Civilian clean coke and production method thereof

A production method and clean technology, applied in coking ovens, petroleum industry, etc., can solve problems such as low calorific value, high carbon content in ash residue, poor sulfur fixation effect, etc., to reduce smog weather, wide source of raw materials, improve Environmental Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

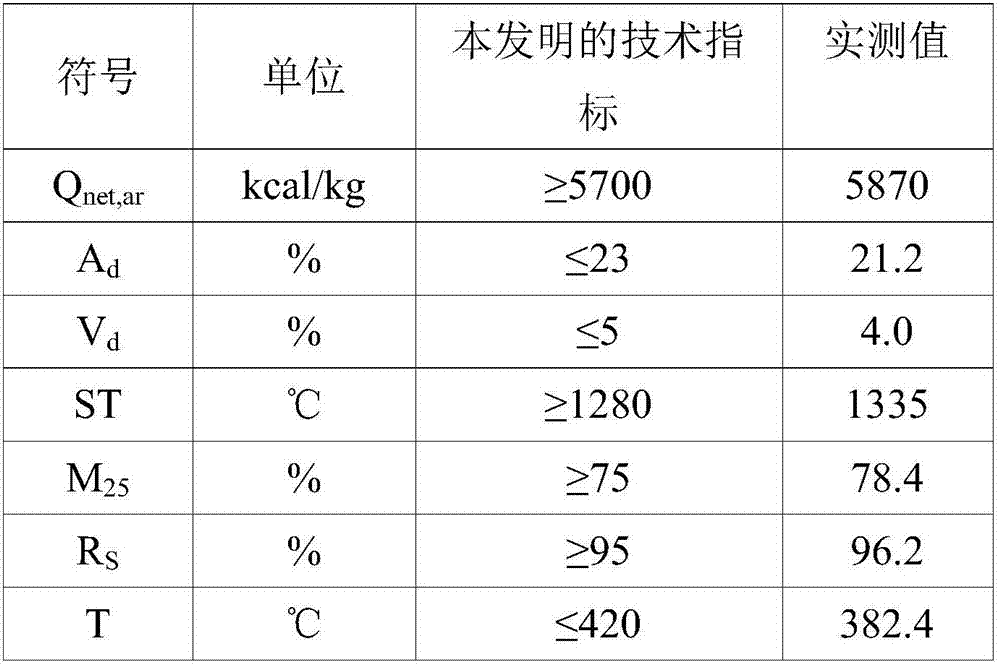

Embodiment 1

[0036] (1) Coarsely crush and finely crush limestone, hematite and manganese dioxide raw materials to particle size ≤ 3mm;

[0037] (2) Weigh respectively 20kg of broken limestone, 10kg of hematite, and 5kg of manganese dioxide successively, and simultaneously take by weighing sorghum straw powder (main composition: 42.2wt% of cellulose, 31.6wt% of hemicellulose, 7.6wt% of lignin, Other 18.6wt%) 70kg, mix it together, and stir;

[0038] (3) The evenly stirred mixture is dried at 100°C for 2 hours, and then dry-milled to make the particle size of the raw material ≤150 mesh (0.1mm); then cooled to room temperature, it is the straw powder compound additive (specific composition: cellulose 28.1wt%, hemicellulose 21.1wt%, lignin 5.1wt%, CaCO 3 18.2wt%, MnO 2 4.8wt%, CaO5.9wt%, Al 2 o 3 0.7wt%, SiO 2 8.8wt%, Fe 2 o 3 6.9wt%, MgO0.5wt%).

[0039] (4) Coarsely crush and finely crush the dried limestone, barium slag, manganese ore, alumina and other additive raw materials to a ...

