A permanent magnet synchronous motor temperature control system for new energy vehicles

A permanent magnet synchronous motor, new energy vehicle technology, applied in electromechanical devices, electrical components, electric components and other directions, can solve the problems of reducing the cooling effect of air-conditioning, untimely cooling of the rotor, and limited cooling, so as to achieve accelerated cooling effect, The effect of improving cooling efficiency and improving the utilization rate of cold air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

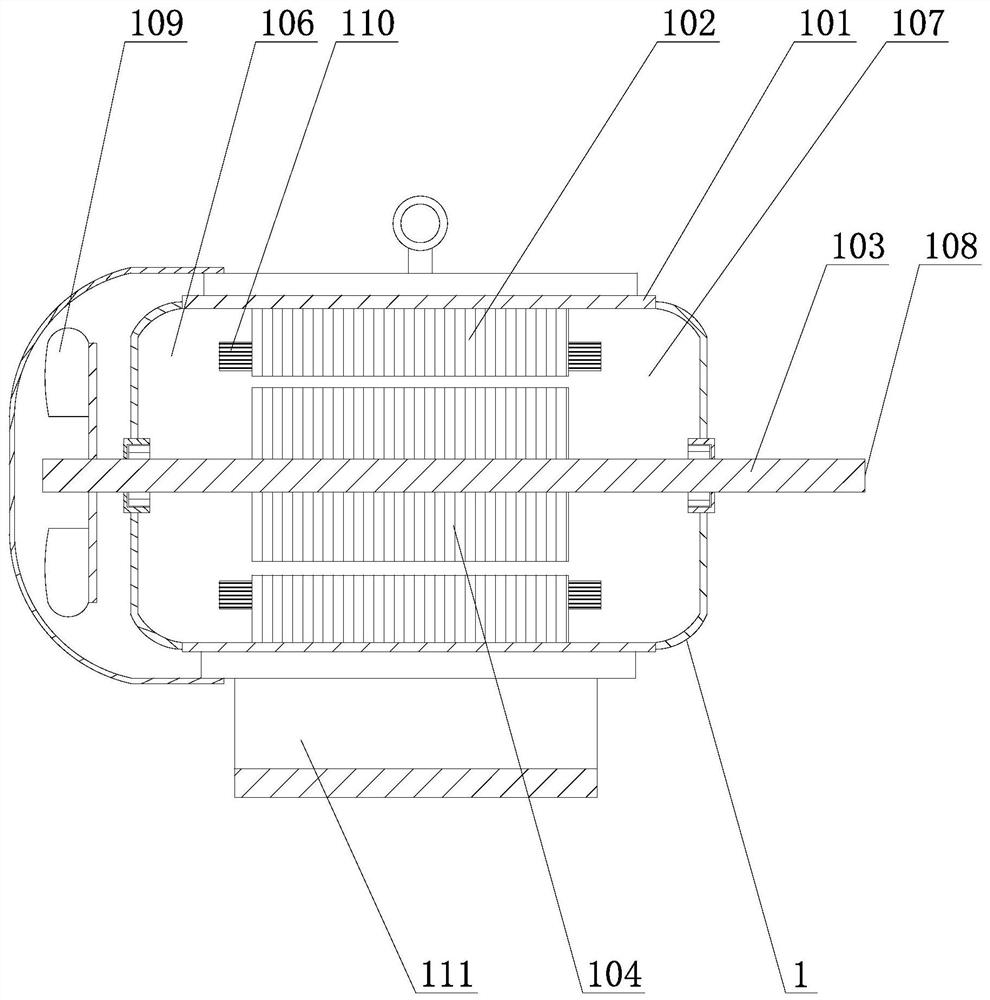

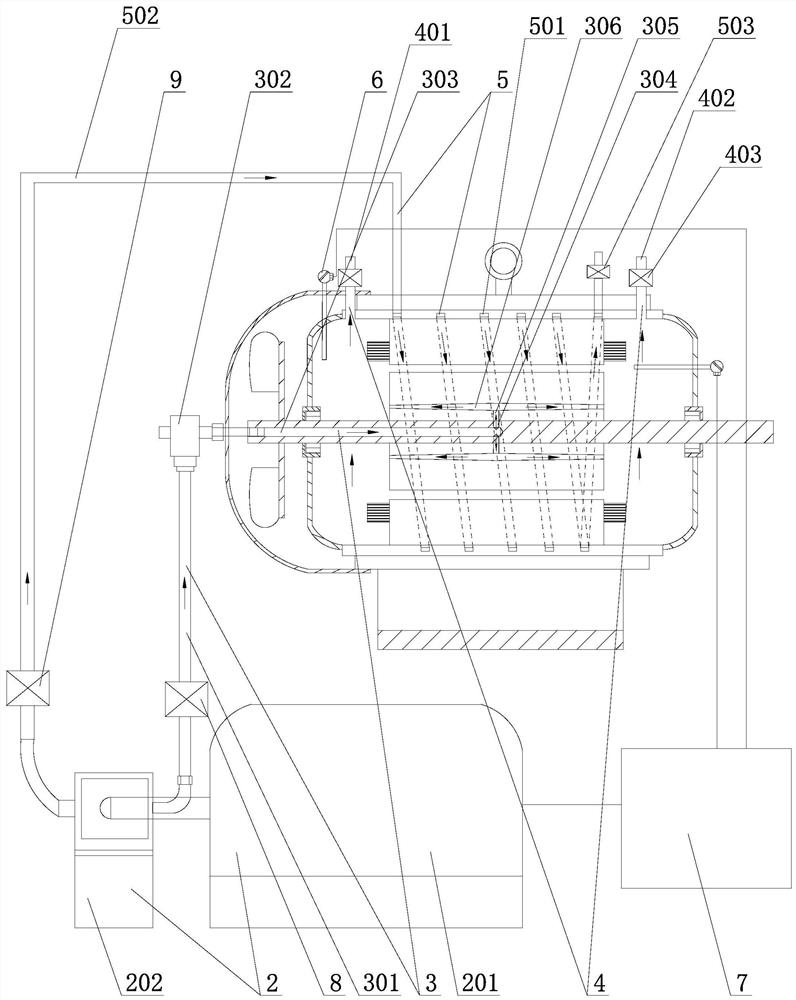

[0037] Such as Figure 1-3 As shown, a permanent magnet synchronous motor temperature control system for new energy vehicles includes a permanent magnet synchronous motor 1, and the permanent magnet synchronous motor 1 includes a casing 101, and a stator 102 is fixed inside the casing 101. A motor shaft 103 is installed in the middle of the casing 101, and a rotor 104 is installed on the motor shaft 103, and a V-shaped radial permanent magnet 105 is embedded in the rotor 104, and the two ends of the rotor 104 are formed with the casing 101. Cavity A106 and cavity B107 are two cavities. The stator core is provided with 24 slots, and windings 110 are provided on the slots. The permanent magnet synchronous motor can adopt a more commonly used 4-pole form, and the motor windings are divided into three phases. 