Patents

Literature

271results about "Phosphatisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

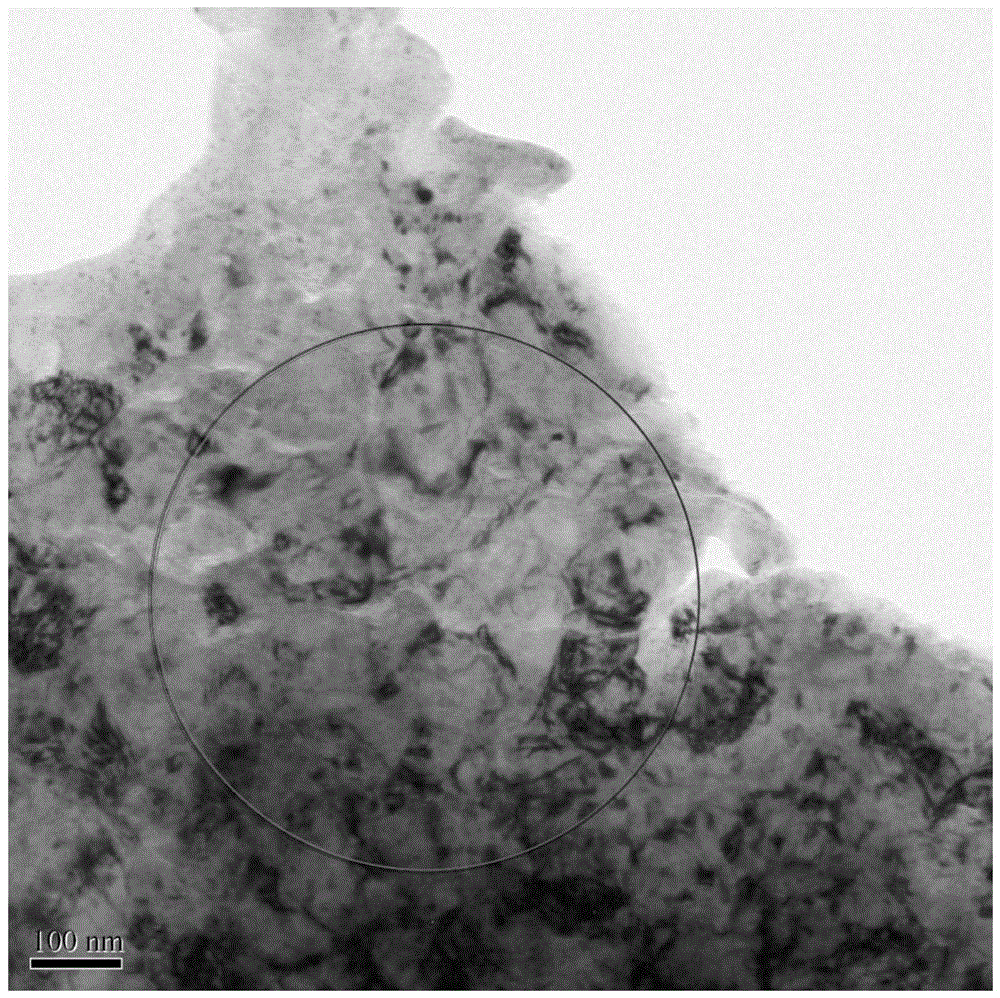

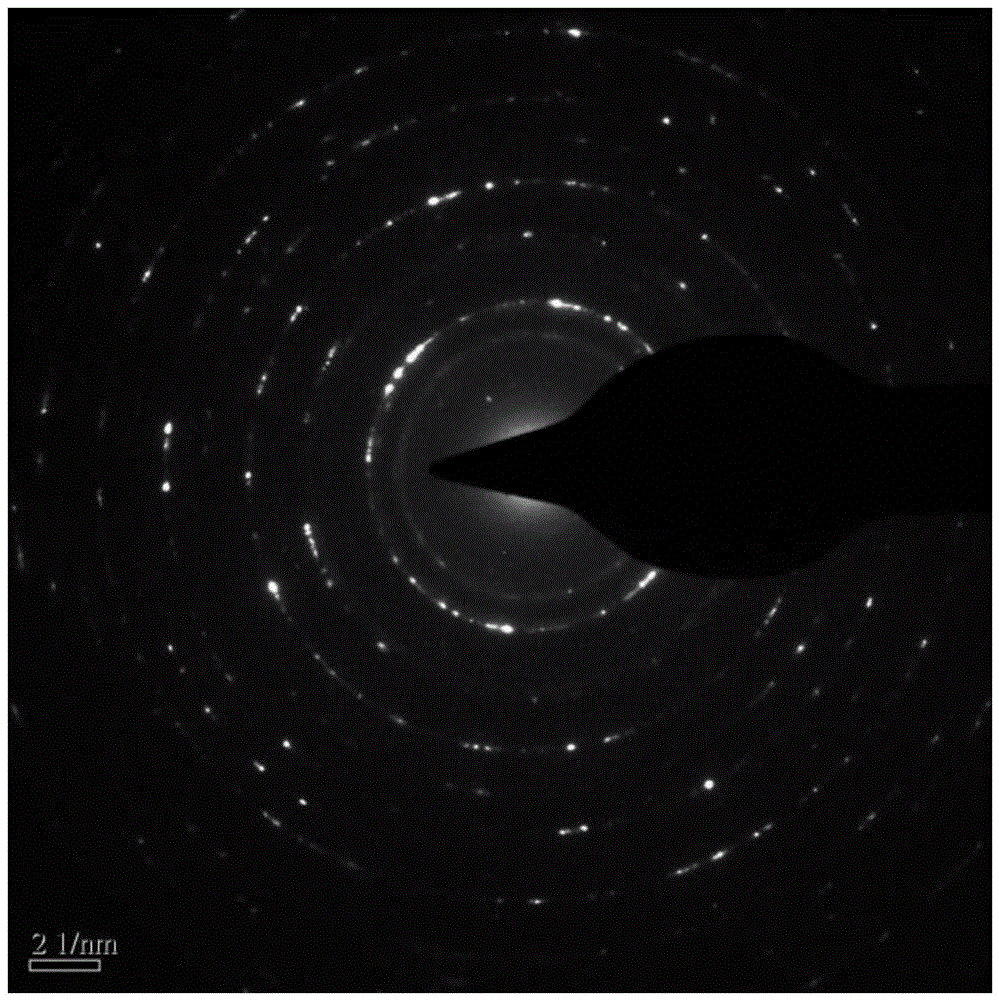

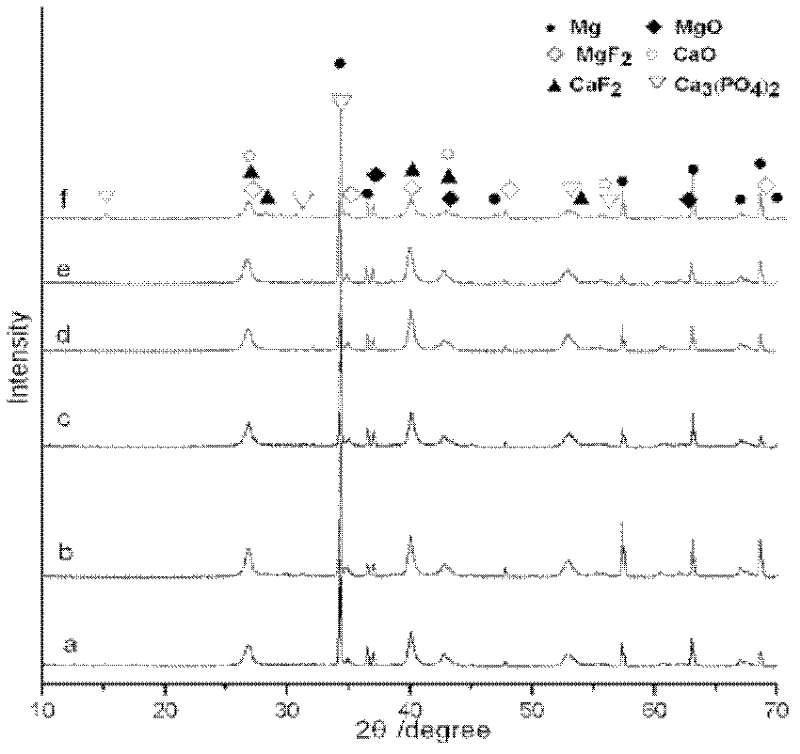

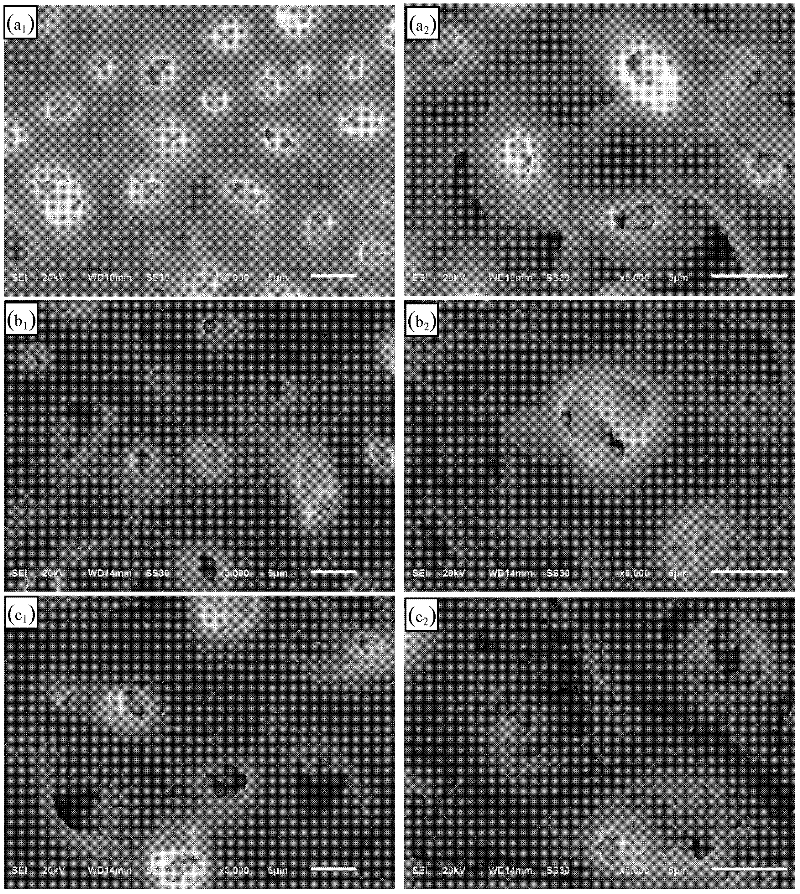

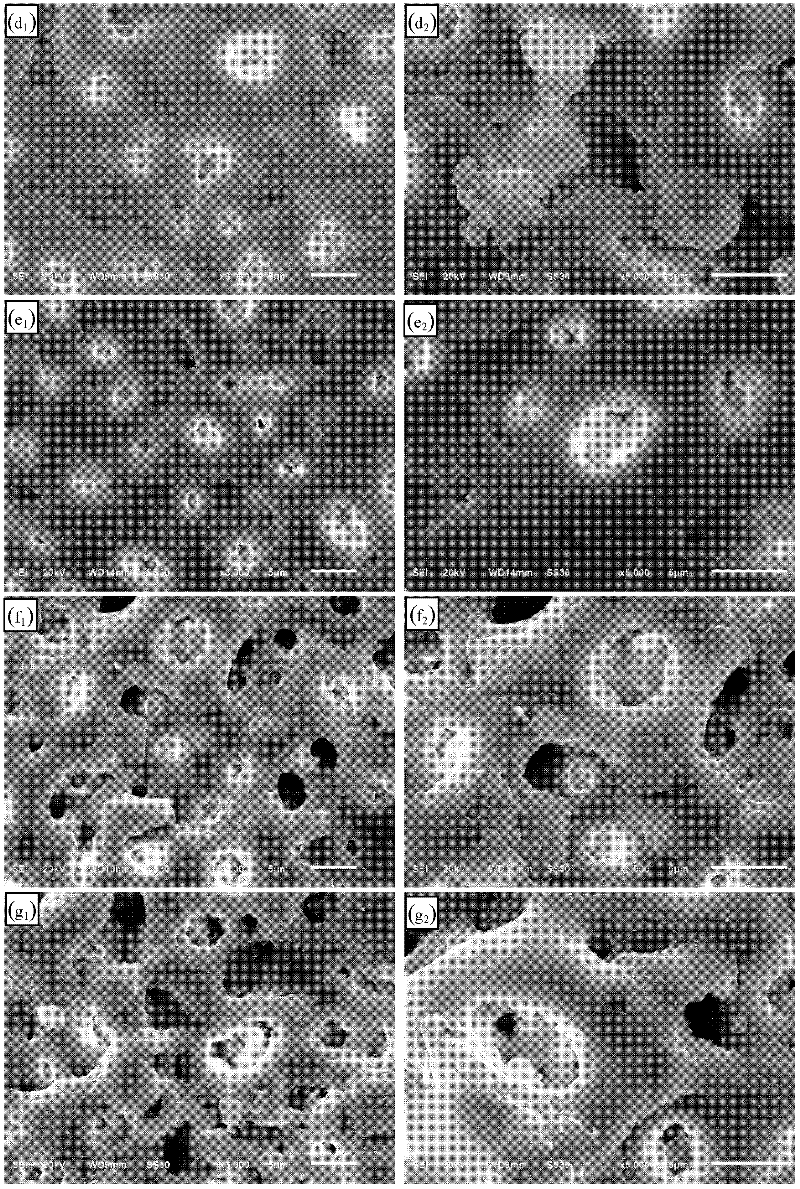

Preparation method of biological ceramic coating rich in calcium and phosphate phases on surface of magnesium alloy

ActiveCN102220620AHigh hardnessHigh densityAnodisationPhosphatisationPlasma electrolytic oxidationMicro arc oxidation

