Patents

Literature

296results about How to "Meet process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

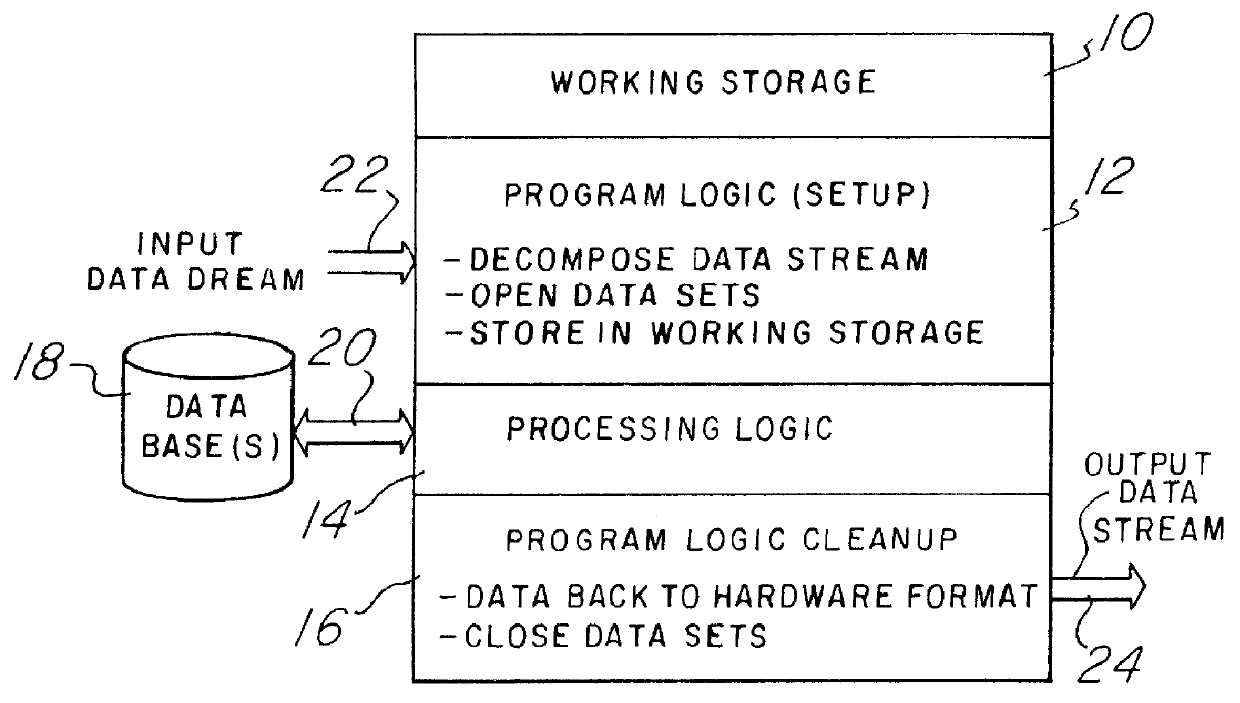

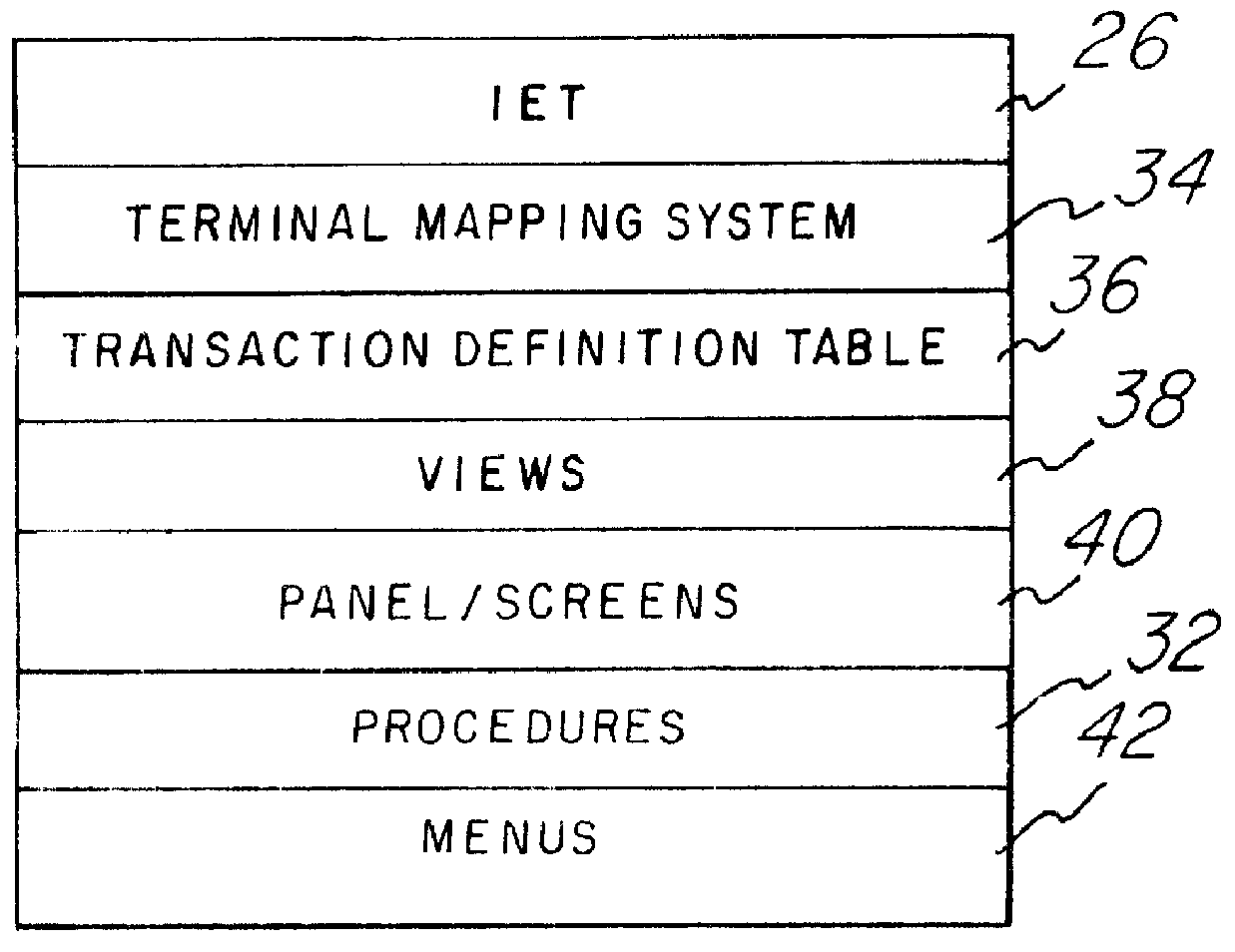

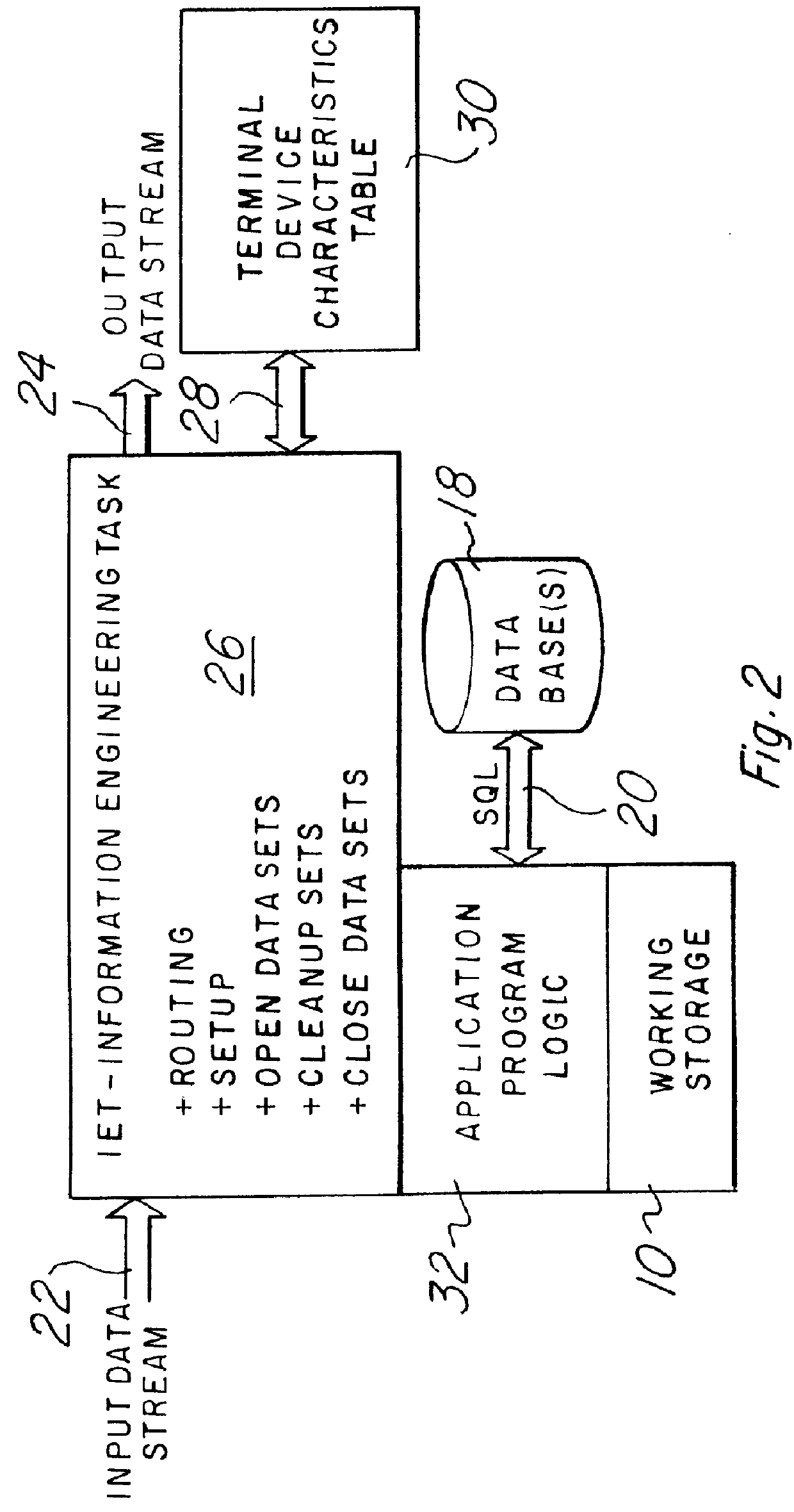

Method and apparatus for generating transactions and a dialog flow manager

InactiveUS6115711AImprove productivityReduce needData processing applicationsProgram control using stored programsApplication procedureTheoretical computer science

A method for generating distributed application architecture transactions includes providing menus to obtain names and relationships of variables for desired transaction and input data form from an application developer. The input data is stored At least one transaction definition table, information interchange panel and application procedure in binary form is constructed based on the input data. The binary form is link-edited into an executable transaction.