4-pole layout, using single-layer chain winding, energized to generate 4-pole rotating magnetic field, the permanent magnet rotor core is made of silicon steel sheets, which ...

Embodiment 2

[0048] Embodiment 2: the difference between this embodiment and embodiment 1 is:

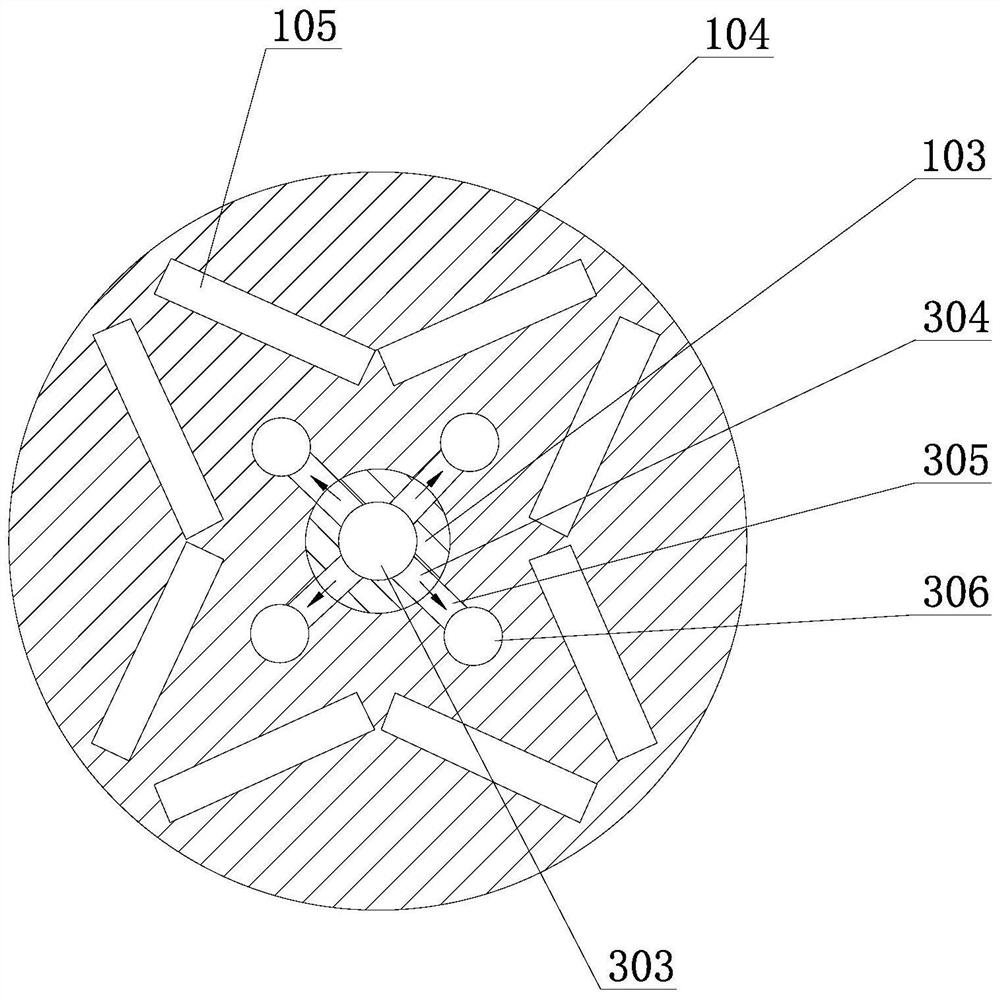

[0049] Such as Figure 4 As shown, at least one radial cold air channel B304 is provided on the motor shaft 103 corresponding to the middle position of the rotor 103, generally two cold air channels B304 are arranged symmetrically, and the middle part of the rotor 103 corresponds to the position of the cold air channel B304. Annular cold air channel E307, the cold air channel B304 communicates with the annular cold air channel E307, and the central part of the rotor 104 is radially provided with a cold air channel C305 that communicates the annular cold air channel E307 with the middle part of the cold air channel D306, where the cold air channel It is only meaningful if the number of D is greater than 2, preferably 3 to 5 times the number of B in the air-conditioning channel. Adopting this structural design can realize cooling air through more cold air passages D306 under the premise of reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com