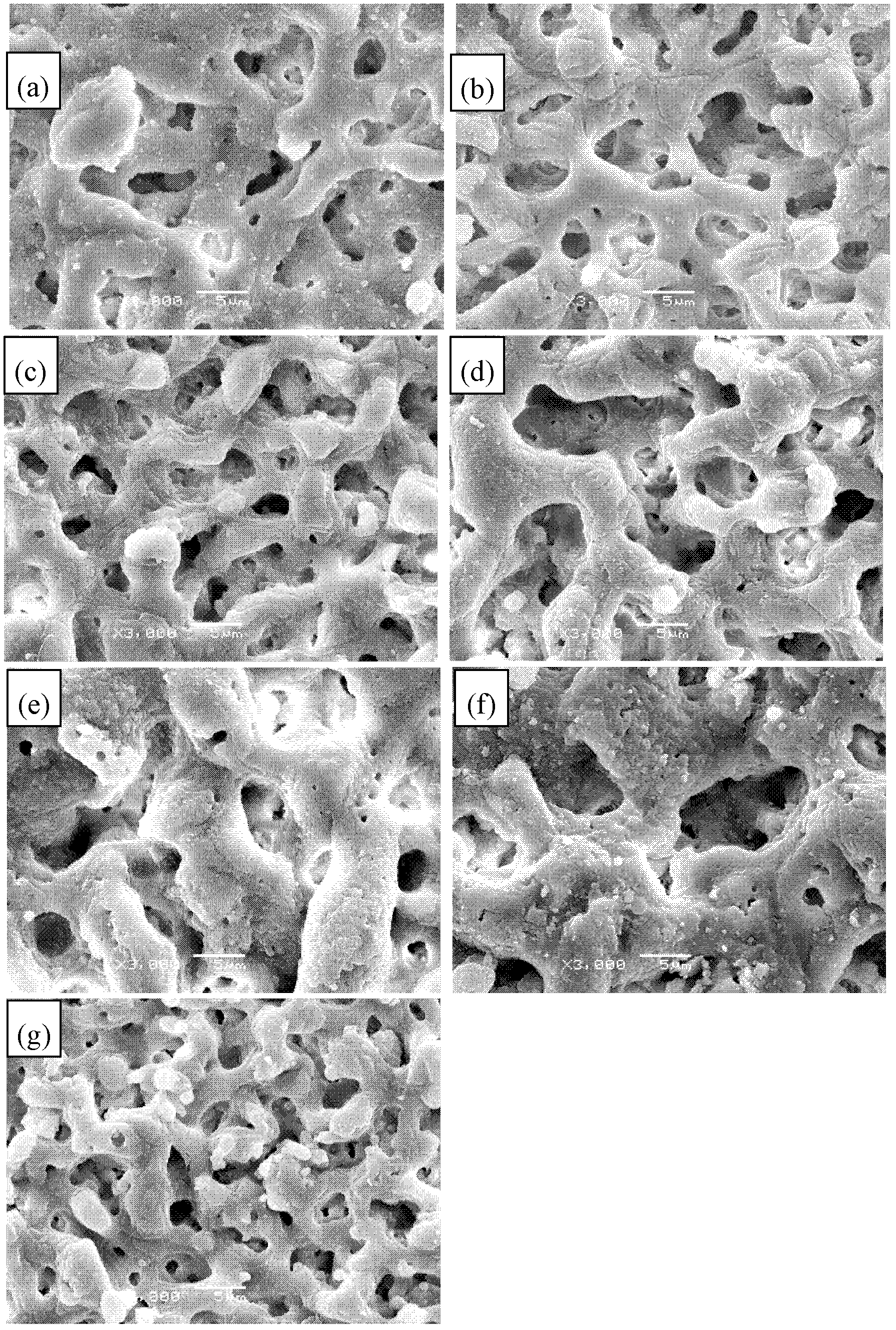

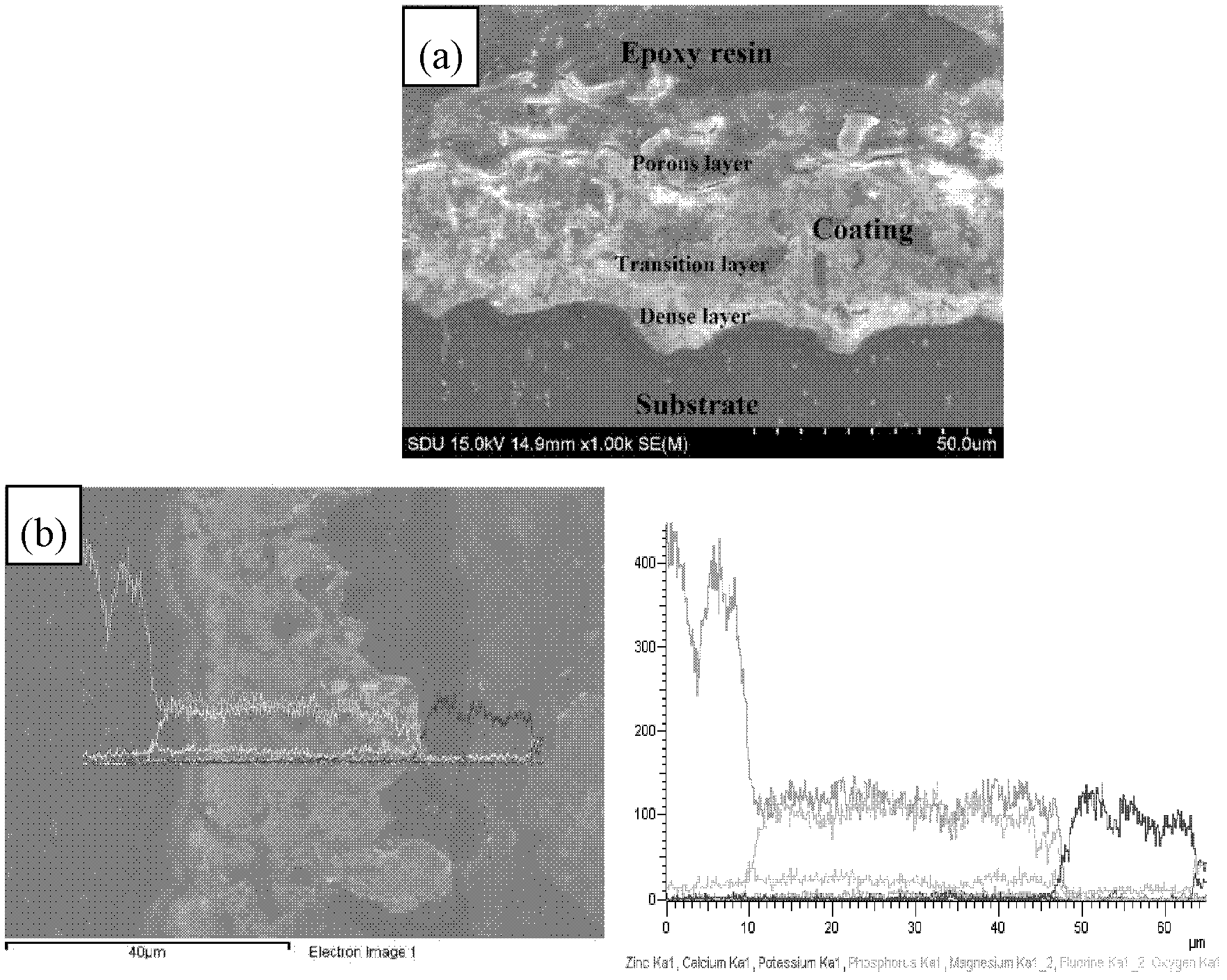

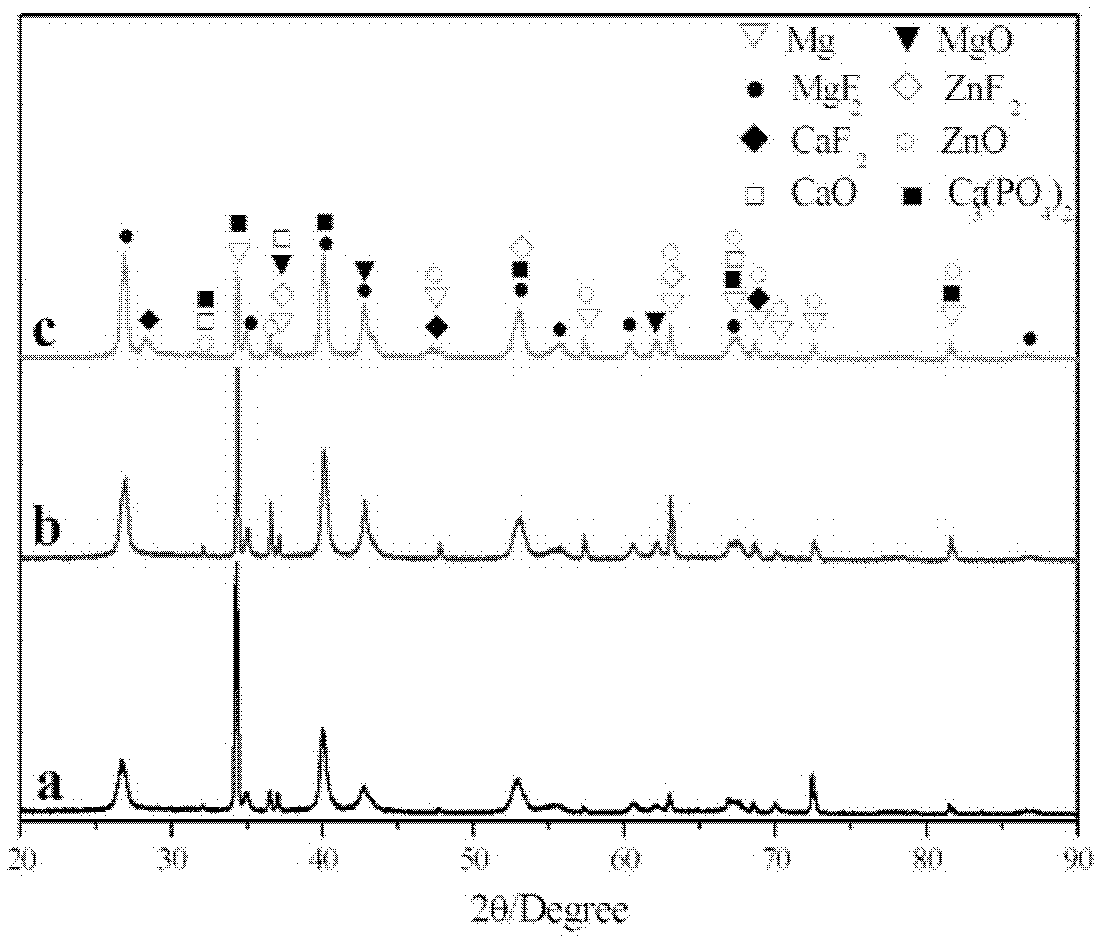

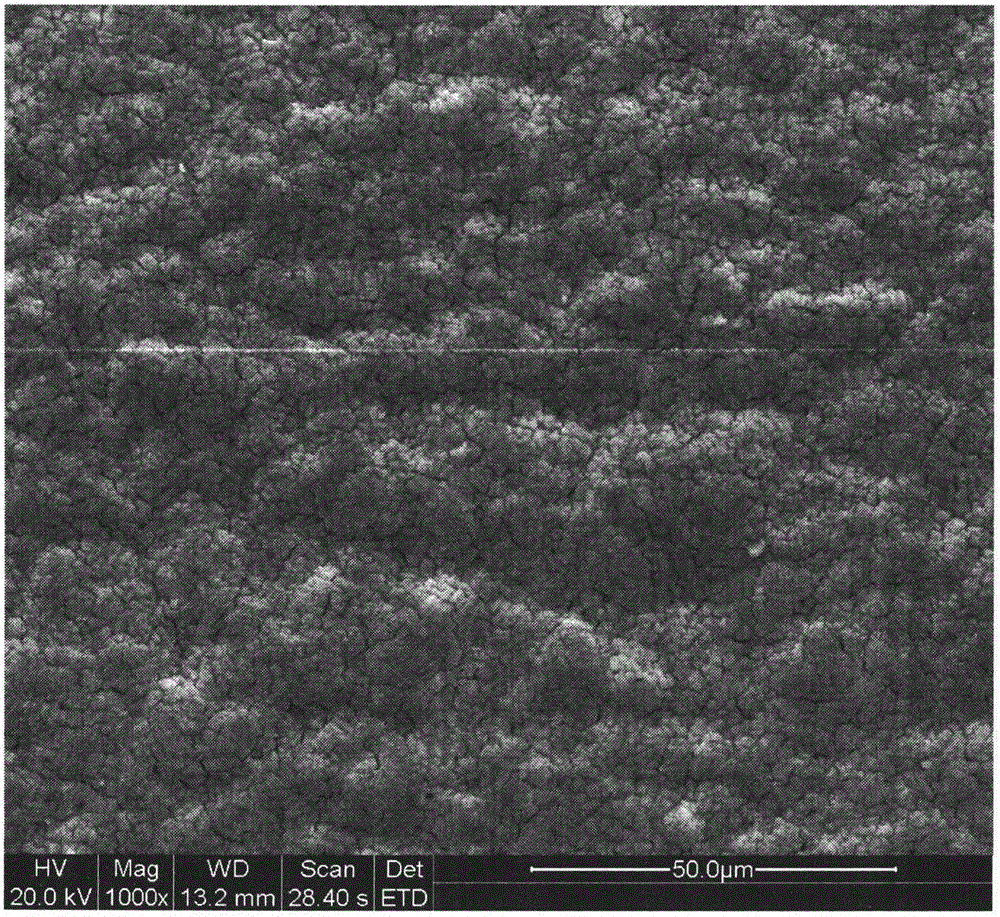

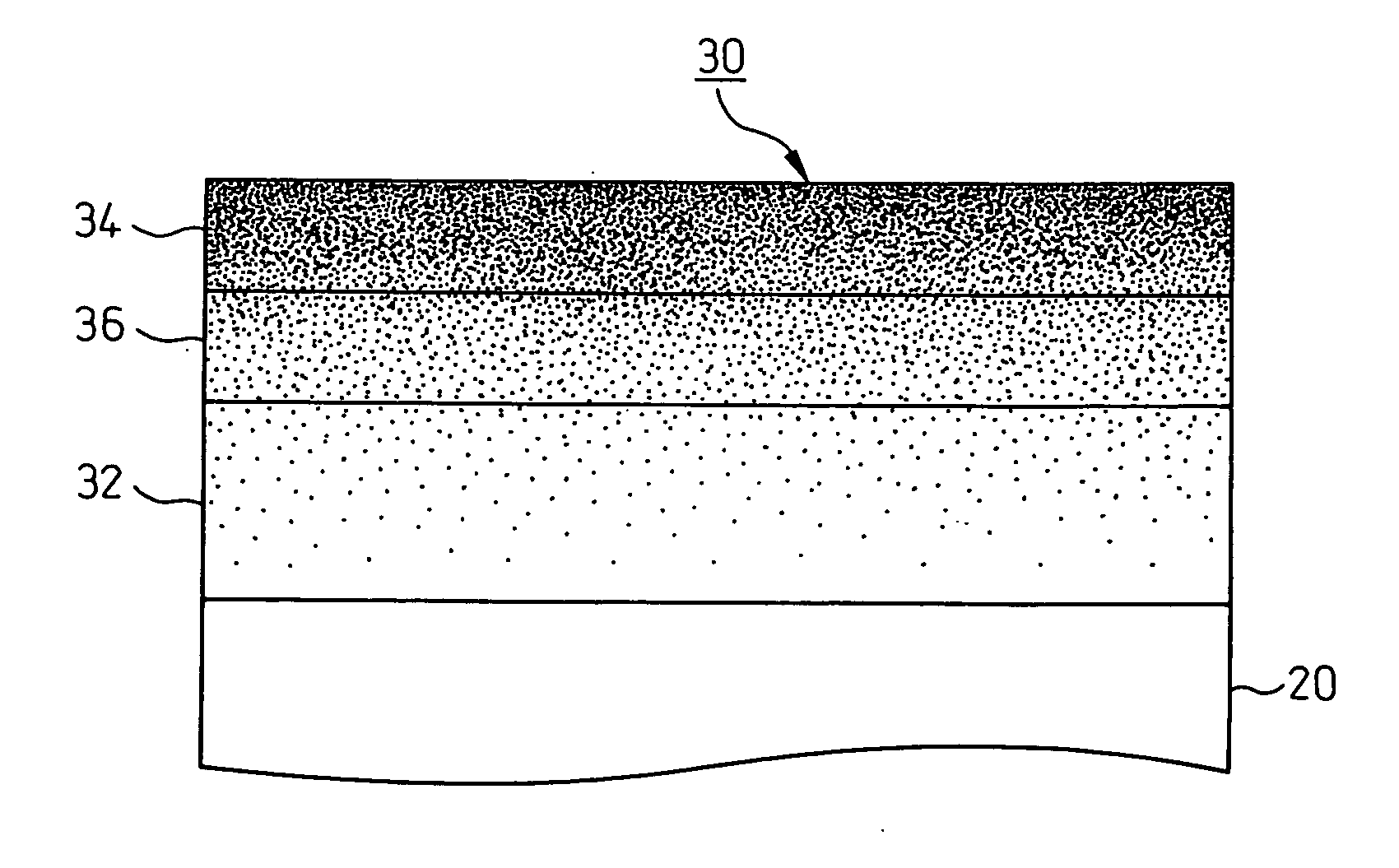

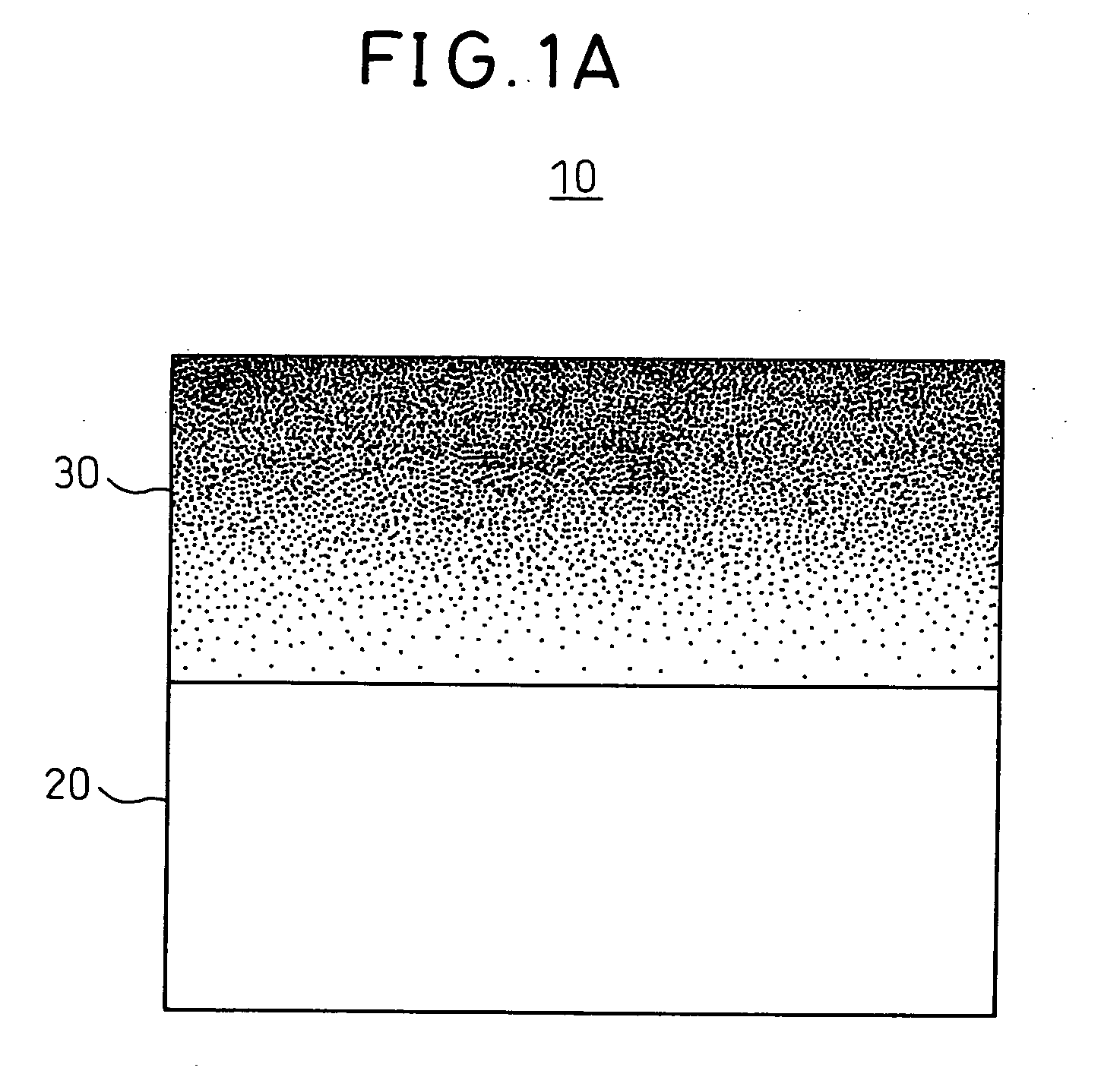

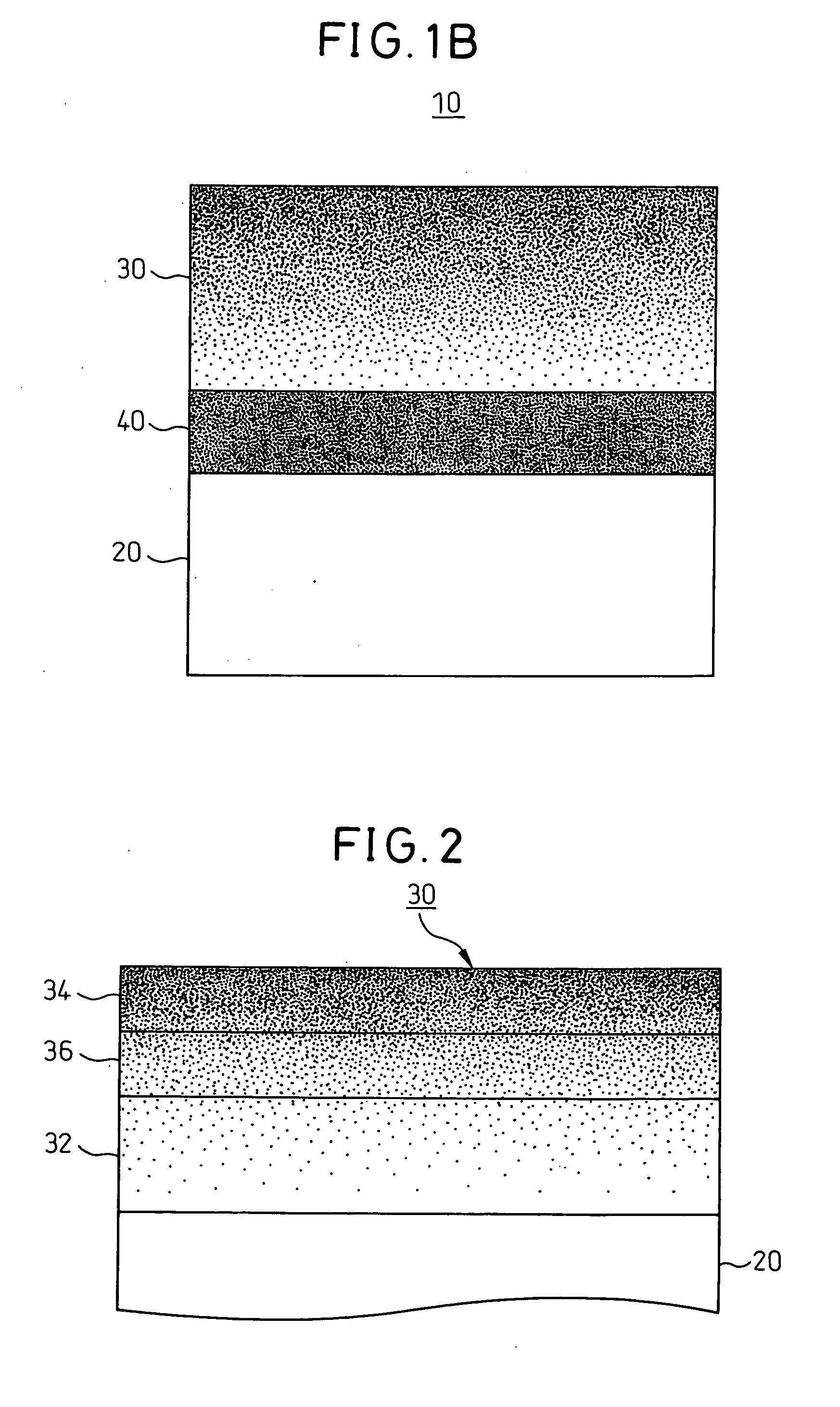

The invention relates to a preparation method of a biological ceramic coating rich in calcium and phosphate phases on the surface of magnesium alloy, comprising the following steps of: adding (C6H5O7)2Ca3.4H2O and Na3PO4 to deionized water, and simultaneously adding KOH, NH4HF2, N(CH2CH2OH)3, C3H8O3 and H2O2 to prepare an electrolyte with a certain concentration ratio of calcium and phosphate; disposing the magnesium alloy in the electrolyte as an anode which is prepared through micro arc oxidation energization reaction. The calcium-phosphate ceramic coating obtained by the preparation methodconsists of three layers of a loose layer, a transition layer and a compact layer, wherein the surface of the loose layer consists of a plurality of uniformly distributed micropores, the transition layer is between the loose layer and the compact layer, and the compact layer and a substrate body form good metallurgical bonding; therefore, the coating has high rigidity, high density, high bonding force and good corrosion resistance and abrasion resistance; simultaneously, the mouse acute systemic toxicity test indicates that the coating has good biocompatibility, and the simulated body fluid soaking test indicates that the coating has good biological activity.

Owner:SHANDONG UNIV

Implant and Method for Manufacturing Same

The present invention relates to a method for manufacturing an implant, in particular an intraluminal endoprosthesis, with a body containing metallic material, preferably iron. To control the degradation of the implant, the method comprises the following steps: a) preparing the body of the implant, and b) incorporating hydrogen into at least a portion of the structure of the implant body near the surface. Furthermore, such an implant is described.

Owner:BIOTRONIK AG

Slag-free low-temperature rapid electrolytic phosphorizing liquid and phosphorizing process thereof

ActiveCN102719872AIncrease productivityPhosphating temperature is lowPhosphatisationWire rodZinc phosphate

The invention provides slag-free low-temperature rapid electrolytic phosphorizing liquid and a phosphorizing process thereof. The phosphorizing liquid comprises, by mass, zinc ions 10-80g / L, phosphate radicals 10-120g / L, accelerators 41-160g / L, organic acid 0-5g / L and dissolved metal elements 0.1-10g / L, wherein the phosphate radicals refer to P2O5. According to the process, inert titanium plates or titanium nets serve as anodes while treated steel wire rods serve as cathodes, a zinc phosphate film is uniformly formed on the surfaces of the steel wire rods by applying a certain current, and the film weight is higher than 4g / m<2> so as to meet drawing requirements. The phosphorizing temperature ranges from 10 DEG C to 60 DEG C, the phosphorizing time is 5-120 seconds, phosphorized slags are avoided, and accordingly the phosphorizing process has the obvious advantages of high efficiency, energy conservation and environmental protection.