Owner:COMP ASSOC THINK INC

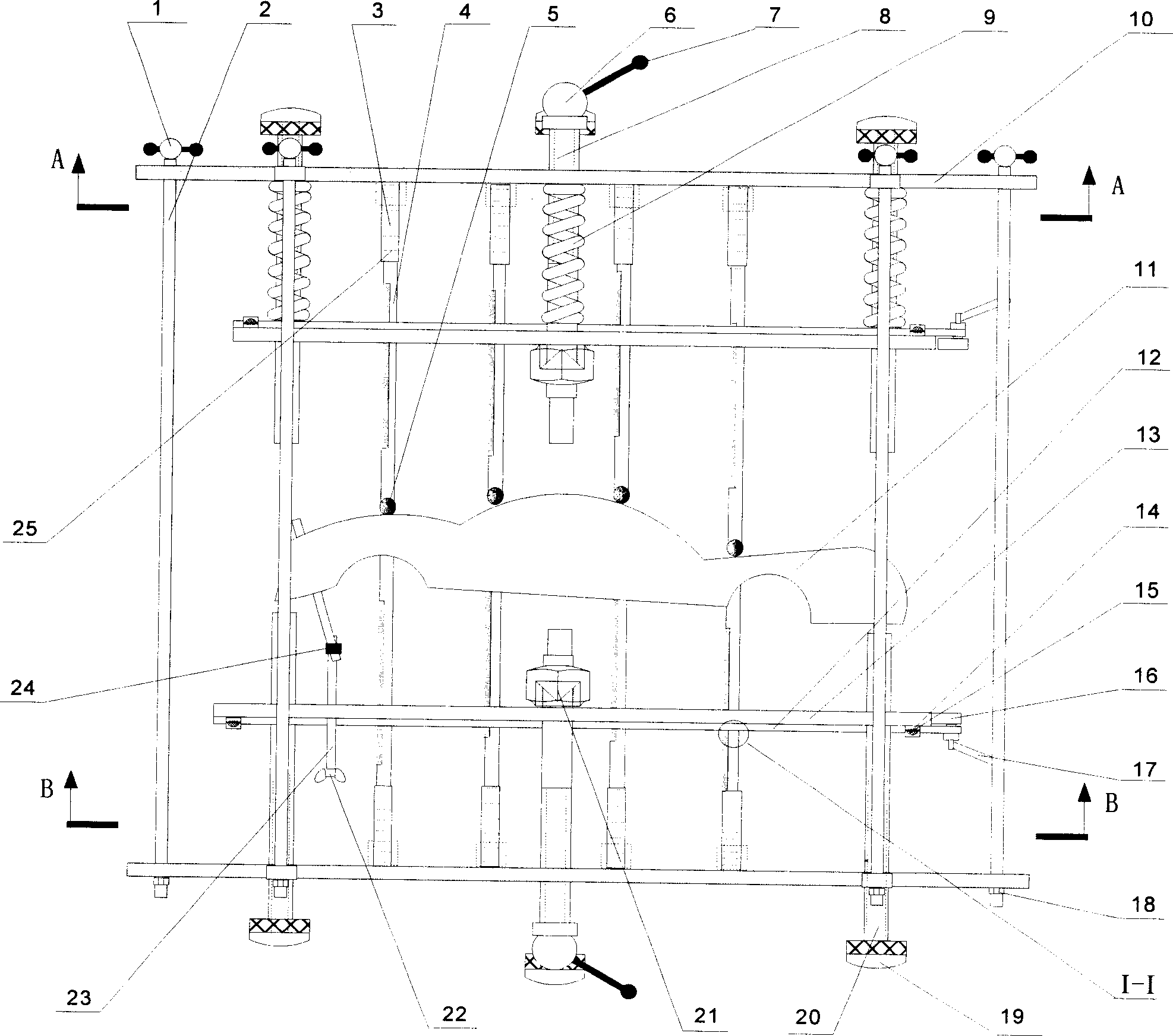

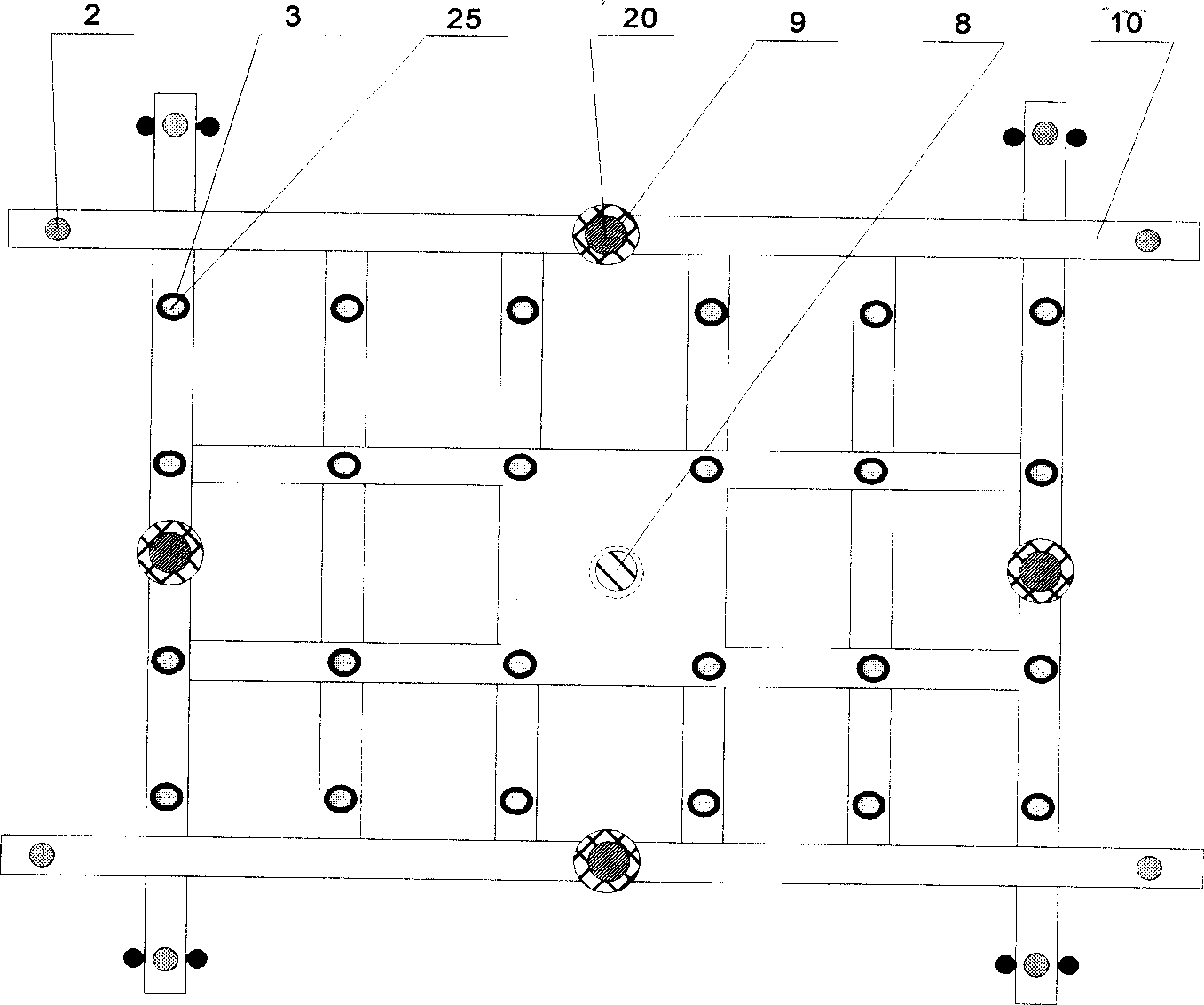

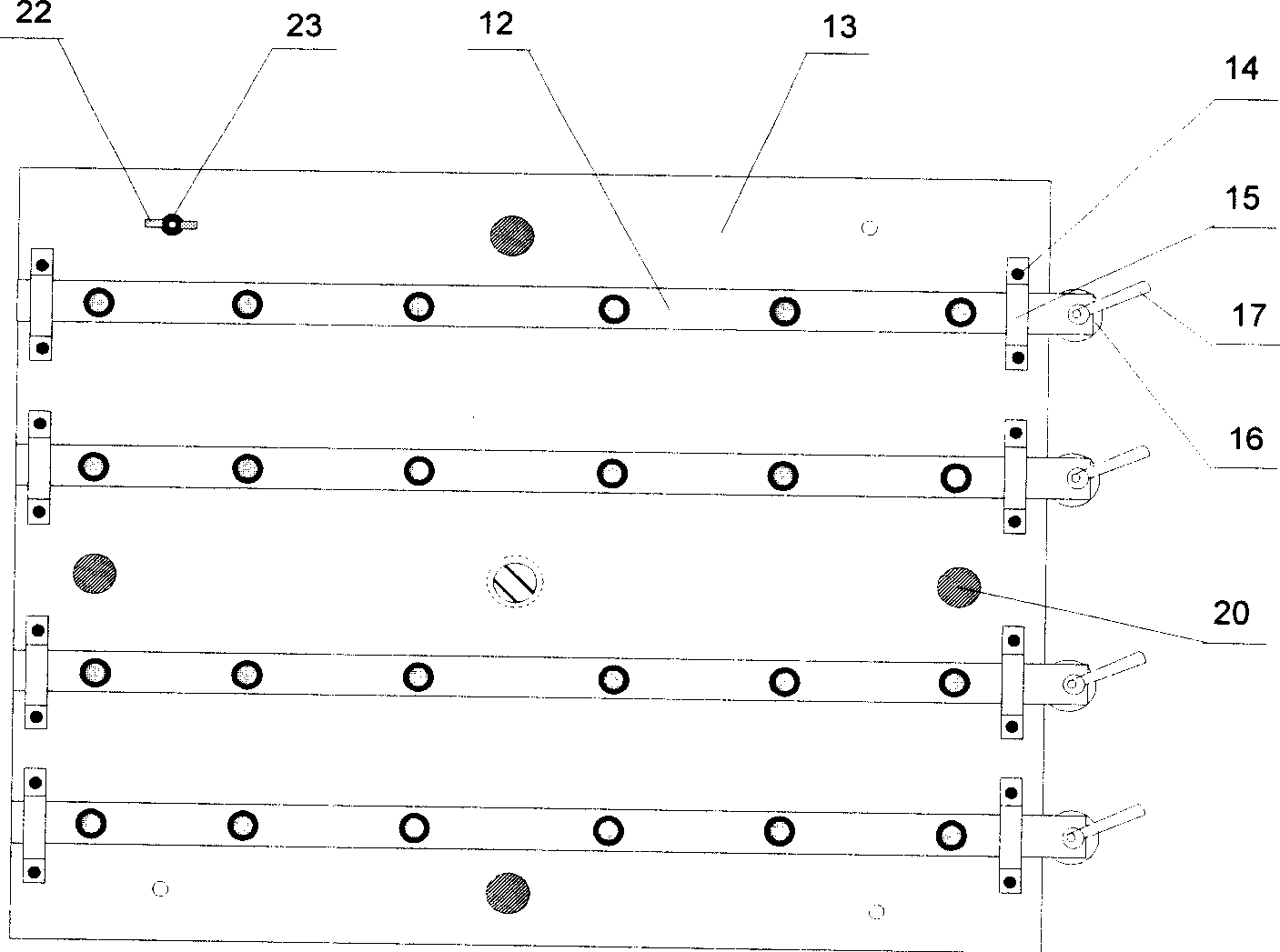

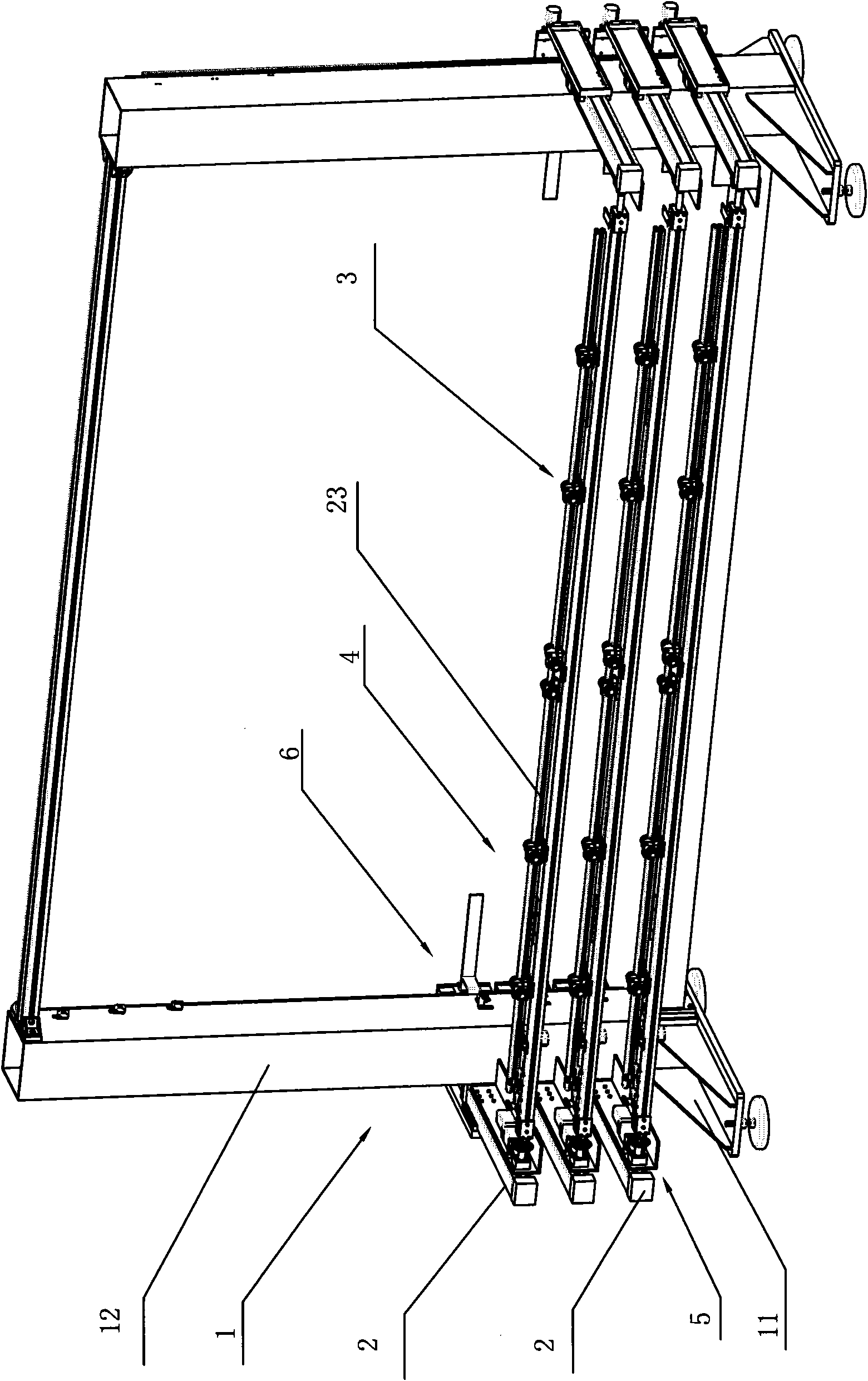

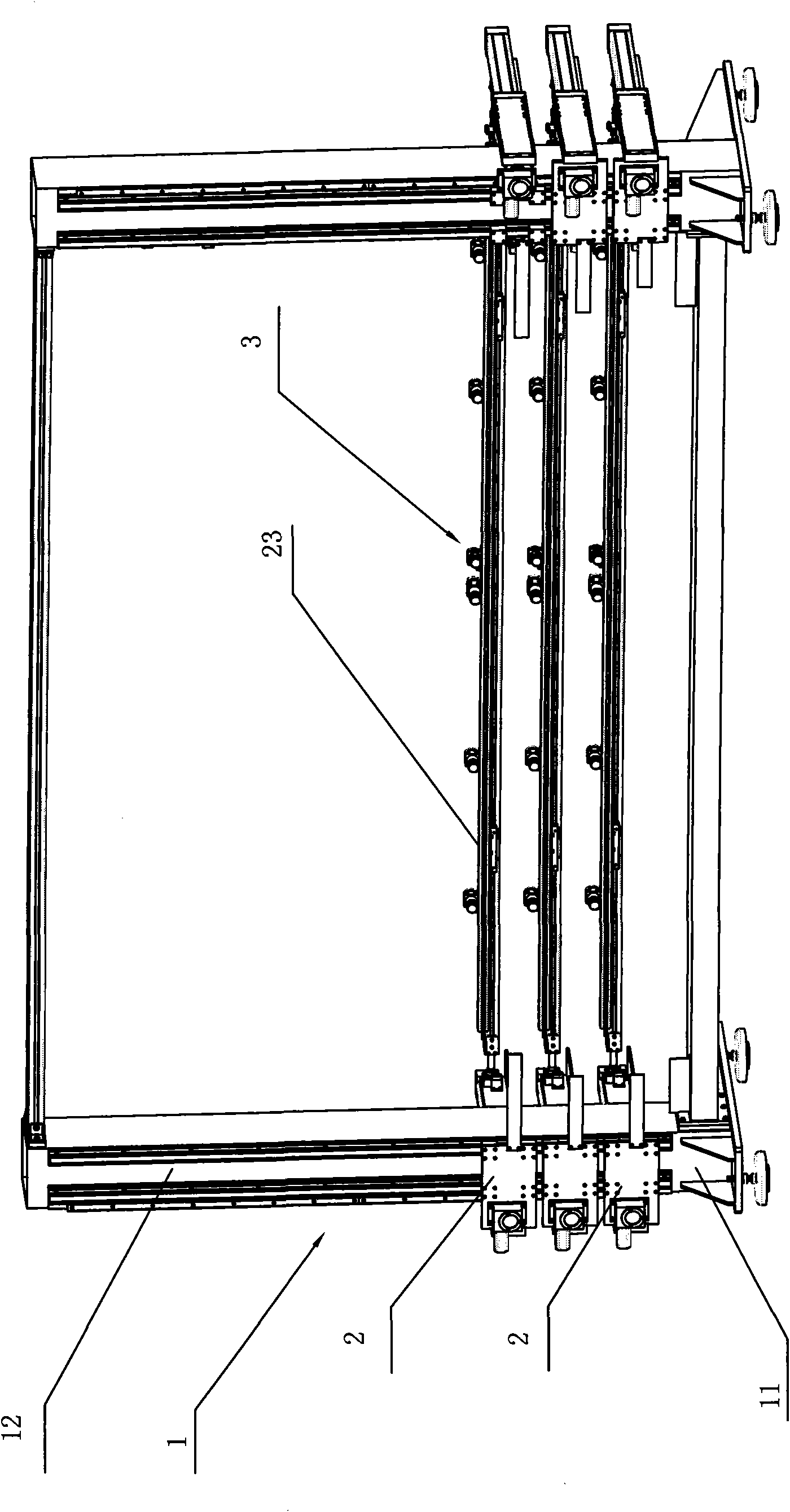

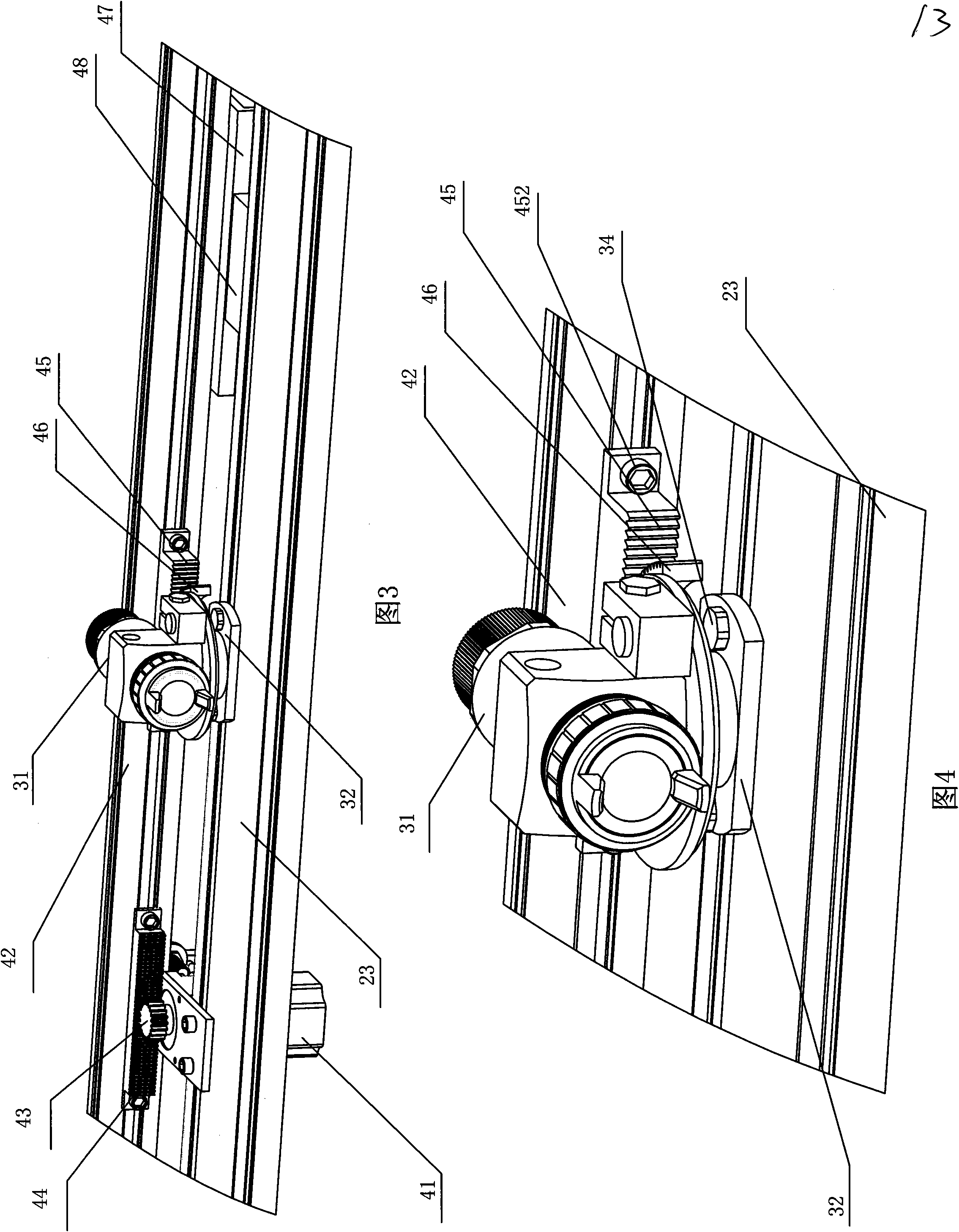

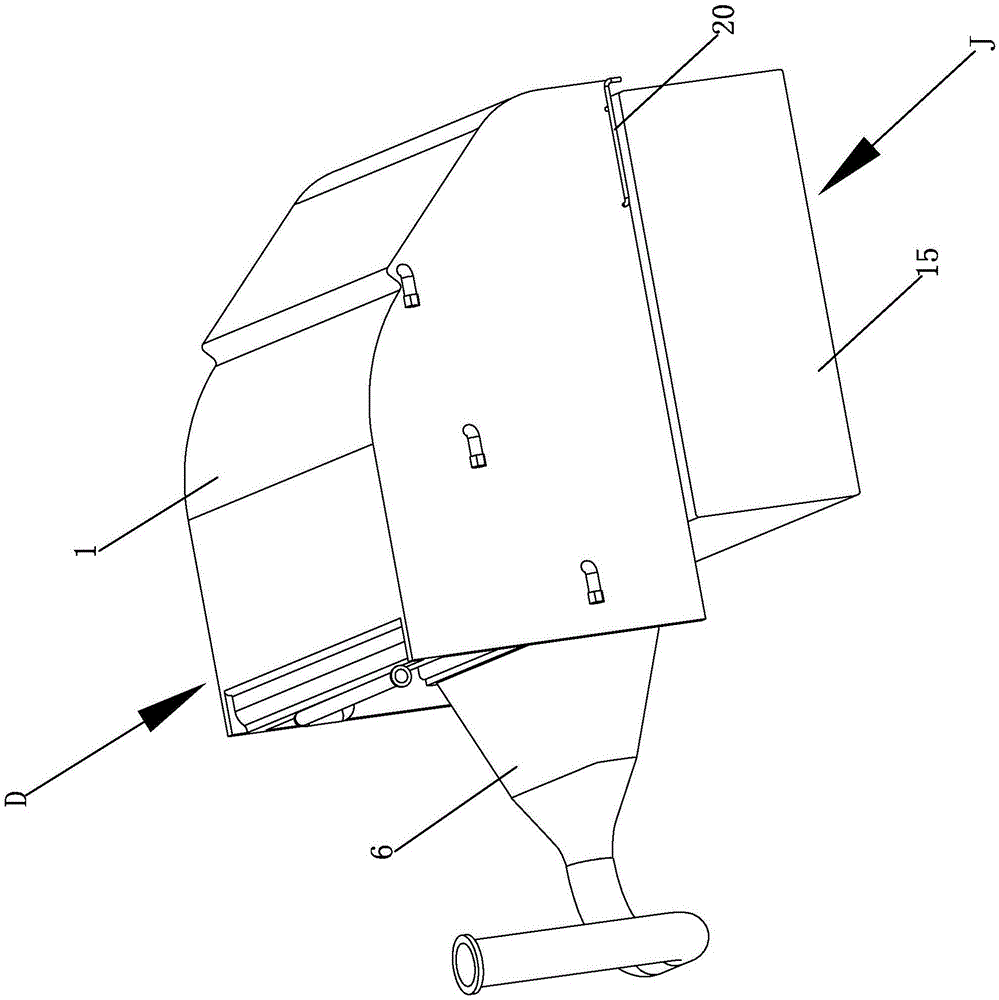

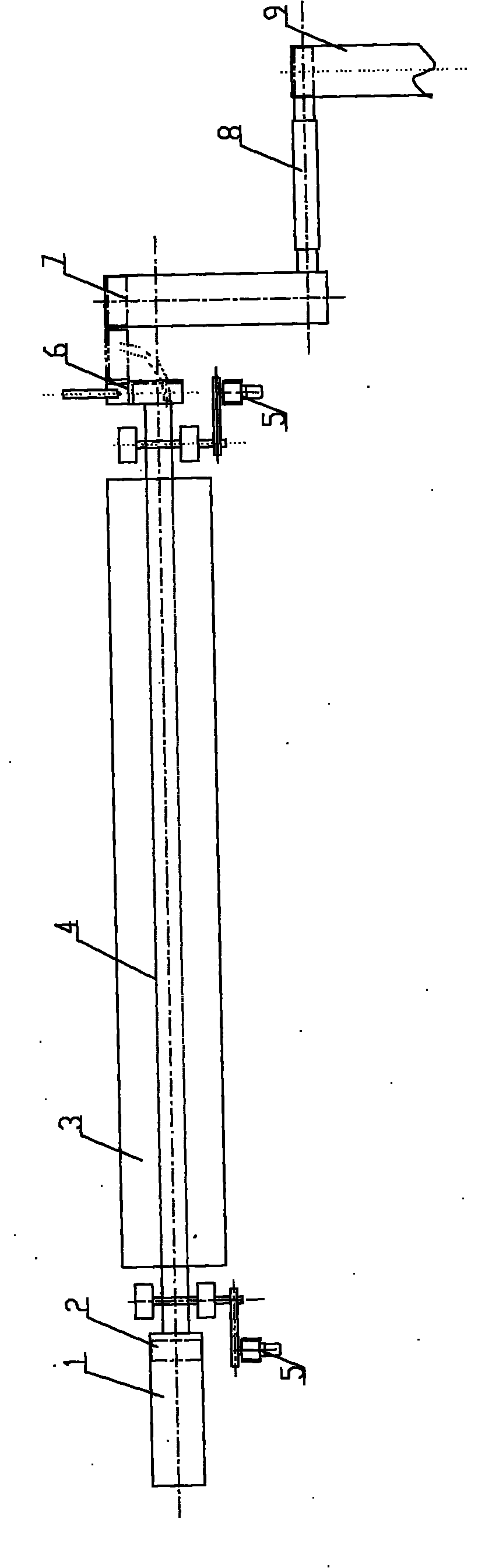

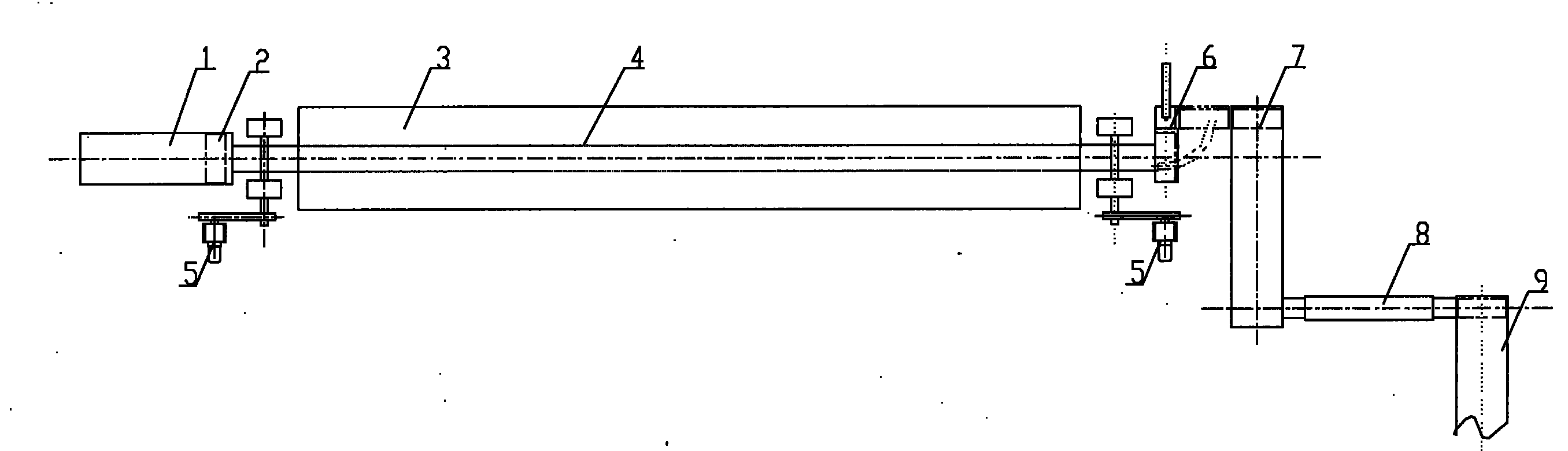

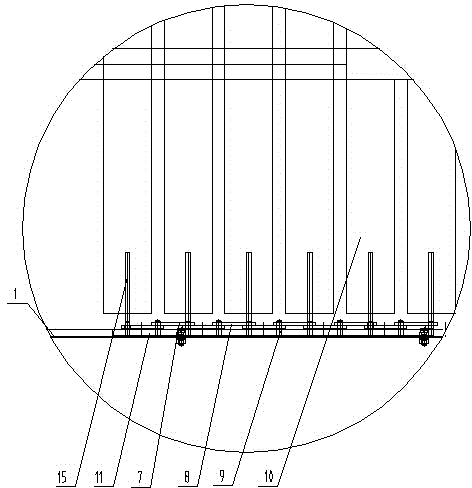

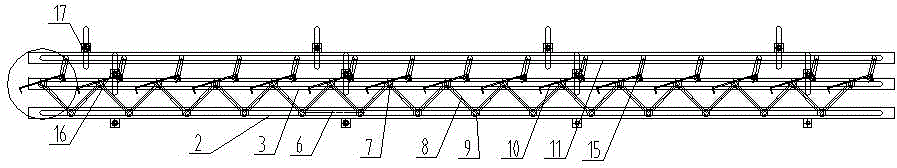

Flexible device for multipoint clamping and positioning spatial 3D thin wall part

