Slag-free low-temperature rapid electrolytic phosphorizing liquid and phosphorizing process thereof

An electrolytic phosphating solution and electrolytic phosphating technology, applied in the field of electrolytic phosphating solution, can solve the problems affecting the stability of the solution and producing solid waste residue, and achieve the effects of meeting the requirements of industrial production, preventing pollution and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

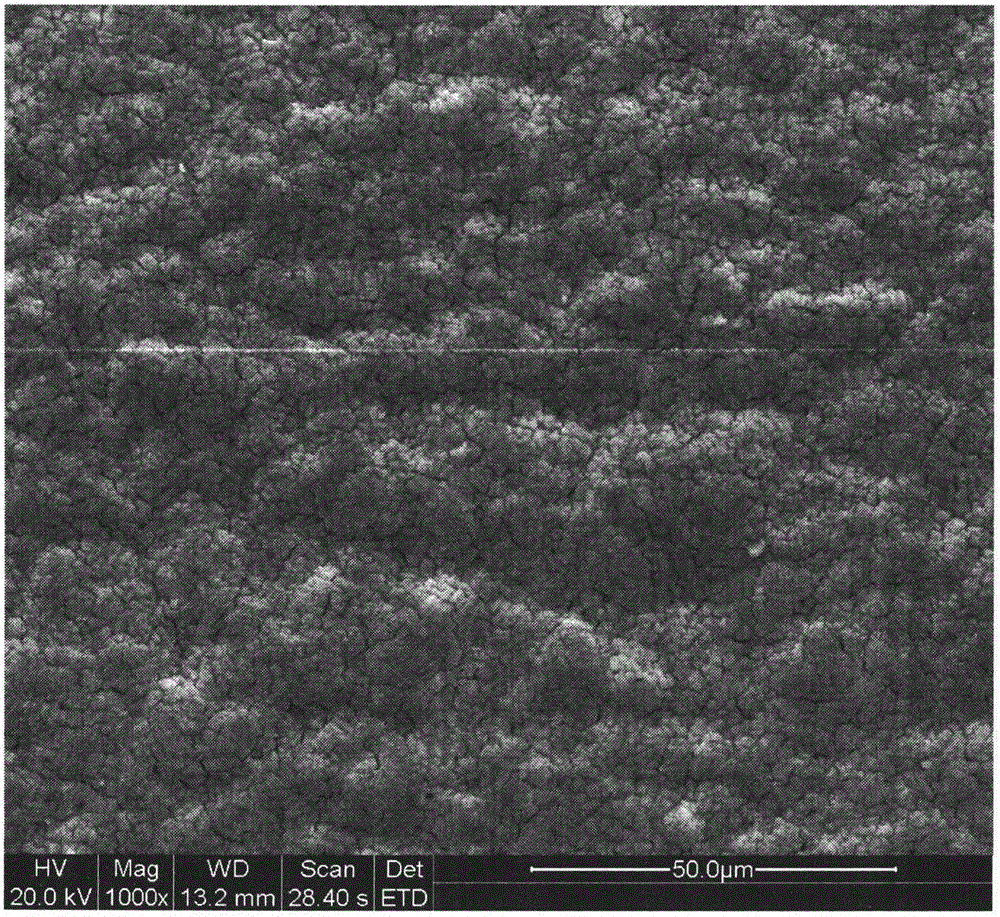

Image

Examples

Embodiment 1

[0031] A slag-free low-temperature rapid electrolytic phosphating solution and phosphating process, including zinc ions 10g / L, calcium ions 2g / L, phosphate 10g / L, nitrate 40g / L, nitroguanidine 2g / L and nickel 0.1g / L, for 70# steel wire with a wire diameter of 3.0mm, the phosphating temperature is 45°C, the phosphating time is 120 seconds, and the current density is 3A / dm 2 , the film weight after phosphating is 4g / m 2 , the phosphating film is complete, and the color is gray and black.

Embodiment 2

[0033] A slag-free low-temperature rapid electrolytic phosphating solution and phosphating process, including zinc ions 30g / L, calcium ions 2g / L, phosphate 60g / L, nitrate 90g / L, hydroxylamine sulfate 5g / L, chlorate 2g / L L and nickel 1g / L, used for 70# steel wire with a wire diameter of 3.0mm, phosphating temperature 45°C, phosphating 60 seconds, current density 5A / dm 2 , the film weight after phosphating is 10g / m 2 , the phosphating film is complete, and the color is black.

Embodiment 3

[0035] A slag-free low-temperature rapid electrolytic phosphating solution, containing zinc ions 80 / L, phosphate 120g / L, nitrate 150g / L, hydroxylamine sulfate 10g / L, citric acid 5g / L, nickel 3g / L and magnesium 7g / L L, for 70# steel wire with a wire diameter of 3.0mm, the temperature of the phosphating solution is 45°C, phosphating for 5 seconds, and the current density is 20A / dm 2 , the film weight after phosphating is 14.7g / m 2 , the phosphating film is complete, and the color is gray and black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film weight | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com