A kind of preparation method of degradable magnesium alloy implant material

A magnesium alloy and implant technology, which is applied in the field of preparation of degradable implant materials, can solve the problems of poor electrolyte stability, too fast coating degradation, low biological activity, etc., and achieves improved biological activity and high bonding strength. , the effect of promoting bone tissue growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

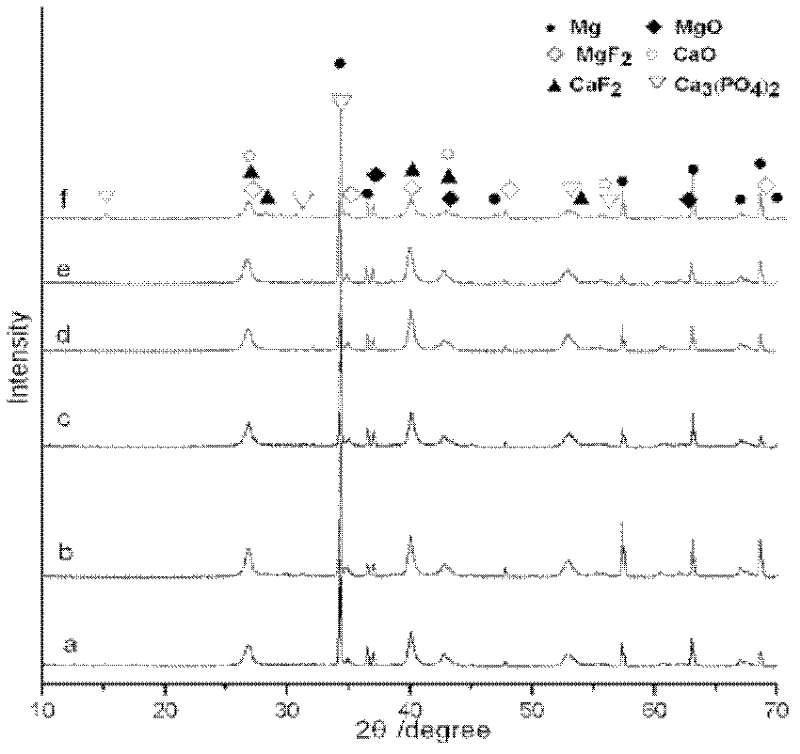

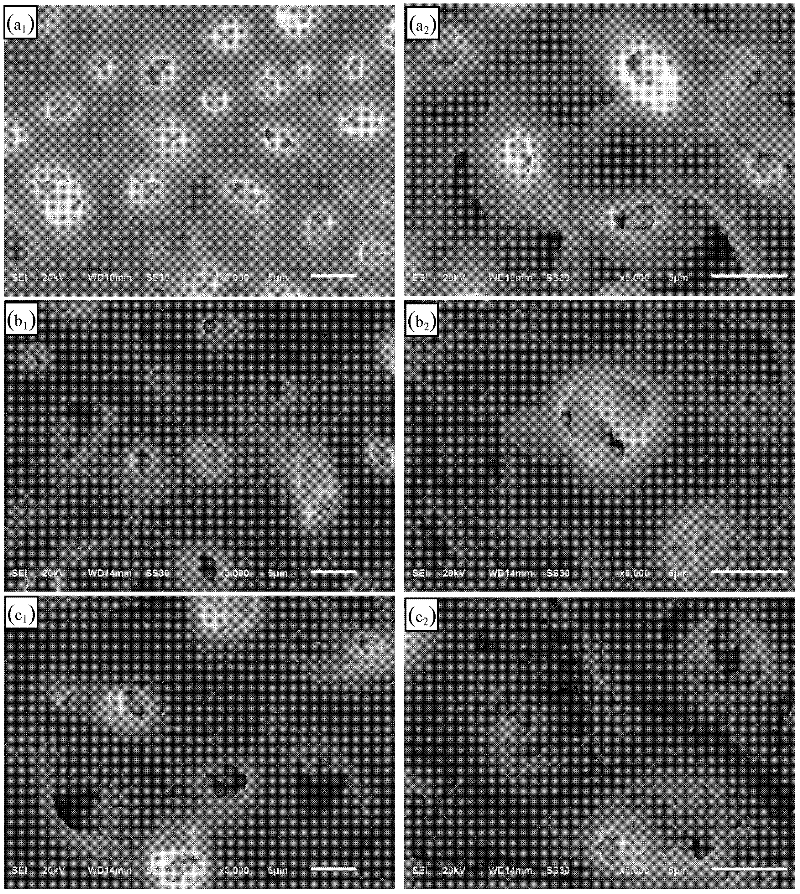

[0044] Embodiment 1 The preparation method of degradable magnesium alloy implant material

[0045] Proceed as follows:

[0046] (1) Preparation of electrolyte: add (CH 3 COO) 2 Ca as a calcium source, and adding Na 2 HPO 4 , (NaPO 3 ) 6 、Na 3 PO 4 or CaHPO 4 As a phosphorus additive, an electrolyte containing calcium and phosphorus salts is prepared.

[0047] The basic electrolyte is composed of deionized water, KOH, NH 4 HF 2 、C 3 h 8 o 3 and H 2 o 2 Prepared, wherein, the concentration of KOH is 0.0891mol / L, NH 4 HF 2 The concentration is 0.1227mol / L, C 3 h 8 o 3 The volume fraction is 0.5%, H 2 o 2 The volume fraction is 1.5%. The calcium source in the electrolyte used in each group of samples (CH 3 COO) 2 Ca and phosphorus additive Na 2 HPO 4 , (NaPO 3 ) 6 、Na 3 PO 4 or CaHPO 4 The specific content of is shown in Table 1-1;

[0048] (2) Preparation of base material: using ZK60 magnesium alloy as the base material, the plate-shaped material ...

