Sacrificial silicon carbide seed crystal protective film

A silicon carbide seed and sacrificial technology, which is applied in the field of silicon carbide seed protective film, can solve the problems of crystal quality degradation, crystal scrapping, crystal unusability, etc., to achieve the purpose of suppressing volatilization, preventing excessive burn-through, and reducing volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

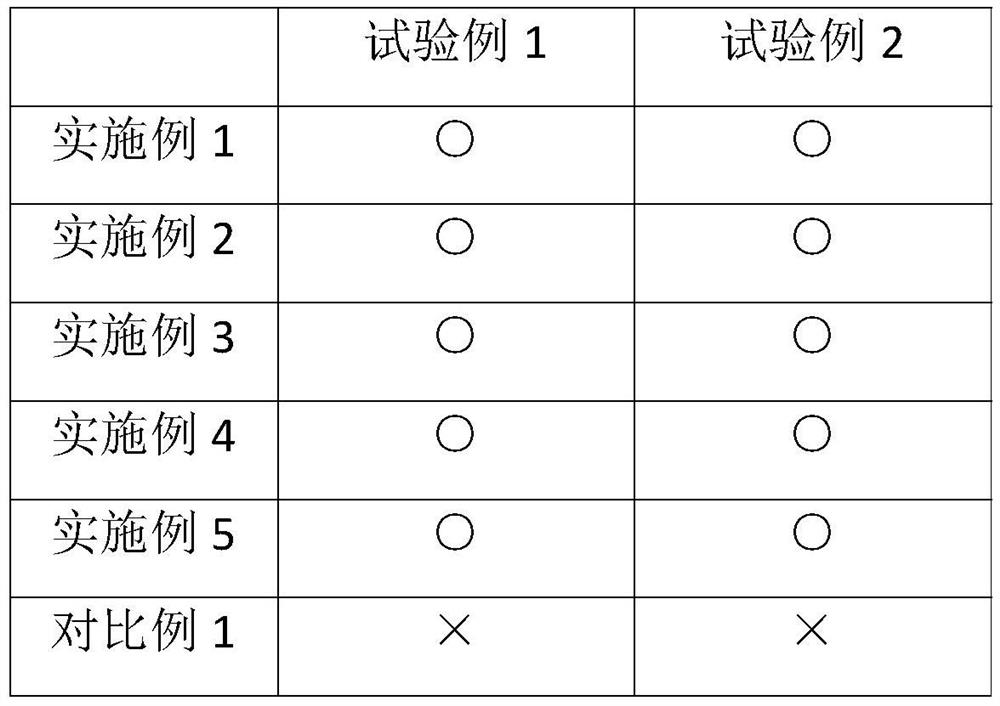

Examples

Embodiment 1

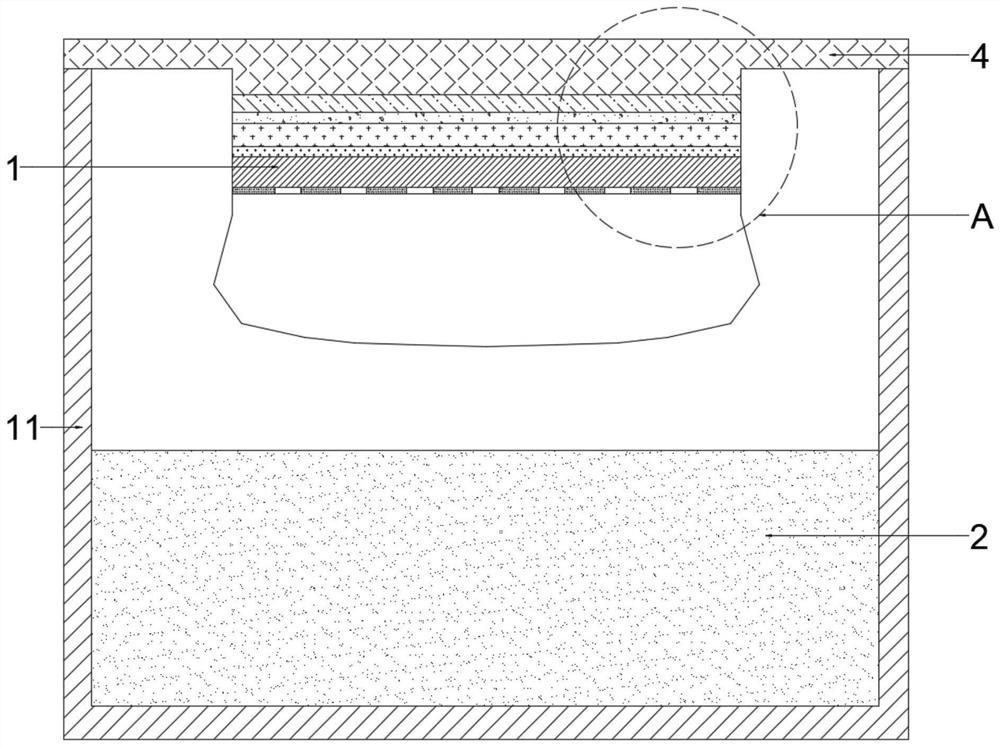

[0024] The growth of silicon carbide crystals is carried out in the silicon carbide growth chamber 11, the top of the silicon carbide growth chamber 11 is fixed with a seed crystal tray 4, the bottom of the silicon carbide growth chamber 11 is filled with silicon carbide raw materials 2, and the seed crystal 1 is fixed on the seed crystal tray 4. The bottom surface. In this embodiment, the side of the seed crystal 1 close to the seed crystal tray 4 is defined as the back side of the seed crystal 1, and the side of the seed crystal 1 close to the silicon carbide raw material 2 is defined as the front side of the seed crystal 1.

