Modified master batch for enhancing toughness of PPR water supply pipe

A water supply pipe and modification technology, which is applied in the field of modified masterbatch, can solve the problems of poor comprehensive performance of PPR pipes, inability to take into account low temperature toughness, impact performance and other service properties.

- Summary

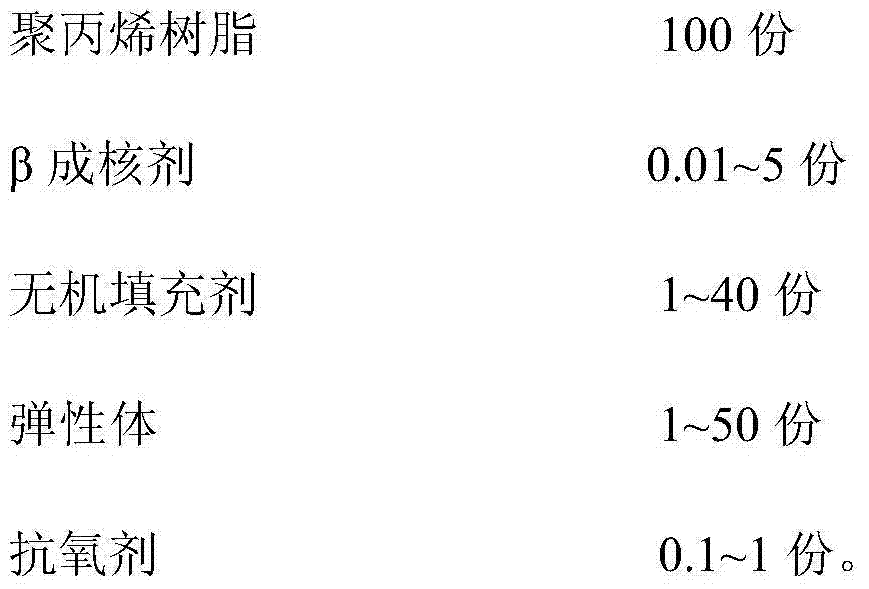

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

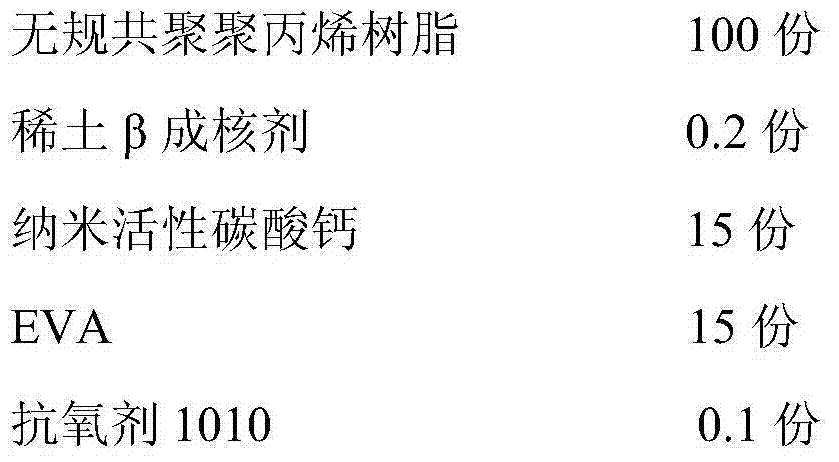

Embodiment 1

[0041]

[0042] Wherein the melt index of the random copolymerized polypropylene resin at 230° C. under 2.16 kg is 8 g / 10 min; the model of the rare earth β nucleating agent is WBG-II; the content of VA in the EVA is 18%.

[0043] The above-mentioned substances are first dispersed evenly by a high-grade mixer, then added to a twin-screw extruder for extrusion, cooling, and granulation. The extrusion temperature of the twin-screw extruder is 190-210°C, and the high Special modified masterbatch for toughness enhancement.

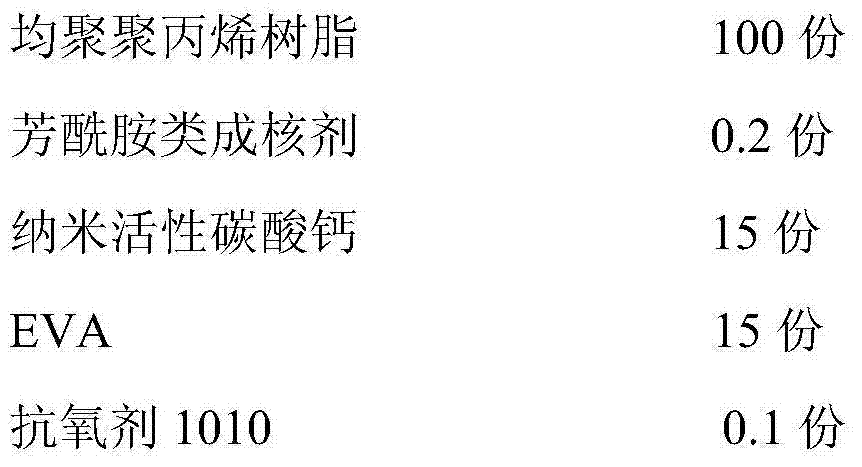

Embodiment 2

[0045]

[0046] The above-mentioned substances are first dispersed uniformly by a high-speed mixer, and then extruded and granulated by twin-screws to obtain a special modified masterbatch for strengthening the high toughness of the PPR water supply pipe.

[0047] Wherein the homopolypropylene resin has a melt index of 2.1g / 10min at 230°C and 2.16kg; the model of the aramid nucleating agent is NB-328; the VA content in the EVA is 25%.

[0048] Add the above components into a high-speed mixer and mix them evenly, and then extrude them in a twin-screw extruder to obtain a modified masterbatch for enhancing the toughness of the PPR water supply pipe. The extrusion temperature of the twin-screw extruder is 190-210°C.

Embodiment 3

[0050]

[0051] The above-mentioned substances are first dispersed uniformly by a high-speed mixer, and then extruded and granulated by twin-screws to obtain a special modified masterbatch for strengthening the high toughness of the PPR water supply pipe.

[0052] The melt index of the homopolypropylene resin at 230° C. under 2.16 kg is 1.2 g / 10 min. The model of the aromatic amide nucleating agent is NB-328; the VA content in the EVA is 15%.

[0053] The modified masterbatch prepared in Examples 1, 2 and 3 was evenly mixed with the pipe material PPR, and then extruded and granulated by a twin-screw extruder. Wherein the extrusion temperature of the twin-screw extruder is 200-230° C., wherein the head temperature is 200-225° C., the screw speed is 270 rpm; the residence time is 1 minute; the vacuum degree is 2.5 MPa.

[0054]In Examples 1 to 3, the PPR pipeline splines doped with the above-mentioned modified masterbatch are prepared according to the common methods in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com