Spindle thermal distortion compensation method for precision horizontal machining center

A machining center and compensation method technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of increasing cost and increasing system complexity, and achieve the effect of reducing thermal error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

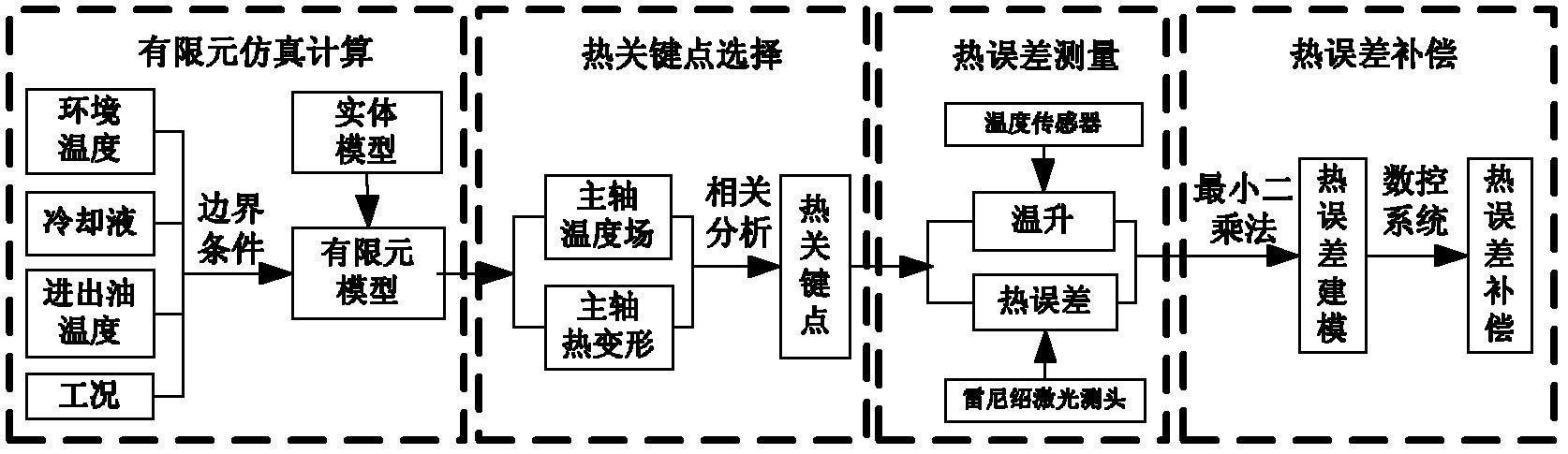

[0018] see figure 1 , 1. Finite element simulation of the temperature field and thermal deformation of the spindle system of the precision horizontal machining center

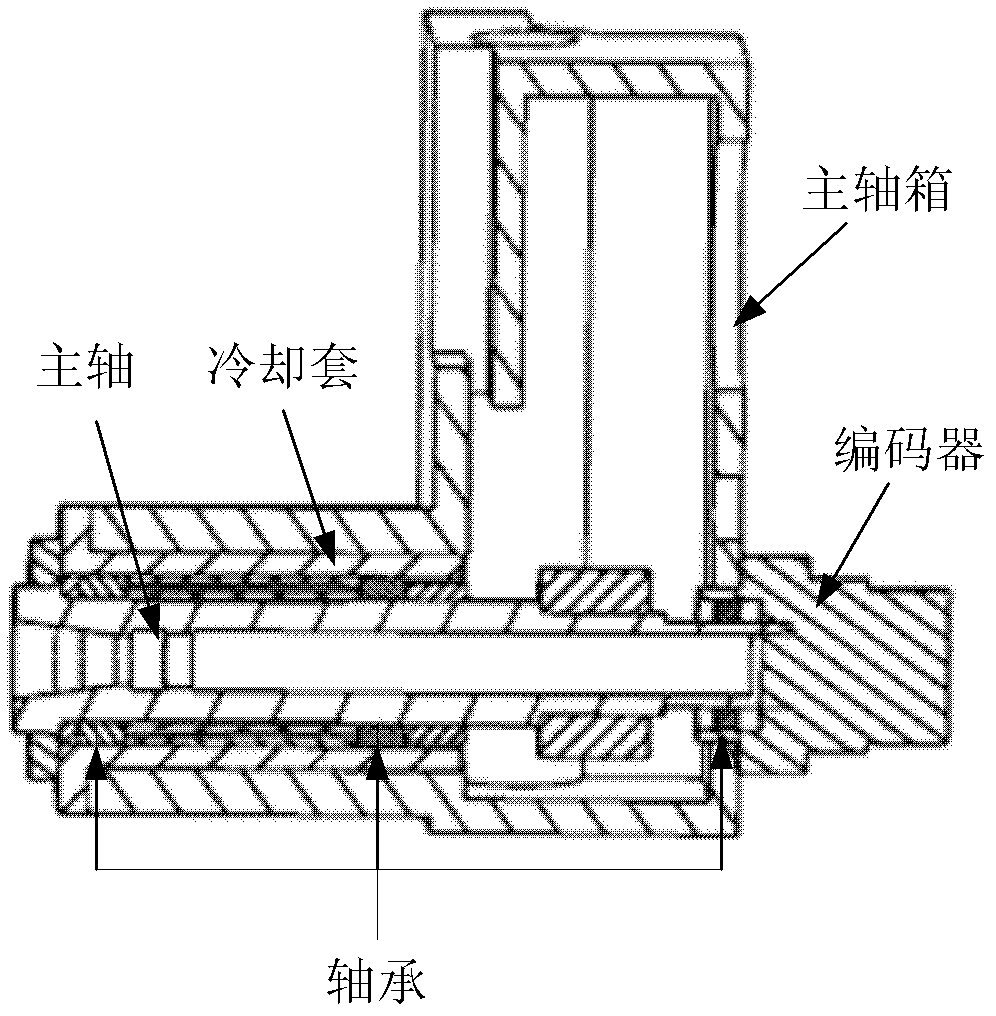

[0019] 1) The establishment of the finite element model and the application of boundary conditions: first, according to the structural characteristics of the machine tool spindle system, the spindle system of the precision horizontal machining center is simplified by Pro / E software, and the simplified solid model is imported into the ANSYS / Workbench analysis software for analysis. Mesh division: select different division methods according to the structural characteristics of different parts of the spindle system, such as selecting sweep division for regular structural cylinders and cubes, and selecting tetrahedron division or free division for components with complex structures. Combined with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com