Dry deslagging continuous feeding biomass gasification furnace

A biomass and dry slag removal technology, applied in the field of energy science, can solve the problems of poor airtightness, reduced gasification strength, partial burn-through of gasifier, etc. The effect of preventing partial burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

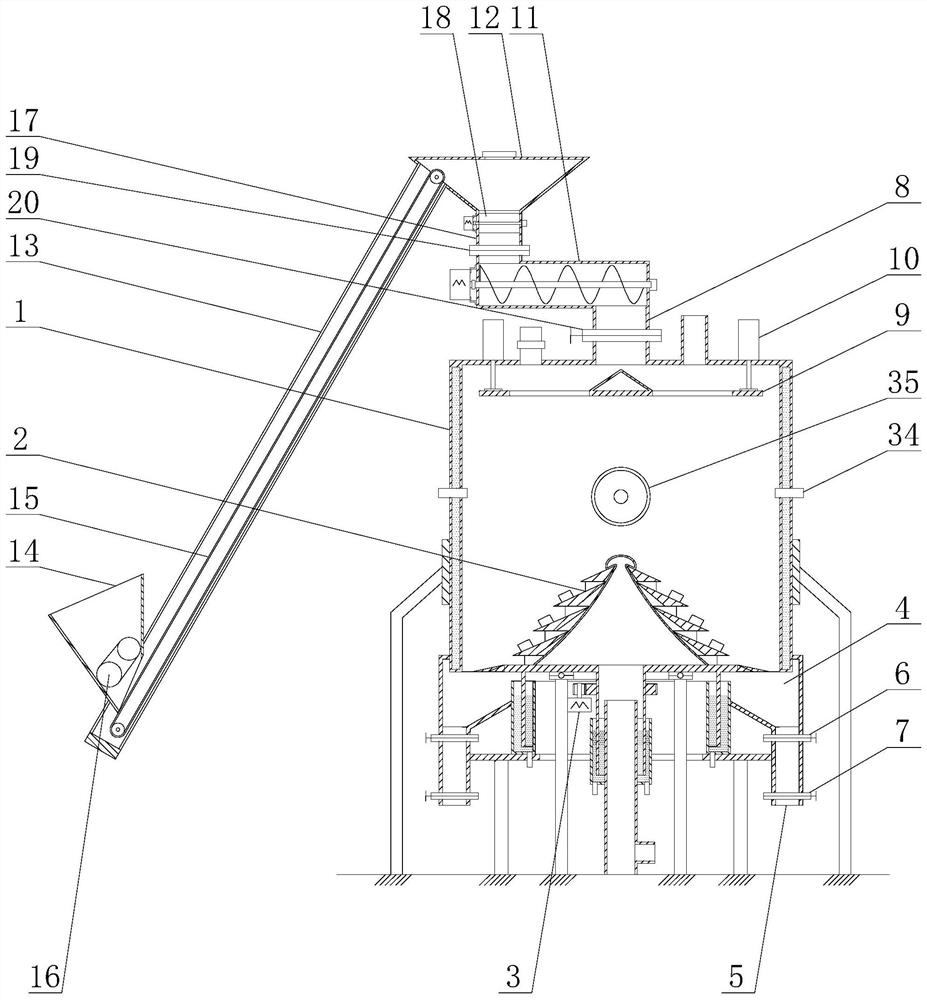

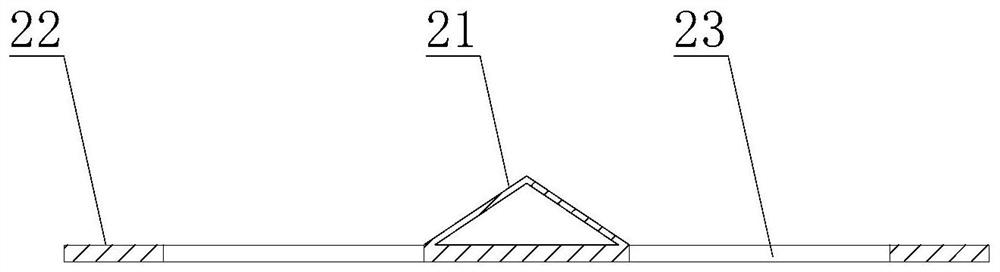

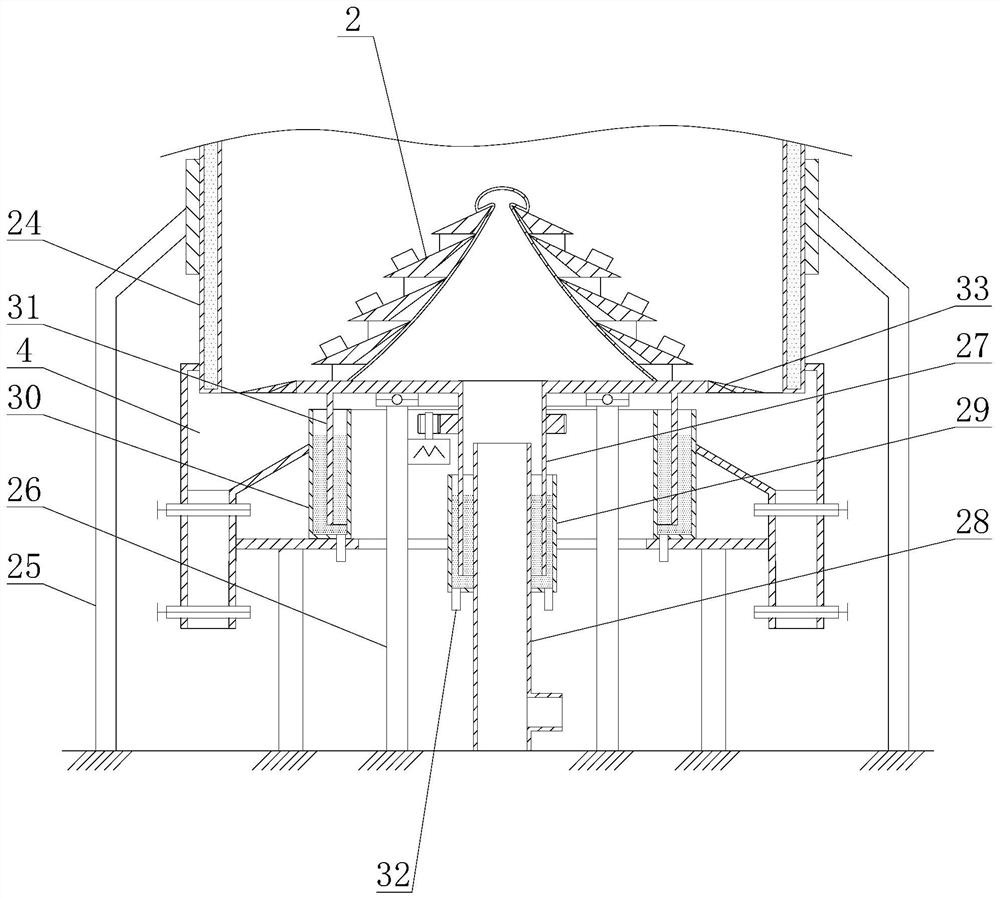

[0027] Example: as attached Figure 1-3As shown, the present invention is a dry slagging continuous feed biomass gasifier, including a furnace body 1, which can be designed as a water jacket, and the furnace body 1 is provided with a wind distribution plate 2 1. The wind disk driving device 3 that drives the wind distribution disk 2 to rotate, the outside of the bottom of the air distribution disk 2 is provided with a slag storage chamber 4, the slag storage chamber 4 is an annular chamber with an opening at the top, and the slag storage chamber 4 It is fixedly connected with the furnace body 1. Preferably, the furnace body 1 includes a cylinder body 24, a cylinder body bracket 25 fixed on the bottom of the cylinder body 24, an air pan bracket 26 providing support for the air distribution pan 2, and the air distribution pan 2 Horizontally placed on the top of the fan tray bracket 26, a turntable bearing is installed between the fan tray 2 and the fan tray bracket 26, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com