Focal plane assembly adjusting device and method

A technology for adjusting devices and focal planes, applied in installation, optical components, optics, etc., can solve the problems of bulkiness, large device size, and inability to realize six-dimensional adjustment, and achieve six-dimensional adjustment, stable and reliable performance, and The effect of the lock function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

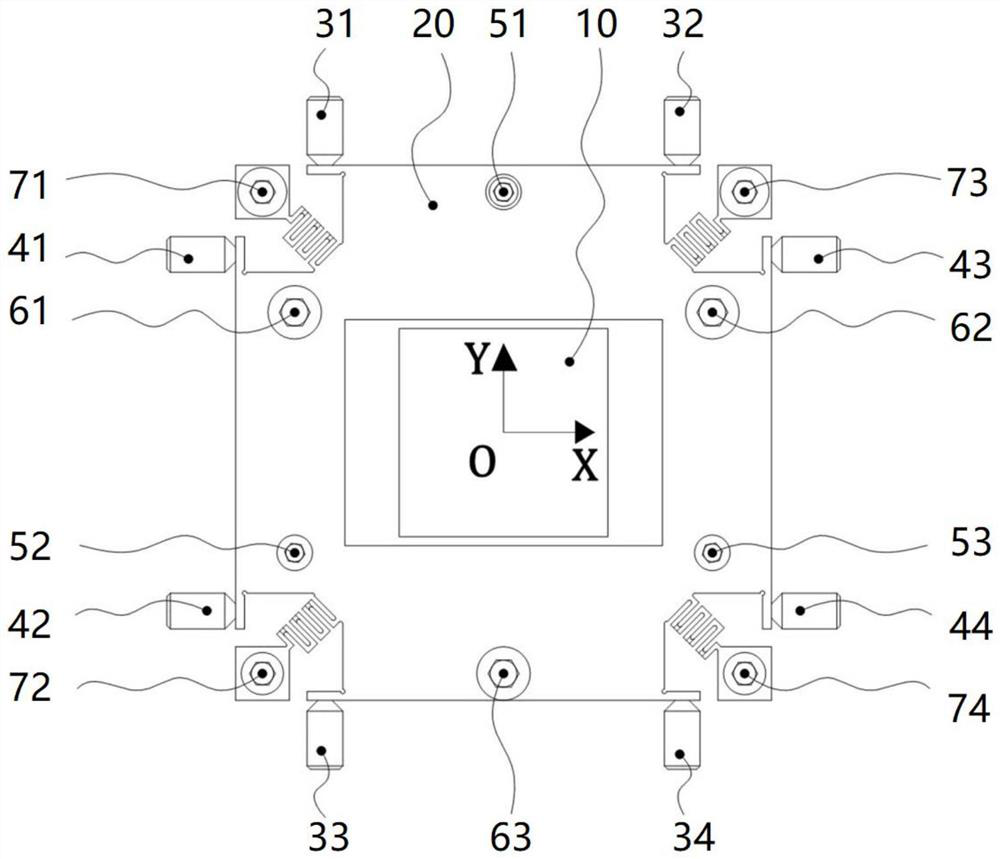

[0053] Such as figure 1As shown, a focal plane assembly adjustment device of the present invention includes a detector 10, a detector mounting plate 20, fixing screws 71-74, locking screws 61-63, and the first set of screws 31-63 for adjusting and tightening. 34. The second set of screws 41-44, and the third set of screws 51-53.

