Surface conditioning agent and preparation method thereof

A surface conditioning and accelerator technology, applied in the field of surface conditioning and its preparation, can solve the problems of insufficiently uniform and dense structure, coarse phosphating film crystals, etc., and achieve the effects of shortening phosphating time, enhancing effect, and improving apparent appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

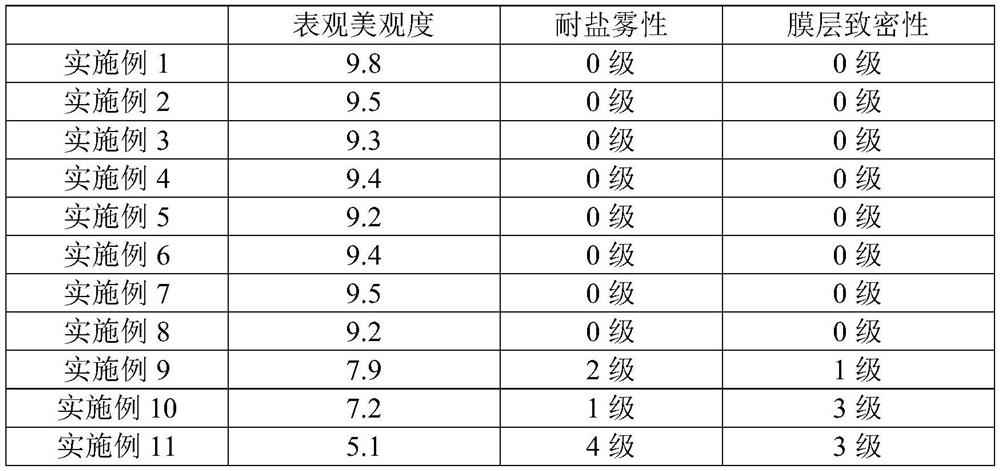

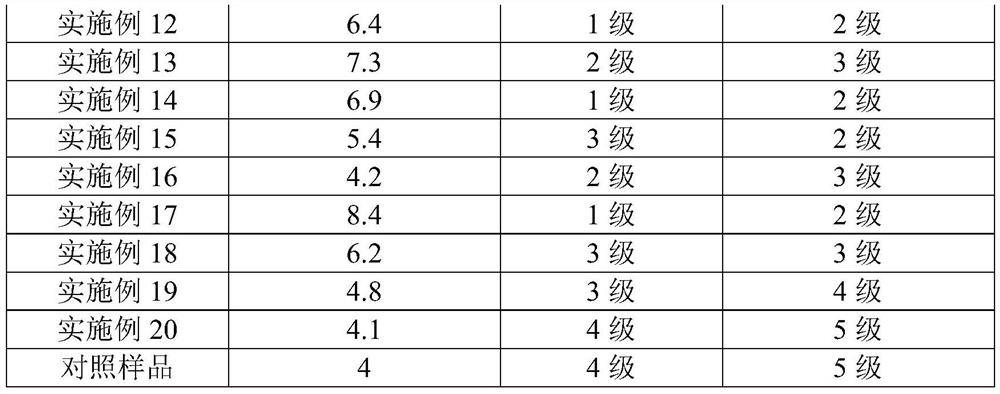

Examples

preparation example Construction

[0042] The second aspect of the present invention provides a method for preparing a surface conditioner. The specific preparation steps of the surface conditioner include: weighing raw materials according to the formula amount, adding the raw materials into a reaction kettle and mixing them uniformly, standing still, and packaging to obtain the finished product.

[0043] In some preferred embodiments, the standing time is 5-8 days.

[0044] In some preferred embodiments, the surface conditioner is suitable for surface treatment of zinc-based phosphating agents, manganese-based phosphating agents, and calcium-based phosphating agents; further preferably, the surface conditioner is especially suitable for manganese-based phosphating agents. The surface treatment of the workpiece before the use of phosphating agent.

Embodiment 1

[0048] This embodiment provides a surface conditioner. According to weight percentage, its raw materials include: 15% soap, 7.6% manganese salt, 0.12% blackening aid, 8% sodium salt, 0.4% accelerator, and water to make up the balance.

[0049] The soap is purchased from Shanghai Soap Co., Ltd., specifically Guben Soap.

[0050] The manganese salt is manganese nitrate, manganese carbonate and manganese dihydrogen phosphate; the weight ratio of manganese nitrate, manganese carbonate and manganese dihydrogen phosphate is 1.2:0.4:6.

[0051] The sodium salt is sodium bicarbonate and sodium pyrophosphate; the weight ratio of sodium bicarbonate and sodium pyrophosphate is 3:1.

[0052] The accelerator is ferric nitrate, purchased from Jinan Qiaofu Chemical Co., Ltd.

[0053] The blackening aid is bismuth nitrate, purchased from Shenyang Shengrunjie Chemical Co., Ltd.

[0054] The specific preparation steps of the surface regulator include: weighing the raw materials according to t...

Embodiment 2

[0056] This embodiment provides a surface conditioner. According to weight percentage, its raw materials include: 13% soap, 6% manganese salt, 0.1% blackening aid, 7% sodium salt, 0.4% accelerator, and water to make up the balance.

[0057] The soap is purchased from Shanghai Soap Co., Ltd., specifically Guben Soap.

[0058] The manganese salt is manganese nitrate, manganese carbonate and manganese dihydrogen phosphate; the weight ratio of manganese nitrate, manganese carbonate and manganese dihydrogen phosphate is 1.2:0.4:6.

[0059] The sodium salt is sodium bicarbonate and sodium pyrophosphate; the weight ratio of sodium bicarbonate and sodium pyrophosphate is 3:1.

[0060] The accelerator is ferric nitrate, purchased from Jinan Qiaofu Chemical Co., Ltd.

[0061] The blackening aid is bismuth nitrate, purchased from Shenyang Shengrunjie Chemical Co., Ltd.

[0062] The specific preparation steps of the surface regulator include: weighing the raw materials according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com