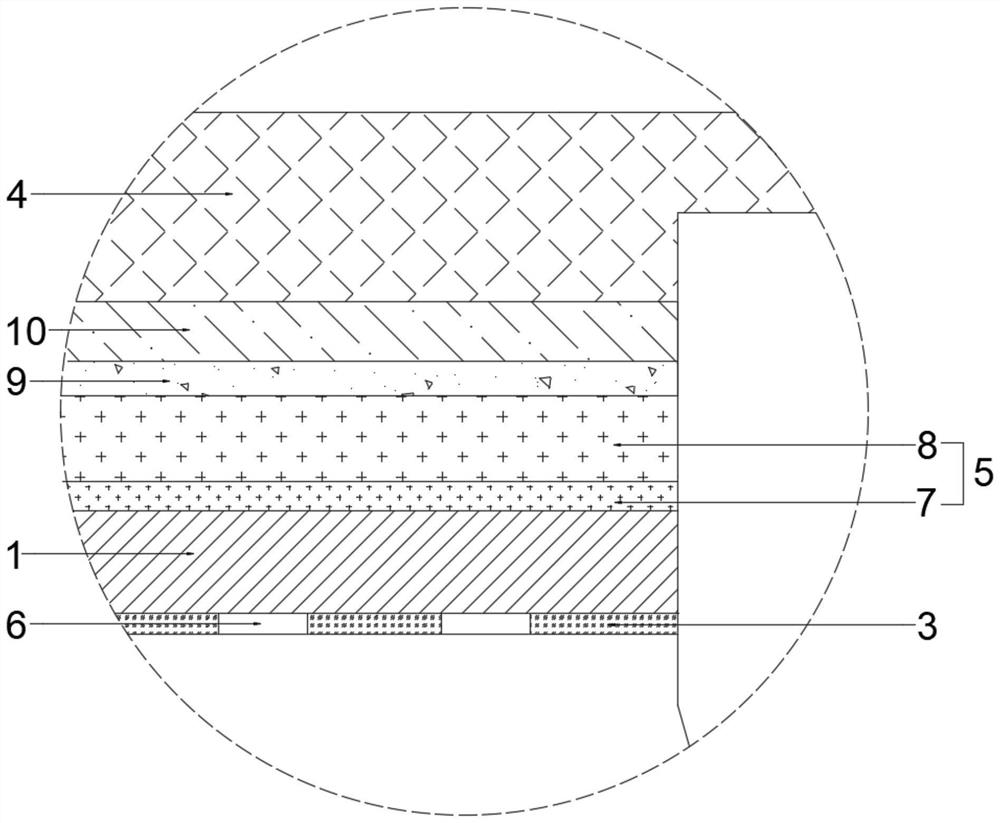

[0025] Such as figure 1 and figure 2 As shown, a sacrificial silicon carbide seed crystal protective film includes a first silicon carbide polycrystalline film 3 covering the front surface of the seed crystal 1 and a second silicon carbide polycrystalline film 5 covering the back surface of the seed crystal 1; that is The first silicon carbide polycr...

Embodiment 2

[0032] A sacrificial silicon carbide seed crystal protective film, comprising a first silicon carbide polycrystalline film 3 covering the front of the seed crystal 1 and a second silicon carbide polycrystalline film 5 covering the back of the seed crystal 1; the first Nanoscale through holes 6 are evenly distributed on the silicon carbide polycrystalline film 3; the second silicon carbide polycrystalline film 5 is a double-layer composite film, which sequentially includes a first film layer 7 and a second film layer 8; the seed crystal 1. A second silicon carbide polycrystalline film 5, a carbon film 9 and graphite paper 10 are sequentially pasted on the side close to the seed crystal tray 4, and the carbon film 9 is bonded to the graphite paper 10.

[0033] The first silicon carbide polycrystalline film 3 and the second silicon carbide polycrystalline film 5 cover the surface of the seed crystal 1 by directly reacting and sintering on the seed crystal 1 .

[0034]The binder i...

Embodiment 3

[0039] A sacrificial silicon carbide seed crystal protective film, comprising a first silicon carbide polycrystalline film 3 fixed on the front side of the seed crystal 1 and a second silicon carbide polycrystalline film 5 covering the back side of the seed crystal 1; the first Nanoscale through holes 6 are evenly distributed on the silicon carbide polycrystalline film 3; the second silicon carbide polycrystalline film 5 is a double-layer composite film, which sequentially includes a first film layer 7 and a second film layer 8; the seed crystal 1. A second silicon carbide polycrystalline film 5, a carbon film 9 and graphite paper 10 are sequentially pasted on the side close to the seed crystal tray 4, and the carbon film 9 and the graphite paper 10 are bonded together.

[0040] The first silicon carbide polycrystalline film 3 and the second silicon carbide polycrystalline film 5 cover the surface of the seed crystal 1 by directly reacting and sintering on the seed crystal 1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com