Patents

Literature

46results about How to "Not easy to slagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing biomass lump coal

The invention discloses a method for preparing lump coal by adopting biomass as raw material and relates to the preparation method for the lump coal. The method comprises the following steps: (1) crushing straws into thick-filament straws, and crushing firewood and twigs into sawdust; (2) mixing the thick-filament straws and the sawdust, then, soaking the mixture with an aqueous alkaline solution, then, fermenting the mixture, and then, continuing to ferment under the condition of high-speed stirring; (3) crushing cattle manure and combustible refuse in municipal domestic waste, then, adding the crushed material into a fermentation softening solution, soaking the crushed material, and then, fermenting for 6 to 10 hours; (4) standing the fermented solution, and filtering out moisture, thereby obtaining viscous biomass slurry; (5) crushing barks, then, adding water to the crushed barks, heating, and then adding starch; and (6) uniformly mixing coal slurry, a binder and the biomass slurry which are in the mass ratio of 1 to (2 to 3) to (40 to 45), and then, carrying out compacting molding at molding pressure, thereby obtaining the finished product. The method disclosed by the invention has the advantages that the method is low in cost and easy to operate, and the product is easy to mold, high in mechanical strength, difficult in slag-bonding and little in smoke dust.

Owner:SHANXI TIANRUNFENG AGRI TECH DEV CO LTD

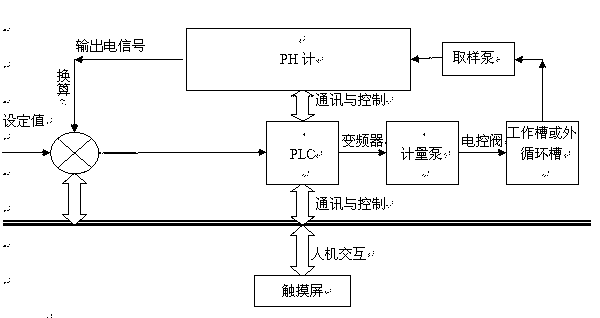

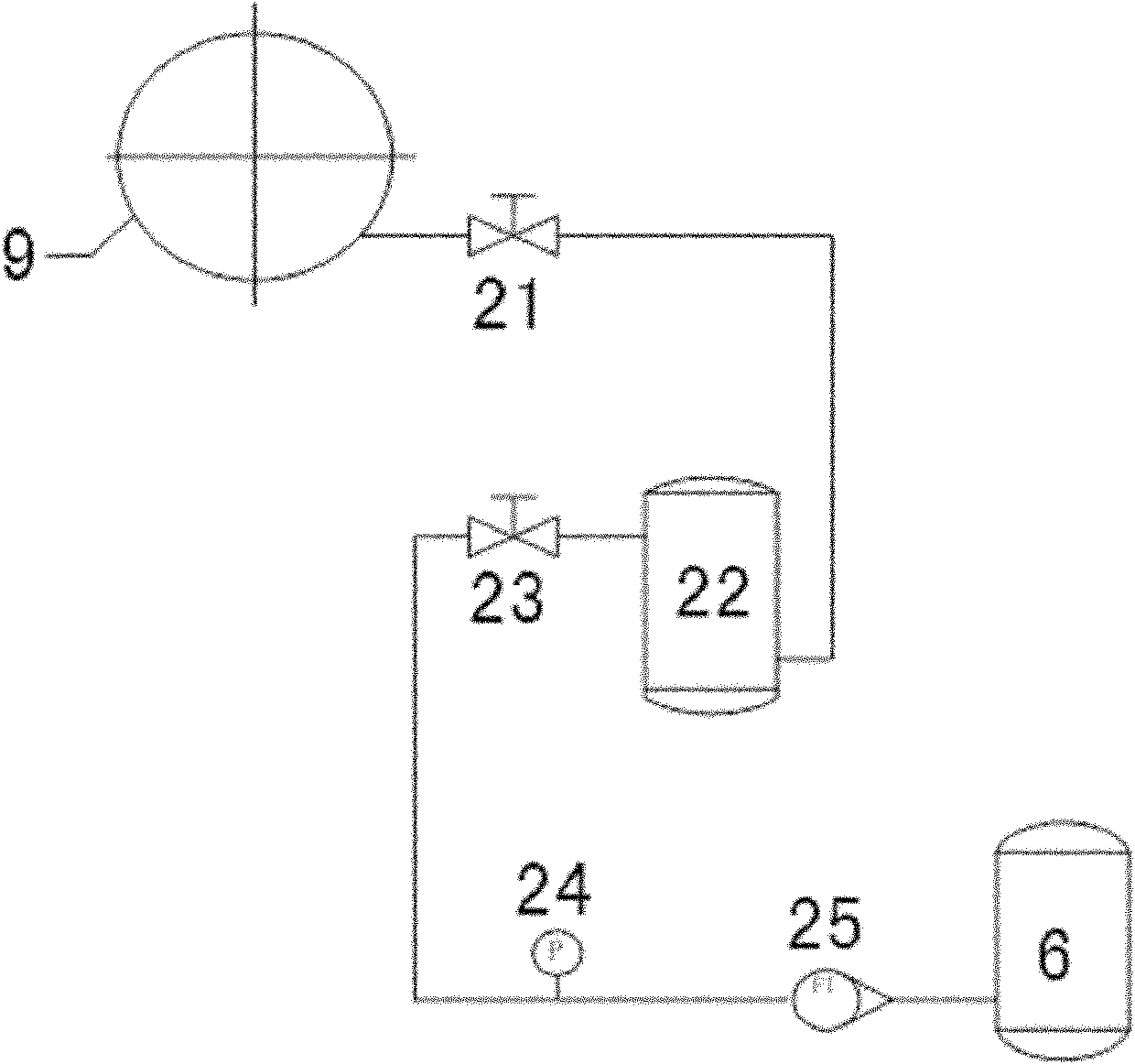

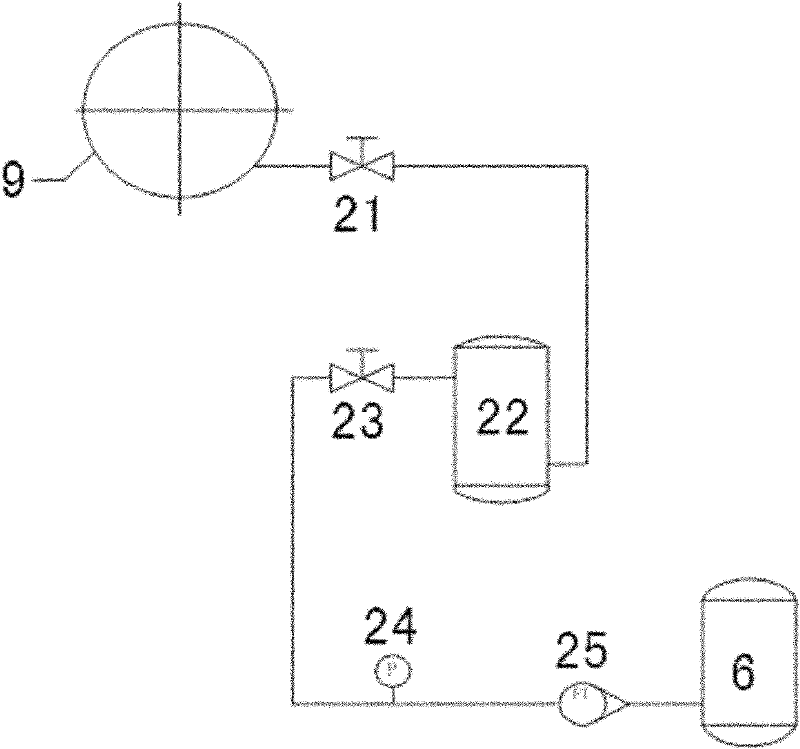

Phosphating solution online-monitoring and automatic-supplementing apparatus

InactiveCN103266316AImplement auto-replenishmentNot easy to slaggingCellsPhosphatisationEngineeringPh probe

The invention provides a phosphating solution online-monitoring and automatic-supplementing apparatus. The apparatus comprises a work tank or a circulation tank, a measuring pool, a concentrate pool and pipelines, and the work tank or the circulation tank is connected with a metering pump to the concentrate pool through a pipeline; the work tank or the circulation tank is connected to the measuring pool through a pipeline; the work tank or the circulation tank is connected with a condenser through a pipeline, the condenser is connected with a sampling pump, and the sampling pump is connected to the measuring pool through a float flow meter; and a temperature sensor and a pH probe are arranged in the measuring pool, and the measuring pool is connected to a control portion through a pH meter and a communication line. The online monitoring and automatic supplementing of a phosphating solution are realized through adopting a real-time control technology. The apparatus which allows the fluctuation of technological indexes of the phosphating work tank solution to be controlled in a small range guarantees the product quality stability, increases the labor efficiency and improves the labor environment of workers.

Owner:DONGFENG MOTOR FASTENER CO LTD

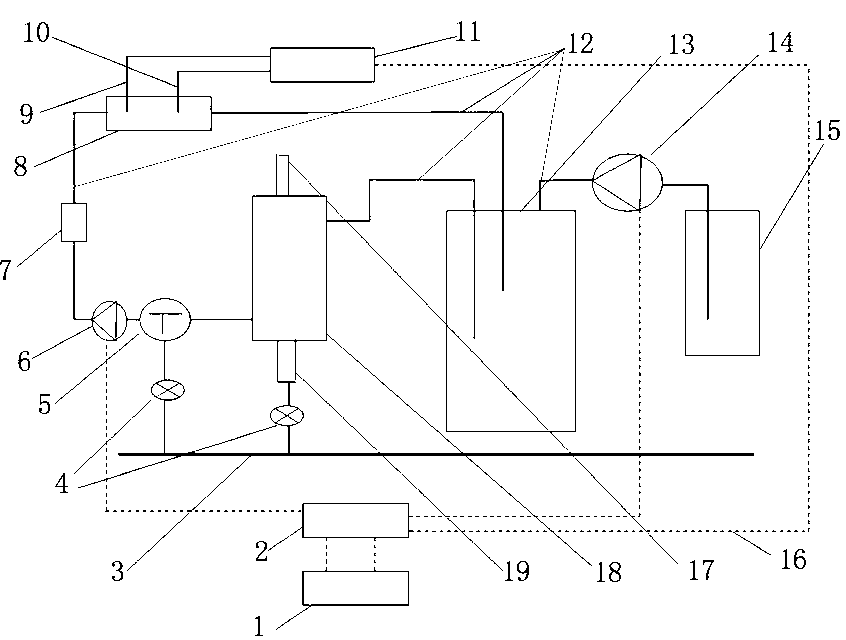

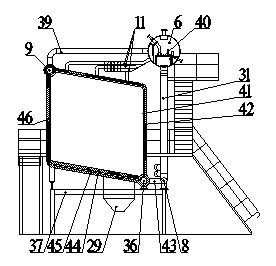

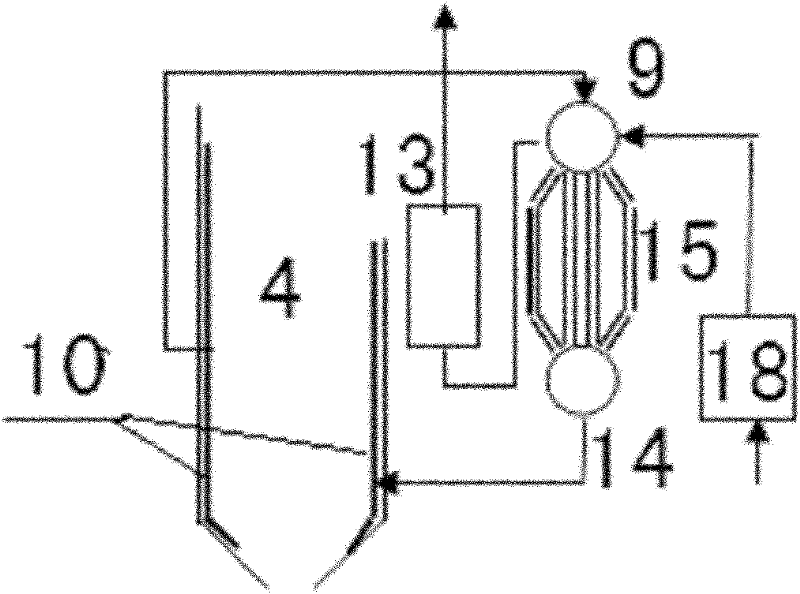

Circulating fluid bed waste incineration boiler with open-type furnace chamber

InactiveCN102305406AEasy to wrapLong continuous running timeIncinerator apparatusCooling chamberSuperheater

The invention relates to a circulating fluid bed waste incineration boiler with an open-type furnace chamber. The circulating fluid bed waste incineration boiler comprises the open-type furnace chamber, a cyclone separator, a cooling chamber and a tail convection flue which are connected with one another in turn, wherein the lower end of the cyclone separator is connected with an external heat exchanger, and the other end of the external heat exchanger is connected with the open-type furnace chamber; a high-temperature over-heater is arranged in the external heat exchanger; a plurality of air distribution tubes are arranged on the same horizontal plane equidistantly to form an open-type air distribution plate which is arranged at the bottom of the open-type furnace chamber; an ash hopper is connected below the open-type air distribution plate; a fuel ash valve is arranged below the ash hopper; the open-type air distribution plate separates the upper part of the open-type furnace chamber and the ash hopper; and the open-type air distribution plate consists of the plurality of air distribution tubes. The circulating fluid bed waste incineration boiler can successfully discharge materials which can be easily wound on an air cap, or large-particle or even blocky materials such as iron wires, iron nails and the like in wastes, can uniformly distribute air, is difficult to coke and clinker, and fulfills the aims of prolonging the continuous operation time of the waste incineration boiler and saving energy resources.

