Patents

Literature

32results about How to "Effective control of temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

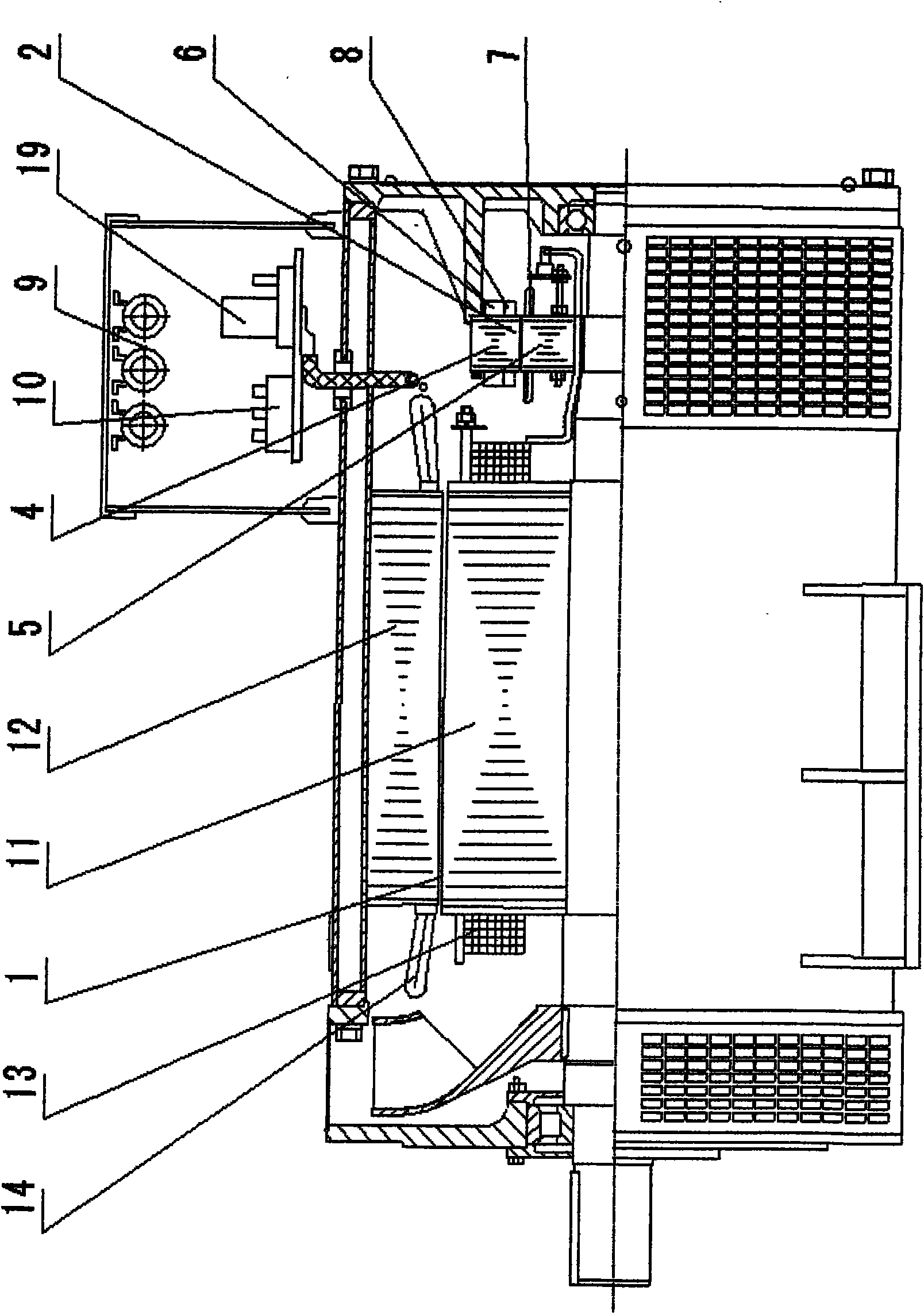

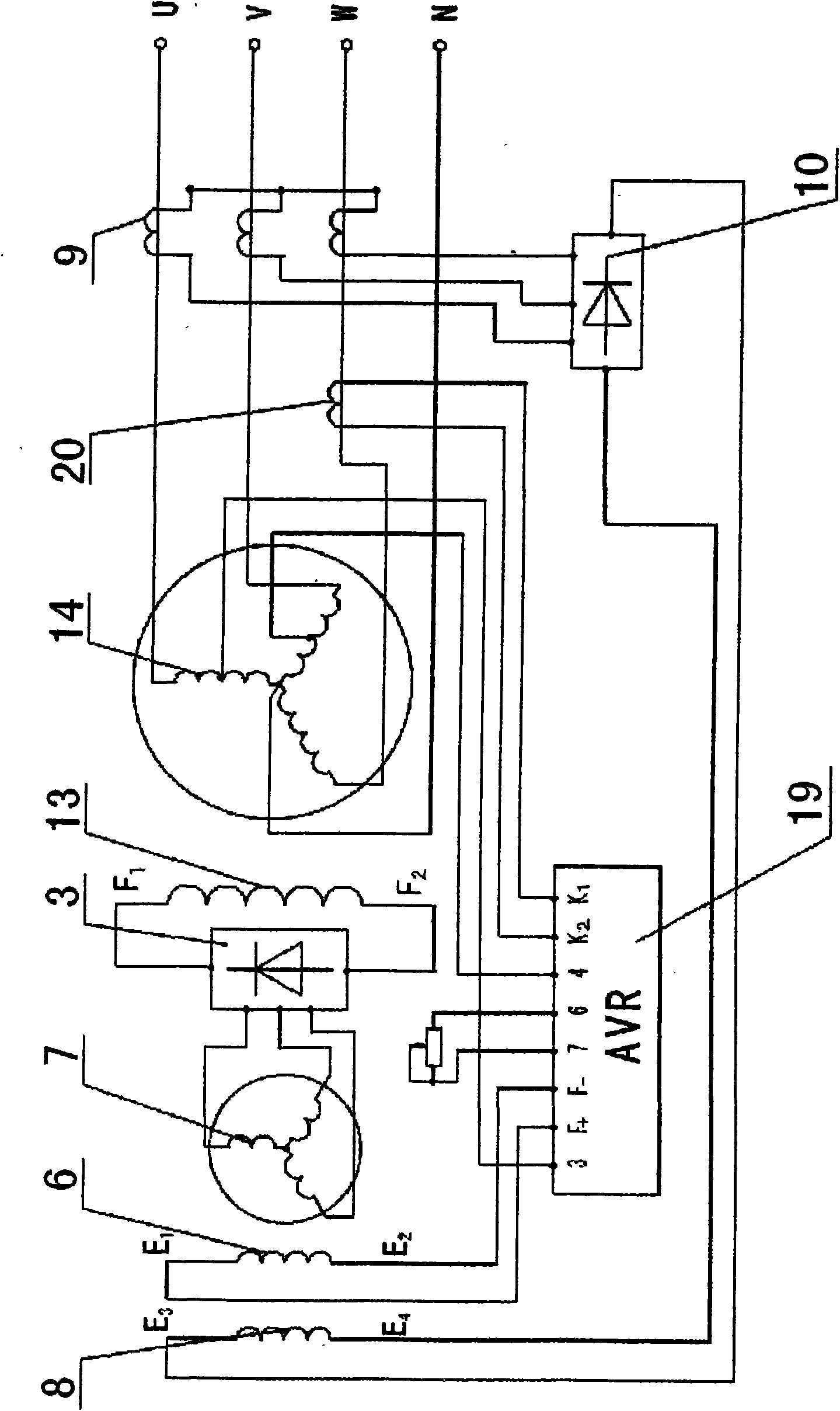

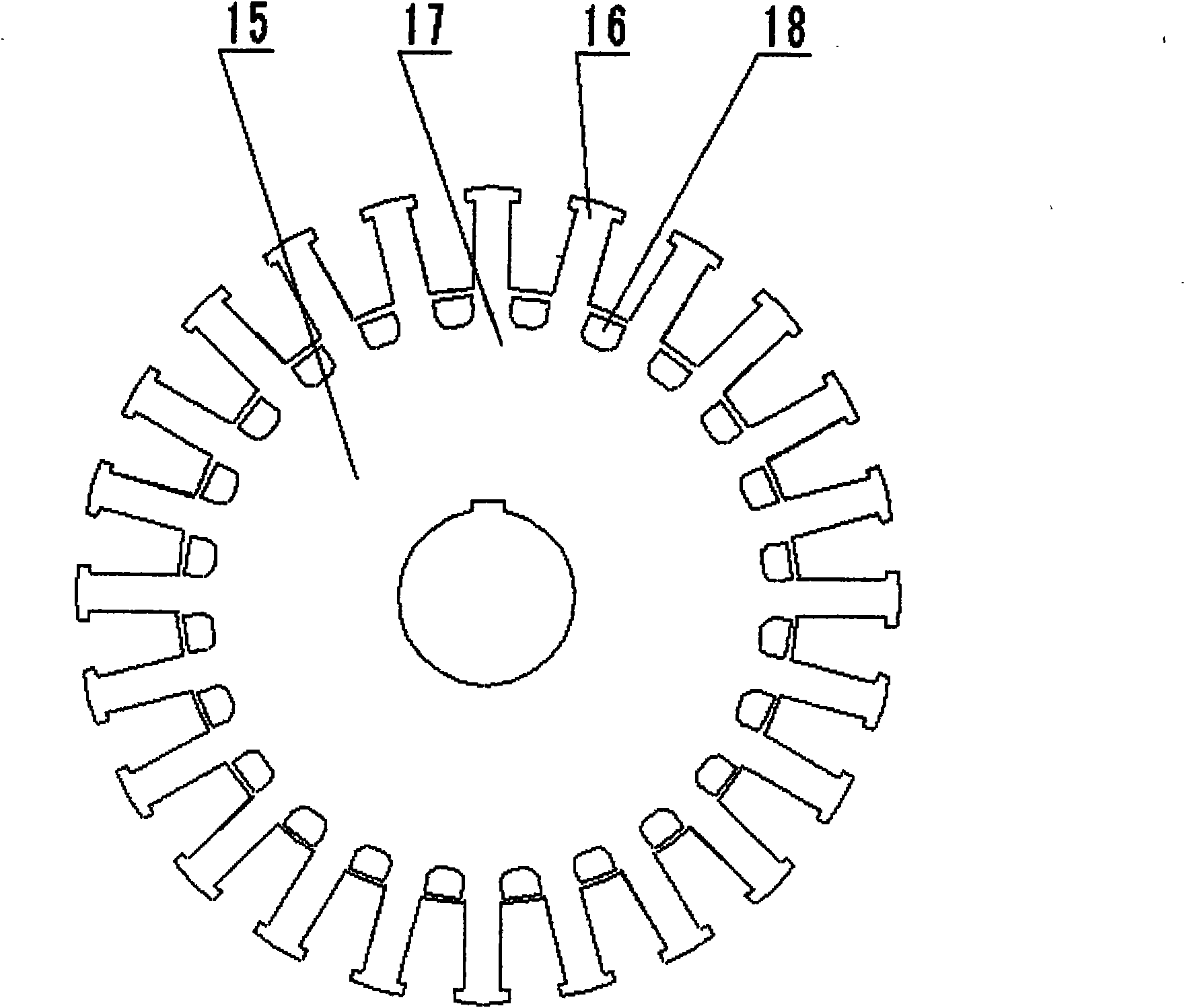

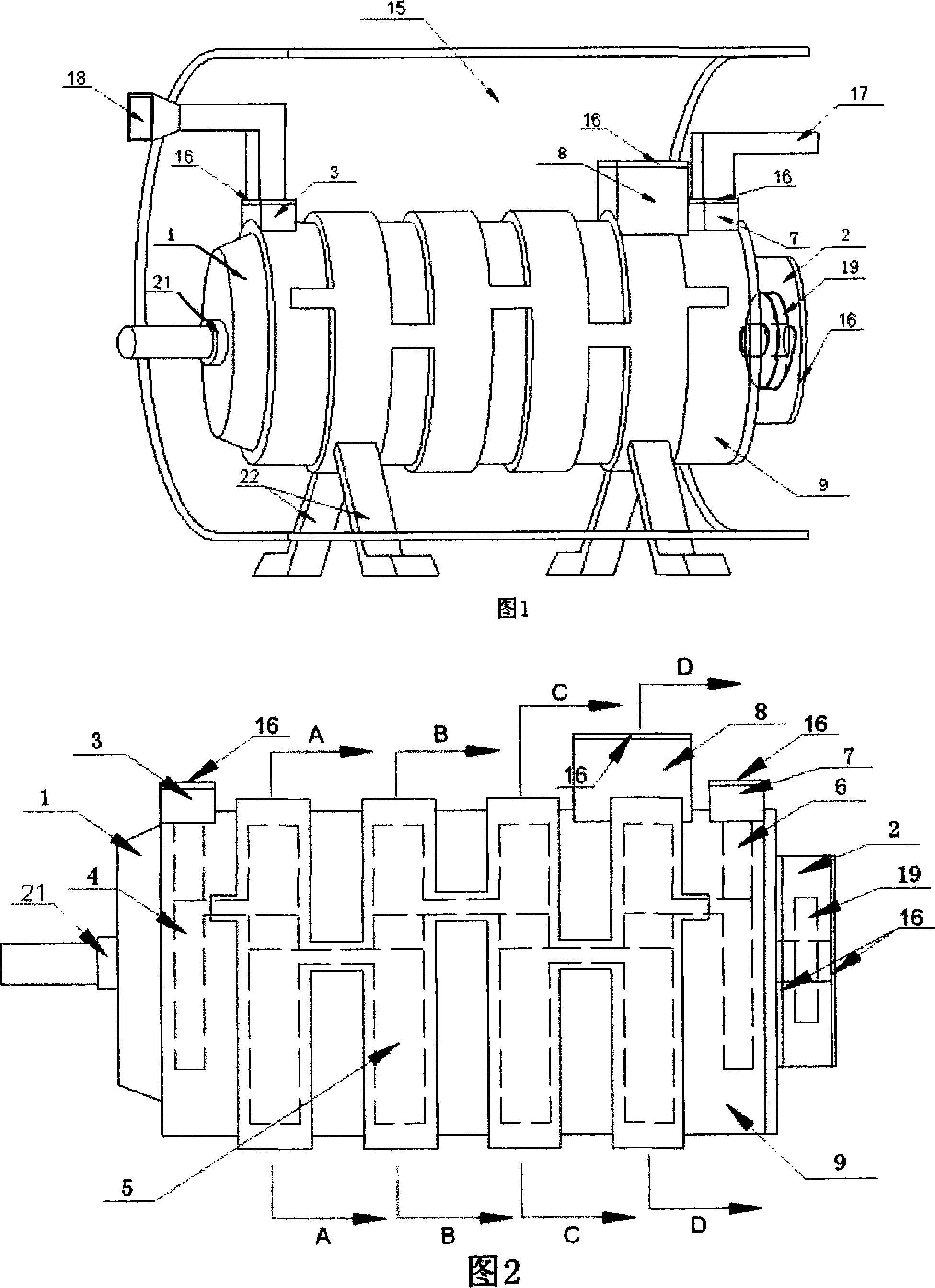

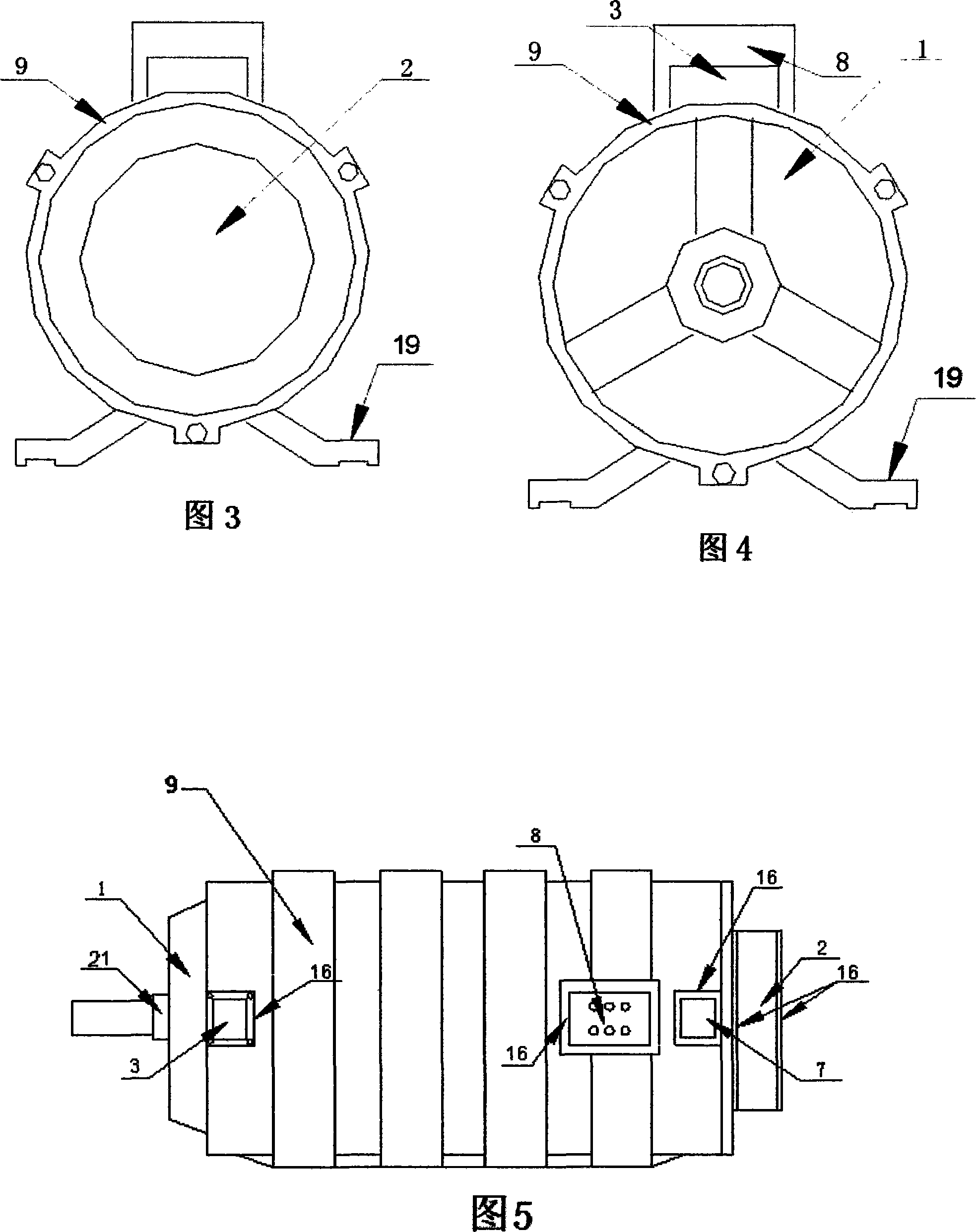

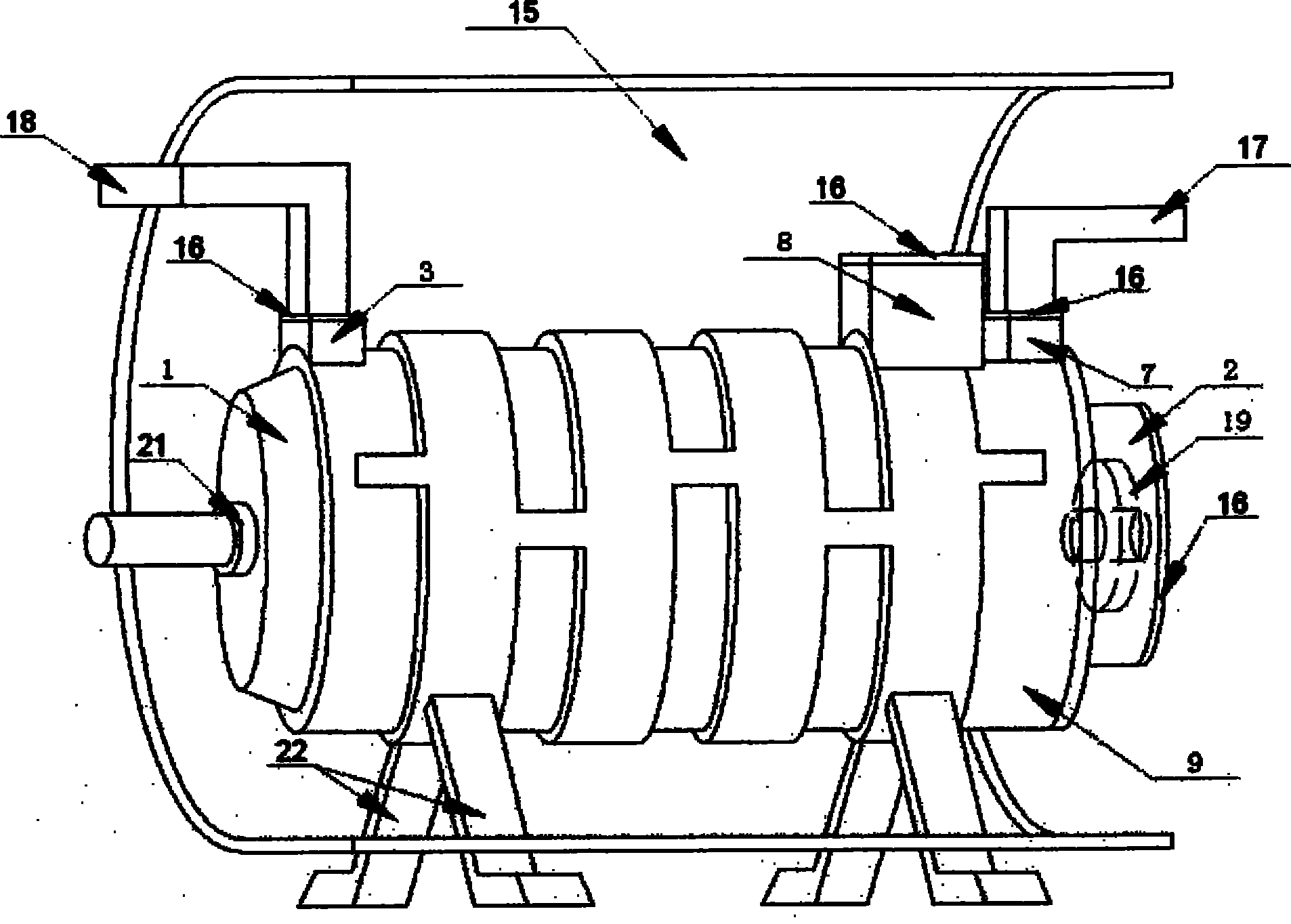

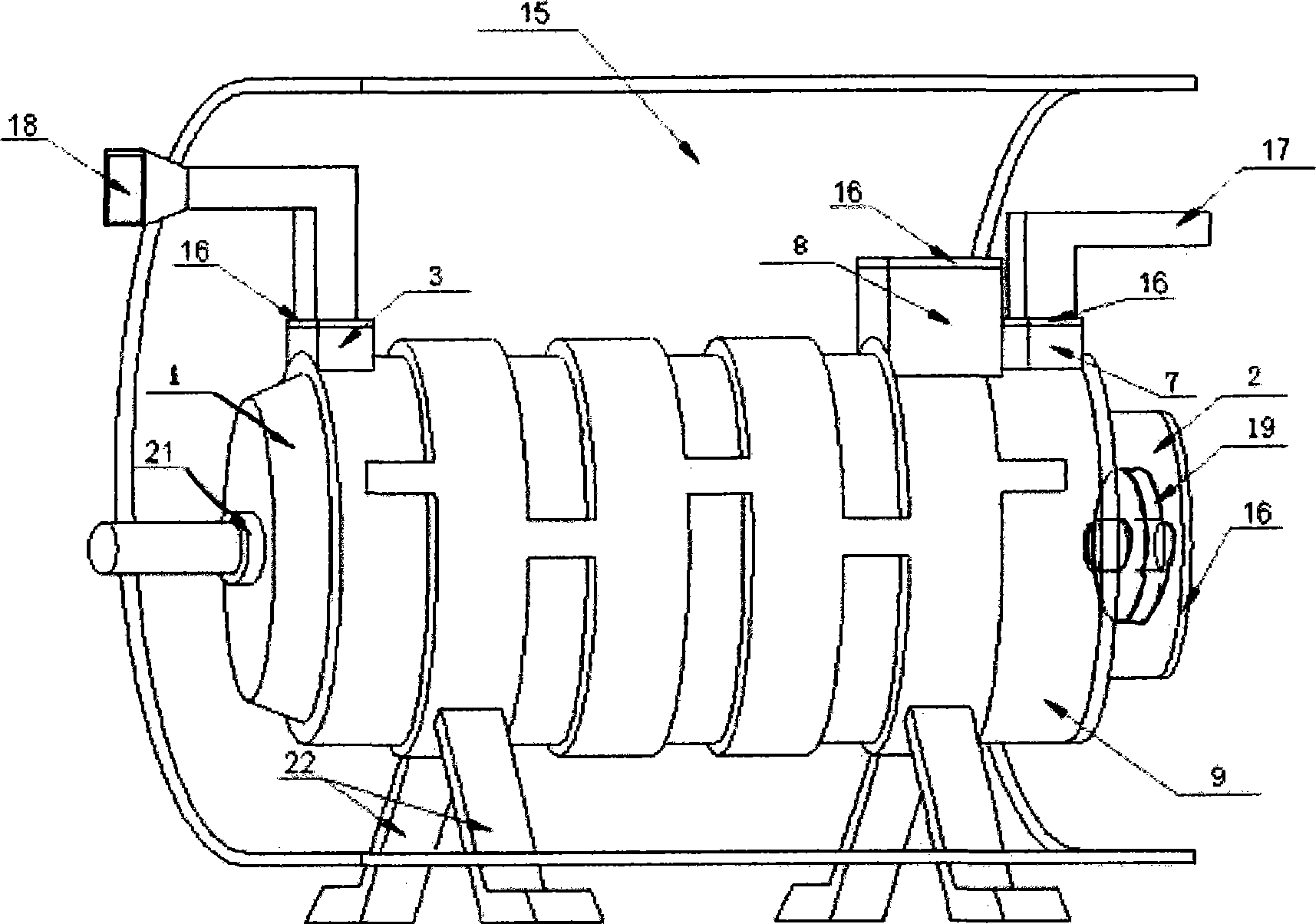

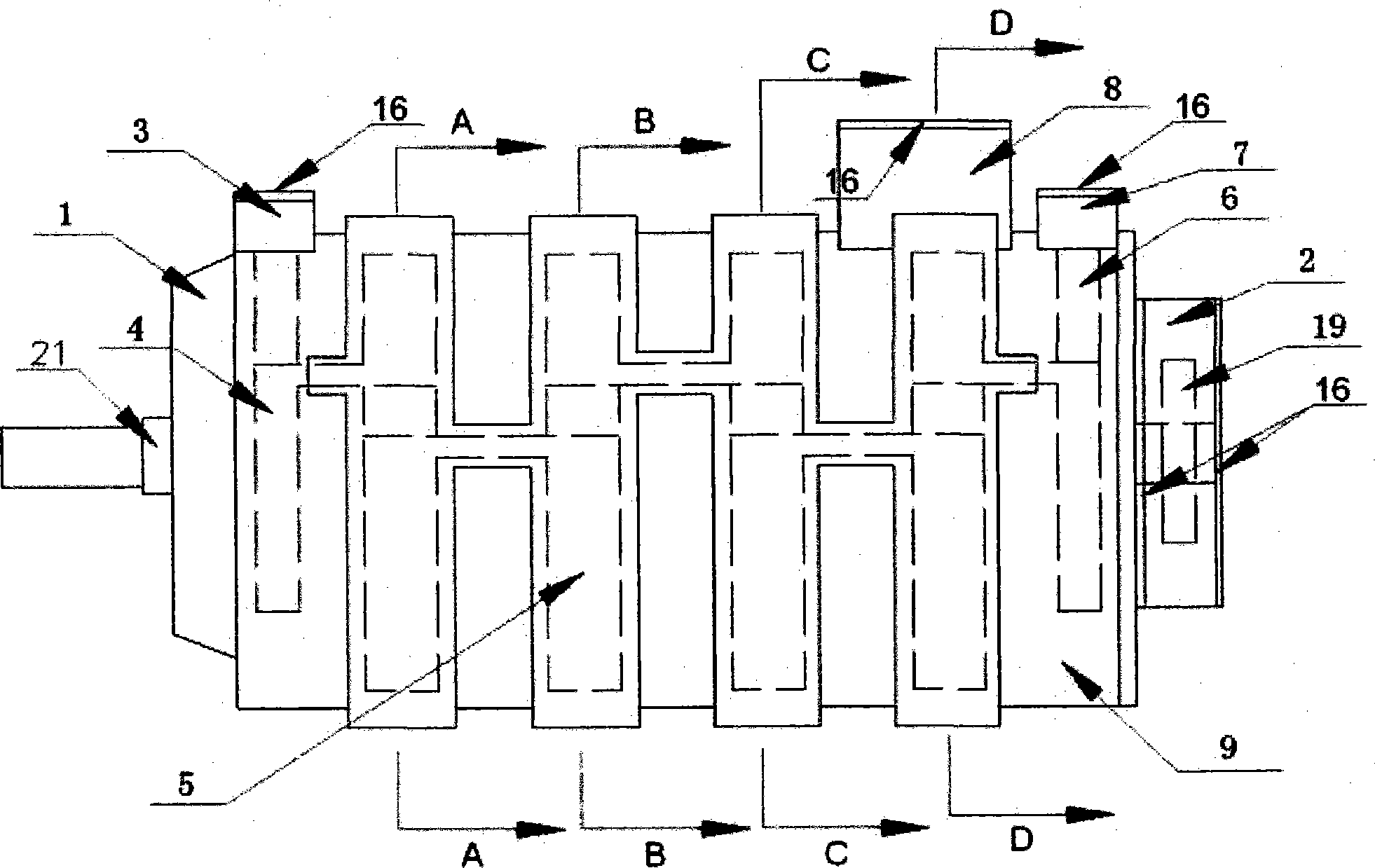

Overall salient type intermediate-frequency brushless excitation synchronous generator

InactiveCN101795040AThe voltage is basically constantStator magnetic field enhancementSynchronous generatorsCooling/ventillation arrangementIntermediate frequencyTransformer

The invention relates to an overall salient type intermediate-frequency brushless excitation synchronous generator, which comprises a main generator, an exciter, an excitation regulating system. The excitation regulating system consists of a compound excitation device, a rotating rectifier and an AVR automatic voltage regulator, wherein the compound excitation device consists of a compound excitation winding, a compound excitation current transformer and a three-phase rectifier bridge, the stator of the main generator adopts a fractional slot type short-range winding, the slot number per pole and per phase q is a fractional value, the rotor of the main generator is formed by lamination of multi-pole rotor core laminated pieces, the rotor core of the main generator is of an overall salient type rotor core structure and is formed by overall punching and lamination of rotor core laminated pieces, each rotor core laminated piece is formed with a magnetic pole and a magnetic yoke integrated, and an axial air-cooling hole is arranged at the magnetic yoke. The generator realizes the brushless excitation intermediate-frequency generation, outputs the single-phase or three-phase intermediate-frequency voltage, and has the advantages of excellent performance, stable and reliable operation and high output power.

