Patents

Literature

50results about How to "Phosphating time is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for cold extrusion forming of one-way device spline sleeve

InactiveCN104148888AEliminates drilling/boring stepsDrilling/boring steps meetEngineeringUltimate tensile strength

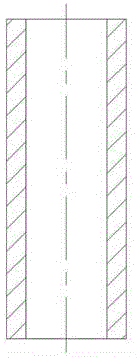

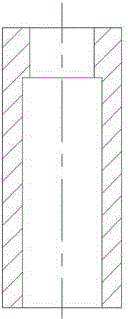

The invention provides a process for cold extrusion forming of a one-way device spline sleeve. The process comprises the steps of utilizing hollow pipes to serve as raw materials, performing blanking according to specified dimensions, sequentially performing annealing, head flattening, shot blasting, phosphatization and saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, shot blasting, cleaning and grinding machine processing, and obtaining finished product one-way device spline sleeves. The one-way device spline sleeves obtained through the process are high in precision, small in individual differences, good in strength performance and long in service lives.

Owner:宁波惠山汽配制造有限公司

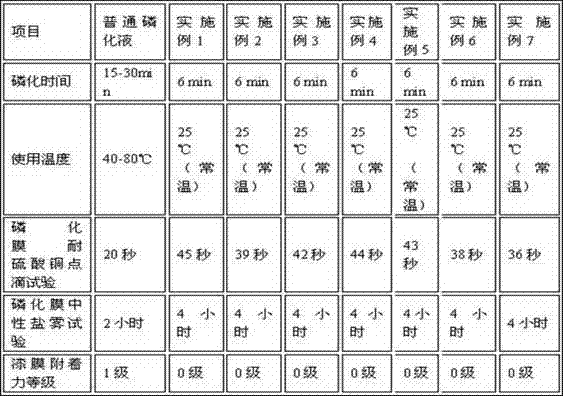

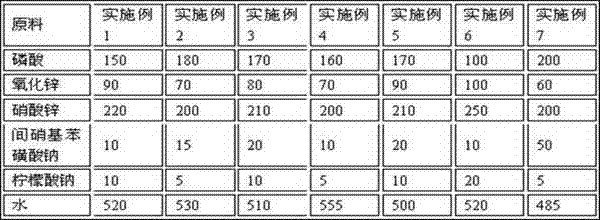

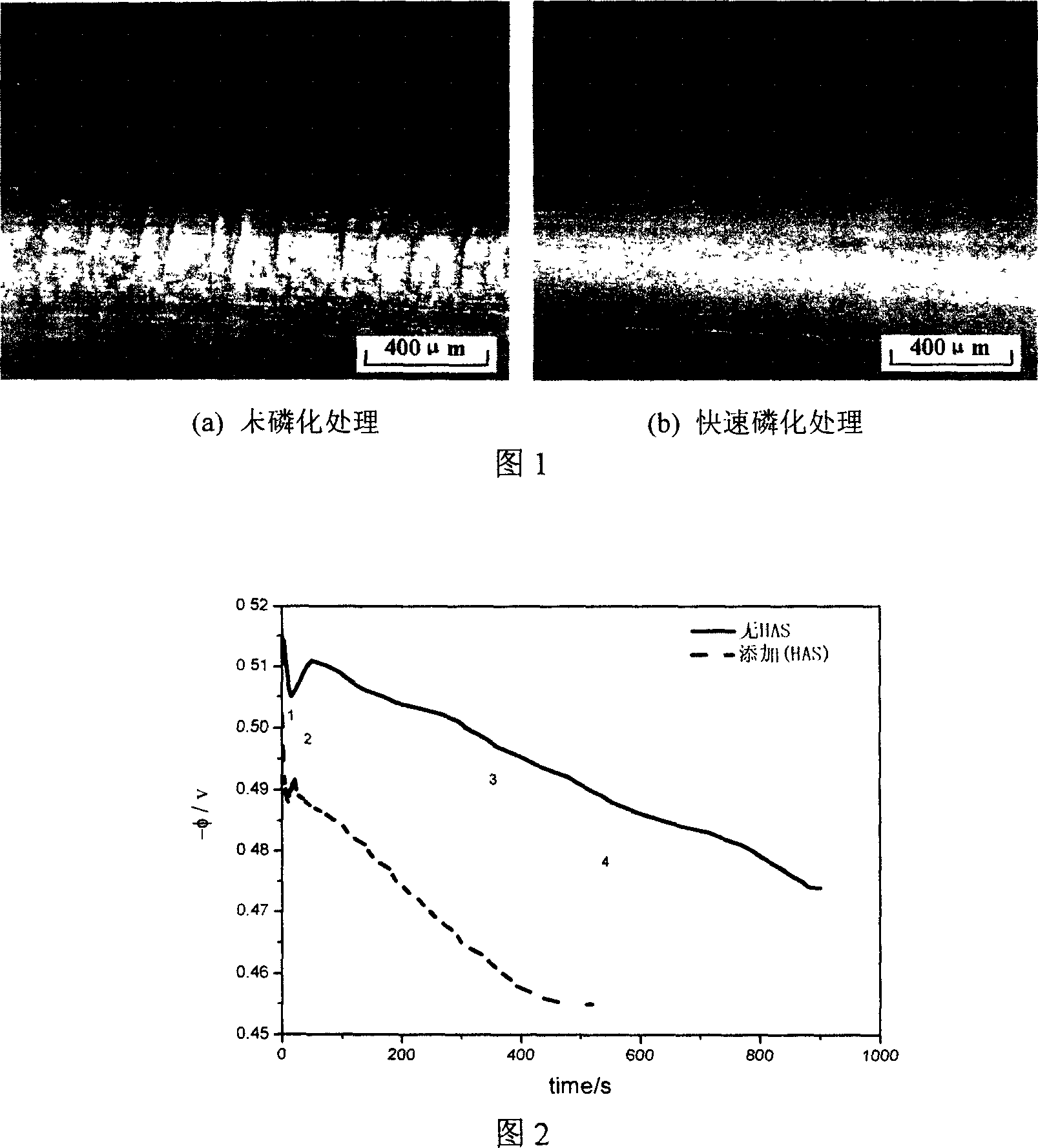

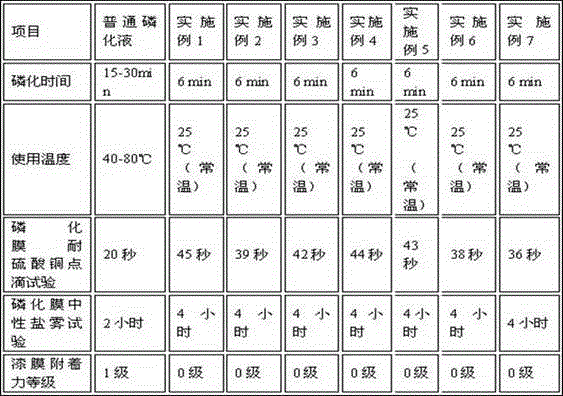

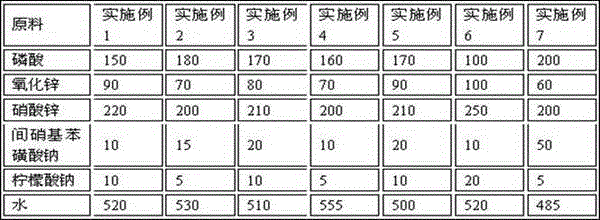

Normal-temperature rapid phosphating solution and preparing method thereof

ActiveCN103668149APhosphating time is shortReduce the use temperatureMetallic material coating processesSulfonatePhosphoric acid

The invention provides a normal-temperature rapid phosphating solution and a preparing method thereof. The normal-temperature rapid phosphating solution comprises the following raw materials in percentage by mass: 10-20 percent of phosphoric acid, 6-10 percent of zinc oxide, 20-25 percent of zinc nitrate, 1-5 percent of sodium 3-nitrobenzene sulfonate, 0.5-2 percent of sodium citrate and water in balancing amount. A coating which is phosphated by the normal-temperature rapid phosphating solution can last 45 seconds in a copper sulfate drip test and can last 4 hours in a neutral salt mist test, and the adhesive force of a paint coating reaches 0 grade. Meanwhile, the normal-temperature rapid phosphating solution has the characteristics of short phosphating time and low use temperature. The production efficiency is increased, and a large quantity of energy is saved.

Owner:HUNAN JINYU CHEM

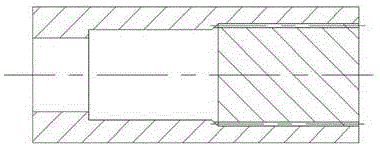

Surface treatment method for composite sulfuric acid-phosphomycin calcium applicable to warm extrusion

InactiveCN103643230AMeet extrusion requirementsLow costMetallic material coating processesPhosphoric acidDehydrogenation

The invention relates to the field of metal surface treatment, and in particular relates to a surface treatment method for black metal in warm extrusion, wherein a black metal blank is subjected to surface treatment by using a sulfuric acid-phosphomycin calcium solution, and a high-temperature resisting sulfuric acid-phosphomycin calcium film, so that the service life of a mold is prolonged. The surface treatment method comprises the following steps: mixing calcium oxide CaO superfine powder, calcium sulfate CaSo4 superfine powder, monocalcium phosphate Ca(H2PO4)2 superfine powder, phosphoric acid H3PO4, sulfuric acid H2SO4 and distilled water H2O in proportion, reacting to generate a calcium sulfate CaSO4 and monocalcium phosphate Ca(H2PO4)2 solution, performing shot blasting and pickling on the blank, performing phosphorization, dehydrogenation and saponification on the solution so as to obtain a black metal extruded blank with a composite sulfuric acid-phosphomycin calcium surface film.