Owner:派诺(湖北)绿色化学智造有限公司

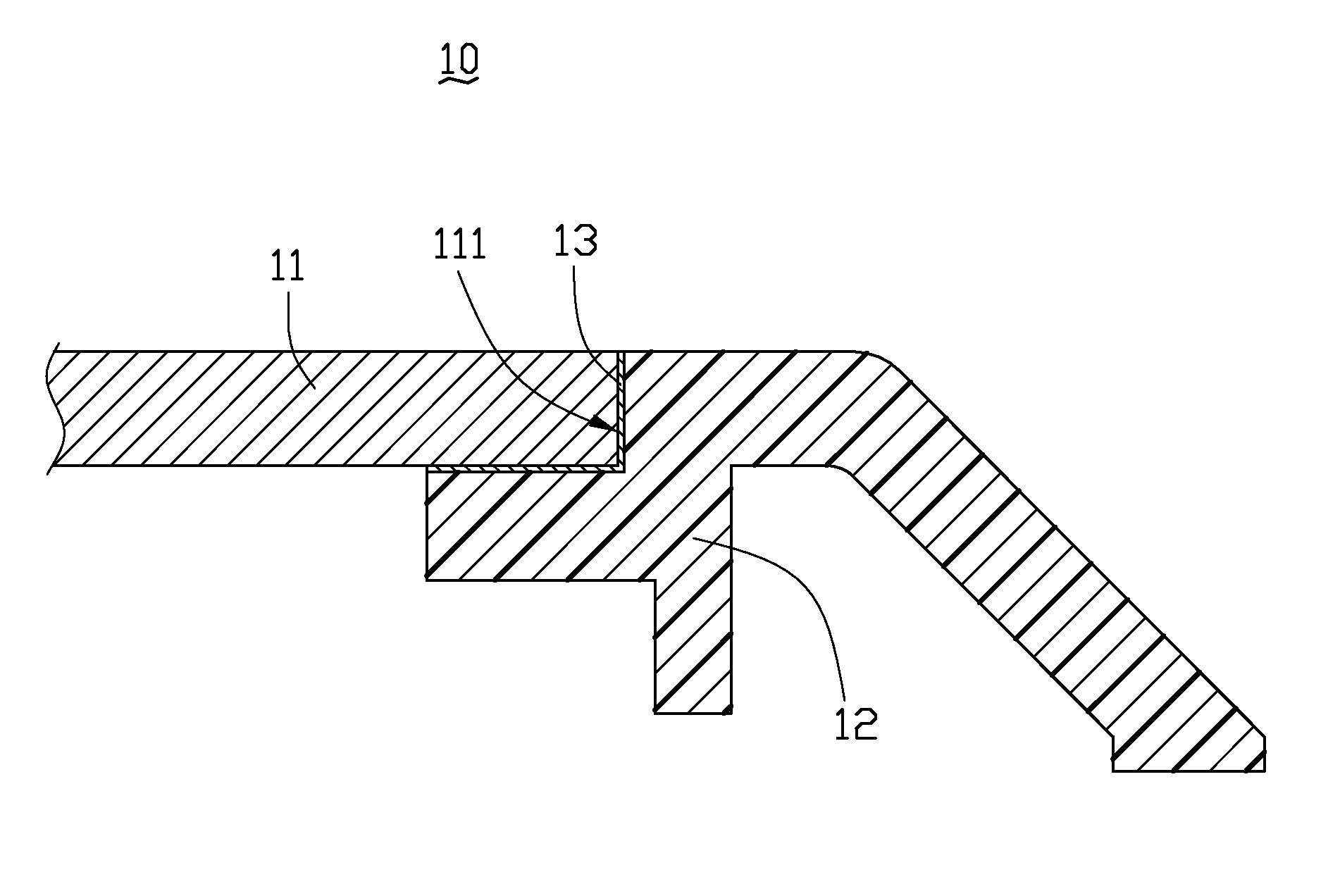

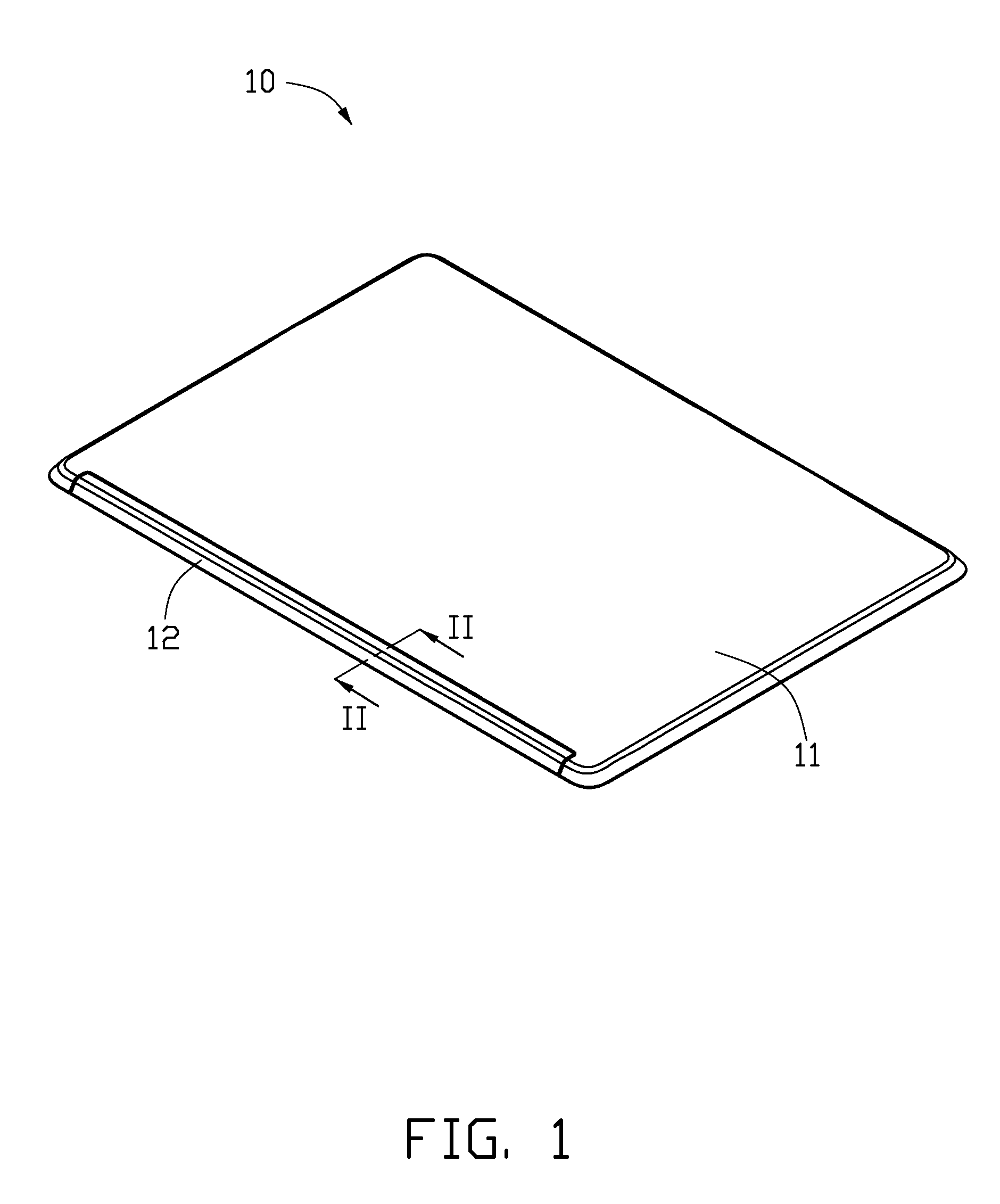

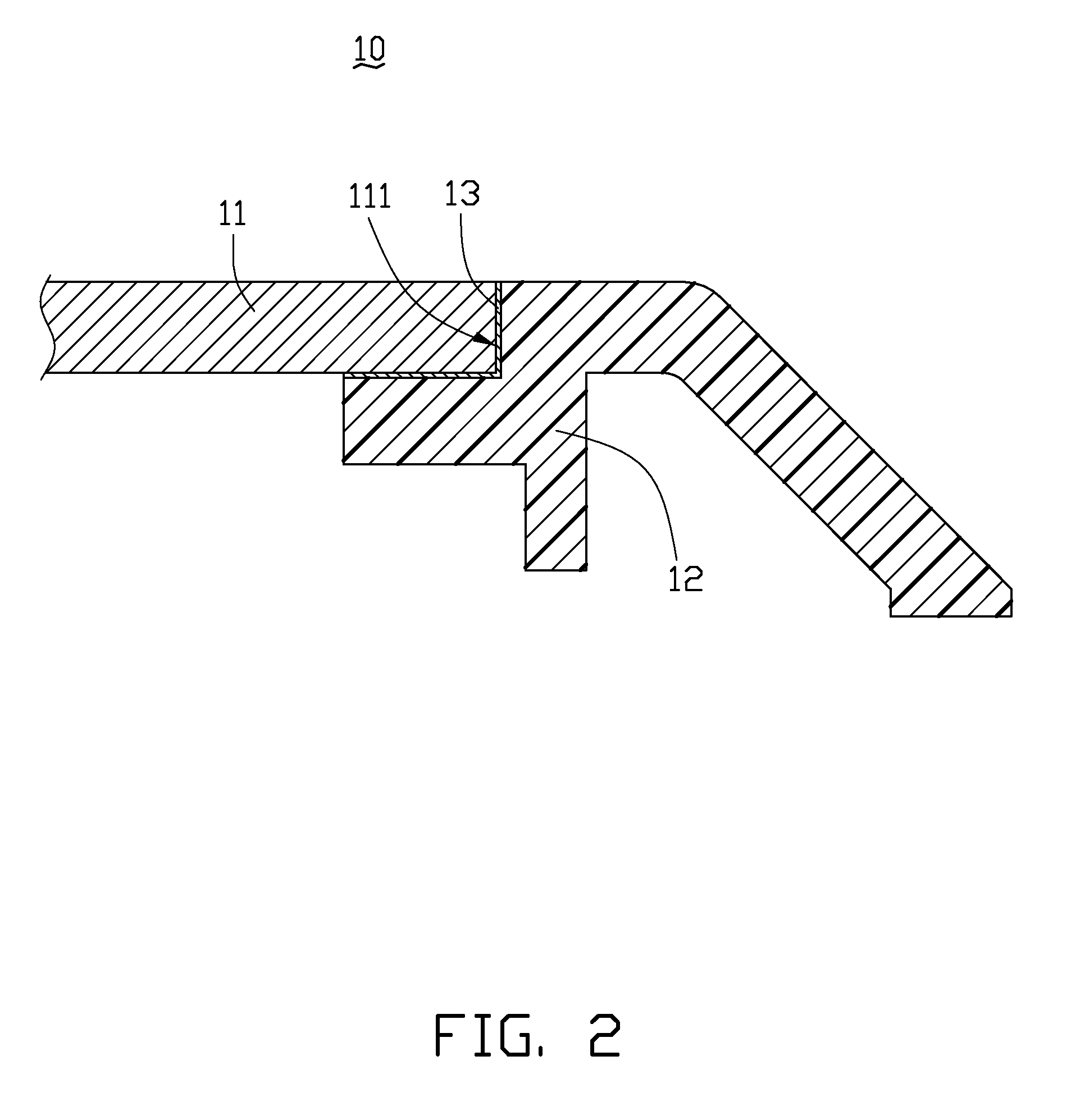

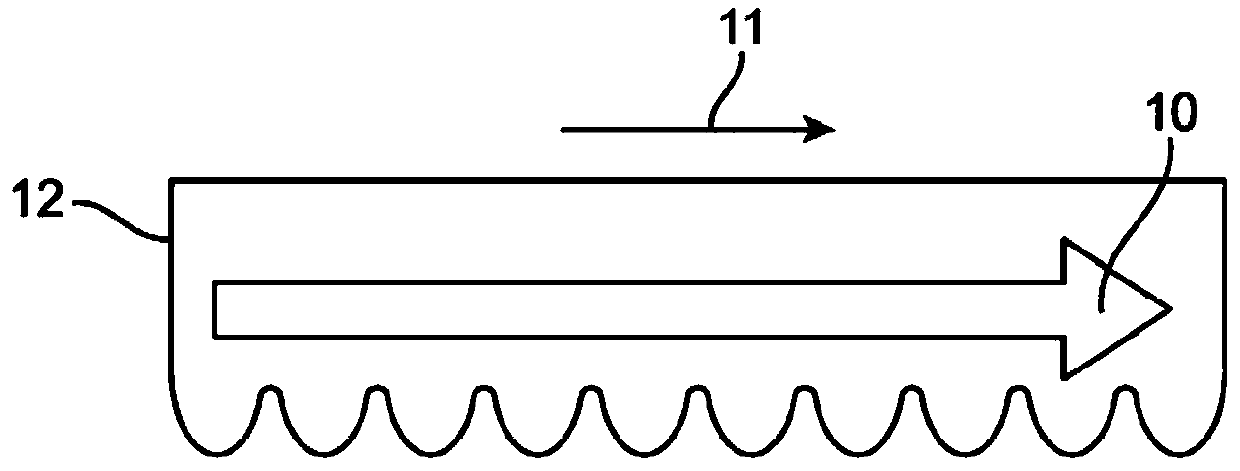

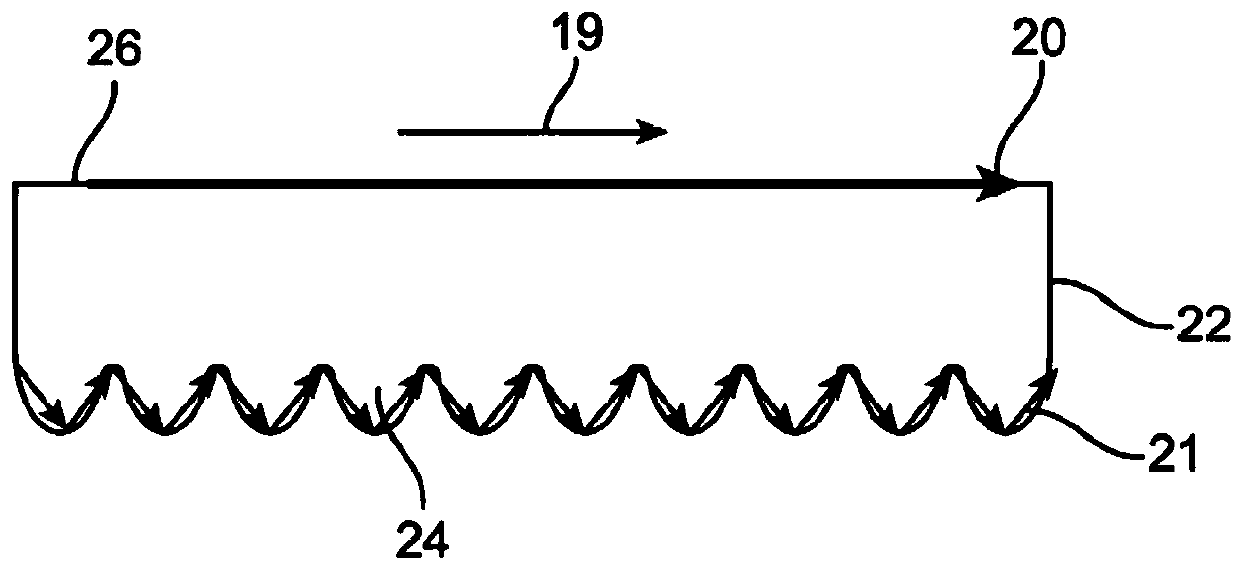

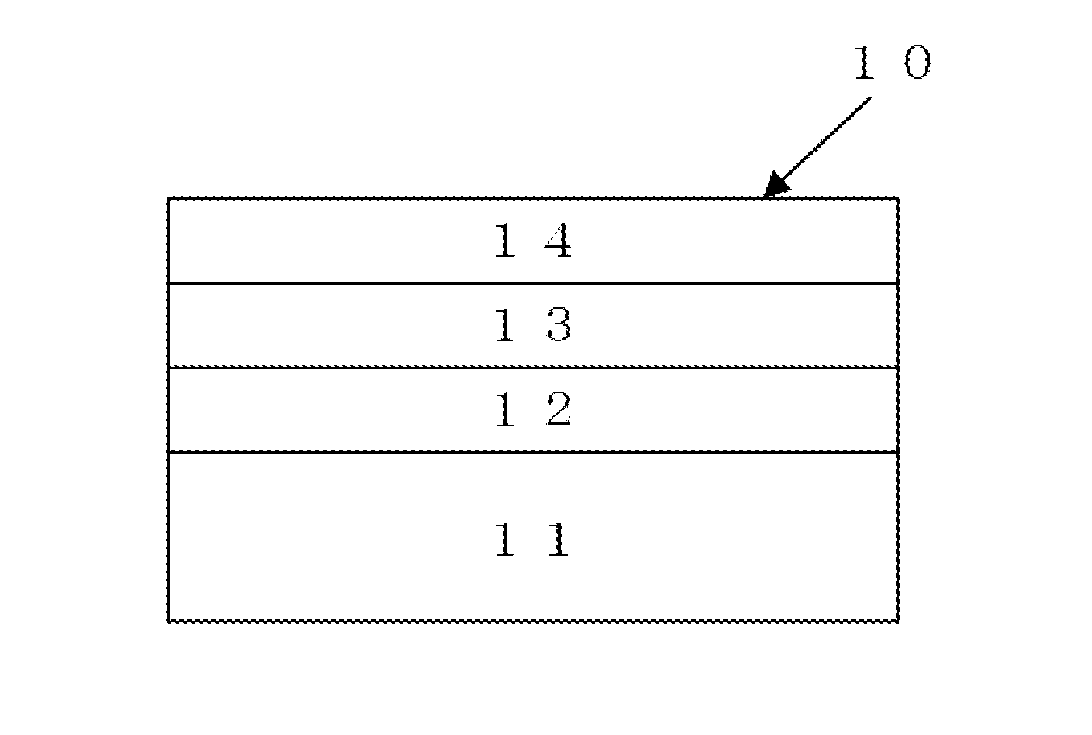

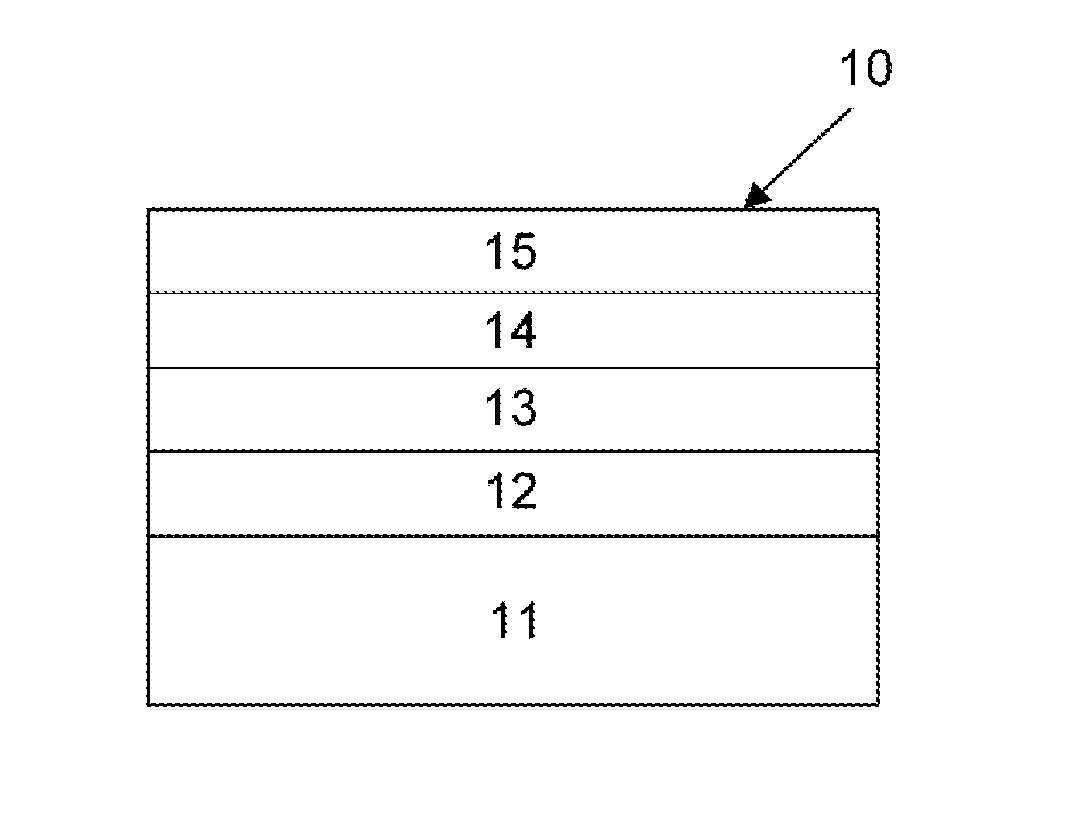

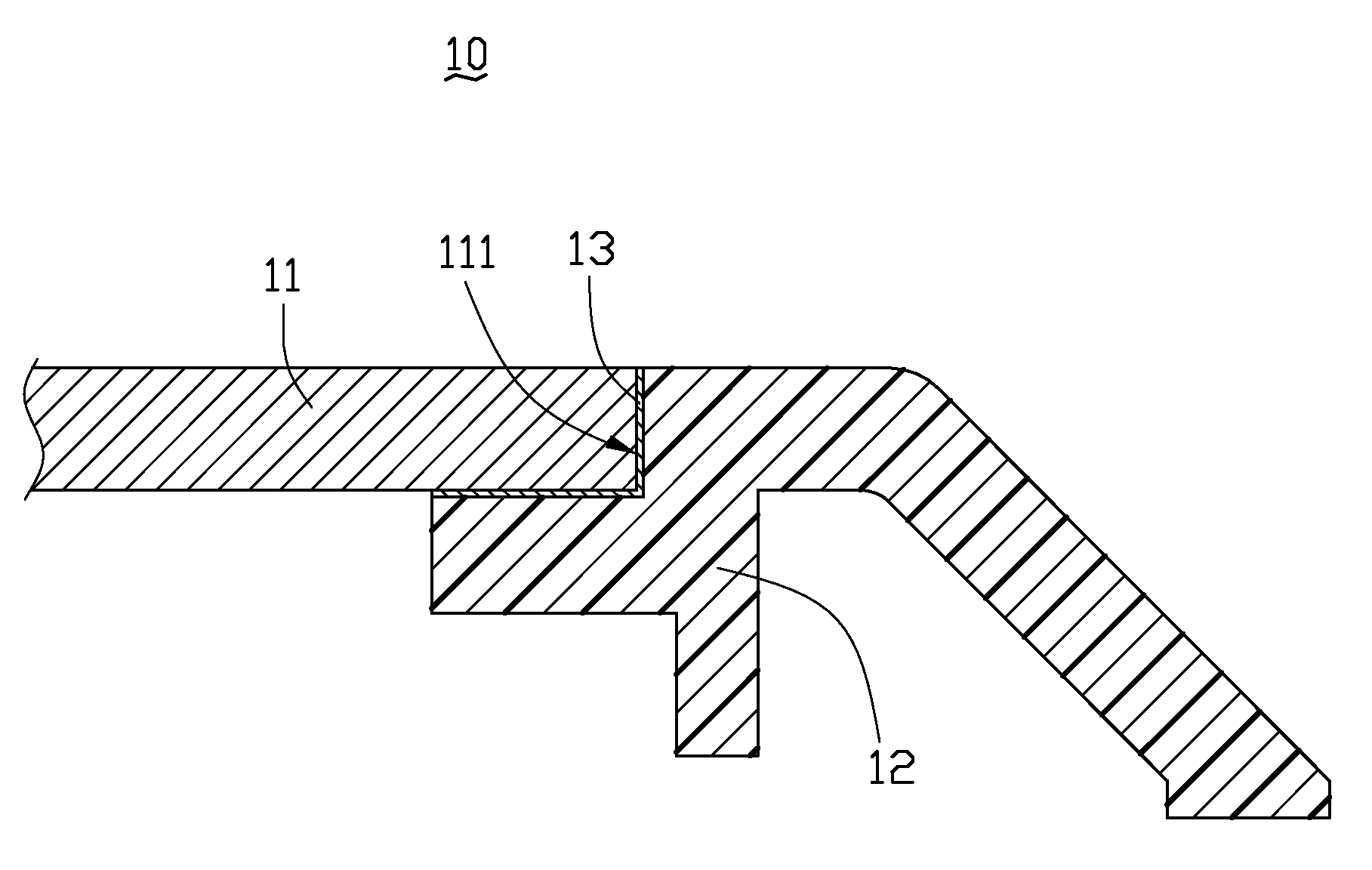

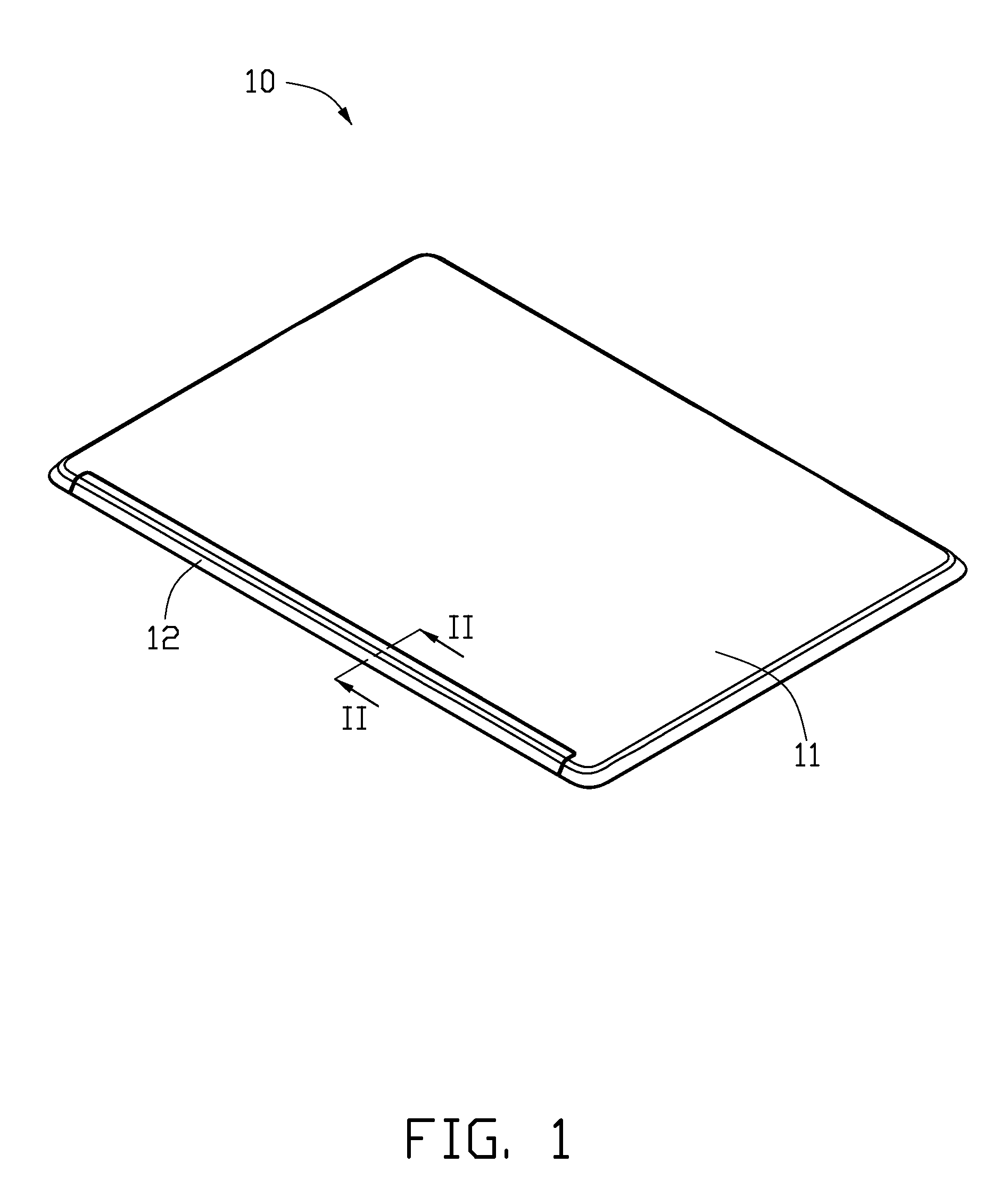

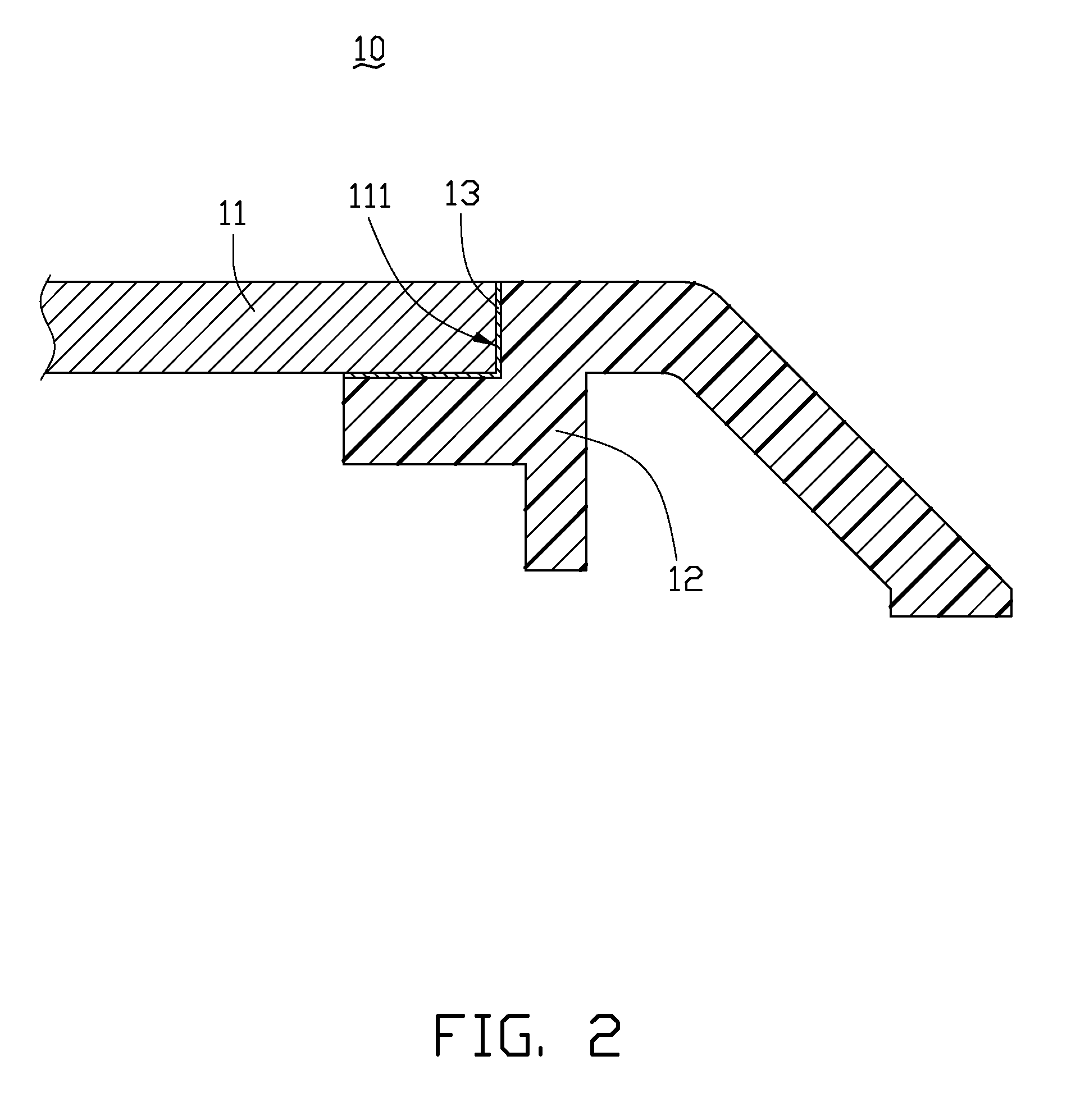

Insert-molded cover and method for manufacturing same

An exemplary insert-molded cover (10) for electronic devices includes a metallic body (11), a plastic antenna lid (12) integrally formed with the metallic body and an oxide film (12) formed on a surface (111) of the metallic body for attaching the plastic antenna lid. The present invention also relates a method for manufacturing the insert-molded cover for electronic devices.

Owner:HON HAI PRECISION IND CO LTD

Method for preparing solid aluminum electrolytic capacitor

InactiveCN101510469AReduce leakage currentImprove adsorption capacitySolid electrolytic capacitorsPhosphatisationAluminum electrolytic capacitorOxide

The invention discloses a preparation method of a solid aluminum electrolytic capacitor, which aims at providing a preparation method that can reduce leakage current (LC) so as to improve the electrical property of the capacitor. The preparation method comprises the following steps: after going through formation and carbonization treatment, a well-winded core package is subjected to forming liquid restoration treatment technique and can also be subjected to carbonization treatment for a plurality of times and formation treatment for a plurality of times; carbonization treatment can improve the adsorption effect of impregnation liquid, increase the density of polymer, improve conducting effect and reduce ESR. Repeated formation can better restore the damage of an oxide film caused by foil cutting, nail rolling and carbonization, and reduce leakage current of the capacitor.