Owner:上海强辉电机有限公司

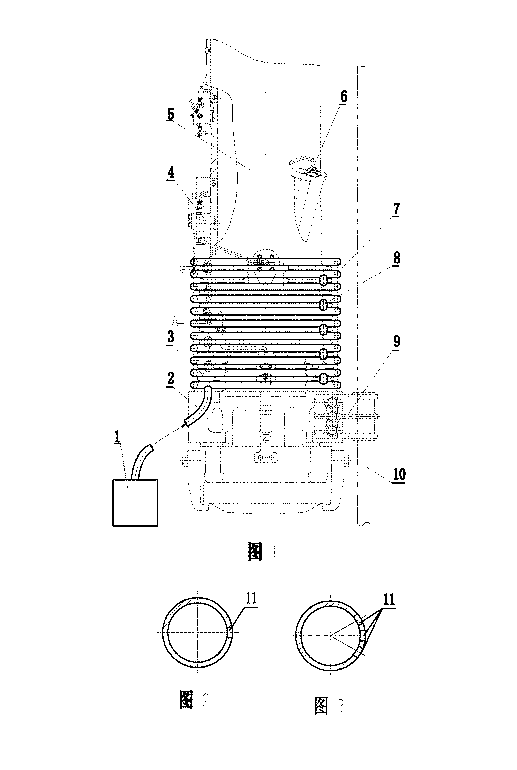

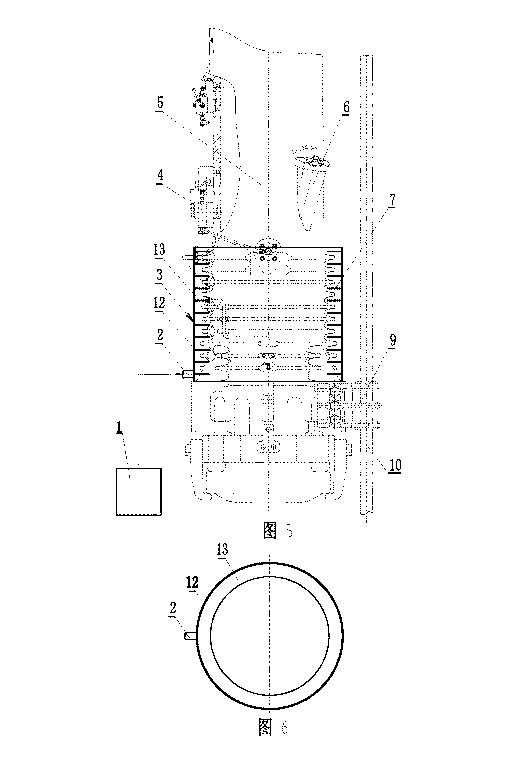

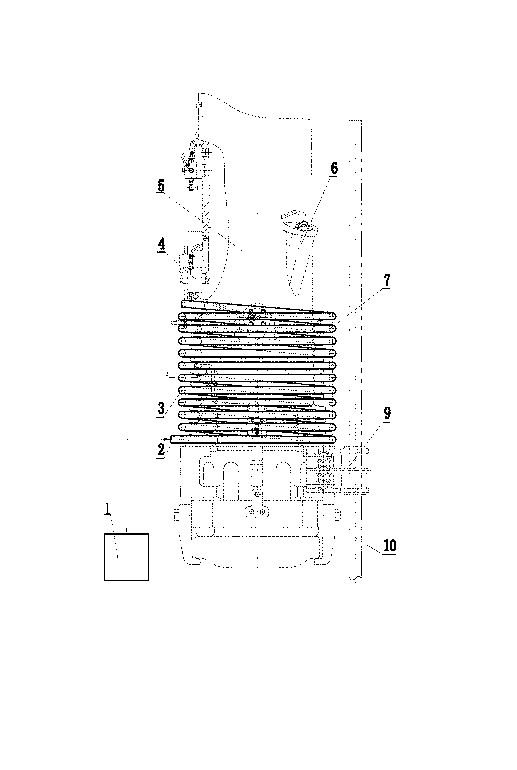

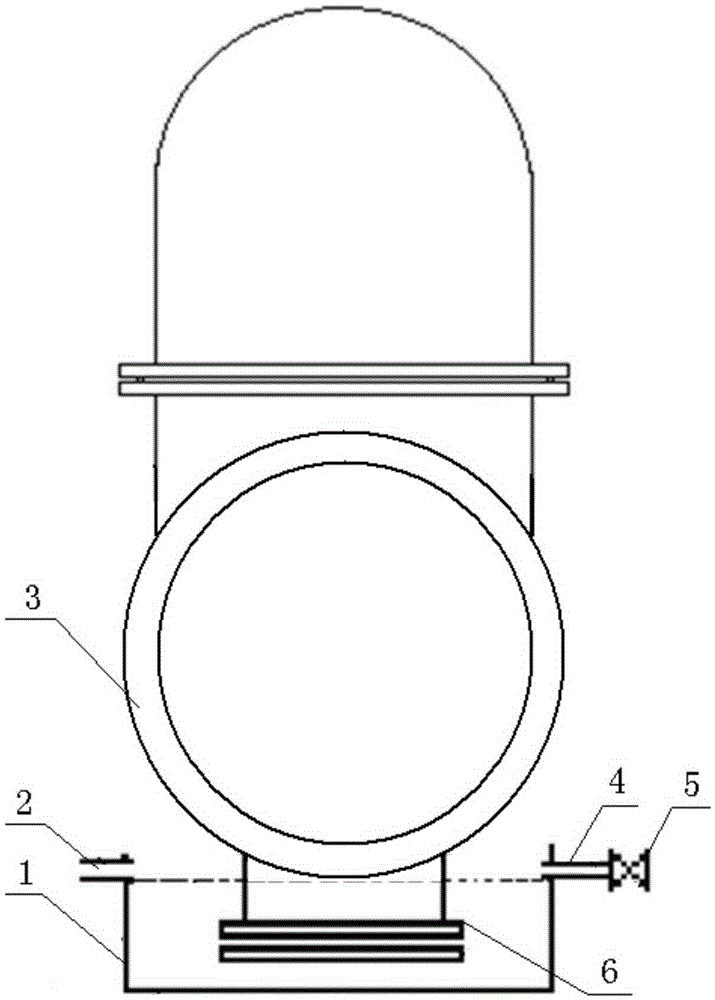

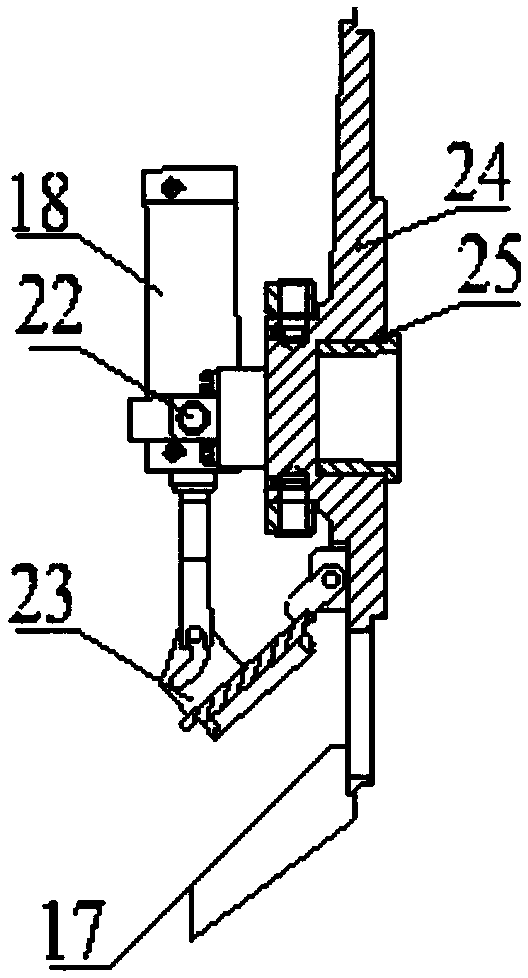

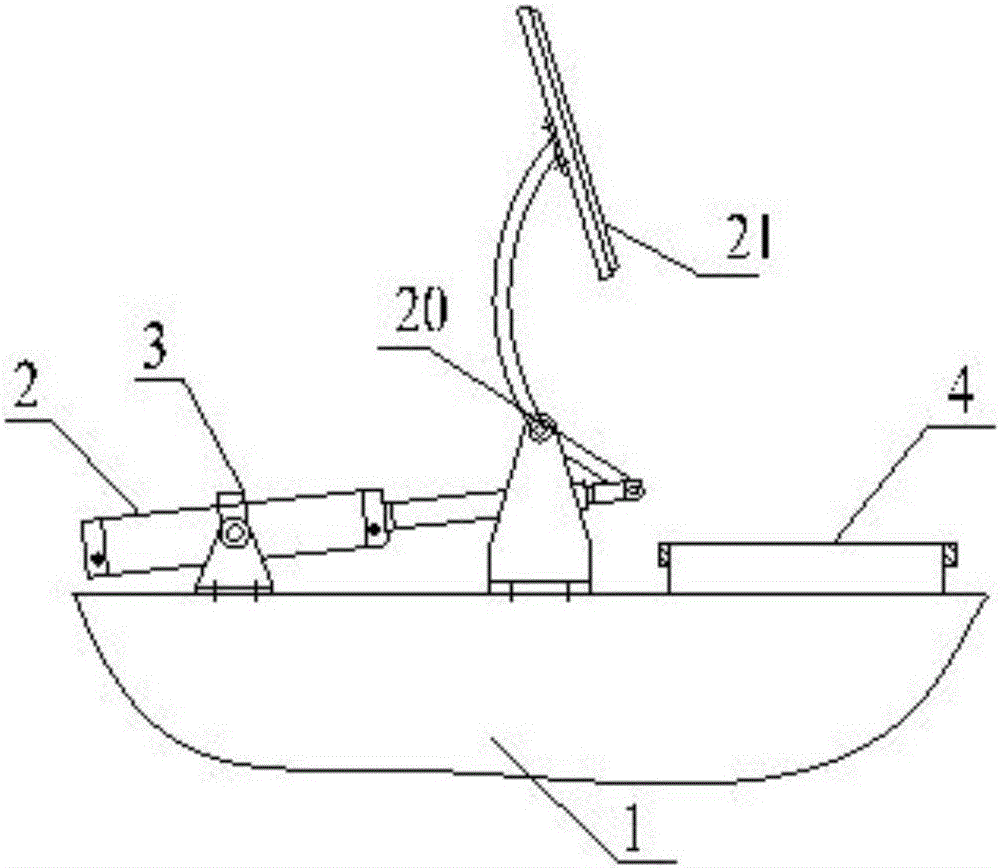

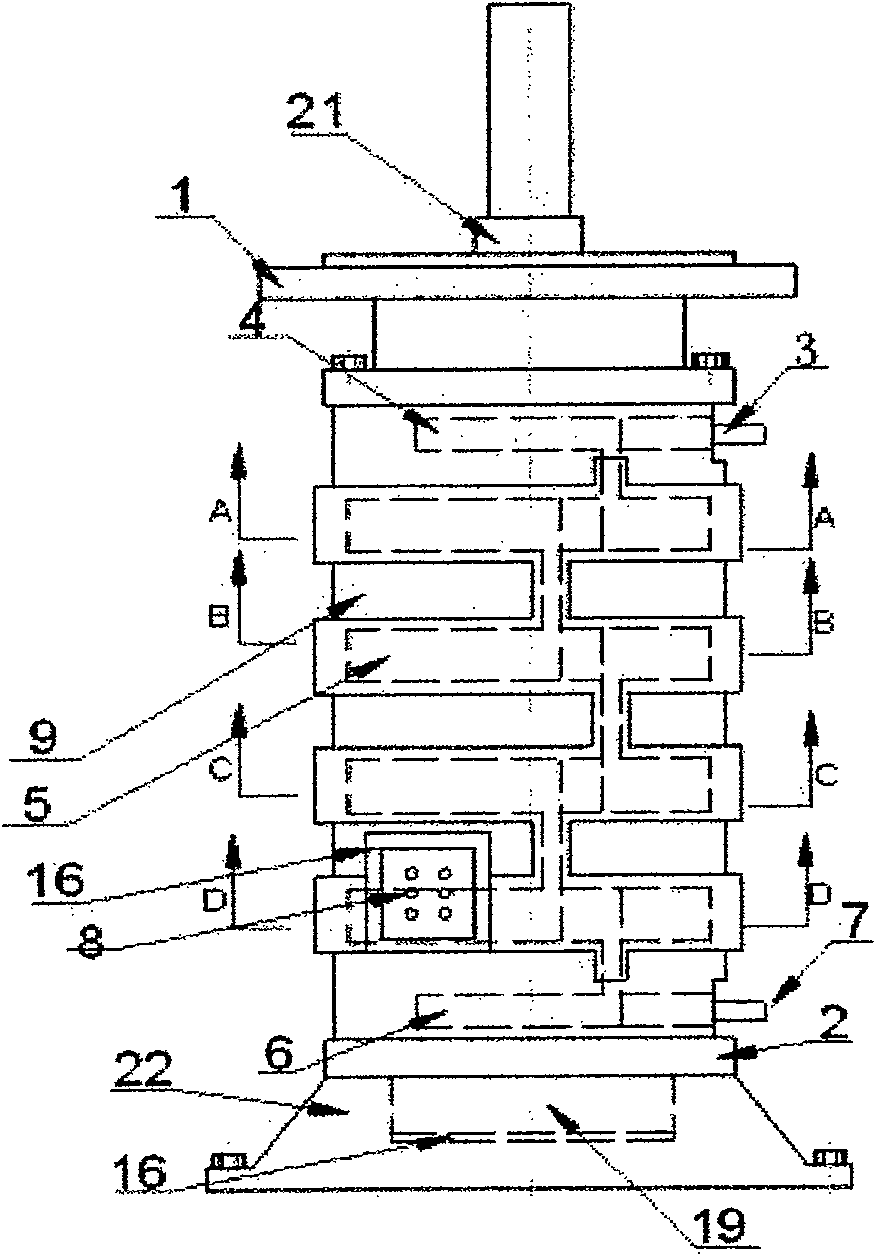

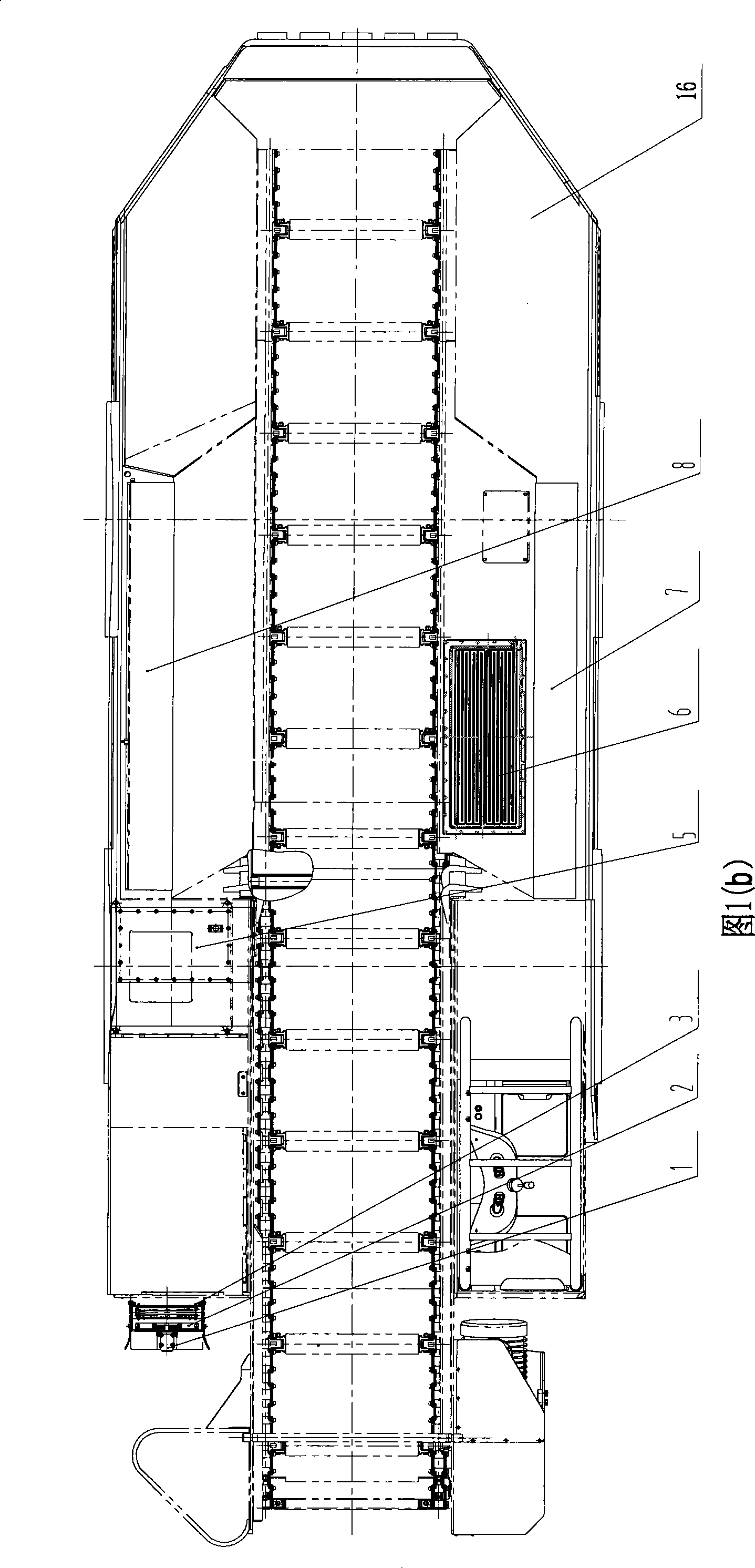

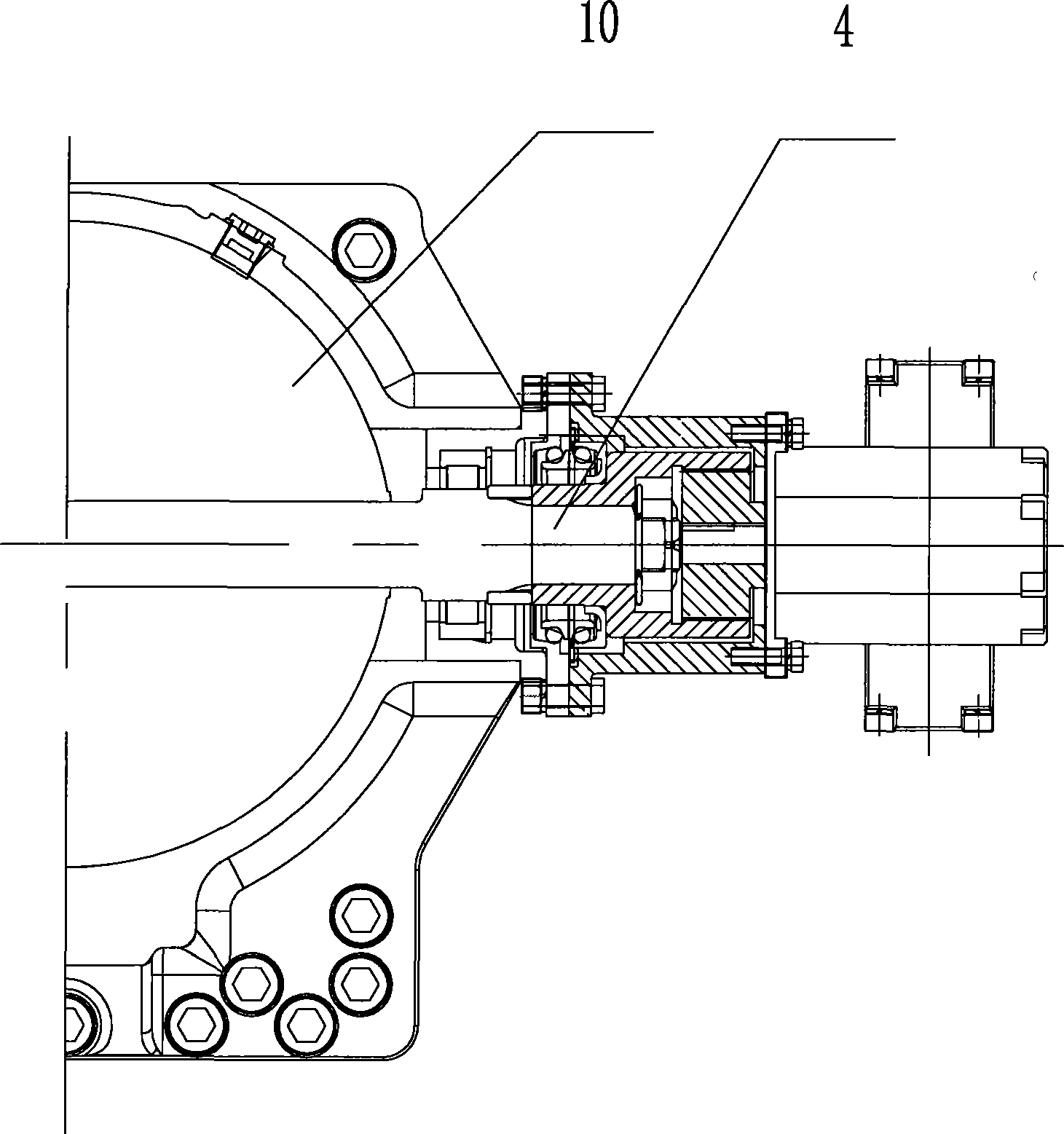

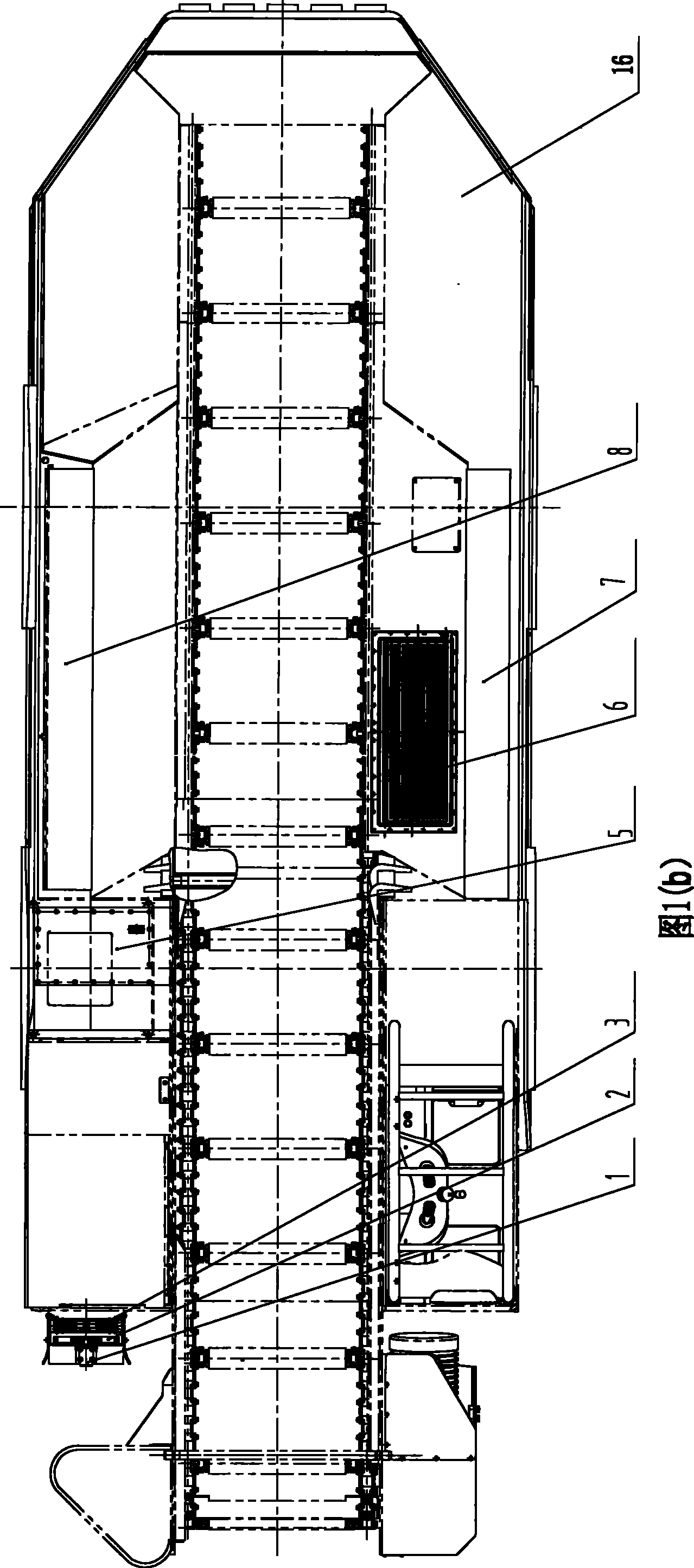

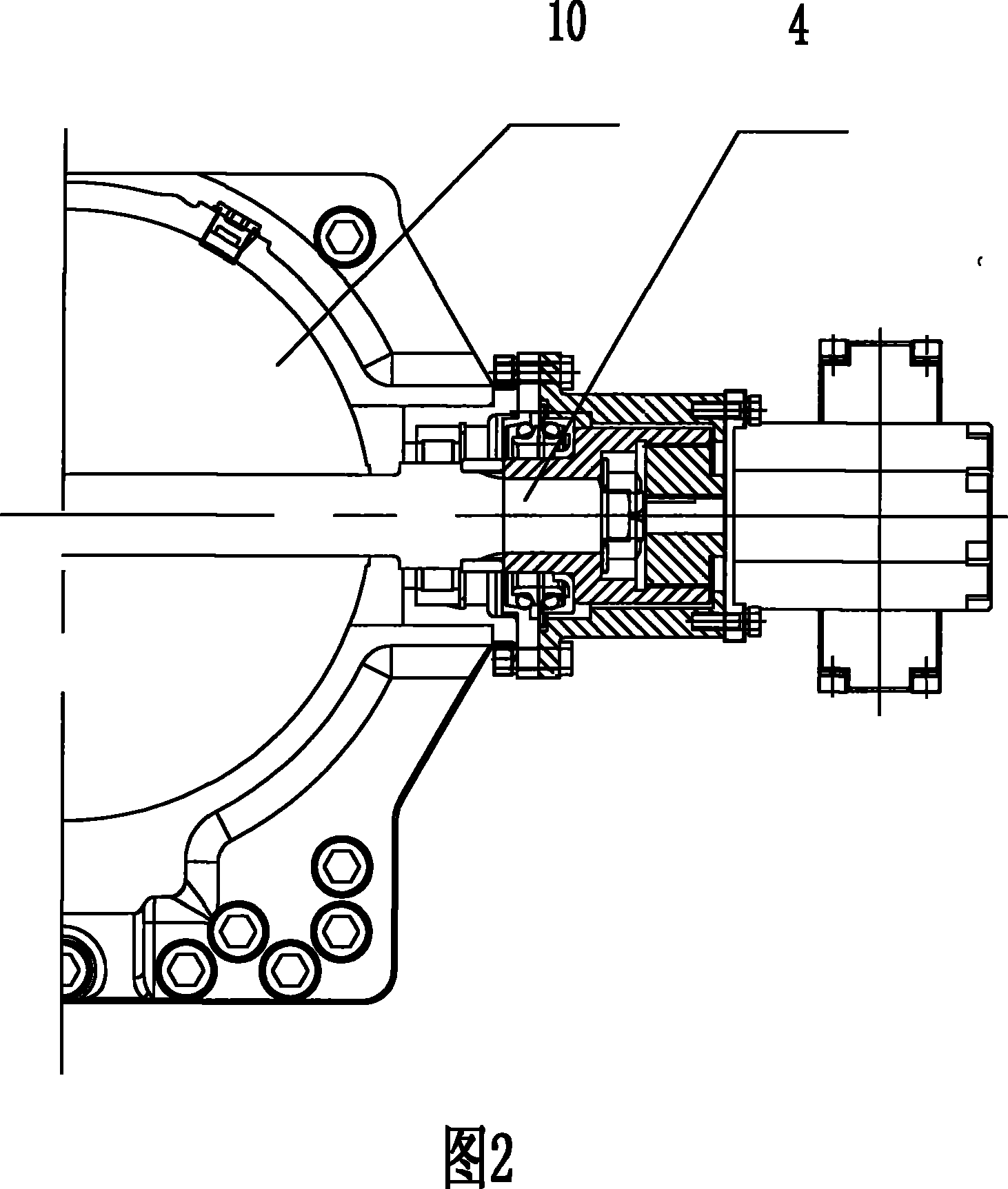

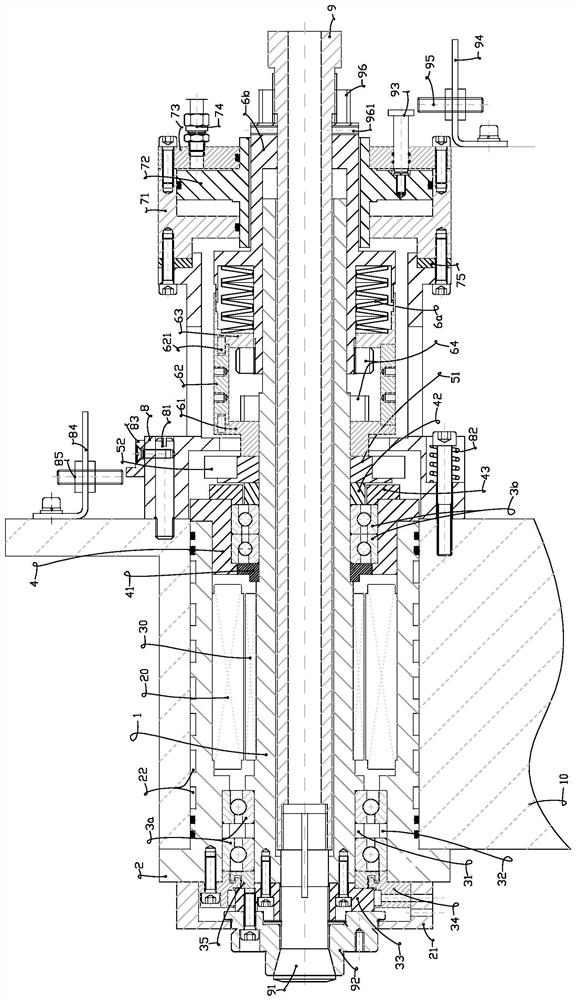

Cylindrical diesel pile hammer with forced cooling function

ActiveCN102797258AHeat dissipation fastEffective control of temperature riseBulkheads/pilesCoolant flowEngineering

The invention discloses a cylindrical diesel pile hammer with a forced cooling function. The cylindrical diesel pile hammer comprises a lower cylinder, wherein a fuel pump and an air sucking and exhausting port are arranged on a lower cylinder body; the fuel pump is communicated with an oil nozzle; the air sucking and exhausting port runs through the wall of the lower cylinder body; a coolant forced flowing device is arranged on the periphery of the lower cylinder body, and is capable of guiding a coolant to flow through the external surface of the lower cylinder body; the coolant flowing device is communicated with a pressure coolant source; and a plurality of radiating plates are arranged on the external surface of the lower cylinder body and corresponds to the coolant forced flowing device in position. The cylindrical diesel pile hammer with the forced cooling function is simple in structure, convenient to maintain and manufacture, capable of quickly and timely radiating and effectively controlling the temperature rise of the cylinder, and can be widely applied to the cylindrical diesel pile hammers of various specifications and types.