Owner:WUXI TAIHU BOILER

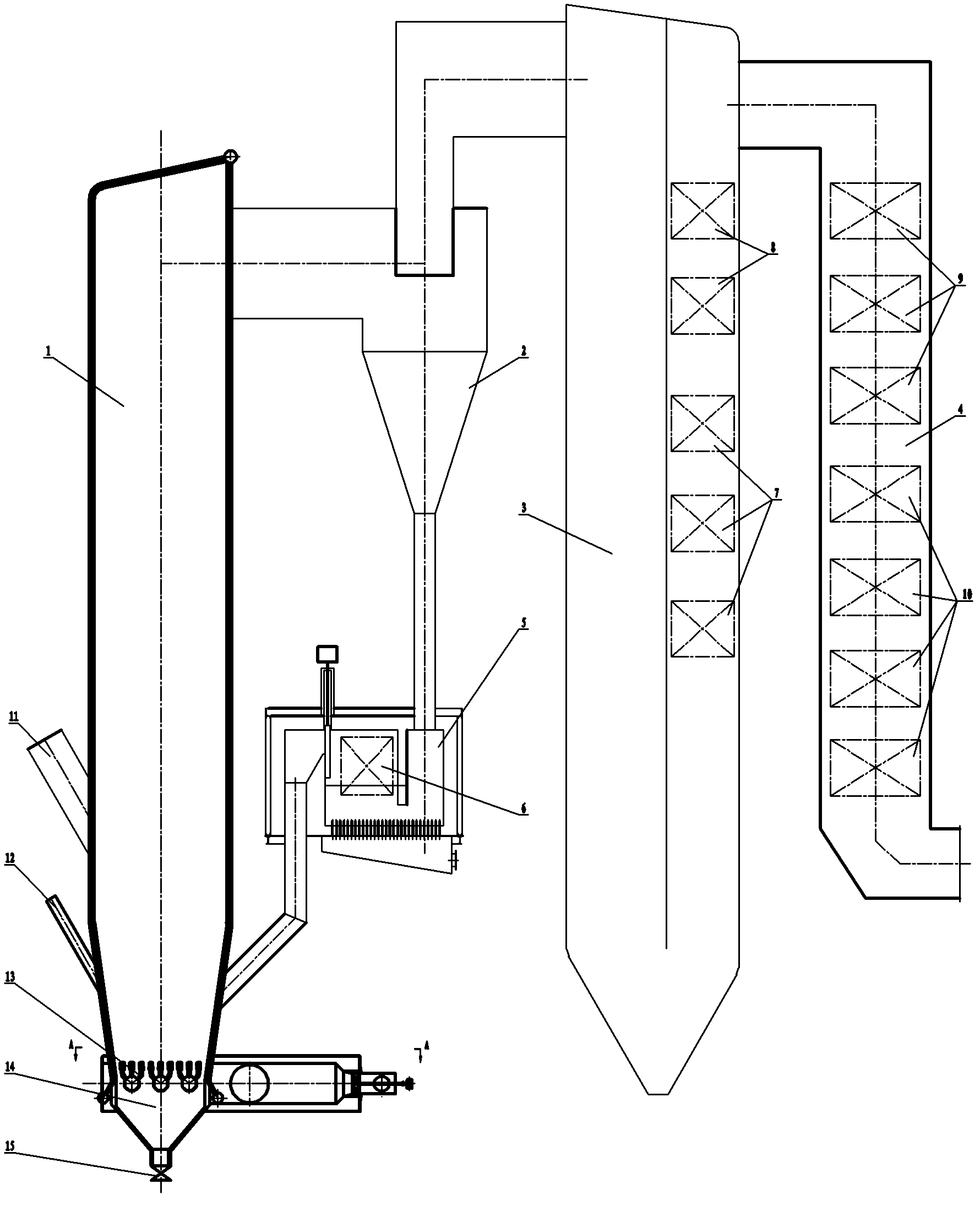

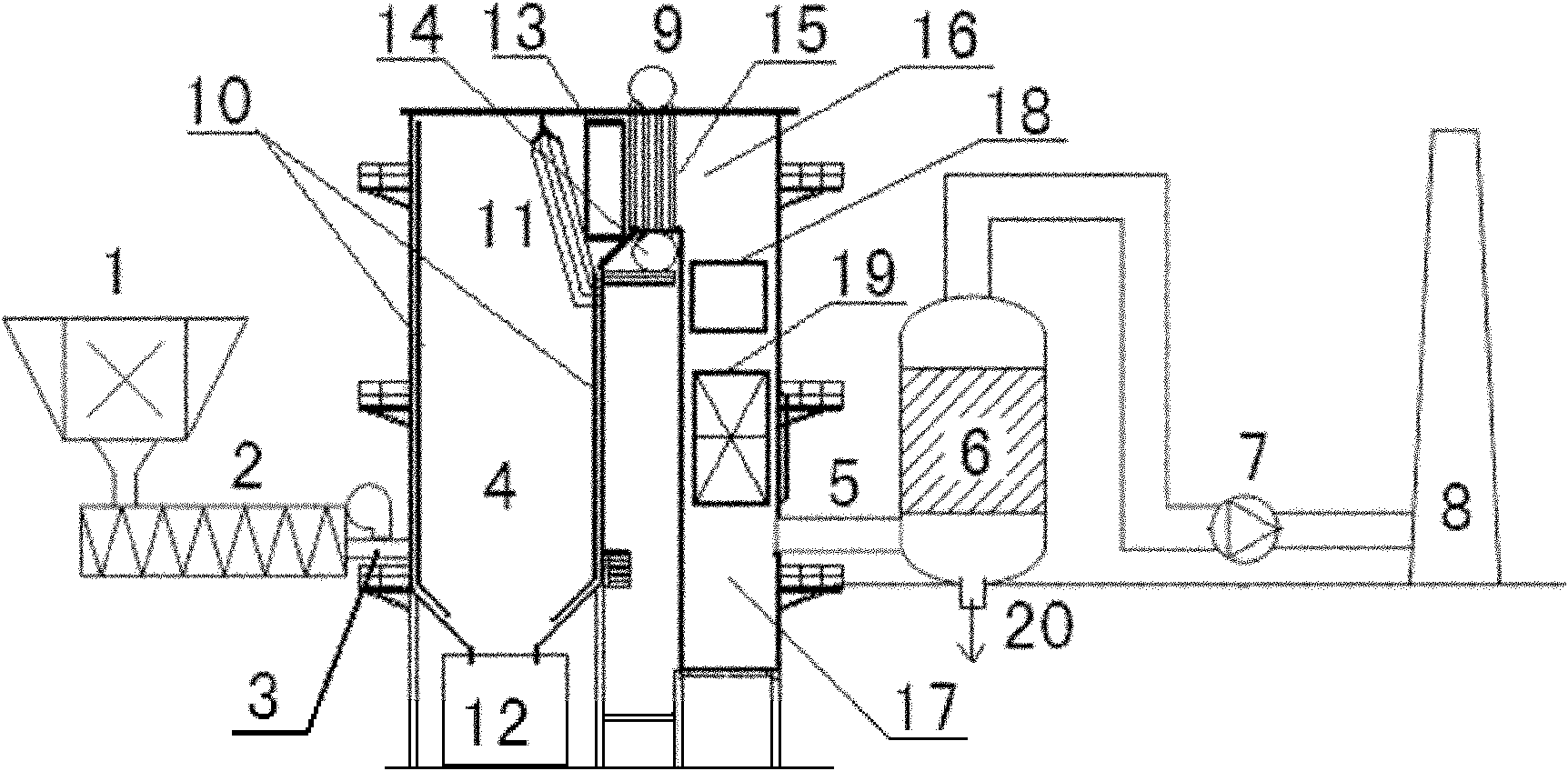

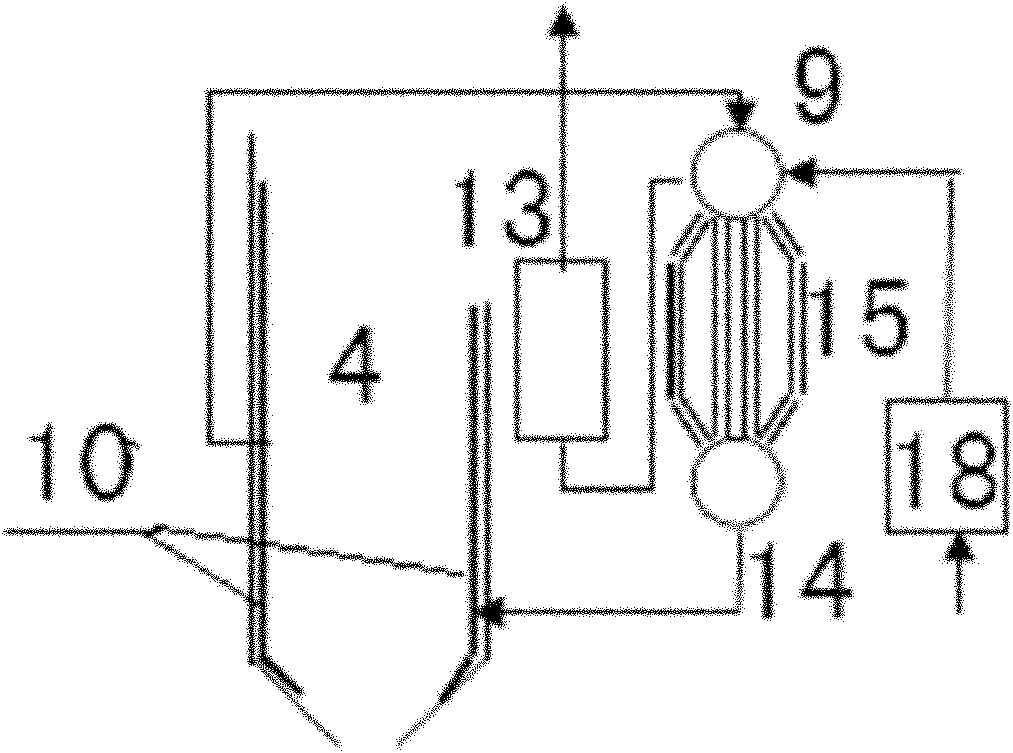

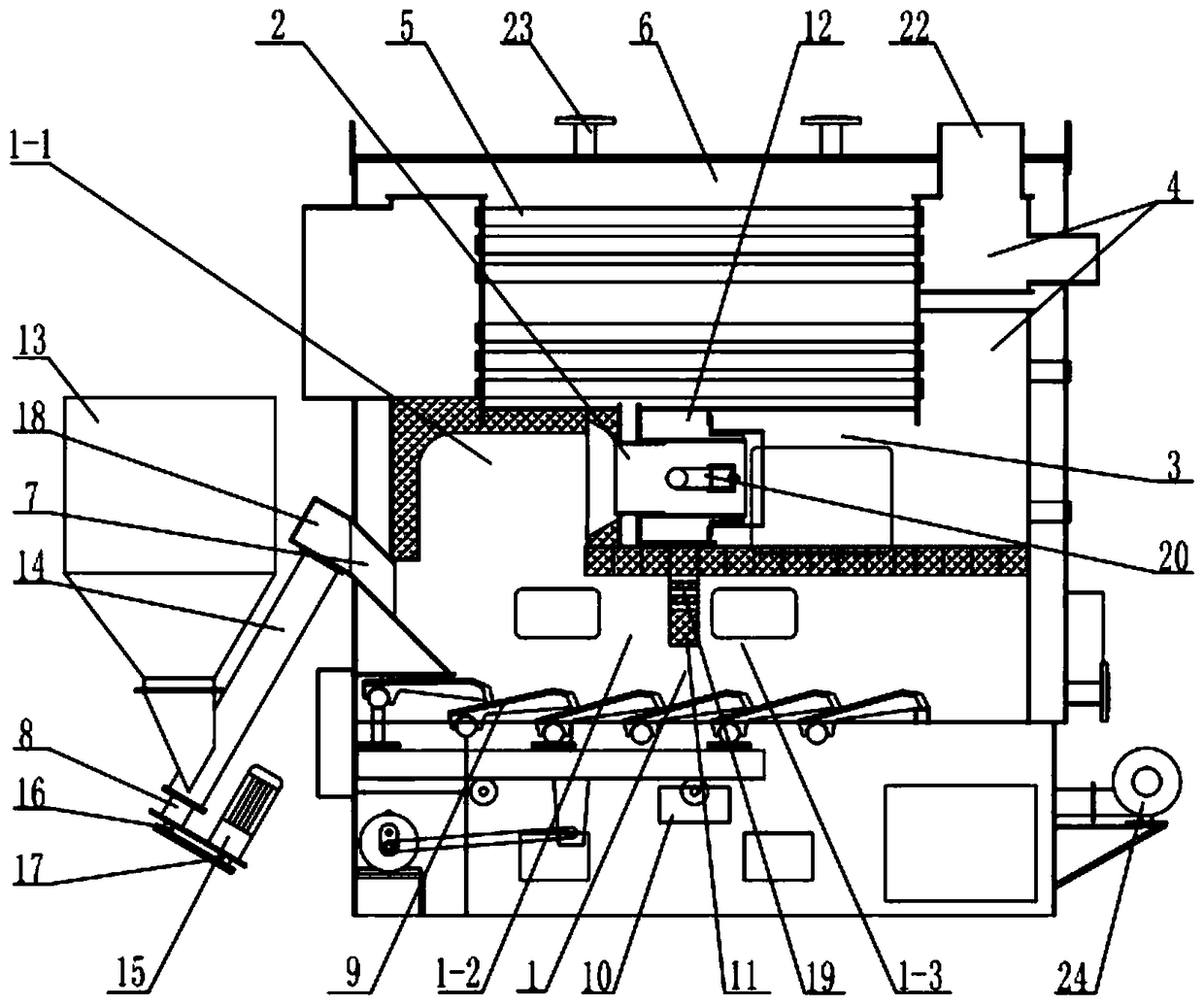

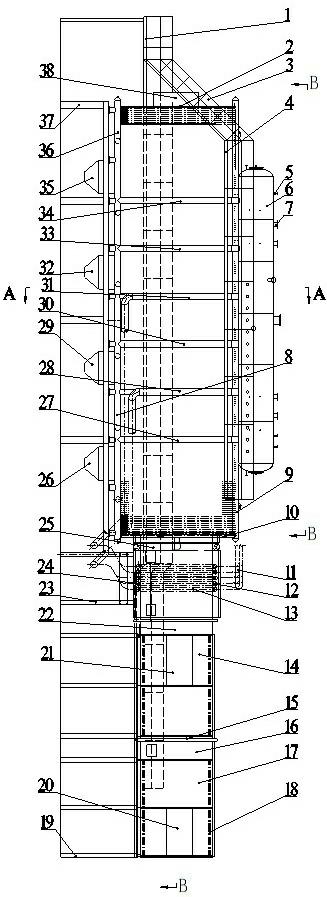

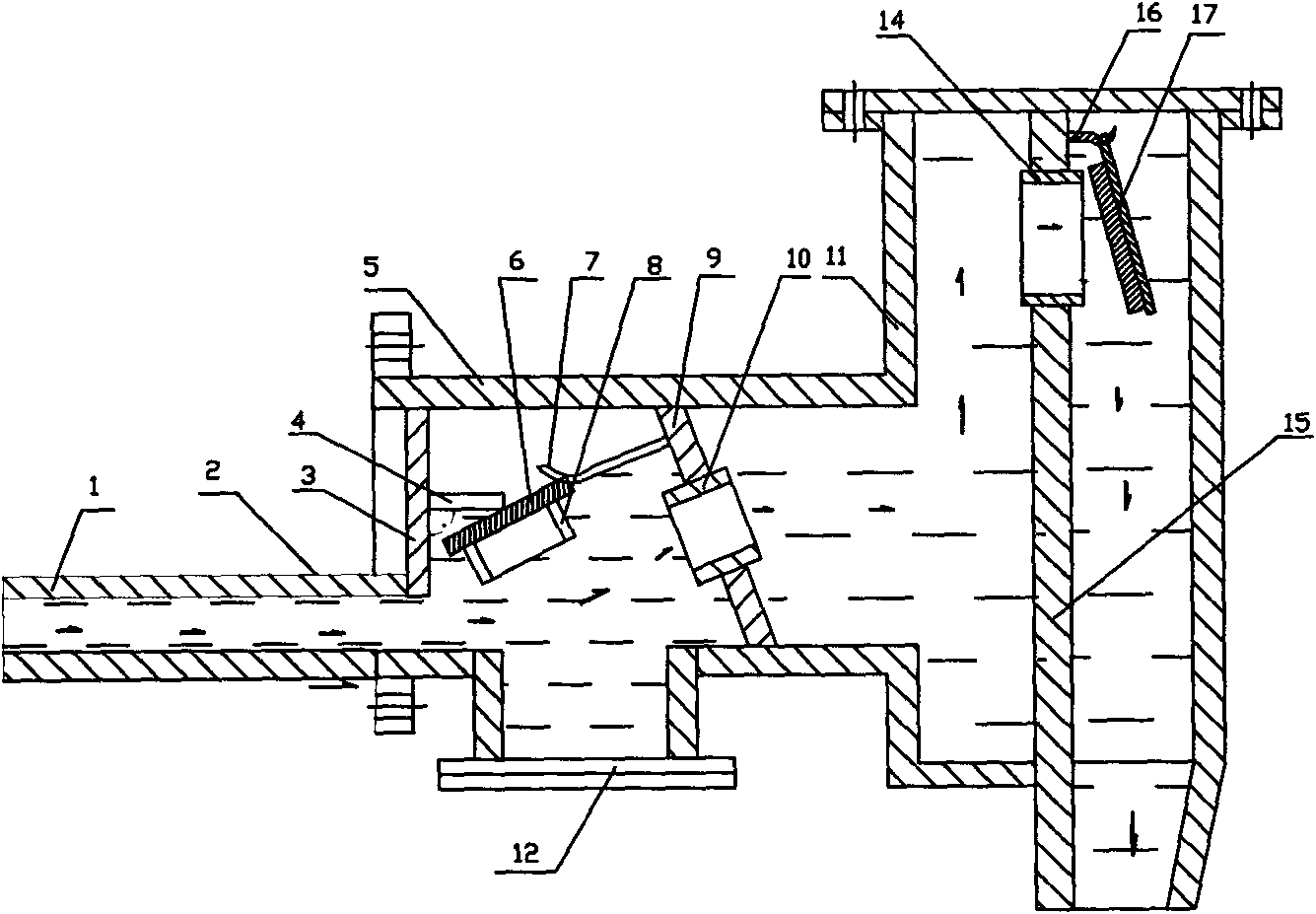

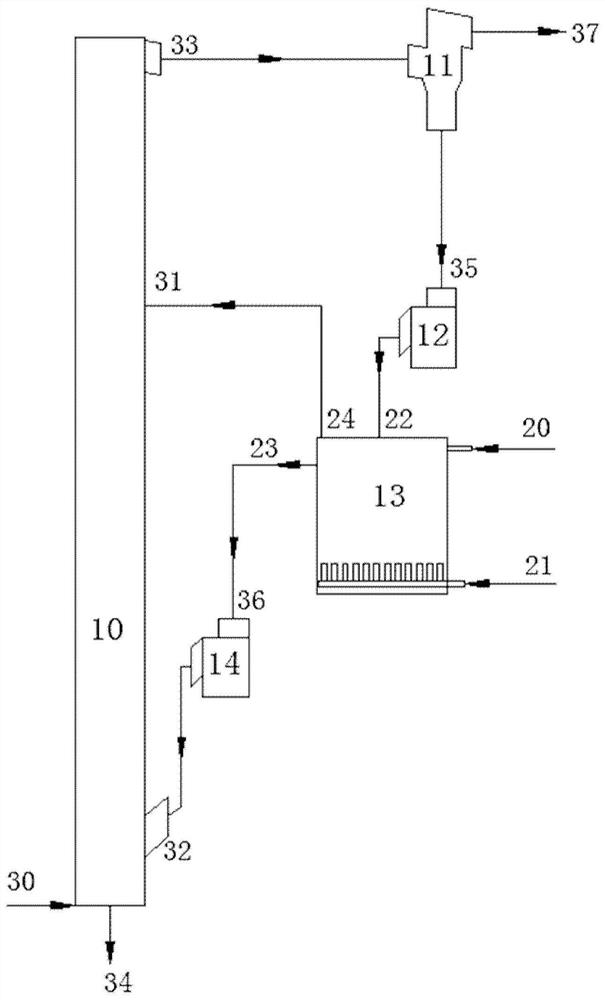

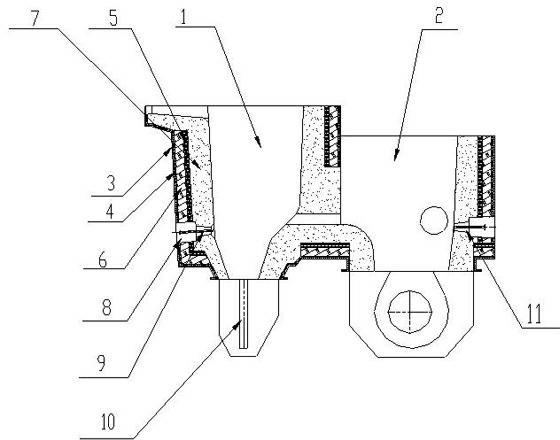

Vertical industrial pulverized coal boiler system

InactiveCN101929669AImprove air tightnessReduce air leakageCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterSlag

The invention discloses a vertical industrial pulverized coal boiler system, which comprises a stokehole pulverization device connected with a pulverized coal boiler body through a combustor, and the pulverized coal boiler body is connected with a chimney through a flue gas processing device. The vertical industrial pulverized coal boiler system is characterized in that: the pulverized coal boiler body comprises a horizontal flue, a hearth respectively communicated with two ends of the horizontal flue, and a vertical smoke well which are arranged in a vertical inverted U shape; the hearth consists of membrane water walls; a position of the hearth communicated with the outlet of the horizontal flue is provided with a slag condensing bank used for preventing high temperature flue gas from slagging; the horizontal flue behind the slag condensing pipe bundle is provided with a superheater and an convection bank inside in turn; the convection bank is connected to upper and lower boiler barrels positioned on upper and lower sides of the horizontal flue; the vertical smoke well is provided with an economizer and an air preheater inside from top to bottom; and the lower part of the vertical smoke well is connected with the flue gas processing device through a connecting flue. The vertical industrial pulverized coal boiler system has the advantages of high integration degree, small occupied area, high combustion efficiency, energy conservation, environmental protection, and wide market application prospect.

Owner:XI AN JIAOTONG UNIV

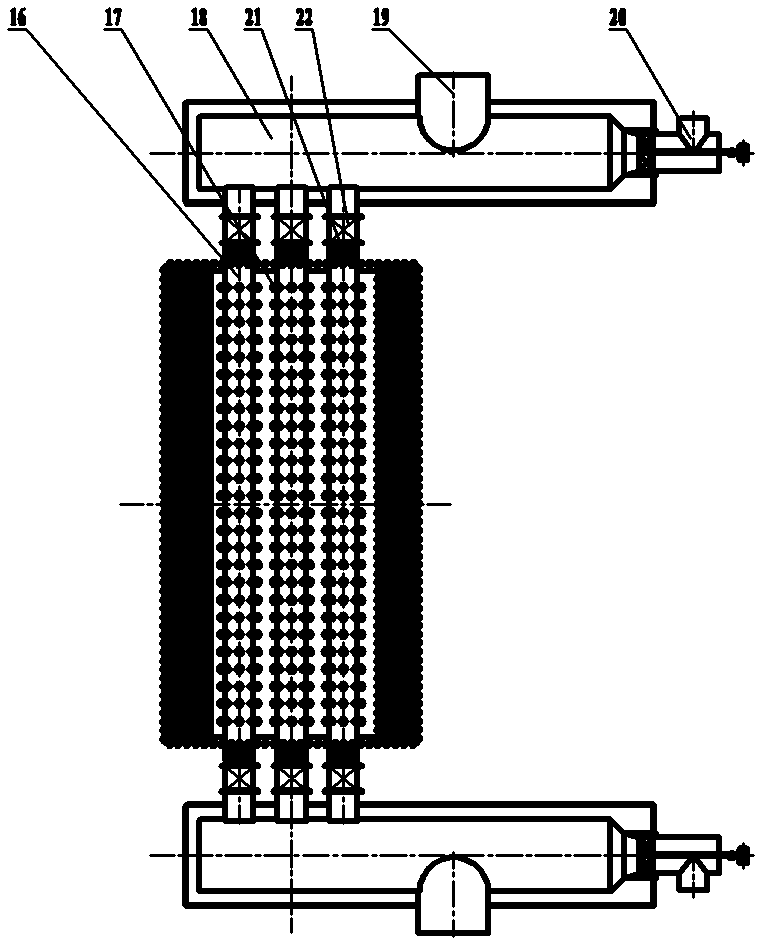

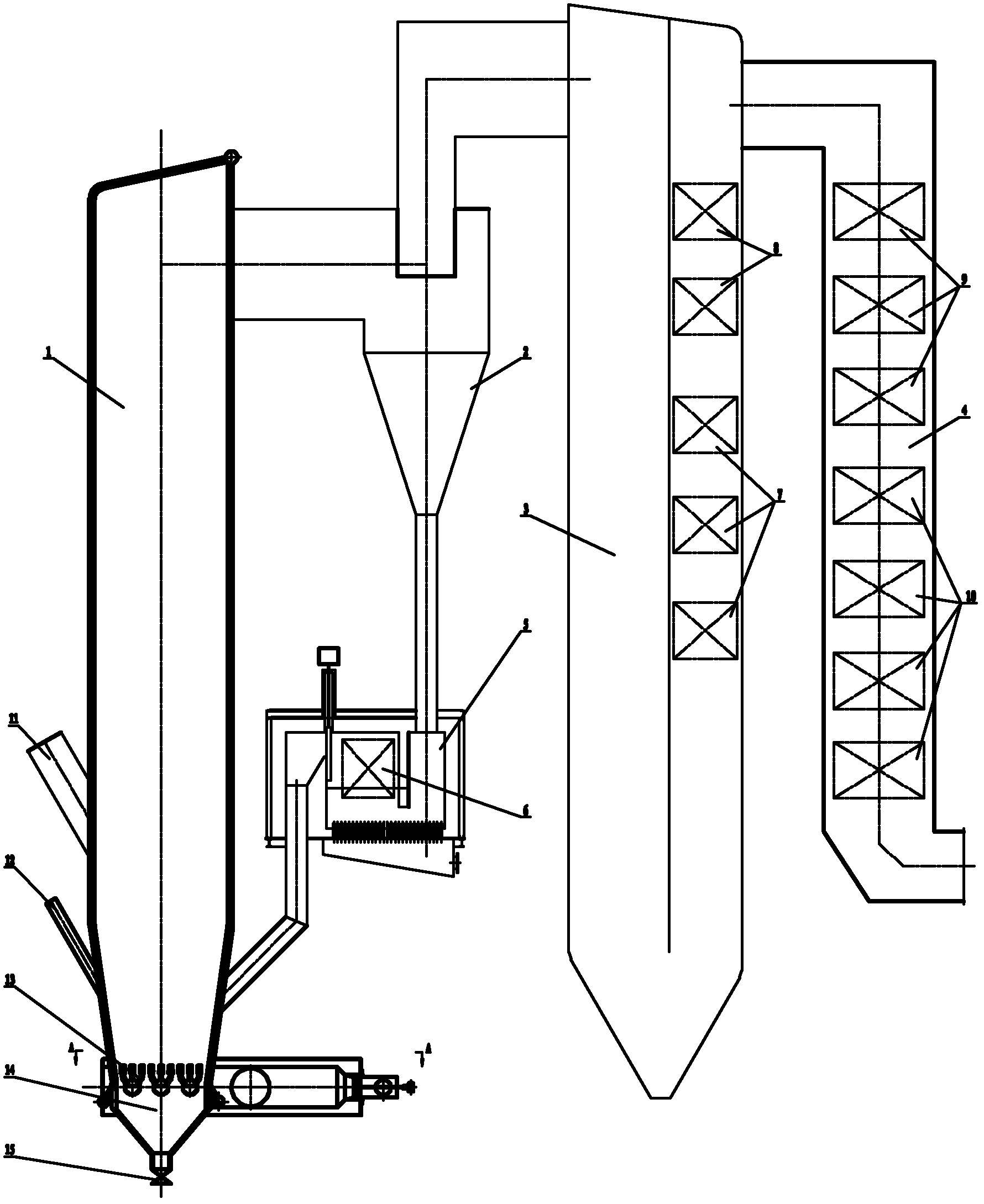

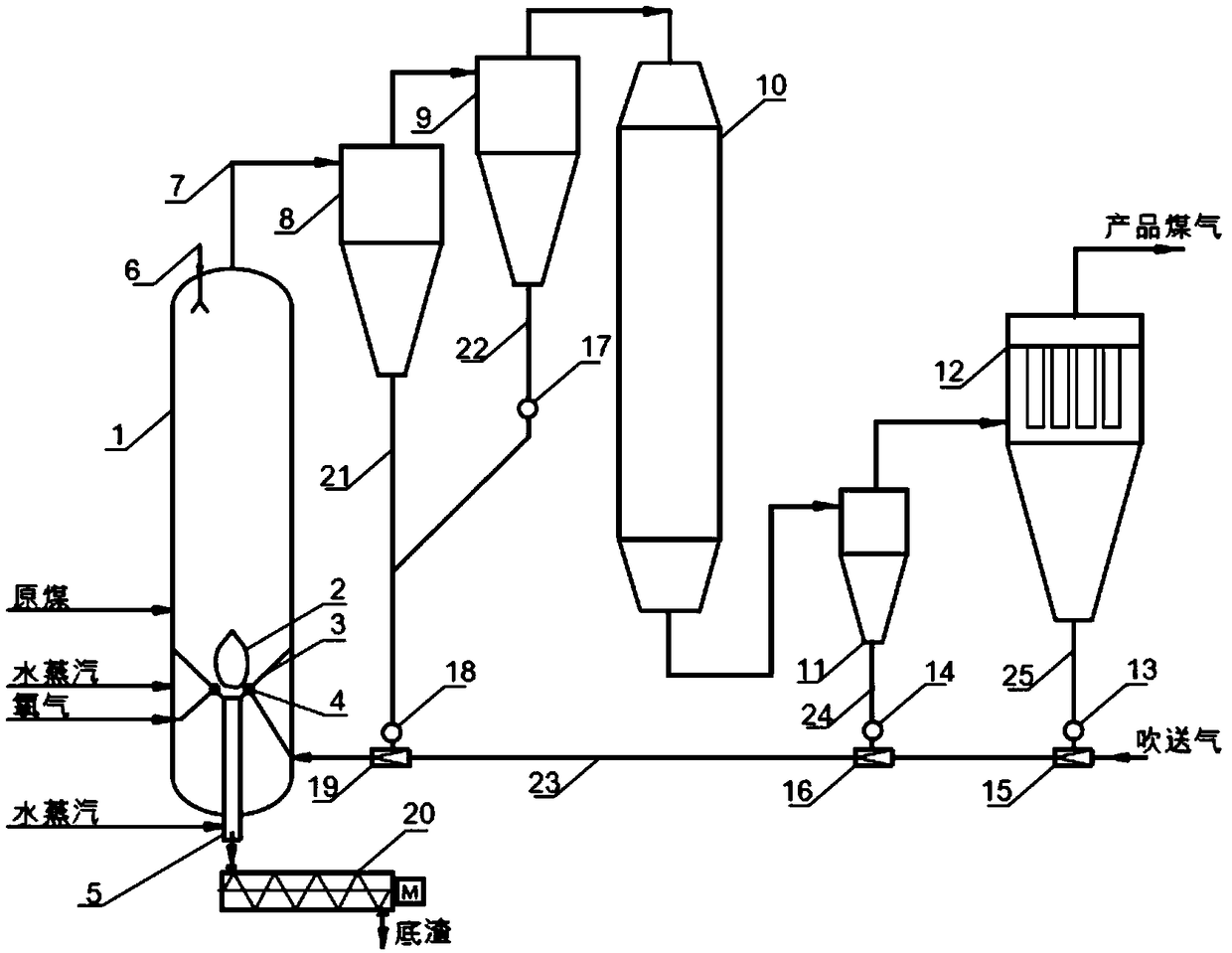

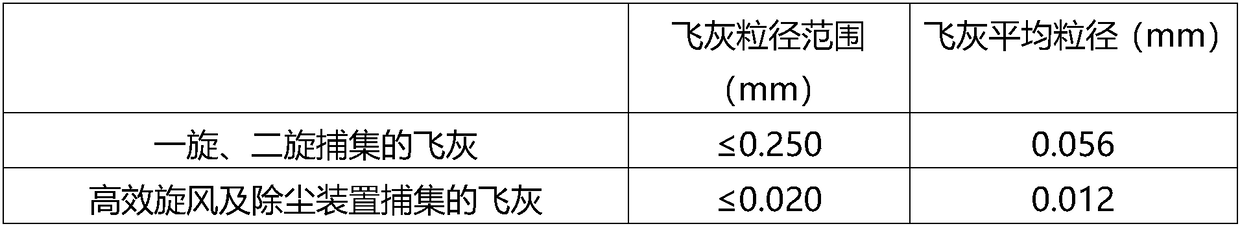

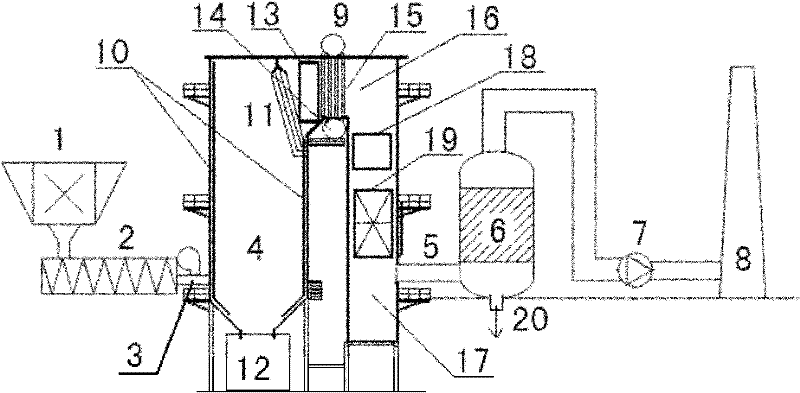

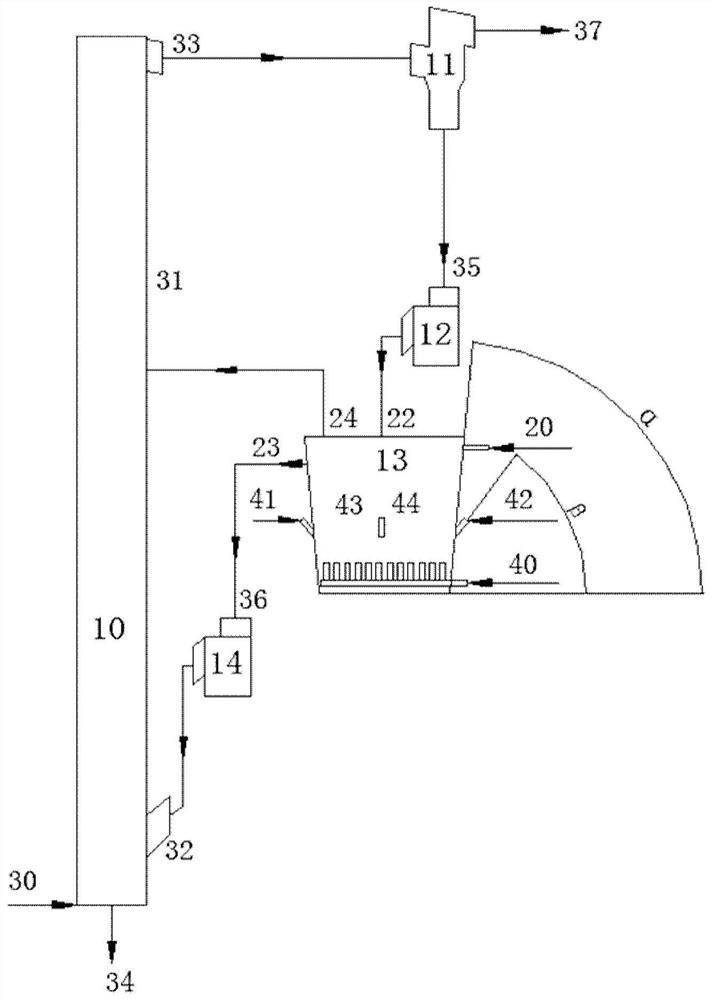

Fluidized bed pulverized coal gasification device and technology with zero emission of fly ash

PendingCN108753367AImprove the reunion effectGuaranteed long-term operationEnergy inputGasification processes detailsCycloneFluidized bed

The invention discloses a fluidized bed pulverized coal gasification device and technology with zero emission of fly ash. The fluidized bed pulverized coal gasification device includes a gasificationsystem consisting of a gasifier, a high temperature cyclone separator, a waste heat boiler, a high efficiency cyclone separator and a dust collector, and a material return system consisting of a one spin dipleg, a one spin loop seal, a two spin dipleg, a two spin loop seal, a high efficiency cyclone dipleg, a high efficiency cyclone loop seal, a dust collector dipleg and a dust collector loop seal, a primary ejector, a secondary ejector, a tertiary ejector and a material return pipe. The cooperative usage of the gasification system and the material return system of the fluidized bed pulverizedcoal gasification device can directly and completely return coarse fly ash and fine fly ash captured by a gas-solid separator under high pressure to a high temperature central jet zone of the gasifier and maintain temperature and pressure in the original gasifier unchanged, thereby achieving the zero emission of the fly ash and maximizing the effect of ash agglomeration in the gasifier. And meanwhile the fluidized bed pulverized coal gasification device and technology with the zero emission of the fly ash optimize the production environment and are a coal gasification technology with high gasification efficiency, long-term stable operation and environmental friendliness.