InactiveCN1695896APrecise liftingConvenient location changeWelding/cutting auxillary devicesWork holdersCircular discMultiple point

Owner:SHANGHAI JIAO TONG UNIV

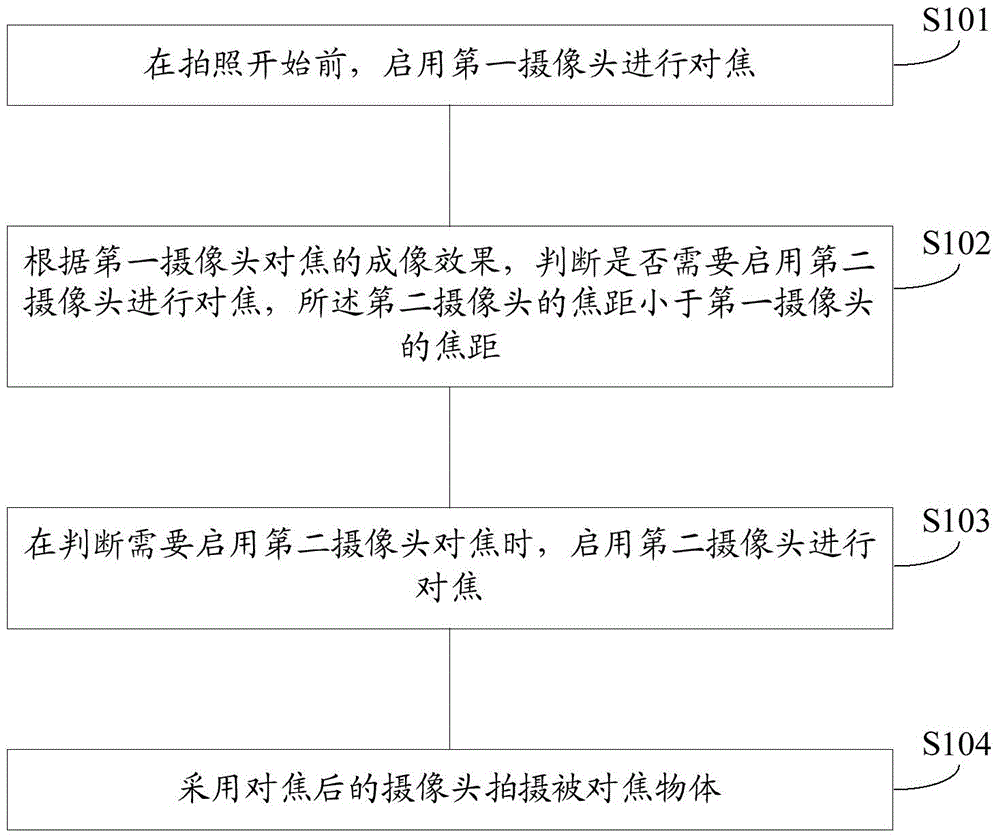

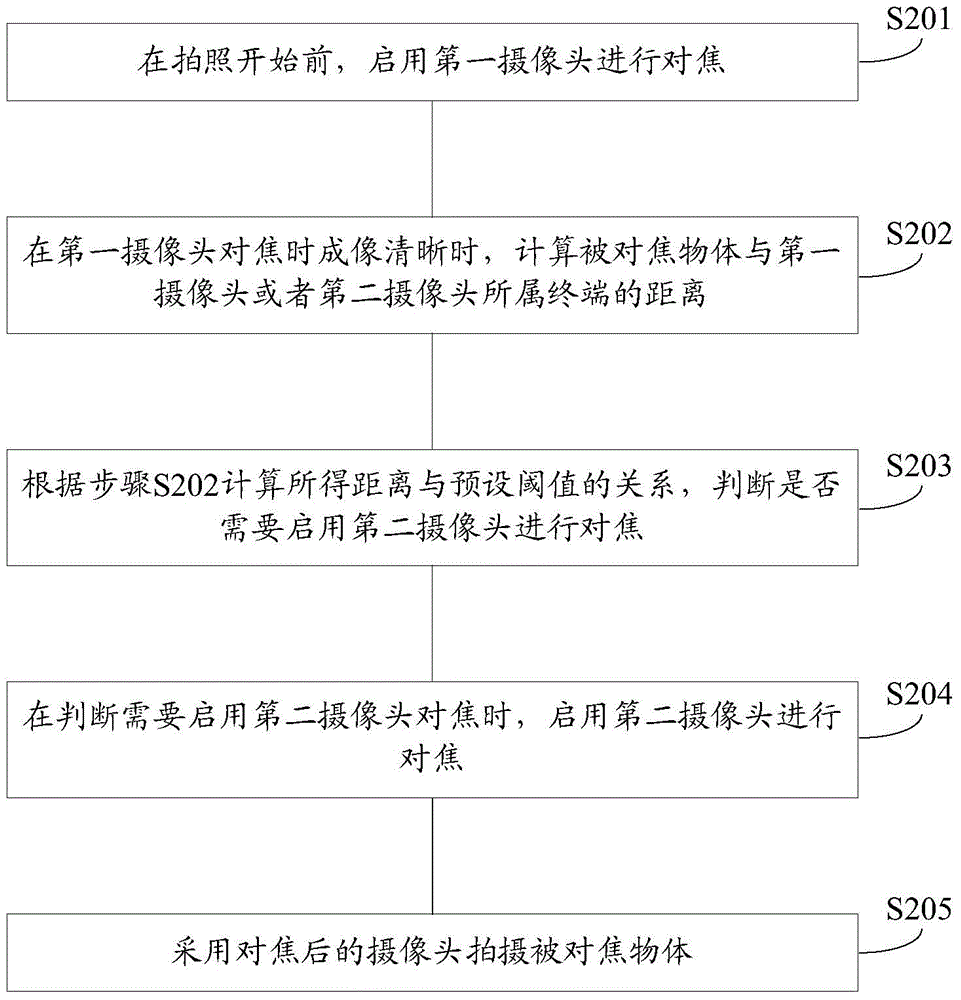

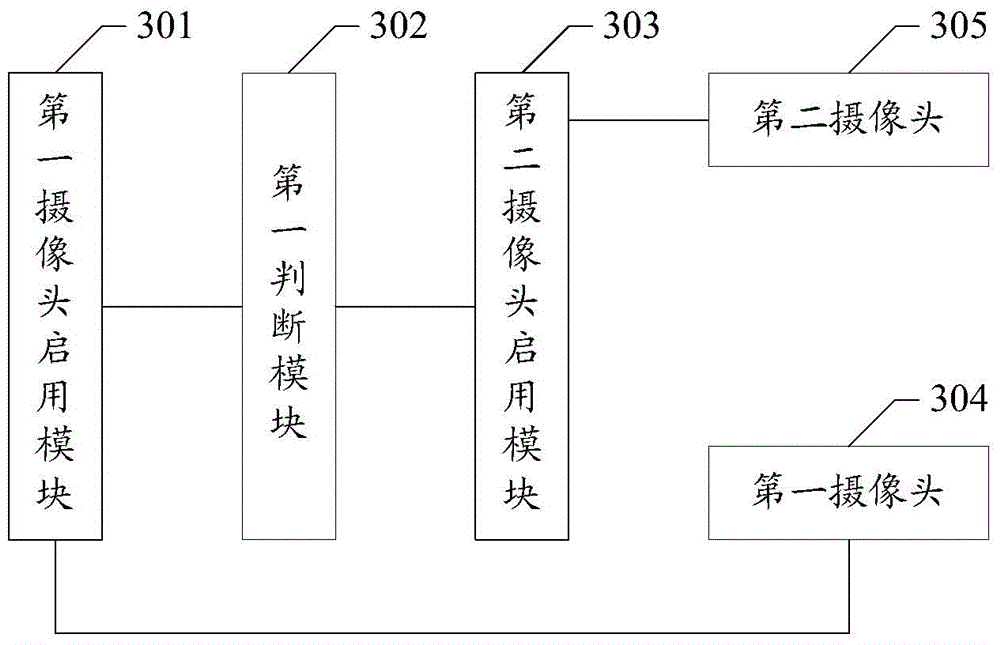

Shooting method by use of cameras with different focal lengths and terminal

ActiveCN104363379AQuality improvementGuaranteed not to stand outTelevision system detailsColor television detailsCamera lensShooting method

The invention discloses a shooting method by use of cameras with different focal lengths and a terminal. A high-quality image can be still acquired under a condition that the lens module is not increased. The method comprises the following steps: starting a first camera for focusing before shooting; judging whether to start a second camera for focusing according to the imaging effect of the first camera after focusing, wherein the focal length of the second camera is less than that of the first camera; if the second camera is judged to be required to be started for focusing, starting the second camera for focusing; and shooting a focused object by the camera after focusing; as the focal length of the second camera is less than that of the first camera, when the object in a close range is shot, the second camera is only started for focusing and shooting, and the high-quality image can be acquired; and besides, the lens is ensured not to protrude out of the terminal, so that the space of the lens module is reduced, the terminal of the camera can be manufactured to be light and small, and the process requirements of a user for the terminal can be met.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

