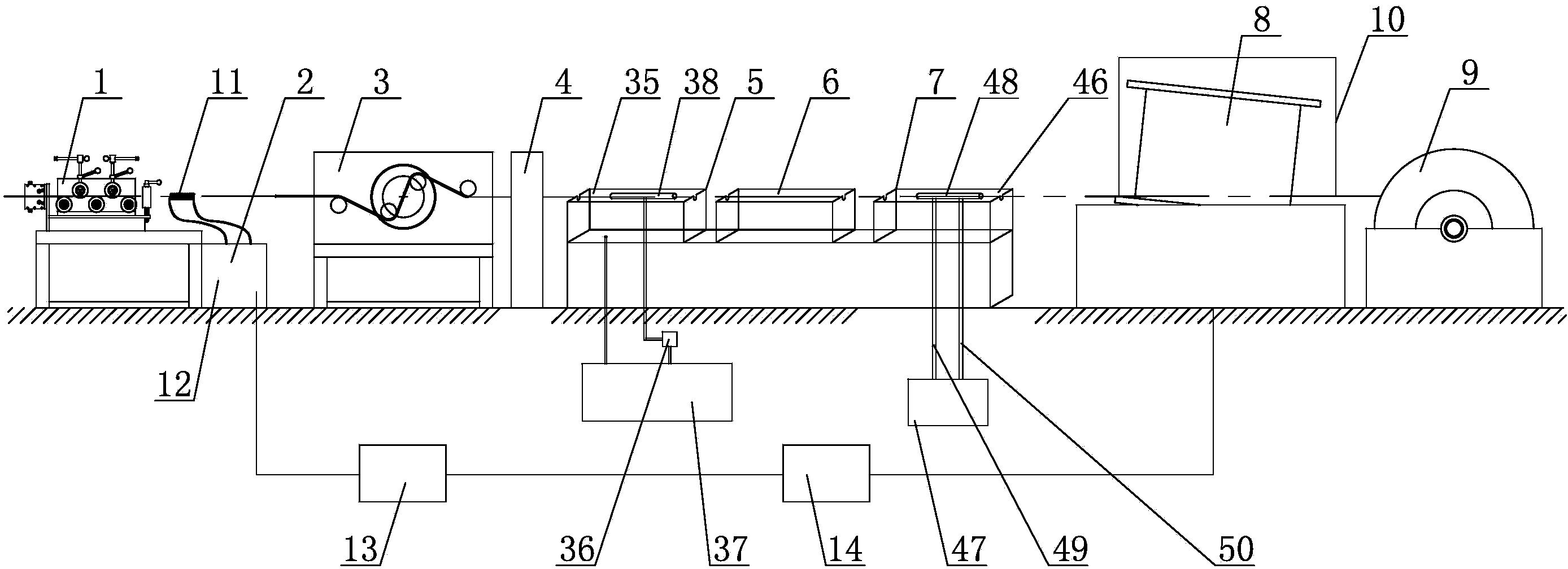

Steel strand production device and electrolysis phosphating technology

A production device and electrolytic phosphating technology, applied in phosphating, engineering safety devices, manufacturing tools, etc., can solve the problems of poor phosphating effect, low production efficiency, complicated maintenance, etc., and achieve fast hot air speed and improved drying efficiency. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