Owner:SHANDONG JIANZHU UNIV

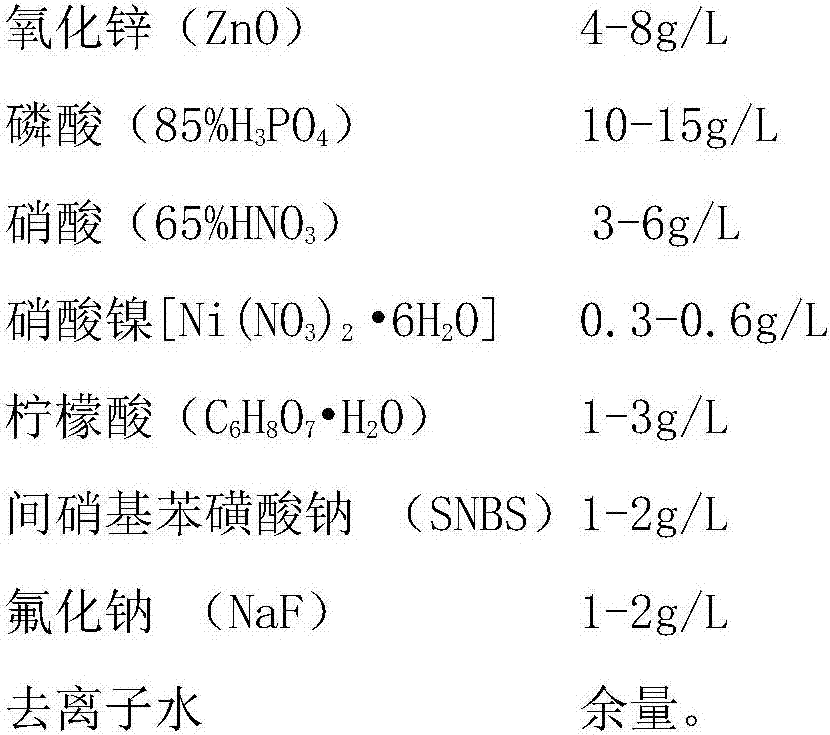

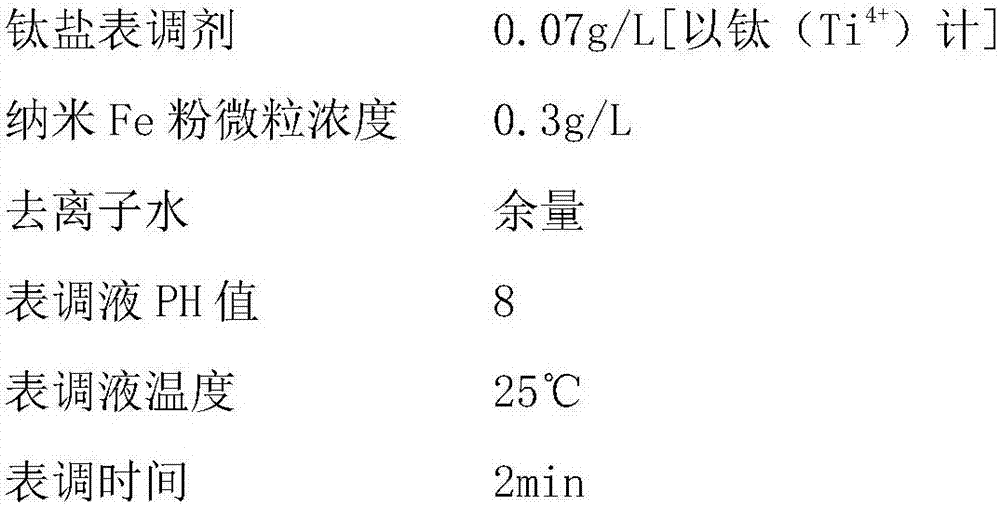

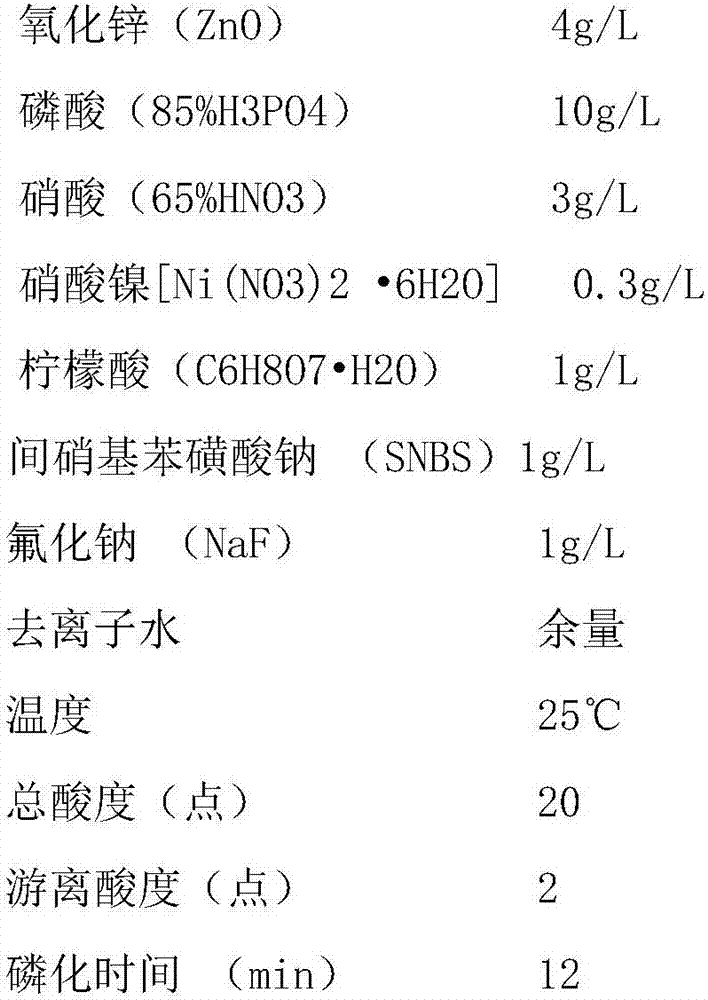

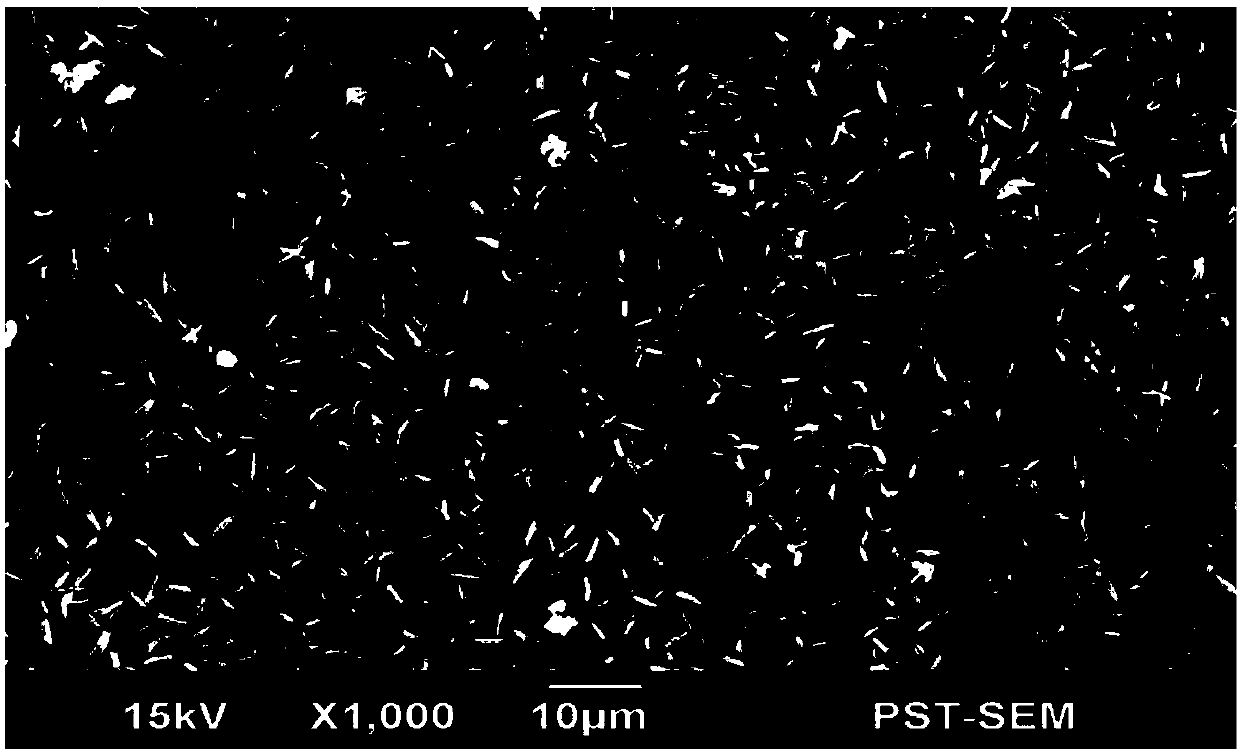

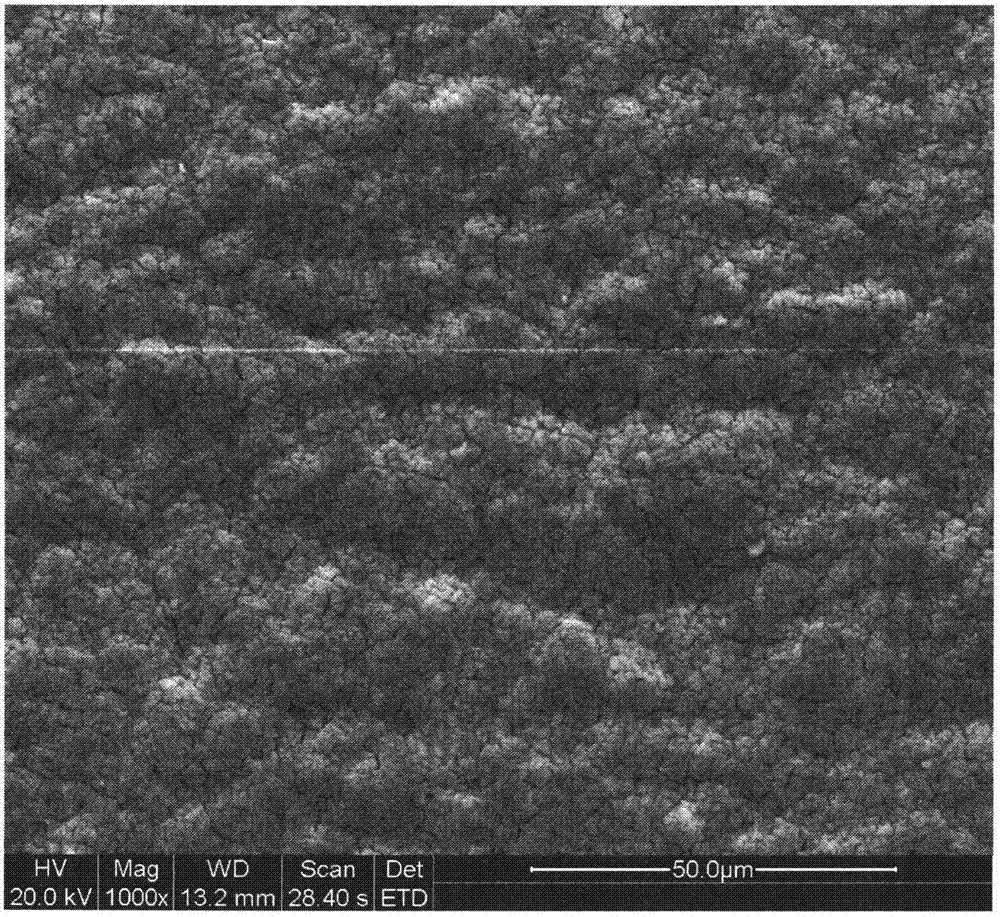

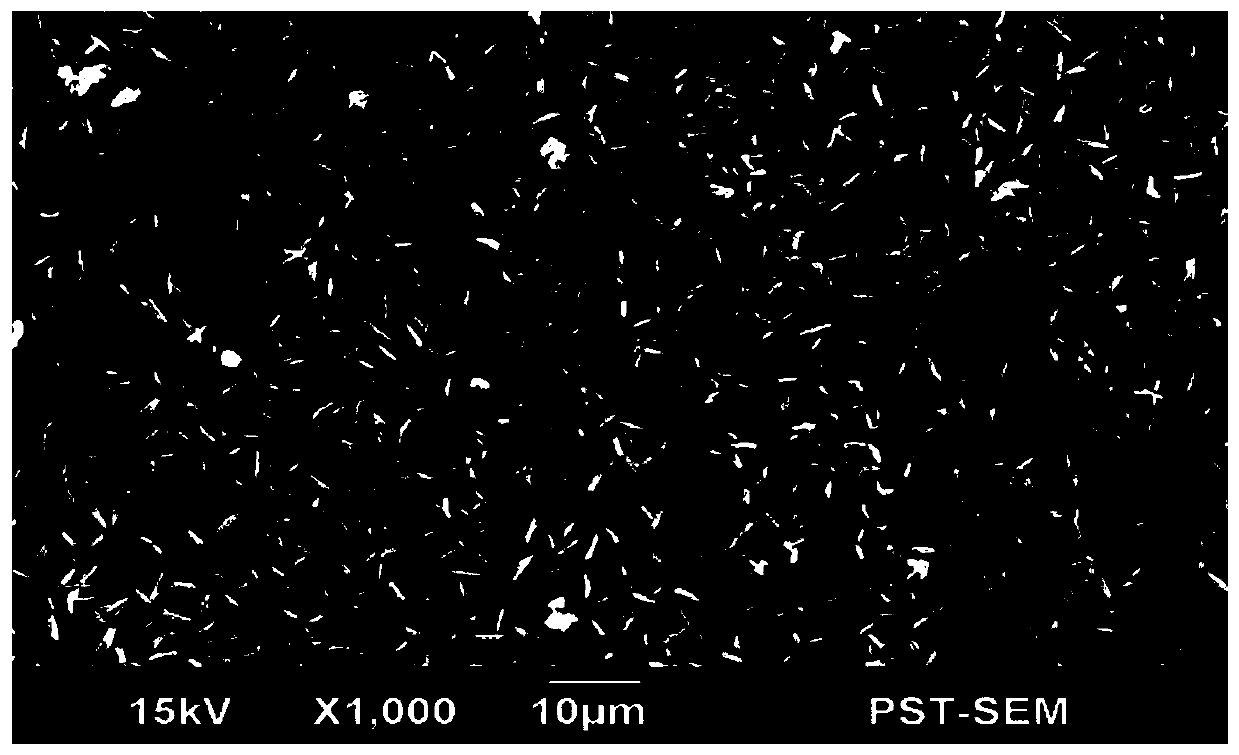

Method for improving corrosion resistance of sintered neodymium iron boron permanent magnet phosphating film

ActiveCN107164754AImprove corrosion resistanceExcellent adhesionMetallic material coating processesFiltrationTitanium

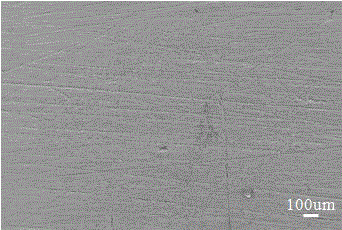

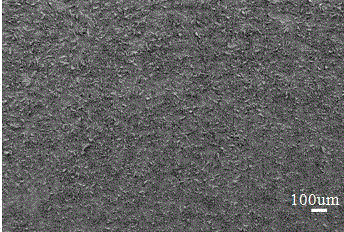

The invention discloses a method for improving corrosion resistance of a sintered neodymium iron boron permanent magnet phosphating film. The method comprises the steps that a machined and formed neodymium iron boron magnet is subjected to chamfering processing and is subjected to oil removing, acid pickling and water washing processing in sequence; in the stirring situation, the magnet is placed into surface conditioning liquid at the temperature of 20-30 DEG C for surface conditioning for 1-3 minutes, and the surface conditioning liquid is composed of a titanium salt surface conditioning agent, nanometer Fe powder particles and deionized water; and finally, the magnet is placed into a phosphating solution at the temperature of 20-40 DEG C for phosphating treatment for 10-20 minutes, and circulating filtration is performed. After the magnet is subjected to jointed surface conditioning by the titanium salt solution mixed with the nanometer Fe powder particles, the surface of the magnet is uniformly provided with a plurality of activated points and film forming factors, therefore the magnet can obtain the more uniform, more fine and more complete phosphating film in the phosphating reaction process, and thus corrosion resistance of the magnet is greatly improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Anhydrous phosphating agent

InactiveCN106399987ASimplify the painting processReduce processing timeMetallic material coating processesPolyvinyl butyralOrganic solvent