Owner:ZHUHAI LEAGUER CAPACITOR

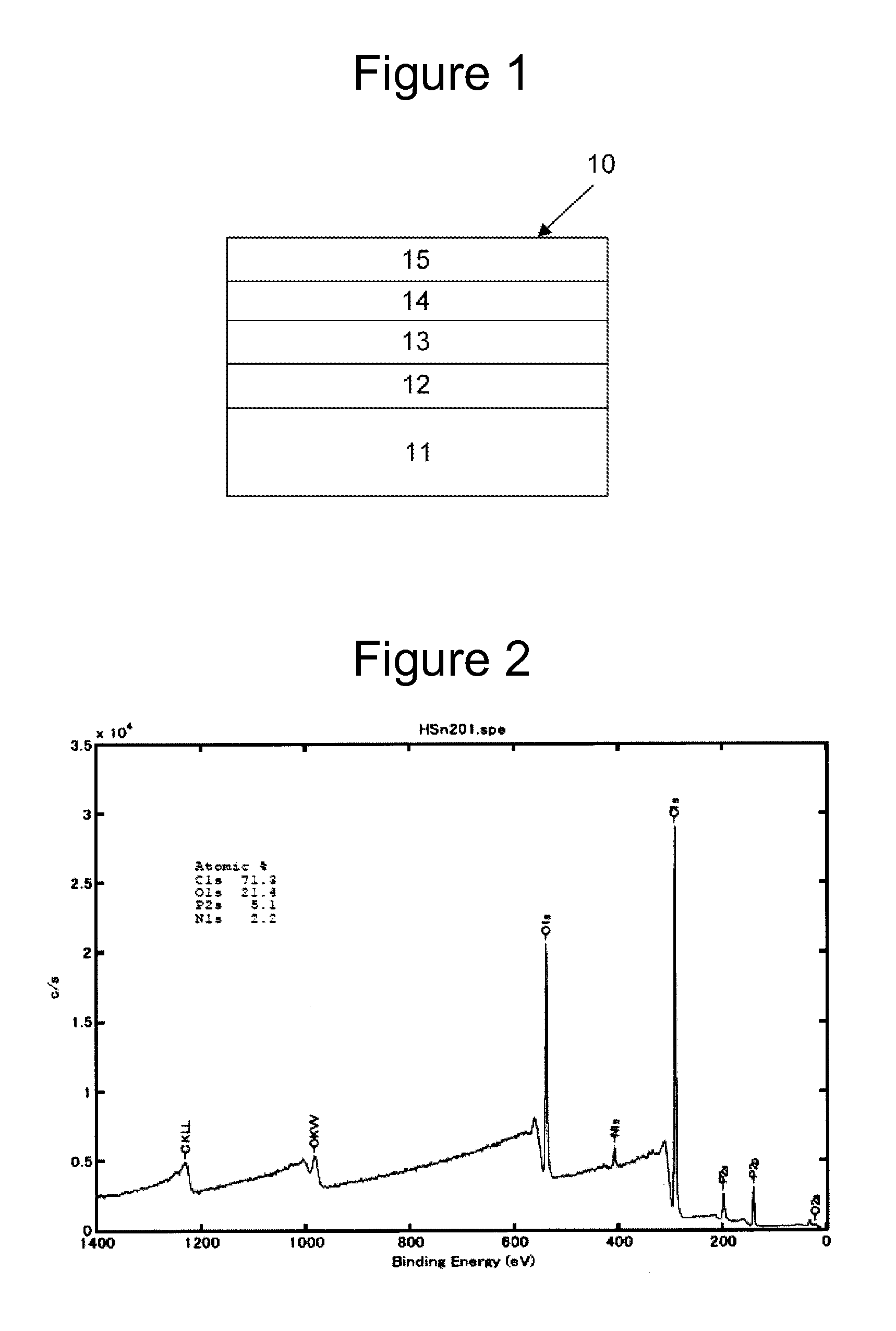

Steel sheet for container use and method of production of same

ActiveUS20110300402A1Improve corrosion resistanceSuperior canmaking abilityAnodisationPhosphatisationSheet steelTotal thickness

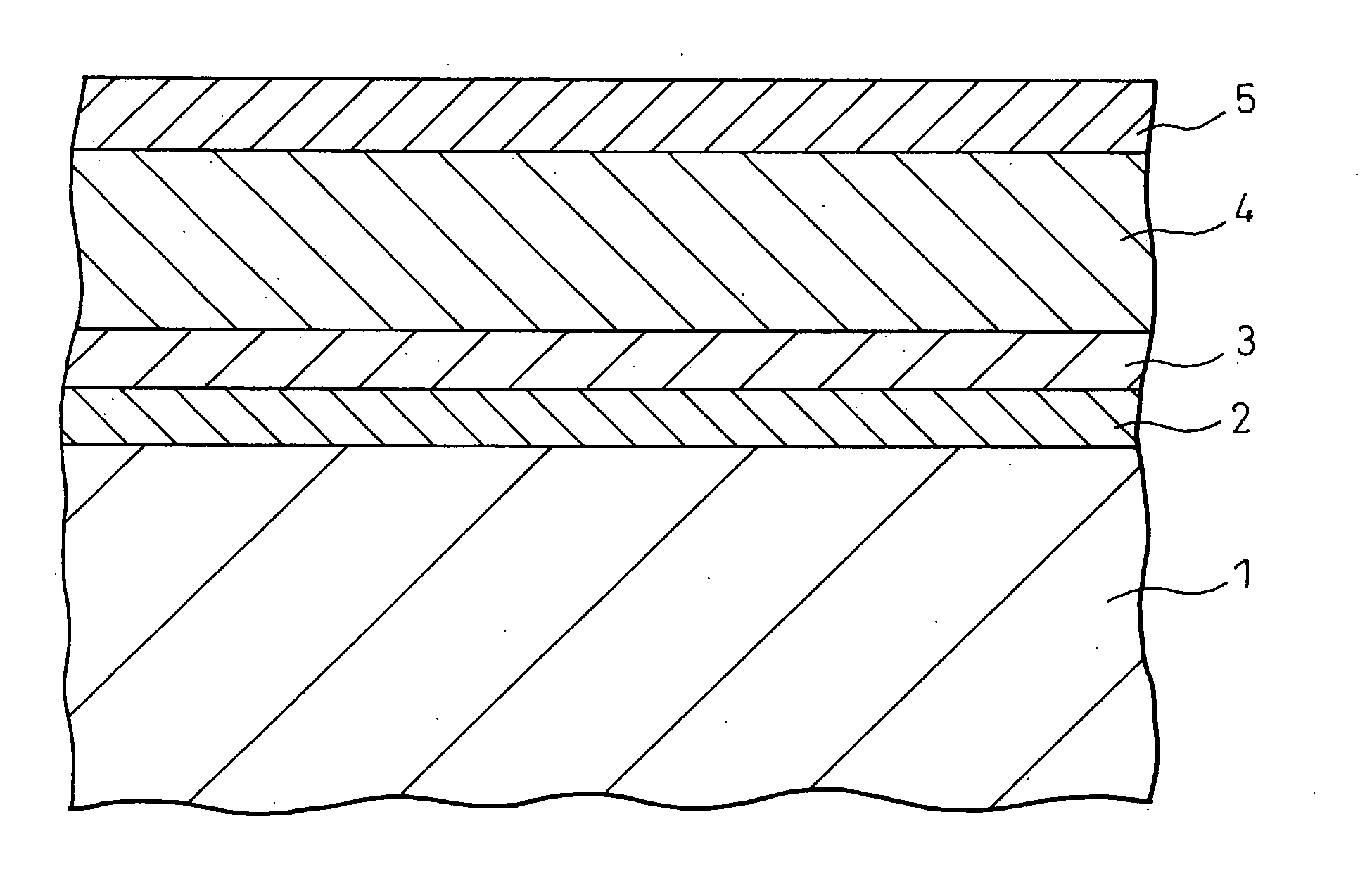

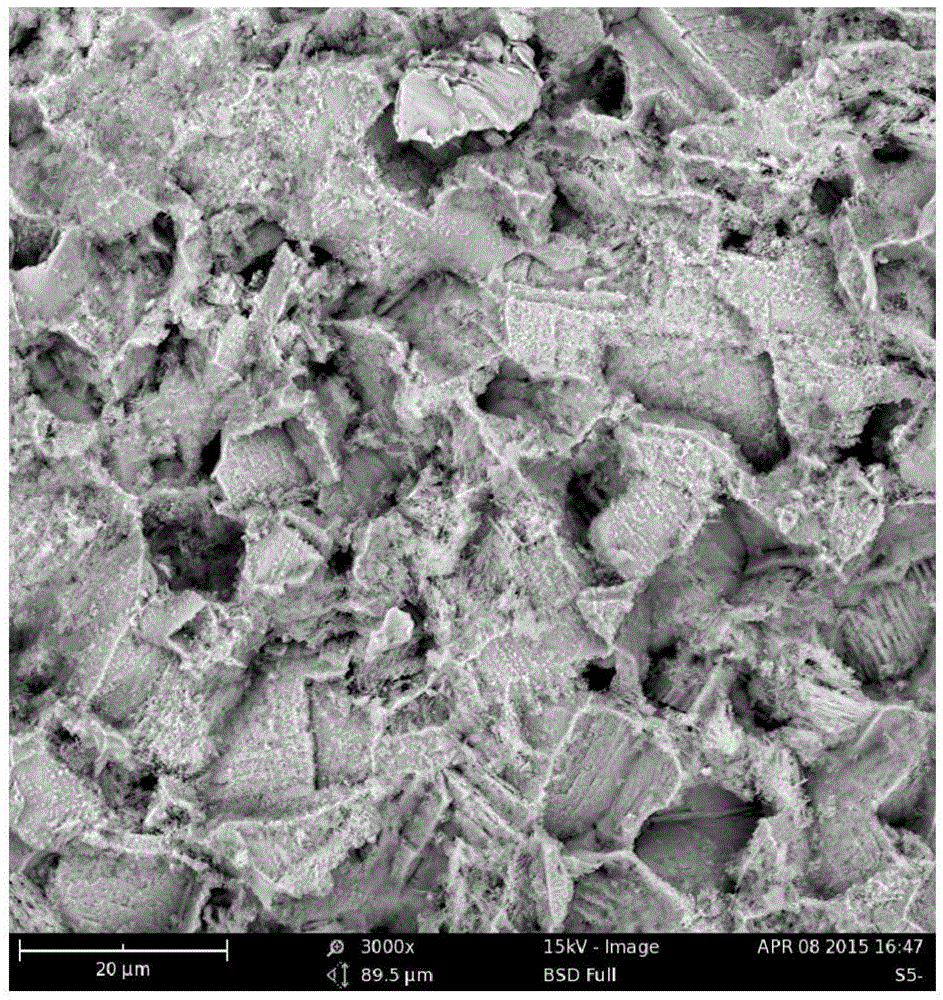

Steel sheet for container use able to realize superior corrosion resistance and canmaking ability, wherein at least one side of the steel sheet is provided with a chemical conversion coating film including a mixture of a zirconium oxide compound and a zirconium phosphate compound, the zirconium oxide compound is segregated at part or all of a region of 40 to 100% from the surface with respect to the total thickness of the chemical conversion coating film, and the zirconium phosphate compound is segregated at part or all of a region of 0 to 40% from the surface with respect to the total thickness of the chemical conversion coating film.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Brilliant tin plate chromium-free passivation solution and passivation method

InactiveCN101358342AImprove corrosion resistanceImprove antioxidant capacityPhosphatisationMetallic material coating processesChromium freeSodium molybdate

The invention discloses bright tin plate non-chromium passivation solution, wherein, each liter of passivation solution contains 20g to 70g of trisodium phosphate, 0.1g to 5g of cobalt sulfate, 0.5g to 3g of sodium molybdate, 20g to 75g of phosphoric acid, the rest is water, and the ph value of the passivation solution is 3 to 5. The invention also discloses a tinplate passivation method; in the passivation with the non-chromium passivation solution of the invention, the working temperature of the passivation solution is 50 DEG C to 80 DEG C, the passivation time is 1s to 20s, and the passivation method is electro-chemical cathode passivation or chemical passivation. The tin plate non-chromium passivation solution of the invention does not contain hexavalent chrome, conducts chemical passivation or electro-chemical cathode passivation to the tinplate, and enables the tinplate to have the same high corrosion resistance and high oxidation resistance with a chromate passivation process. The welding performance, the adhesion performance to the coating and the like of the tinplate passivated through the non-chromium passivation process also meet the level of the tinplate passivated by chromate, which fundamentally solves the harm of the tinplate passivated by chromate with hexavalent chrome to the human body and the environment.

Owner:WUHAN IRON & STEEL (GROUP) CORP

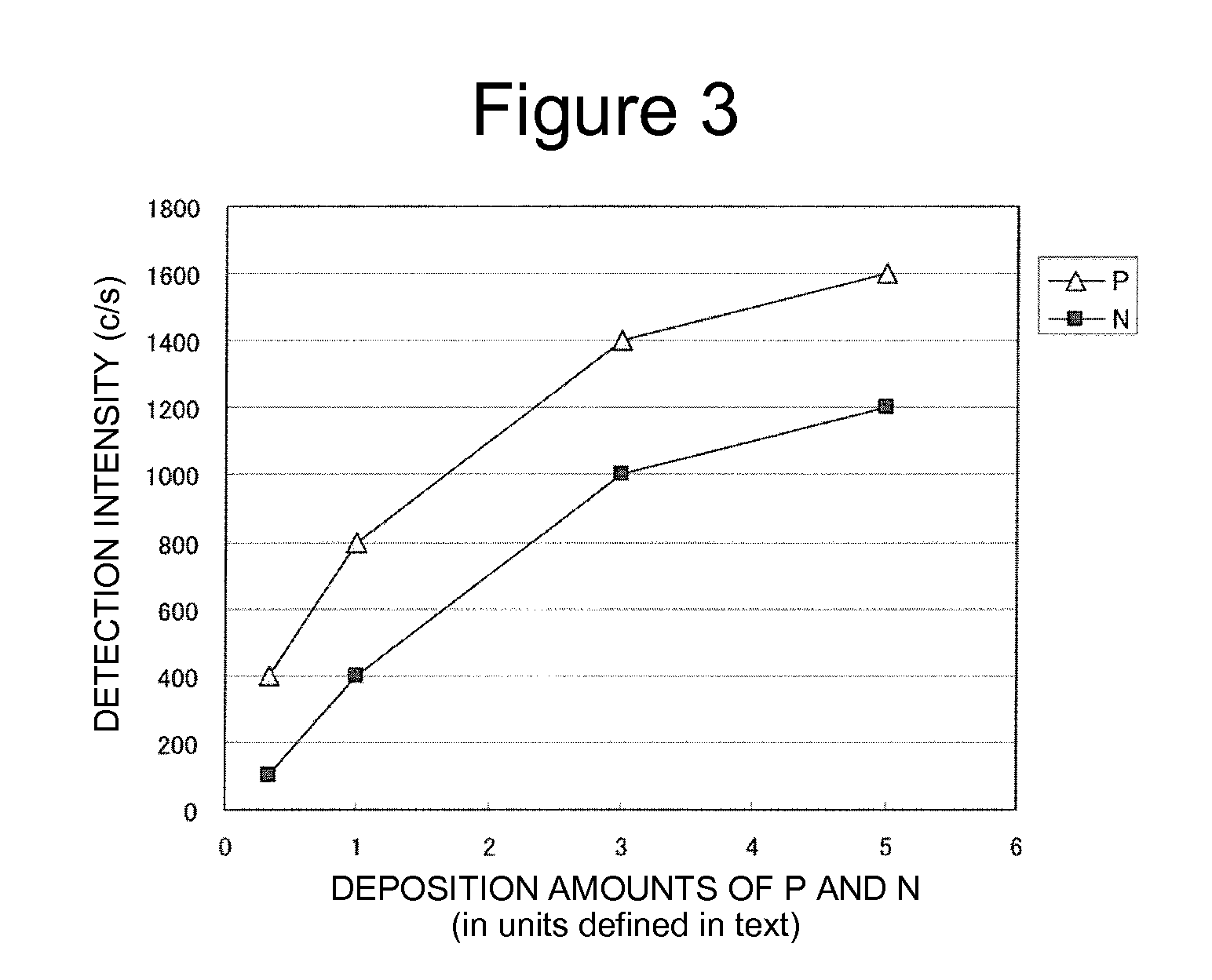

Plated steel sheet for cans and production method thereof

ActiveUS20100119867A1Excellent secondary adhesionImprove corrosion resistanceHot-dipping/immersion processesAnodisationOrganic filmElectricity

A plated steel sheet for cans with excellent secondary adhesion of an organic film and high corrosion resistance is provided, that is, a plated steel sheet for cans, which is a plated steel sheet having a alloy tin layer and a metallic tin layer in sequence from the steel sheet side, wherein a chemical conversion layer comprising tin oxide in an amount of 0.3 to 5.0 mC / cm2 in terms of electricity necessary for reduction and tin phosphate in an amount of 0.5 to 5.0 mg / m2 in terms of P is provided on the metallic tin layer and zirconium(IV) oxide in an amount of 0.2 to 5 mg / m2 in terms of Zr is provided on the chemical conversion layer. A production method thereof is also provided.

Owner:NIPPON STEEL CORP

Method for manufacturing low-pressure chemical synthesis foil for aluminum electrolysis capacitor and middle treatment groove

InactiveCN101235529ANo loss of capacitanceHigh passivation treatment efficiencyElectrolytic capacitorsPhosphatisationChemical synthesisElectricity

The invention relates to a method for forming foil by low voltage of an aluminum electrolytic capacitor and a treatment groove for forming foil, wherein the method comprises the following steps: placing the formed foil which is treated by forming treatment under the highest forming voltage into a medium treatment groove and a groove solution, and proceeding the medium treatment, then proceeding subsequent forming treatment, an electrode plate which is corresponded with the formed foil is arranged in the treatment groove, the groove solution comprises phosphorus acid and / or ammonium phosphate component, the medium treatment comprises the following steps: placing the anode of direct current power supply on the formed foil, placing the cathode of the direct current power supply on an electrode plate, imposing electricity to the forming foil, the voltage value of the imposing electrical treatment is lower than that of the highest formed. The forming method of the invention and the treatment groove has the advantages that the efficiency of deactivation treatment is high, the coverage of the deactivation treatment is more comprehensive and thoroughly, which can simultaneously obtain higher electrostatic capacity, good water resistance and hydratability.

Owner:乳源县立东电子科技有限公司

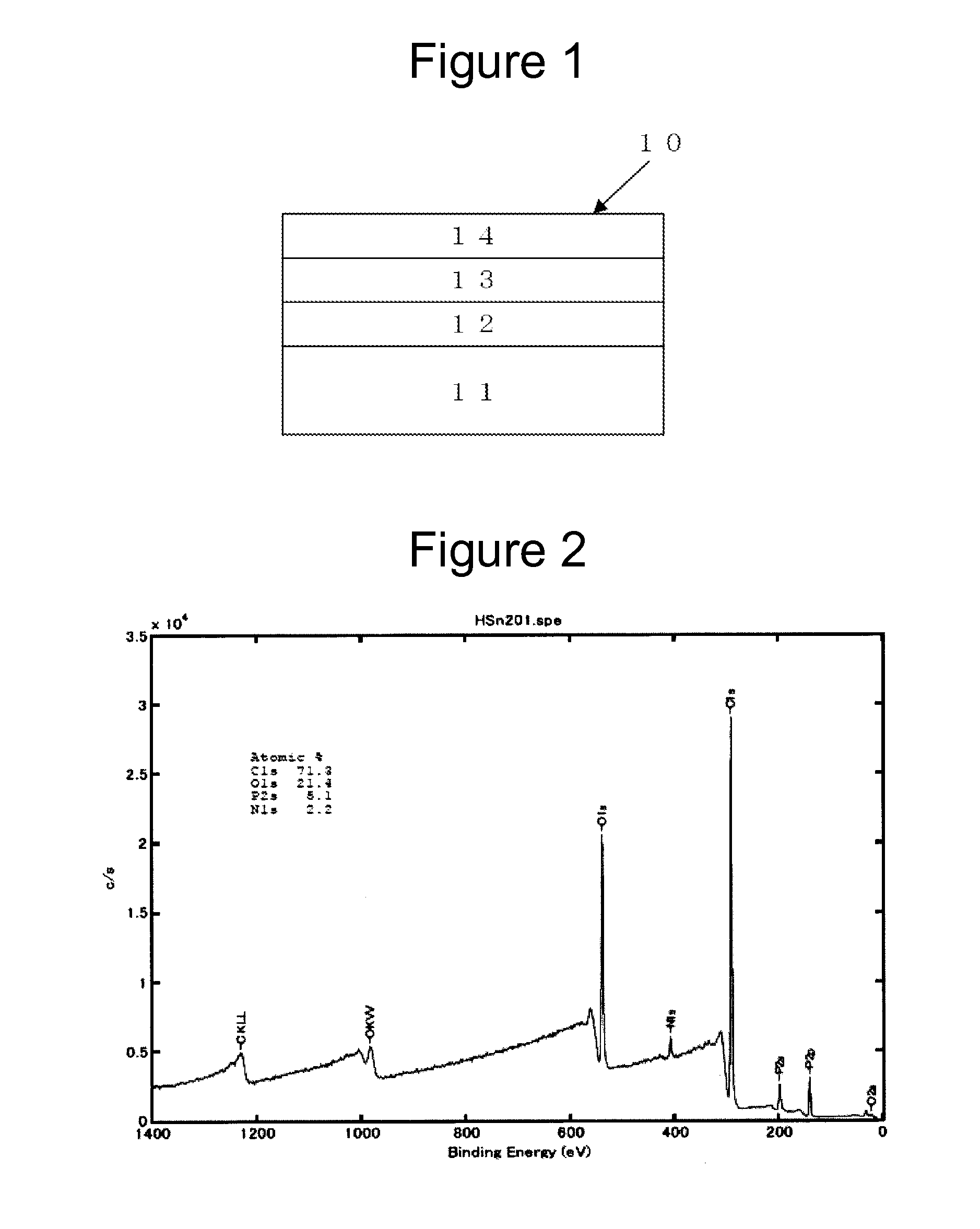

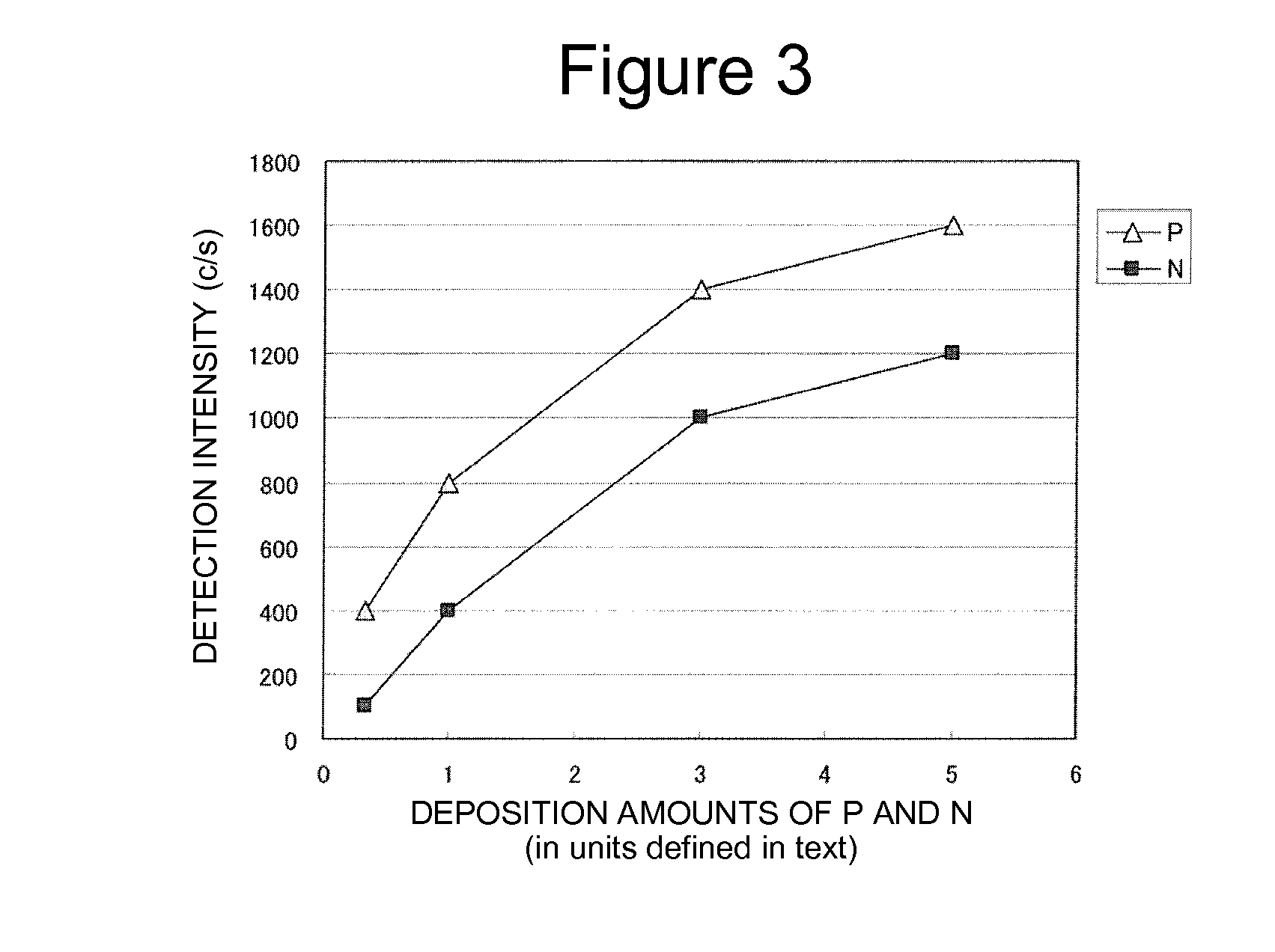

Stainless steel plate, method of manufacturing the same, and rubber-coated stainless steel plate gasket

InactiveUS20050057004A1Improve adhesionEfficient productionEngine sealsPhosphatisationCompound (substance)Hydroxide

This invention provides a rubber-coated stainless steel plate suitable as a gasket core material with excellent adhesion to the rubber layer, a method of manufacturing the same, and a gasket comprising the rubber-coated stainless steel plate. The following are provided by the present invention: a stainless steel plate having a roughened surface on which chrome hydroxide, chrome oxide, iron hydroxide, and iron oxide are deposited; a rubber-coated stainless steel plate formed by coating the surface of the stainless steel plate with a rubber layer; a gasket comprising the rubber-coated stainless steel plate; and a method of manufacturing the stainless steel plate, wherein the stainless steel plate is roughened with at least one of chemical roughening and electrochemical roughening and is then subjected to cathode electrolytic treatment in an alkaline solution.

