Process for cold extrusion forming of one-way device spline sleeve

A spline sleeve and forming process technology, applied in the field of machine parts processing, can solve the problems affecting the density distribution and overall uniformity of the finished product, and it is difficult to ensure the size, accuracy of the finished product, and uneven thickness of the phosphate layer, so as to save raw materials and batches. Small differences and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is further described in detail. It should be pointed out that the following specific descriptions are all exemplary, and are intended to provide further description of the present invention. Unless otherwise specified, all scientific and technical terms used in this invention have the same meaning as commonly understood by those skilled in the art to which this invention belongs.

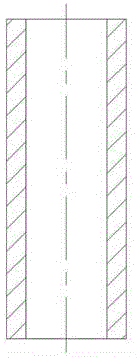

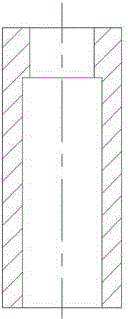

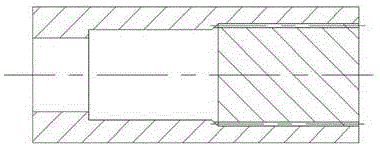

[0031] The cold extrusion molding process of the ND series one-way device spline sleeve of the present embodiment comprises the following steps: with 20CrMo hollow tube (such as figure 1 Shown) is the raw material, according to the size (generally refers to the length) sawing machine blanking, followed by annealing, flat head, shot blasting, phosphorus saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, Shot blasting, cleaning, and grinding machine processing to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com