Owner:JIANGSU JUWEI MACHINERY

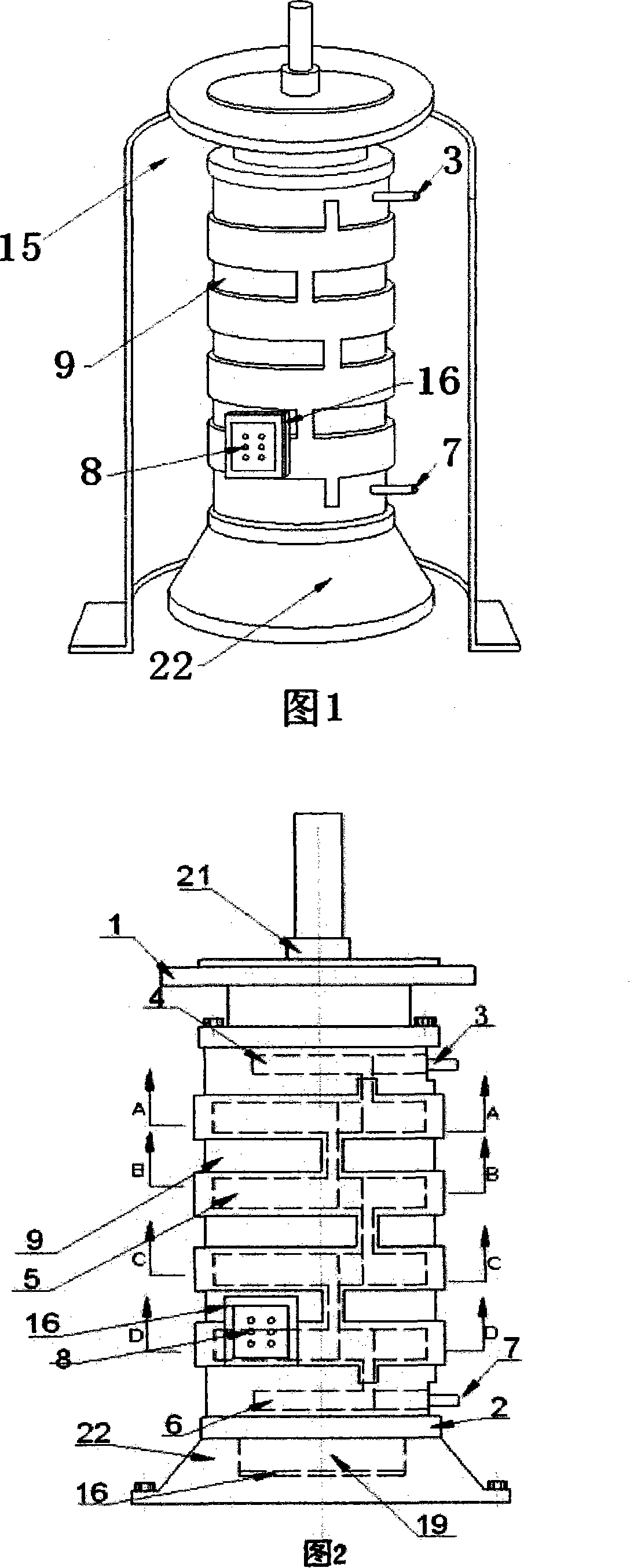

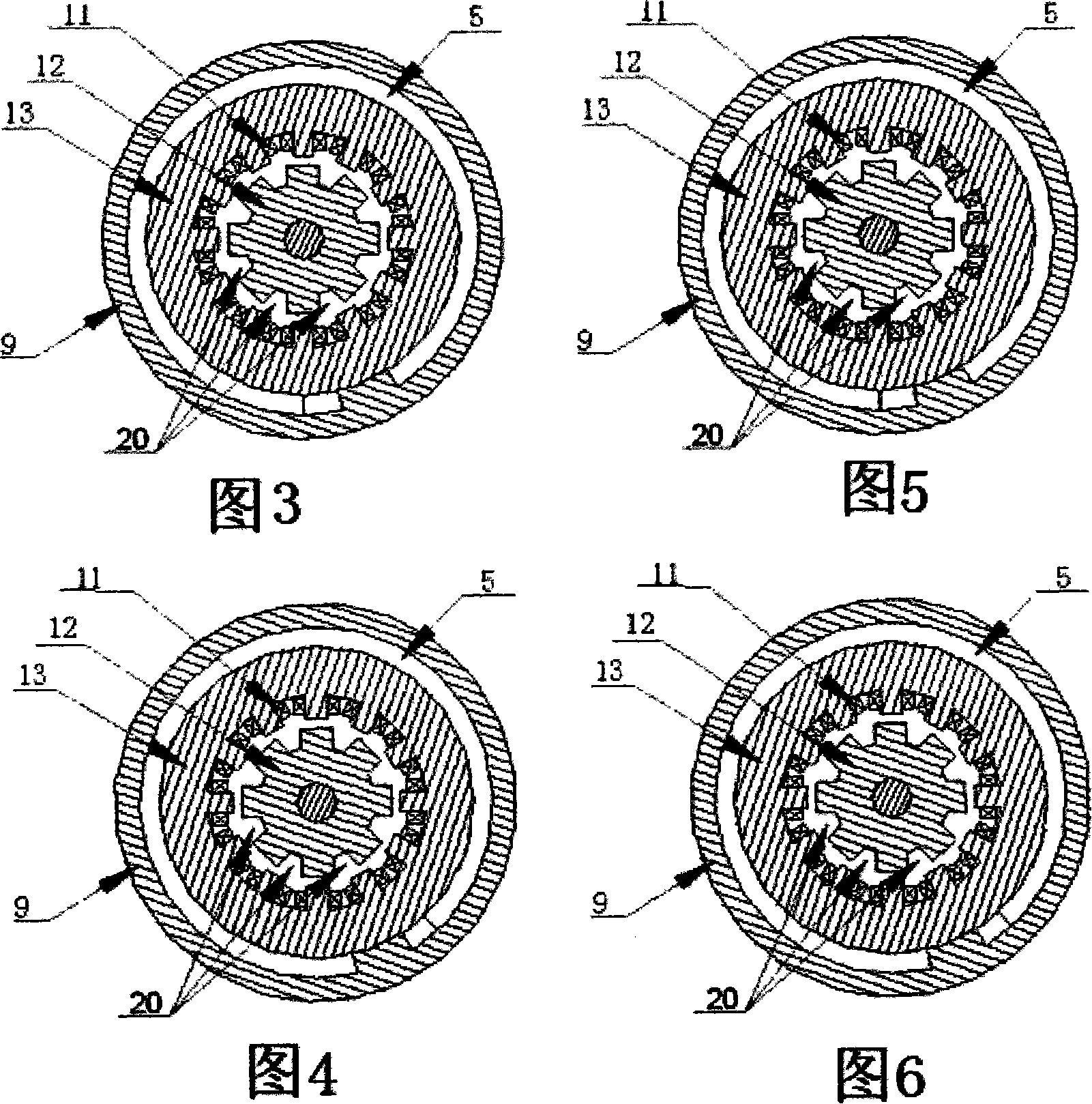

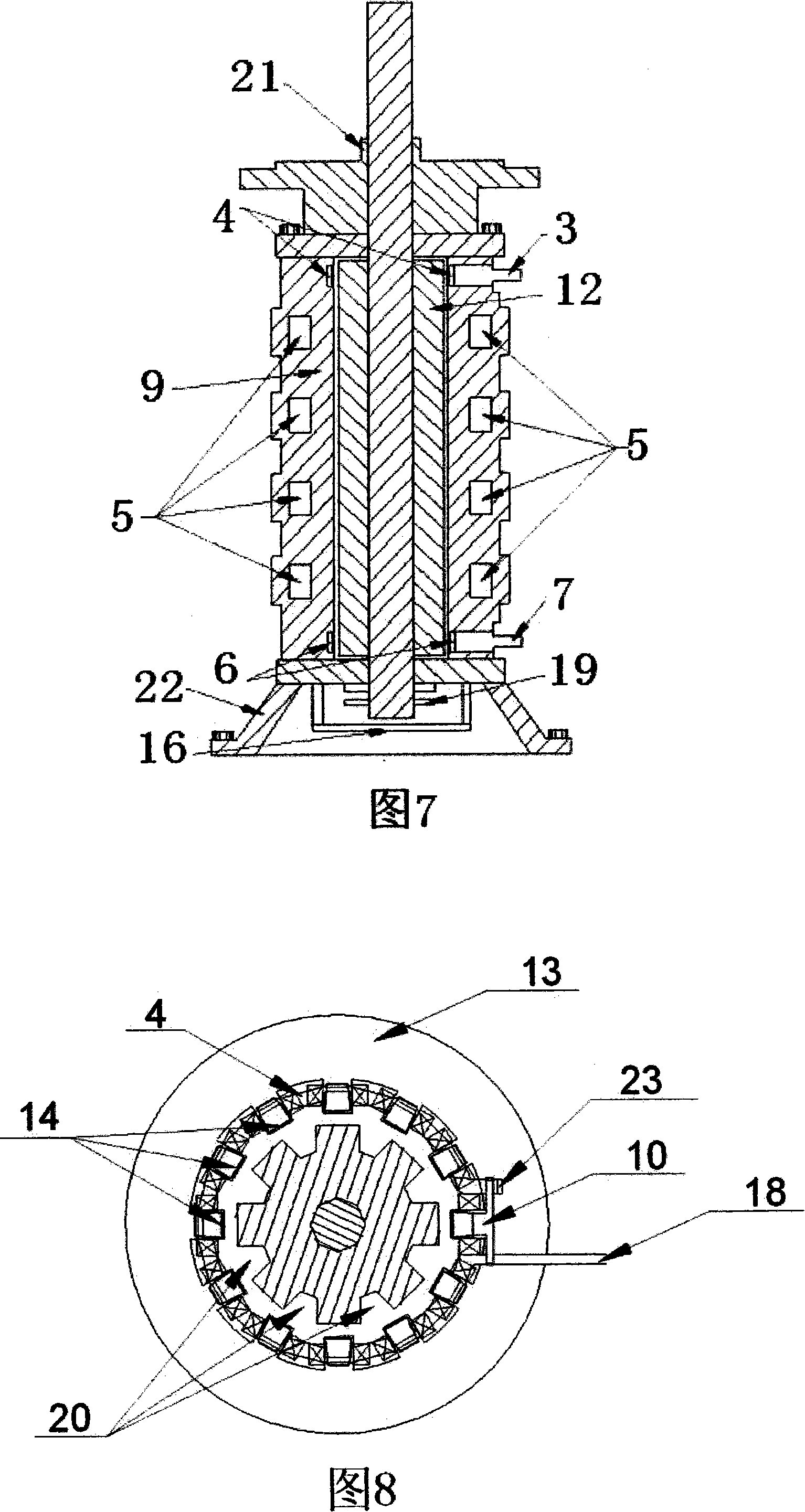

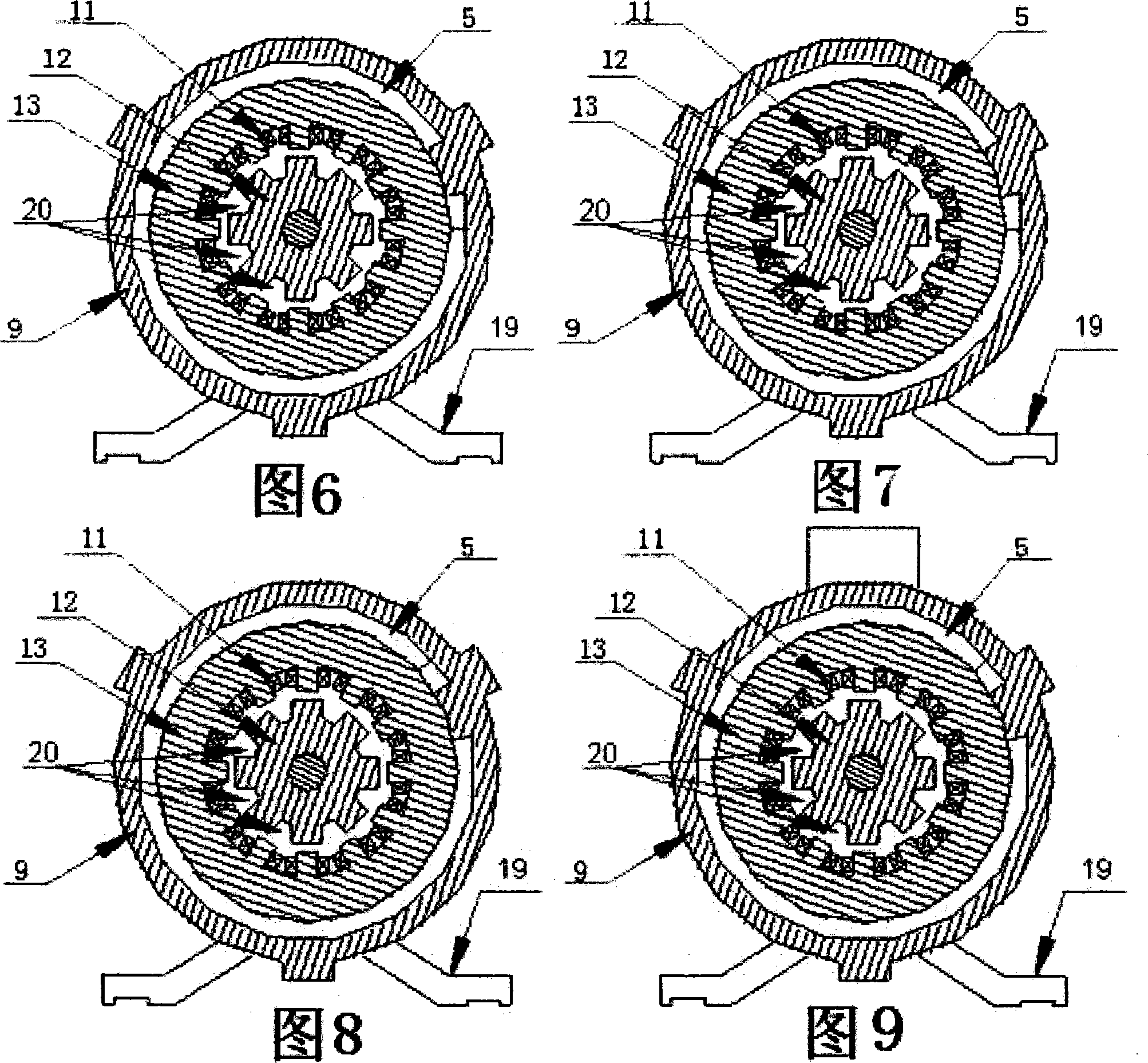

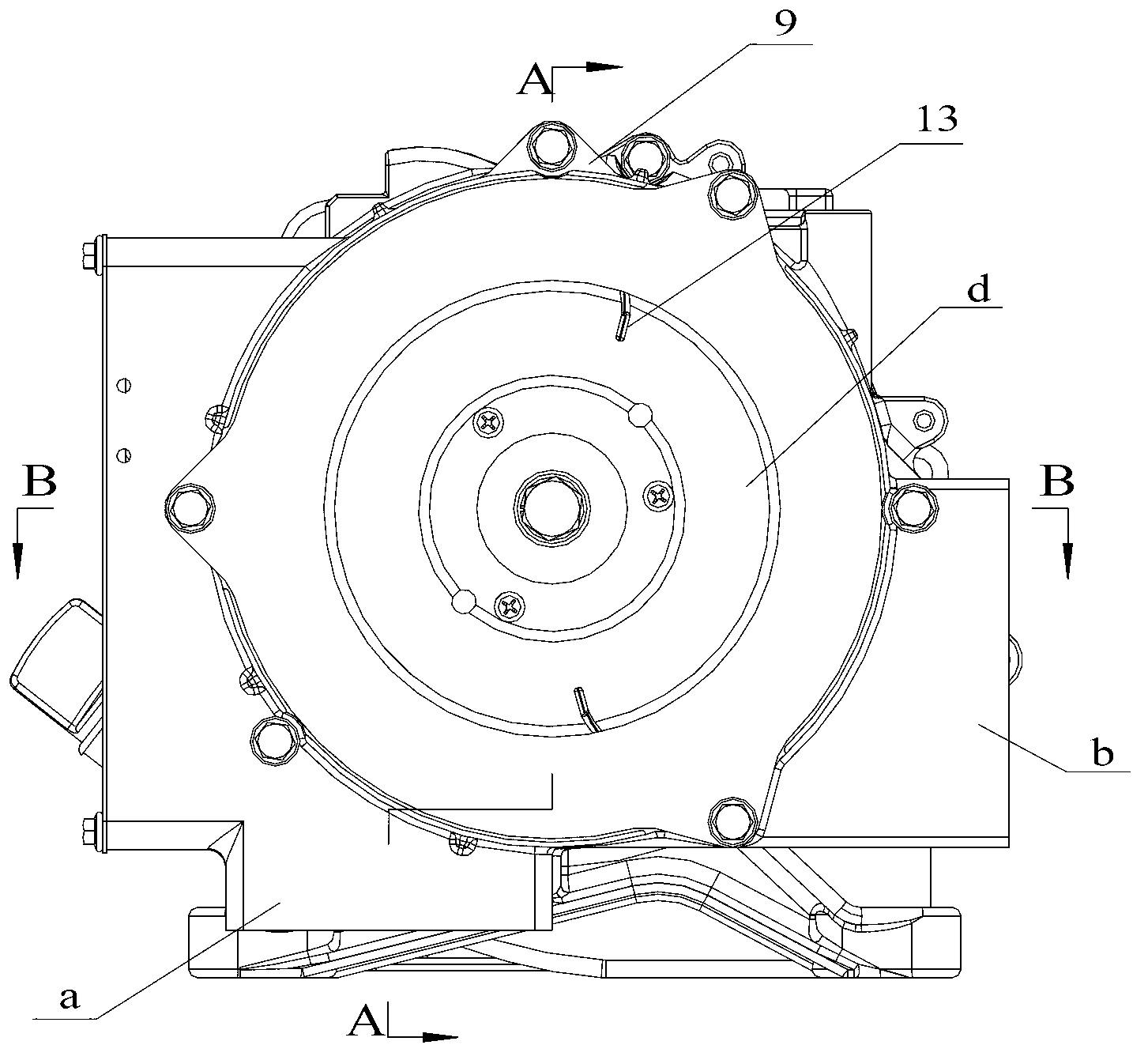

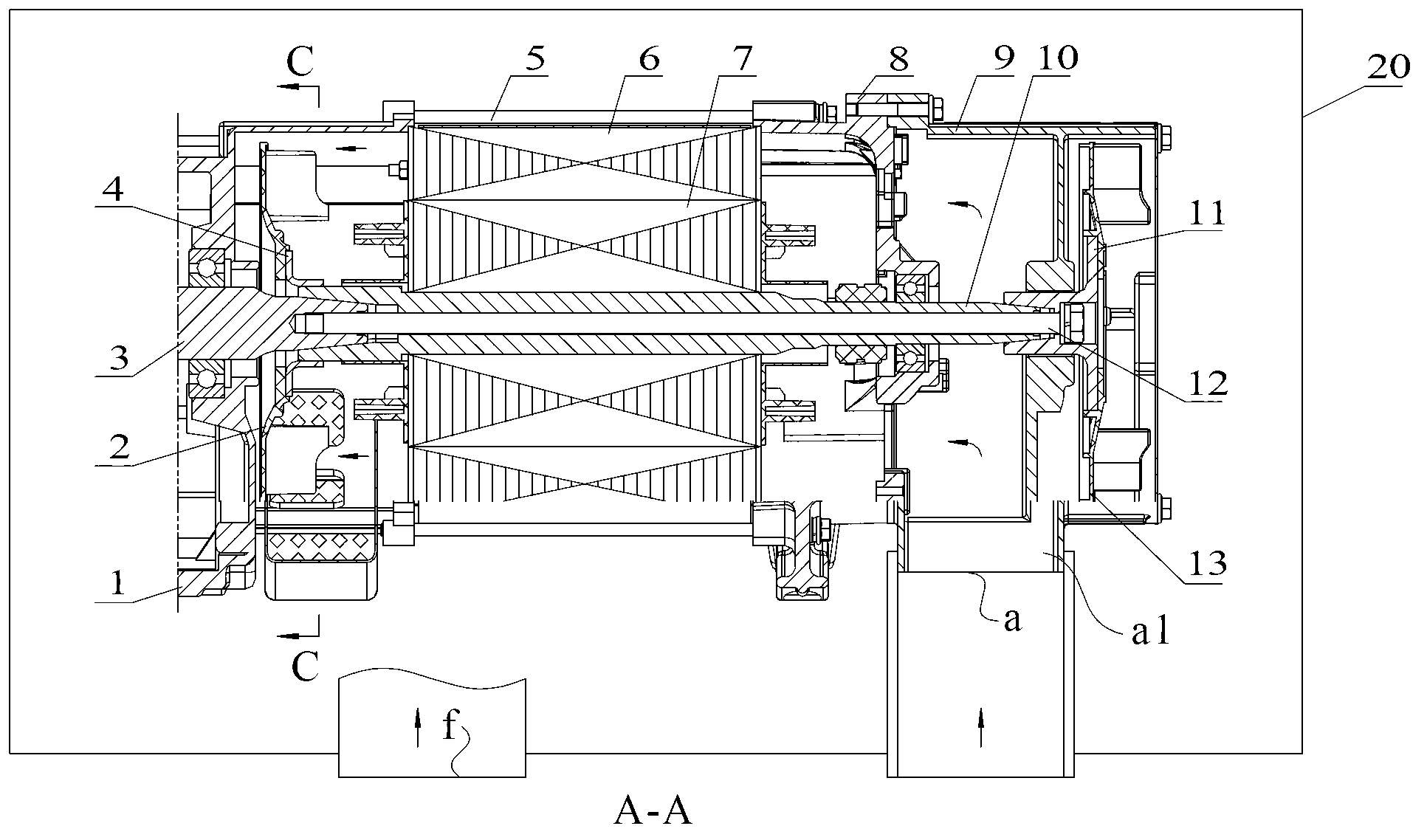

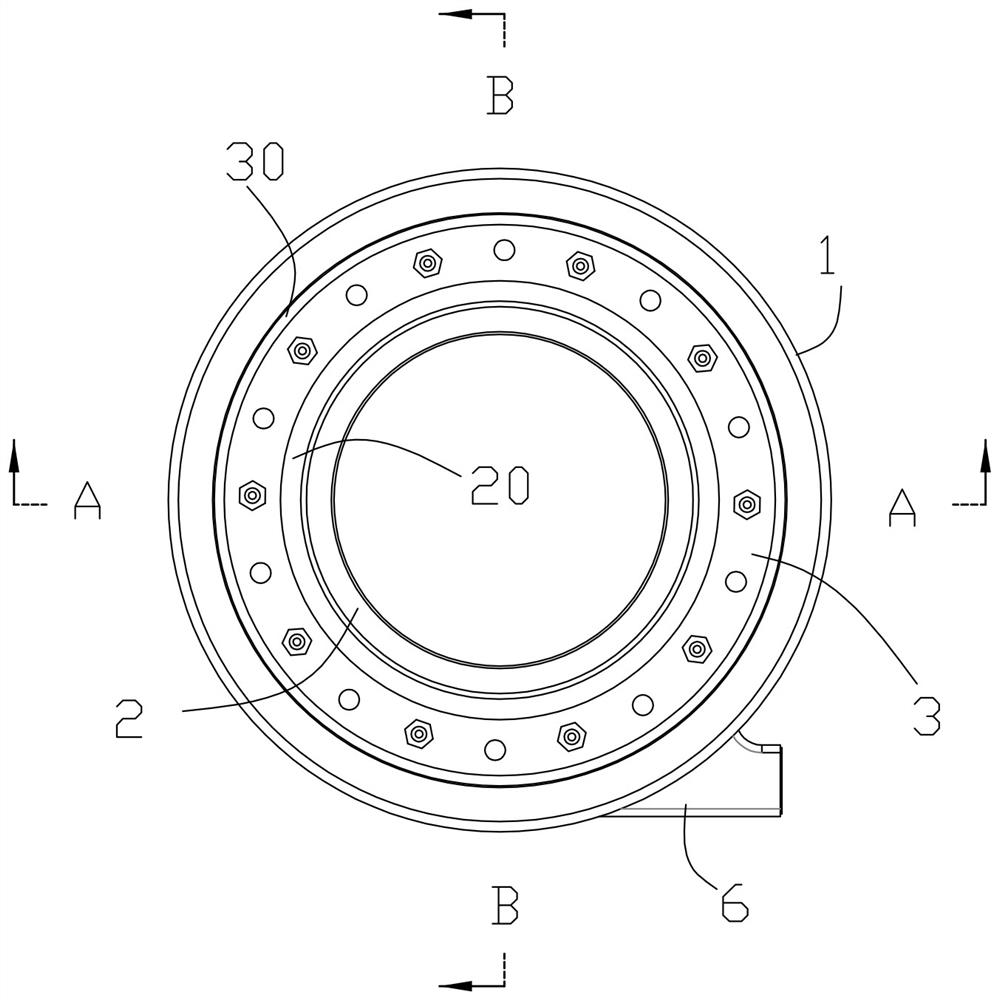

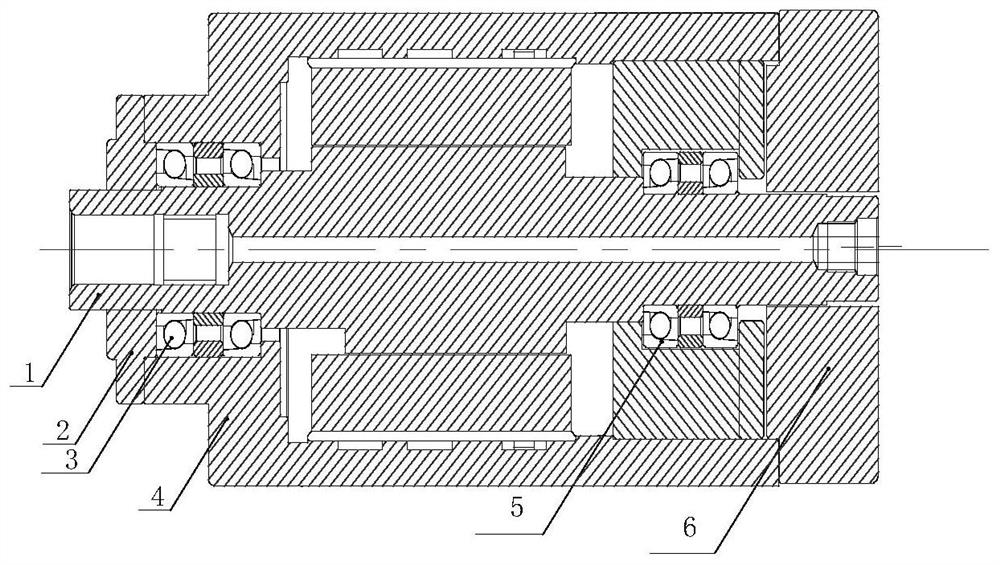

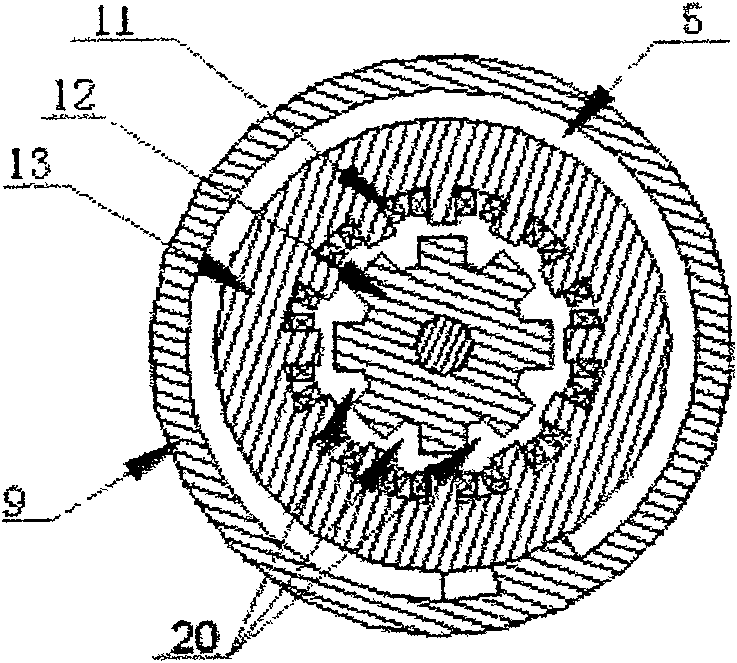

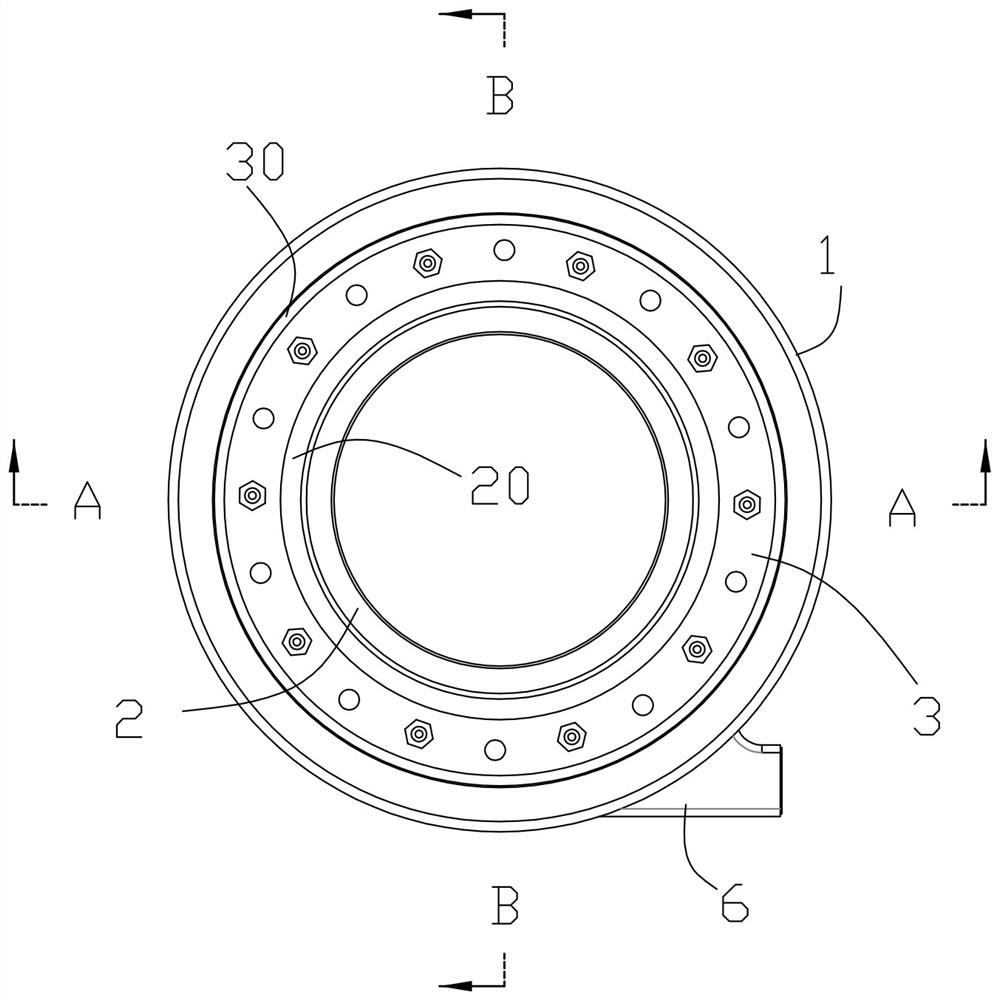

Electric vehicle-mounted complete closed internal liquid cooling, external wind cooling type switch reluctance motor

InactiveCN101119055AThe waterproof structure can effectively achieve the purpose of waterproofing the motorTo achieve the purpose of waterproofingCooling/ventillation arrangementSupports/enclosures/casingsLow noiseElectric machine

The present invention relates to a totally closed internal liquid cooling and external wind cooling type switch reluctance electric machine carried by electrically-propelled vehicle, comprising a sealing machine casing, a stator, a rotor, an internal liquid cooling and external wind cooling heat dispersion mechanism and an electric machine waterproof structure. The present invention is characterized in that the heat dispersion mechanism is capable of making the stator winding obtains the double heat dispersion effect of the internal liquid cooling and the external wind cooling at the same time, thereby solving the problem that the stator winding has a halfway heat dispersion. In addition, dedicated gland seals are arranged at the end cap opening of the electric machine, the ends of the axes and the wiring mouthpiece, achieving the aim of the electric machine with a good waterproof performance. The invention has the advantages of large torque, good dynamic performance, high efficiency, good energy saving effect, low noise and reliable seal. The technique is capable of effectively controlling the temperature rise of the electric machine when running up, in particular to the temperature rise of the end part of the stator winding. The present invention is capable of effectively waterproofing, guaranteeing the safe operation of the electric machine on the wet conditions or the seeper of the road surfaces, thereby increasing the work efficiency, the safety performance and the degree of protection of the electric machine, extending the service time.

Owner:BIJIE TIANYU POWER TECH

Electric vehicle-mounted complete closed switch reluctance motor

InactiveCN101136569ASolve poor heat dissipationSave copperCooling/ventillation arrangementSupports/enclosures/casingsIn vehicleElectric vehicle

This invention relates to an electromotive car carried closed switch reluctance motor including a shell, a stator, a rotor, internal and external air-cooling radiation units and a water-proof unit characterizing that the radiation unit enables the stator winding to get dual radiation of air cooling outside and inside at the same time, besides, special sealing devices are set at the end of the motor, the shaft end and the connection port to prevent water.