The invention discloses an anhydrous phosphating agent. The anhydrous phosphating agent is prepared from, by weight, 20 parts to 40 parts of phosphoric acid, 3 parts to 15 parts of polyvinyl butyral, 3 parts to 12 parts of silicone oil, 5 parts to 10 parts of sodium borate, 8 parts to 18 parts of resin, 3 parts to 14 parts of citric acid and 30 parts to 60 parts of organic solvents. A preparation method of the anhydrous phosphating agent includes the following steps that a, mixed liquid of polyvinyl butyral resin and the organic solvents is prepared; b, phosphoric acid and citric acid organic solvent mixed liquid is prepared; and c, mixing is performed, wherein the solutions obtained in the steps of a and b, silicone oil and sodium borate are mixed according to the formula, and the phosphating agent is prepared in a stirring manner. The phosphating agent is good in phosphating effect, small in sewage discharge amount, free of corrosivity, simple in preparation process and low in cost.

Owner:广州市汇盛金丰科技企业孵化器有限公司

Liquid surface conditioning agent capable of improving film-forming property of phosphating film and preparation method thereof

ActiveCN107937901AImprove versatilityRefined grain sizeMetallic material coating processesPolyvinyl alcoholZinc nitrate

The invention discloses a liquid surface conditioning agent capable of improving the film-forming property of a phosphating film and a preparation method of the liquid surface conditioning agent capable of improving the film-forming property of the phosphating film. The liquid surface conditioning agent comprises the components, by weight, of 3%-9% of zinc nitrate, 1%-5% of calcium nitrate, 8%-15%of disodium hydrogen phosphate, 2%-4% of polyvinyl alcohol, 3%-7% of sodium alcohol ether sulphate, 2%-5% of trisodium pyrophosphate and 55%-81% of deionized water. The liquid surface conditioning agent is especially suitable for surface pretreatment of steel, aluminum and zinc before phosphating of zinc-calcium series and high in universality; crystallization active points in phosphating can beincreased, the grain size and binding force of the phosphating film are improved significantly, uniform growth of the phosphating film is facilitated, meanwhile, the phosphating temperature can be decreased, the phosphating time is shortened, the appearance quality of the phosphating film is improved, and corrosion resistance and abrasion resistance after phosphating are improved; and the preparation condition is gentle, and repeatability is high.