Owner:NIPPON KINZOKU CO LTD +1

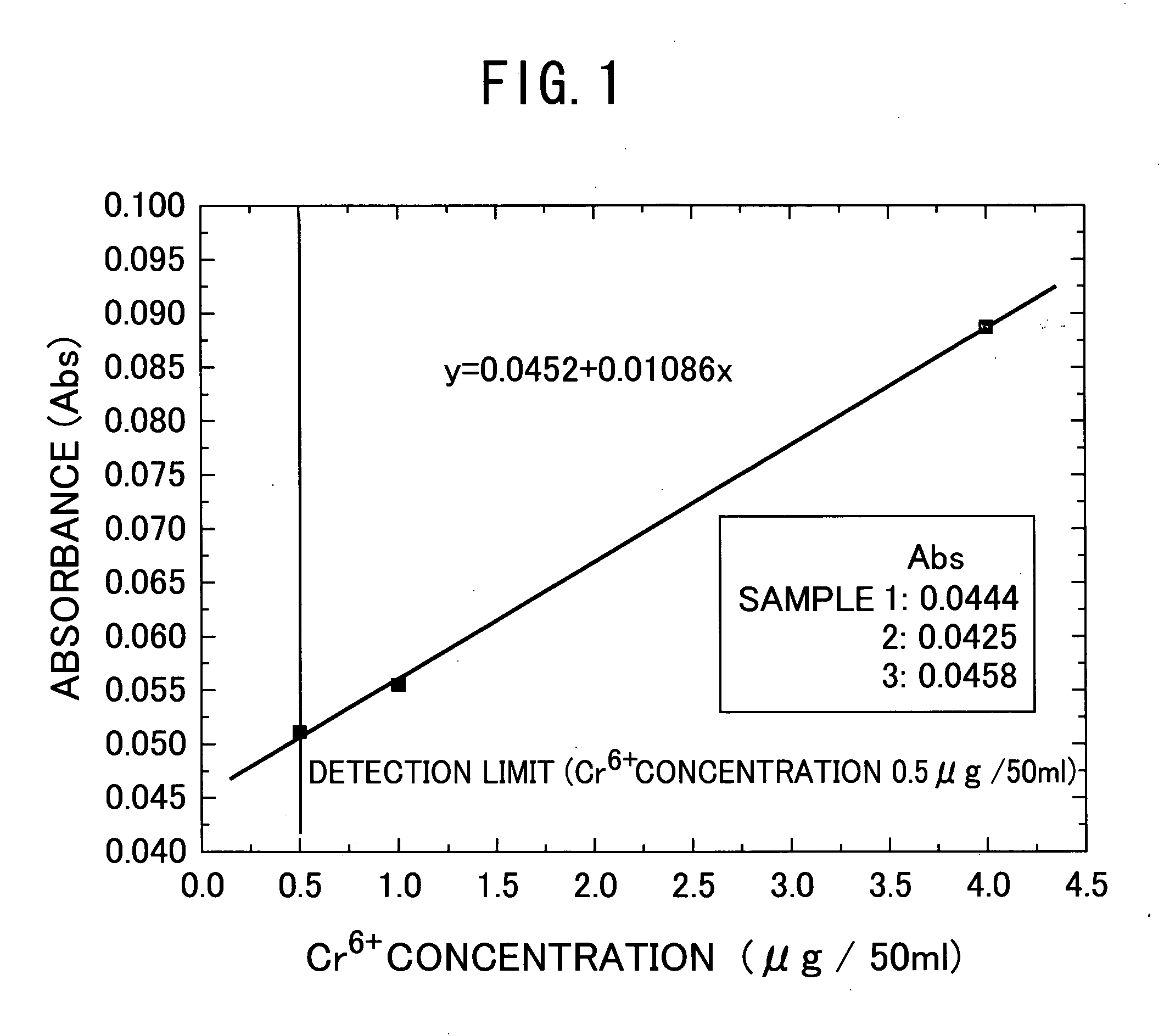

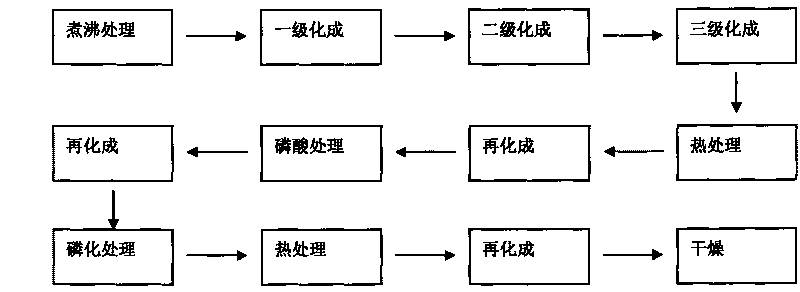

Method for manufacturing anodic foil of aluminum electrolytic capacitor

InactiveCN101707141AHydration resistance boost time reducedImprove bending strengthElectrolytic capacitorsPhosphatisationAfter treatmentPhosphoric acid

The invention discloses a method for manufacturing an anodic foil of an aluminum electrolytic capacitor, which comprises the following steps of boiling treatment, three polarization, heat treatment, formation, phosphate treatment, formation, heat treatment, and reformation. Different from the prior art, the phosphate treatment is carried out before the second heat treatment, and an after-treatment is removed. The phosphate treatment is dipping treatment performed under the conditions of the concentration of a phosphate treating agent of between 1 and 5 v / v%, and the temperature of between 20 and 80 DEG C for 1 to 10 minutes. The method can ensure that after three months of storage, the anodic foil of the aluminum electrolytic capacitor has short boosting time, short hydration resistance boosting time, stable pressure resistance and good bending performance.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

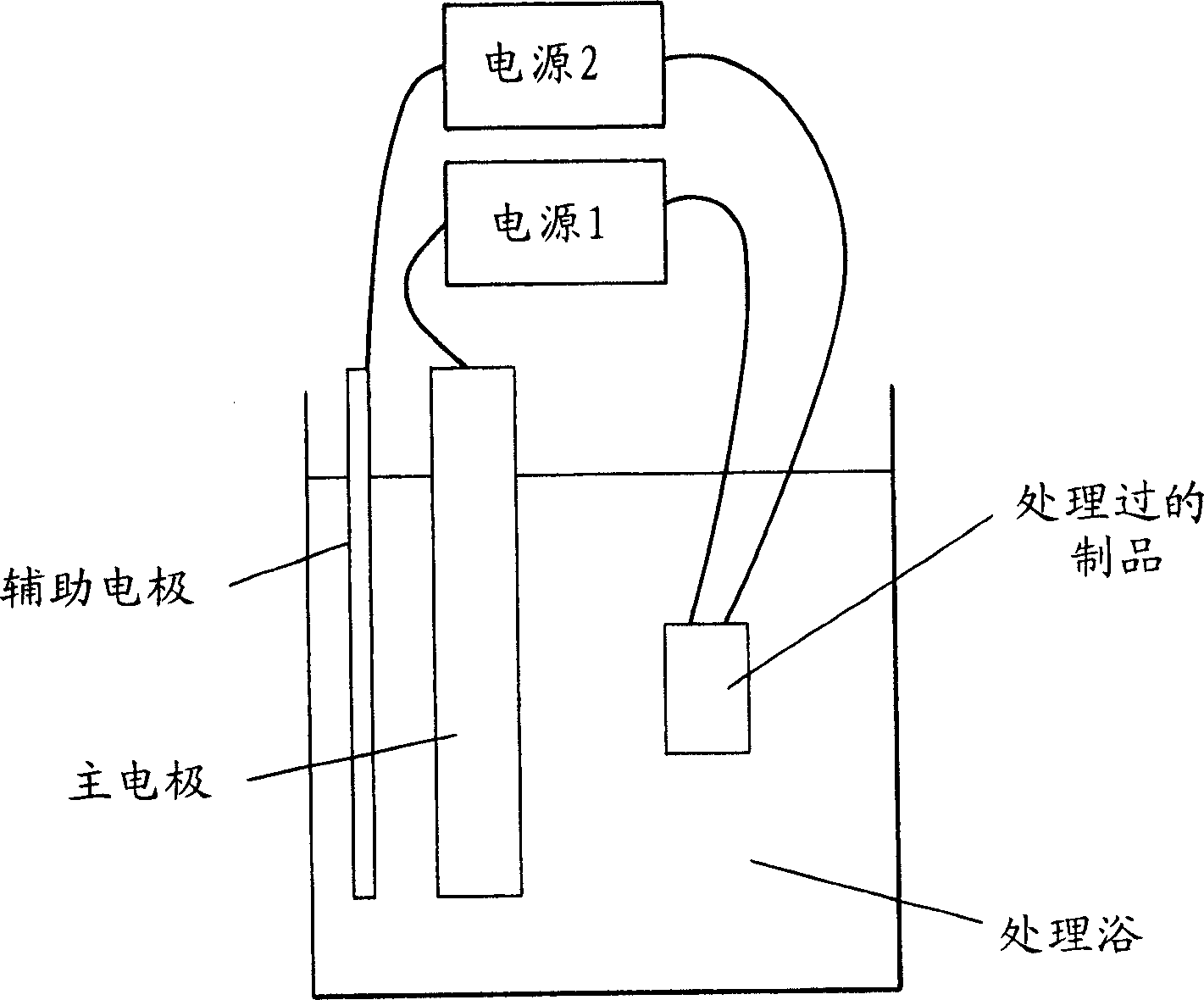

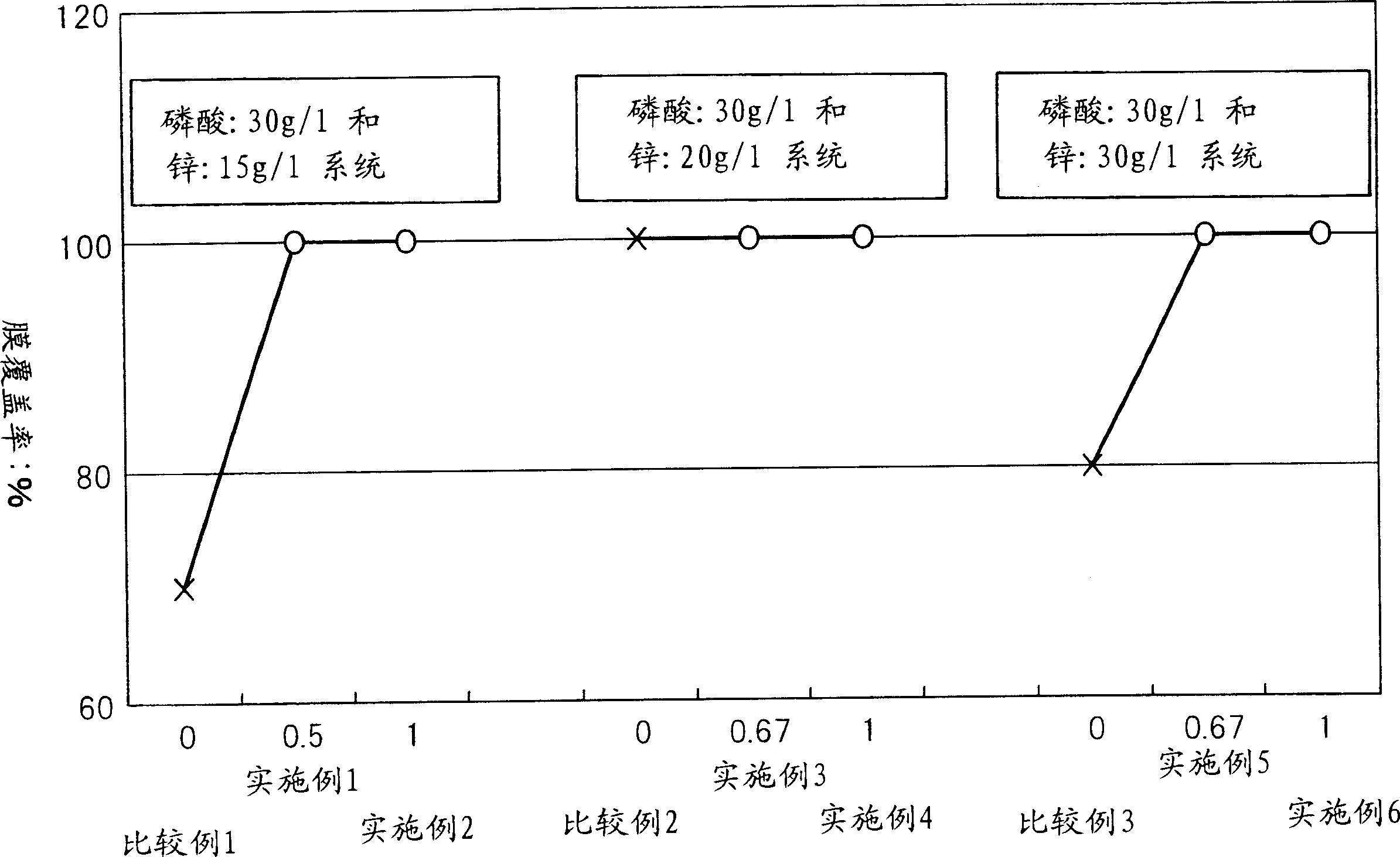

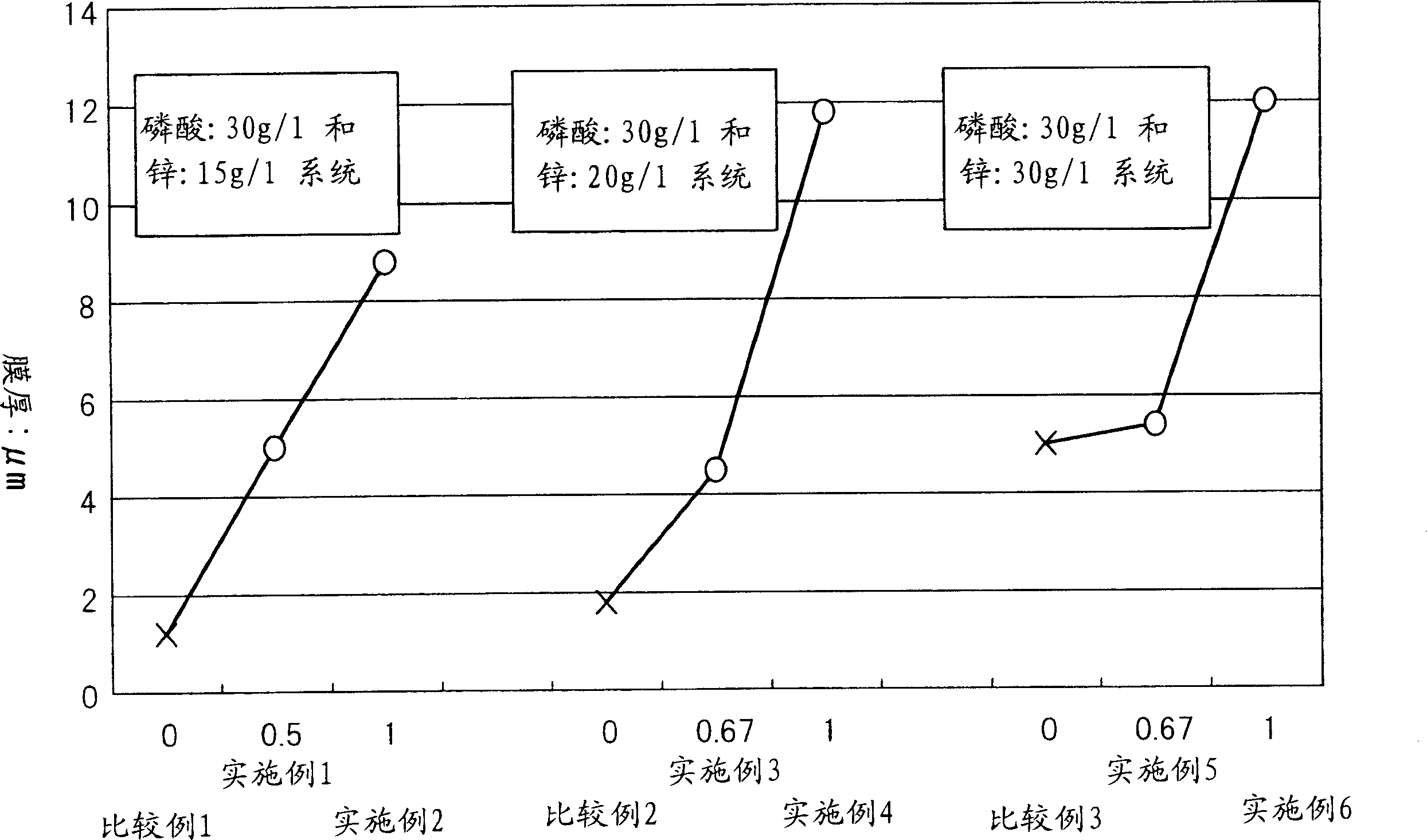

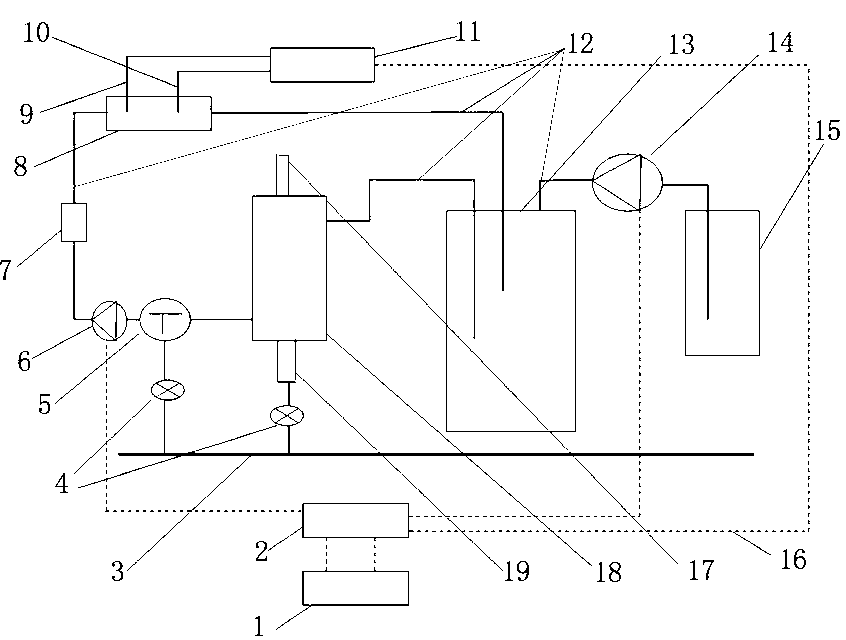

Electrolytic phosphating process

InactiveCN1891865AShorten phosphating treatment timeSmall sizeElectrolytic inorganic material coatingPhosphatisationPhosphate ionPhosphoric acid

This invention provides a phosphating process that can form a film suitable for a cold forging foundation within 60 seconds and preferably 30 seconds or less. The process uses a treatment bath that is formed of a phosphate ion solution (H2PO4-+Zn2+), made by dissolving zinc in phosphoric acid, contains phosphoric acid (H3PO4), phosphate ions, zinc ions and nitrate ions, may contain at least one kind of metal ion selected from the group consisting of nickel ions, cobalt ions, copper ions, manganese ions and iron ions, and further contains 0.5 g / l or below of metal ions other than the film forming components. The process involves electrolytic treatment by applying a voltage between a metal as a positive electrode and a treated article as a negative electrode and forms a phosphate film on the surface of the treated article. The phosphate ion solution prepared by dissolving zinc in phosphoric acid (H2PO4-+Zn2+) is a solution obtained by dissolving 8 parts by mass to a maximum dissolution concentration of zinc in 100 parts by mass of phosphoric acid.

