Method for cooling air leaking flange of supporting plate of hot blast valve

A technology of hot blast valve and flange, which is applied in the direction of furnace, furnace type, blast furnace parts, etc., can solve the problems of increasing spare parts cost and maintenance cost, affecting blast furnace output, blast furnace long shutdown, etc., so as to reduce spare parts consumption and avoid Stop the wind accident and ensure the effect of smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

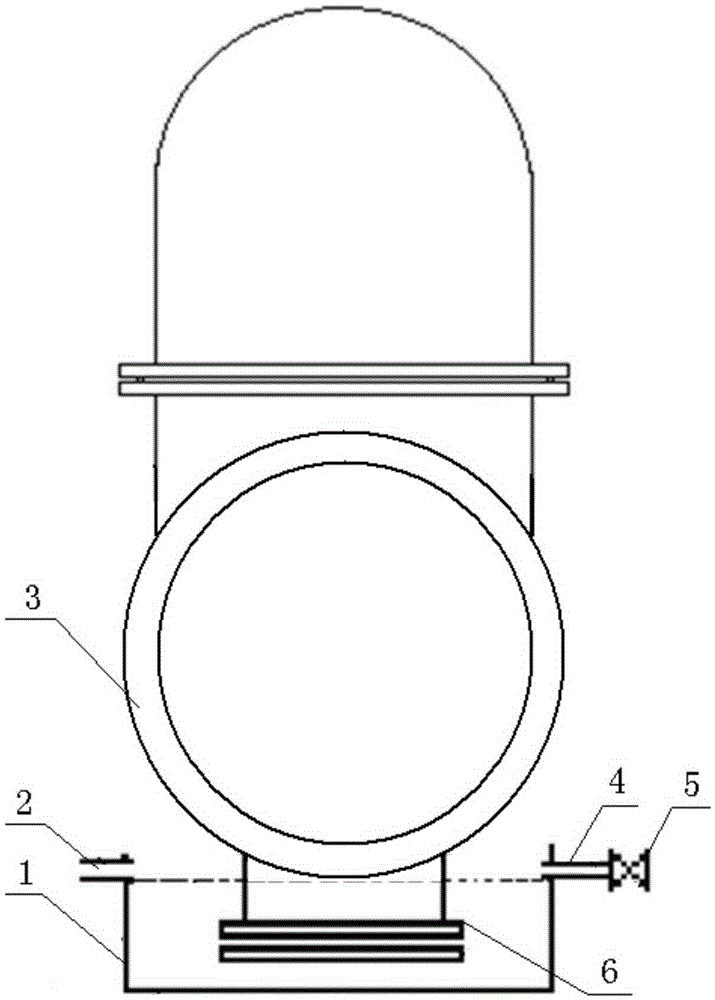

[0018] The cooling method of the air leakage of the flange of the hot air valve supporting plate of the present invention is as follows:

[0019] 1. Wrap the thin copper strands around the air leakage of the flange 6 of the supporting plate first, and apply force by fastening the bolts of the flange 6 to reduce the air leakage.

[0020] 2. Weld an open cooling water tank 1 with a 5 mm thick steel plate on the lower bracket of the hot air valve 3, and the upper edge of the cooling water tank 1 is 100 mm higher than the upper surface of the flange 6 that leaks air, so that the flange 6 can be fully immersed in the cooling water in the water.

[0021] 3. Weld a replenishing water pipe 4 with an outer diameter of 15mm on the upper right side of the cooling water tank 1, and install a ball valve 5 on the replenishing pipe 4 to control the replenishing water flow. The rear end of the ball valve 5 is connected with a cloth rubber hose with an inner diameter of 15mm, and the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com