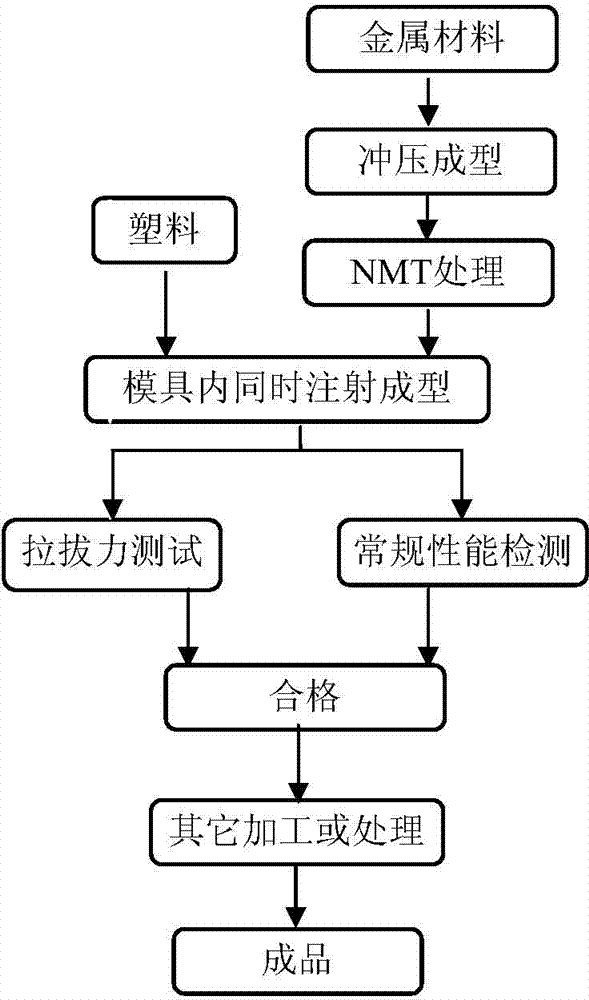

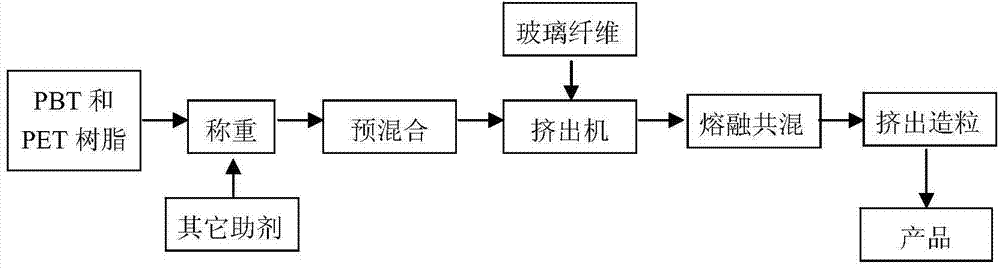

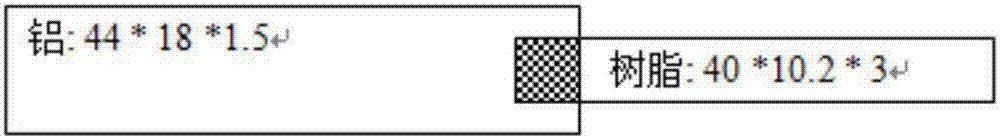

PBT (polybutylece terephthalate) engineering plastic composition used for NMT (Nano Molding Technology)

ActiveCN104845297AImprove mechanical propertiesImprove heat resistanceAntioxidantPolyethylene glycol

The invention provides a PBT (polybutylece terephthalate) engineering plastic composition used for a NMT (Nano Molding Technology) and a preparation method thereof. The PBT engineering plastic composition used for the NMT comprises the following components in parts by mass: 60 parts of PBT resin, 5 to 60 parts of PET (polyethylene glycol terephthalate) resin, 10 to 16 parts of glass fibers, 5 to 15 parts of flexibilizer, 0.3 to 3 parts of antioxidants, 0.3 to 2 parts of heat stabilizers, and 0.5 to 3 parts of lubricants, wherein the flexibilizers are selected from the mixture of at least two of unsaturated carboxylic ester, unsaturated carboxylic ester copolymers, saturated carboxylic acid vinyl ester, saturated carboxylic acid vinyl ester copolymers, unsaturated epoxy compounds, unsaturated epoxy copolymers, unsaturated carboxylic acid, unsaturated carboxylic acid copolymers, unsaturated acid anhydride or unsaturated acid anhydride copolymers. The bond force between the PBT engineering plastic composition and a metal material is excellent, and the NMT process requirements can be met; meanwhile, excellent mechanical performance and heat resistance are realized.

Owner:SHENZHEN HALCYON NEW MATERIALS

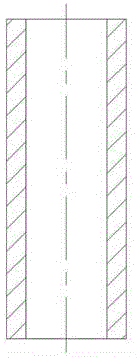

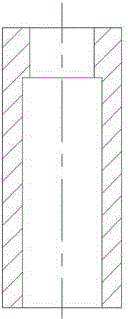

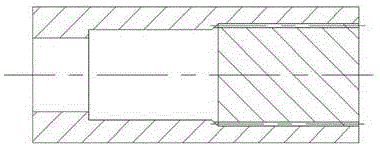

Process for cold extrusion forming of one-way device spline sleeve

InactiveCN104148888AEliminates drilling/boring stepsDrilling/boring steps meetEngineeringUltimate tensile strength

The invention provides a process for cold extrusion forming of a one-way device spline sleeve. The process comprises the steps of utilizing hollow pipes to serve as raw materials, performing blanking according to specified dimensions, sequentially performing annealing, head flattening, shot blasting, phosphatization and saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, shot blasting, cleaning and grinding machine processing, and obtaining finished product one-way device spline sleeves. The one-way device spline sleeves obtained through the process are high in precision, small in individual differences, good in strength performance and long in service lives.

