Phosphating solution online-monitoring and automatic-supplementing apparatus

A technology of automatic replenishment and phosphating, applied in phosphating, cells, electrolysis process, etc., can solve the problems of affecting the accuracy, blocking the pipeline, reducing the service life of the PH meter, etc., to improve labor efficiency, improve labor environment, product Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

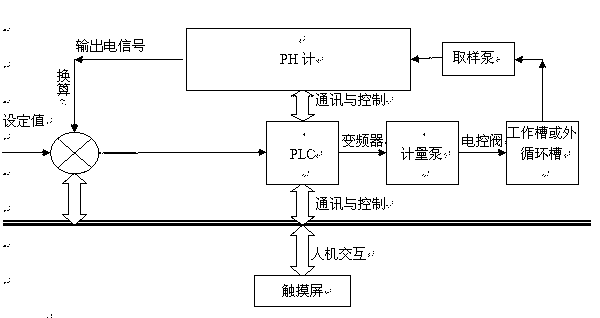

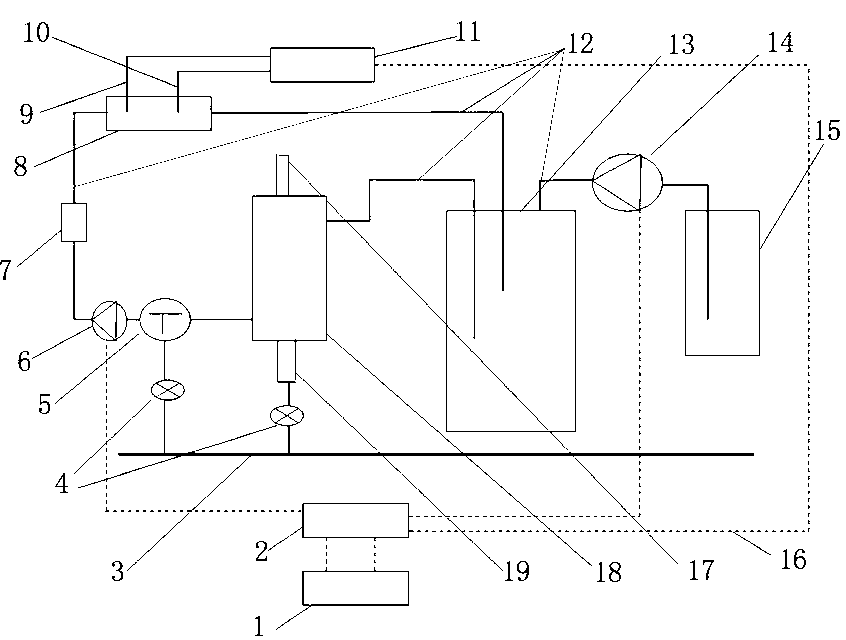

[0022] The present invention as figure 1 , 2 shown.

[0023] A device for on-line monitoring and automatic replenishment of phosphating solution, comprising a working tank or circulation tank 13, a measuring tank 8, a concentrated solution pool 15, and a pipeline 12. The working tank or circulation tank 13 is connected to a metering pump 14 through the pipeline 12 to concentrate Liquid pool 15; working tank or circulating tank 13 is connected to measuring pool 8 by pipeline 12; working tank or circulating tank 13 is connected with condenser 18 by pipeline 12, and condenser 18 is connected with sampling pump 6 by tee 5, and sampling The pump 6 is connected to the measuring tank 8 through the float flow meter 7, and the other end of the tee 5 is connected to the circulating water pipeline 3 through the valve 4; The communication line 16 is connected to the PLC module 2 and the touch screen 1 .

[0024] Among them, the control part adopts PLC module 2 and touch screen 1, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com