A calculation method for assembling performance of outer sealing strip of car windowsill

A calculation method and sealing strip technology, which is applied in the calculation field of the assembly performance of the outer sealing strip of the window sill of a car, can solve the problems of unsuitable assembly performance of the sealing strip, improve design quality and efficiency, improve calculation efficiency, and save development costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

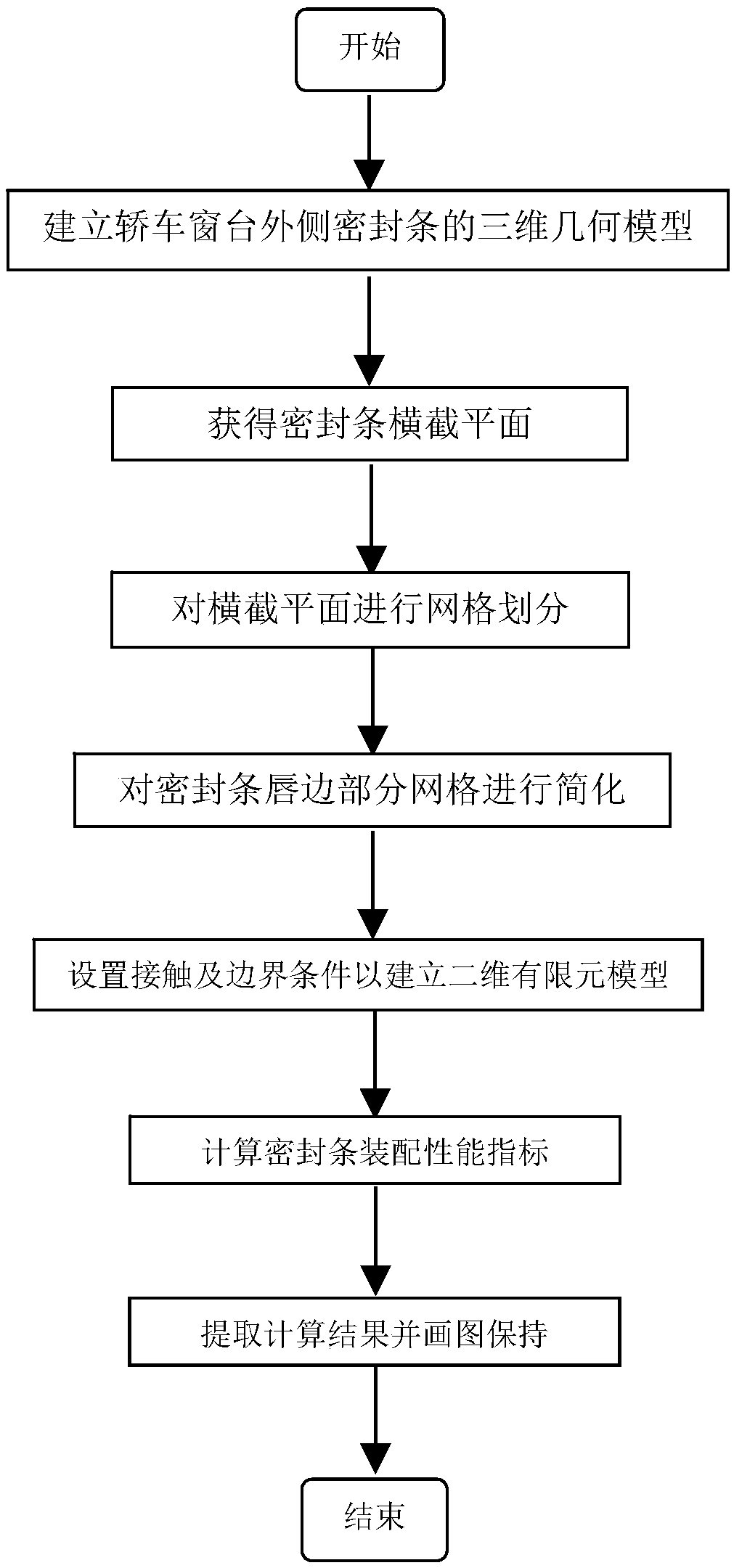

[0039] According to attached figure 1 As shown in the flow diagram of the calculation method for the assembly performance of the outer sealing strip of the car window sill, a calculation method for the assembly performance of the outer sealing strip of the car window sill includes the following steps:

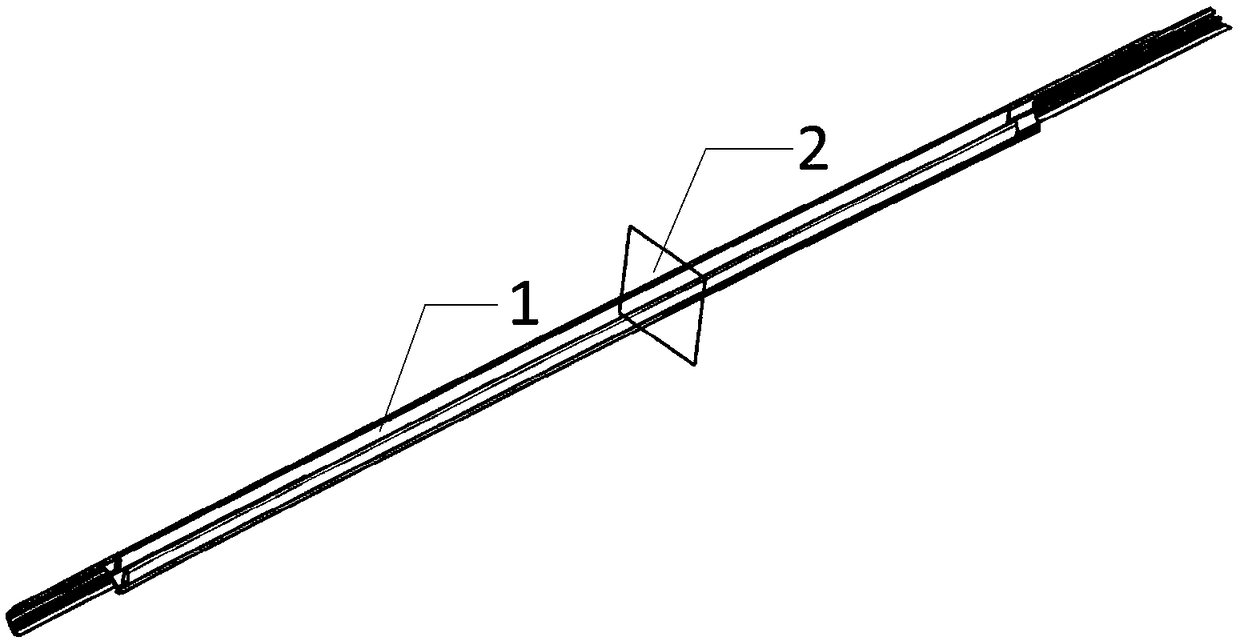

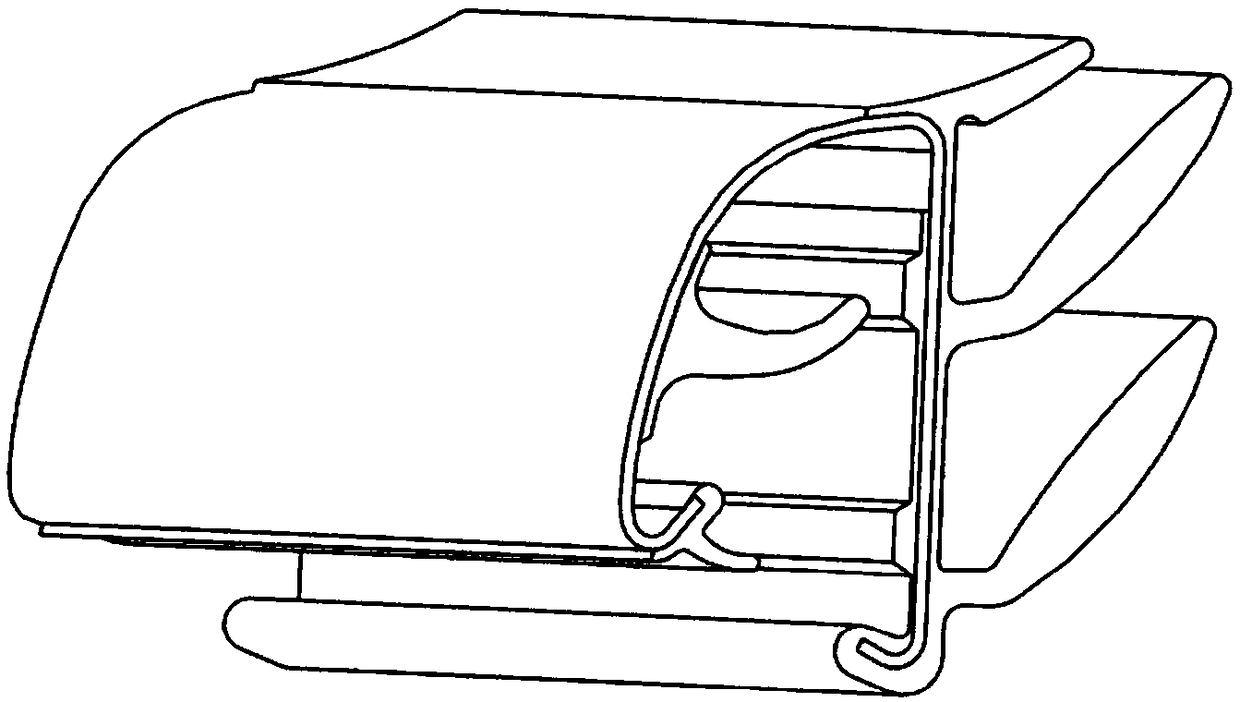

[0040] (1) Use the 3D modeling software UG to establish the 3D geometric model 1 of the outer sealing strip of the car window sill, and create a 3D geometric model 1 on the 3D geometric model 1 figure 2 The geometric plane 2 is shown, and the geometric plane 2 is perpendicular to the feature line on the 3D geometric model 1; the 3D geometric model 1 is split through the geometric plane 2, and the result is as follows image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com