Owner:BIJIE TIANYU POWER TECH

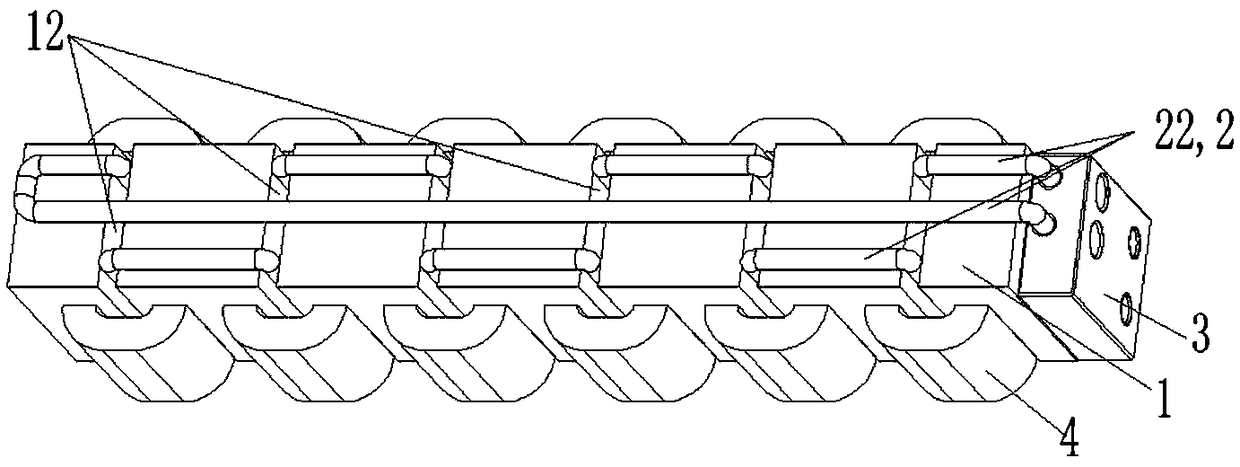

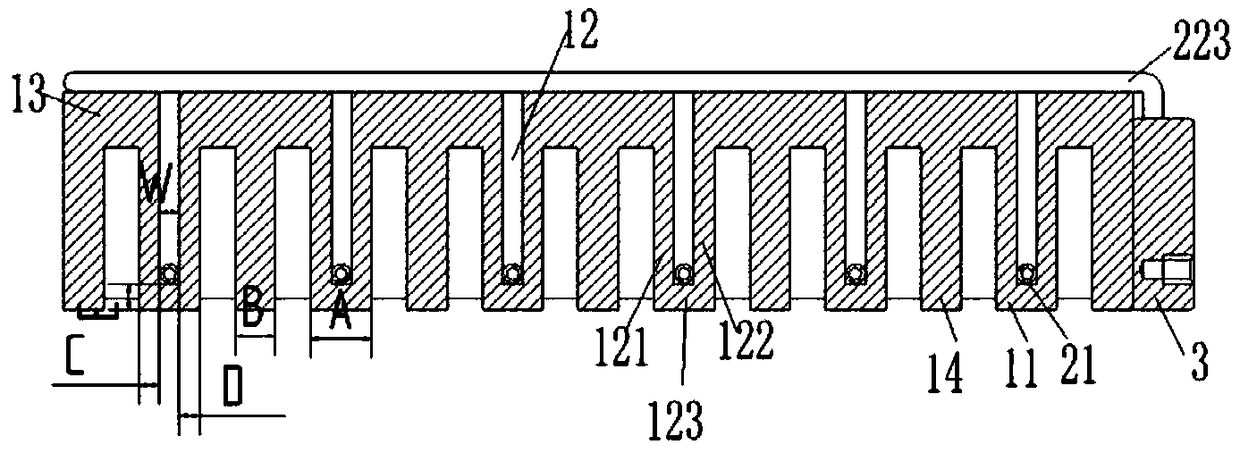

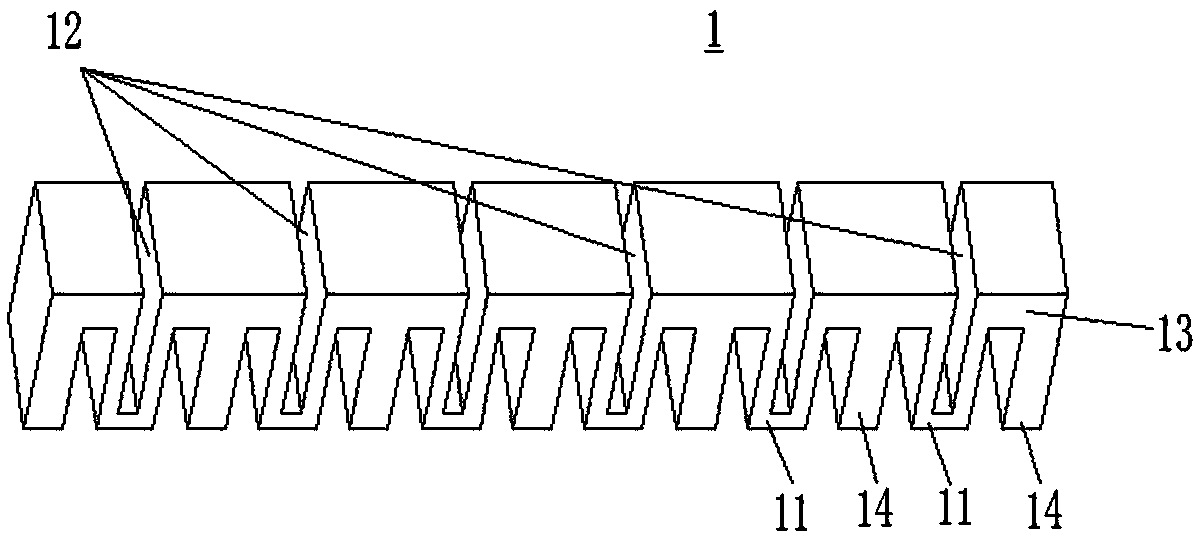

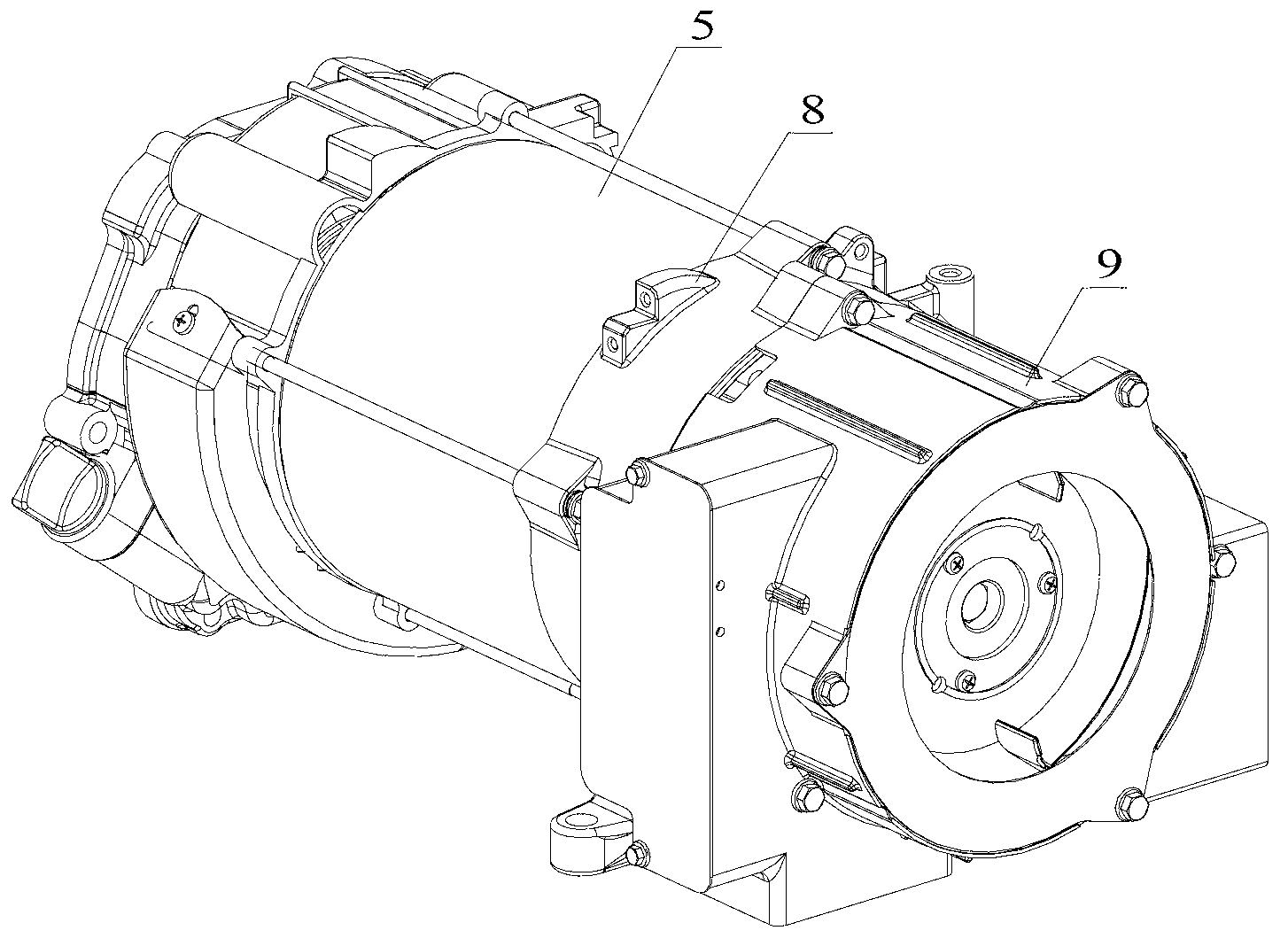

Mover module and linear motor

PendingCN108964405AImprove compactnessReduce the difficulty of assembly and manufacturingMagnetic circuit rotating partsPropulsion systemsLinear motorConductor Coil

The present invention provides a mover module and a linear motor. The mover module comprises a mover iron core, the mover iron core comprises a first tooth portion, a holding cavity is constructed atthe inner side of the first tooth portion, the mover module further comprises a cooling pipeline, and the cooling pipeline comprises a tooth portion pipe section which is arranged in the holding pipe.The mover module and the linear motor can greatly improve the structure compaction of the mover module, can reduce the assembling and manufacturing difficulty of the mover module, can effectively control the temperature rise of the mover module and even the linear motor through targeted cooling of the mover iron core tooth portion and the coil winding and can facilitate ensuring of the performance reliability and the operation stability of the motor.

Owner:GREE ELECTRIC APPLIANCES INC

Generator

InactiveCN103187830ASpeed up the flowReduce the temperatureCooling/ventillation arrangementSupports/enclosures/casingsAerospace engineeringStator

The invention discloses a generator which comprises an end cover, a generator part, a motor bracket and an induced air shell, wherein the generator part consists of a stator, a rotor, a rotor shaft and a generator cooling fan; the induced air shell is divided into two cavities by a middle clapboard, the front cavity is connected with the motor bracket and is provided with an air inlet in the side wall, and the rear cavity is provided with a fan which is coaxially connected with the rotor and is provided with an air outlet in the side wall; and one side, which is axially opposite to the middle clapboard, of the rear cavity is provided with an exhaust opening. A ventilation channel is arranged in the manner that for the first ventilation channel, cooling air is sucked into the front cavity of the induced air shell from the air inlet in the side wall of the front cavity of the induced air shell, cools the generator and then is exhausted by the generator cooling fan through the air outlet of the generator; and for the second ventilation channel, air is sucked from the exhaust opening in the cavity from the fan in the rear cavity of the induced air shell and is exhausted through the air outlet in the side wall of the cavity. The generator has the advantages of small noise, temperature rise and invariable output power.

