Precision metal part wax mold assembly automatic adhesion machine and precision metal part wax mold assembly automatic adhesion method

An automatic bonding and component technology, applied in the direction of casting molding equipment, etc., can solve the problems of high position accuracy requirements, unguaranteed, insecure, etc., to achieve the effect of precise bonding position, saving grinding time, and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

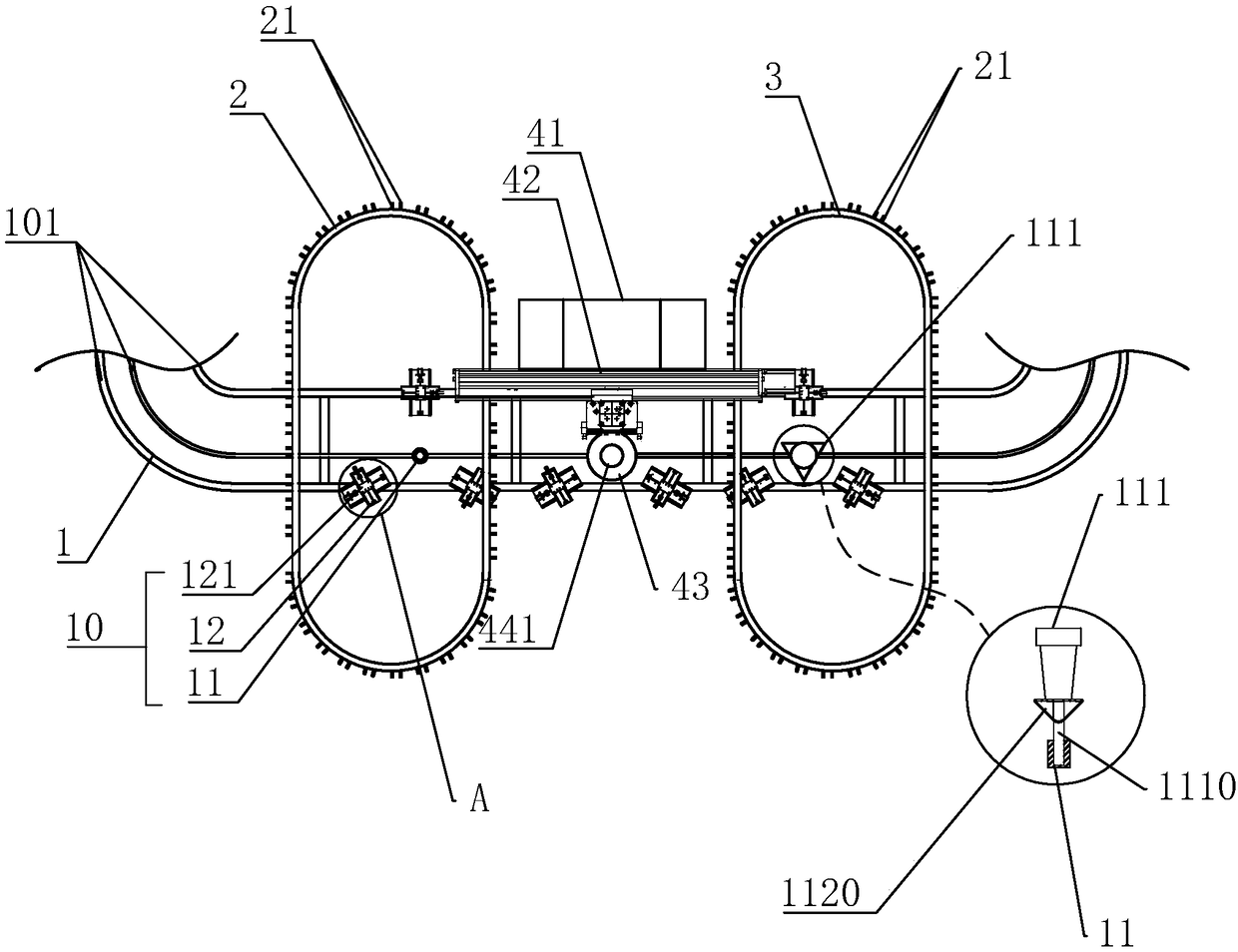

