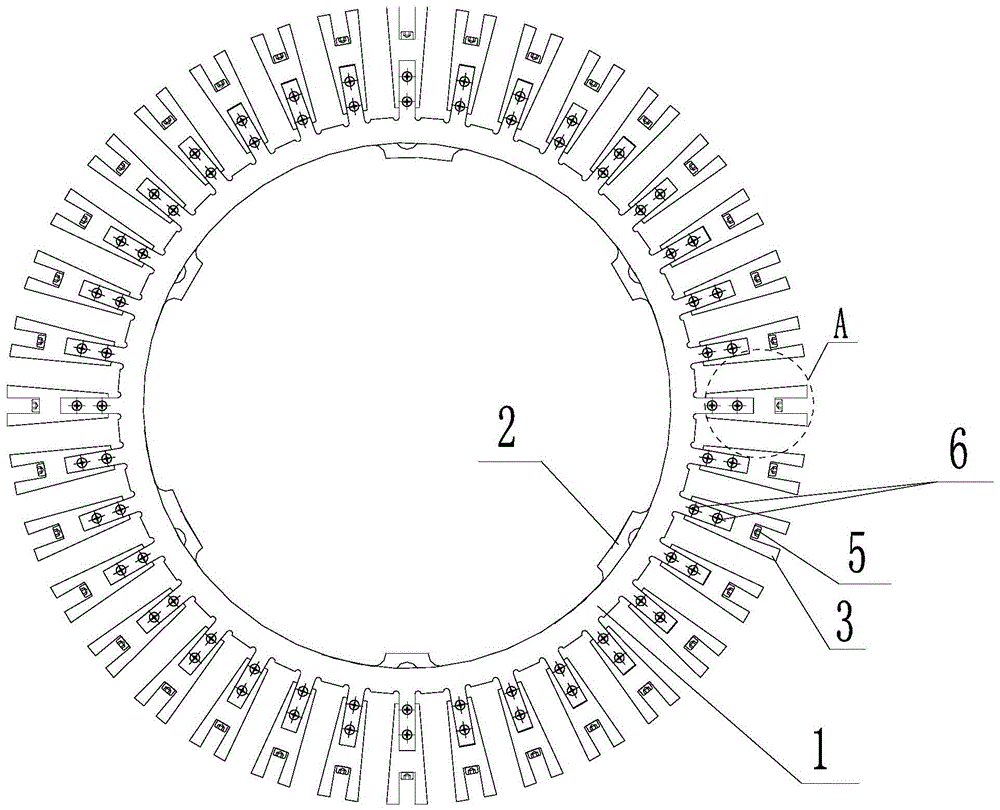

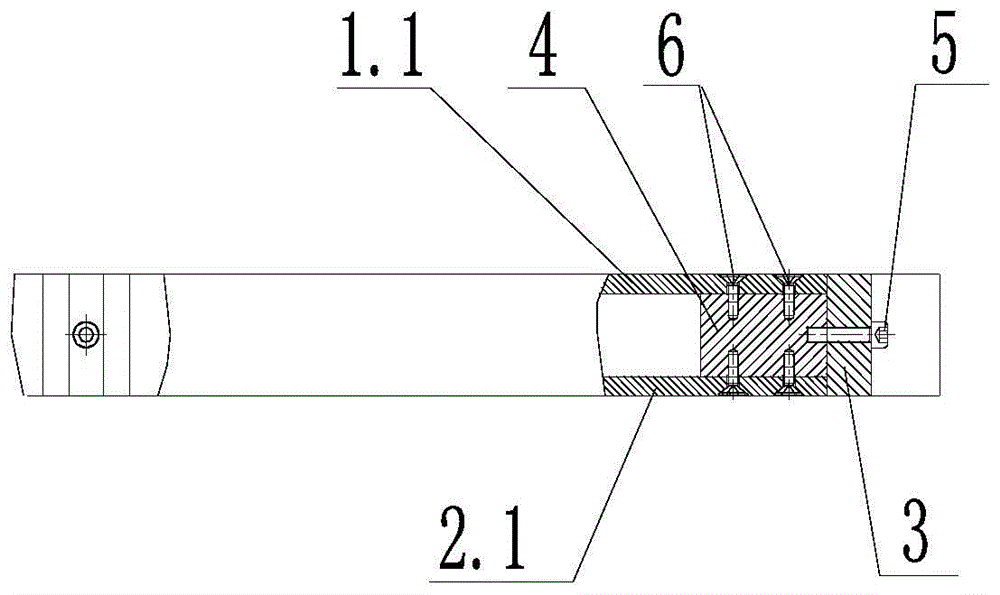

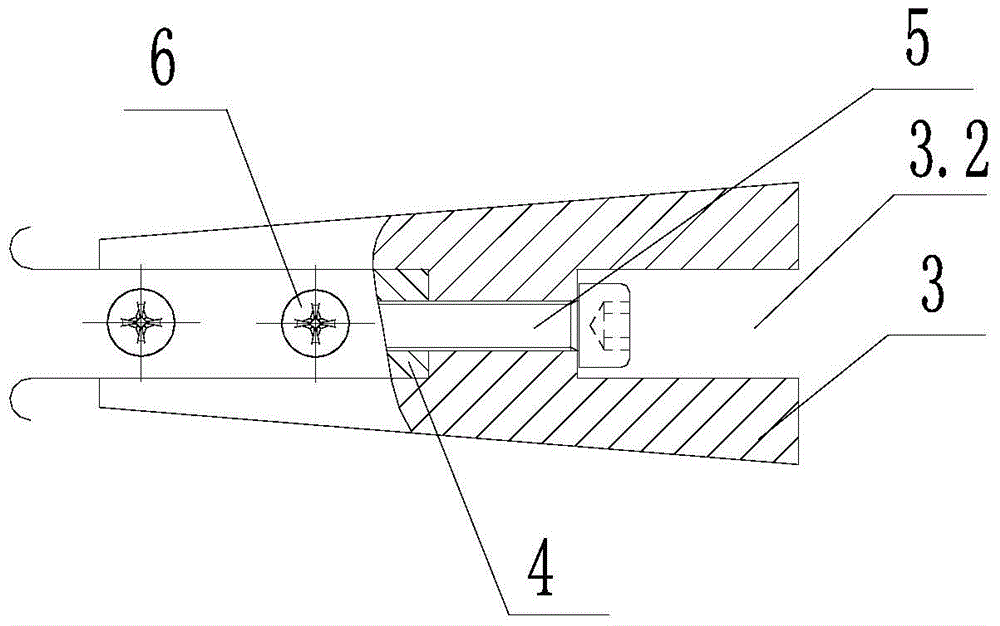

[0017] Example: such as Figure 1 to Figure 5 The shown drying wheel of a cigarette hard box packaging machine includes an upper turntable 1 and a lower turntable 2 coaxially arranged, and the corresponding positions of the edges of the upper turntable 1 and the lower turntable 2 are respectively provided with upper The fixed rod 1.1 and the lower fixed rod 2.1, and the nylon module 3 is fixed between the upper fixed rod 1.1 and the lower fixed rod 2.1. The nylon module 3 is an isosceles trapezoidal column, and a first through-slot 3.1 and a second through-slot 3.2 are provided along the middle parts of the upper bottom surface and the lower bottom surface of the nylon module 3 which are parallel to each other.

[0018] The first through-slot 3.1 and the second through-slot 3.2 are communicated through a through-hole 3.3, and a connection block 4 is placed in the first through-slot 3.1, and the position of the connection block 4 corresponding to the through-hole 3.3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com