Owner:武汉钢铁有限公司

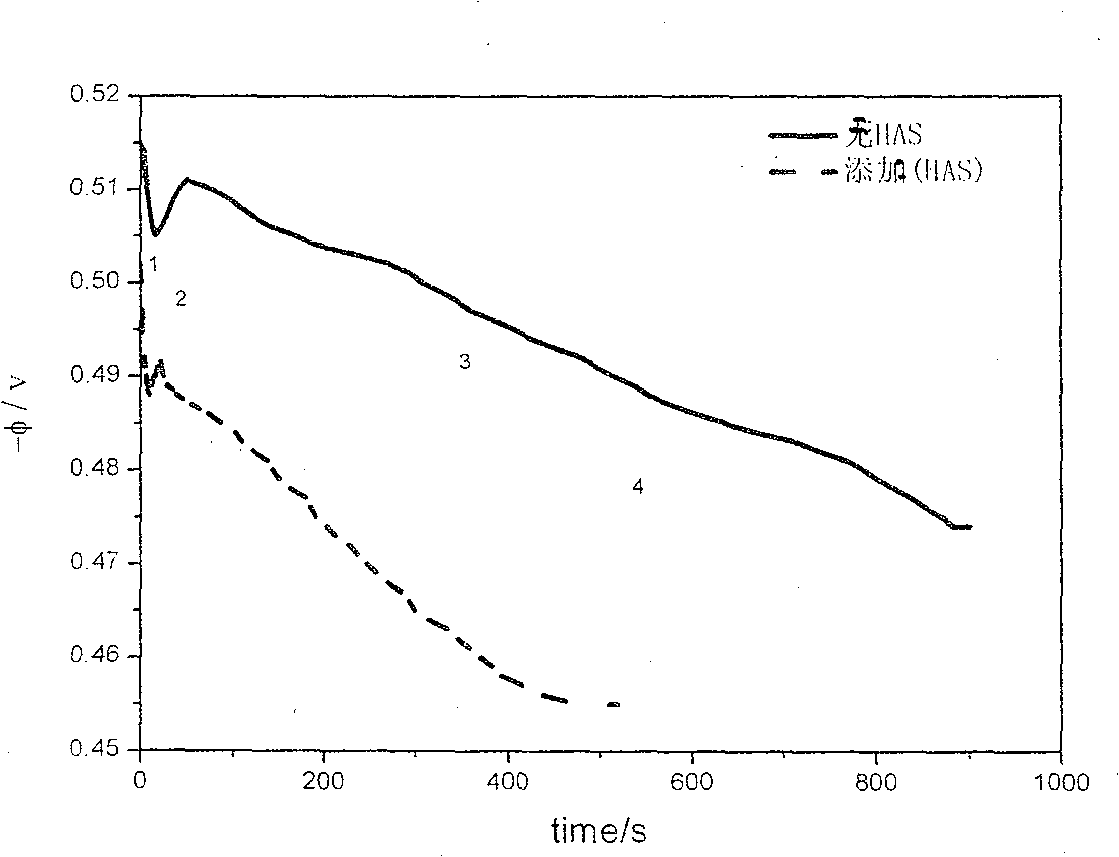

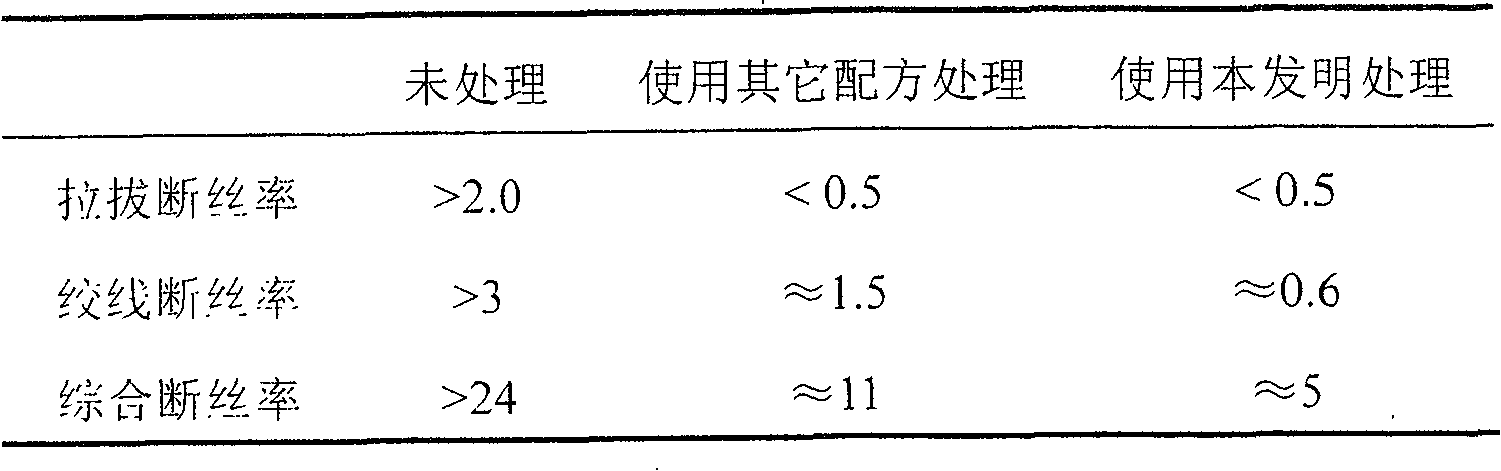

Low temperature rapid phosphorization liquid for drawing wire and phosphorization process

InactiveCN1664166APhosphate treatmentEasy to operateMetallic material coating processesGrinding wheelMaterials science

The invention discloses a low-temperature rapidly phosphatising liquid in wiredrawing of metallic production trade, which comprises Zn (H2PO4), Zn (NO3)2, H3PO4 and H2O, wherein the mass ratio is: (60-100):(15-40):(8-50):(808-912). The phosphatising art is: rubbing out the oxide skin in the surface of the welding point of the rod bundle through the fine grinding wheel, sanding it again, spraying said liquid evenly on the welding surface, weathering the remaining liquid and repeating again.

Owner:SOUTHEAST UNIV

Method for preparing automobile hub high-temperature phosphating solution

InactiveCN108018545AImprove Phosphating EfficiencyHigh activityMetallic material coating processesChemistrySurface-active agents

The invention discloses a method for preparing an automobile hub high-temperature phosphating solution, and relates to the field of hub processing equipment and technologies. The method includes the steps that a reaction still is heated and then connected with nitrogen, uncovering cooling is performed after sealed storage, phosphoric acid, zinc nitrate, thiourea, zinc oxide, oxalic acid, sodium fluoride and nickel nitrate are added into the reaction still for stirring, ethyl alcohol is further added after stirring, and temperature-rise stirring is conducted after sealing; citric acid, ammoniumfluozirconate, hydrofluoric acid, boric acid, EDTA, zinc molybdate, tartaric acid and an accelerant are mixed together and further subjected to ultraviolet sterilization, and the mixture is put intoa refrigerating chamber for conducting low-temperature storage; the mixture is further added into the reaction still to be stirred; clear water is added to be heated; and sodium silicate, magnesium chloride, a surface active agent, white vinegar, graphite powder and nanometer silicon powder are added into the mixture to be evenly stirred and accordingly the automobile hub high-temperature phosphating solution can be prepared. By adoption of the method, the raw materials are added in sequential order, the effect that early-stage phosphorization raw materials are mixed and collaborated more evenly can be guaranteed, then all the raw materials are mixed, phosphatizing agents can be made evener under the strict temperature and stirring condition action, and therefore the phosphorization effectcan be improved.

Owner:BENGBU FUWOTE WHEEL MFG TECH

Low temperature fast phosphating solution for drawing wire and its phosphating process

InactiveCN1986884APhosphate treatmentEasy to operateMetallic material coating processesHigh carbonHydroxylamine sulfate

The present invention discloses a kind of low temperature fast phosphatizing solution for treating the welded area in drawn high carbon coil rod and its phosphatizing process. The low temperature fast phosphatizing solution of the present invention has lubrication on the welded area to avoid crack and breaking. The low temperature fast phosphatizing solution has hydroxylamine sulfate to replace traditional harmful NaNO2, and possesses environment friendship, high stability and long service period.

