Optical-mechanical integrated rapid control reflector

A fast control, mirror technology, applied in optics, optical components, installation, etc., can solve problems such as reducing quality, and achieve the effect of increasing resonance frequency, reducing load, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

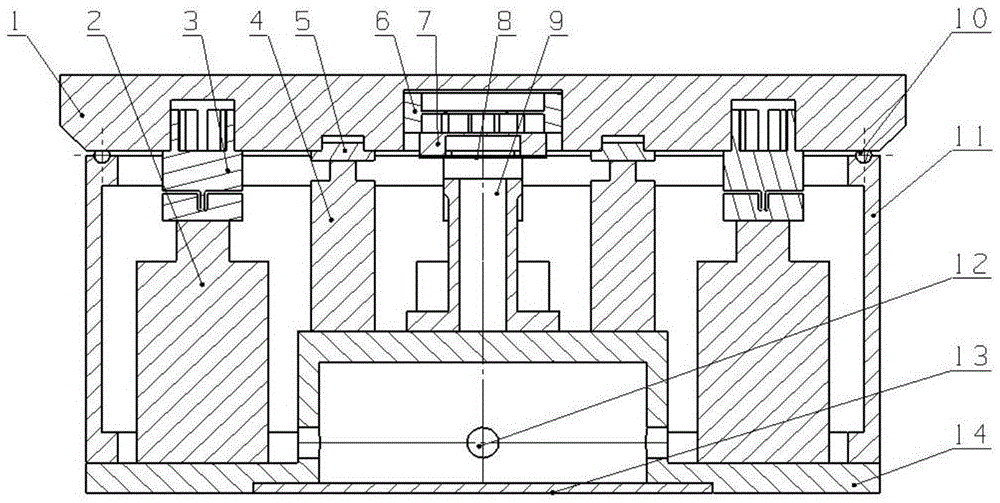

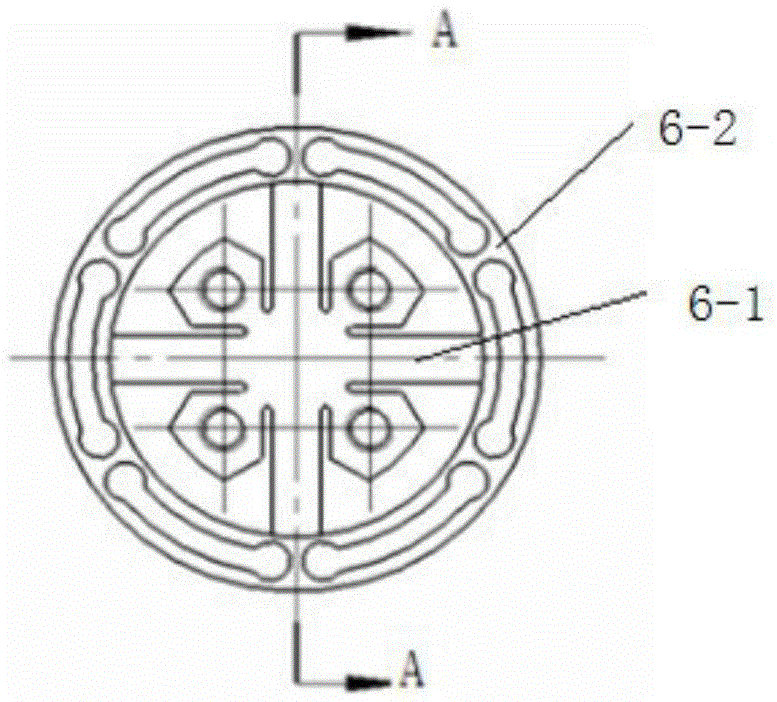

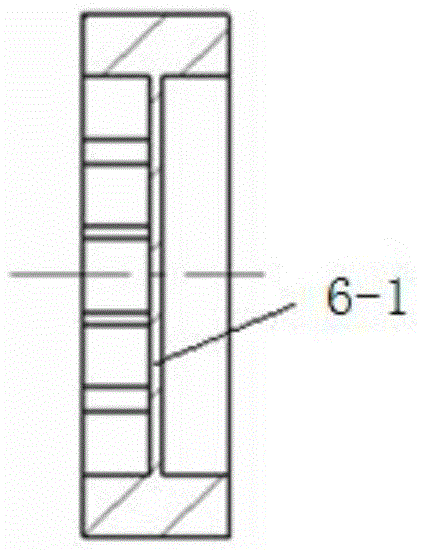

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 3 In this embodiment, the optical-mechanical integration quickly controls the mirror, including the mirror 1, the actuator 2, the elastic sleeve 3, the sensor 4, the sensor sensing pad 5, the elastic rotary center ring 6, and the first axial elastic piece 7 , The second axial elastic piece 8, the central support seat 9, the protective ring 10, the shell 11, the electric control base plate 13 and the base 14.

[0016] The number and layout of the actuator 2, the elastic sleeve 3, the sensor 4 and the sensor sensing pad 5 are consistent. The sensor sensing pad 5 is fixed on the mirror 1 . The reflector 1 is fixedly connected with the actuator 2 through the elastic sleeve 3 . The elastic rotating center ring 6 is connected to the central hole of the reflector in the radial direction, and is connected in series with the first axial elastic sheet 7, the second axial elastic sheet 8 and the central support base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com