Continuously operated biomass forming fuel gasification combustor

A molding fuel and burner technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of low nitrogen oxide concentration, high heat utilization rate, good environmental protection effect, etc., and achieve low nitrogen oxide concentration , High heat utilization rate, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

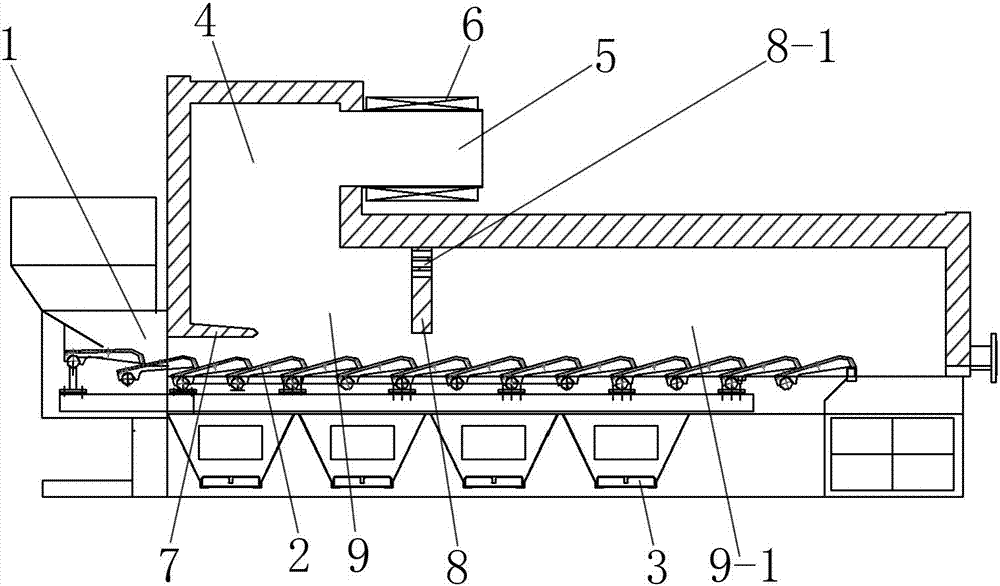

[0009] refer to figure 1 , a continuously operating biomass briquette fuel gasification burner, which includes a burner body, the burner body includes a gasification combustion chamber, a feed port 1 is arranged on one side of the gasification combustion chamber, and the gasification combustion chamber A grate 2 and a primary tuyere 3 are provided at the bottom of the gasification combustion chamber, a gas collection area 4 is provided above the gasification combustion chamber, and a gas nozzle 5 is provided on the side of the gas collection area 4 that is far from the feed port 1. The nozzle 5 is provided with a secondary tuyere 6; the grate 2 adopts a reciprocating grate 2, and the reciprocating motion of the grate 2 can effectively prevent slagging of the biomass molding fuel; An anti-flashback wall 7 is arranged at the edge to prevent the flame from escaping from the feed port 1; a partition wall 8 perpendicular to the direction of the grate 2 is arranged in the gasificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com