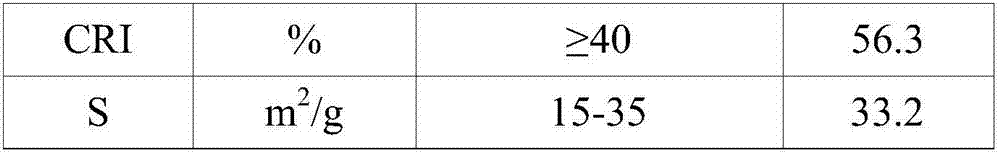

Embodiment 2

[0047] (1) Coarsely crush and finely crush limestone, hematite and manganese dioxide raw materials to particle size ≤ 3mm;

[0048] (2) Weigh respectively 22.5kg of crushed limestone, 13kg of hematite, and 6.3kg of manganese dioxide in turn, and simultaneously weigh rice straw powder (main composition: cellulose 39.6wt%, hemicellulose 34.8wt%, lignin 6.3wt%) %, other 19.3wt%) 65kg, mix it together, and stir;

[0049] (3) The evenly stirred mixture is dried at 112.5°C for 1.8 hours, and then dry-milled to make the particle size of the raw material ≤ 150 mesh (0.1mm); then cooled to room temperature, it is the straw powder compound additive (specific composition: cellulose 24.1wt%, hemicellulose 21.2wt%, lignin 3.8wt%, CaCO 3 20.1wt%, MnO 2 5.9wt%, CaO5.9wt%, Al 2 o 3 0.8wt%, SiO 2 8.8wt%, Fe 2 o 3 8.8wt%, MgO0.6wt%).

[0050] (4) Coarsely crush and finely crush the dried limestone, potassium feldspar, silicon dioxide, magnesium carbonate and other additive raw materials...

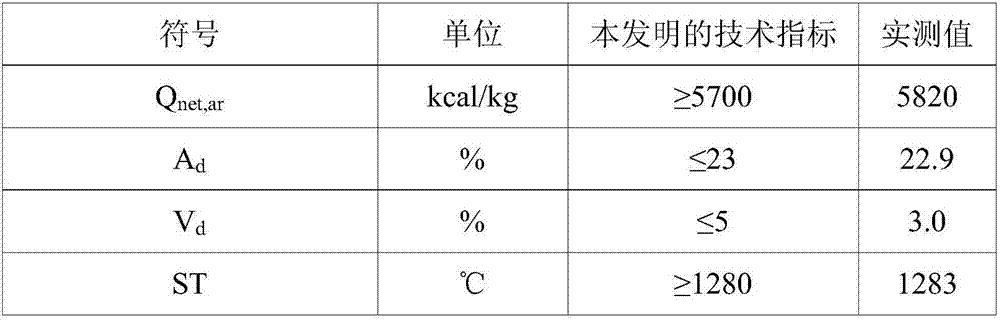

Embodiment 3

[0059] (1) Coarsely crush and finely crush limestone, hematite and manganese dioxide raw materials to particle size ≤ 3mm;

[0060] (2) Weigh respectively 25kg of crushed limestone, 15kg of hematite, and 7.5kg of manganese dioxide, and simultaneously weigh wheat straw powder (main composition: cellulose 43.2wt%, hemicellulose 22.4wt%, lignin 9.5wt%) , other 24.9wt%) 60kg, mix it together, and stir;

[0061] (3) The evenly stirred mixture is dried at 125°C for 1.5 hours, and then dry-grinded to make the raw material particle size ≤ 150 mesh (0.1mm); then cooled to room temperature, it is the straw powder composite additive (specific composition: cellulose 24.1wt%, hemicellulose 12.5wt%, lignin 5.3wt%, CaCO 3 22.2wt%, MnO 2 7.0wt%, CaO7.0wt%, Al 2 o 3 1.0wt%, SiO 2 10.3wt%, Fe 2 o 3 10.0wt%, MgO0.7wt%).

[0062] (4) Coarsely crush and finely crush the dried limestone, barium slag, manganese ore, alumina and other additive raw materials to a particle size of ≤3mm;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com