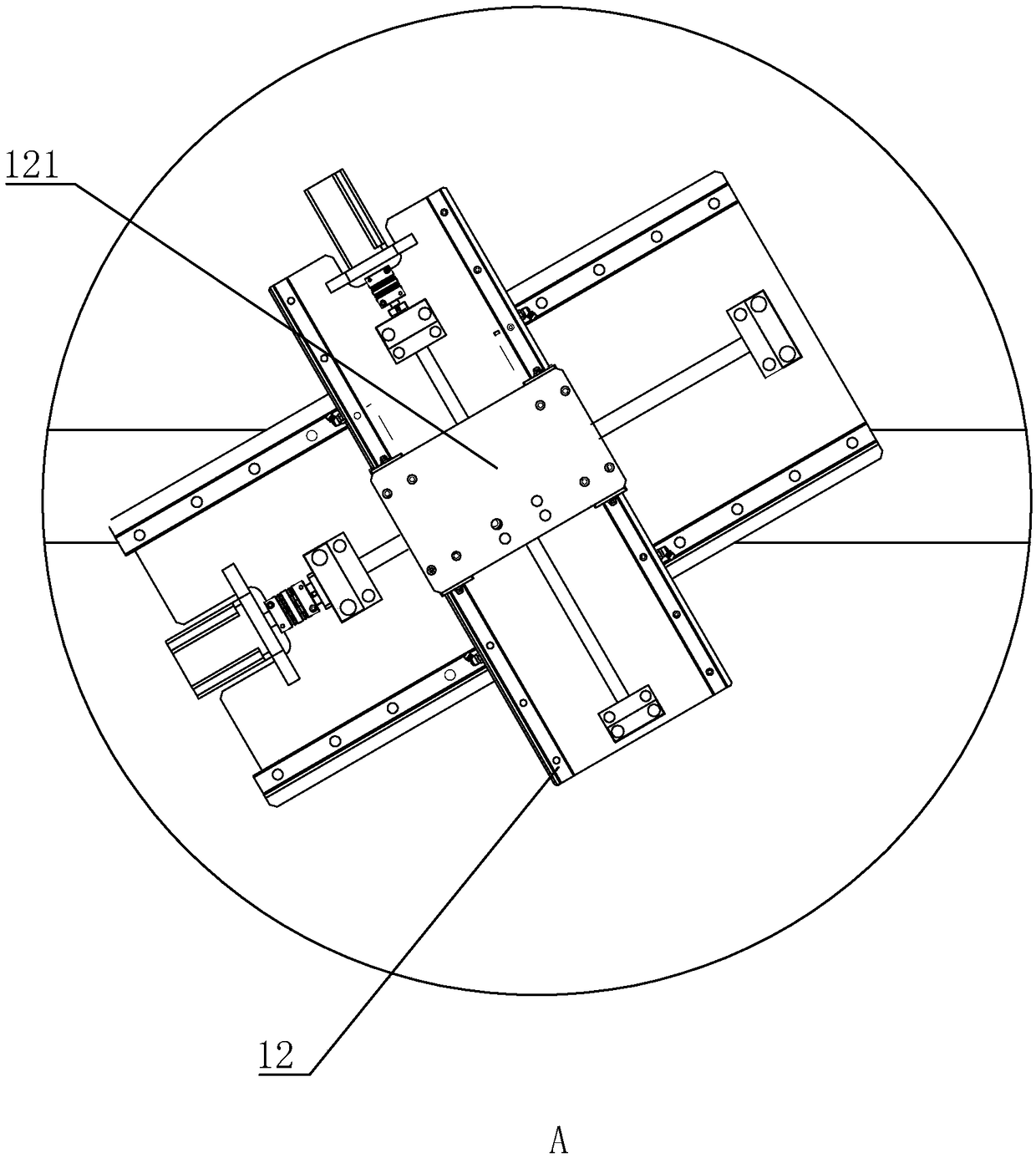

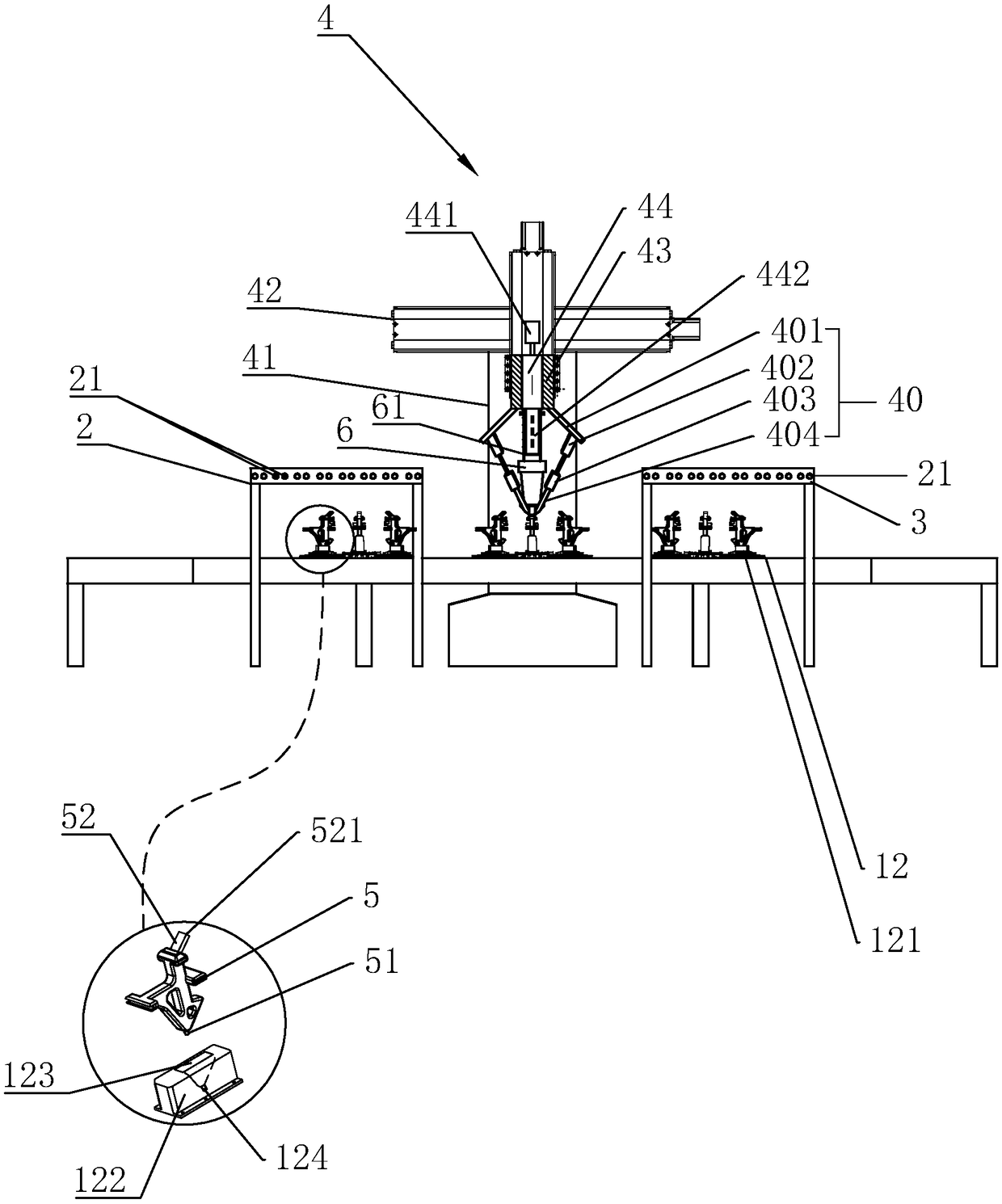

[0045] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0046] Investment casting, also known as lost wax casting, includes mold design and making, wax pattern making, slurry dipping, sand showering, wax melting, casting molten metal and subsequent processing.

[0047] Such as Figure 4 and 5 Shown, wax pattern making of the present invention comprises wax injection and group tree. Wax injection is to inject wax in a well-made mold to form a wax model. After the wax injection process, the present invention obtains the wax model 5 to be bonded and the connector 6 for grouping trees, and the shape of the wax model 5 to be bonded. It is the shape of the casting to be processed. The upper end of the wax model 5 to be bonded is designed with a connecting portion 52 for connecting with the connecting piece 5 , and above the connecting portion 52 is a connecting surface 1 521 . When the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com