Owner:上海卓旋化工科技有限公司

Highly regenerative fireproof ball

The heat accumulating refractory ball consists of high-aluminum alumina as aggregate 58-62 wt%, refined bauxite as stuffing 29-31 wt%, high-grade white clay as high temperature adhesive 9-11 wt% and paper pulp as adhesive 3 wt%. The high-aluminum alumina contains Al2O3 not less than 70 % and has granular size of 2-4 mm, the refined bauxite contains Al2O3 not less than 85 % and has granular size of 300 mesh, and the while clay contains Al2O3 not less than 36 %. The refractory ball of the present invention has good heat accumulating performance, bulk density of 2.6 g / cu cm and strength of 25 KN each ball, has less scaling and breaking, no jamming of ventilation channel and high heat utilization rate.

Owner:郑州豫兴氮氧结合耐火材料有限公司

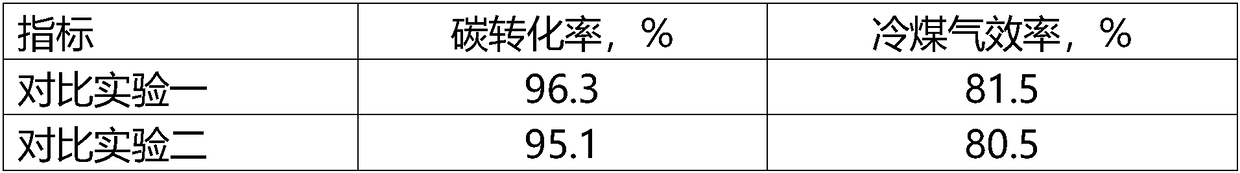

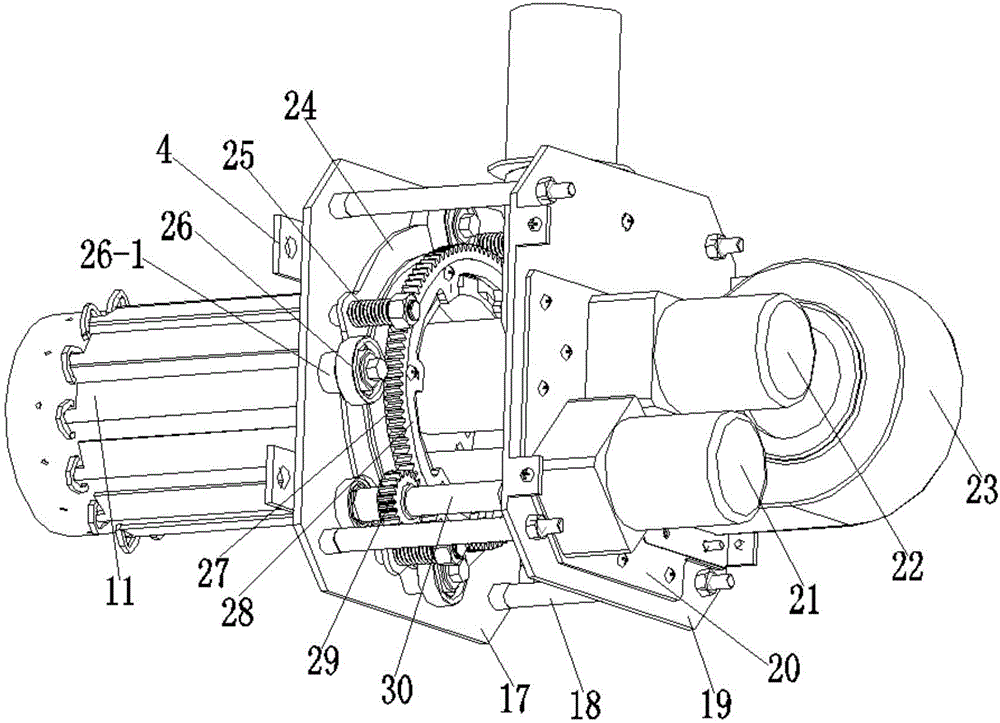

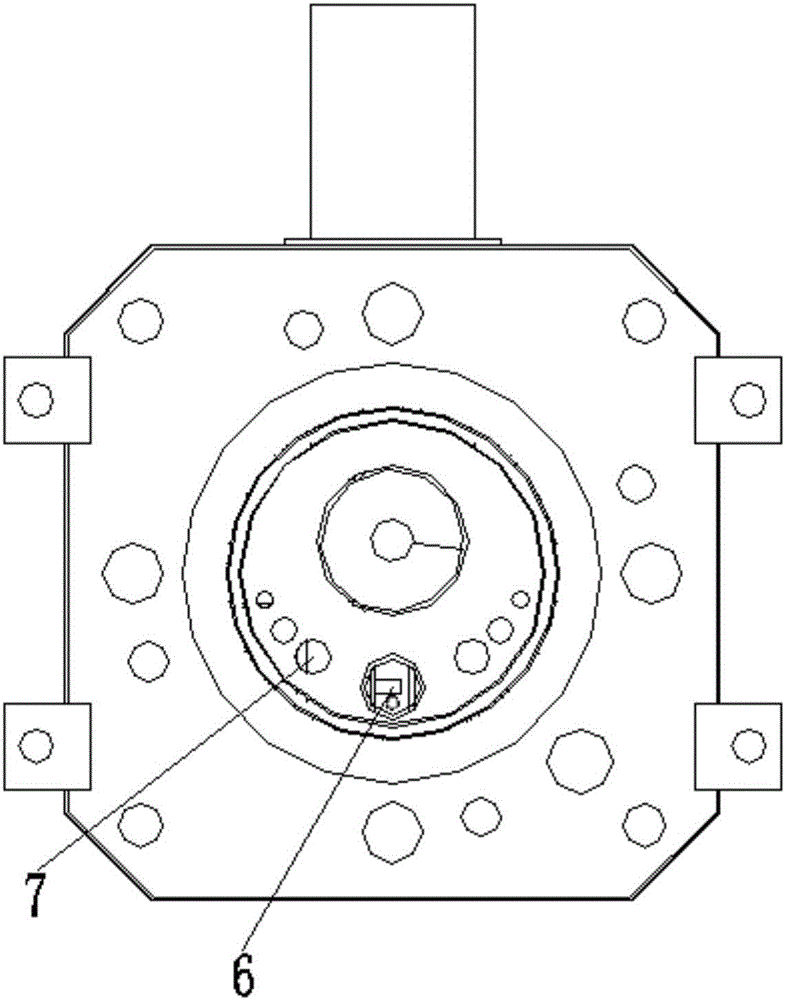

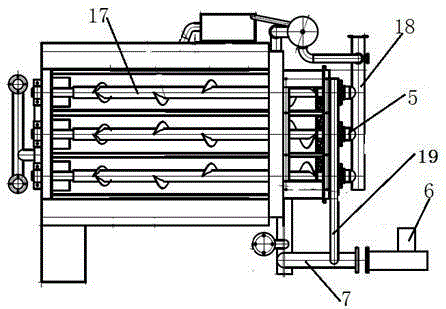

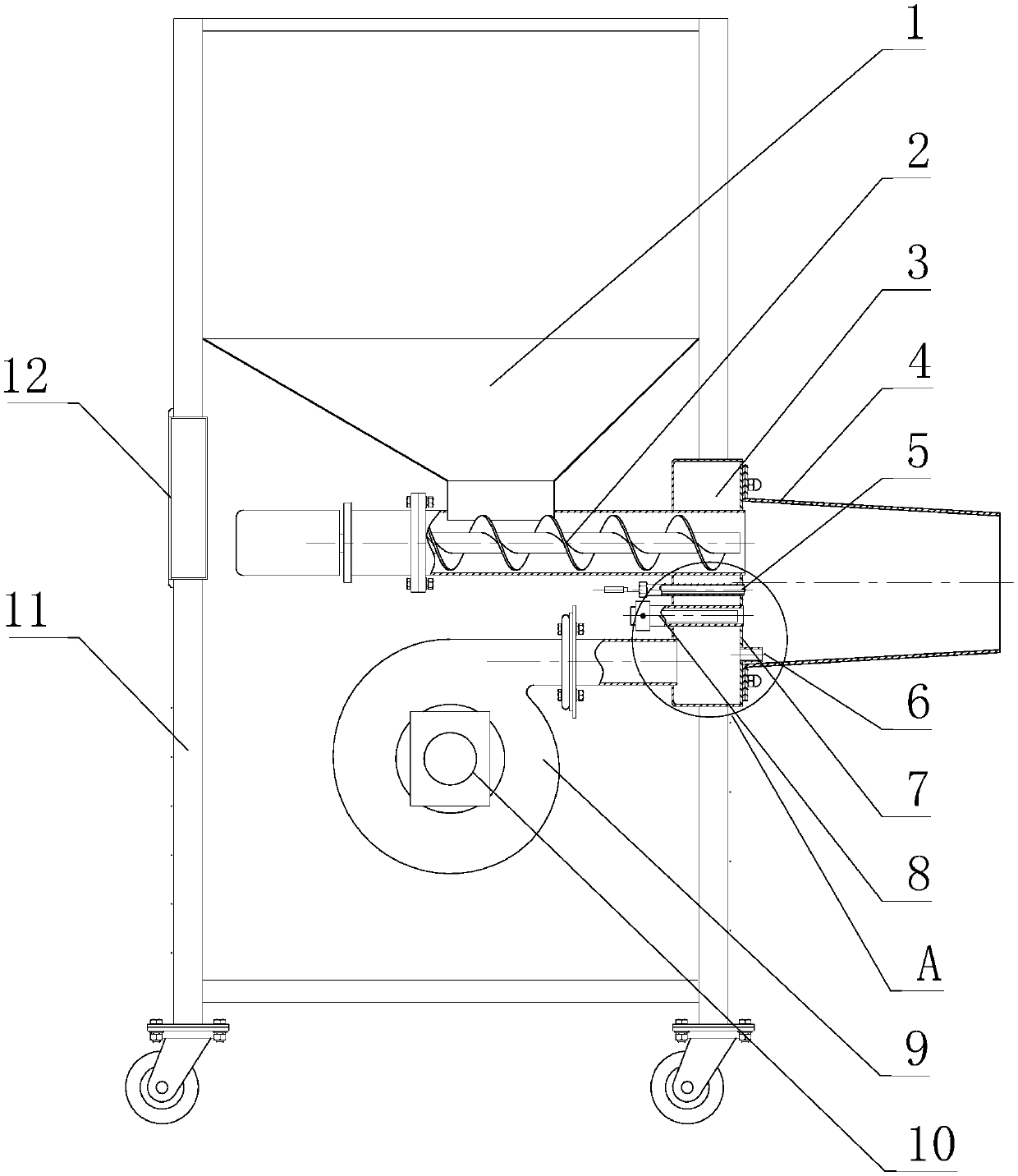

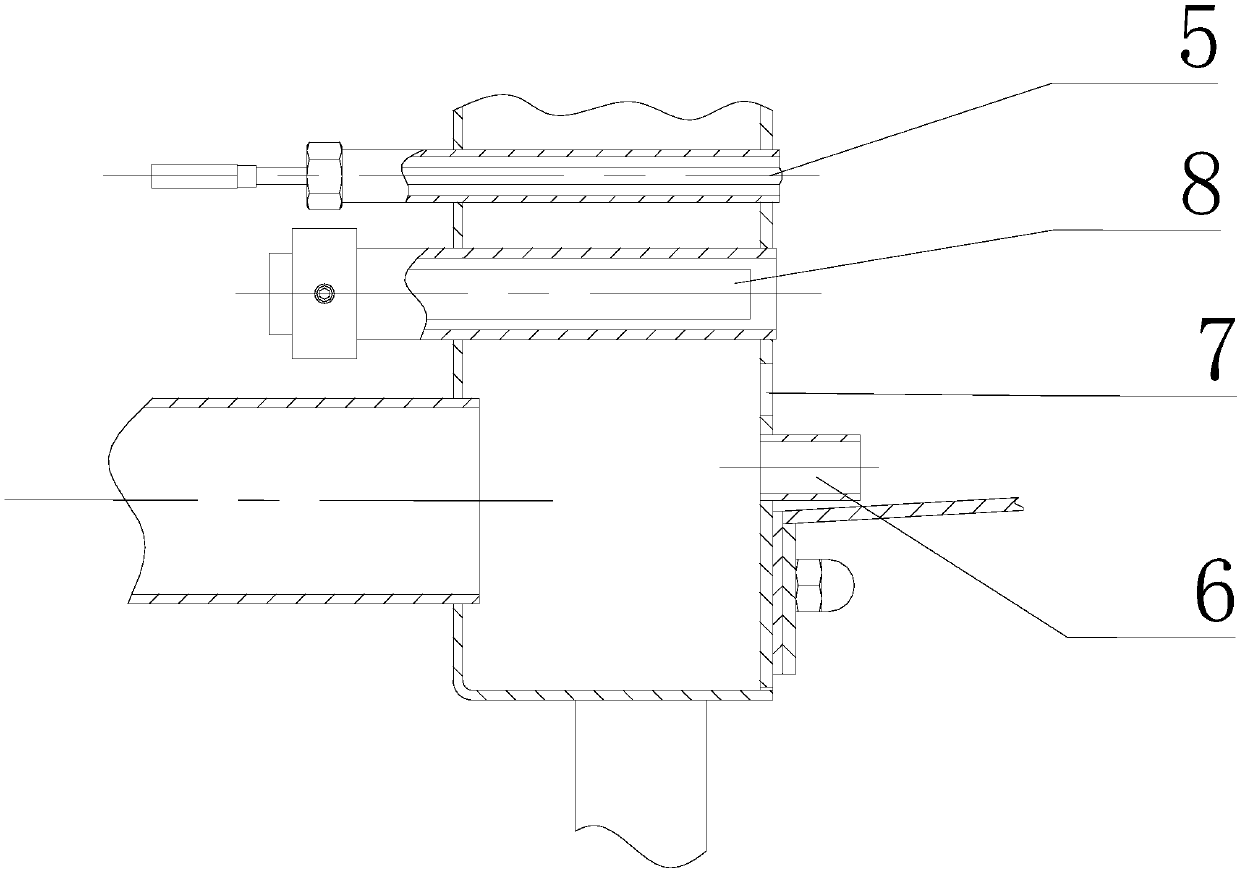

Inner cylinder rotating type biomass particle burner

ActiveCN106152168ACompact structureReduce volumeSolid fuel combustionAir/fuel supply for combustionGear driveSlag

The invention discloses an inner cylinder rotating type biomass particle burner. The burner comprises a front mounting plate and a back mounting plate which are arranged oppositely and are connected; an inner burning cylinder and an outer burning cylinder are mounted on one surface, far away from the back mounting plate, of the front mounting plate; the inner burning cylinder is coaxially sleeved with the outer burning cylinder; a gap is reserved between the inner burning cylinder and the outer burning cylinder; multiple rows of tangential secondary air holes are axially formed in the outer wall of the inner burning cylinder; each row of the tangential secondary air holes are formed circumferentially and are tangential with the same circle; a feeding device is arranged at the upper part between the front mounting plate and the back mounting plate; an ignition device is arranged below the feeding device; a gear driving motor, a feeding driving motor and a fan are mounted on one surface, far away from the front mounting plate, of the back mounting plate; and the fan and the feeding device communicate with the burning cylinders. With the burner, problems that biomass particles in biomass burning devices in the prior art cannot be burnt sufficiently and slag easily are solved.