Owner:SUMEC MACHINERY & ELECTRIC

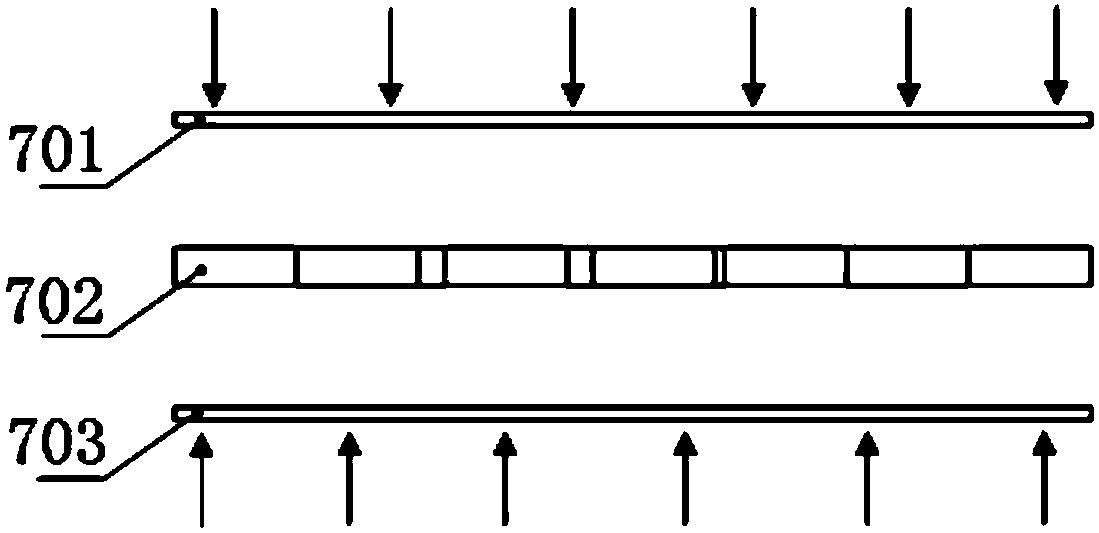

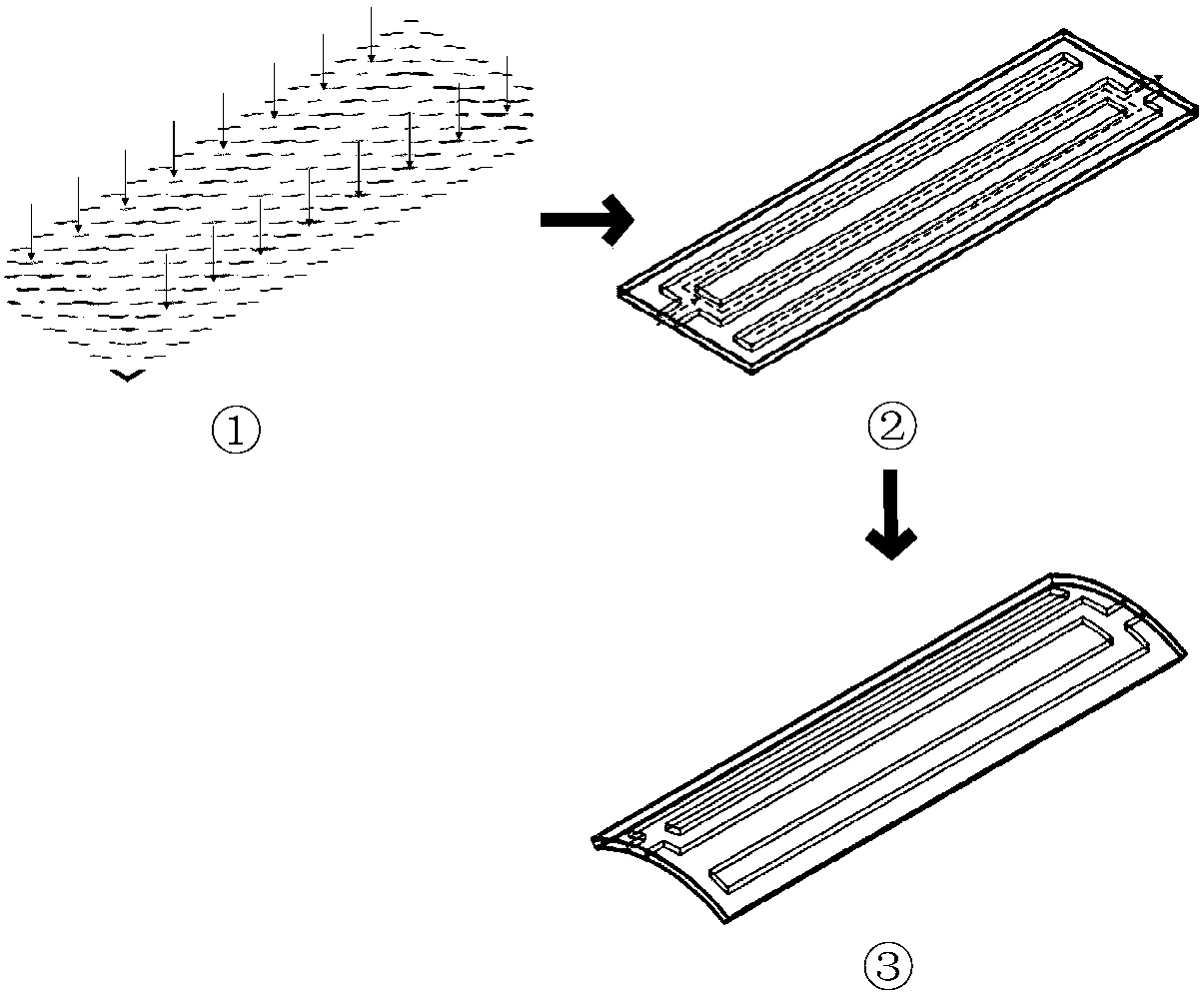

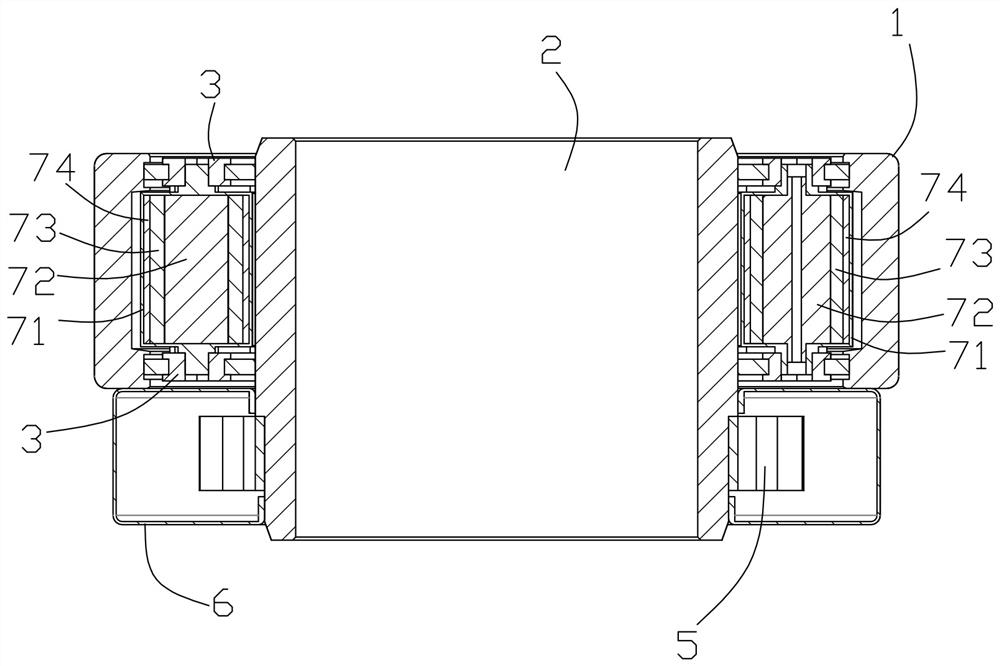

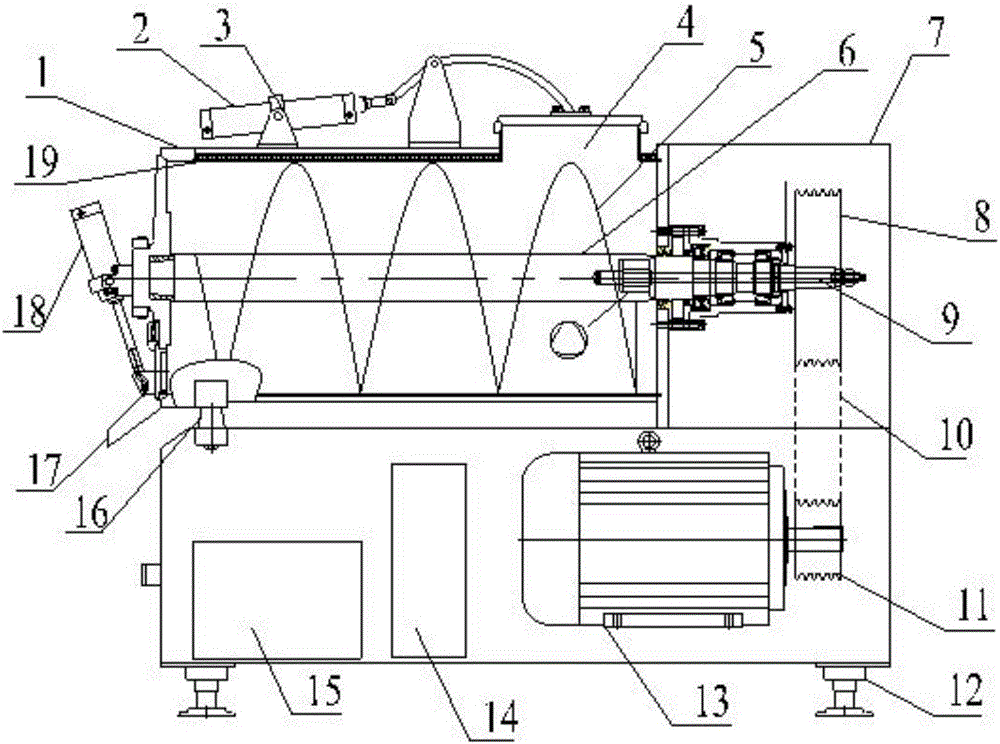

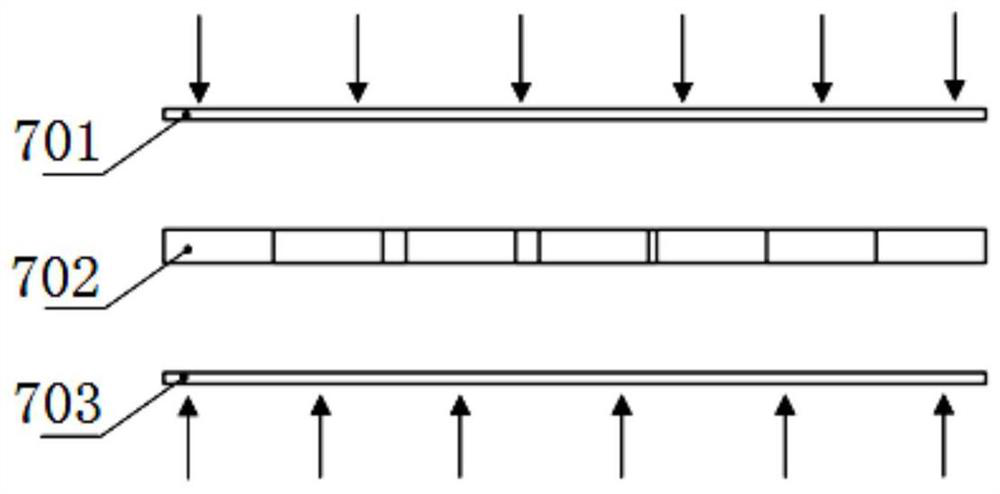

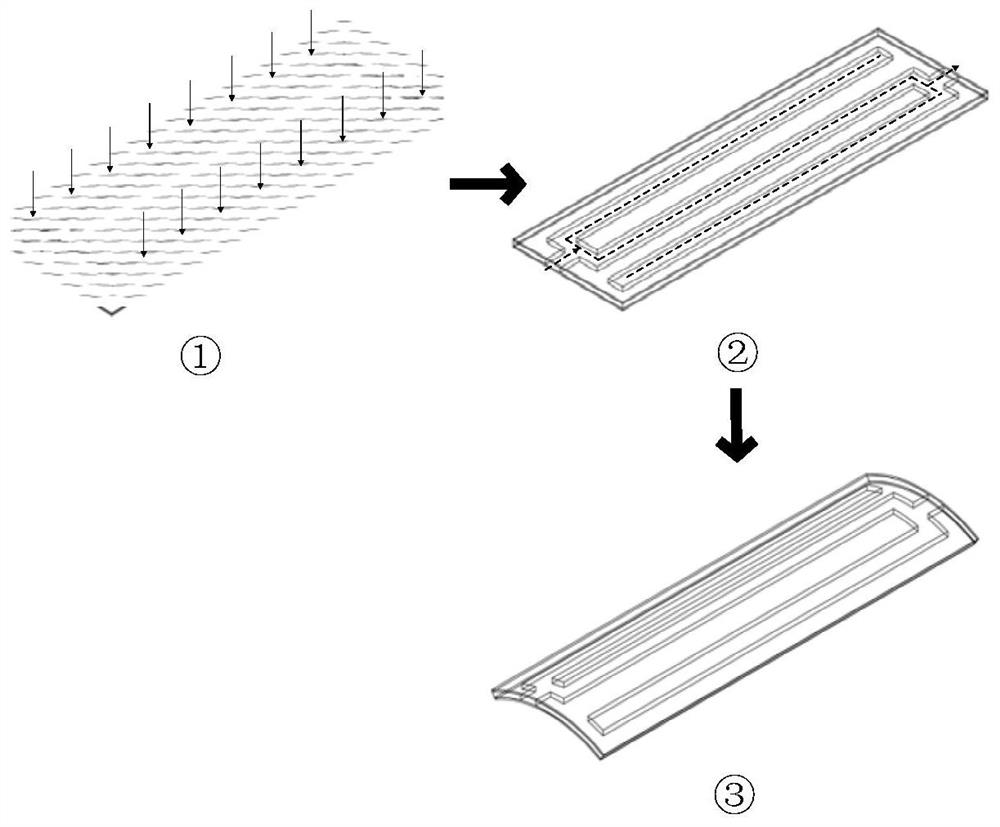

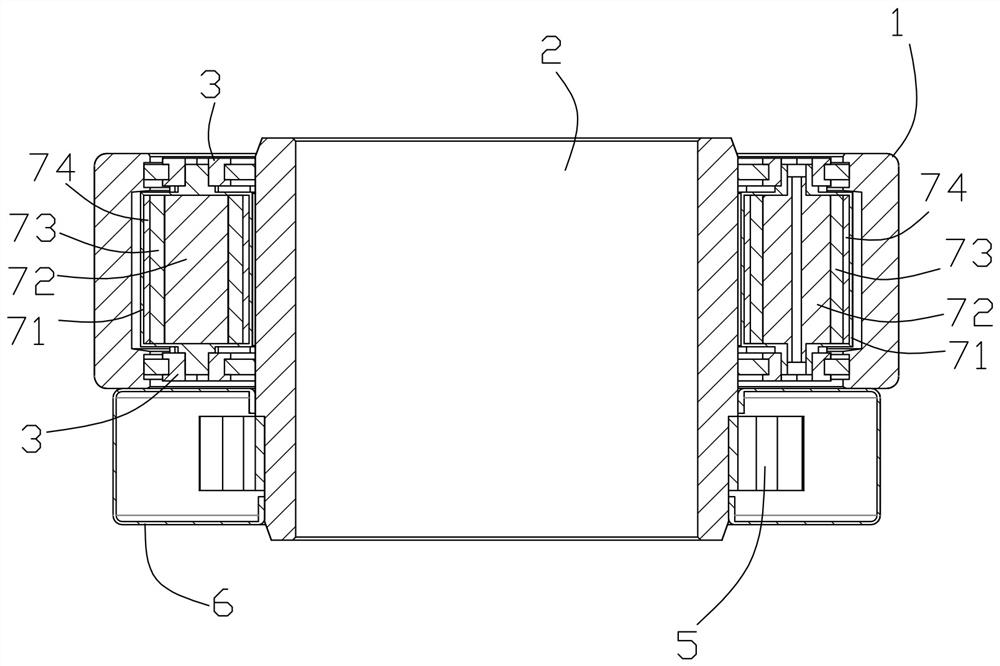

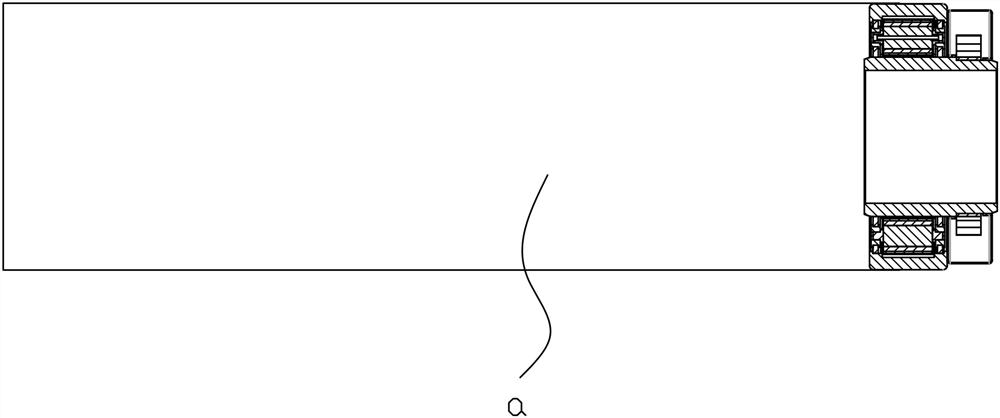

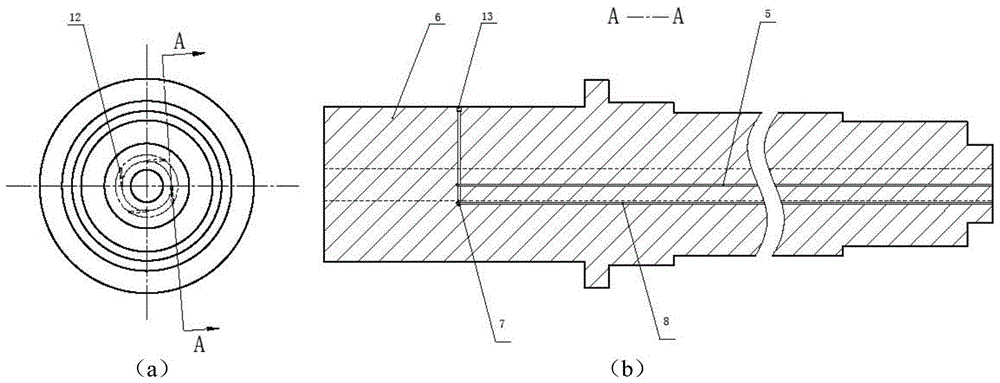

Flexible heat pipe used for cooling surface of rotating shaft of high-speed motorized spindle

ActiveCN108568703AImprove machining accuracyCompact structureMaintainance and safety accessoriesSurface coolingElectricity

The invention discloses a flexible heat pipe used for cooling the surface of a rotating shaft of a high-speed motorized spindle. The flexible heat pipe (7) comprises a substrate (701), a runner plate(702) and a cover plate (703), the substrate (701), the runner plate (702) and the cover plate (703) are sequentially bonded from top to bottom, wherein the runner plate (702) is provided with a heatpipe runner, and a sealed heat transfer fluid is filled in the heat pipe runner. The flexible heat pipe is adhered on the surface of the rotating shaft by bending in use. The temperature of the rotating shaft is obviously increased because of the loss of an internal motor, the generation of heat by friction of front and rear bearings and wind motor of the rotating shaft at the operation state of the motorized spindle. The provided flexible heat pipe has an excellent heat transfer performance at the high centrifugal force, the local temperature rise of the rotating shaft is effectively controlled, the thermal deformation caused by the uneven temperature distribution is reduced, the influence of thermal deformation of the rotating shaft on the machining precision of the high-speed motorizedspindle is effectively controlled, meanwhile, the original structure of the motorized spindle is less changed, and the flexible heat pipe has the advantages of high reliability, low cost, easiness inpromotion and implementation and the like.

Owner:XI AN JIAOTONG UNIV

Electric vehicle-mounted complete closed switch reluctance motor

InactiveCN101136569BWaterproof up toTo achieve the purpose of waterproofingCooling/ventillation arrangementSupports/enclosures/casingsIn vehicleRoad surface

This invention relates to an electromotive car carried closed switch reluctance motor including a shell, a stator, a rotor, internal and external air-cooling radiation units and a water-proof unit characterizing that the radiation unit enables the stator winding to get dual radiation of air cooling outside and inside at the same time, besides, special sealing devices are set at the end of the motor, the shaft end and the connection port to prevent water.

Owner:BIJIE TIANYU POWER TECH

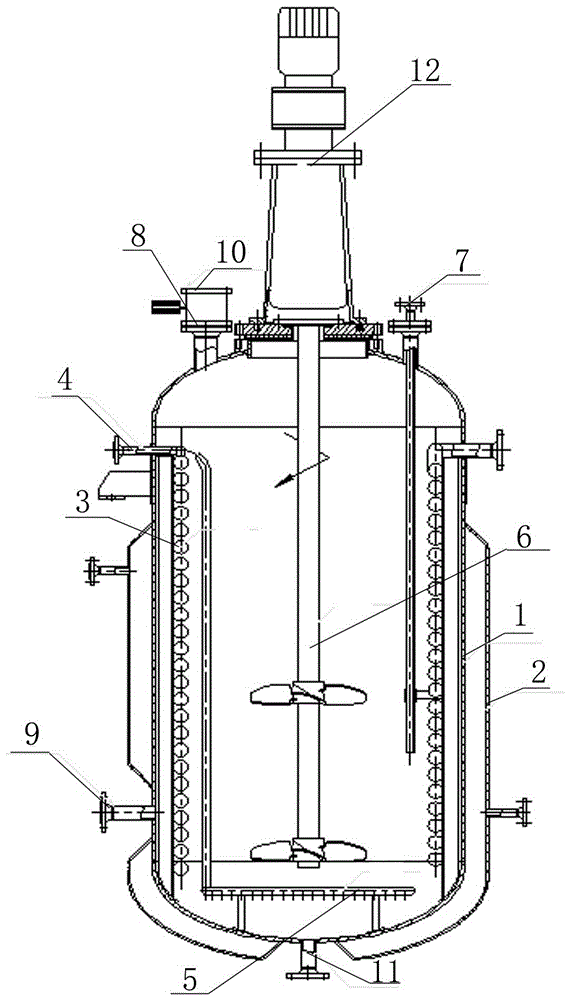

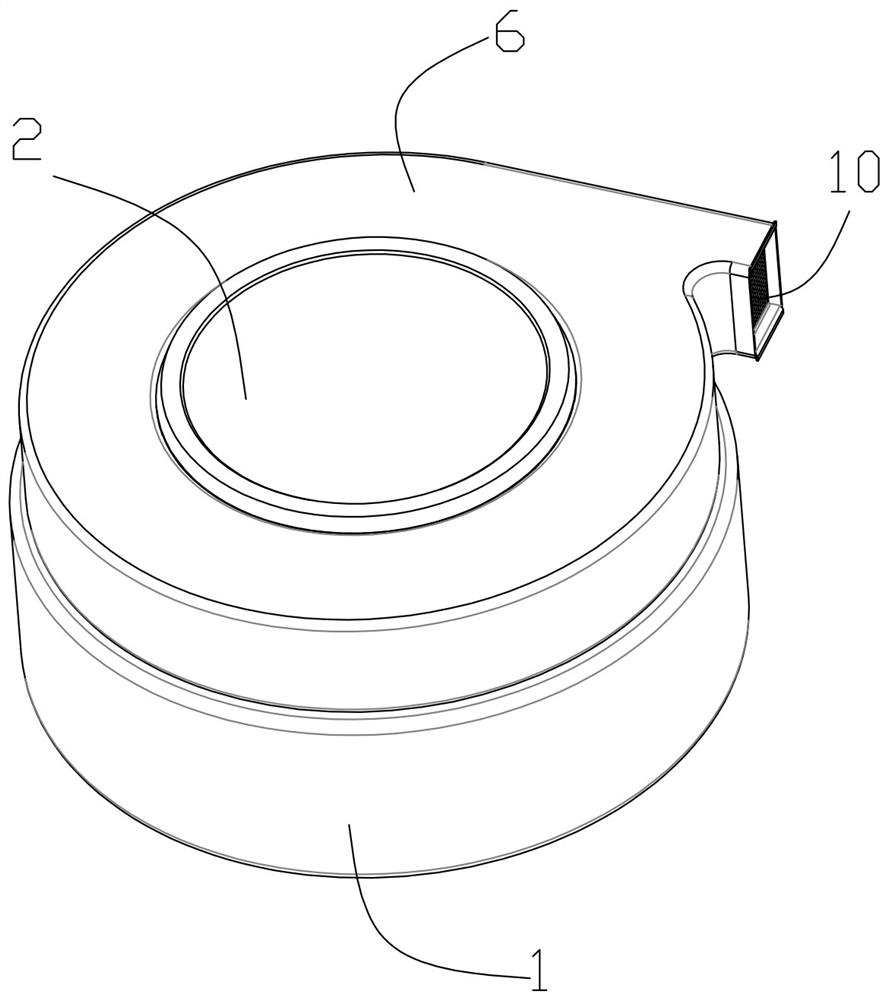

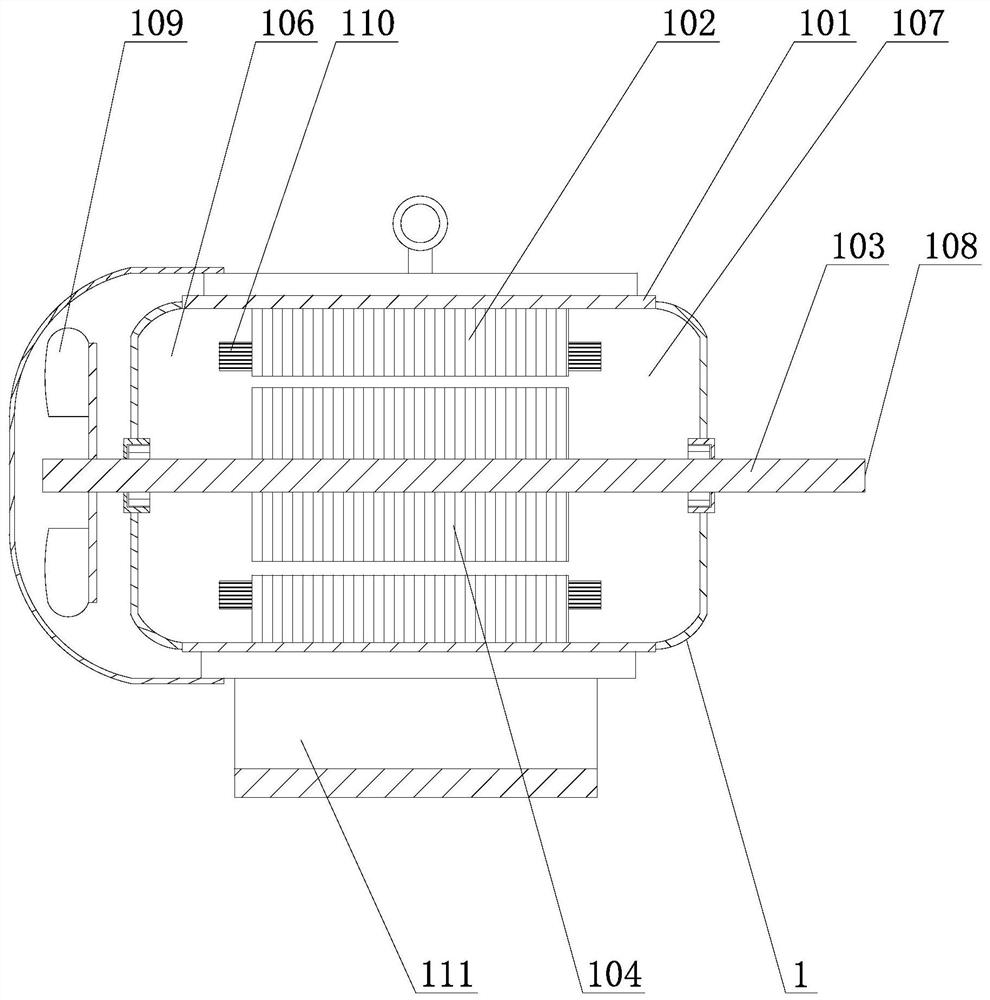

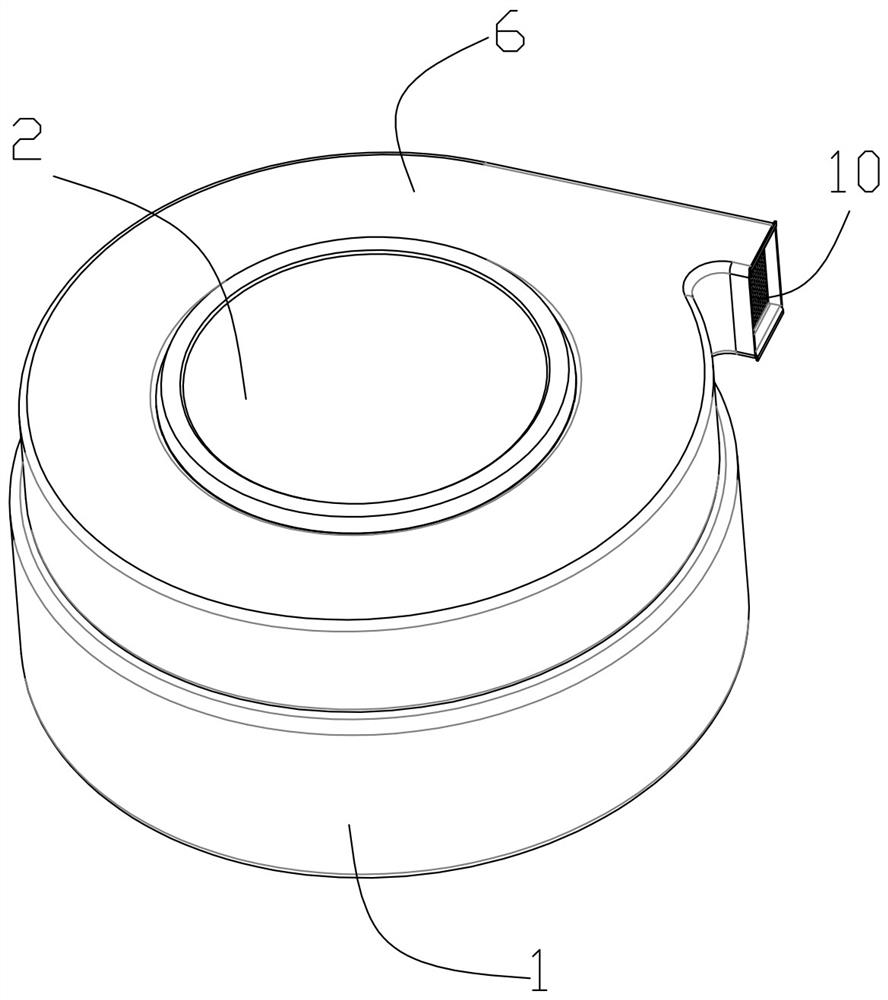

5-fluorocytosine fluorination reactor with stirring function

PendingCN105709665AGuaranteed mass transfer effectGuaranteed leakOrganic chemistryChemical/physical processesFluid phaseElectric discharge

The invention discloses a 5-fluorocytosine fluorination reactor with the stirring function. The outer surface of a barrel (1) is sleeved with a cooling jacket (2); the middle of the upper portion of the barrel (1) is provided with a solid material adding device (12); one side of the upper portion of the barrel (1) is provided with a gaseous phase outlet (10) which is internally provided with an electric discharging valve (8); the other side of the upper portion of the barrel (1) is provided with a temperature measuring sleeve (7); the upper portion of the temperature measuring sleeve (7) is located outside the barrel (1); the lower portion of the temperature measuring sleeve (7) is located in the barrel (1); the upper portion of the side face of the barrel (1) is provided with a fluorine and nitrogen inlet pipe (4) which is communicated with the interior of the barrel (1); a gas distributor (5) is arranged at the bottom of the barrel (1); a cooling coil pipe (3) is arranged on the inner surface of the barrel (1); a stirrer (6) is arranged at the center of the barrel (1); a liquid level meter port (9) is formed in the side face of the lower portion of the barrel (1); a liquid phase discharge port (11) is formed in the bottom of the barrel (1).