Owner:宁波惠山汽配制造有限公司

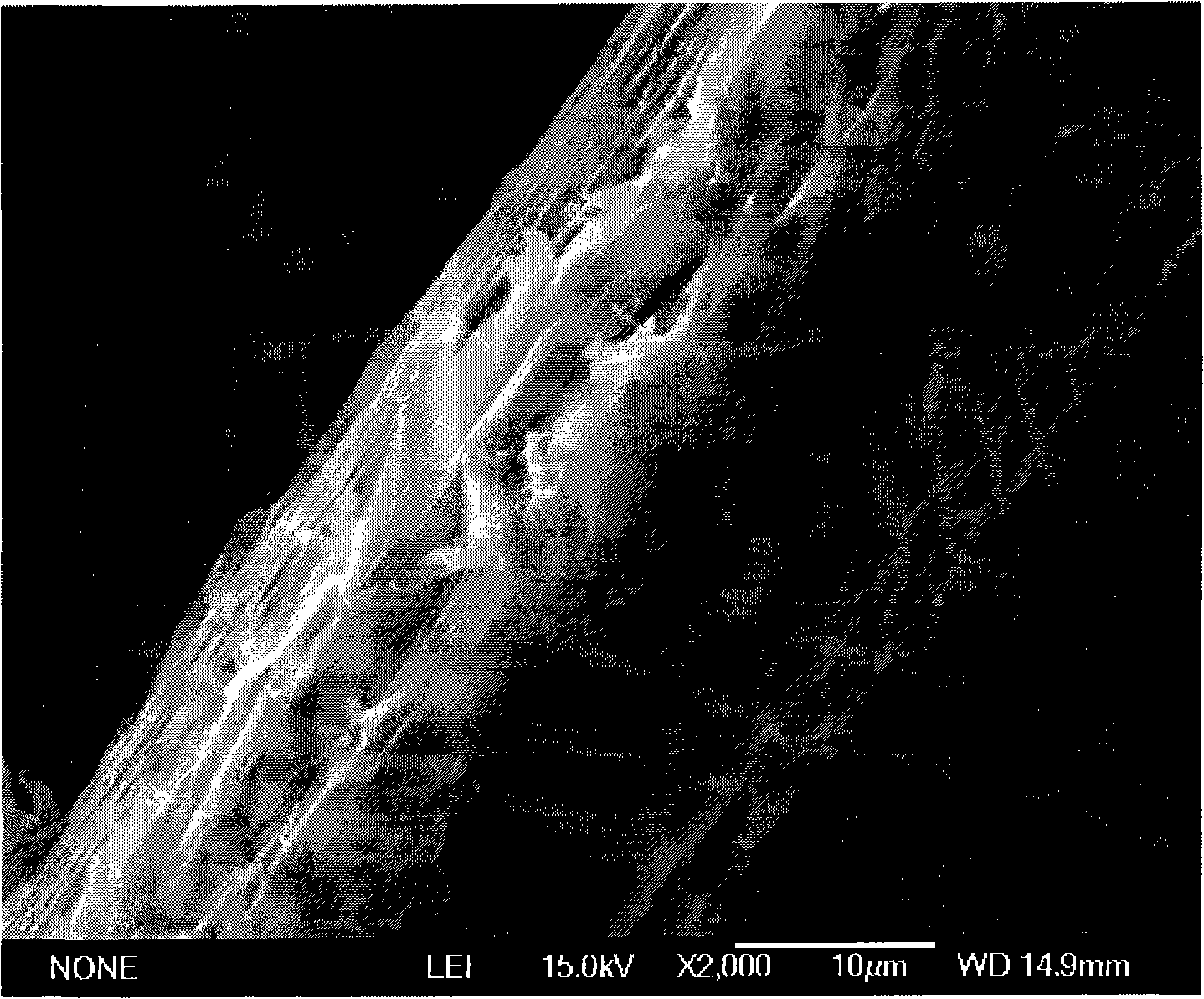

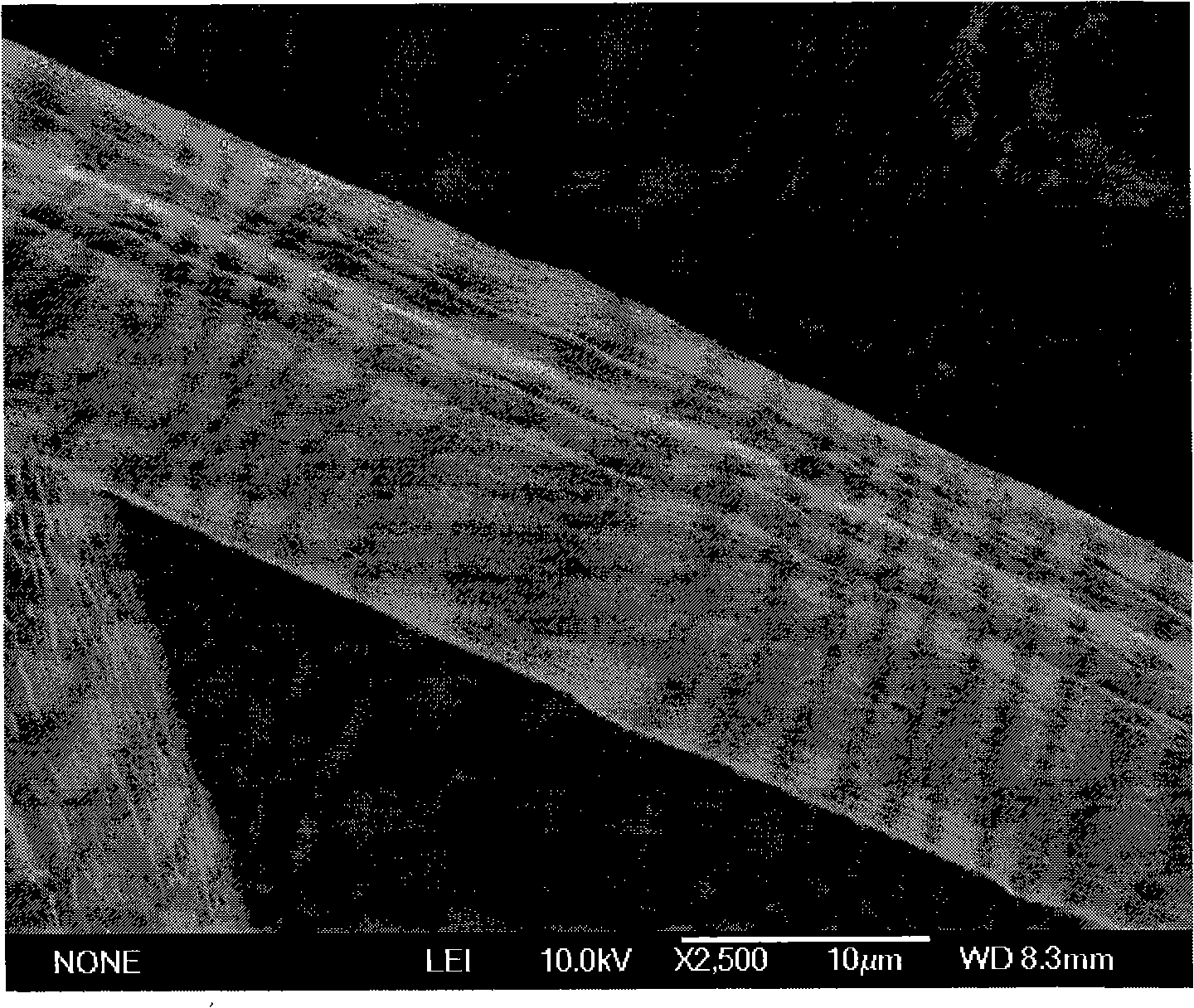

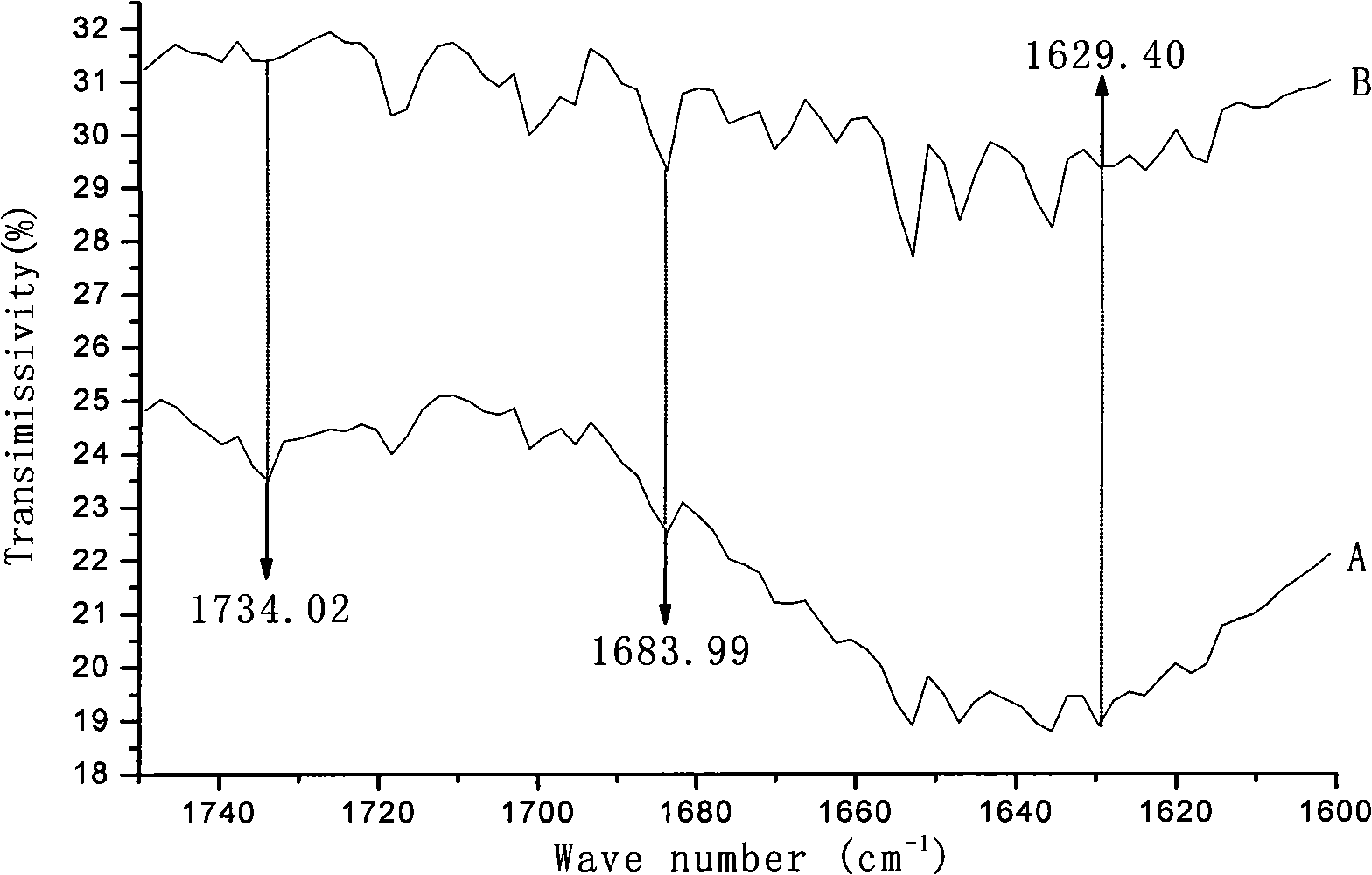

Frozen-irradiated auxiliary degumming process for china-hemp fibers

InactiveCN101275289AConvenient lengthImprove finenessFibre treatment to obtain bast fibreQuenchingHemp fiber

The invention discloses a hemp fiber freezing radiation auxiliary de-gumming technique, comprising the following steps of undergoing UV radiation, quenching, and heating treatment after hot bath, acid pre-etching, and pre-chlorination, and then undergoing base oxygen-mechanical associative de-gumming treatment, finally adding a softener for secondary scouring. The hemp fiber surface de-gumming effect treated by the technique is prior to ordinary base oxygen method and mechanical de-gumming, and the former meets the requirement of product of national first grade; the lignin content meets requirement of finishing technique after spinning, which obtains good whiteness and flexibility, and controls breaking strength and tensile stretch of fiber in requirement of spinnability, with improved length and fineness of fiber is improved, greatly improved serviceability, and less pollutant effluents discharged, so that the invention is environment-friendly.