Owner:XUCHANG TONGXING MODERN AGRI SCI & TECH

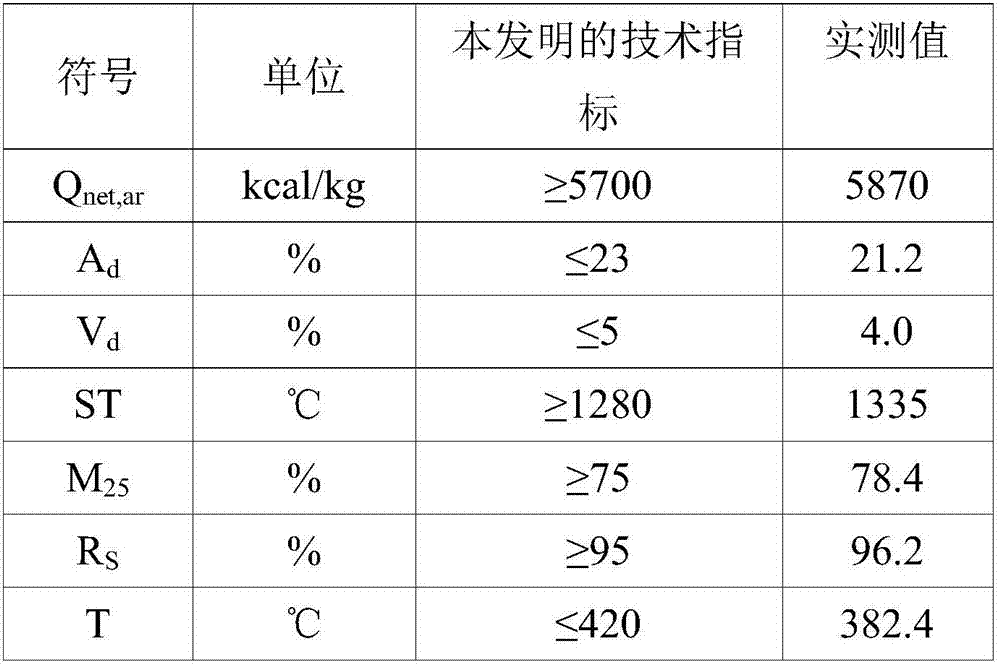

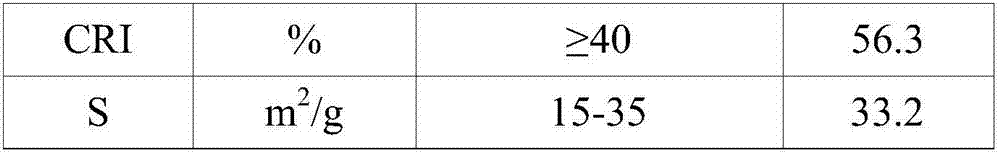

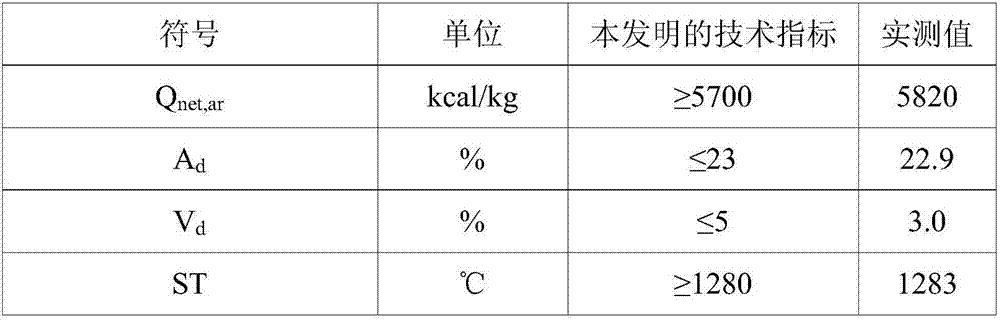

Civilian clean coke and production method thereof

The invention discloses civilian clean coke which comprises the following main quality indexes: the heating amount is more than or equal to 5,700 kcal / kg, the ash content is less than or equal to 23 percent, the content of volatile components is less than or equal to 5 percent, the ash fusion point is more than or equal to 1,280 DEG C, the crushing strength is more than or equal to 75 percent, the sulfur fixation rate is more than or equal to 95 percent, the ignition temperature is less than or equal to 420 DEG C, the reactivity is higher than or equal to 40 percent, and the specific surface is 15 to 35 m<2> / g. The civilian clean coke has the advantages of ignitability, long flame, high heating speed, long combustion duration and good desulfuration effect.

Owner:TAIYUAN UNIV OF TECH +1

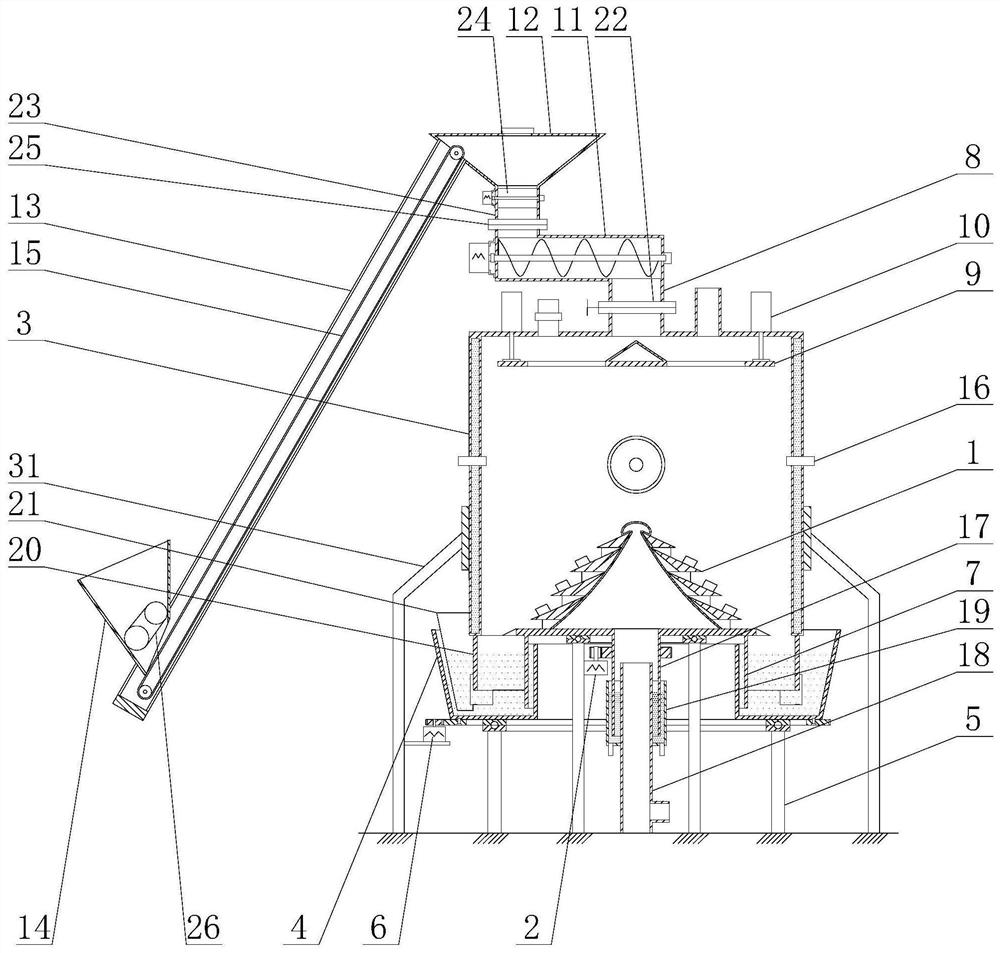

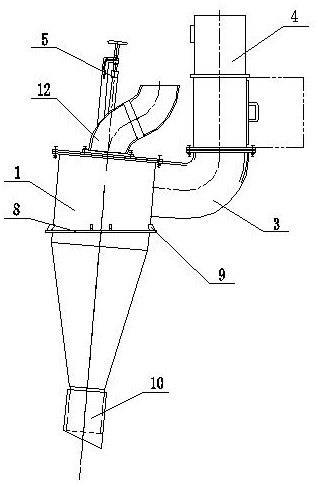

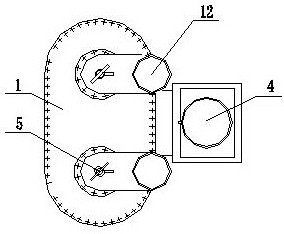

Differential rotating bed continuous feeding biomass gasification furnace

InactiveCN112126468AAdjustable speedNot easy to slaggingProductsGasifier feeding meansProcess engineeringBiomass gasifier

The invention discloses a differential rotating bed continuous feeding biomass gasification furnace, and mainly relates to the technical field of energy science. The furnace comprises a furnace body,an air distribution disc and an air disc driving device for driving the air distribution disc to rotate are arranged in the furnace body, the furnace body comprises a cylinder body and a cylinder bodysupport located on the outer side of the cylinder body and used for supporting the cylinder body, an ash bin is arranged on the lower side of the cylinder body, and an ash bin driving device for driving the ash bin to rotate is arranged on the cylinder body support. A blanking pipe is arranged at the top of the furnace body, a conical distributor is arranged on the lower side of the blanking pipe, a spiral sealing feeder is arranged at the top of the blanking pipe, a buffer bin is arranged at the top of the end, away from the blanking pipe, of the spiral sealing feeder, and a feeding barrel with the closed bottom end is obliquely arranged on one side of the buffer bin. The biomass gasification furnace can realize continuous sealed feeding in the gasification process, can effectively prevent partial burning deviation and burning through, is easy to control the thickness of an ash layer, can enhance the disturbance of biomass in the furnace, and improves the gasification strength.

Owner:山东信科环境科学研究院有限公司

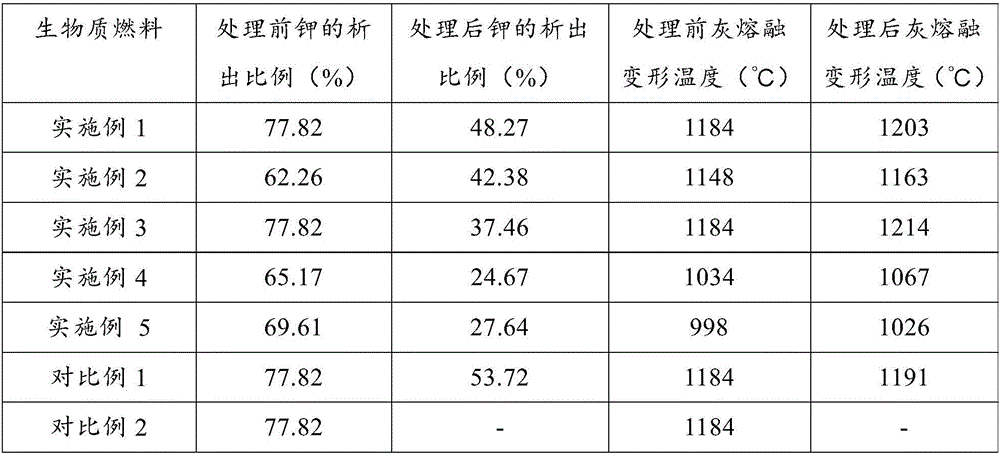

Potassium fixing method for biomass fuels

InactiveCN106433845ANot easy to slaggingReduce adverse effectsBiofuelsSolid fuelsChemistryAdverse effect

The invention relates to a potassium fixing method for biomass fuels. The potassium fixing method includes the steps of pretreatment, drying and high-temperature utilization, wherein during pretreatment, a silica sol solution is evenly sprayed on biomass fuel containing potassium elements or the biomass fuel is soaked into the silica sol solution. The potassium fixing method for the biomass fuels has the advantages of simplicity, low silica sol price, low cost and capabilities of effectively fixing potassium, benefiting improvement on reaction efficiency and weakening adverse effect of the potassium component in the biomass fuels on equipment such as a boiler during combustion.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR

Biomass particle fuel gasification combustion normal-pressure water boiler

PendingCN108692456ABurn fullySafe and reliableSolid fuel combustionWater heatersFuel gasificationProcess engineering

The invention discloses a biomass particle fuel gasification combustion normal-pressure water boiler. The biomass particle fuel gasification combustion normal-pressure water boiler comprises a boilerbody, a spiral feeding device, a fire grate and a flue. A feeding port of the boiler body is connected with a discharging port of the spiral feeding device. The fire grate is arranged at the bottom ofthe boiler body. The flue is arranged at the upper portion of the boiler body. The biomass particle fuel gasification combustion energy-saving and environment-friendly normal-pressure water boiler which adopts biomass particles as fuel, and is efficient, capable of saving energy, low in pollution, capable of achieving zero emission, safe and environment-friendly is disclosed and provided.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

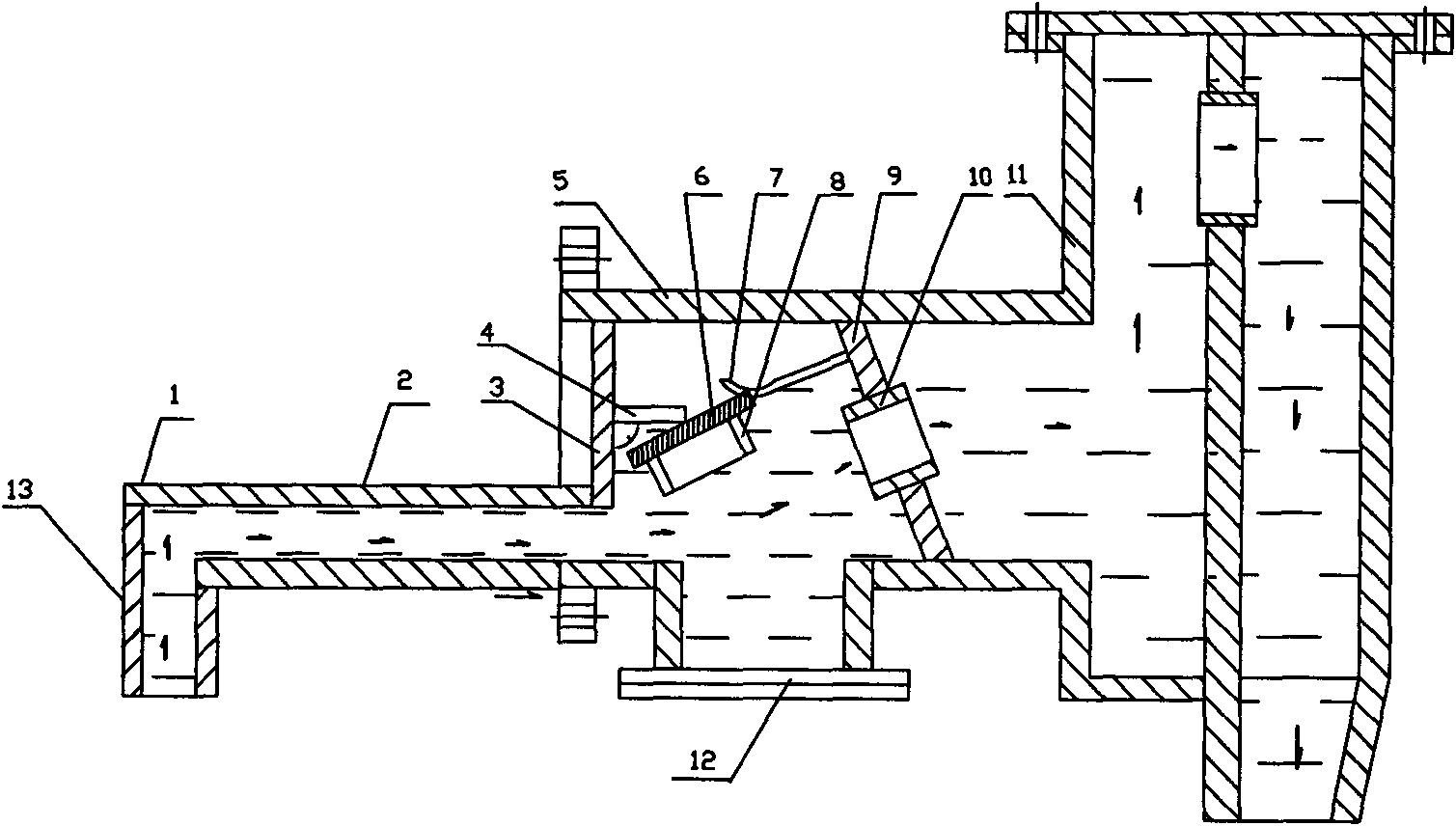

Biomass briquette gasified combustion normal pressure hot-water boiler

PendingCN107036283APrevent slaggingNot easy to slaggingSolid fuel combustionWater heatersWater pipeCombustion chamber