Owner:江苏梅兰化工有限公司

Method for cooling air leaking flange of supporting plate of hot blast valve

InactiveCN106702063APrevent burn-throughReduce consumptionBlast furnace detailsHeating stovesDraining tubeCopper wire

The invention provides a method for cooling an air leaking flange of a supporting plate of a hot blast valve. The method comprises the following steps: winding an air leaking position by using a thin copper wire strand at first, and fastening and stressing through bolts of the flange; welding a cooling water tank to the lower part of the hot blast valve, and enabling the upper edge of the cooling water tank to be higher than the air leaking flange; respectively welding a water replenishing tube and a water draining tube to the upper part of the cooling water tank; connecting the water replenishing tube to a water tube through a ball valve and a cloth inserted hose, and meanwhile welding an overflow tube to the upper edge of the cooling water tank; then opening the ball valve on the water replenishing tube to carry out water replenishing; after water flows out from the water draining tube, adjusting the open degree of the ball valve, enabling water replenishing and water draining amount to be balanced, and cooling the flange submerged in cooling water through the flowing cooling water. The problem of rising of temperature caused by air leakage of the supporting plate of the hot blast valve can be controlled effectively, burn-through of the supporting plate is prevented, blast stopping accidents of a blast furnace are avoided, consumption of spare parts is reduced, repair costs are reduced, yield loss is avoided, and smooth production of the blast furnace is guaranteed.

Owner:ANGANG STEEL CO LTD

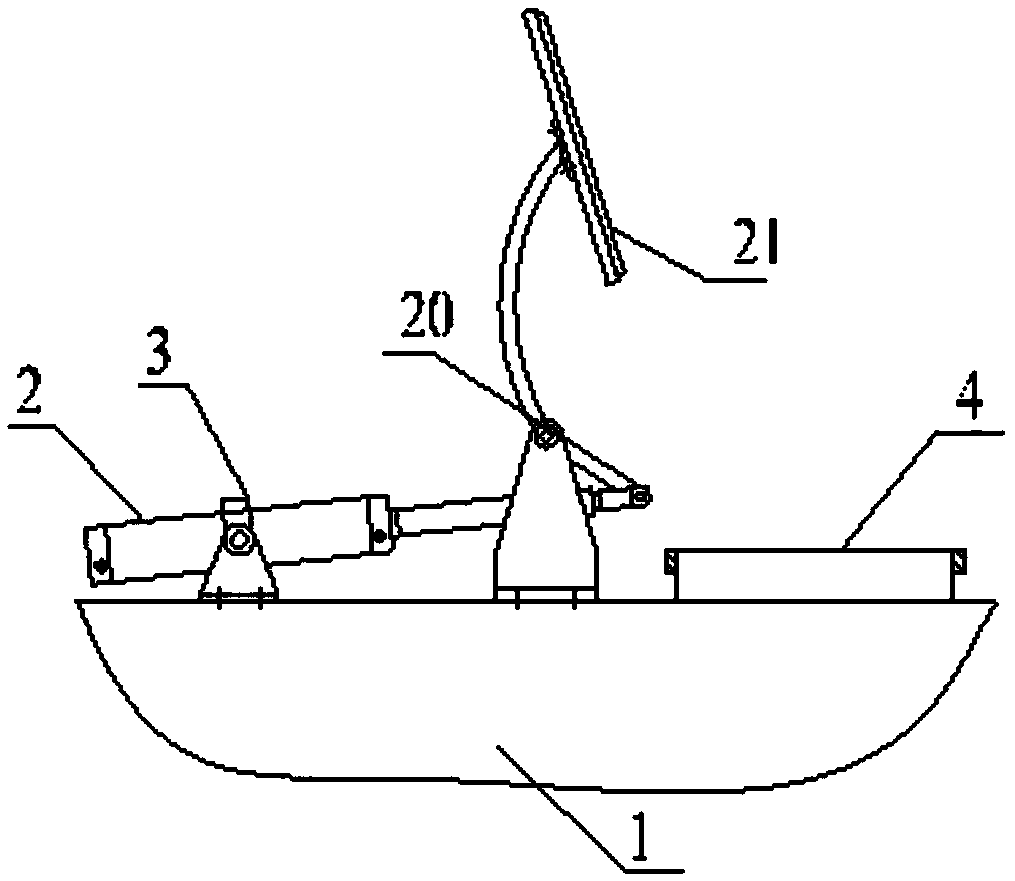

a stuffing machine

ActiveCN106617240BEasy to operateEffective control of temperature riseFood shapingDrive shaftFree state

Owner:SUNBY MACHINERY CO LTD

A bearing with heat dissipation and lubrication functions

ActiveCN110671433BAchieve automatic cooling functionTo achieve the role of lubricationRolling contact bearingsShaftsImpellerEngineering

The invention discloses a bearing with heat dissipation and lubricating functions, which comprises an outer ring, an inner ring and a retainer, the rolling elements are rotated and connected at equal intervals on the retainer, the length of the inner ring is longer than that of the outer ring, and the fixed sleeve of the inner ring is provided with compressed air The impeller also includes an airflow cover, which covers the compressed air impeller and is fixed on the outer ring. The rolling body is provided with a first central hole and a plurality of dispersion holes. The center hole communicates with the round hole when the cage rotates with the inner ring. The airflow cover is also equipped with an air inlet. A roller coating lubrication unit is installed between two adjacent rolling elements to rotate with the rolling elements. The roller coating lubrication unit is used Coating graphite to the rolling body; the invention can realize the automatic heat dissipation function of the bearing, effectively control the temperature rise of the bearing, and realize automatic lubrication without manually adding lubricating oil, with simple operation and high efficiency, which is beneficial to prolong the service life of the bearing, and Take good care of the bearings.

Owner:常山县鑫龙轴承有限公司

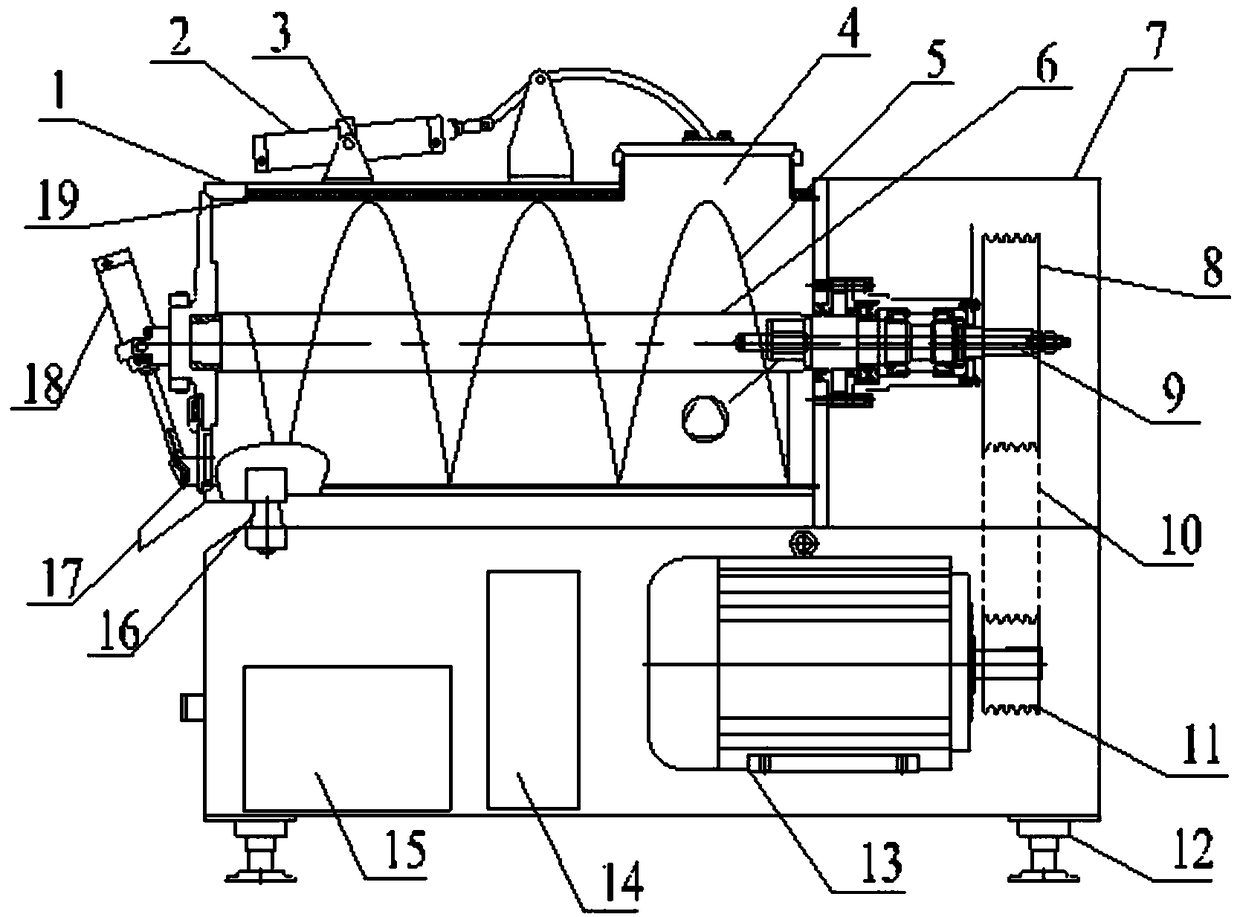

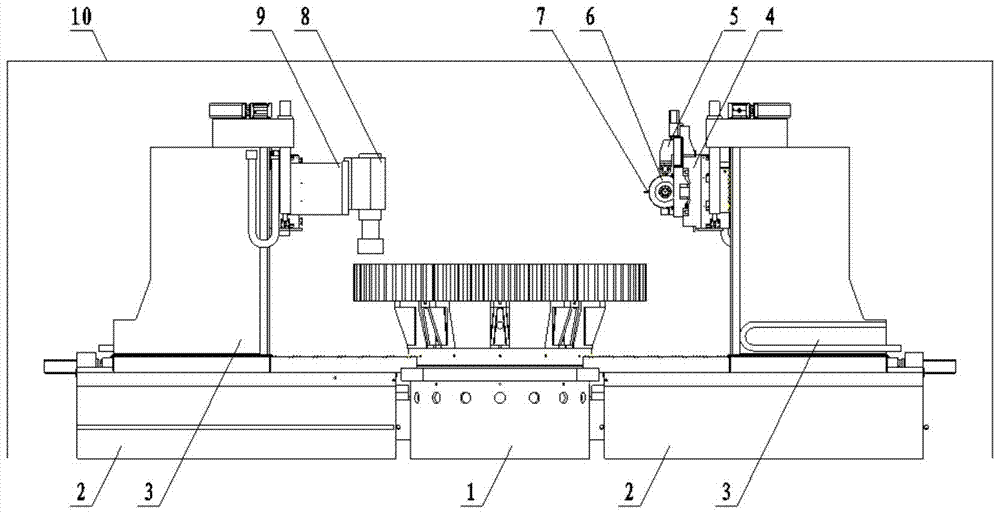

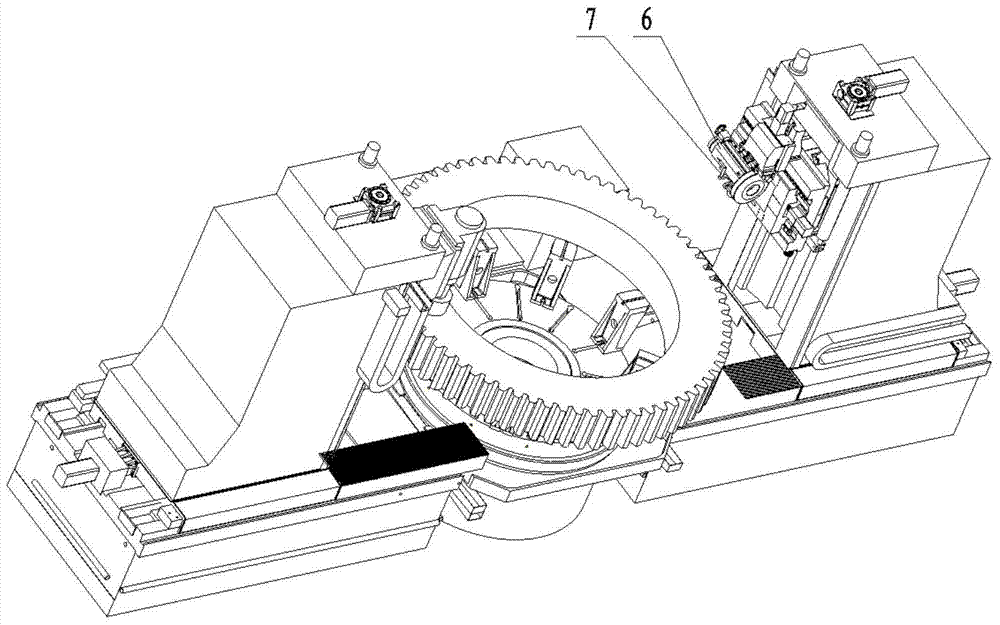

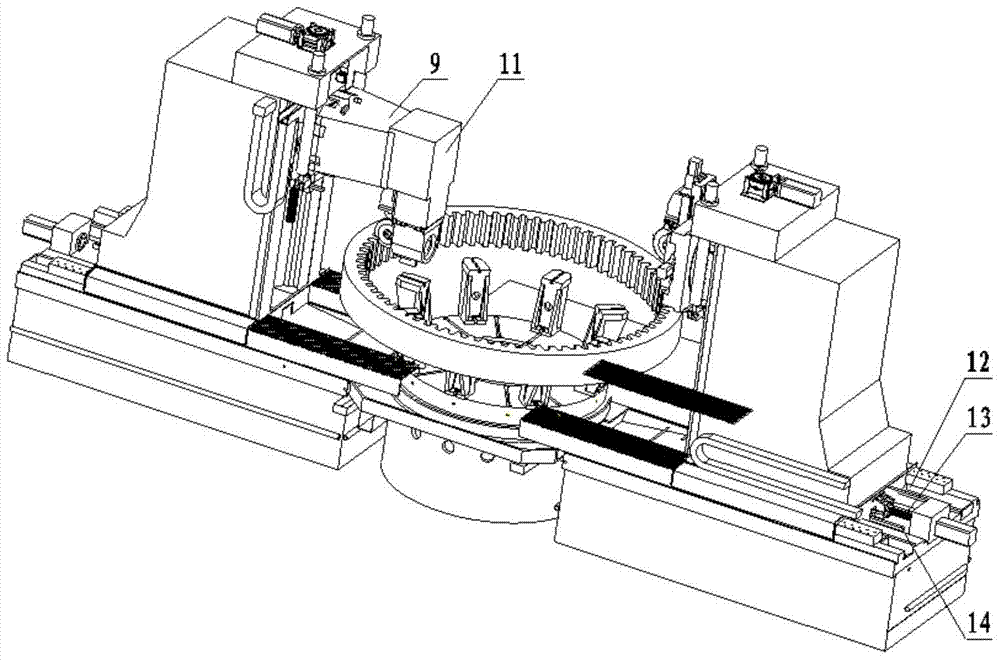

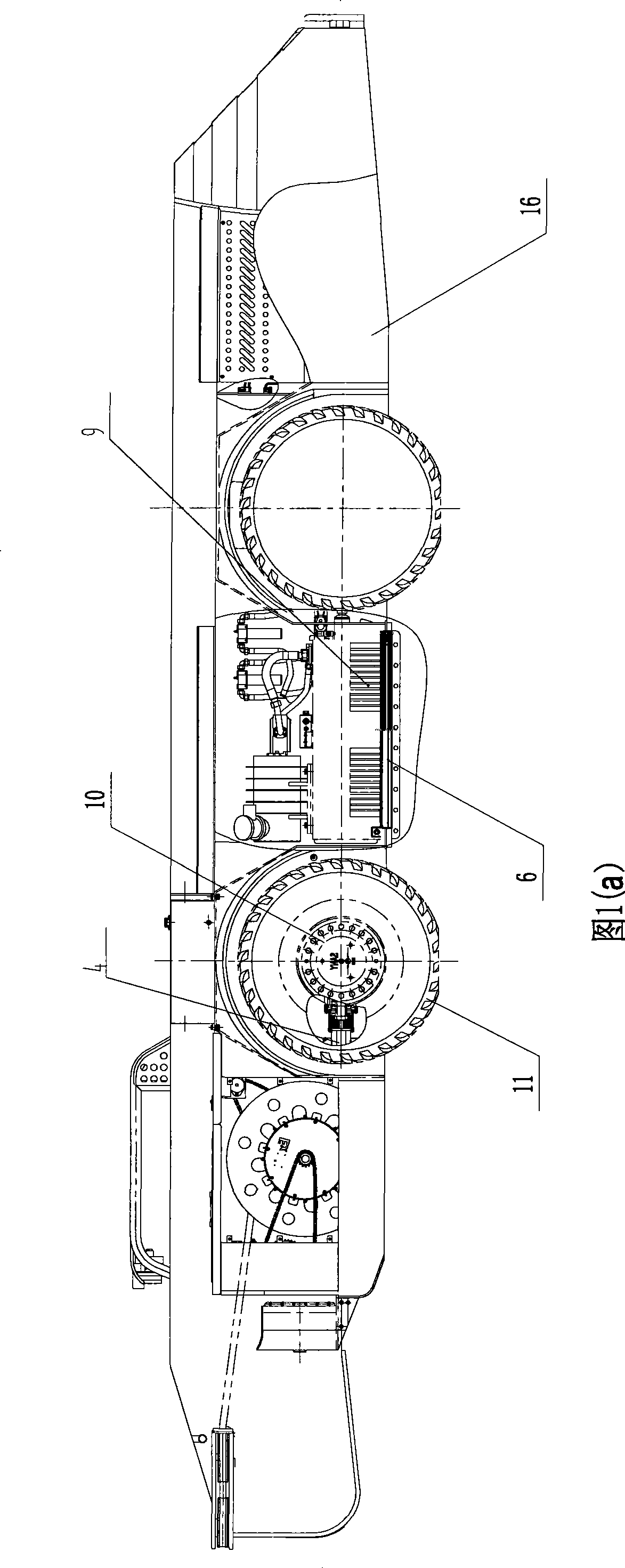

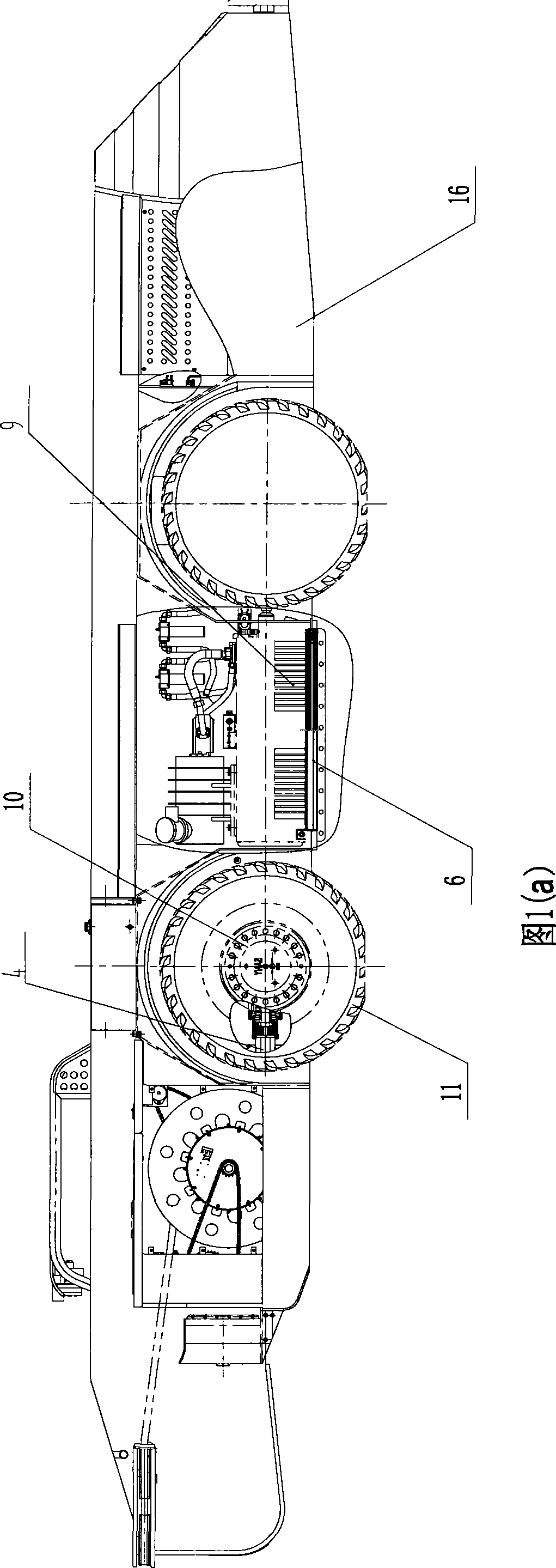

Large-scale high-precision gear compound grinding center

ActiveCN104889863BReduce in quantityReduce auxiliary timeGrinding carriagesGrinding feed controlGear grindingGear wheel

Owner:秦川机床工具集团股份公司

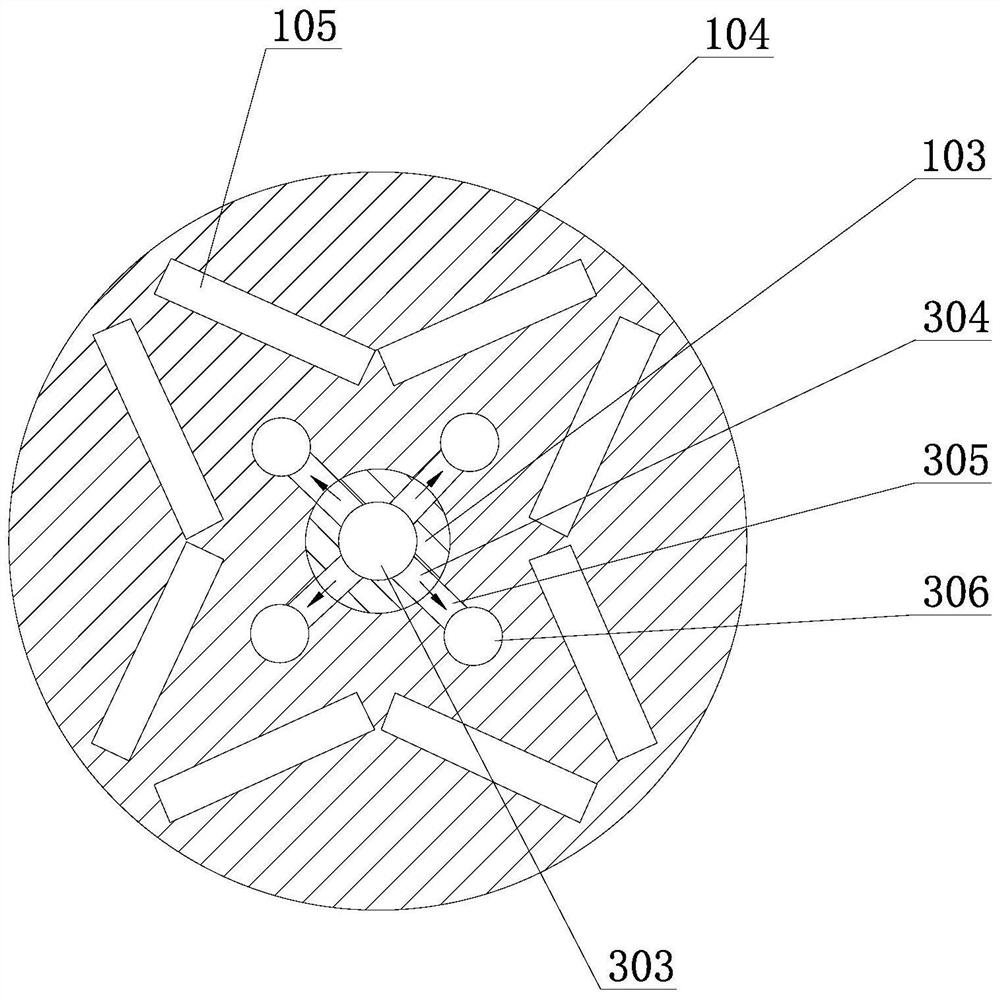

Meat chopping machine

ActiveCN106617240AEasy to operateEffective control of temperature riseFood shapingDrive shaftFree state

The invention discloses a meat chopping machine. The meat chopping machine comprises a housing, a driving mechanism, a screw shaft, a tank body, a refrigerating machine and a vacuum pump, wherein the tank body is fixedly arranged at the top end of the housing; a feed opening is formed in the top of the tank body; a discharge opening is formed in one side of the tank body; the screw shaft is arranged in the tank body; screw blades are fixedly connected to the screw shaft; one end of the screw shaft is connected with the driving mechanism through a main transmission shaft; the driving mechanism, the refrigerating machine and the vacuum pump are arranged in the housing; refrigerating space is formed in the inner wall of the tank body; the refrigerating space communicates with the refrigerating machine; and the vacuum pump communicates with the tank body. According to the meat chopping machine disclosed by the invention, the refrigerating machine and the tank body are connected, so that the temperature rise of materials, which is generated during operation, can be effectively controlled, and the taste, service life and the like of products cannot be affected due to over high temperature of the materials; and the vacuum pump is arranged, so that vacuum treatment can be performed in the tank body, raw materials in the tank body are compact in structure and are in an oxygen-free state after the vacuum treatment, bacteria, micro-organisms and the like are not liable to multiply, the quality of the products is improved, and the storage life is prolonged.