Owner:SOUTHEAST UNIV

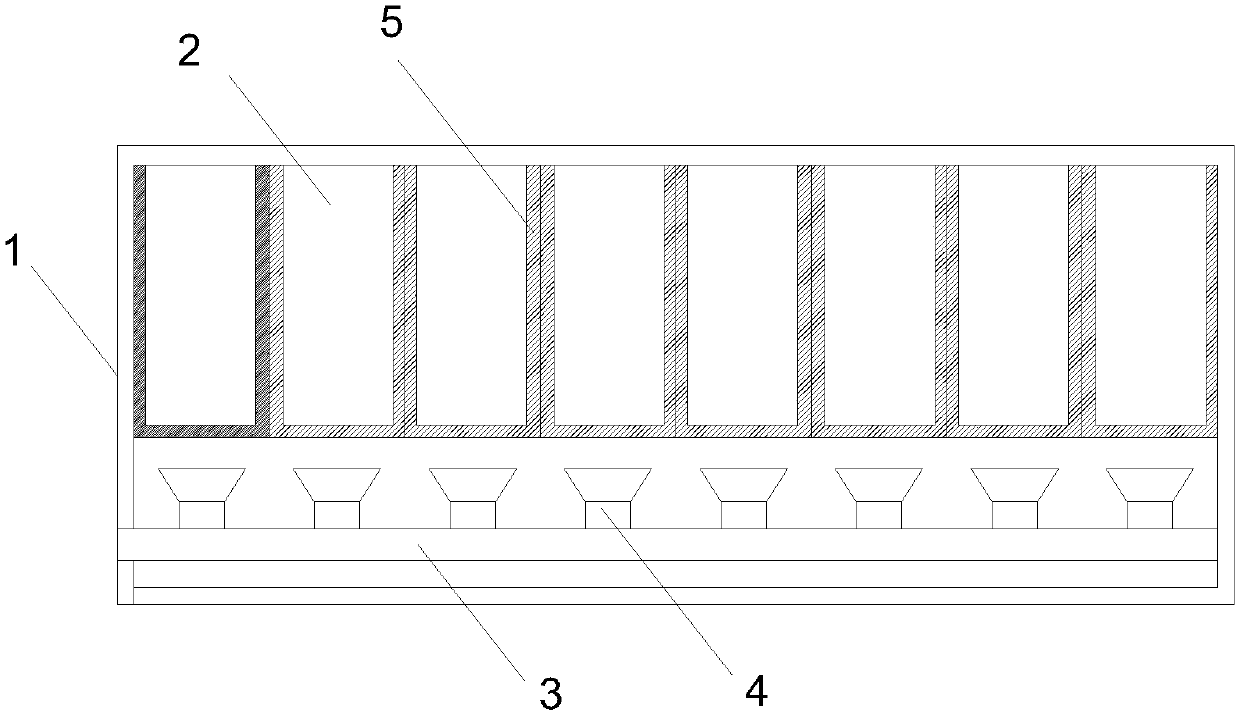

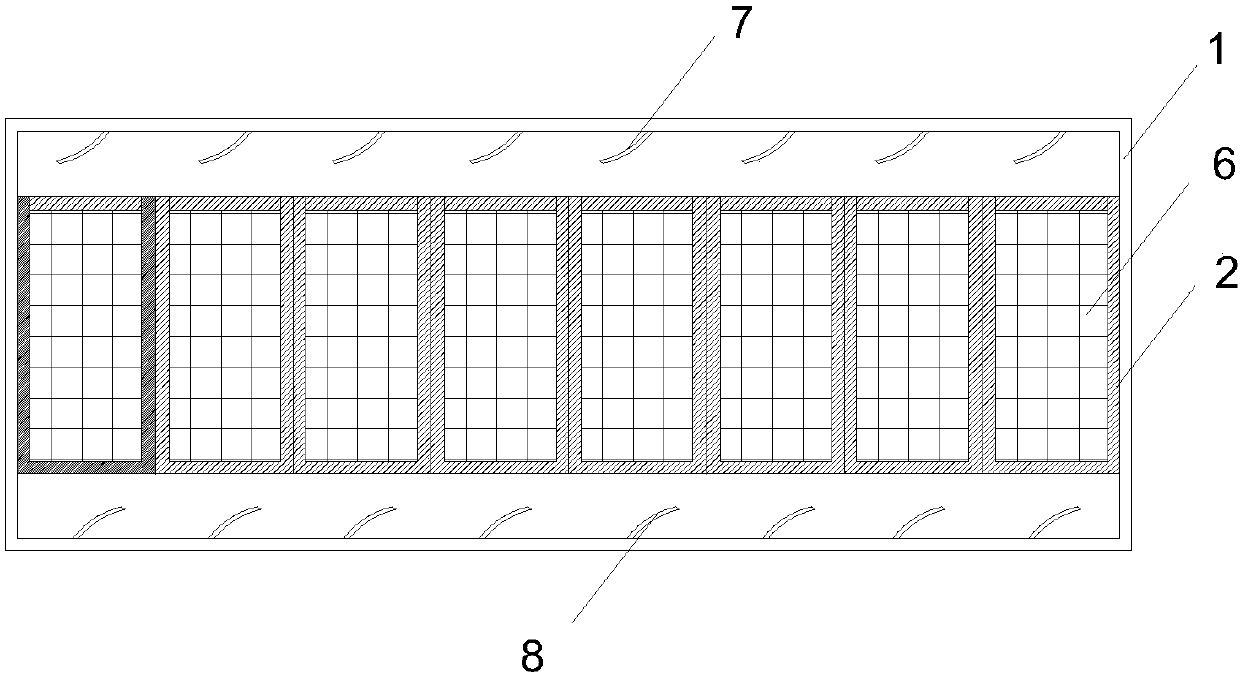

Production process of plastic coated pipe fitting without secondary tapping

ActiveCN102410408AQuality assuranceIncrease anti-rust processRigid pipesLower tooth socketPipe fitting

The invention provides a production process of a plastic coated pipe fitting without secondary tapping in order to overcome the defects of high rejection rate, high cost and the like, which are caused by secondary tapping on tooth patterns of a product after coating plastic in the prior art process. The production process comprises the following steps of: removing oil and rust from a malleable cast iron pipe fitting, neutralizing through swimming immersion, water washing through swimming immersion, surface conditioning through swimming immersion, high-temperature phosphating, water washing through swimming immersion, water washing through spraying, preheating, installing a tooth socket, coating plastic internally and externally, dismounting the tooth socket, curing and leveling, cooling, checking, preventing rust of the tooth patterns, and obtaining the finished product. Compared with the prior art, the production process has the beneficial effects that: due to the adoption of high-temperature Zn-Ca phosphating, the phosphating time is shortened, the quality of a phosphating film is ensured, the product has stable properties, such as adhesion force, impact property and the like, the production procedure is simple, the production efficiency is high, labor investment and high rejection rate caused by factors, such as secondary tapping and the like, are reduced, and the quality of the product is improved because a tooth pattern rust-preventing process is added.

Owner:GUANGDONG LIANSU TECH INDAL

Phosphating solution and preparation method thereof

InactiveCN103255401ALess sedimentEasy maintenanceMetallic material coating processesNitrateCrack resistance

The invention aims to provide a phosphating solution and a preparation method thereof. The phosphating solution is mainly prepared from hydroxylamine sulphate, phosphoric acid, sodium dihydrogen phosphate, fatty alcohol-polyoxyethylene ether, cerous nitrate, zinc oxide, manganese phosphate and water. The preparation technology is simple, feasible and easy to operate. The phosphating solution provided by the invention has certain capability of removing rusts and oil dirt; by a sand blasting treatment technology, an overall phosphating working procedure is saved; a phosphated film generated after phosphating treatment is high in cracking resistance, deformation resistance and impact resistance, can be well combined with an organic coating film and is a high-quality bottom layer for film coating; a phosphating process can be executed at normal temperature; the phosphating time is short; and the phosphating effect is good.

Owner:广西建工第五建筑工程集团有限公司

Composition for steel phosphating and preparation method thereof

ActiveCN104357818ABright colorFast phosphatingMetallic material coating processesPhosphatePolyethylene glycol

The invention discloses a composition for steel phosphating and a preparation method thereof. The composition is composed of the following components in parts by mass: 2-6 parts of sodium nitrate, 2-4 parts of sodium citrate, 15-25 parts of iron manganese dihydrogen phosphate, 5-10 parts of magnesium oxide, 10-20 parts of nickel nitrate, 2-5 parts of copper sulfate, 1-3 parts of sulfosalicylic acid, 2-5 parts of polyethyleneglycol and 500-900 parts of deionized water. The preparation method comprises the following steps: a. weighing the components according to parts by mass; b. adding the sodium citrate, sulfosalicylic acid and polyethyleneglycol into another deionized water; and c. uniformly mixing the solutions obtained in the step a and step b. The composition for steel phosphating can complete phosphating within 8-10 minutes, and has the advantages of high phosphating speed and short required lime for phosphating; and the surface of the phosphated steel has bright color.