The invention discloses a biomass briquette gasified combustion normal pressure hot-water boiler, and belongs to the technical field of biomass briquette boilers. The problems existing in an existing biomass briquette boiler are solved. The biomass briquette gasified combustion normal pressure hot-water boiler comprises a burner, a gas combustion chamber and a flue. The burner comprises a gasification combustion chamber. The bottom of the gasification combustion chamber is provided with a fire grate and primary air openings. A gas nozzle is arranged at the side, far away from a feeding inlet, of a gas collecting area, and a secondary air opening is formed in the gas nozzle. The gas combustion chamber is arranged in front of the gas nozzle. A reciprocating grate is adopted in the fire grate. A separating wall perpendicular to the fire grate direction is arranged inside the gasification combustion chamber, and air holes are formed in the upper side of the separating wall. Rotational flow blades are arranged in the secondary air opening. Threaded smoke tubes are arranged inside the flue, and a normal pressure water tank is arranged outside the threaded smoke tubes. Heat exchange water pipes are arranged inside the normal pressure water tank and located above the threaded smoke tubes. The biomass briquette gasified combustion normal pressure hot-water boiler is used for biomass briquette gasified combustion heat supply.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

Online switching method aluminum-zinc-magnesium coated steel plate and preparation method thereof

ActiveCN111270183AGood surface qualityNot easy to slaggingHot-dipping/immersion processesSteel platesCorrosion resistant

The invention relates to the technical field of hot-dip coating, in particular to an online switching method aluminum-zinc-magnesium coated steel plate and a preparation method thereof. The online switching method aluminum-zinc-magnesium coated steel plate comprises a steel plate substrate and an aluminum-zinc-magnesium coating located on the surface of the steel plate substrate. The online switching method aluminum-zinc-magnesium coated steel plate is characterized in that the aluminum-zinc-magnesium coating comprises, by mass percent, 51-55% of Al, 1.0-1.2% of Mg, 0-0.2% of Si, 0.02-0.05% ofRe and the balance Zn and other inevitable impurities. The preparation method comprises the following steps that the zinc liquid component in a main pot is adjusted to obtain an aluminum-zinc-magnesium plating solution; and a strip steel substrate is put in the aluminum-zinc-magnesium plating solution in the main pot to be subjected to hot-dip coating, and the aluminum-zinc-magnesium coated steelplate is obtained. According to the online switching method aluminum-zinc-magnesium coated steel plate and the preparation method thereof, based on the aluminum-zinc-magnesium plating solution, the components of the plating solution in the main pot are subjected to online switching, related technological parameters are adjusted, the step for extracting zinc liquid from the main pot is omitted, and the obtained aluminum-zinc-magnesium coated steel plate is high in corrosion resistance; and the strength of bonding between the coating and the steel plate substrate is high, the coating is difficult to peel, and the aluminum-zinc-magnesium coated steel plate can adapt to poor working conditions.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

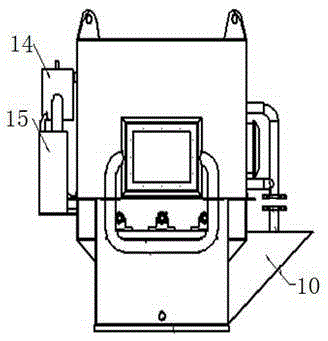

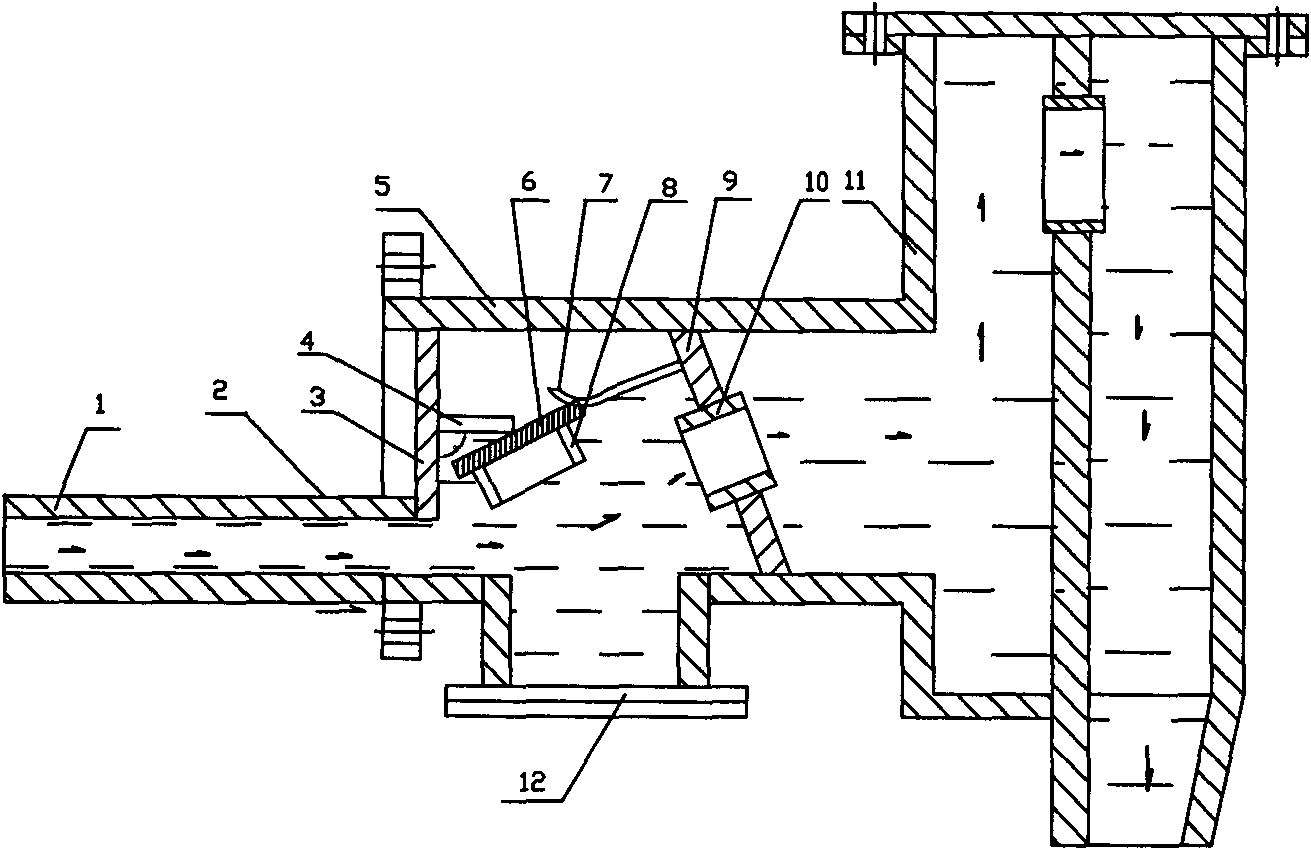

Continuously operated biomass forming fuel gasification combustor

PendingCN107036075APrevent slaggingNot easy to slaggingSolid fuel combustionNon-combustible gases/liquids supplyCombustion chamberEnvironmental geology

The invention discloses a continuously operated biomass forming fuel gasification combustor, belongs to the technical field of combustion of biomass forming fuels, and solves the problems in a traditional biomass forming fuel combustor. The continuously operated biomass forming fuel gasification combustor comprises a combustor body; the combustor body comprises a gasification combustion chamber; a feed port is formed in one side of the gasification combustion chamber; a fire grate and a primary wind port are arranged at the bottom of the gasification combustion chamber; a gas gathering area is arranged above the gasification combustion chamber; a gas nozzle is arranged on one side, farther from the feed port, of the gas gathering area; a secondary wind port is formed in the gas nozzle; the fire grate adopts a reciprocating fire grate; a tempering prevention wall is arranged in the upper side edge position of the feed port in the gasification combustion chamber; an isolation wall perpendicular to the fire grate is arranged in the gasification combustion chamber for dividing the gasification combustion chamber into two areas; an air hole is formed in the upper side of the isolation wall; and cyclone blades are arranged in the secondary wind port. The continuously operated biomass forming fuel gasification combustor is applied to gasification combustion of the biomass forming fuels.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

Large dynamic gasification combustion biomass burning machine

ActiveCN105371270AAvoid the risk of flashbackAvoid pollutionSolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberEngineering

The invention discloses a large dynamic gasification combustion biomass burning machine, and in particular, relates to the technical field of renewable energy. The large dynamic gasification combustion biomass burning machine comprises a horizontally arranged combustion chamber, a material transmission system and an air way system, wherein the material transmission system comprises a material box and at least one feed auger; a discharge port at the lower part of the material box is connected to the input end of the feed auger; the output end of the feed auger is connected with the combustion chamber; a water tank is arranged around the combustion chamber clinging to the outer wall, and is connected with a steam box; a rotating shaft at the output end of the feed auger extends and penetrates through the combustion chamber, and is fixed on a shell of the combustion chamber through a bearing base; the rotating shaft is a hollow shaft provided with a hole; one end of the hollow shaft is connected with a right air blowing pipe; the right air blowing pipe is provided with an air blowing port for blowing air into the hollow shaft; and the right air blowing pipe is communicated with the steam box through a steam pipe. The large dynamic gasification combustion biomass burning machine can enable fuels to be fully burnt, improves the burning efficiency, and prevents the environmental pollution caused by harmful gas discharged by insufficient combustion.

Owner:HENAN JUFENG BIO ENERGY DEV

Energy-saving boiler special for combustion test stand

ActiveCN102252522ATake advantage ofEfficient use ofCombustion processFurnace typesAir preheaterCold air

The invention discloses an energy-saving boiler special for a combustion test stand. The energy-saving boiler special for the combustion test stand mainly comprises a combustion chamber, a boiler barrel, an evaporimeter, an air preheater, and a support frame assembly. The evaporimeter is distributed at the outlet of the combustion chamber; the air preheater is distributed on the rear part of the evaporimeter in a horizontal mode; an expansion joint is arranged between the evaporimeter and the combustion chamber and between the evaporimeter and the air preheater; the outlet of the evaporimeteris provided with a manhole for overhauling; a refractory belt with an adjustable area is arranged on the front half part of the bottom of the combustion chamber; the bottom of the combustion chamber is provided with a plurality of slag holes and ash buckets along the longitudinal direction; a cooling section pipe box of the air preheater is provided with two cold air ports and can adapt to an oilcombustor and a coal combustor simultaneously; by a membrane water cooled wall, the boiler wall thickness of the combustion chamber and the weight of the combustion chamber are greatly reduced, and the combustion chamber has high tightness and is not easy to slag; the evaporimeter is arranged, so that heat of the discharged smoke can be fully used, and the temperature of the discharged smoke is greatly reduced; and by using a spiral grooved tube, the flowing smoke is subjected to strong turbulence and perturbance, the heat exchange is enhanced, the temperature of the discharged smoke is effectively reduced, the combustion in the boiler is enhanced, and the economy of the combustion is improved.

Owner:JIANGSU SIFANG BOILER +1

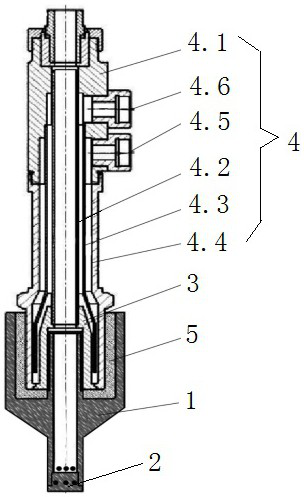

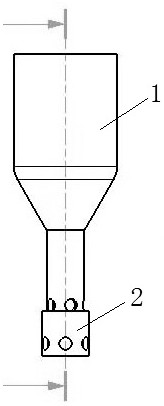

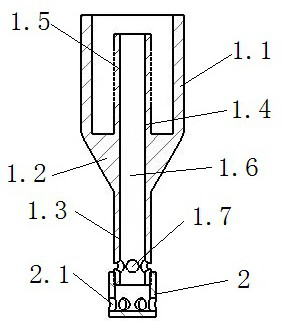

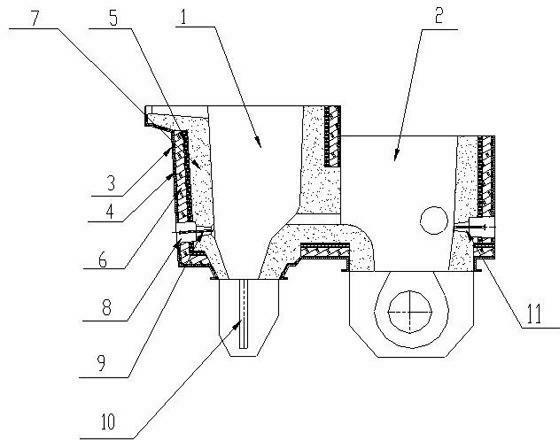

Oxygen-free copper rod mold

The invention relates to an oxygen-free copper rod mold. The oxygen-free copper rod mold comprises an integrated graphite die, the integrated graphite die comprises a large-diameter cylindrical section, a conical section and a small-diameter cylindrical section which are sequentially arranged, a cavity is formed in the large-diameter cylindrical section, a boss is arranged in the cavity, an external thread is arranged at the top of the boss, a through hole is formed in the boss, and the through hole extends downwards to communicate the conical section with the small-diameter cylindrical section. According to the oxygen-free copper rod mold, the large-diameter cylindrical section, the conical section and the small-diameter cylindrical section are integrally formed without gaps, refractory mortar is not used for filling the gaps, long-time baking does not need, slagging is not likely to happen in molten copper, and meanwhile cracks and gaps are prevented from being generated in a primarycooling area, namely an external thread connector, of a mold body, Due to arrangement of the conical section, when the mold is inserted into the heat preservation furnace, a copper liquid surface covering agent graphite phosphorus sheet cannot be brought into the furnace, and meanwhile furnace slag in the furnace is not prone to gathering and slagging below the large-diameter cylindrical section,and the double-row liquid flow holes greatly improve the yield and the production efficiency, and the quality of the copper rod is ensured.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