Embodiment 2

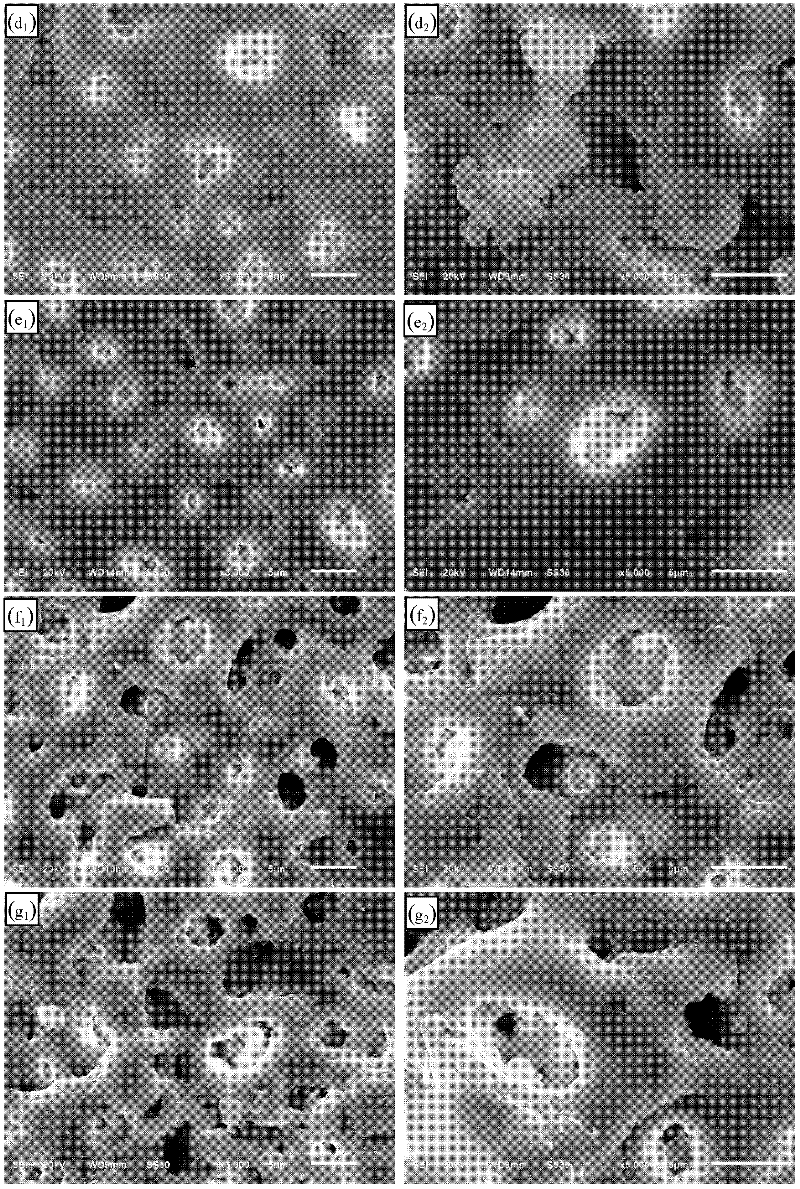

[0064] Embodiment 2 The preparation method of degradable magnesium alloy implant material

[0065] Proceed as follows:

[0066] (1) Preparation of electrolyte: add (CH 3 COO) 2 Ca as a calcium source with addition of CaHPO 4 As phosphorus additive, NH 4 HF 2 and C 3 h 8 o 3 , to prepare electrolytes containing calcium and phosphate salts. where (CH 3 COO) 2 The concentration of Ca is 0.010mol / L, CaHPO 4 The concentration is 0.005mol / L, NH 4 HF 2 The concentration is 0.1227mol / L, C 3 h 8 o 3 The volume fraction is 0.5%;

[0067] (2) Preparation of base material: using ZK60 magnesium alloy as the base material, the plate-shaped material is divided into 8×10×12mm by wire cutting 3 Drill holes and tap threads on the small surface of the cuboid to facilitate clamping during the micro-arc oxidation test; grind on sandpaper of different thicknesses, and the last sandpaper is 1000 # , use acetone to remove the grease on the surface of the magnesium alloy, then ultras...

Embodiment 3

[0084] Embodiment 3 The preparation method of degradable magnesium alloy implant material

[0085] Proceed as follows:

[0086] (1) Preparation of electrolyte: add (CH 3 COO) 2 Ca as a calcium source with addition of CaHPO 4 As a phosphorus additive, an electrolyte containing calcium and phosphorus salts is prepared. where (CH 3 COO) 2 The concentration of Ca is 0.010mol / L, CaHPO 4 The concentration is 0.005mol / L, NH 4 HF 2 The concentration is 0.1227mol / L, C 3 h 8 o 3 The volume fraction is 0.5%;

[0087] (2) Preparation of base material: using ZK60 magnesium alloy as the base material, the plate-shaped material is divided into 8×10×12mm by wire cutting 3 Drill holes and tap threads on the small surface of the cuboid to facilitate clamping during the micro-arc oxidation test; grind on sandpaper of different thicknesses, and the last sandpaper is 1000 # , use acetone to remove the grease on the surface of the magnesium alloy, then ultrasonically clean it in alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com