Owner:浙江迪特高强度螺栓有限公司

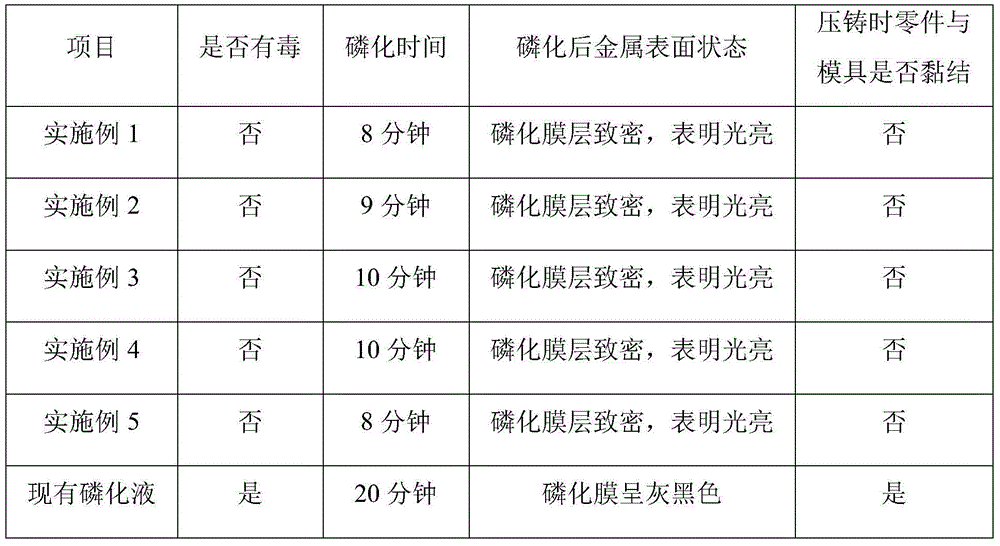

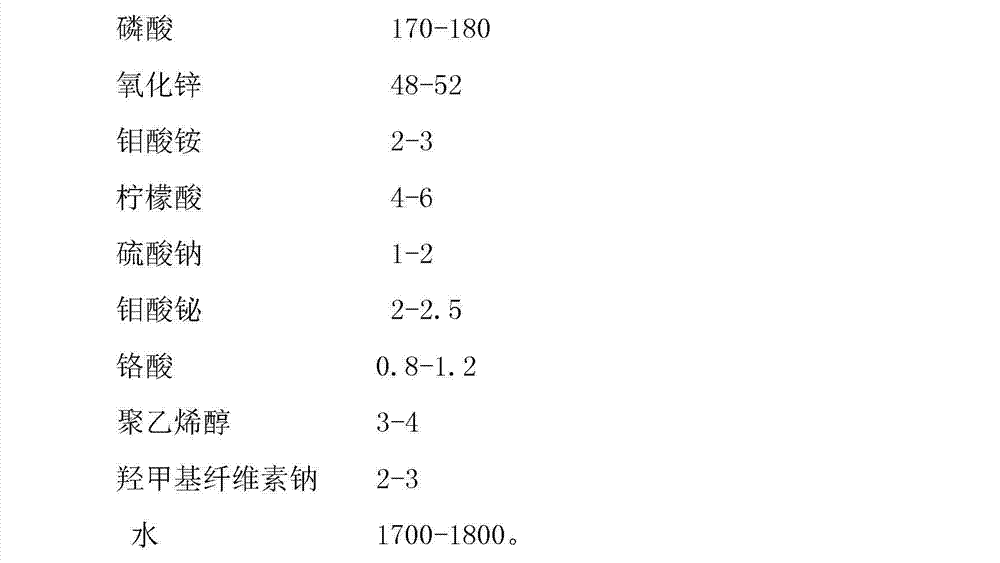

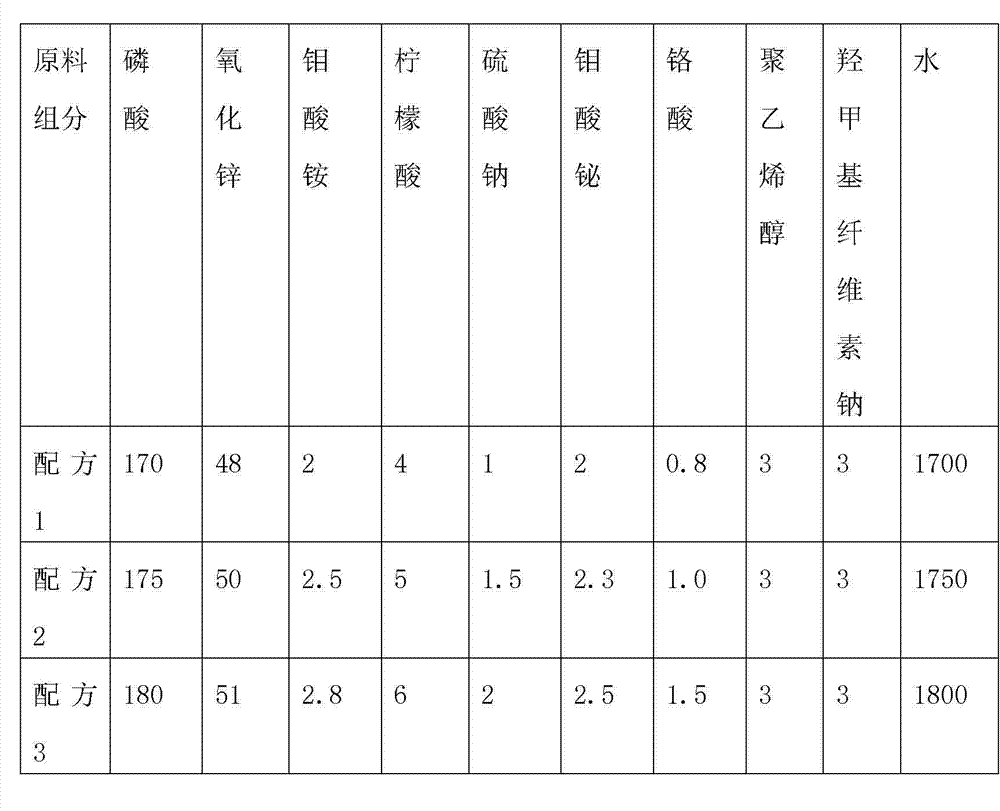

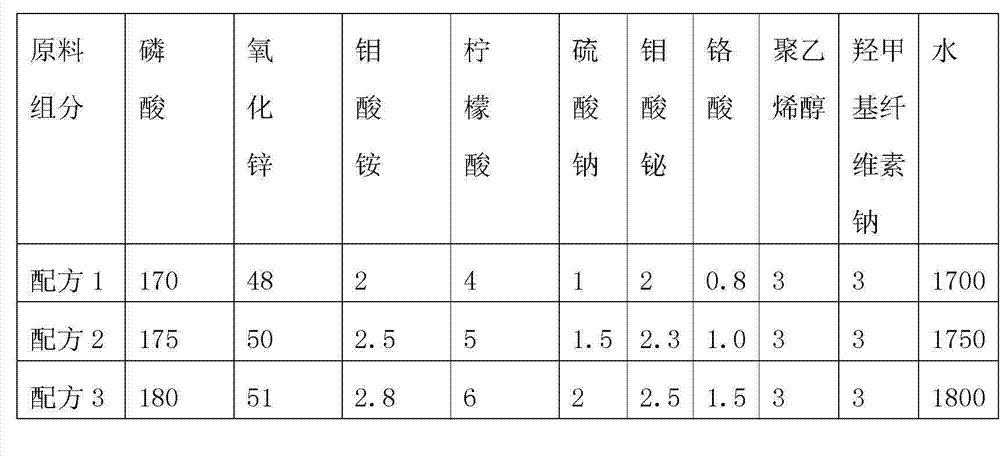

Low-temperature phosphating solution containing chromic acid

InactiveCN102817025ALower working temperatureReduce energy consumptionMetallic material coating processesMolybdatePhosphoric acid

The invention provides a low-temperature phosphating solution containing chromic acid. The phosphating solution is prepared by the following components by weight: 170 to 180 parts of phosphoric acid, 48 to 52 parts of zinc oxide, 2 to 3 parts of ammonium molybdate, 4 to 6 parts of citric acid, 1 to 2 parts of sodium sulfate, 2 to 2.5 parts of bismuth molybdate, 0.8 to 1.2 parts of chromic acid and 1700 to 1800 parts of water. The phosphating solution has the advantages of low working temperature, low energy consumption, little sediment, short phosphating time, high working efficiency, reduction in pollution, environment protection, uniform and dense phosphating film, and good luster appearance. After the phosphating solution is used for spraying or soaking steel iron, a dense phosphated crystallized film with excellent performance can be formed on the surface of the steel iron.

Owner:BENGBU FUWOTE WHEEL MFG TECH

Cold extrusion machining process of brake shoe roller shafts

InactiveCN110872709AEnsure consistent qualityImprove quality consistencyFurnace typesMetallic material coating processesMachine partsTempering

The invention discloses a cold extrusion machining process of brake shoe roller shafts, and belongs to the technical field of machine part machining. The cold extrusion machining process includes thefollowing steps that 45# steel is used as the raw material; and after blanking is conducted according to specified sizes, annealing, end flattening, shot blasting, phosphorus saponification processing, cold extrusion shaping, machining, quenching, tempering, shot blasting, washing, grinding machine machining and waste material recycling are sequentially conducted to obtain the finished product brake shoe roller shafts. The brake shoe roller shafts obtained through the process are high in precision, small in differences among individuals, good in strength performance and long in service life.

Owner:谷城天兴机械有限公司

A kind of slag-free low-temperature rapid electrolytic phosphating solution and its phosphating process

ActiveCN102719872BPhosphating temperature is lowPhosphate treatmentPhosphatisationOrganic acidZinc phosphate

The invention provides a slag-free low-temperature rapid electrolytic phosphating solution and a phosphating process thereof. The phosphating solution contains zinc ions, phosphate radicals, accelerators, organic acids and dissolved metal elements, and its mass components are as follows: zinc ions 10-80g / L, phosphate radicals 10-120g / L, accelerators 41-160g / L , organic acid 0‑5g / L, dissolved metal elements 0.1‑10g / L, where phosphate is calculated as P2O5. This process uses an inert titanium plate or mesh as the positive electrode, and the treated steel wire as the negative electrode. A certain current is applied to form a uniform zinc phosphate film on the surface of the steel wire. The film weight reaches more than 4g / m2, which meets the drawing requirements. The phosphating temperature of the invention is 10-60 DEG C, the phosphating time is 5-120 seconds, and no phosphating slag is generated, so it has the obvious advantages of high efficiency, energy saving and environmental protection.

Owner:派诺(湖北)绿色化学智造有限公司

Intermediate-temperate zinc phosphating solution and preparation method thereof

InactiveCN110205615ARapid responsePhosphating time is shortMetallic material coating processesPhosphoric acidChemistry

The invention discloses an intermediate-temperate zinc phosphating solution and a preparation method thereof. 10%-12% of zinc oxide proportioned according to the mass percent is firstly put into a container to be stirred, wherein the container contains water and is provided with a stirring device; then 10%-13% of nitric acid and 15%-22% of phosphoric acid proportioned according to the mass percentare sequentially added into the container, and stirring continues; then 1%-2% of manganous nitrate, 0.5%-1% of sodium molybdate, 1%-2.7% of sodium gluconate and 0.1%-1% of sodium chlorate proportioned according to the mass percent are sequentially added into the container, and stirring continues; and the continuous stirring time and the rotating speed of the stirring device are controlled, and the intermediate-temperate zinc phosphating solution is obtained. Environmental protection and safety are embodied; the solid waste disposal expenses are reduced; economical performance is embodied; application is wide; the best phosphating effect is achieved; resources are saved, and the phosphating cost is reduced; and the process is simple, and no harsh equipment and process elements exist.

Owner:季新春

Preparation method for phosphating ferrous lithium high-temperature-resistant phosphating film material for metal

ActiveCN105063589AMeet the requirements of warm extrusionMeet extrusion requirementsMetallic material coating processesLithium iron phosphateChemical composition

The invention relates to a preparation method for a phosphating ferrous lithium high-temperature-resistant phosphating film material for metal and belongs to the technical field of metal surface treatment. The preparation method includes the following steps that firstly, a metal matrix is selected, the surface of the metal is cleaned, chemical components are given according to the method, and the mass ratio of the chemical components is (159.68):(65.88):(115.03):(254.11):(12); the components are placed in a crucible, fully and evenly stirred through a glass bar and then placed in a box-type resistance furnace, the temperature is slowly increased from the room temperature of 20 DEG C, heat preservation is conducted for 30 min when the temperature of the resistance furnace is increased to 500-800 DEG C, and solid lithium iron phosphate is obtained; a phosphating solution is prepared from the obtained powder lithium iron phosphate and phosphoric acid according to the mass ratio of 1:2, a blank to be treated is placed in the phosphating solution, and a dark grey phosphating film can be obtained by the blank; a heating dehydrogenation process is finally conducted on the blank, so that the hazard of hydrogen embrittlement is reduced; and a saponification process is conducted, so that lubrication between the squeezed blank and a die is further enhanced.