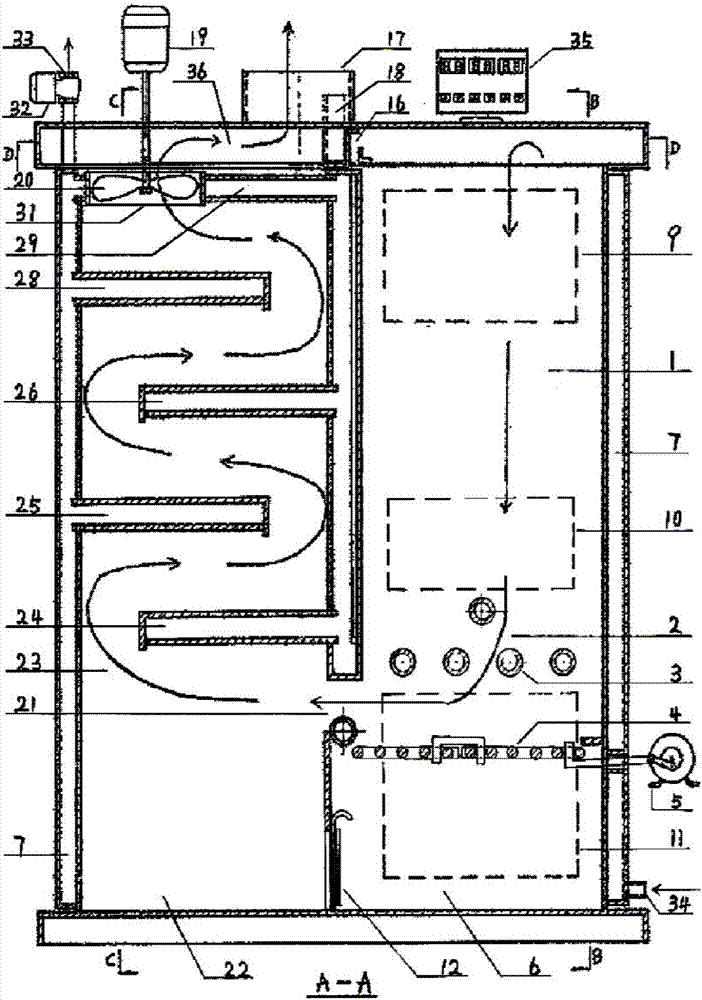

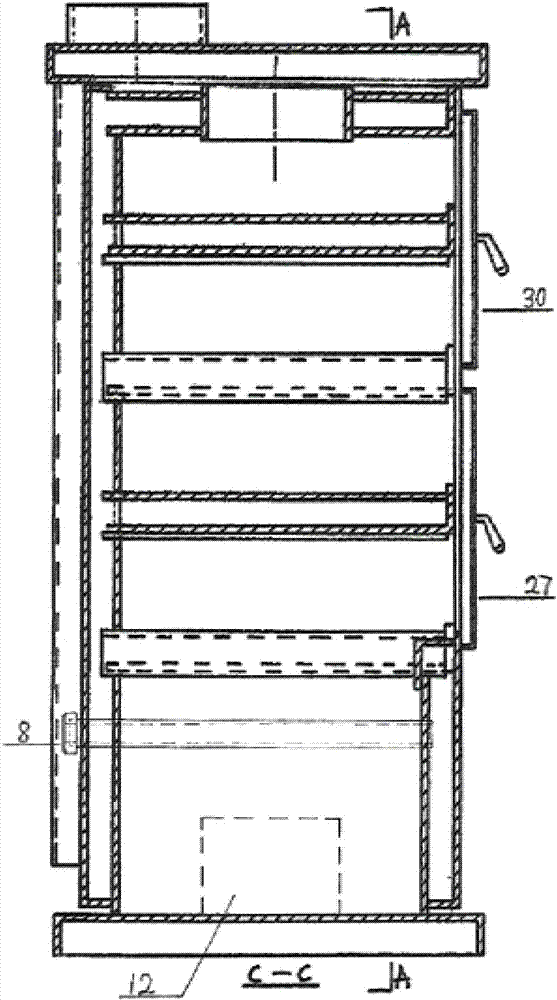

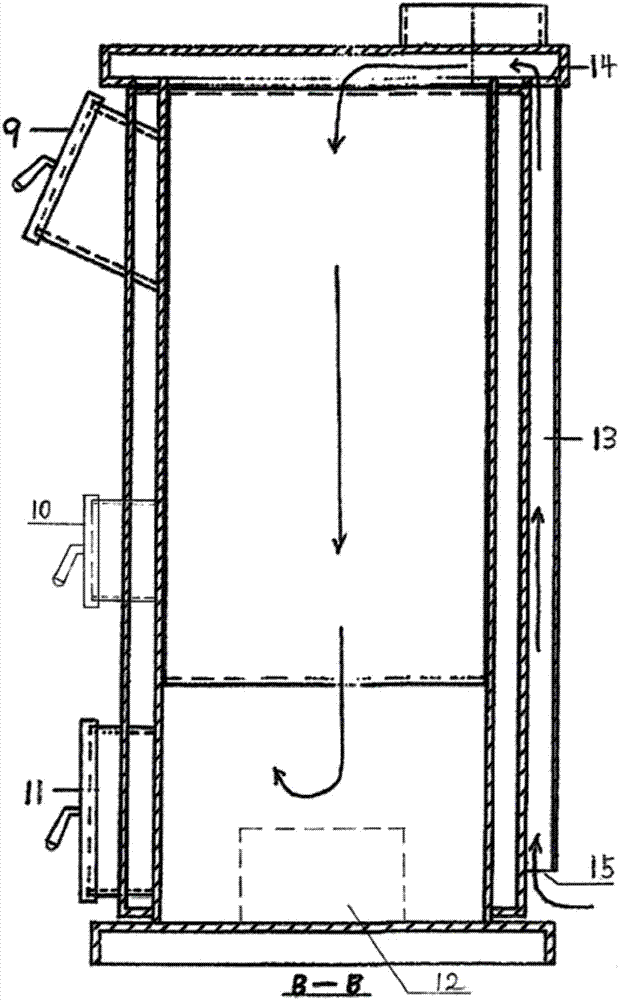

Energy saving and emission reduction intelligent furnace

PendingCN107388285ASolve the disadvantages of holding smoke and exhausting smoke outside the furnacePrevent moreCombustion processStove/ranges for heating waterComing outAir volume

The invention discloses an energy saving and emission reduction intelligent furnace to combust briquetted straw stalks, combustible briquetted garbage, firewood waste, combustible waste, clean coal, coal and the like. During combustion, the ash temperature is lowered, and slagging is not prone to happening. Timely ash removing is conducted through an intelligent combined ash falling fire grate, air is not prone to being blocked by ash, and a normal combustion effect is achieved. A large-size furnace can adopt a walking type fire grate to discharge ash, and a small-size furnace can adopt a manual fire grate to remove ash. Combustible materials are fully combusted in sequence, flames grill a large-area transverse flat plate heat absorption water jacket, through long-distance water jacket heat absorption, the heat of an exhaust outlet is very small, the heat efficiency is high, and temperature increasing is rapid. According to the energy saving and emission reduction intelligent furnace, an intelligent axial-flow induced draft fan without a shell is arranged, and the shell of the draft fan is omitted, so that raw materials are saved, electricity is saved, the air volume is large, and the noise is low; the intelligent axial-flow induced draft fan can be automatically opened according to the temperature needed in a room, so that the temperature is increased, and the intelligent axial-flow induced draft fan can be automatically stopped according to the temperature needed in the room, so that the temperature is lowered; and the energy saving and emission reduction intelligent furnace is controllable in temperature, high in heat efficiency and rapid in temperature increasing, smoke is not prone to being emitted, and tar is not prone to coming out.

Owner:刘明

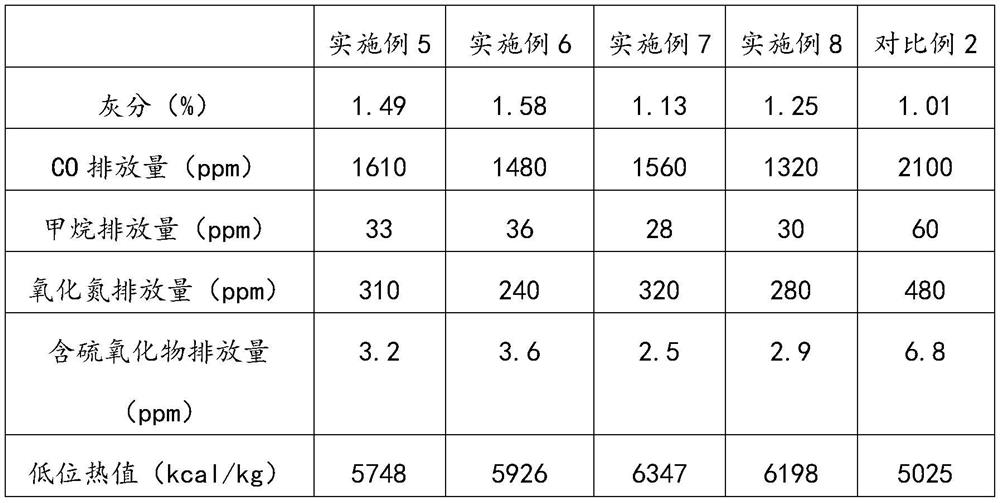

Composite biomass fuel

InactiveCN106675692AReduce moisture contentHigh lignin contentBiofuelsSolid fuelsAlkaline earth metalSlag

The invention discloses a composite biomass fuel, and belongs to the technical field of the composite biomass fuel. The composite biomass fuel is prepared from, by weight, 40-50 parts of straw stalk, 30-40 parts of wood flour, 10-15 parts of kaolin, 5-10 parts of aluminum oxide, and 10-20 parts of wood charcoal. The biomass fuel is low in water content, low in alkaline earth metal content and high in lignin content; compared with the regular biomass fuel grain compressed and shaped by straw, the biomass fuel is high in burning value and long in burning time; through adjusting alkali metal in the biomass fuel grain by the added kaolin and aluminum oxide, the fuel is not easy to form slag; the biomass fuel grain is free from emission of harmful gas after burning.

Owner:安徽润发生物能源科技有限公司

Bamboo grain fuel production method

A bamboo grain fuel production method includes steps of preparing raw materials of 80 parts of bamboo scraps, 2 parts of hard weedtree, 4 parts of soft weedtree, 8 parts of crop straws, 2 parts of adhesives, and 2 parts of bulking agent; smashing the raw materials into powder, and controlling granularity between 40-60 meshes; stirring and mixing 80 parts of bamboo scraps, 2 parts of hard weedtree, 4 parts of soft weedtree, 8 parts of crop straws, and 2 parts of adhesive; adding 2 parts of bulking agent after mixing for 45 minutes, and then keeping mixing for 3 minutes; drying the mixed powder at 60 DEG C for 15 minutes; granulating the dry powder in an extruder to obtain bamboo fuel grains.The bamboo grain fuel produced is moderate in compactness, is neither loose nor slagged, and is more sufficient in burning and high in burning degree.

Owner:HUOSHAN FENGLE BAMBOO & PLASTIC NEW ENVIRONMENTAL MATERIALS CO LTD

Biomass granular fuel and preparation method thereof

InactiveCN112111311AReduce porosityImprove molding rateBiofuelsSolid fuelsProcess engineeringEnvironmental engineering

The invention discloses a biomass granular fuel and a preparation method thereof, and relates to the field of development and utilization of waste biomass resources. The biomass granular fuel disclosed by the invention is prepared by the following steps: drying and crushing a biomass raw material to obtain powder, adding the lignin-based binder and the additive into the powder, uniformly stirringby virtue of a stirrer, mechanically compressing, granulating and cooling, thereby obtaining the biomass granular fuel. The lignin-based binder is obtained by adding a polyacrylic acid / urea polymer into a suspension containing lignin particles, adjusting the pH value, stirring, filtering, drying and crushing. According to the biomass granular fuel provided by the invention, by adding the lignin-based binder, the forming rate of the biomass granular fuel is increased, the biomass granular fuel is not easy to break in the transportation process, the combustion speed is stable, slag bonding is not liable to generate in the combustion process, the combustion efficiency is improved, the service life of a combustion device is prolonged, and the environmental pollution is reduced.

Owner:桃江县新辉生物质颗粒有限公司

Novel overpressure protector for coal gas drainer

The invention relates to a novel overpressure protector for coal gas drainer, which is applicable to various field situations. The invention comprises a gas-water separator and a leakage stopping device which is connected with the gas-water separator, and is characterized in that the gas-water separator is composed of a water baffle, a gas-guide tube for gas-water separator and a draft tube for gas-water separator, wherein, the water baffle is arranged in the inner side of the water inlet of a drain pipe of the leakage stopping device and is connected with the upper part of the drain pipe of the leakage stopping device; the gas-guide tube for gas-water separator is arranged on the water baffle; the draft tube for gas-water separator is connected with the lower part of the drain pipe of the leakage stopping device; the upper surface of the outlet of the gas water separator draft pipe is on the same horizontal line with the bottom end of the valve cap of the leakage stopping device in vertical state; the valve cap with a sealing ring in the leakage stopping device is manufactured by adopting materials with buoyance force characteristics. Compared with current overpressure protector for coal gas drainer, the invention has simpler structure, no flexible parts, easy manufacturing, convenient checking and maintenance, reliable performance and long service life; the critical zone is zero; the invention can restrain tightly overpressure coal gas, drain away water in great quantities unobstructedly, and prevent the evaporation of water content.

Owner:于晓峰

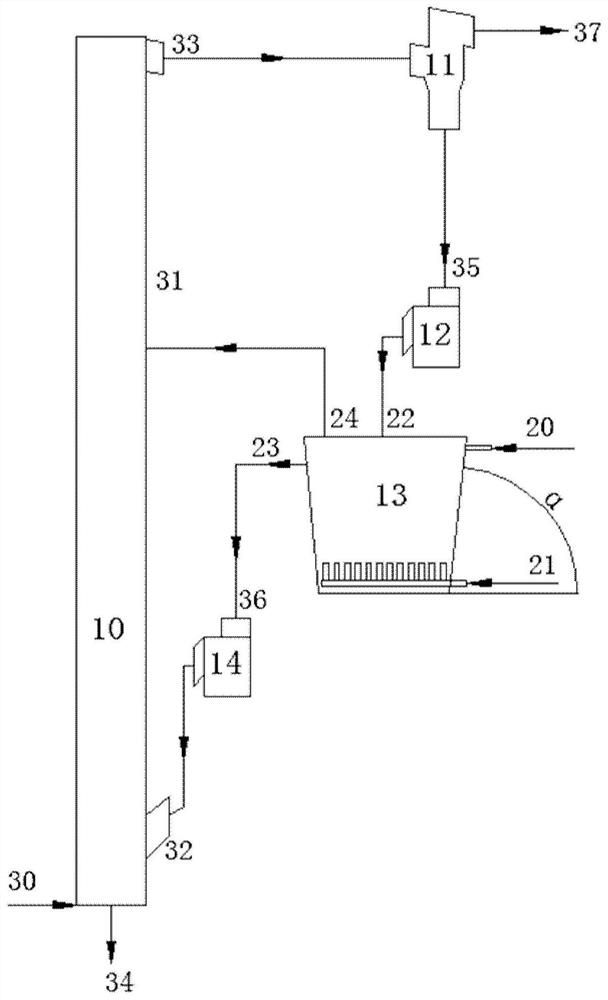

Vertical industrial pulverized coal boiler system

InactiveCN101929669BImprove air tightnessReduce air leakageCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterSlag

The invention discloses a vertical industrial pulverized coal boiler system, which comprises a stokehole pulverization device connected with a pulverized coal boiler body through a combustor, and the pulverized coal boiler body is connected with a chimney through a flue gas processing device. The vertical industrial pulverized coal boiler system is characterized in that: the pulverized coal boiler body comprises a horizontal flue, a hearth respectively communicated with two ends of the horizontal flue, and a vertical smoke well which are arranged in a vertical inverted U shape; the hearth consists of membrane water walls; a position of the hearth communicated with the outlet of the horizontal flue is provided with a slag condensing bank used for preventing high temperature flue gas from slagging; the horizontal flue behind the slag condensing pipe bundle is provided with a superheater and an convection bank inside in turn; the convection bank is connected to upper and lower boiler barrels positioned on upper and lower sides of the horizontal flue; the vertical smoke well is provided with an economizer and an air preheater inside from top to bottom; and the lower part of the vertical smoke well is connected with the flue gas processing device through a connecting flue. The vertical industrial pulverized coal boiler system has the advantages of high integration degree, small occupied area, high combustion efficiency, energy conservation, environmental protection, and wide market application prospect.

Owner:XI AN JIAOTONG UNIV

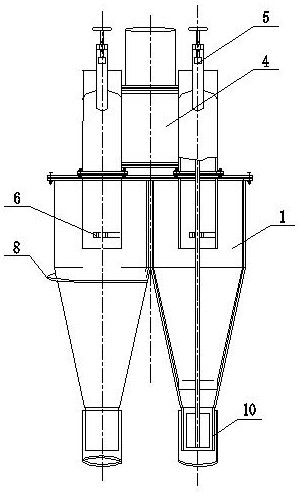

Fuel dealkalization device and method thereof and circulating fluidized bed gasification device and method thereof

ActiveCN112852498ASimplify dealkalization processRun at scaleGranular/pulverulent flues gasificationSlagSolid fuel

The invention discloses a fuel dealkalization device and a method and a circulating fluidized bed gasification device and a method thereof, and the fuel dealkalization device is a bubbling fluidized bed and comprises a fuel inlet which is located at the upper part of the fuel dealkalization device and is used for conveying fuel to the fuel dealkalization device; an auxiliary gasifying agent inlet positioned at the lower part of the fuel dealkalization device and used for conveying an auxiliary gasifying agent to the fuel dealkalization device, wherein the fuel and the auxiliary gasifying agent are subjected to dealkalization reaction under heating; a dealkalized solid fuel overflow port positioned at the upper part of the fuel dealkalization device and used for outputting the dealkalized solid fuel generated by the dealkalization reaction; and an alkali-rich fuel gas outlet is positioned at the upper part of the fuel dealkalization device and used for outputting alkali-rich fuel gas generated by the dealkalization reaction. The invention further provides the fuel dealkalization method and the circulating fluidized bed gasification device and the method thereof. The method solves the technical problem of slag bonding caused by high alkali metal content of the high-alkali coal, realizes safe and reliable utilization of the high-alkali coal, and has a wide market application prospect.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Level layer blow-out type biomass particle burner

PendingCN107816716AReduce resistanceThe overall thickness is thinSolid fuel combustionSolid removalThermodynamicsNew energy

The invention belongs to the technical field of new energy resources and energy saving and particularly relates to a level layer blow-out type biomass particle burner. The level layer blow-out type biomass particle burner comprises a material bin, a feeding mechanism, a burner port and an ignition device, wherein the material outlet end of the feeding mechanism communicates with the tail end of the burner port; the level layer blow-out type biomass particle burner further comprises an air distribution chamber; the air distribution chamber is connected with the tail end of the burner port and communicates with an air outlet pipe of a burning-supporting fan; and the air distribution chamber is provided with a burning-supporting air pipe pointing to an inner cavity of the burner port and a slag blowing pipe stretching into the burner port and located in the lower portion of the inner cavity of the burner port. The level layer blow-out type biomass particle burner adopts a level layer burning mode, the structure is simple, reliability is high, the maintenance workload is small, slag bonding is not liable to occur in the burning process, ash can be discharged automatically, the problemof blocking of the burner port is solved effectively, continuous feeding and continuous ash discharging can be achieved in working of the level layer blow-out type biomass particle burner, and heat supply is stable.