Owner:DENSO CORP

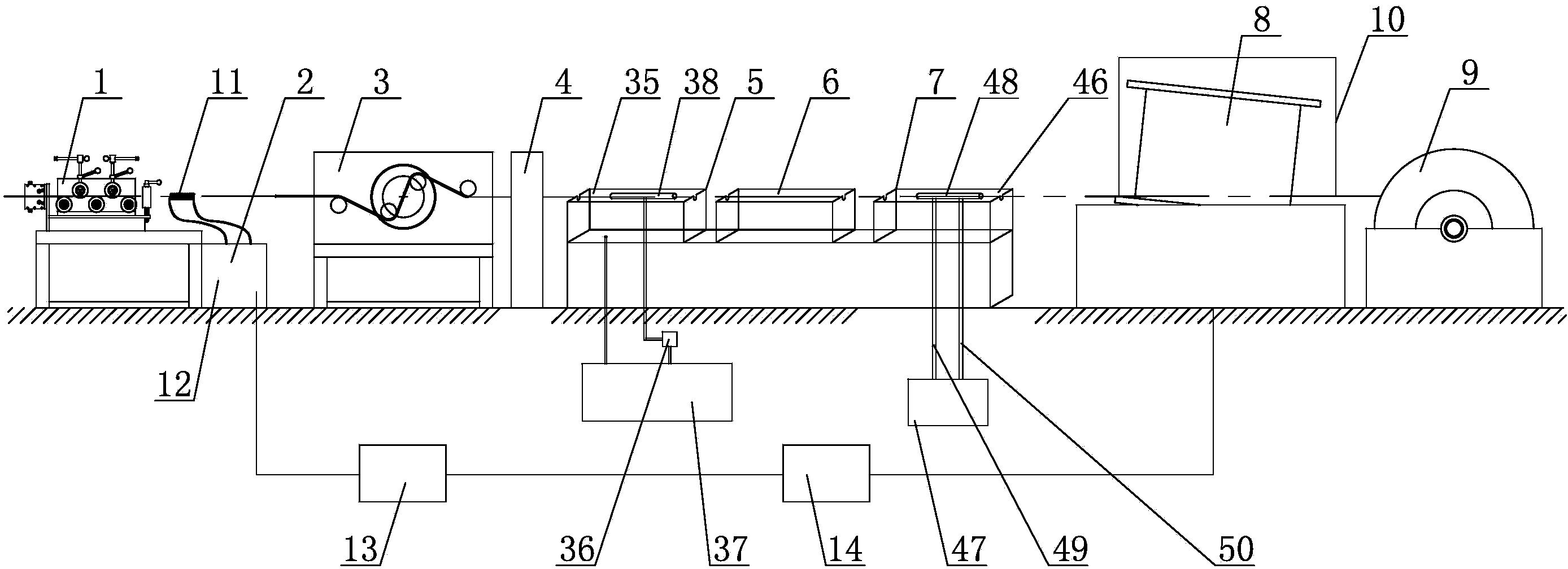

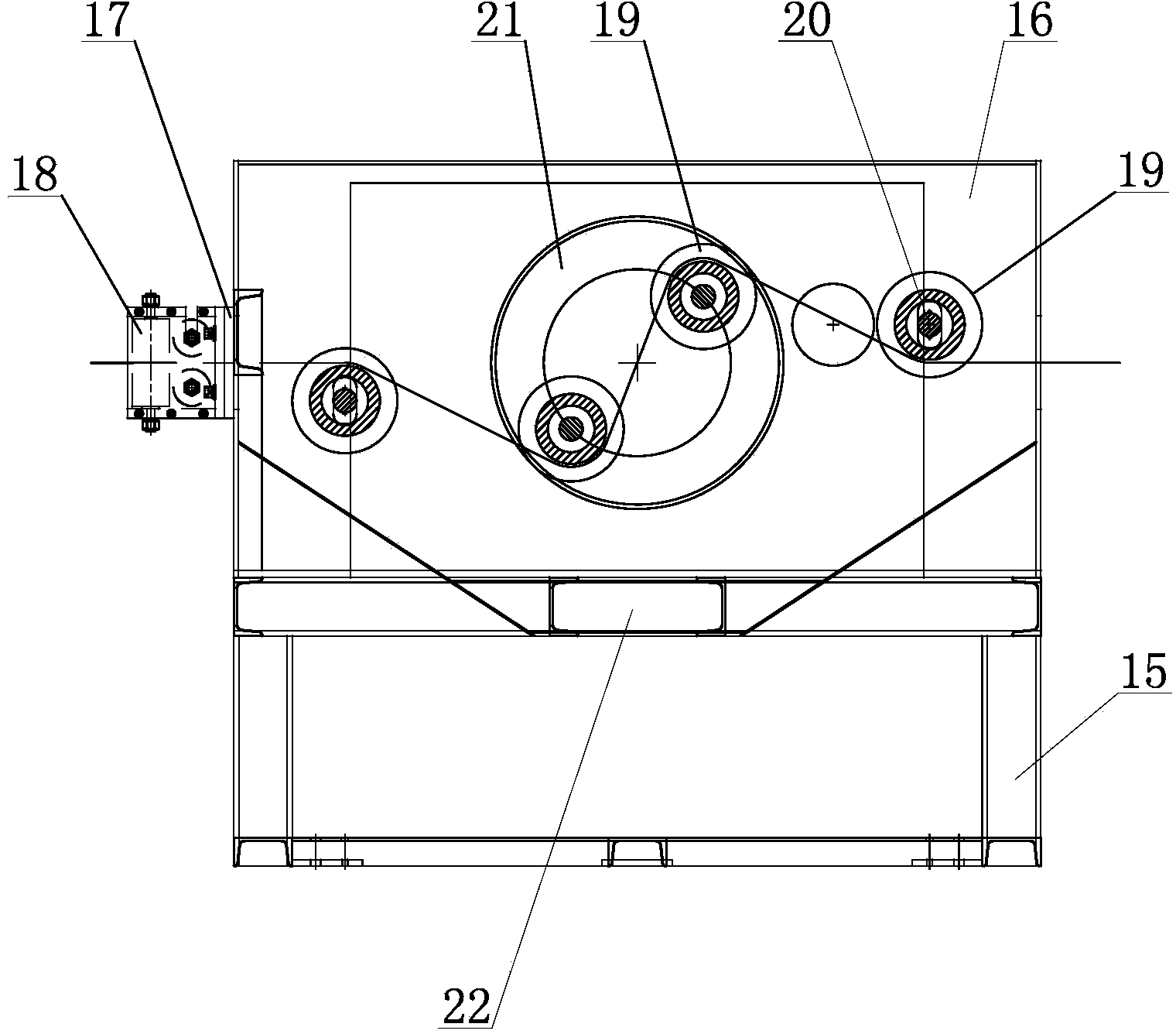

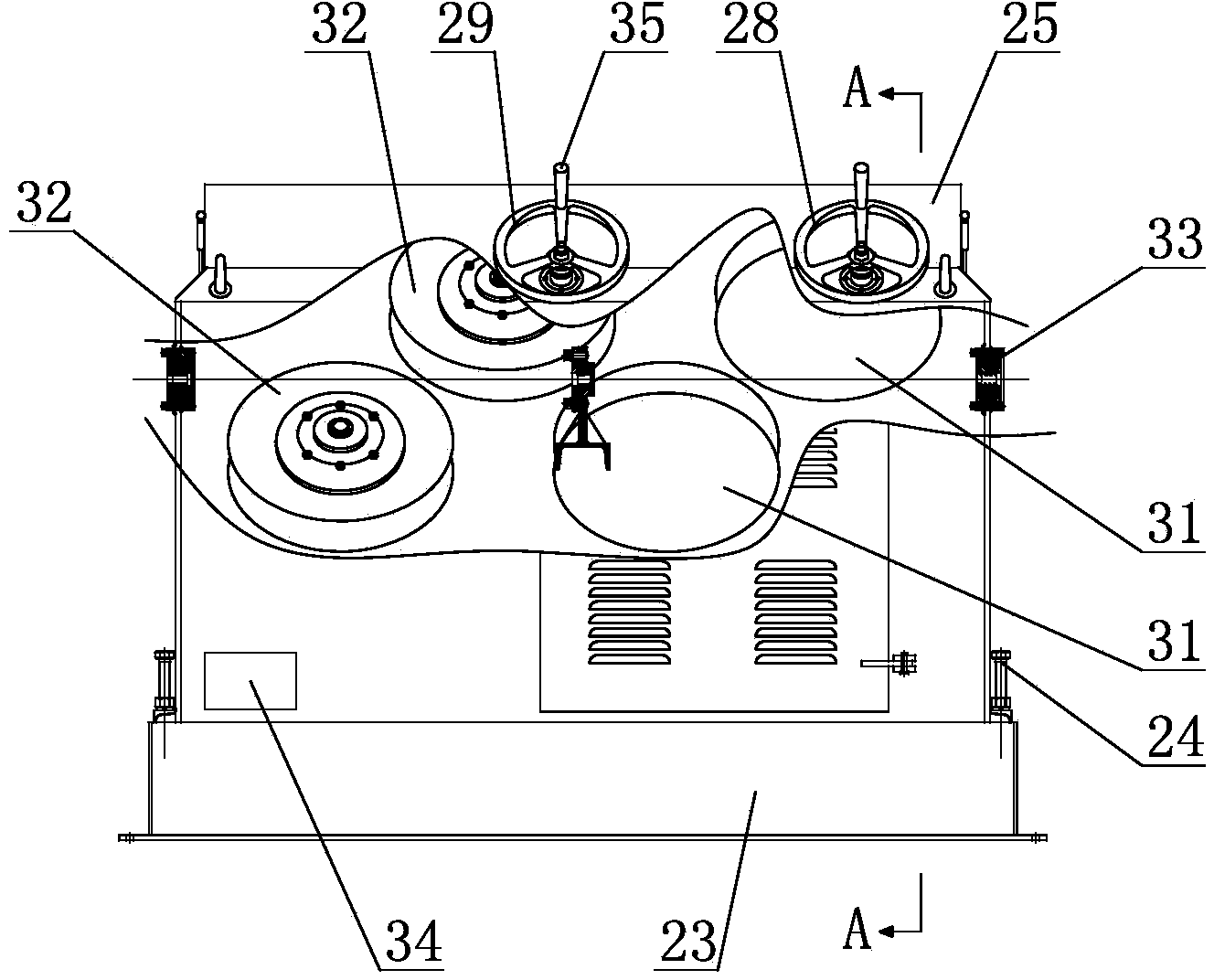

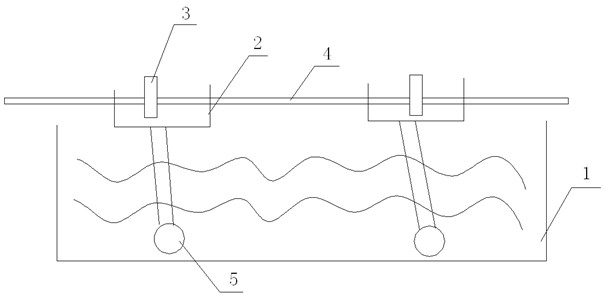

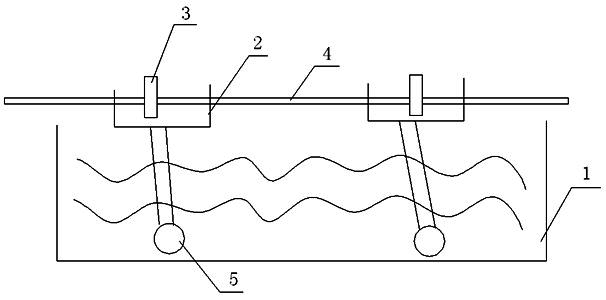

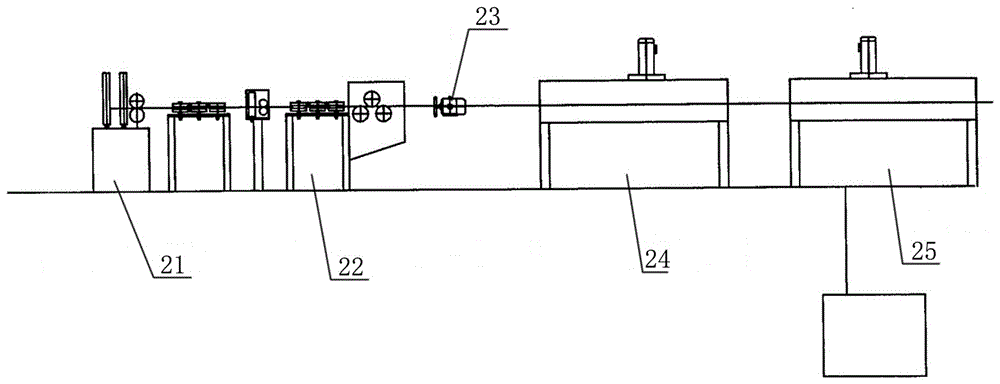

Steel strand production device and electrolysis phosphating technology

ActiveCN103769432ANot brittleGuaranteed to peel completelyPhosphatisationDrying gas arrangementsElectrolysisMetallurgy

The invention provides a steel strand production device and an electrolysis phosphating technology. The steel strand production device and the electrolysis phosphating technology are used for solving the technical problems of complicated maintenance, low production efficiency and relatively high cost in a conventional steel strand production technology and poor phosphating effect, low efficiency and high cost in a phosphating process in a production technology. The steel strand production device is provided with a steel bar straightening press, a peeling machine, a dust removal machine, an online phosphating saponification device, a wiredrawing device and a wire take-up device, wherein the online phosphating saponification device is provided with an electrolysis phosphating tank. The steel strand production device is also provided with a heating device, a surface conditioning device, a drying device and a wiredrawing protective device. The electrolysis phosphating technology provided by the invention can be widely applied to production of steel strands.

Owner:威海银兴预应力线材有限公司

Method for producing chromium-containing multilayer coating and a coated object

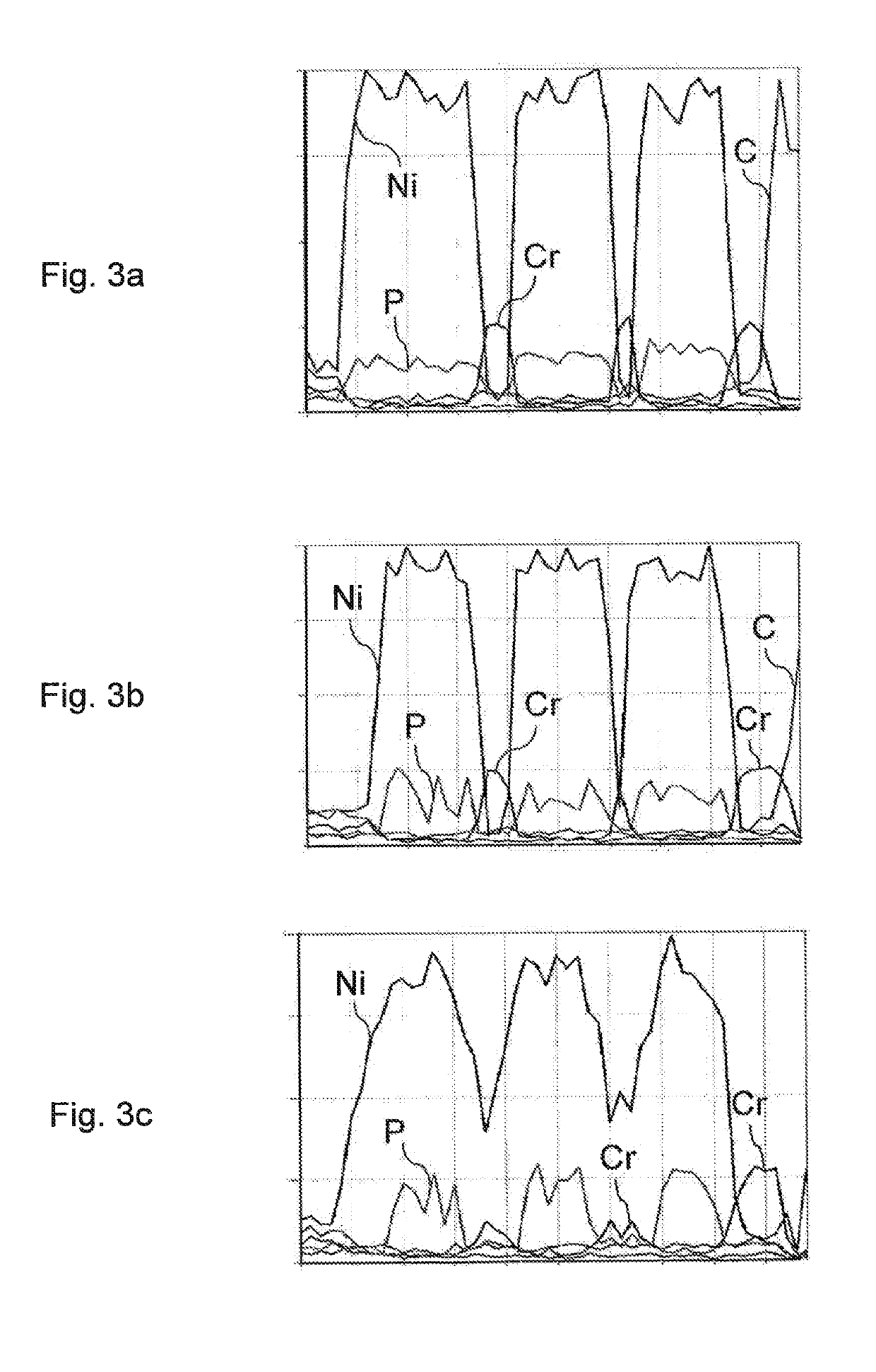

ActiveUS10443142B2Improve adhesionGood physical and mechanical propertiesPhosphatisationVacuum evaporation coatingAlloyPhysical property

Owner:SAVROC

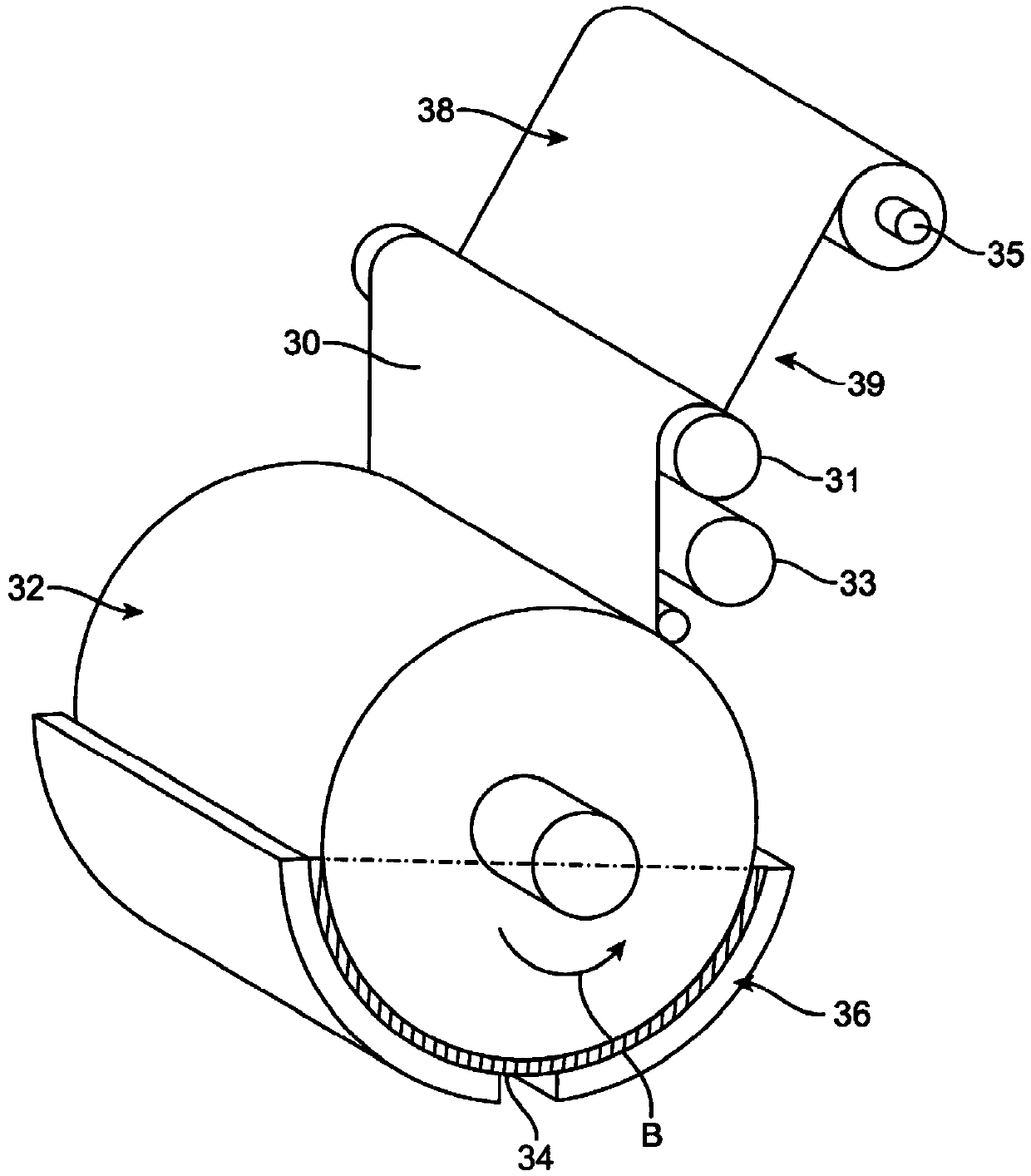

Surface Treated Copper Foil for High Speed Printed Circuit Board Products Including the Copper Foil and Methods of Making

ActiveCN110004467AAvoid signal lossSolve the problem of signal lossLiquid surface applicatorsPhosphatisationAviationElectrolysis

Surface treated copper foils for use in high speed circuits on the order of 100 MHz or greater contain a reverse treated layer of copper nodules on the drum side of the electrolytically deposited copper foil to form a lamination side to be laminated to a dielectric material to form a copper clad laminate. Methods of forming the surface treated copper foil, and printed circuit boards (PCB) from thecopper clad laminates are also described. The surface treated copper foils, copper clad laminates and PCBs can be incorporated into various electronic devices in which high speed signals are employed, including personal computers, mobile communications, including cellular telephones and wearables, self-driving vehicles, including cars and trucks, and aviation devices, including manned and unmanned vehicles, including airplanes, drones, missiles and space equipment including satellites, spacecraft, space stations and extra-terrestrial habitats and vehicles.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

Metallic Material For Electronic Components And Method For Producing Same, And Connector Terminals, Connectors And Electronic Components Using Same

ActiveUS20150194746A1Low degreeIncreased durabilitySingle bars/rods/wires/strips conductorsPhosphatisationMetallic materialsOptoelectronics

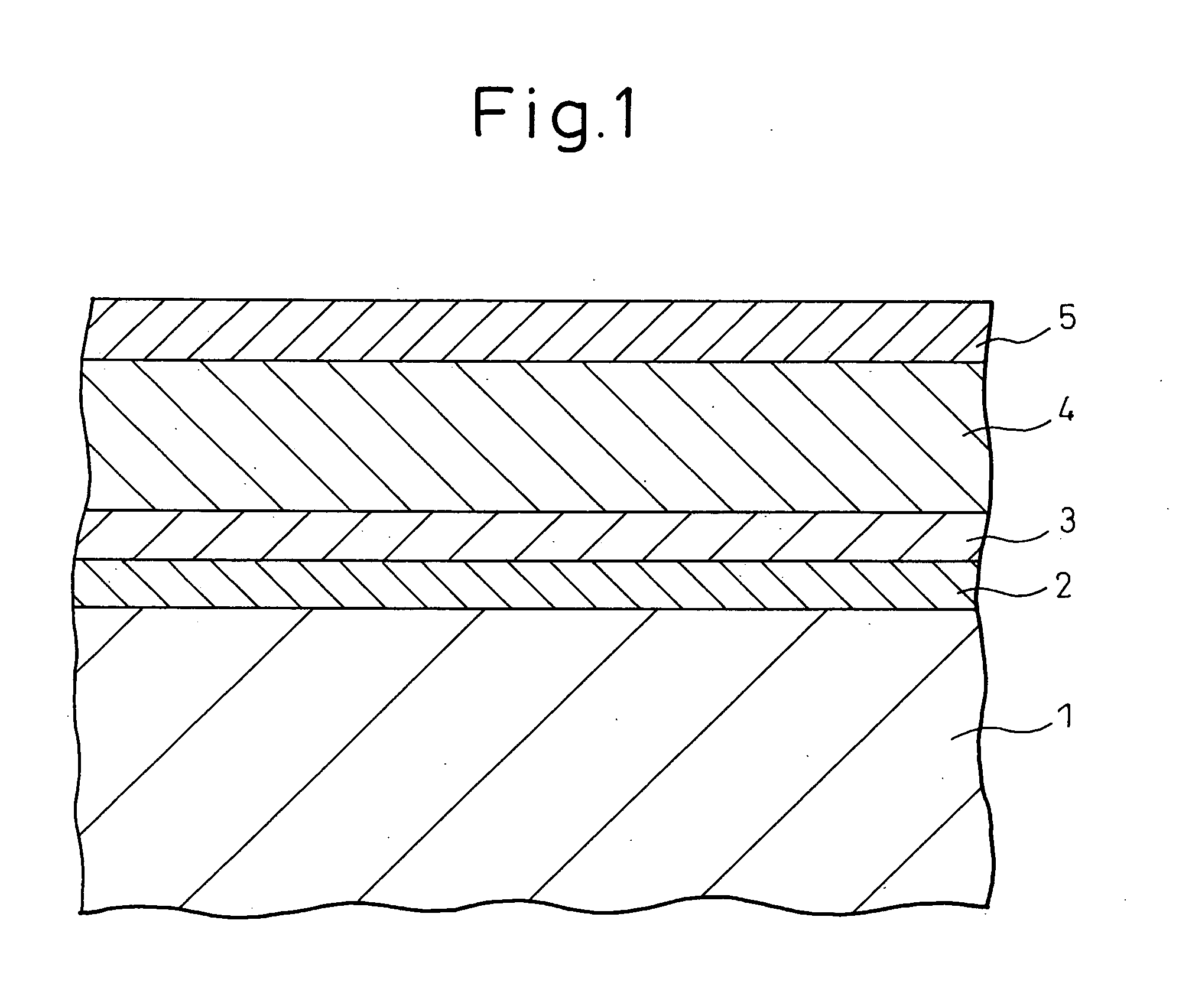

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer being constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir; and an upper layer formed on the intermediate layer, the upper layer being constituted with an alloy composed of one or two or more selected from the constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.01 μm or more and less than 0.50 μm; and the thickness of the upper layer is 0.02 μm or more and less than 0.80 μm.

Owner:JX NIPPON MINING& METALS CORP

Tin plate chromium-free passivation solution and passivation method

InactiveCN101358340AImprove corrosion resistanceImprove antioxidant capacityPhosphatisationMetallic material coating processesChromium freeWorking temperature

The invention discloses tin plate non-chromium passivation solution, wherein, each liter of the passivation solution contains 20g to 70g of trisodium phosphate, 0.1g to 5g of cobalt chloride, 20g to 75g of phosphoric acid, the rest is water, and the ph value of the passivation solution is 3 to 5. The invention also discloses a tinplate passivation method; in the passivation with the non-chromium passivation solution of the invention, the working temperature of the passivation solution is 50 DEG C to 80 DEG C, the passivation time is 1s to 20s, and the passivation method is electro-chemical cathode passivation or chemical passivation. The tin plate non-chromium passivation solution of the invention does not contain hexavalent chrome, conducts chemical passivation or electro-chemical cathode passivation to the tinplate, and enables the tinplate to have the same high corrosion resistance and high oxidation resistance with a chromate passivation process. The welding performance, the adhesion performance to the coating and the like of the tinplate passivated through the non-chromium passivation process also meet the level of the tinplate passivated by chromate, which fundamentally solves the harm of the tinplate passivated by chromate with hexavalent chrome to the human body and the environment.