Owner:SUNBY MACHINERY CO LTD

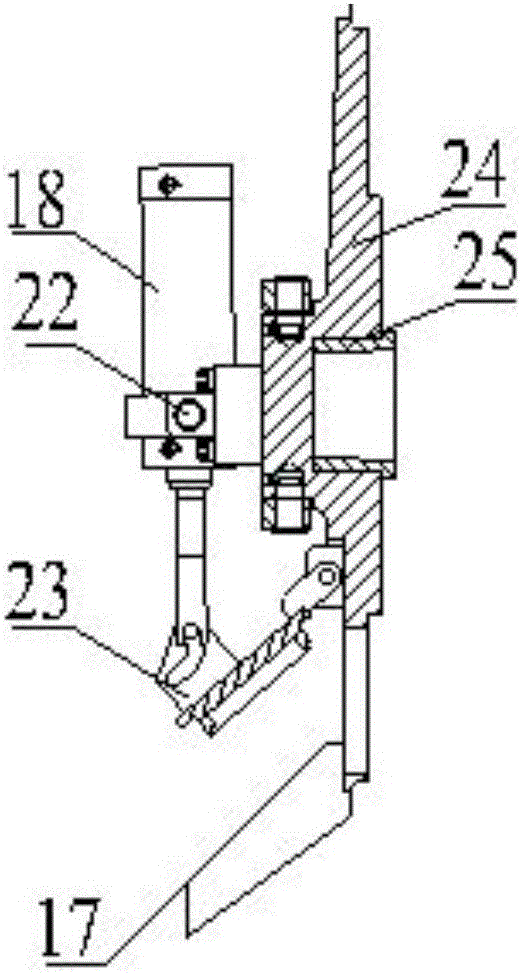

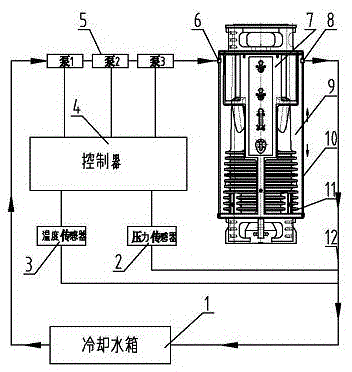

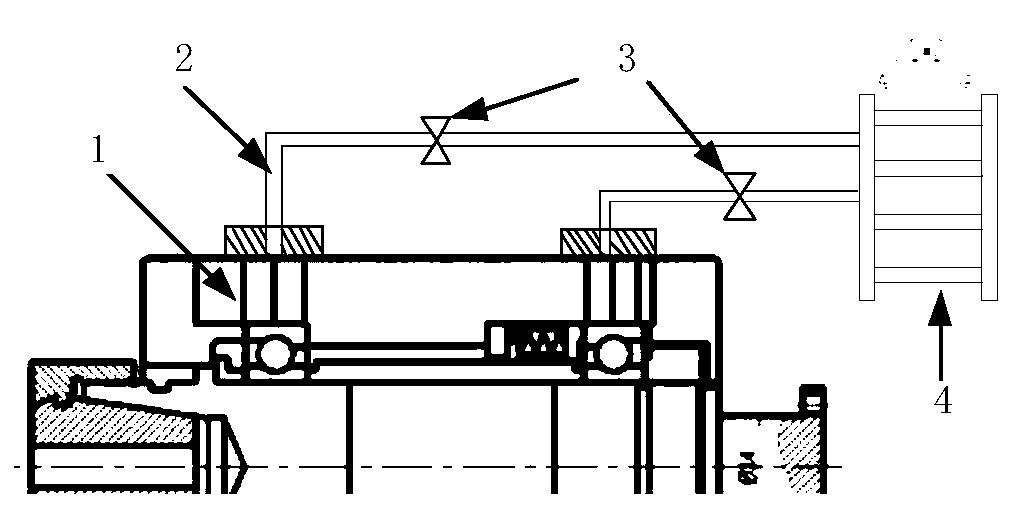

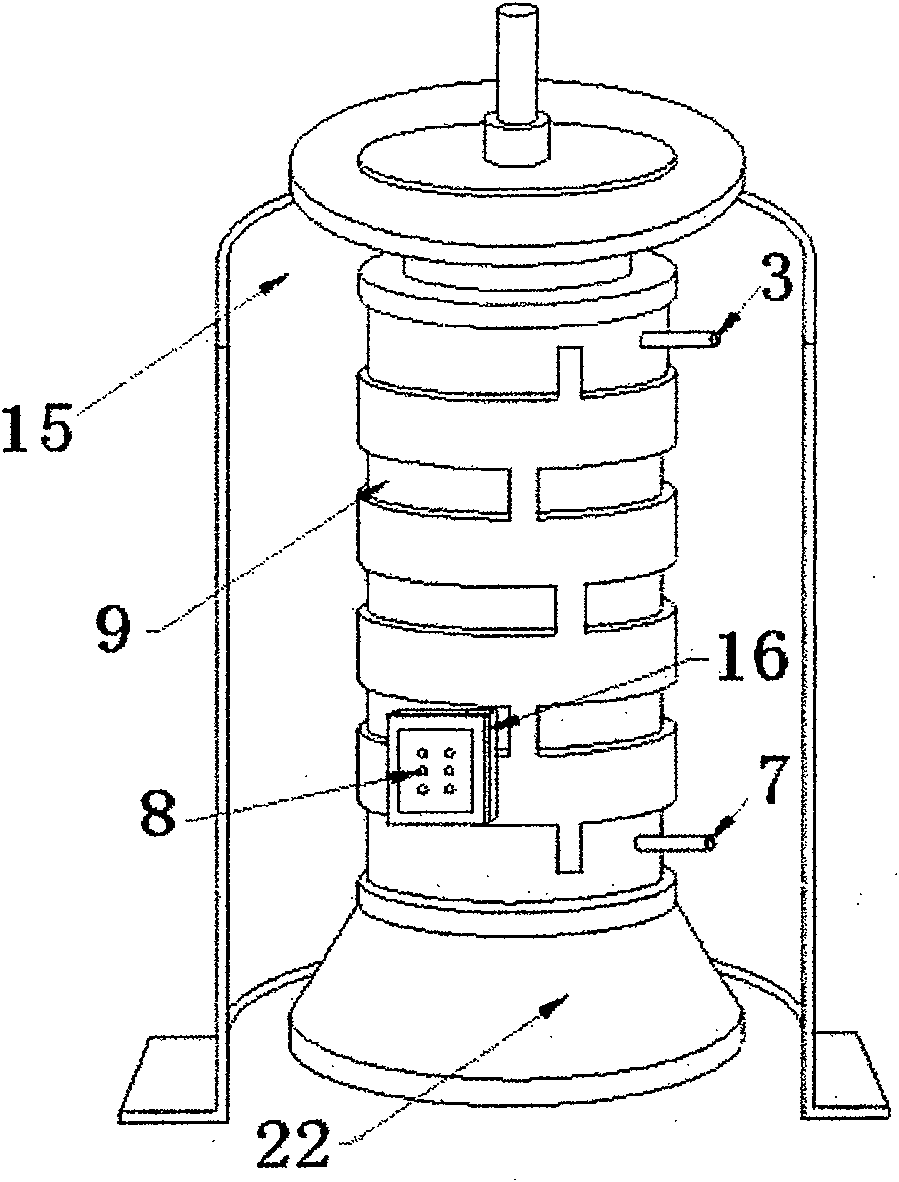

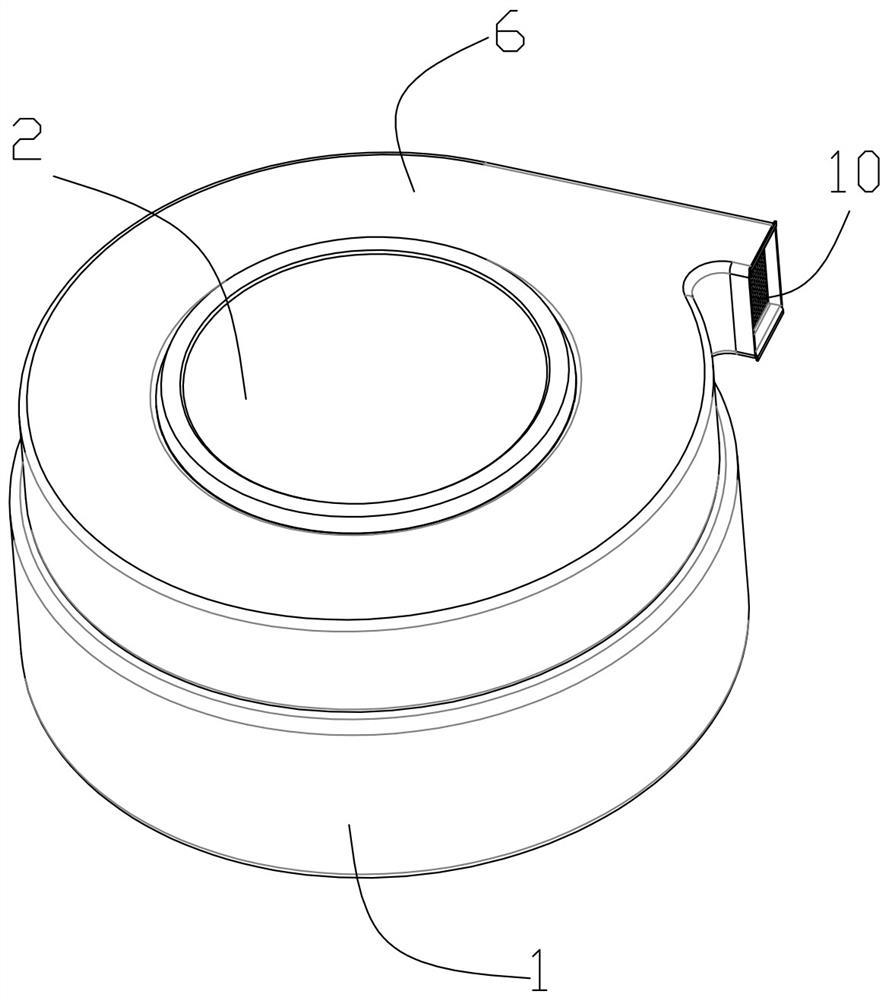

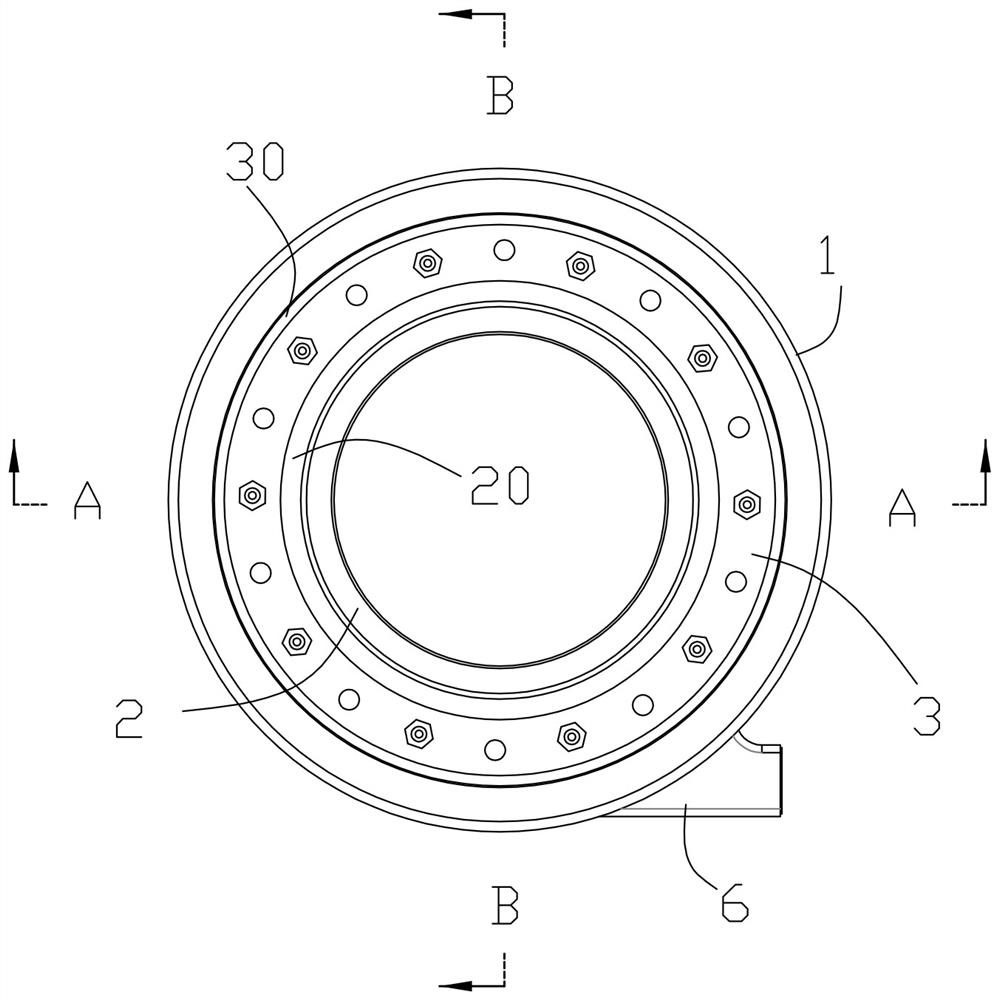

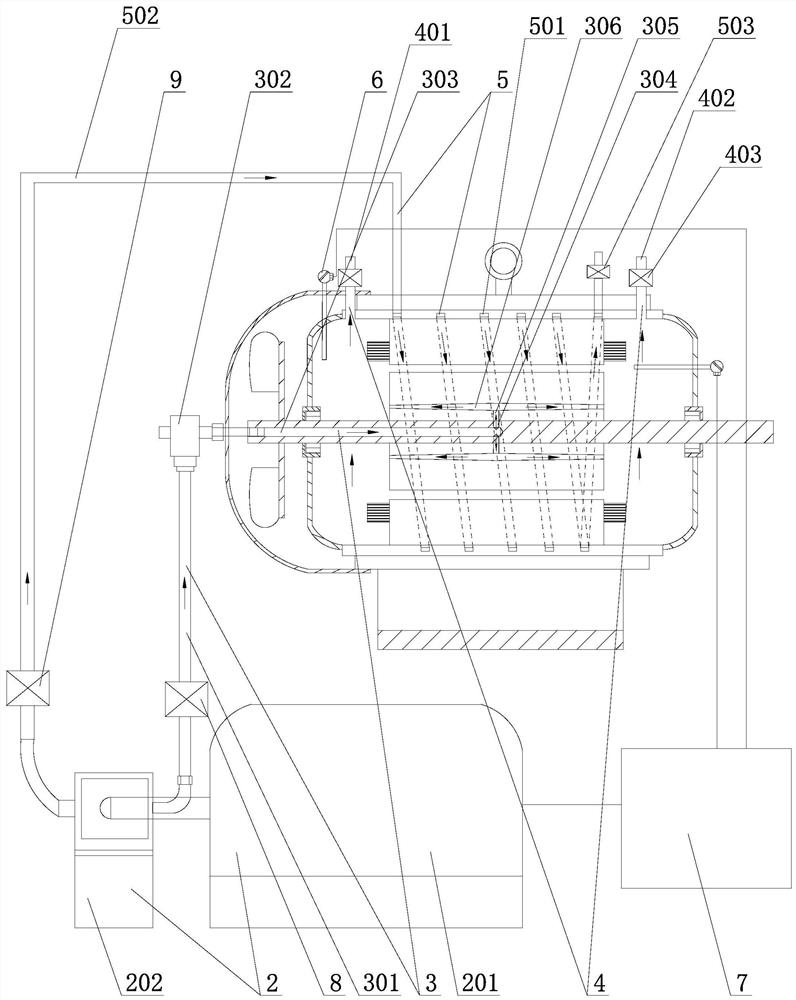

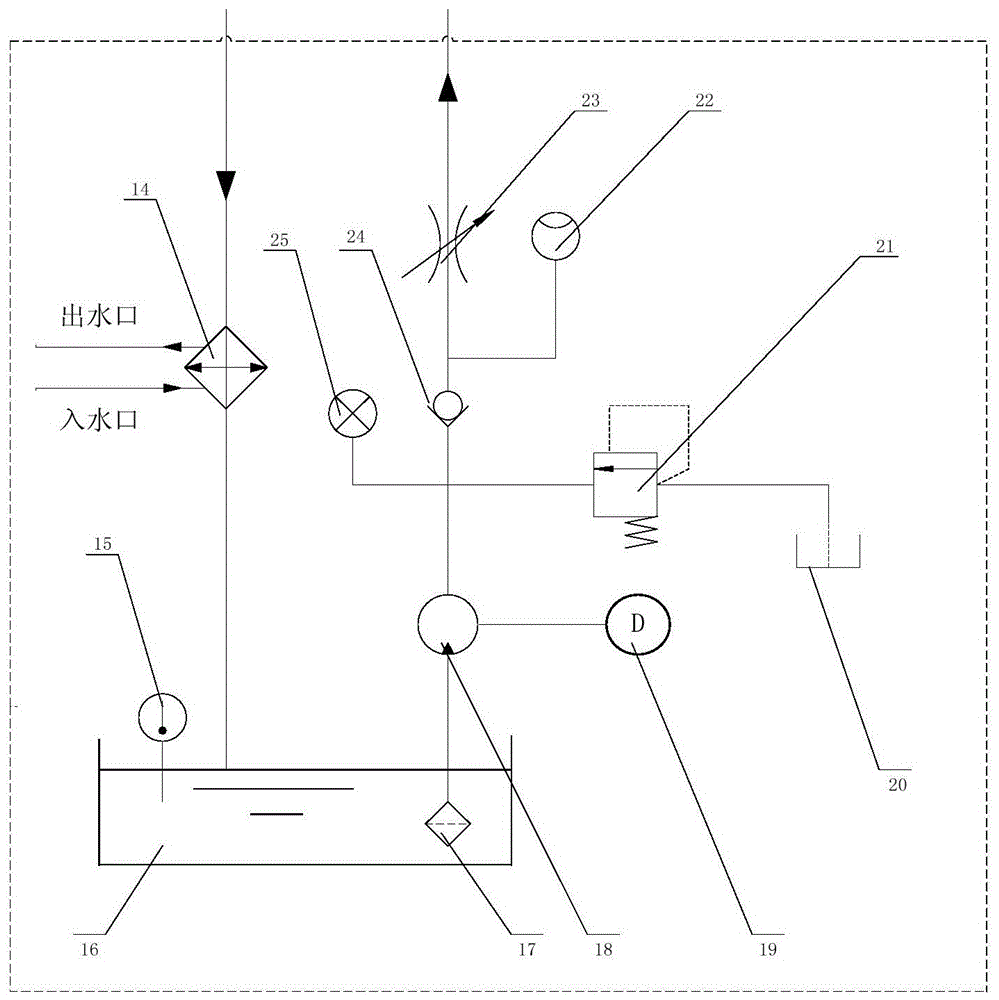

Barrel-hammer-following circulating water cooling system

InactiveCN105604059AFast and reliable heat dissipationEffective control of temperature riseBulkheads/pilesWater pipeElectricity

The invention discloses a barrel-hammer-following circulating water cooling system which comprises a lower cylinder and a water-cavity outer wall fixedly connected on the lower cylinder. A cooling water cavity is formed between the lower cylinder and the water-cavity outer wall, a cooling water tank and a circulating pump unit are serially connected between a water outlet and a water inlet of the cooling water cavity through a cooling water pipe, the circulating pump unit is electrically connected with a controller, a water outlet of the cooling water cavity is communicated with a pressure sensor and a temperature sensor which are electrically connected with the controller respectively, and at least one section of the cooling water pipe is a soft water pipe. Through circulation of cooling water outside the water cavity, quick dissipation of heat of a lower cylinder of a barrel hammer is realized, so that temperature rise of the lower cylinder is controlled effectively and large-tonnage continuous running of the barrel hammer is realized.

Owner:JIANGSU JUWEI MACHINERY

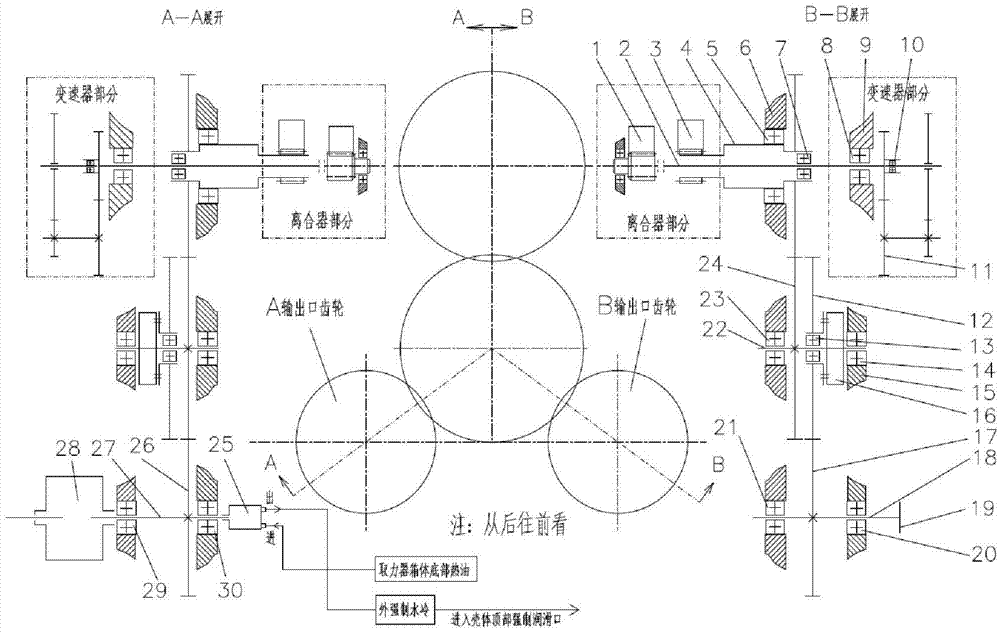

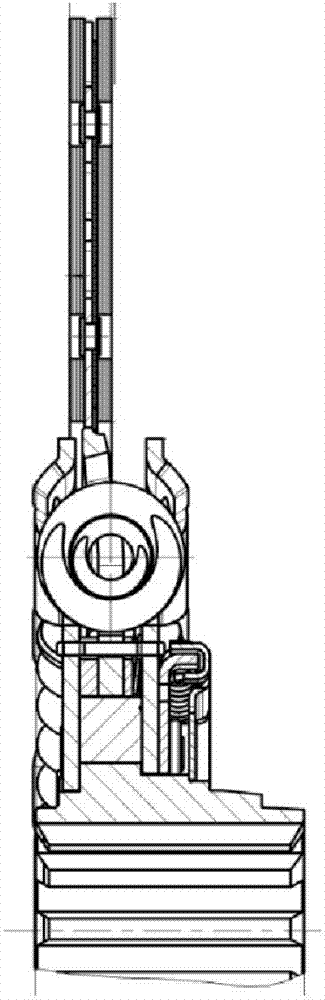

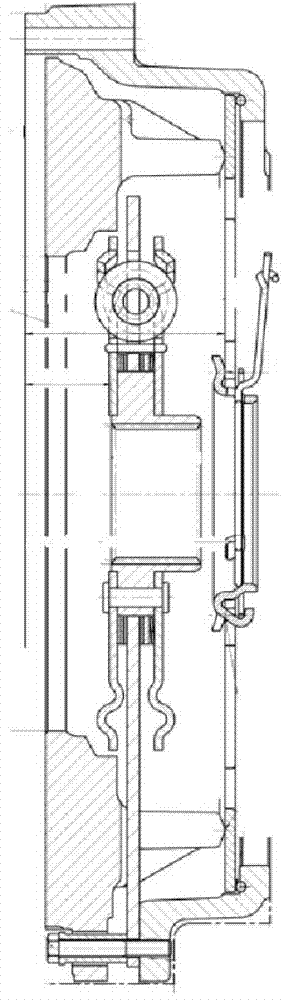

Automobile full-power power takeoff

InactiveCN104728398AMeet the requirements of the combinationSolve switching difficultiesGearboxesGear lubrication/coolingElectromagnetic clutchStatic mode

The invention belongs to the technical field of power takeoffs, and particularly relates to an automobile full-power power takeoff which comprises an input hollow gear axle and a power takeoff second axle which are arranged in a power takeoff shell in an up and down mode; a port A output axle and a port B output axle are symmetrically arranged below the power takeoff second axle; a spline shaft of the front portion of the input hollow gear axle is bound with a splined hub of a PTO clutch through a spline, and the power takeoff second axle is bound with a second axle normally engaged gear through the spline and connected with a second axle idler gear in a sleeved mode through a cylinder roller bearing; the second axle normally engaged gear is normally engaged with a gear portion of the rear portion of the input hollow gear axle, the second axle idler gear is bound with a stable sheet of an electromagnetic clutch in a static mode, and a movable sheet of the electromagnetic clutch and a push plate are bound with the spline of the power takeoff second axle; the middle of the port B output axle is bound with a port B output gear through the spline, and the rear portion of the port B output axle is bound with a port B output flange through the spline; the front portion of the port A output axle is bound with a port A output gear through the spline, and the rear portion of the port A output axle is bound with a hydraulic clutch through the spline. The automobile full-power power takeoff has the advantages of being low in cost and high in safety.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

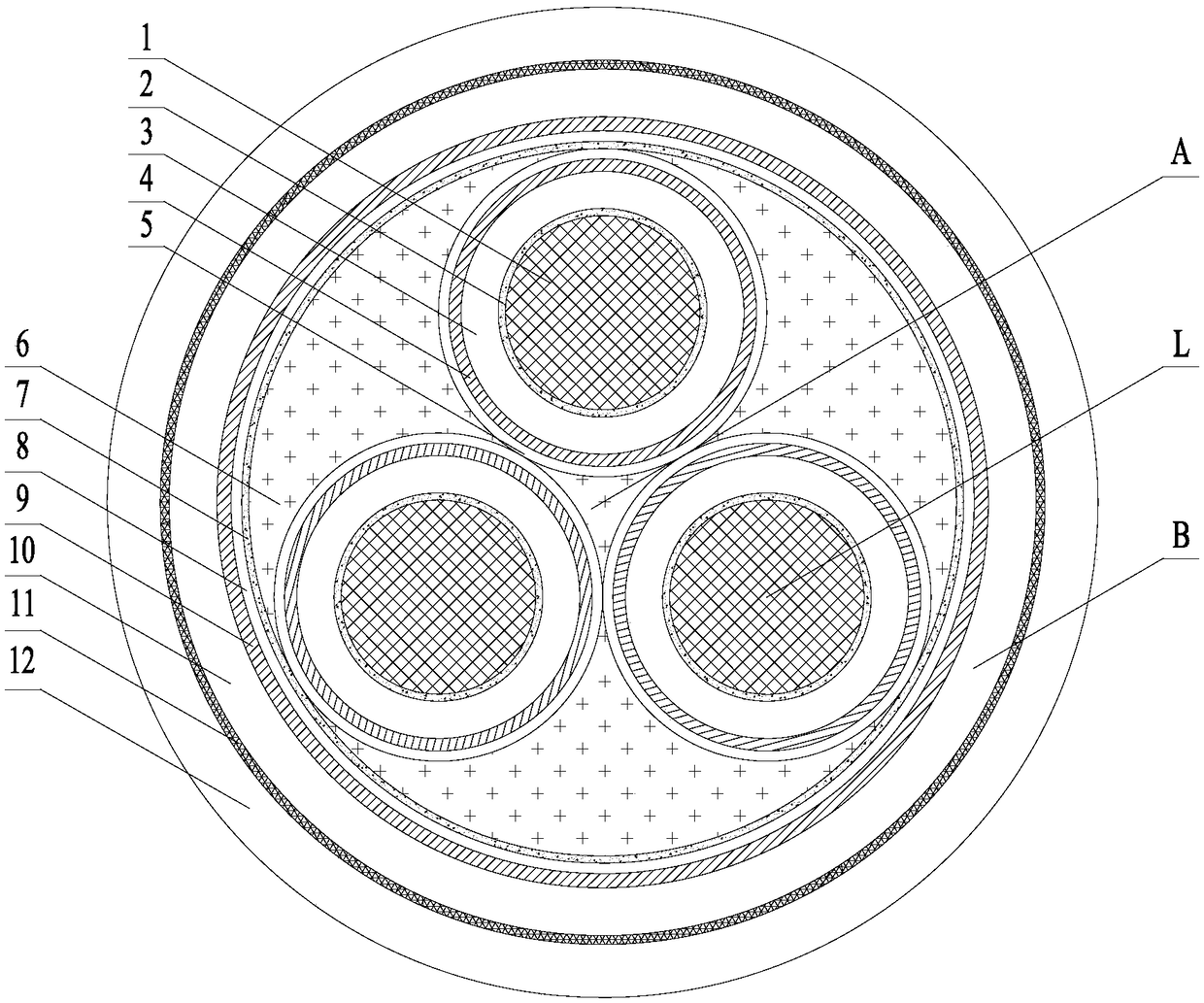

Hydrate temperature control heat dissipation low-voltage cable

ActiveCN108511116ALarge carrying capacitySolve the problem of longevityInsulated cablesDetails of conductive coresElectrical conductorInsulation layer

The present invention relates to a hydrate temperature control heat dissipation low-voltage cable. The whole cable is formed by a conductor, a first nano-graphite coating, a rubber insulation layer, an inner shielding layer, a glass fibre protection layer, a hydrate material layer, a second nano-graphite coating, a belting layer, an outer shielding layer, an inner sheath layer, an armor layer andan outer sheath layer. The cable employs the high heat storage density of the hydrate and the good heat-transfer features of nano particles to fill hydrate materials at a twisting gap of a shielding insulation wire, and the nano-graphite coating is added at the inner walls of the conductor outer layer and the belting layer to effectively control the cable temperature rise, improve the carrying capacity and improve the heat dissipation performance. The defects are solved that a traditional low-voltage cable allow the temperature itself to rise caused by heating itself when large-current load work is performed to decrease the insulation level of the cable, shorten the life, increase the device fault rate and increase the fire risk, and therefore, the hydrate temperature control heat dissipation low-voltage cable is especially suitable for buried cables with large heat values caused by an instant peak current and intermittent load.