Owner:昆明康立信电子机械有限公司

A kind of anti-sintering type biomass fuel

The invention relates to the field biological energy sources, in particular to anti-sintering biomass fuel. The anti-sintering biomass fuel comprises the following ingredients in parts by weight: 25-50 parts of stalk, 15-25 parts of straw, 5-10 parts of walnut shell, 5-13 parts of bark and 0.5-2 parts of anti-sintering agent, wherein a molecular formula of the anti-sintering agent is C25H19O4N3Zn. Compared with the conventional biomass fuel particles compressed by the stalk, the biomass fuel has a low water content, a high combustion value and long combustion time, and can be converted into acidic oxide in situ by adding the anti-sintering agent; properties of the biomass fuel particles can be effectively adjusted; the biomass fuel particles have low possibility of slagging; and no harmful gas is emitted after combustion of the biomass fuel particles.

Owner:杭州华政新能源科技有限公司

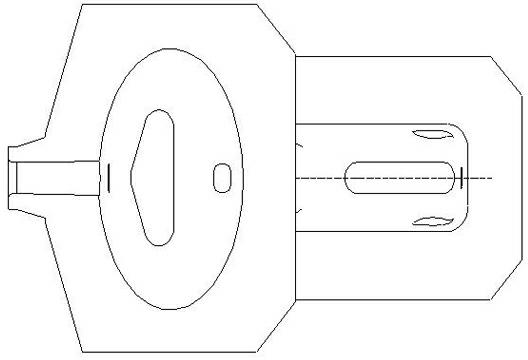

Wear-resistant pulverized coal concentration separation device

InactiveCN112377899ASimple structureEasy to separatePulverulent fuel combustion burnersPower stationCombustion

The invention discloses a wear-resistant pulverized coal concentration separation device. The wear-resistant pulverized coal concentration separation device comprises two cylinders, wherein wear-resistant ceramic is embedded in the cylinders; the two cylinders are symmetrically arranged side by side; the side surfaces of the tops of the cylinders are connected with side surface elbows; the side surface elbows are connected with a pulverized coal feeding port; the tops of the cylinders are connected with two cyclone regulators; the two cyclone regulators are used for controlling the pulverizedcoal flow of the two cylinders respectively; guide vanes are arranged at the lower ends of the cyclone regulators; U-shaped wear-resistant ceramic chips are arranged at the edges of the guide vanes; fixed frames are arranged at the peripheries of the cylinders; reinforcing ribs are arranged on the fixed frames; pulverized coal discharging ports are also formed in the bottoms of the cylinders; andM-shaped wear-resistant ceramic chips are lined in the pulverized coal discharging ports. The wear-resistant pulverized coal concentration separation device has the characteristics of simple structure, good separation effect, high temperature resistance, wear resistance, long service life and the like and can be widely applied to the field of combustion separators of power station boilers.

Owner:湖南西拓新材料科技有限公司

Environment-friendly bio-fuel by utilizing forestry and agricultural residues

InactiveCN109370685AEmission reductionImprove organicBiofuelsSolid fuelsAgricultural residueManganese

The invention discloses environment-friendly bio-fuel by utilizing forestry and agricultural residues. The bio-fuel is prepared from the following raw materials in parts by weight: 34-48 parts of broadbean straws, 39-44 parts of brassica juncea straws, 25-29 parts of sorghum powder straws, 17-23 parts of corn straw powder, 12-19 parts of black pin branches, 7-11 parts of Chinese pine branches, 6-14 parts of locust sawdust, 5-10 parts of mulberry sawdust, 7-11 parts of wheat bran, 8-15 parts of ground coal, 15-23 parts of animal grease, 5-11 parts of diatomite, 6-15 parts of alcohol, 1-4 partsof fatty alcohol-polyoxyethylene ether, 2-5 parts of acetone, 1-4 parts of sodium carbonate and 0.6-1 part of tricarbonyl(methylcyclodienyl)manganese. The bio-fuel is energy-saving and environment-friendly, and has high calorific value, forestry and agricultural residues are sufficiently utilized to replace non-renewable energy resources, and emission of carbon dioxide, sulfur dioxide and other harmful gases can be reduced. Furthermore, biomass formed fuel can radically solve unsafe factors including large floor area, impact on landscape environment, reason of fire disasters and the like caused by piling the residues in rural areas.

Owner:定远县吉利新能源有限公司

Copper furnace for continuously casting copper-aluminium composite material

The invention provides a copper furnace for continuously casting a copper-aluminium composite material. The copper furnace comprises a melting furnace hearth, an insulating furnace hearth and a furnace shell, wherein the furnace shell is internally provided with an asbestos board, an insulating brick, a refractory brick and a casting material in sequence; the lower sides of the melting furnace hearth and the insulating furnace hearth are respectively provided with a temperature measuring port; each temperature measuring port is internally provided with a thermocouple sheathed with a metal ceramic tube; the lower parts of the melting furnace hearth and the insulating furnace hearth are provided with eccentric melting channels with unequal sections; the cross section of the melting furnace hearth is elliptical, and the elliptical eccentricity is 0.7-0.8; the widths b of the two sections of the eccentric melting channels are from 1.45a to 1.7a; the refractory casting material is filled at the periphery of each temperature measuring port; and the outer diameter of the metal ceramic tube is 14-16mm, and the distance from the front end of the metal ceramic tube to the inner walls of the melting furnace hearth and the insulating furnace hearth is 290-320mm. The copper furnace adopts an elliptical structure, has no dead corner, is good in insulating effect, can effectively prevent slagging, is beneficial to removing slag and can achieve uniform temperature; and the side-surface temperature measuring structure avoids direct contact with the upper liquid level of copper water, and avoids a copper furnace opening so as to prevent damage.

Owner:YANTAI FISEND BIMETAL

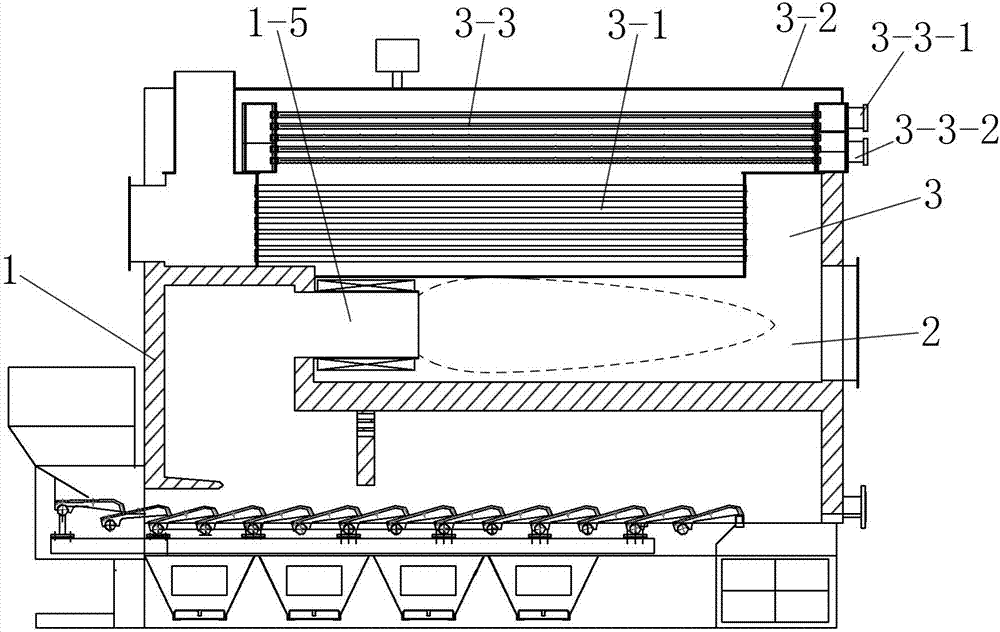

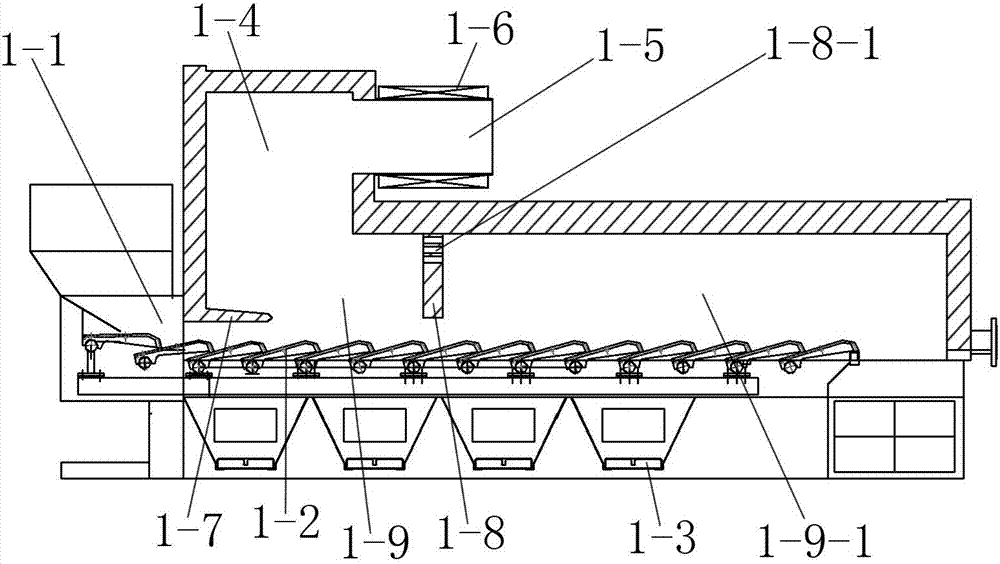

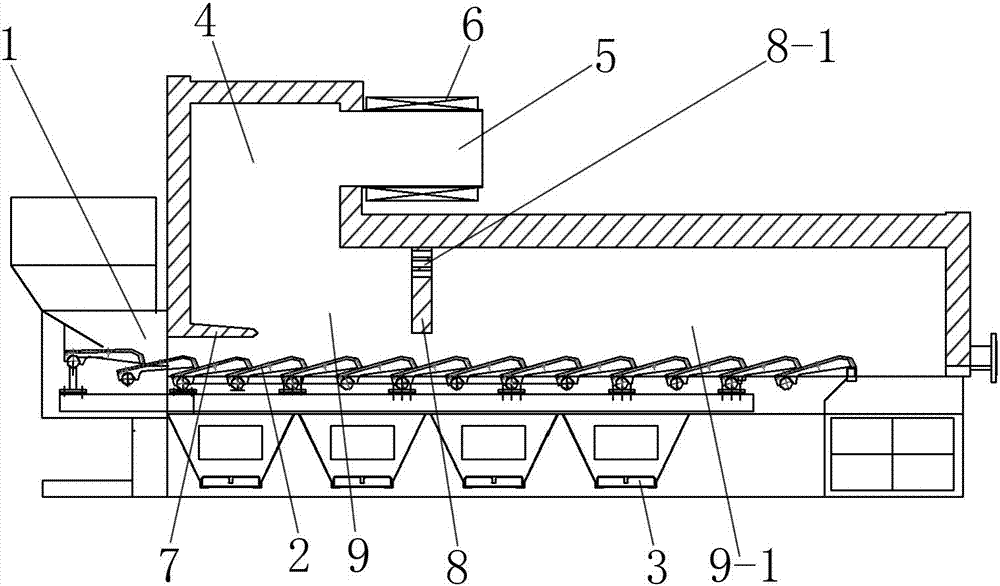

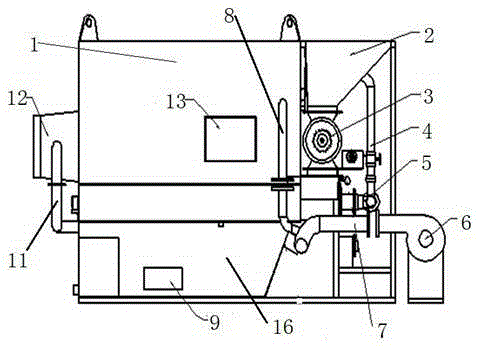

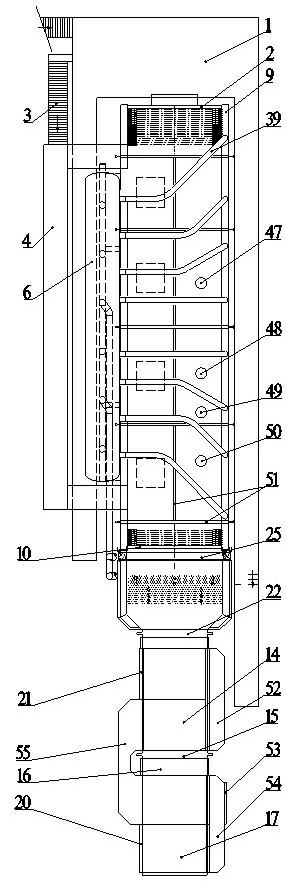

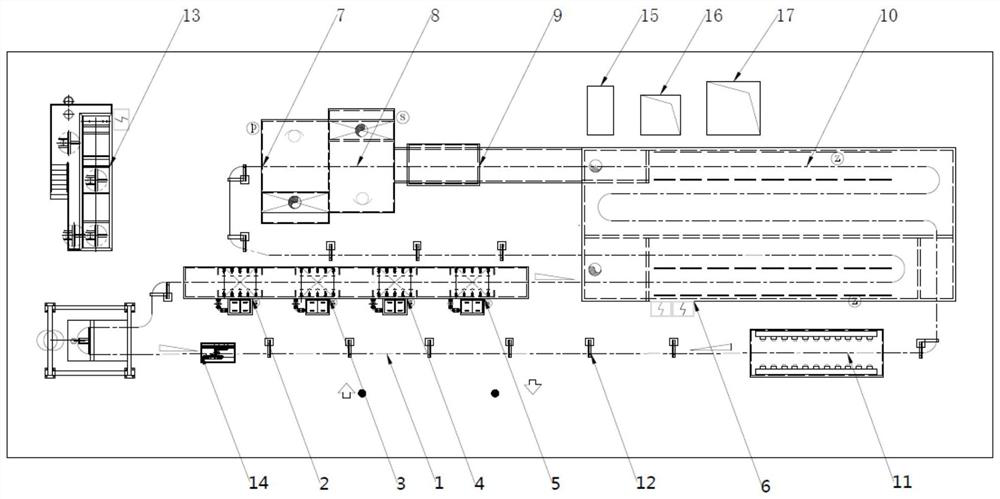

A rail transit integral wheel coating production line and its application method

ActiveCN112076931BReduce painting costQuick changeGas treatmentDispersed particle separationSludgeProcess engineering

The invention discloses a rail transit integral wheel coating production line. The coating production line is sequentially provided with a feeding station 1, a pre-degreasing station 2 for pre-processing the integral wheel, a degreasing station 3, and hot water Cleaning station 4, normal temperature water scoop washing station 5, dehydration and drying station for integral wheels used in rail transit 6, first paint painting station for paint spraying of integral wheels 7, second paint painting station Position 8. Used for the leveling station after the paint coating of the integral wheel for rail transit 9. Used for the paint drying station after the paint leveling of the integral wheel for rail transit 10. Used for drying the paint of the integral wheel for rail transit After the completion of the strong cooling station 11 and the blanking station 12, the coating production line is also equipped with a wastewater treatment station 13 and a sludge filter press station 15. The feeding station 1 is equipped with a cantilever crane, which can realize the hanging type feeding of the wheel hub hole. The invention also discloses a method for using the rail transit integral wheel coating production line.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com