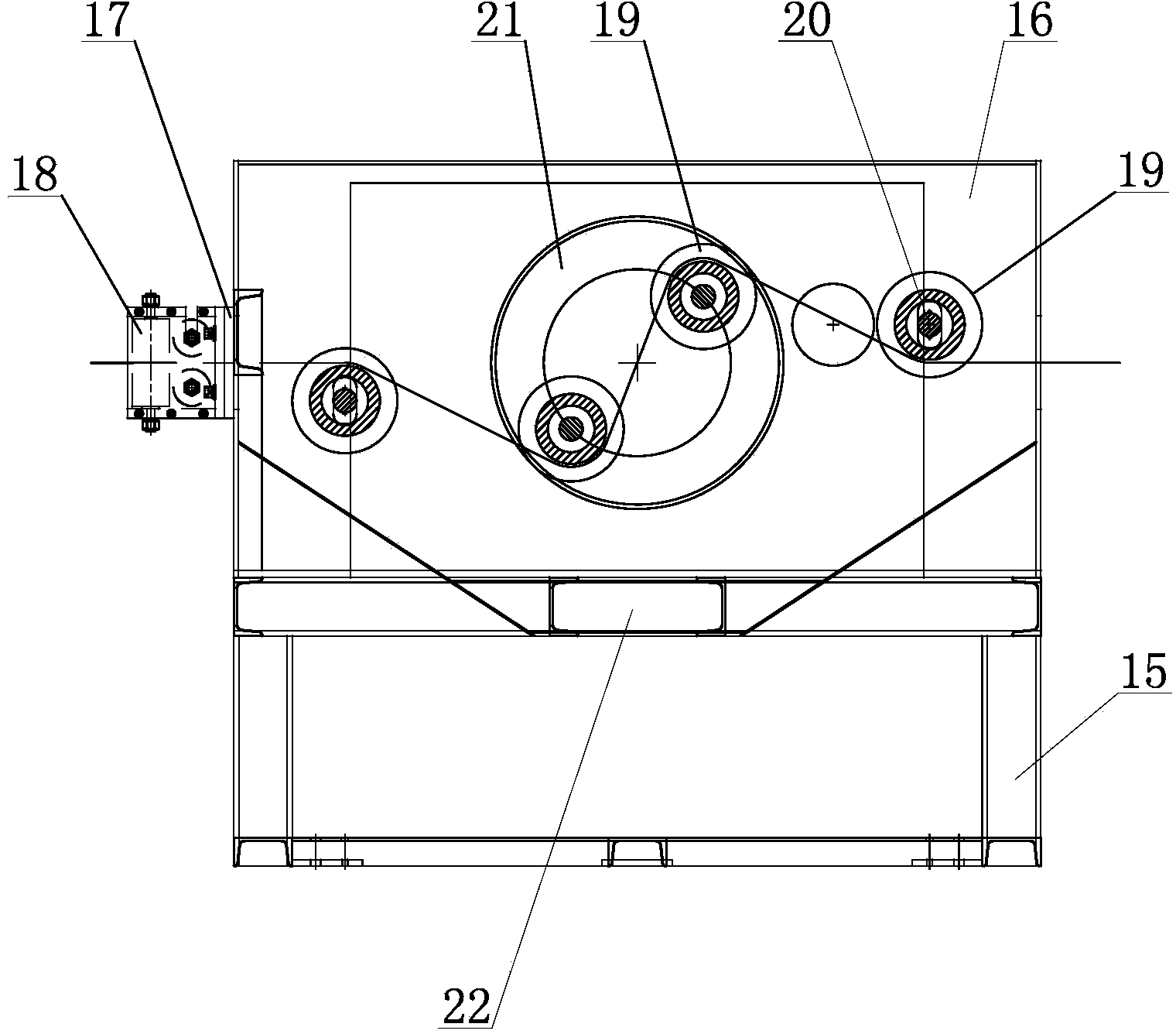

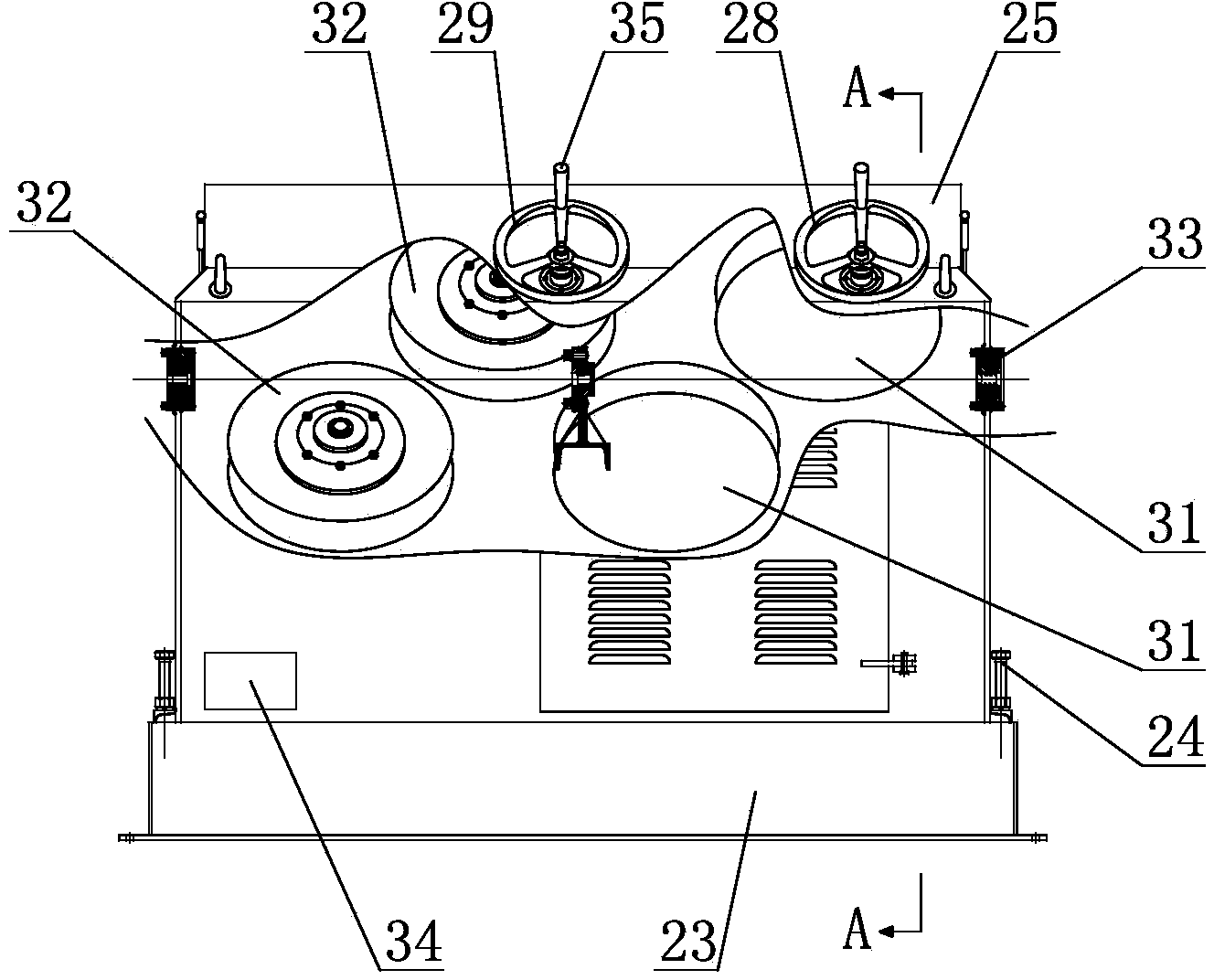

Method used

Image

Examples

Embodiment 1

[0071] The phosphating solution contains zinc ions 45g / L, calcium ions 2g / L, phosphate ions 50g, nitrate ions 25g / L, accelerator sodium chlorate 0.2g / L and nickel ions 0.3g / L, steel wire rod For phosphating, the phosphating temperature is 10°C, the phosphating time is 5 seconds, the current density is 30A / d㎡, the film weight is 5g / ㎡, the phosphating film is dense and complete, and the color is gray and black.

Embodiment 2

[0073] The phosphating solution contains 85g / L of zinc ions, 6g / L of calcium ions, 125g / L of phosphate ions, 70g / L of nitrate ions, 1.1g / L of hydroxylamine sulfate accelerator and 3.4g / L of nickel ions. Phosphate strips, phosphating temperature is 30°C, phosphating time is 8 seconds, current density is 30 / d㎡, film weight is 8g / ㎡, the phosphating film is dense and complete, and the color is gray and black.

Embodiment 3

[0075] The phosphating solution contains 60g / L of zinc ions, 4g / L of calcium ions, 80g / L of phosphate ions, 50g / L of nitrate ions, 1.5g / L of accelerator sodium nitrite, and 6.4g / L of nickel ions. The wire rod is phosphating, the phosphating temperature is 50°C, the phosphating time is 10 seconds, the current density is 30A / d㎡, the film weight is 9.0g / ㎡, the phosphating film is dense and complete, and the color is dark gray.

[0076]In the foregoing embodiments, zinc ions can come from one or both of zinc ingots, zinc oxide, zinc nitrate, and zinc dihydrogen phosphate; calcium ions can come from one or both of calcium oxide, calcium carbonate, and calcium nitrate ; Phosphate ion can come from one or both of phosphoric acid, sodium dihydrogen phosphate, potassium dihydrogen phosphate, and zinc dihydrogen phosphate; nitrate ion can come from one or both of nitric acid and zinc nitrate; Accelerator It can come from one or three of nitrate, nitrite, chlorate, molybdate, hydroxylami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film weight | aaaaa | aaaaa |

| Film weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com