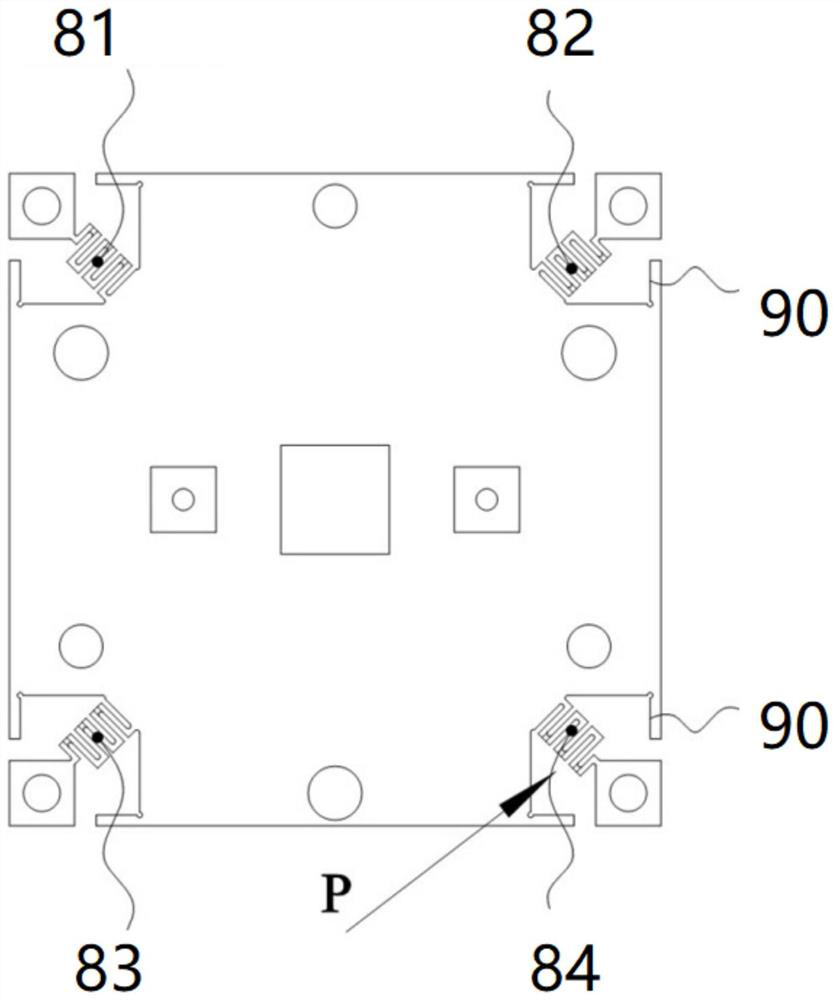

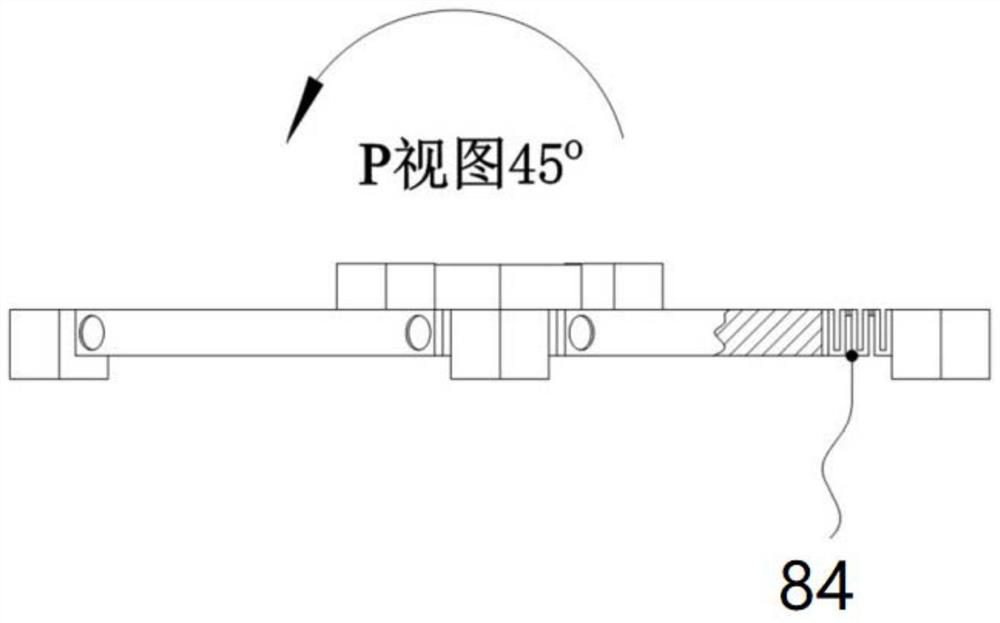

[0054] Cooperate see figure 1 , Figure 2a , Figure 2b , Figure 3a , Figure 3b As shown, the detector 10 is fixed on the detector mounting plate 20; the fixing screws 71-74 are used to initially fix the detector mounting plate 20 on the base 100; the screws 31-34, 41-44, 51-53 are divided into three parts. The group is used for six-dimensional adjustment; the locking screws 61-63 are used to fix and lock the detector mounting plate 20.

[0055] The detector mounting plate 20 has four fixing screw holes for setting corresponding fixing screws 71-74. The mounting blocks for the four fixing screw holes are located at the four corners of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com