Owner:东莞市颖兴金属表面处理材料有限公司

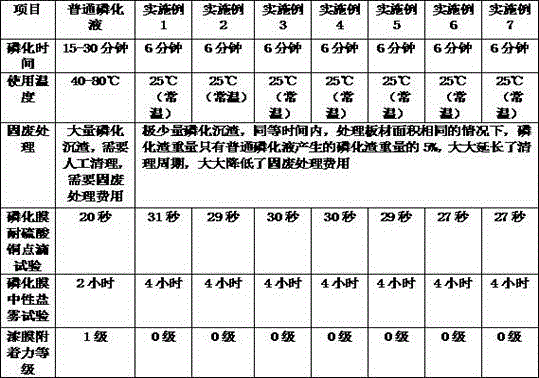

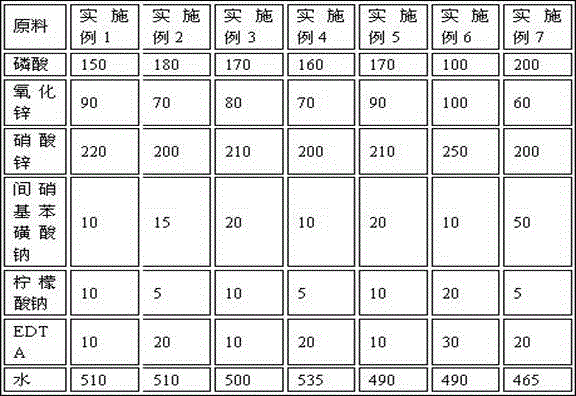

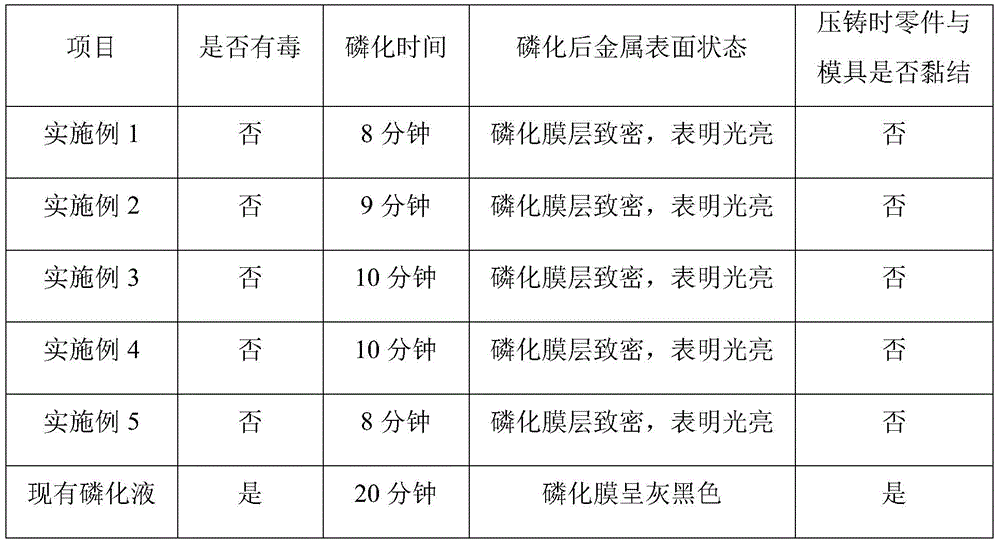

Normal temperature slag-free rapid phosphating solution and preparation method thereof

ActiveCN103695881BReduce processing costsPhosphating time is shortMetallic material coating processesSalt spray testSlag

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Surface conditioning agent and preparation method thereof

ActiveCN112877683AImprove corrosion resistanceImprove processing efficiencyMetallic material coating processesManganesePhysical chemistry

The invention relates to the technical field of surface treatment, in particular to a surface conditioning agent and a preparation method thereof. The raw materials comprise 5%-10% of manganese salt, 0.07%-0.15% of a blackening aid, 6%-10% of sodium salt, 0.1%-1% of an accelerant and the balance water. The surface conditioning agent prepared by the invention has the following advantages that (1) a workpiece treated by the surface conditioning agent can obtain a more uniform and compact film layer after phosphorization, and the corrosion resistance of the workpiece is improved; (2) the obtained surface conditioning agent can improve the workpiece surface treatment efficiency and shorten the phosphating time; (3) the obtained surface conditioning agent can improve the appearance attractiveness of the workpiece, so that a phosphating film is glittering, translucent, smoother, black and brighter; and (4) the obtained surface conditioning agent is high in adaptability, can achieve a synergistic effect with various phosphating agents, has an excellent enhancement effect, is easy in raw material obtaining and simple and convenient in process, has the advantages of economy and environmental protection, and is wide in application prospect.

Owner:厦门腾兴隆化工有限公司

Chromium-free chemical conversion treatment method for magnesium alloy surface

InactiveCN104928663ALower operating temperaturePhosphating time is shortMetallic material coating processesMg alloysHexamethylenetetramine

The invention relates to a chromium-free chemical conversion treatment method for a magnesium alloy surface. The chromium-free chemical conversion treatment method for the magnesium alloy surface comprises the steps of surface pretreatment, alkaline washing for oil removing, water washing, acid pickling, water washing, phosphorization and water washing. Treating fluid used for phosphorization is composed of 20-80 g.L<-1> of sodium dihydrogen phosphate, 1-167 g.L<-1> of calcium hypophosphite and 0.1-10 g.L<-1> of hexamethylenetetramine. The phosphorization treatment temperature is 10-60 DEG C, the pH value is 2.8-7.0, and the phosphorization time is 1-50 minutes. A phosphating film surface prepared through the method is uniform, compact and high in corrosion resistance and can be used independently or serve as the bottom layer of a coating film, and the adhesive force of the coating film to a base body is improved. The reaction temperature is low, the condition is mild, the elements of a phosphating solution are simple, and the technique universality is high; no special requirements exist for equipment and the technique, and industrialized application is facilitated; production cost is reduced; meanwhile, energy resources are saved.

Owner:SOUTH CHINA UNIV OF TECH

Low temperature fast phosphating solution for drawing wire and its phosphating process

InactiveCN100478495CPhosphate treatmentEasy to operateMetallic material coating processesHigh carbonHydroxylamine sulfate

Owner:SOUTHEAST UNIV

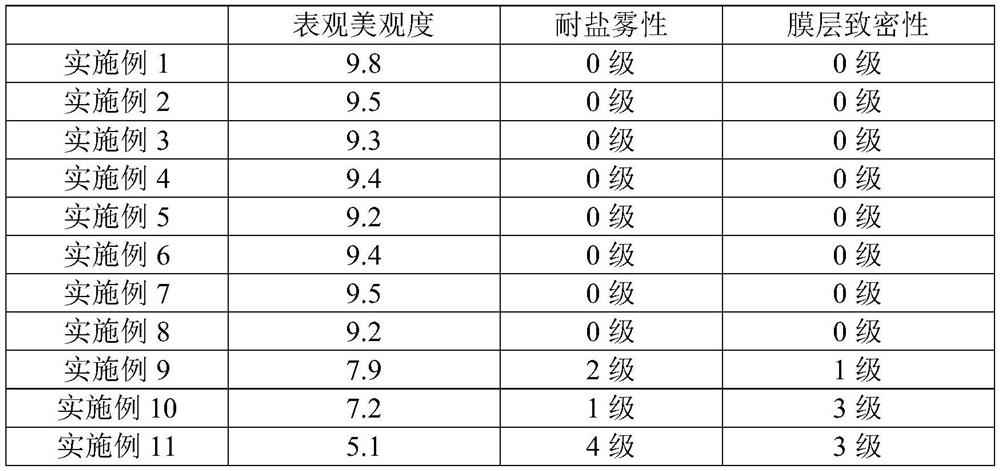

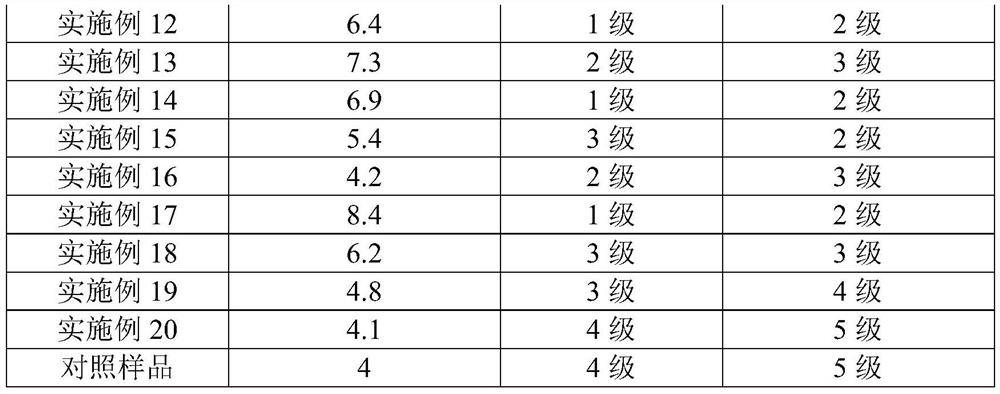

Phosphating solution and preparation method thereof

InactiveCN106906461APhosphating time is shortReduce the use temperatureMetallic material coating processesPhosphoric acidOxide

The invention provides a phosphating solution and a preparation method thereof. The phosphating solution is made from the following raw materials, by weight, 15%-20% of phosphoric acid, 6%-10% of zinc oxide, 20%-25% of zinc nitrate, 1%-5% of ethylenediamine tetraacetic acid, 0.5%-2% of citric acid and the balance water. According to the normal-temperature and quick phosphating solution, the time of a phosphating film copper sulfate droplet test reaches 45 sec, the time of a neutral salt spray test reaches 4 hours, paint film adhesive force reaches 0 stage, meanwhile, the phosphating solution has the characteristics that the phosphating time is short and the using temperature is low, the production efficiency is improved, and a great deal of energy is saved.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Liquid surface regulator capable of improving film-forming performance of phosphating film and preparation method thereof

ActiveCN107937901BImprove versatilityRefined grain sizeMetallic material coating processesPolyvinyl alcoholActive point

The invention discloses a liquid surface conditioning agent capable of improving the film-forming property of a phosphating film and a preparation method of the liquid surface conditioning agent capable of improving the film-forming property of the phosphating film. The liquid surface conditioning agent comprises the components, by weight, of 3%-9% of zinc nitrate, 1%-5% of calcium nitrate, 8%-15%of disodium hydrogen phosphate, 2%-4% of polyvinyl alcohol, 3%-7% of sodium alcohol ether sulphate, 2%-5% of trisodium pyrophosphate and 55%-81% of deionized water. The liquid surface conditioning agent is especially suitable for surface pretreatment of steel, aluminum and zinc before phosphating of zinc-calcium series and high in universality; crystallization active points in phosphating can beincreased, the grain size and binding force of the phosphating film are improved significantly, uniform growth of the phosphating film is facilitated, meanwhile, the phosphating temperature can be decreased, the phosphating time is shortened, the appearance quality of the phosphating film is improved, and corrosion resistance and abrasion resistance after phosphating are improved; and the preparation condition is gentle, and repeatability is high.

