Stretching and compressing both-way steel wire rope vibration isolator

A technology of stretching and compressing steel wire rope, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of excessive volume and mass, and achieve the effect of high bearing capacity, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

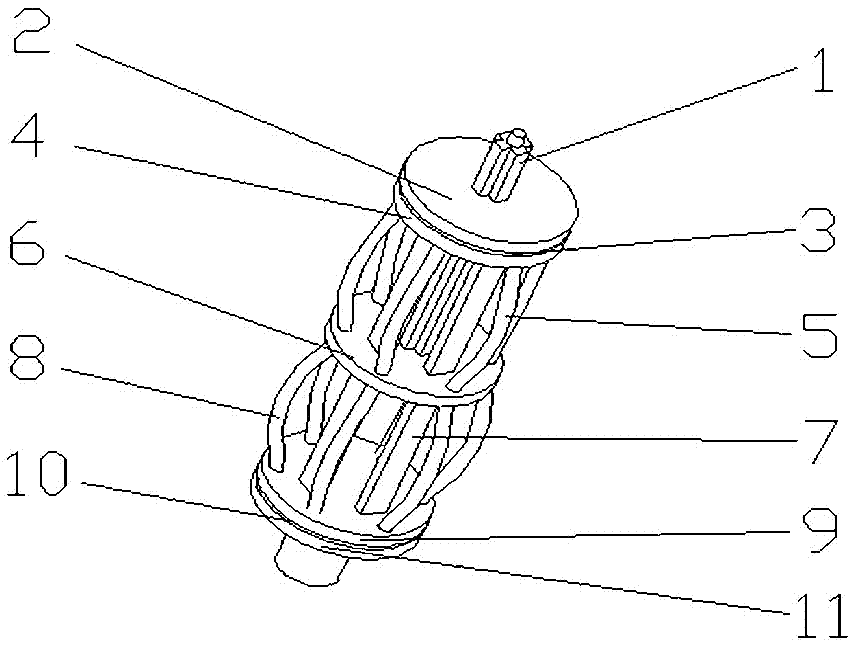

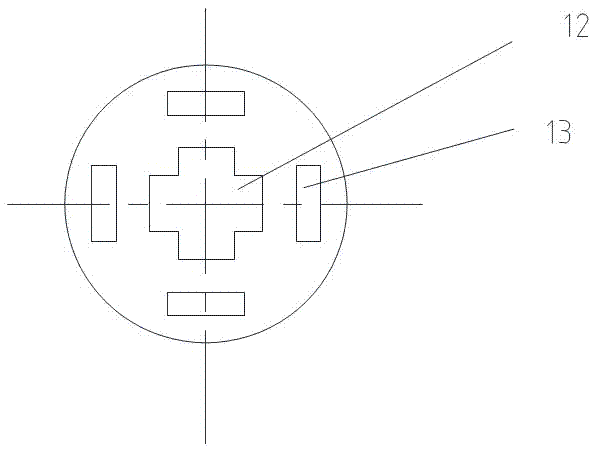

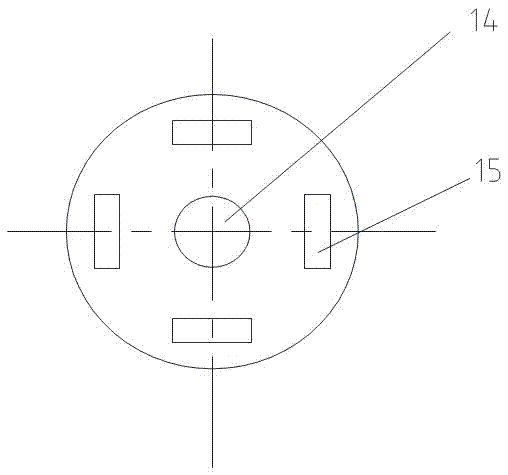

[0064] Embodiment: This embodiment consists of a cross guide rod 1, an upper outer limit block 2, an upper rubber damper 3, an upper inner limit block 4, an upper vibration isolation wire rope 5, a sliding block 6, a plate-like connector 7, and a lower vibration isolation The steel wire rope 8, the lower inner limit block 9, the lower rubber damper 10, and the lower outer limit block 11 are formed. The upper rubber damper 3 is fixed together with the upper outer limit block 2 by adhesive, the lower rubber damper 10 is fixed together with the lower outer limit block 11 by adhesive, and the cross outer surface of the cross guide rod 1 is connected with the upper outer The limit block 2, the upper rubber damper 3, the cross hole in the sliding block 6 adopt clearance fit, and the surface of the cross sliding block 1 is coated with lubricating oil, which not only ensures the smooth operation of the vibration isolator, but also ensures that the vibration isolator can be restrained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com