Owner:CHANGZHOU UNIV

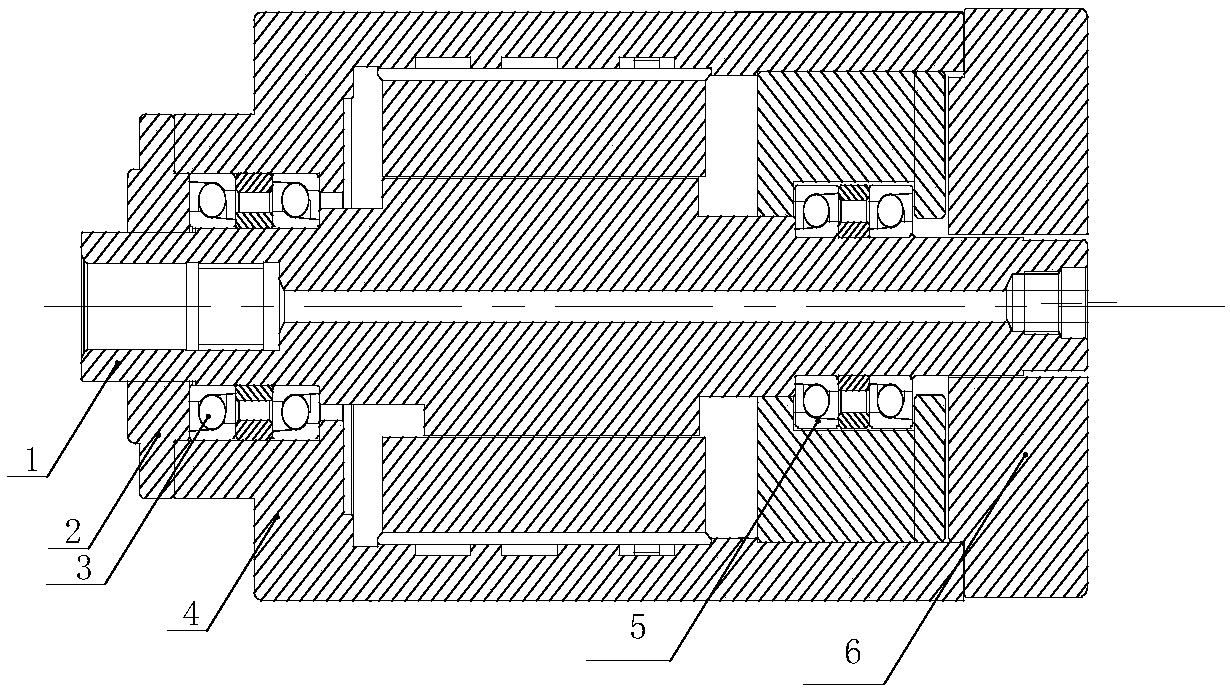

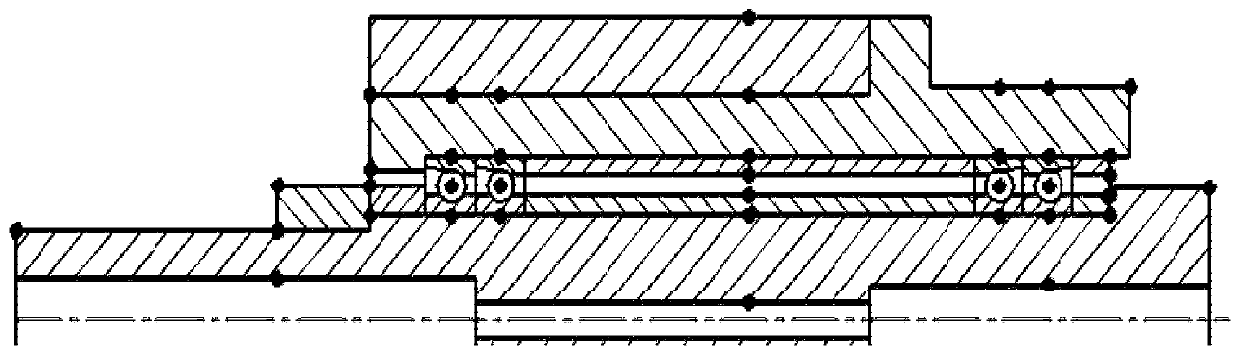

Precision machine tool spindle cooling system and centralized heat dissipation method based on heat conduction channel

ActiveCN109571134BImprove heat dissipationEffective control of temperature riseMaintainance and safety accessoriesElectric machineryMachine tool

The invention discloses a heat conduction passage-based cooling system and centralized heat dissipation method for a spindle of a precision machine tool. The cooling system comprises heat conduction passages, a cooling pipeline, valves and a heat dissipation device; in allusion to a mechanical spindle and a motorized spindle of the precision machine tool, the heat conduction passages are established in bearing blocks and a spindle shell in a radial direction and a high-efficiency heat conduction material fills each heat conduction passage, and thus, the emitted heat of each internal heat source can be rapidly and efficiently transmitted to the outside of the spindle in a manner of heat conduction, and then centralized cooling is performed; and by taking maximization of heat dissipation intensity as a target, the reasonable layout of the heat conduction passages is determined according to different temperature fields in the axial direction and the circumferential direction of each of bearings at the front end and the rear end of the spindle and in the axial direction and the circumferential direction of a motor so as to achieve a balance between temperature rises in the axial direction and the circumferential direction of a spindle system and room temperature. The cooling system and centralized heat dissipation method disclosed by the invention are capable of overcoming abuses that efficiency is low, and the heat still can be absorbed by the spindle shell and installation parts by employing a traditional heat dissipation method, and have a better engineering application prospect.

Owner:XI AN JIAOTONG UNIV

A flexible heat pipe for surface cooling of high-speed electric spindle shaft

ActiveCN108568703BImprove machining accuracyCompact structureMaintainance and safety accessoriesSurface coolingElectric machinery

The invention discloses a flexible heat pipe used for cooling the surface of a rotating shaft of a high-speed motorized spindle. The flexible heat pipe (7) comprises a substrate (701), a runner plate(702) and a cover plate (703), the substrate (701), the runner plate (702) and the cover plate (703) are sequentially bonded from top to bottom, wherein the runner plate (702) is provided with a heatpipe runner, and a sealed heat transfer fluid is filled in the heat pipe runner. The flexible heat pipe is adhered on the surface of the rotating shaft by bending in use. The temperature of the rotating shaft is obviously increased because of the loss of an internal motor, the generation of heat by friction of front and rear bearings and wind motor of the rotating shaft at the operation state of the motorized spindle. The provided flexible heat pipe has an excellent heat transfer performance at the high centrifugal force, the local temperature rise of the rotating shaft is effectively controlled, the thermal deformation caused by the uneven temperature distribution is reduced, the influence of thermal deformation of the rotating shaft on the machining precision of the high-speed motorizedspindle is effectively controlled, meanwhile, the original structure of the motorized spindle is less changed, and the flexible heat pipe has the advantages of high reliability, low cost, easiness inpromotion and implementation and the like.

Owner:XI AN JIAOTONG UNIV

Electric vehicle-mounted complete closed internal liquid cooling, external wind cooling type switch reluctance motor

InactiveCN100570997CTo achieve the purpose of waterproofingImprove cooling effectCooling/ventillation arrangementSupports/enclosures/casingsLow noiseCooling effect

The invention relates to an electric vehicle-mounted fully enclosed internal liquid-cooled and external air-cooled switched reluctance motor, which includes a sealed casing, a stator, a rotor, an internal liquid-cooled and external air-cooled heat dissipation mechanism and a motor waterproof structure, and is characterized in that the heat dissipation mechanism The stator winding can obtain the double heat dissipation effect of internal liquid cooling and external air cooling at the same time, thereby solving the problem of poor heat dissipation of the stator winding. In addition, a special sealing device is added at the motor end cover, shaft end, wiring port, etc. to achieve a good motor waterproof purpose. The fully enclosed internal liquid-cooled and external air-cooled switched reluctance motor for the electric vehicle of the present invention has large torque, good dynamic performance, high efficiency and energy saving, low noise, and reliable airtightness. This technology can effectively control the temperature rise when the motor is running at high speed, especially the temperature rise at the end of the stator winding. It can be effectively waterproof and ensure the safe operation of the motor in rainy days or when there is water on the road, thereby improving the working efficiency of the motor, the safety performance and protection level of the motor, and prolonging its service life.

Owner:BIJIE TIANYU POWER TECH

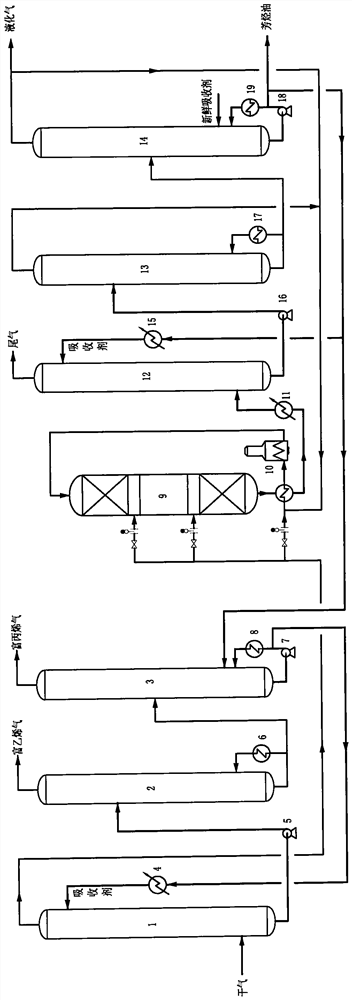

Method for preparing gasoline by double absorption and desorption of dry gas

ActiveCN114214089AIncrease in sizeHigh energy consumptionLiquid hydrocarbon mixtures productionHydrocarbon oils treatment productsExhaust gasDry gas

The invention discloses a method for preparing gasoline by double absorption and desorption of dry gas. The method is characterized in that the raw material dry gas is subjected to first group absorption and desorption to remove part of olefin, and high-value ethylene and propylene are recovered while the olefin concentration in the dry gas feed is reduced; dry tail gas enters the second group for absorption and desorption, part of ethane, propane and butane is separated out and recycled back to the reactor, the olefin concentration in the fed dry gas is reduced, and meanwhile propane, butane and C5 are recycled. The double-absorption desorption reduces the olefin concentration in the fed dry gas from two aspects of separating the olefin in the raw material and recycling the alkane in the tail gas, effectively controls the temperature rise of the reactor, solves the problem that the reaction temperature is difficult to control in the process of preparing gasoline from the dry gas, and is suitable for dry gas raw materials with different sources and different olefin concentrations.

Owner:北京惠尔三吉绿色化学科技有限公司

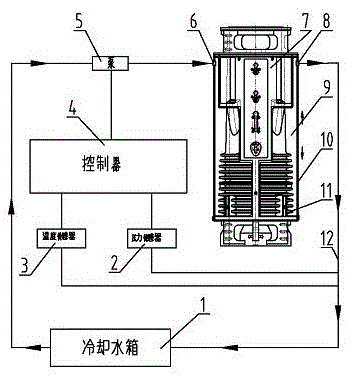

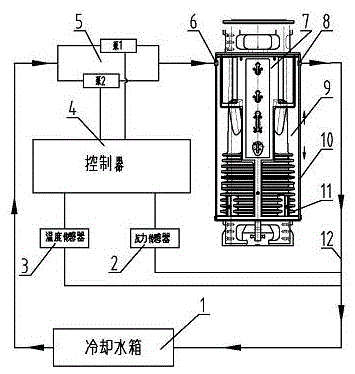

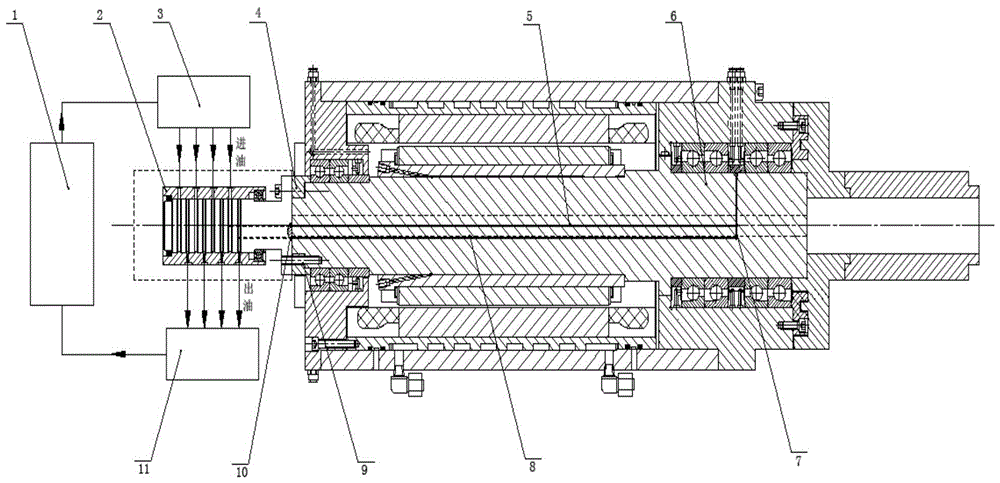

Cooling device for variable frequency controller

InactiveCN101442251ASave effective spaceEffective control of temperature riseStationary conduit assembliesCooling/ventilation/heating modificationsHydraulic motorWorking temperature

The invention relates to variable frequency controller cooling technology, in particular to a variable frequency controller cooling device for a shutter vehicle used for a coal mine, which is used for effectively cooling the heat produced by a variable frequency controller. The device is provided with a circulating power system, a water tank, and a circulating water channel, the water tank is connected to the circulating water channel of cooling water via a circulating motor of the circulating power system through a pipeline, and the circulating water channel is placed on the bottom of the variable frequency controller. The device takes away the heat produced by the variable frequency controller through the circulating water channel of the cooling water arranged on the bottom of the variable frequency controller, drives a circulating water hydraulic motor to ensure that the cooling water finishes the circulation by means of the power produced by the running driving of a vehicle body, drives a fan through a fan hydraulic motor to make the fan cool a circulating water heat exchanger, stores the cooling water through a cooling water tank, and utilizes the surface of the cooling water tank to assist in heat dissipation. The device can solve the problems such as effective cooling of the variable frequency controller and so on, effectively control the working temperature rise of the variable frequency controller, and ensure that the variable frequency controller normally works within the specified temperature range.

Owner:SANY HEAVY EQUIP

Heat dissipation method of bearing having heat dissipation and lubrication functions

InactiveCN112283252AAchieve automatic cooling functionTo achieve the role of lubricationRolling contact bearingsShaftsAir compressionImpeller

The invention discloses a heat dissipation method of a bearing having heat dissipation and lubrication functions. The bearing comprises an outer ring, an inner ring and a retainer; rolling bodies arerotationally connected to the retainer at equal intervals; the length of the inner ring is larger than that of the outer ring; the inner ring is fixedly sleeved with an air compression impeller; the bearing further comprises an airflow cover which covers the air compression impeller and is fixed to the outer ring; each rolling body is provided with a first center hole and multiple dispersion holes; a round hole is formed in the side, close to the outer ring, of the airflow cover; the first center holes communicate with the round hole under the condition that the retainer rotates along with theinner ring; the airflow cover is further provided with an air inlet; a roller coating lubricating unit rotating along with the rolling bodies is arranged between every two adjacent rolling bodies; and the roller coating lubricating units are used for coating the rolling bodies with graphite. According to the method, the automatic heat dissipation function of the bearing can be realized, the temperature rise of the bearing can be effectively controlled, automatic lubrication can be realized, lubricating oil is not required to be added manually, operation is easy, the efficiency is high, the service life of the bearing can be prolonged, and the bearing are better protected.

Owner:NANJING YINGHEGU TECH CO LTD

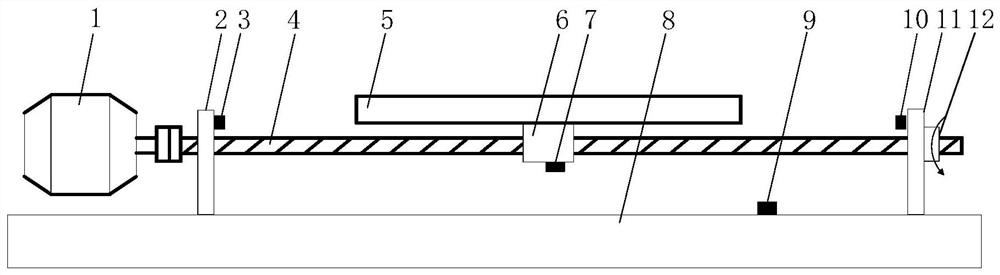

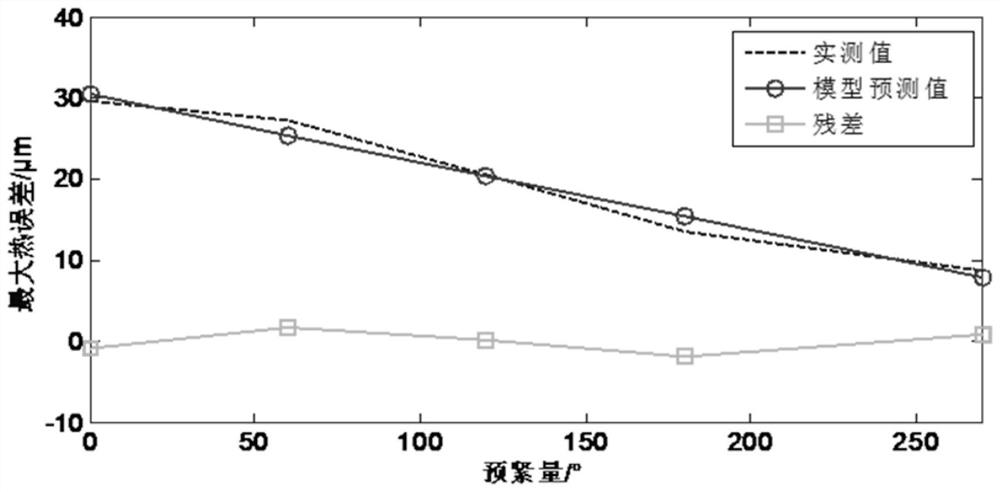

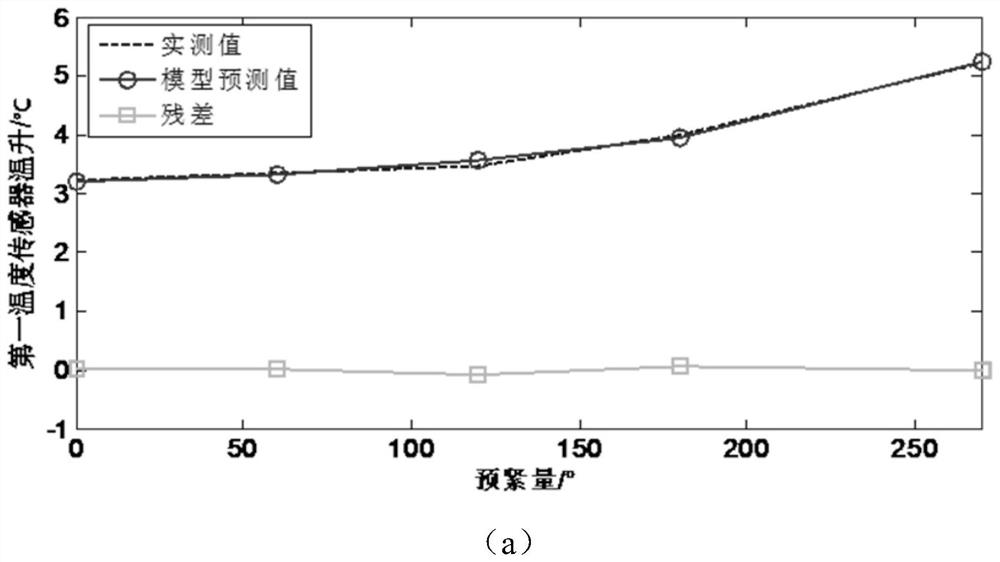

Determination method of lead screw preload based on thermal error and temperature rise weighting

ActiveCN109783975BEffective control of temperature riseControl temperature riseGeometric CADFeeding apparatusProcessing accuracyMoving parts

The invention provides a method for determining the pretightening amount of a lead screw based on thermal error and temperature rise weighting, and belongs to the field of numerical control machine tool assembly. First, under different preload states of the lead screw, the thermal behavior test of the feed shaft under typical working conditions is carried out to obtain the maximum thermal error of the lead screw under various preload states and the temperature rise of key temperature measuring points; then, establish The mathematical model of the screw preload, the maximum thermal error and the temperature rise of key temperature measuring points; finally, the weighted function of the maximum thermal error and the temperature rise of each temperature measuring point is optimized as the objective function, and the optimal prediction of the screw is obtained. Tight amount. This method comprehensively considers the thermal error of the feed shaft and the temperature rise of key points to determine the optimal preload of the screw, which solves the problem that the current experience-based screw preload method is difficult to achieve the optimal effect, and can improve the machining accuracy of the machine tool And precision stability, and ensure the service life of moving parts such as bearings.

Owner:DALIAN UNIV OF TECH

A permanent magnet synchronous motor temperature control system for new energy vehicles

ActiveCN111262391BIncrease profitImprove cooling effectCooling/ventillation arrangementSupports/enclosures/casingsTemperature controlNew energy

The invention relates to a permanent magnet synchronous motor temperature control system for new energy vehicles, which includes a permanent magnet synchronous motor and a cold air supply mechanism. The permanent magnet synchronous motor includes a casing, a stator, a motor shaft and a rotor. Cavity A and cavity B; the cold air intake passage includes a cold air passage A arranged on the motor shaft and a plurality of cold air passages D arranged on the rotor, the cold air passage A communicates with the cold air supply mechanism through a rotary joint and a rubber pipe A, The cold air channel A communicates with the middle of each cold air channel D through multiple radial cold air channels; the cold air exhaust channel includes exhaust channel A and exhaust channel B arranged on the casing, and the exhaust channel A communicates with the cavity , the exhaust passage B communicates with the cavity B, and the exhaust passage A and the exhaust passage B are respectively provided with a gas check valve A. The heat dissipation condition in the motor can be obviously improved, the cooling efficiency is high, the cooling effect is remarkable, and the temperature rise of the motor can be effectively controlled for a long time.

Owner:ZIBO VOCATIONAL INST

Cooling device for variable frequency controller

InactiveCN101442251BSave effective spaceEffective control of temperature riseStationary conduit assembliesCooling/ventilation/heating modificationsHydraulic motorWater channel

The invention relates to variable frequency controller cooling technology, in particular to a variable frequency controller cooling device for a shutter vehicle used for a coal mine, which is used for effectively cooling the heat produced by a variable frequency controller. The device is provided with a circulating power system, a water tank, and a circulating water channel, the water tank is connected to the circulating water channel of cooling water via a circulating motor of the circulating power system through a pipeline, and the circulating water channel is placed on the bottom of the variable frequency controller. The device takes away the heat produced by the variable frequency controller through the circulating water channel of the cooling water arranged on the bottom of the variable frequency controller, drives a circulating water hydraulic motor to ensure that the cooling water finishes the circulation by means of the power produced by the running driving of a vehicle body, drives a fan through a fan hydraulic motor to make the fan cool a circulating water heat exchanger, stores the cooling water through a cooling water tank, and utilizes the surface of the cooling watertank to assist in heat dissipation. The device can solve the problems such as effective cooling of the variable frequency controller and so on, effectively control the working temperature rise of thevariable frequency controller, and ensure that the variable frequency controller normally works within the specified temperature range.

Owner:SANY HEAVY EQUIP CO LTD

Heat dissipation method of roller having heat dissipation function

InactiveCN112283251AAchieve automatic cooling functionTo achieve the role of lubricationRolling contact bearingsShaftsEngineeringGraphite

The invention discloses a heat dissipation method of a roller having a heat dissipation function. The roller comprises a roller body; self-heat-dissipation bearings are arranged at one end and the other end of the roller body; each self-heat-dissipation bearing comprises an outer ring, an inner ring and a retainer, rolling bodies are rotationally connected to the retainer at equal intervals, the length of the inner ring is larger than that of the outer ring, a roller coating lubricating unit rotating along with the rolling bodies is arranged between every two adjacent rolling bodies, and the roller coating lubricating units are used for coating the rolling bodies with graphite. According to the method, the automatic heat dissipation function of the bearings can be realized, the temperaturerise of the bearings can be effectively controlled, automatic lubrication can be realized, lubricating oil is not required to be added manually, operation is easy, the efficiency is high, the servicelife of the bearings can be prolonged, and the bearings are better protected.

Owner:南京荧河谷科技有限公司

A Cooling System for Electric Spindle Core

InactiveCN104108047BIncrease cooling areaIncreased turbulenceMaintainance and safety accessoriesElectricityThermal deformation

The invention discloses an electric spindle core cooling structure and system. An electric spindle core is provided with a plurality of U-shaped cooling units consisting of straight-hole channels; the inflow channel inlet and reflow channel outlet of each cooling channel unit are formed in a staggered way in the back end face of the electric spindle core; a connecting channel is formed inside the electric spindle core close to a front bearing to connect the inflow channel with the reflow channel; specific to the aim of realizing leading-in and leading-out of a cooling channel unit cooling medium, a shaft head flange type multi-channel high-speed rotary joint is tightly connected with the back end face of the conventional electric spindle core through a back bearing sleeve, an inflow channel header and a reflow channel header are provided, and an electric spindle core forced circular cooling system is constructed with an oil-water cooling system. By adopting the electric spindle core cooling structure and system, direct, rapid and efficient forced circular cooling of the electric spindle core can be realized, the problem of heat dissipation caused by long-term high-power processing of an electric spindle is solved, thermal deformation of the electric spindle core is reduced, and the heat stability of the electric spindle is enhanced.

Owner:XI AN JIAOTONG UNIV

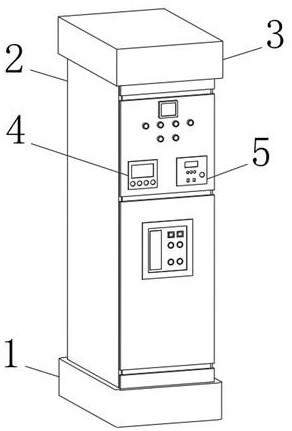

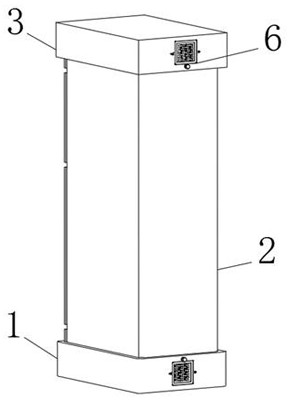

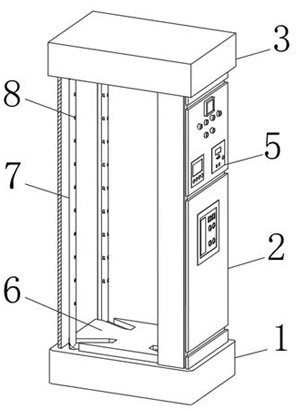

A 12kv switchgear structure with controllable temperature rise

ActiveCN110311316BEnhanced convectionEffective control of temperature riseSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsControl switchRelative humidity

The invention discloses a 12kv switch cabinet capable of controlling the temperature rise, which comprises a bottom base, a cabinet body and a top base, wherein the outer side of the cabinet body is fixedly equipped with a current controller and a temperature and humidity controller, the bottom base and the top base are fixedly installed at the bottom end and the top end of the cabinet body respectively, and both the bottom base and the top base are internally provided with a forced ventilation device. According to the 12kv switch cabinet structure capable of controlling the temperature rise,the design of the ventilation channel of the switch cabinet is optimized, the measure of combining forced air cooling and autonomous ventilation is adopted to promote air convection in the switch cabinet, the current controller is actively started at 70% of the rated current, and the temperature and humidity controller is actively started at 60% of the relative humidity, so that the temperature rise is controlled in a mode that the part which is possibly touched in normal operation is less than 70 DEG C and the temperature rise is less than 30 DEG C, and that the part which cannot be touched in normal operation is less than 80 DEG C and the temperature rise is less than 40 DEG C. Therefore, the temperature rise of the 12kv switch cabinet can be effectively controlled, and thus the 12kv switch cabinet is effectively protected.

Owner:ZHEJIANG DISIWEI ELECTRIC

High-speed high-precision motorized spindle for lathe, material clamping method and material loosening mechanism

ActiveCN112338214AHigh precisionImproved low-speed high-torque characteristicsLarge fixed membersPositioning apparatusForced circulationProduction quality

The invention provides a high-speed high-precision motorized spindle for a lathe, a material clamping method and a material loosening mechanism. The high-speed high-precision motorized spindle comprises a spindle core and a clamping device arranged at the rear end of the spindle core. The clamping device comprises a pull rod, the material clamping mechanism arranged at the rear portion of the pullrod and the material loosening mechanism arranged at the rear end of the material clamping mechanism. According to the high-speed high-precision motorized spindle, materials are clamped through the spring type material clamping mechanism, so that unstable factors generated by a traditional clamping mechanism when a spindle core operates at a high speed are greatly reduced; through the arrangementof the floating type material loosening mechanism, the situation that the service life of a bearing is shortened since an air cylinder exerts thrust on a bearing part in the loosening process is avoided; the operating speed and stability of a spindle are improved in the mode that a built-in stator and rotor are connected with the spindle core to directly drive the spindle core to rotate, the spindle core is forcibly cooled in a forced circulation water cooling mode, high-speed, high-precision and high-stability operating of the spindle core is achieved, and therefore the production quality and the machining efficiency are greatly improved.

Owner:WEIHAI BEST PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com