Cylindrical diesel pile hammer with forced cooling function

A technology of forced cooling and piling hammer, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., and can solve problems such as difficulty in meeting the construction requirements of piling hammer

Active Publication Date: 2012-11-28

JIANGSU JUWEI MACHINERY

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the natural air cooling method is difficult to meet the construction requirements of piling hammers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

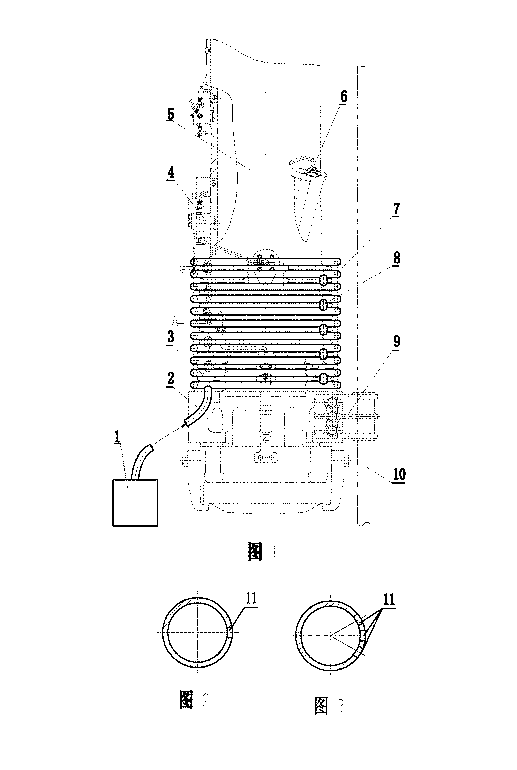

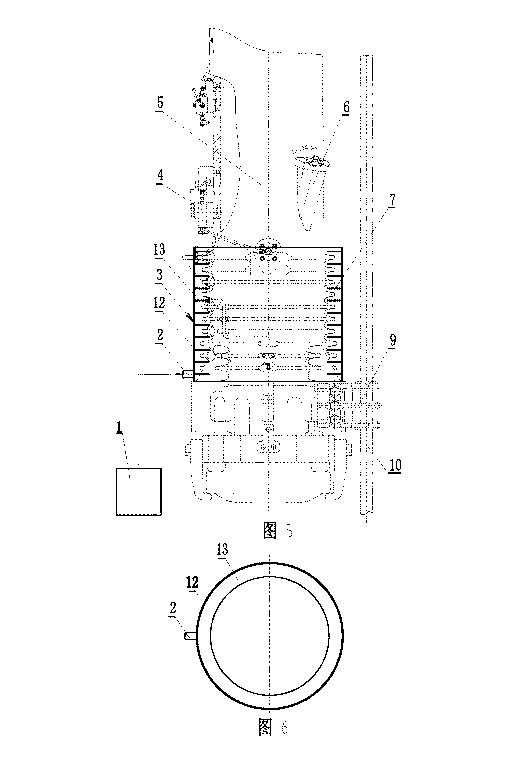

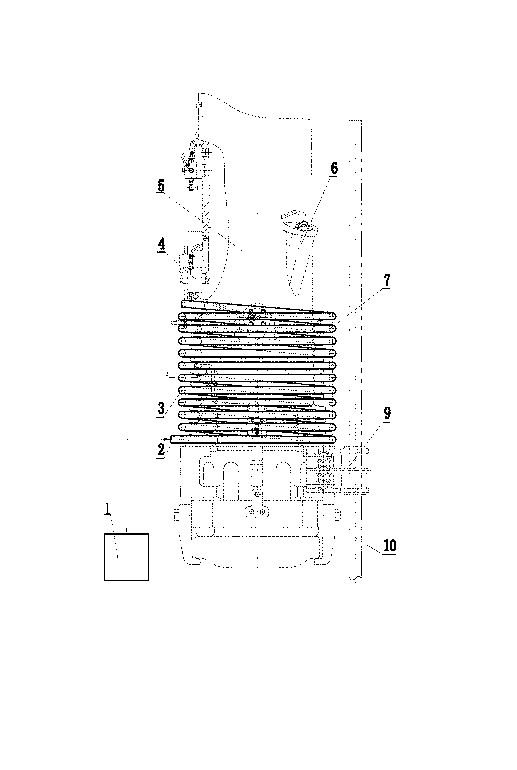

The invention discloses a cylindrical diesel pile hammer with a forced cooling function. The cylindrical diesel pile hammer comprises a lower cylinder, wherein a fuel pump and an air sucking and exhausting port are arranged on a lower cylinder body; the fuel pump is communicated with an oil nozzle; the air sucking and exhausting port runs through the wall of the lower cylinder body; a coolant forced flowing device is arranged on the periphery of the lower cylinder body, and is capable of guiding a coolant to flow through the external surface of the lower cylinder body; the coolant flowing device is communicated with a pressure coolant source; and a plurality of radiating plates are arranged on the external surface of the lower cylinder body and corresponds to the coolant forced flowing device in position. The cylindrical diesel pile hammer with the forced cooling function is simple in structure, convenient to maintain and manufacture, capable of quickly and timely radiating and effectively controlling the temperature rise of the cylinder, and can be widely applied to the cylindrical diesel pile hammers of various specifications and types.

Description

technical field The invention relates to a barrel-type diesel piling hammer used in construction engineering, in particular to a cooling device for a cylinder of the barrel-type diesel piling hammer. Background technique The barrel type diesel piling hammer uses the energy of fuel explosion to push the upper piston to reciprocate upwards to generate impacts for hammering piles. It is widely used for its advantages of large impact force, high work efficiency, strong reliability, and convenient operation and maintenance. In recent years, with the development of my country's economic construction, especially the needs of foundation construction such as modern marine engineering, cross-sea bridges, oil drilling platforms and offshore wind farms, the barrel diesel piling hammer is becoming more and more large-scale. When the barrel type diesel piling hammer is doing construction work, the upper piston falls off the landing gear and falls freely. When the upper piston falls and p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D7/12

Inventor 余有存许向华

Owner JIANGSU JUWEI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com