Owner:武钢集团有限公司

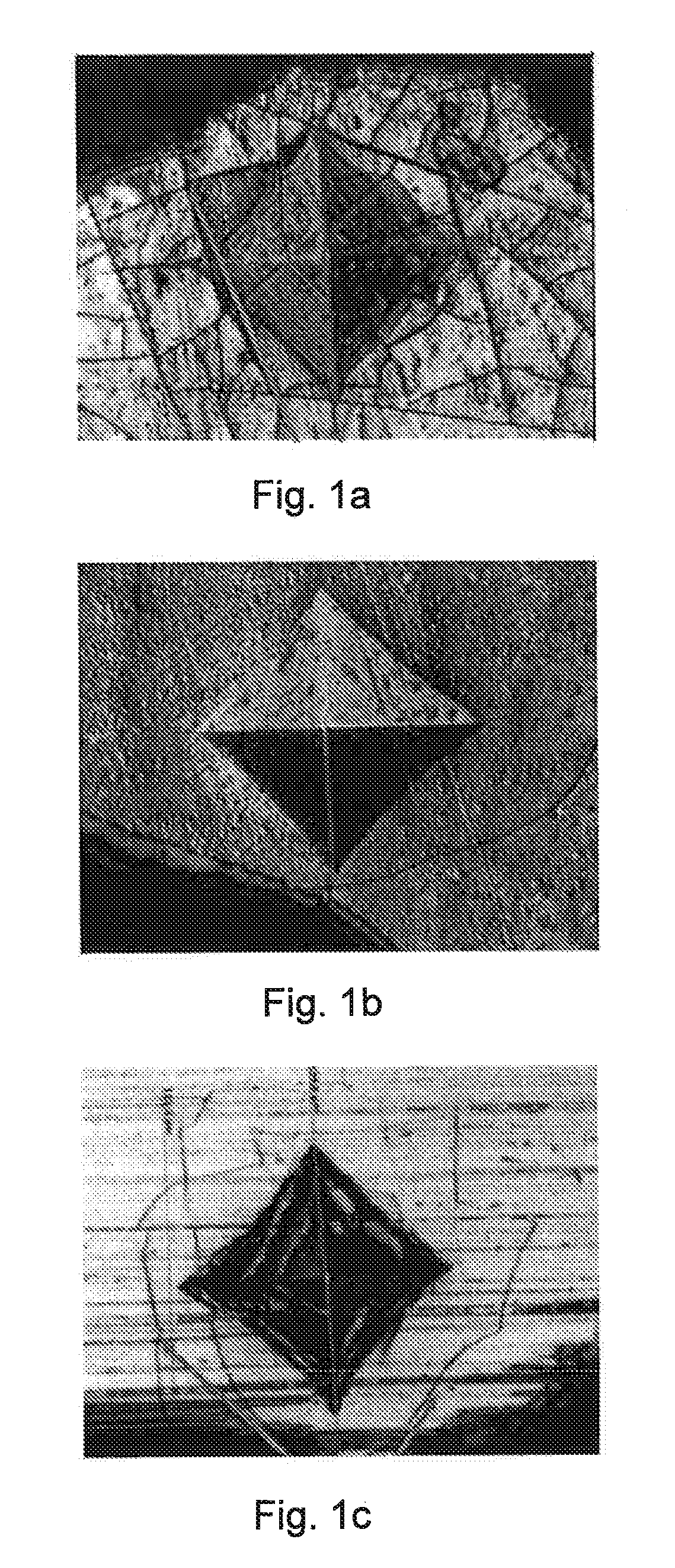

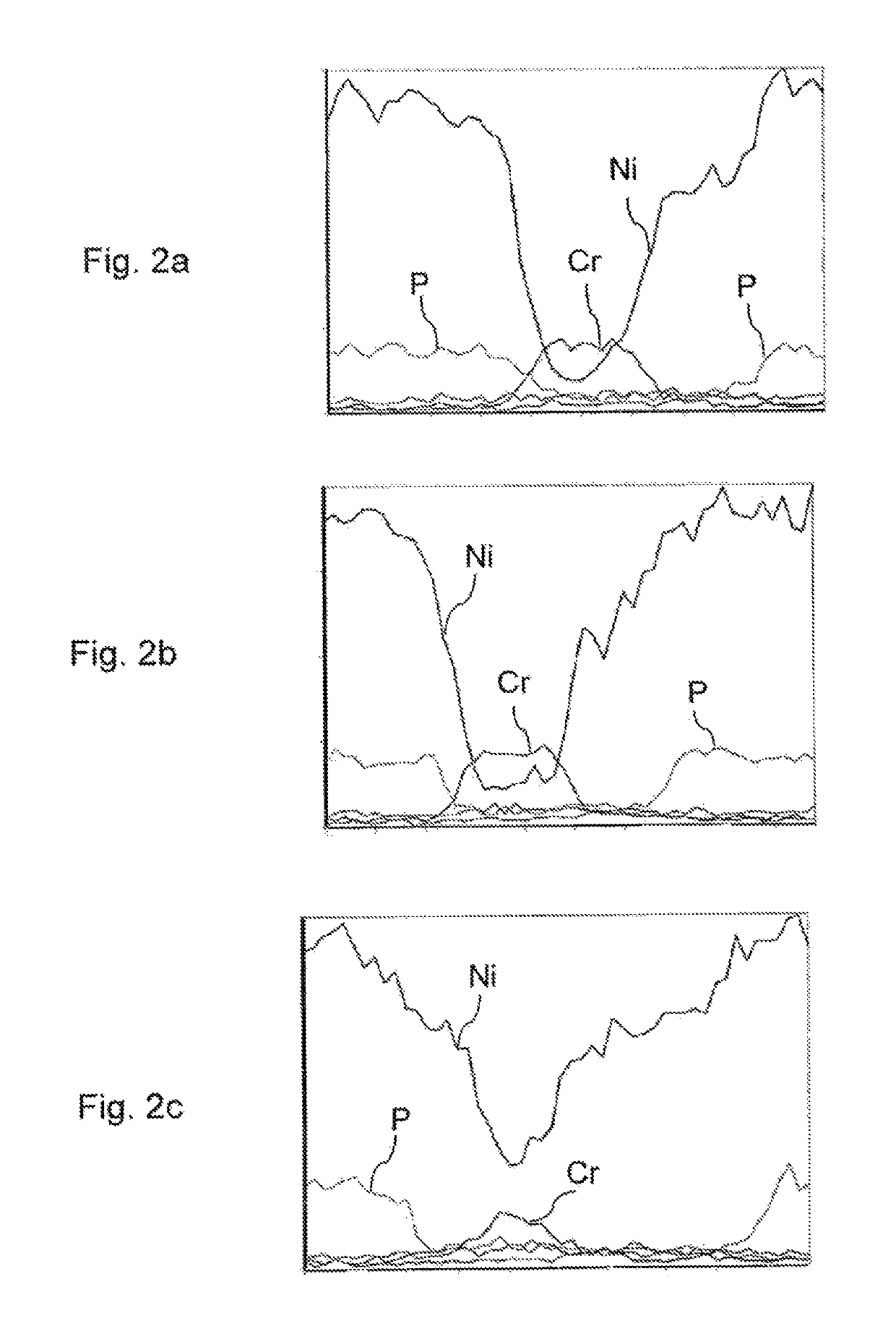

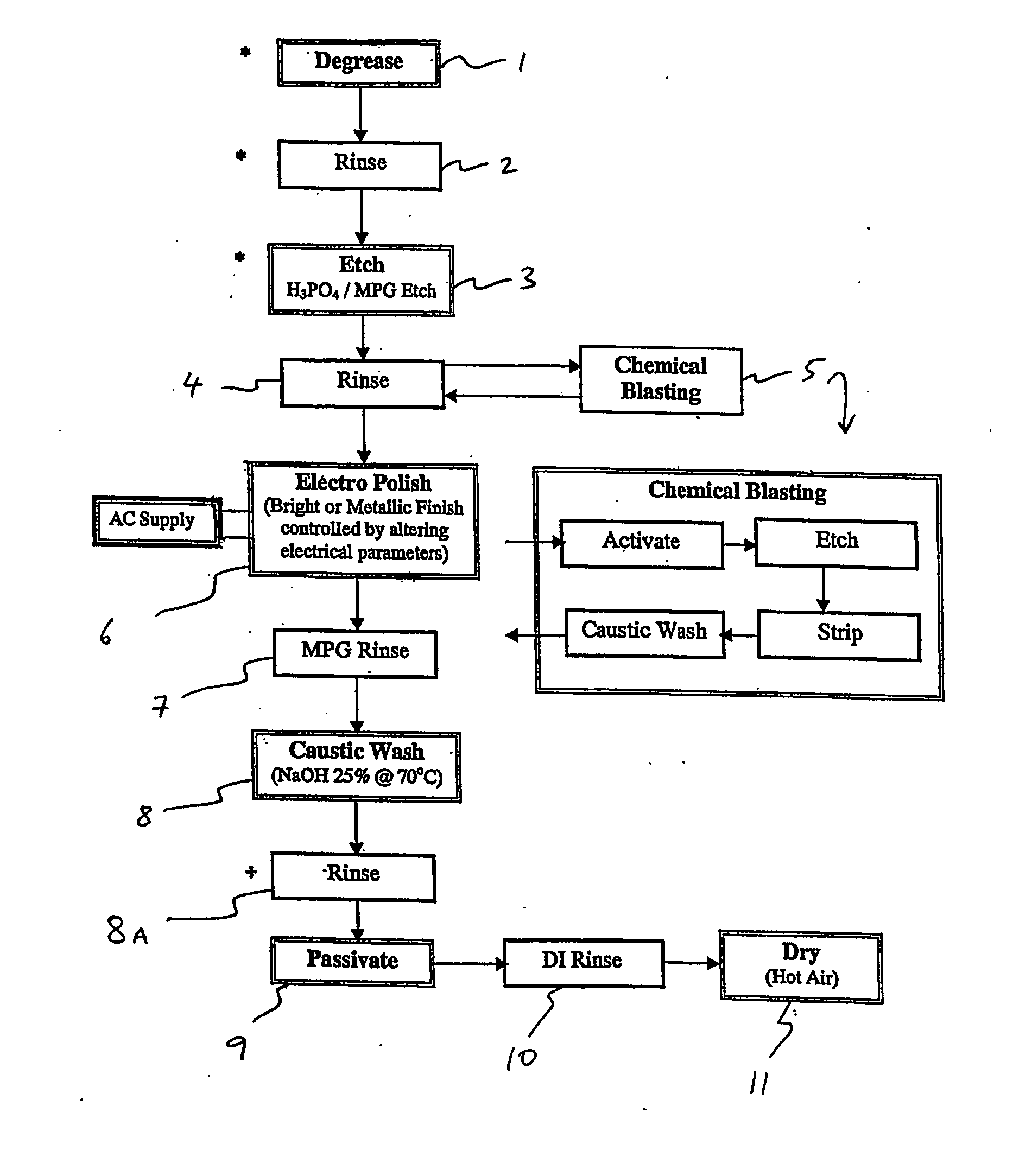

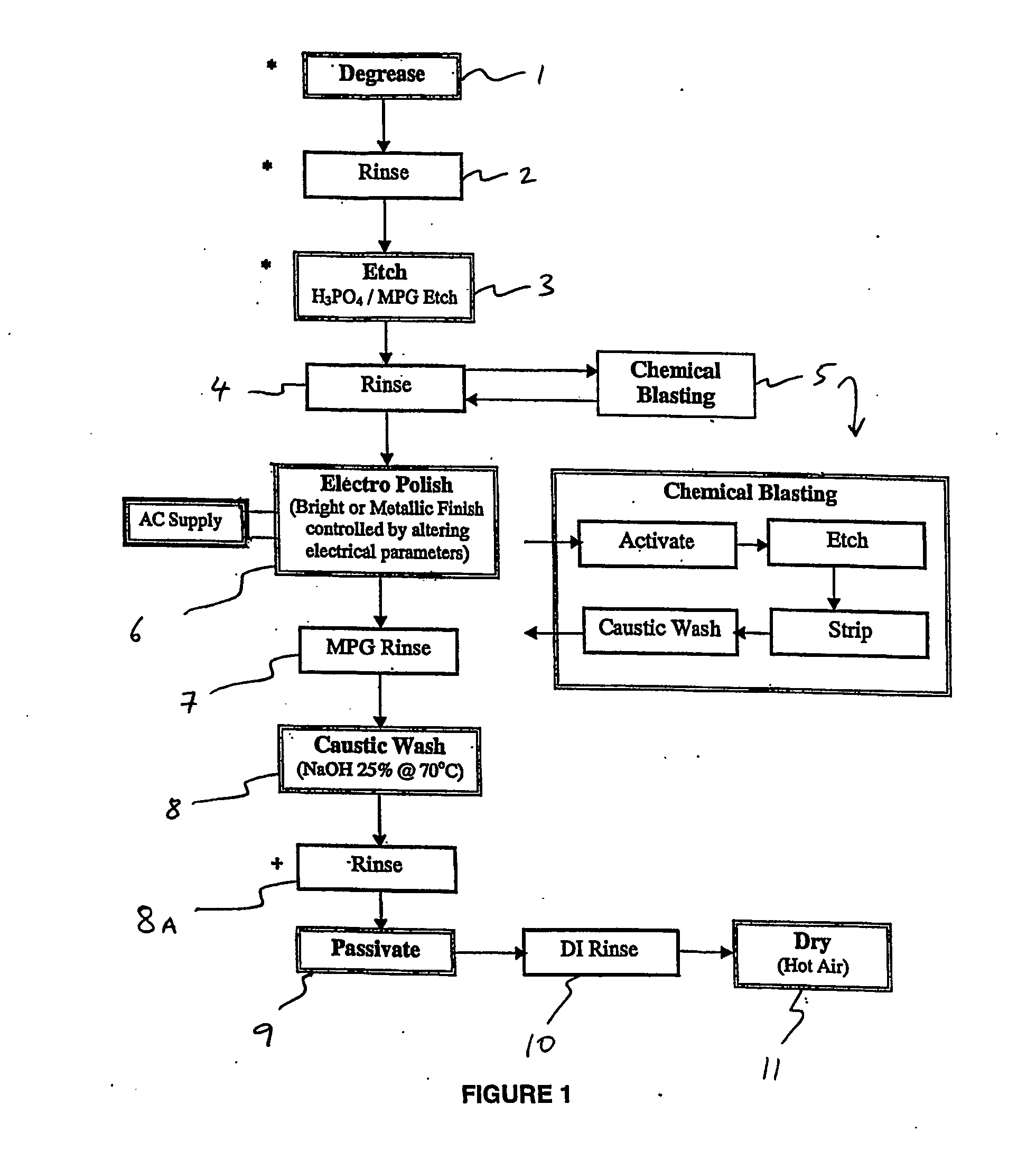

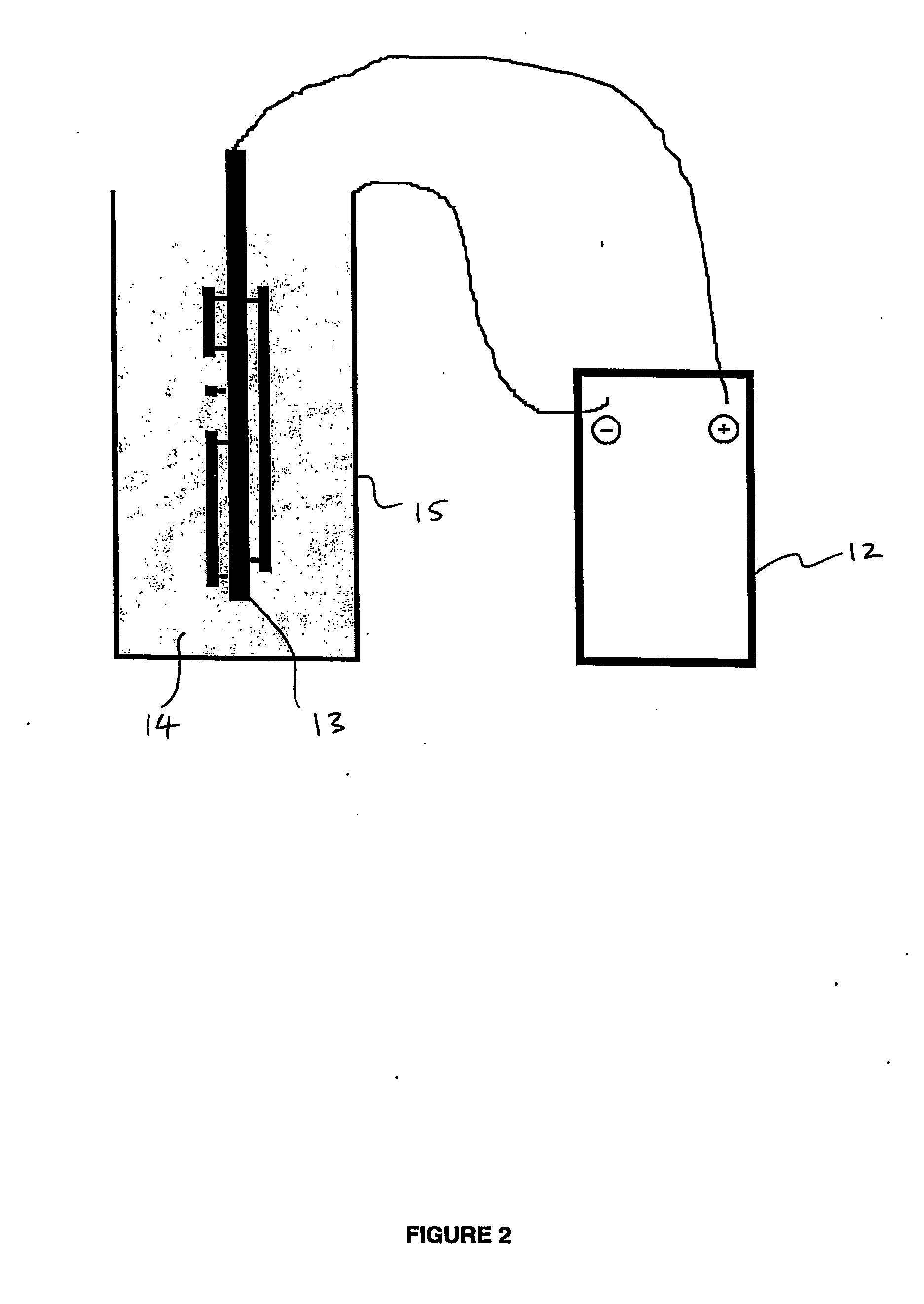

Surface treatment of magnesium and its alloys

InactiveUS20060130936A1Provide protectionReduces microscopic high pointAnodisationChromatisationControl aspectsCorrosion resistant

Methods of polishing and / or brightening surfaces of magnesium or magnesium alloy are disclosed. Polishing and / or brightening methods suitable to both high and low aluminium content magnesium articles are disclosed. In each of the methods, the surface is polished and then passivated. Using the disclosed methods it is possible to control aspects of the appearance of the surface to thereby, for example, obtain a bright and shiny surface to a magnesium or magnesium alloy article which is both stable and corrosion resistant. It is also possible to provide a predetermined texture to the surface using optional steps.