Owner:武汉钢铁有限公司

A kind of preparation method of lithium ferrous phosphide high temperature resistant phosphating film material for metal

ActiveCN105063589BMeet the requirements of warm extrusionMeet extrusion requirementsMetallic material coating processesSurface cleaningPhosphate

The invention discloses a method for preparing a high-temperature-resistant lithium iron phosphide high-temperature-resistant phosphating film material for metals, belonging to the technical field of metal surface treatment, and the invention is obtained through the following steps. Firstly, the metal substrate is selected, and the metal surface is cleaned, and the chemical composition is given according to the invention, and the mass ratio is: (159.68): (65.88): (254.11): (12). Put the above-mentioned substances into a crucible, fully stir them with a glass rod, put them into a box-type resistance furnace, slowly raise the temperature from a room temperature of 20°C, and keep the temperature for 30min when the resistance furnace rises to 500‑800°C to obtain a solid lithium iron phosphate . Put the obtained lithium iron phosphate powder and phosphoric acid in a phosphating solution with a mass ratio of 1:2, put the blank to be treated into the phosphating solution, and the blank can obtain a dark gray phosphating film. Finally, the blank is heated to remove hydrogen to reduce the harm of hydrogen embrittlement. The saponification process is carried out to further enhance the lubrication between the extrusion billet and the die.

Owner:东莞市颖兴金属表面处理材料有限公司

Normal temperature rapid phosphating solution and preparation method thereof

ActiveCN103668149BPhosphating time is shortReduce the use temperatureMetallic material coating processesSalt spray testPhosphoric acid

The invention provides a normal-temperature rapid phosphating solution and a preparing method thereof. The normal-temperature rapid phosphating solution comprises the following raw materials in percentage by mass: 10-20 percent of phosphoric acid, 6-10 percent of zinc oxide, 20-25 percent of zinc nitrate, 1-5 percent of sodium 3-nitrobenzene sulfonate, 0.5-2 percent of sodium citrate and water in balancing amount. A coating which is phosphated by the normal-temperature rapid phosphating solution can last 45 seconds in a copper sulfate drip test and can last 4 hours in a neutral salt mist test, and the adhesive force of a paint coating reaches 0 grade. Meanwhile, the normal-temperature rapid phosphating solution has the characteristics of short phosphating time and low use temperature. The production efficiency is increased, and a large quantity of energy is saved.

Owner:HUNAN JINYU CHEM

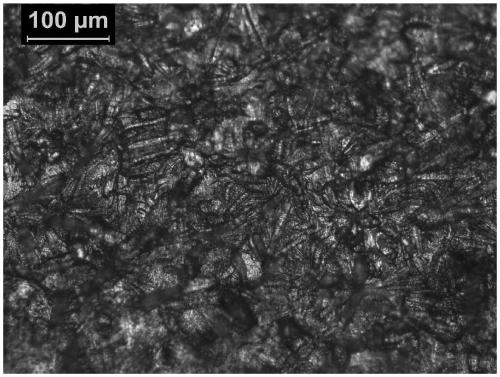

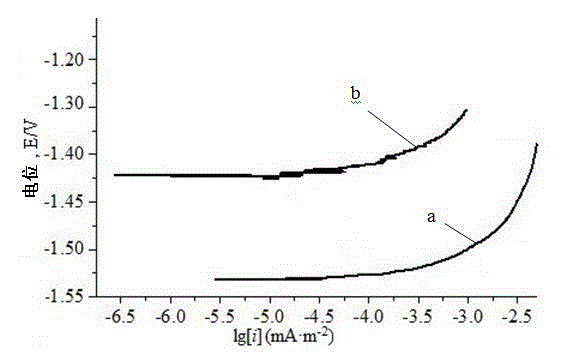

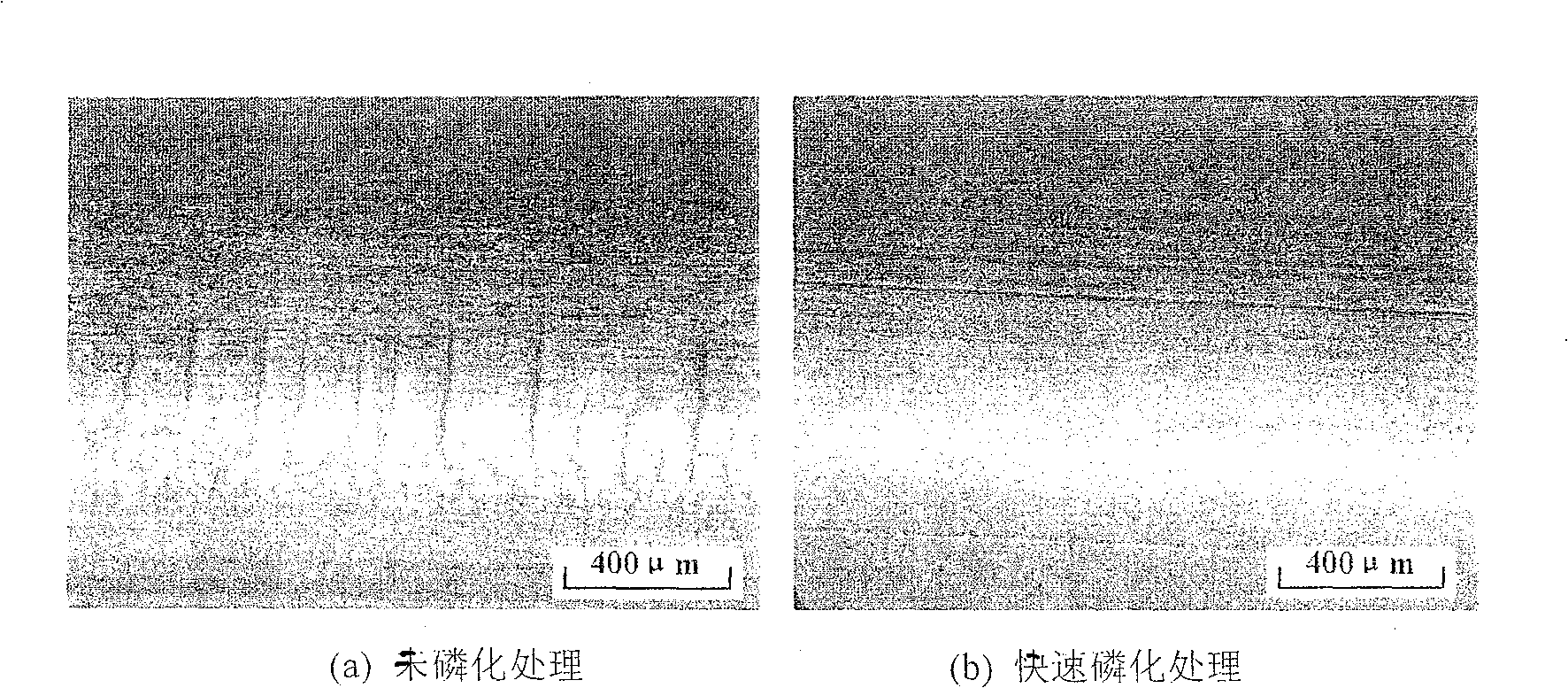

A green low-temperature rapid method for preparing phosphating film

ActiveCN107012453BIncrease spawn rateGray appearanceMetallic material coating processesPh bufferingPhosphate

The invention discloses a method for environment-friendly, low-temperature and rapid preparing of a phosphating film. The method comprises the steps that firstly, raw material components including, by mass, 5-8 parts of dihydric phosphate, 6-9 parts of nitrate, 0.5-3 parts of phosphoric acid, 0.05-0.5 part of oxidized graphene, 0.1-1 part of stabilizer, 6-10 parts of pH buffering agents and 100-120 parts of water are thrown into a reaction kettle, the temperature is increased to 20-40 DEG C, and after stirring is conducted for 20-60 min, the mixture is discharged out of the kettle; and secondly, a prepared phosphating solution is placed in a phosphating pond, the phosphating temperature is increased to 15-40 DEG C, then a steel test piece is placed in the phosphating pond, treatment is conducted for 2-20 min, airing is conducted, and the phosphating film is obtained. The obtained phosphating film is grey and bright in appearance, has good corrosion resistance and is good in attaching force with paint. The phosphating method is high in phosphating speed and low in phosphating temperature. A film layer is fine in crystal, the phosphating liquid is stable, little sediment exists, no toxicity or harm is generated to people and the environment, and cost is low.

Owner:SOUTH CHINA UNIV OF TECH

A Composite Phosphate Film Solution Formula Suitable for Hot Stamping of Ultra-High Strength Steel Sheets

Owner:SHANDONG JIANZHU UNIV

Cold extrusion forming technology of brake shoe roller shaft

InactiveCN110872708AImprove quality consistencyHigh density consistencyFurnace typesMetallic material coating processesTemperingBrake shoe

The invention discloses a cold extrusion forming technology of a brake shoe roller shaft, and belongs to the technical field of part machining. The technology comprises steps as follows: round steel is taken as a raw material, after being subjected to blanking according to specified dimension, the raw material is sequentially subjected to annealing, end facing, shot blasting, phosphorus saponification processing, cold extrusion forming, machining, quenching, tempering, shot blasting, cleaning, grinding machine processing and waste recovery, and a finished brake shoe roller shaft product is obtained. The brake shoe roller shaft obtained with the technology has high accuracy, small inter-individual difference, good strength properties and long service life.

Owner:谷城天兴机械有限公司

A kind of composition for iron and steel phosphating and preparation method thereof

Owner:浙江迪特高强度螺栓有限公司

Steel Phosphating Process

ActiveCN107345296BUniform and dense crystallizationStrong adhesionMetallic material coating processesPotassiumPyrophosphate

The invention relates to a steel phosphorization process. The steel phosphorization process comprises the following process steps including (1) grease removal, (2) water washing, (3) acid pickling, (4) secondary water washing, (5) neutralizing and (6) surface conditioning, wherein steel treated in the step (5) is placed into surface conditioning liquid at the temperature ranging from 40 DEG C to 45 DEG C to be treated for 1 min to 2 min, and the surface conditioning liquid is composed of 0.08-0.3 kg of a surface conditioning agent and the balance water in every 100 L of surface conditioning liquid; raw materials for preparing the surface conditioning agent comprise, by weight, 200-250 parts of water, 60-80 parts of disodium hydrogen phosphate, 40-60 parts of sodium tripolyphosphate, 2-5 parts of sodium hydroxide, 5-8 parts of potassium fluotitanate, 10-25 parts of amino trimethylene phosphonic acid and 2-5 parts of sodium pyrophosphate; and by means of the phosphorization process, all growth processes of a conversion coating can be conveniently completed at the low phosphorization temperature within short time, coating crystals are compact and even, and the attachment force is high.

Owner:FUJIAN ANSHUN TRANSFORMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com