Owner:KERONITE INT LTD

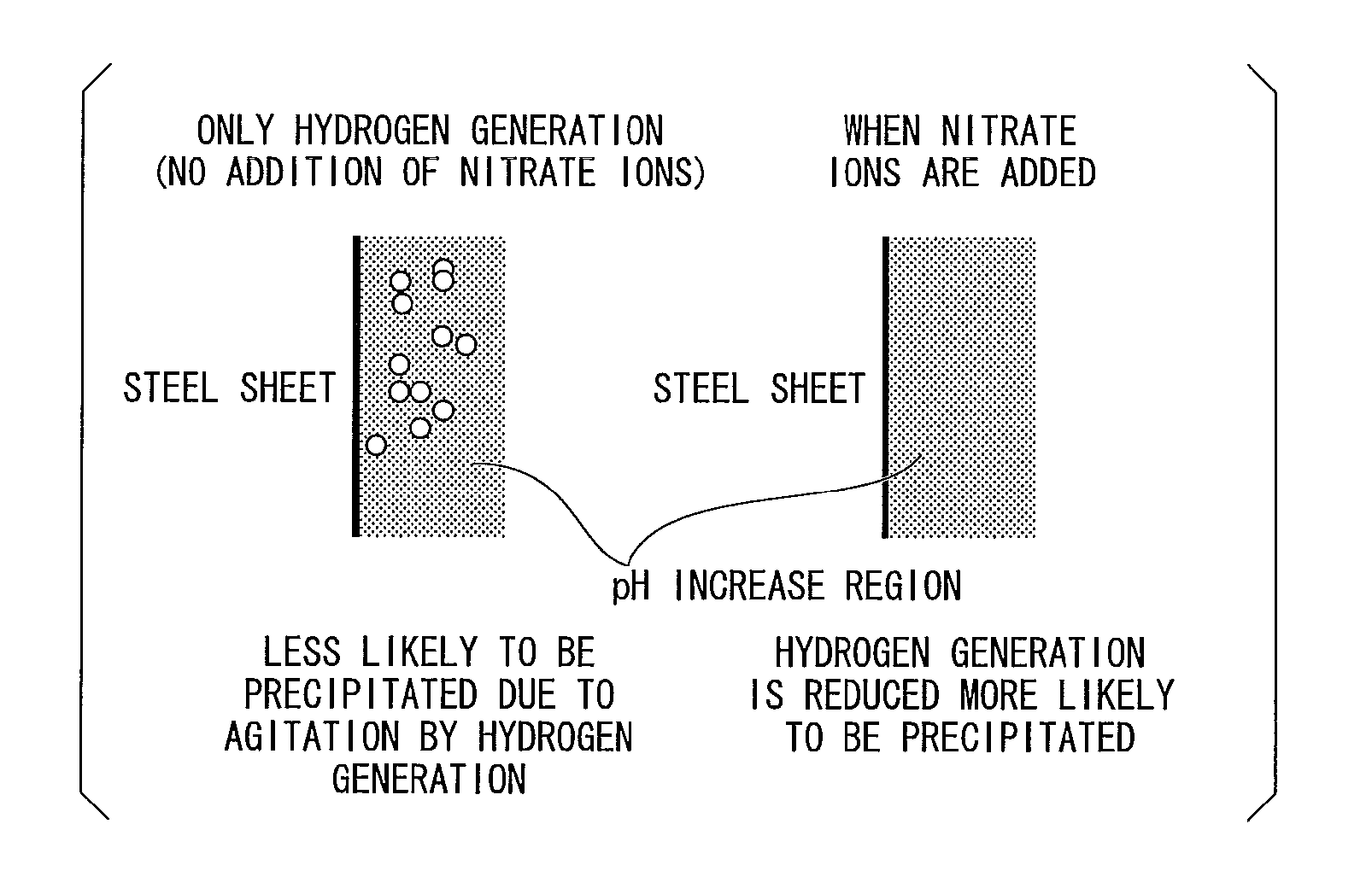

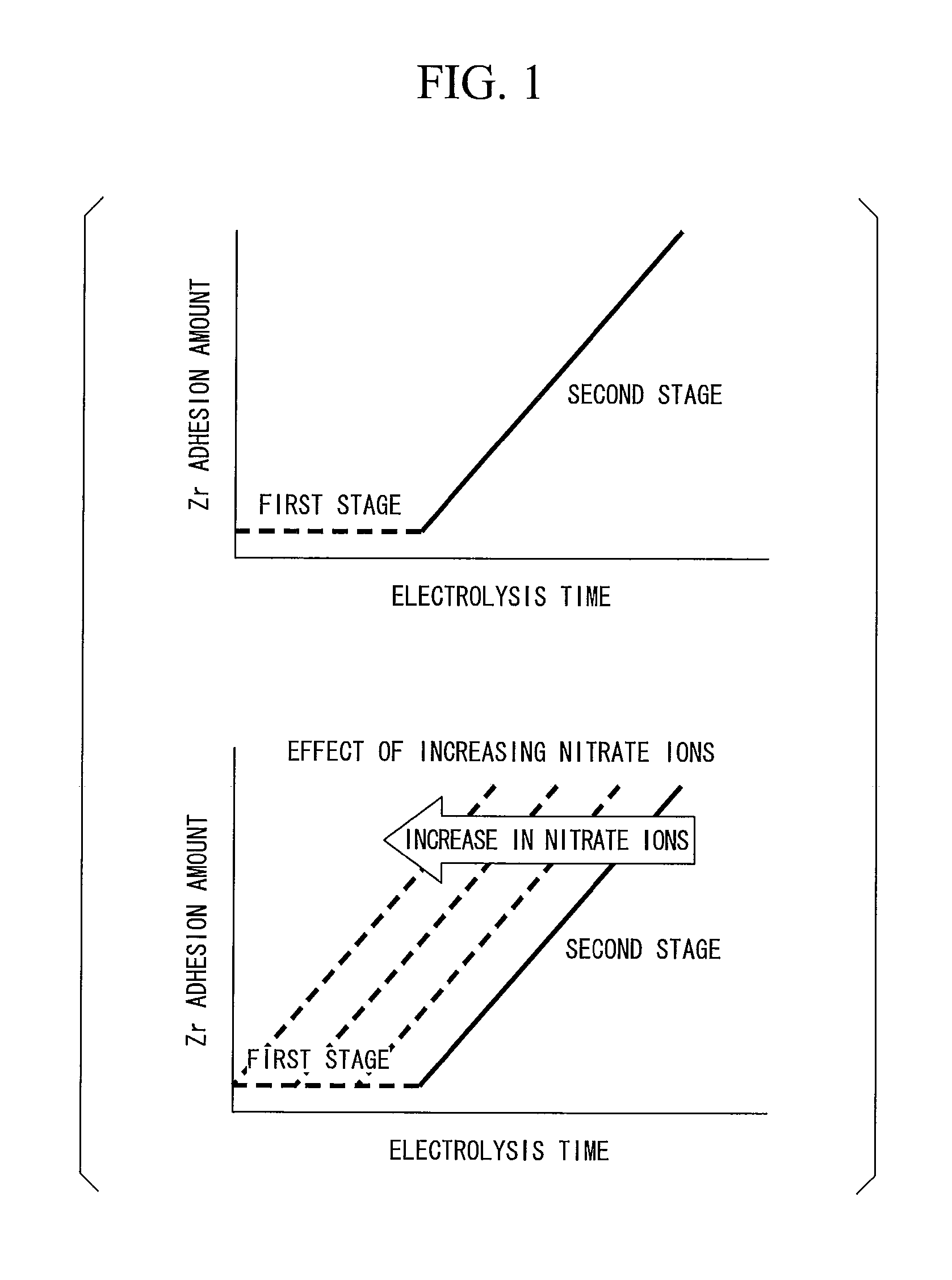

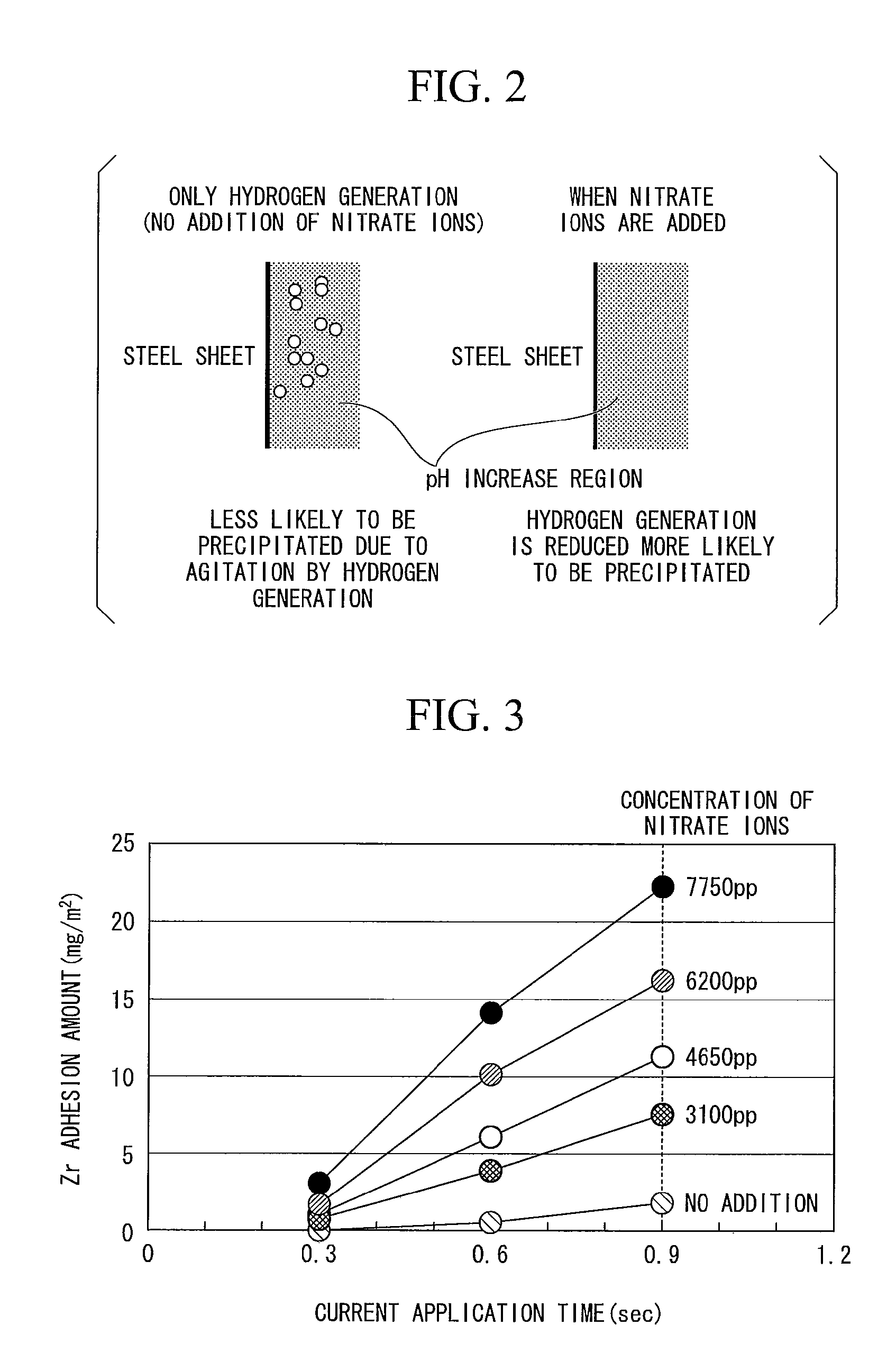

Manufacturing method for steel sheets for containers

InactiveUS20130216714A1Good film adhesionHot-dipping/immersion processesElectrolytic inorganic material coatingBoric acidMetal

Disclosed is a manufacturing method for steel sheets for containers that enables reliable, continuous manufacture of steel sheets, with excellent film adhesion qualities, for containers. The manufacturing method for steel sheets for containers is a method in which a film containing Zr is formed on the surface of the steel sheets by immersing, and / or subjecting to electrolytic treatment, the steel sheets in a solution containing Zr ions, F ions, and at least one reaction accelerating component selected from a group including Al ions, boric acid ions, Cu ions, Ca ions, metal Al, or metal Cu.

Owner:JFE STEEL CORP

Preparation method for low alloy steel surface phosphating film

InactiveCN105603413AFast phosphatingPromote formationPhosphatisationMetallic material coating processesTime rangeMicrosphere

The invention discloses a preparation method for a low alloy steel surface phosphating film. The preparation method includes the steps of workpiece surface nanocrystallization, workpiece pretreatment, phosphating solution preparation, phosphating treatment, phosphating film aftertreatment and the like. When the surface of a workpiece is subjected to nanocrystallization, the surface of the workpiece is treated through microsphere powerful shot blasting, the grain size of the workpiece is on a nano scale, the diameter of adopted stainless steel shots ranges from 0.08 mm to 0.15 mm, the blasting distance ranges from 5.5 cm to 10 cm, the blasting pressure ranges from 0.8 MPa to 1.2 MPa, and the shot blasting time ranges from 5 min to 10 min. According to the preparation method for the low alloy steel surface phosphating film, the steel substrate is subjected to surface microsphere powerful shot blasting nanocrystallization, the metal surface structure is uniform, the metal surface is activated, the phosphating speed of low alloy steel is increased, formation of the phosphating film is promoted, the prepared phosphating film is dense and uniform and has excellent corrosion resistance, salt water resistance performance tests on the phosphating film exceed 72 h and far exceed national standards, the pretreatment process is simple, the effect is remarkable, and high practicality is achieved.

Owner:GUANGDONG UNIV OF TECH

Steel sheet for container and method of manufacturing the same

InactiveUS20130034745A1Improve solderabilityPhosphatisationPretreated surfacesSheet steelPhosphate ion

The present invention provides a steel sheet for a container including: a plated layer containing an adhesion amount of 300 to 1000 mg / m2 of nickel, provided on at least one surface of a steel sheet as metal Ni; and a chemical conversion treatment film formed on the steel sheet by performing immersion or a cathodic electrolytic treatment with a solution containing Zr ions, F ions, and phosphate ions, wherein a metal Zr adhesion amount of the chemical conversion treatment film is 1.0 to 50 mg / m2, an amount of 0.5 to 25 mg / m2 of a phosphate compound is contained in terms of P amount, and an F-atom number density measured by XPS analysis of a plane of 2 nm and a plane of 4 nm in a depth direction obtained by a sputtering treatment is equal to or less than 2 at %.

Owner:NIPPON STEEL CORP

Metallic Material For Electronic Components And Method For Producing Same, And Connector Terminals, Connectors And Electronic Components Using Same

ActiveUS20150171537A1Low degreeIncreased durabilitySingle bars/rods/wires/strips conductorsPhosphatisationMetallic materialsWhiskers

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer being constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir; an upper layer formed on the intermediate layer, the upper layer being constituted with an alloy composed of one or two or more selected from the constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; an outermost layer formed on the upper layer, the upper layer being constituted with one or two selected from the constituent element group C, namely, the group consisting of Sn and In, wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.01 μm or more and less than 0.50 μm; the thickness of the upper layer is less than 0.50 μm; and the thickness of the outermost layer is 0.005 μm or more and less than 0.30 μm.

Owner:JX NIPPON MINING & METALS CO LTD

Electrolytic phosphating method for steel wires

InactiveCN102061503AReduce pollutionReduce energy consumptionPhosphatisationElectrolysisMaterials science

The invention provides an electrolytic phosphating method for steel wires, which comprises a step 1 of removing oxide skins on the surfaces of steel wires subjected to heat treatment, washing at normal temperature, and after the steel wires are washed completely, performing the surface activation treatment on the surfaces of the steel wires. The method is characterized by comprising a step 2 of passing the activated steel wires through an electrolytic phosphating tank with an anode without contacting the anode. When the electrolytic phosphating method for steel wires, which is provided by the invention, is used, the environmental pollution and energy consumption are reduced greatly compared with the conventional chemical phosphating method, and an effect which is the same as that achieved by chemical phosphating can be achieved.

Owner:JIANGSU JULI WIRE ROPE

Insert-molded cover and method for manufacturing same

An exemplary insert-molded cover (10) for electronic devices includes a metallic body (11), a plastic antenna lid (12) integrally formed with the metallic body and an oxide film (12) formed on a surface (111) of the metallic body for attaching the plastic antenna lid. The present invention also relates a method for manufacturing the insert-molded cover for electronic devices.

Owner:HON HAI PRECISION IND CO LTD

On-line low temperature electrolysis phosphating method for steel wires

The invention discloses an on-line low temperature electrolysis phosphating method for steel wires, which comprises the steps of paying off, intermediate-frequency induction heat treatment, water bath quenching, stabilizing treatment, steel wire surface scale treatment, activation, low temperature electrolysis phosphorization, passivation and taking up. The on-line low temperature electrolysis phosphating method for the steel wires has the advantages of being time-saving, labor-saving, green and environment-friendly, good in phosphating effect and short in phosphating time.

Owner:南通高罕金属设备科技有限公司

A kind of preparation method of degradable magnesium alloy implant material

ActiveCN102268712AImprove biological activityHigh affinityAnodisationElectrolytic inorganic material coatingConstant powerPlasma electrolytic oxidation

The invention relates to a method for preparing a degradable magnesium alloy implant material. In the method, (CH3COO)2Ca is added into a base electrolyte to serve as a calcium source, and a phosphate is also added in the base electrolyte to serve as a phosphorus additive to prepare an electrolyte; a magnesium alloy is placed in the electrolyte to serve as an anode; a microarc oxidation power supply is used for supplying electricity, wherein the power supply frequency range is 400-600Hz, the positive duty ratio is 30-50%, the negative duty ratio is 10-30%, and the ratio of the number of the positive pulses to the number of the negative pulses is 1:1; and the degradable magnesium alloy implant material is obtained through electrified reaction under a constant pressure or constant power mode. The implant prepared by the method in the invention has a surface composed of a loose layer and a compact layer, the loose layer surface is distributed with multiple micropores, and the compact layer is in good metallurgic bonding with a basal body so as to ensure a coating to have high hardness, compactness and cohesion as well as good resistance to wear and corrosion; and at the same time, mice acute toxicity tests prove that the coating has good biocompatibility, and simulated body fluid (SBF) soaking tests prove that the coating has good bioactivity, thus the degradable implant materialhas a wide prospect.

Owner:SHANDONG UNIV

Online double phosphating method for steel wires and continuous production equipment for method

ActiveCN105951155AReduce pollutionIncrease multi-purpose usePhosphatisationMetallic material coating processesOne passProduction line

The invention provides an online double phosphating method for steel wires and continuous production equipment for the method. According to the method, a wire drawing machine is adopted to serve as a power source; the steel wires drawn by a pay-off device pass through shucking wheels which are mutually perpendicular, and then a steel brush is adopted to remove residual oxide scales on the surfaces of the steel wires; the steel wires are pickled and activated by phosphoric acid, then enter a medium and low temperature phosphating slot for prephosphating, and subsequently enters an electrolytic phosphating slot for phosphating; and the continuous production equipment consists of the pay-off device, a shucking and pickling device, a double phosphating device and a wire drawing and paying-off device. Compared with an original method for removing the oxide scale by pickling, a mechanical scale removing method adopted by the invention has the advantage that the pollution to the environment is greatly reduced; meanwhile, the invention adopts the double phosphating method, thereby reducing the amount of phosphated residues, shortening phosphating time, changing components and thickness of a phosphating film structure, meeting the demands of multiple products, improving multiple functions of a production line and greatly improving the utilization rate of equipment; and by adopting the wire drawing machine to take up, one-pass drawing is reduced, so that the production cost is further reduced.

Owner:中钢集团郑州金属制品研究院股份有限公司

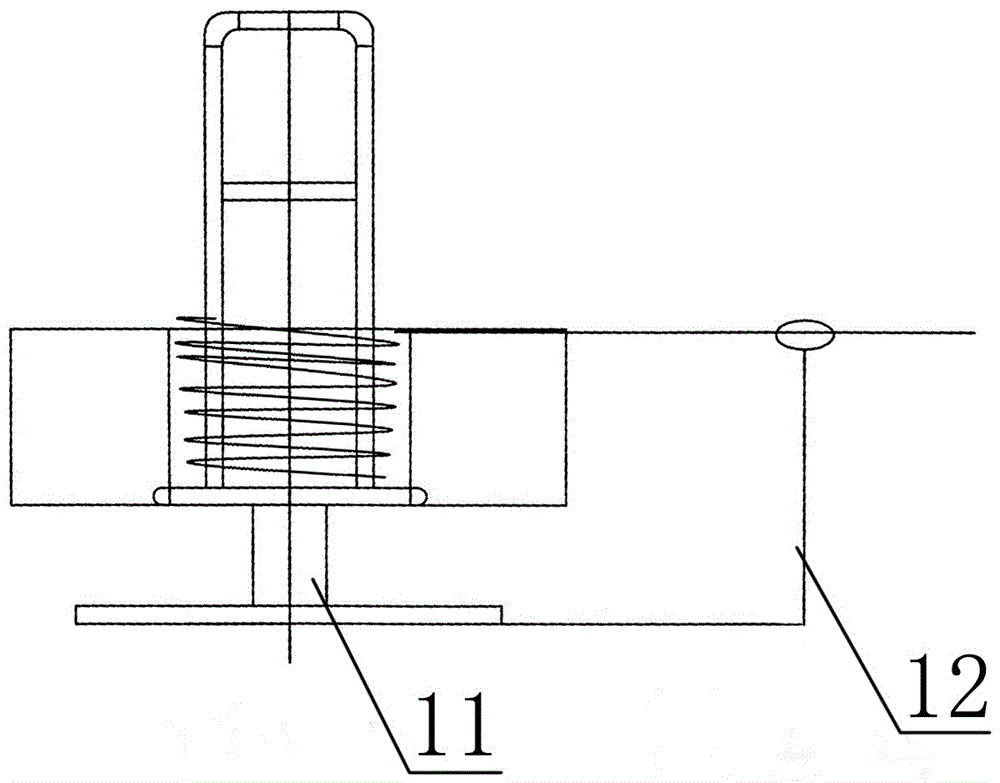

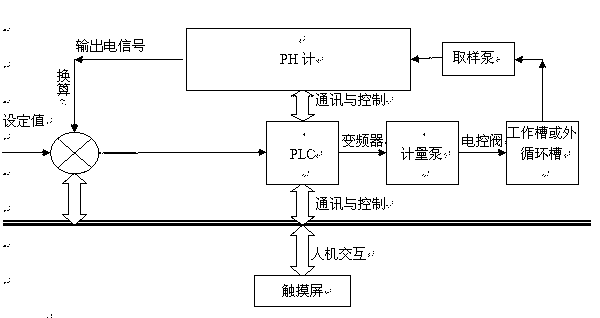

Phosphating solution online-monitoring and automatic-supplementing apparatus

InactiveCN103266316AImplement auto-replenishmentNot easy to slaggingCellsPhosphatisationEngineeringPh probe

The invention provides a phosphating solution online-monitoring and automatic-supplementing apparatus. The apparatus comprises a work tank or a circulation tank, a measuring pool, a concentrate pool and pipelines, and the work tank or the circulation tank is connected with a metering pump to the concentrate pool through a pipeline; the work tank or the circulation tank is connected to the measuring pool through a pipeline; the work tank or the circulation tank is connected with a condenser through a pipeline, the condenser is connected with a sampling pump, and the sampling pump is connected to the measuring pool through a float flow meter; and a temperature sensor and a pH probe are arranged in the measuring pool, and the measuring pool is connected to a control portion through a pH meter and a communication line. The online monitoring and automatic supplementing of a phosphating solution are realized through adopting a real-time control technology. The apparatus which allows the fluctuation of technological indexes of the phosphating work tank solution to be controlled in a small range guarantees the product quality stability, increases the labor efficiency and improves the labor environment of workers.

Owner:DONGFENG MOTOR FASTENER CO LTD

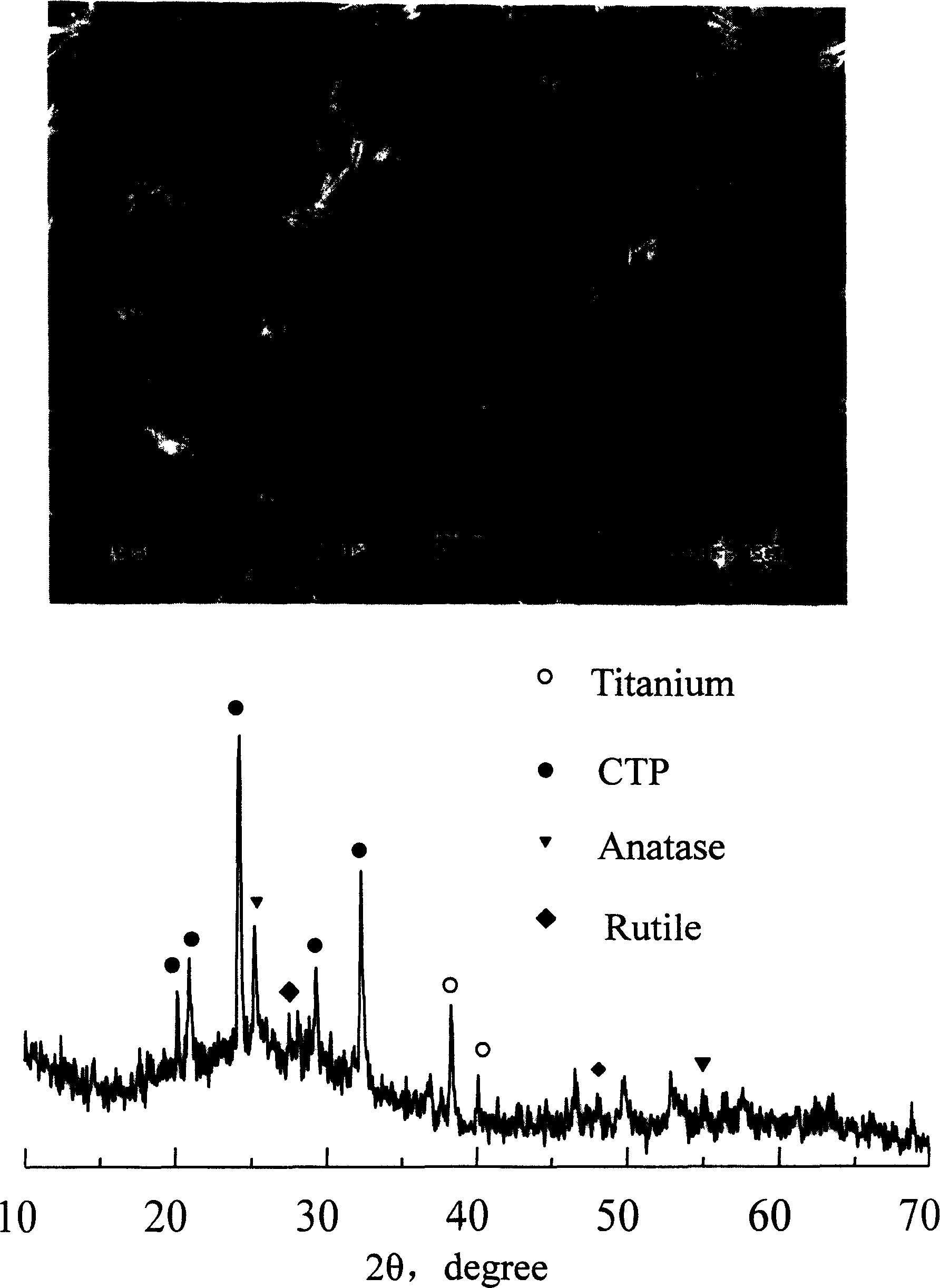

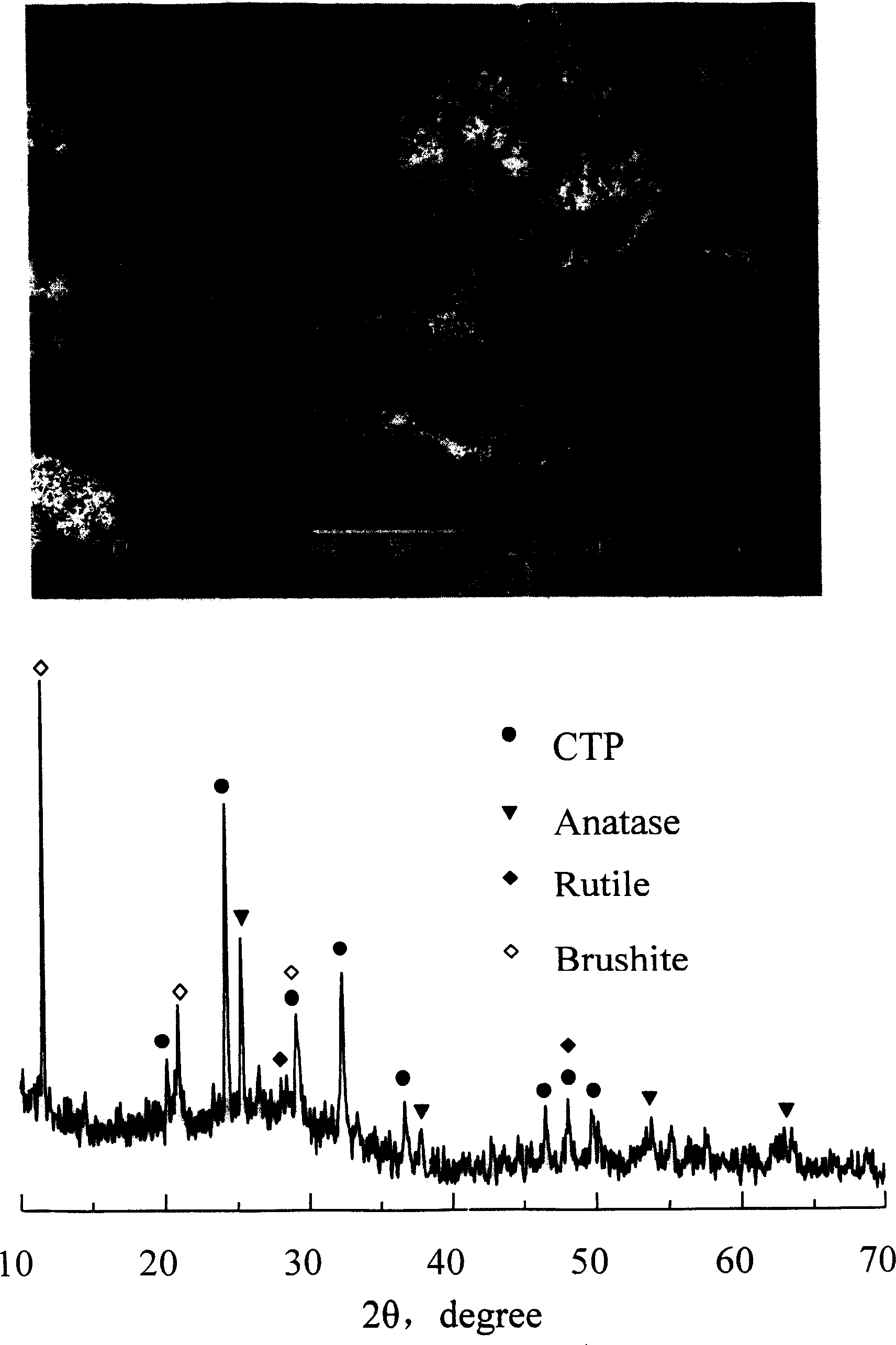

Method for preparing bioceramic membrane

InactiveCN1626702AImprove biological activityHigh bonding strengthPhosphatisationProsthesisMicro arc oxidationPlasma electrolytic oxidation

A process for preparing the CaO-TiO2-ZrO2-P2O5 series bioceramic film on the surface of Ti or Ti-alloy material in order to provide the substitute for reparing the human hard tissue (femur, hip joint, etc) features sue of microarc oxidizing technique, in which Ti or Ti-alloy is used as anode, stainless steel or Ti is used as cathode, and DC power supply or DC pulsive power supply is used. Its advantages are high bioactivity, high adhesion and high chemical stability.

Owner:CENT SOUTH UNIV

Steel sheet for containers

ActiveUS20130209829A1Improve adhesionMaintain good propertiesElectrolytic inorganic material coatingPhosphatisationPhosphatePhosphoric acid

Disclosed is a steel sheet for containers that maintains excellent corrosion resistance even when a surface treatment that replaces a chromate treatment has been conducted, and that has excellent film adhesion qualities and appearance. This steel plate for containers has, on at least one surface thereof, a chemical conversion coating including at least two coatings selected from a zirconium coating that contains zirconium and has a metal zirconium content of 0.1-9 mg / m2, a phosphate coating that contains phosphoric acid and has a phosphorous content of 0.1-8 mg / m2, and a phenolic resin coating that contains phenolic resin in an amount of 0.5-8 mg / m2 in terms of carbon, the percentage of the area of the surface of the chemical conversion coating layer having particles Of a prescribed size being 0.1-50%.

Owner:JFE STEEL CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com