Owner:TAIYUAN UNIV OF TECH

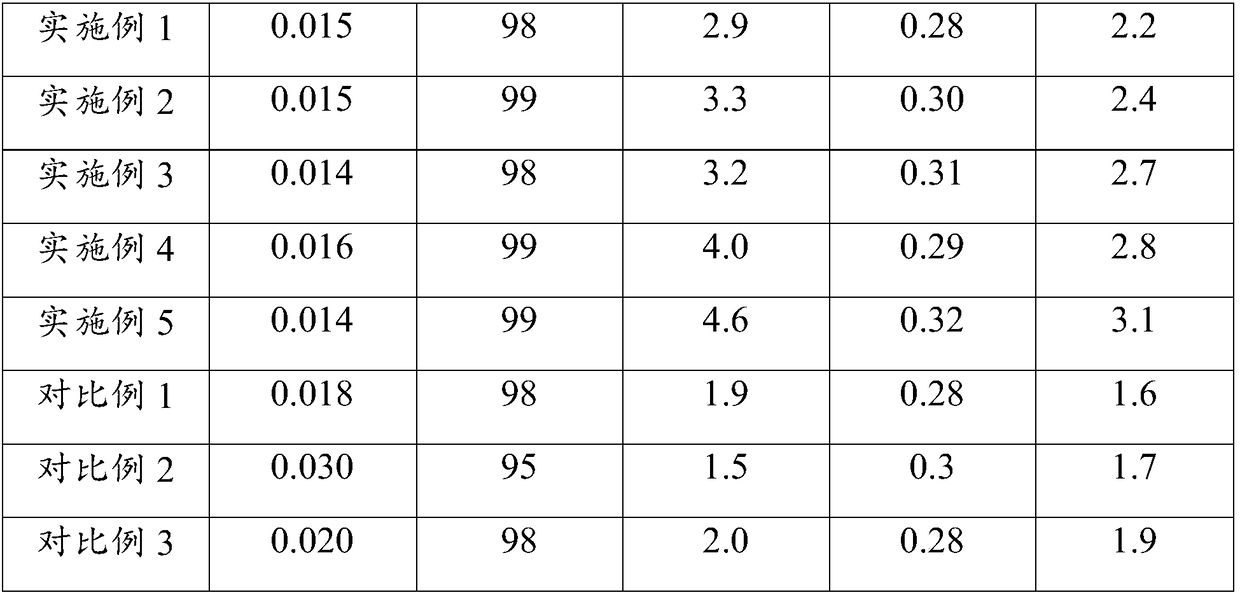

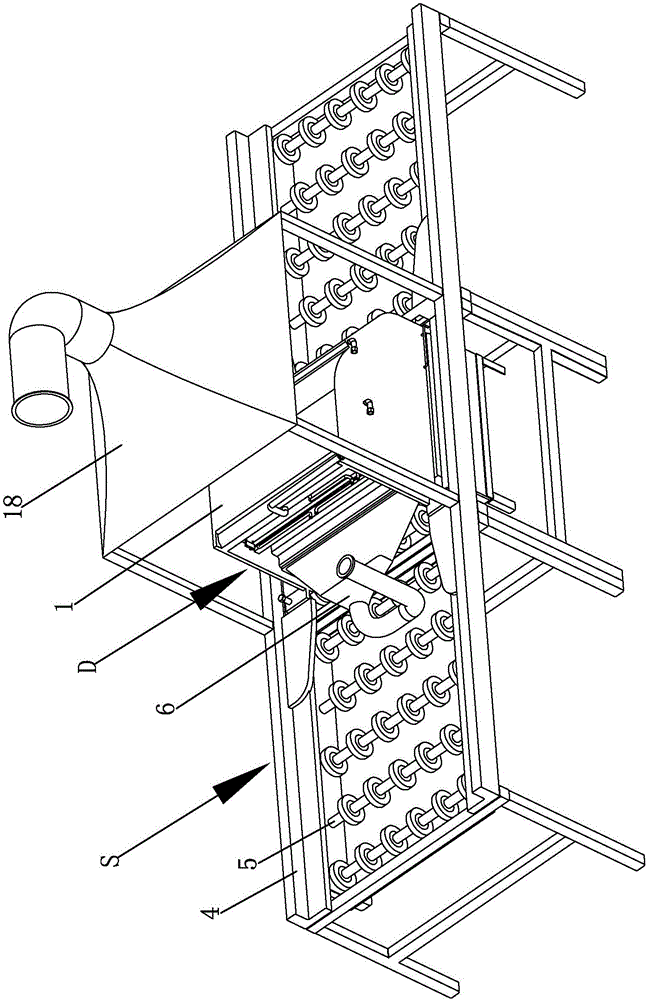

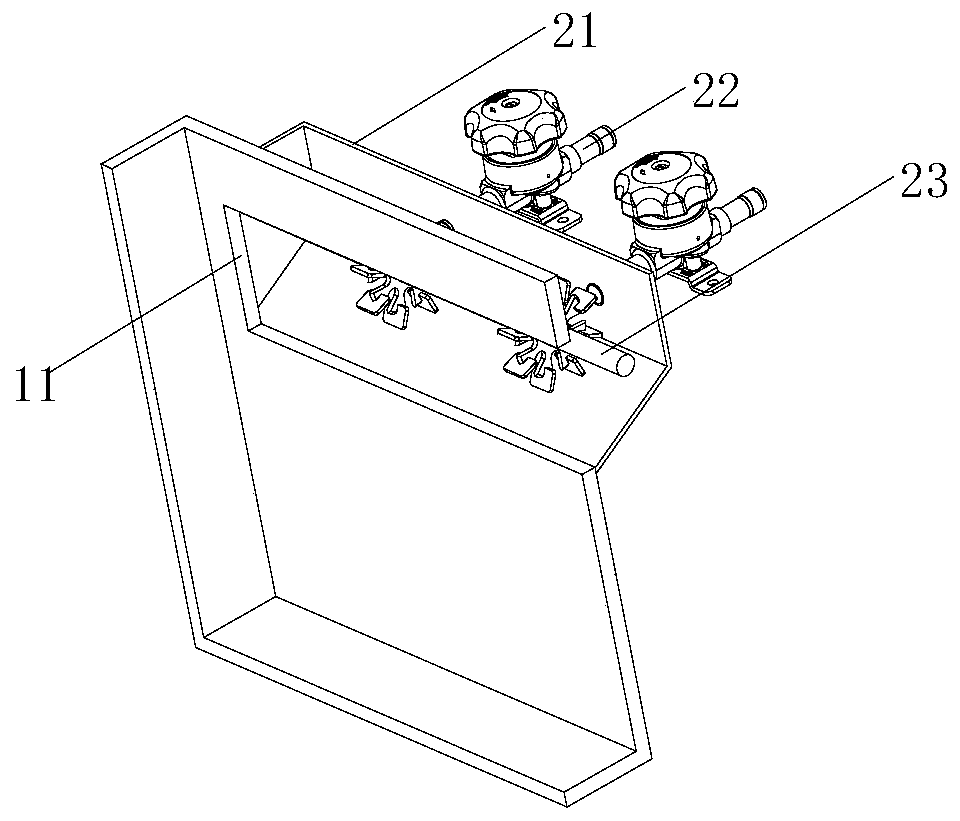

Intelligent spraying device for use in streamline production operation

ActiveCN101862720AReduce investmentMeet process requirementsSpraying apparatusProduction lineElectricity

The invention discloses an intelligent spraying device for use in streamline production operation, which comprises a machine frame and a control device, wherein the machine frame comprises a base and an upright post. The intelligent spraying device is characterized in that: the upright post is provided with at least one layer of working platform; at least one set of spray gun component is arranged on the working platform; the spray gun component is provided with a plane swinging mechanism and a pitching mechanism; the working platform has a lifting mechanism; the control device is electrically connected with the plane swinging mechanism and the pitching mechanism respectively to enable the spray gun component to perform plane scanning and up and down scanning according to programs set in the control device; and the control device is electrically connected with the lifting mechanism to allow the working platform to move up and down according to a program set in the control device. The intelligent spraying device has the advantages that: the posture of the spray gun can be combined at any time so as to meet different spray process requirements; a point-to-point spraying or fuzzy spraying mode can be realized; the high-speed and uniform spraying of workpieces on a steam production line can be realized without reversing the workpieces in a spraying process; and the equipment investment can be reduced greatly.

Owner:宁波能特环保科技有限公司

Environment-friendly water-based ink

An environment-friendly water-based ink comprises the following components by mass percent: 12-22% of alcohol-soluble modified acrylic resin, 10-20% of alcohol-soluble modified aldehyde ketone resin, 35-55% of a diluents, 6-12% of methyl ether, 12-20% of pigment, and 2-5% of a functional auxiliary agent. The environment-friendly water-based ink provided by the invention is an alcohol-soluble gravure ink, adopts more than 95% of alcohol as the auxiliary agent to realize gravure production, is stable in ink performance, uniform in texture, strong in tinting strength, not easy to precipitate, and similar with the printing effect of the traditional offset printing, and has certain antistatic function.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

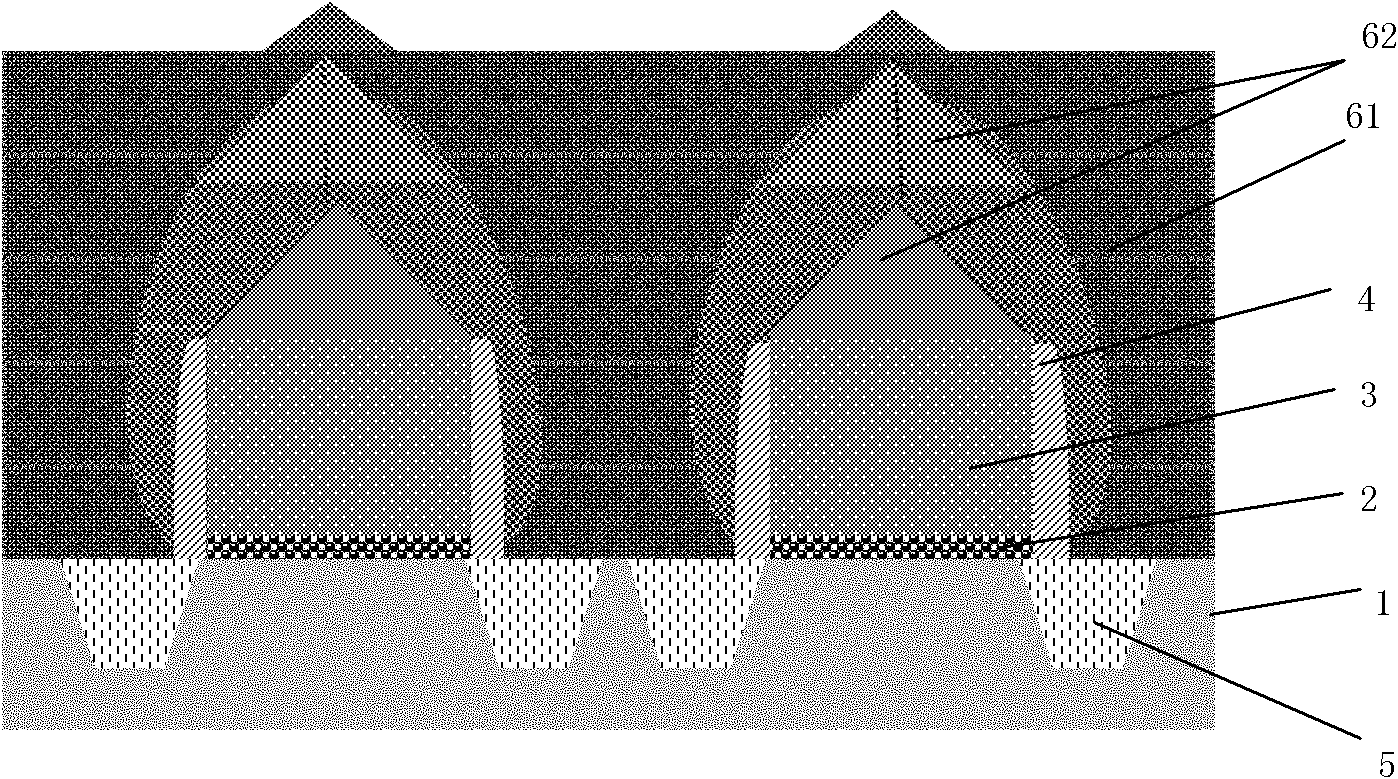

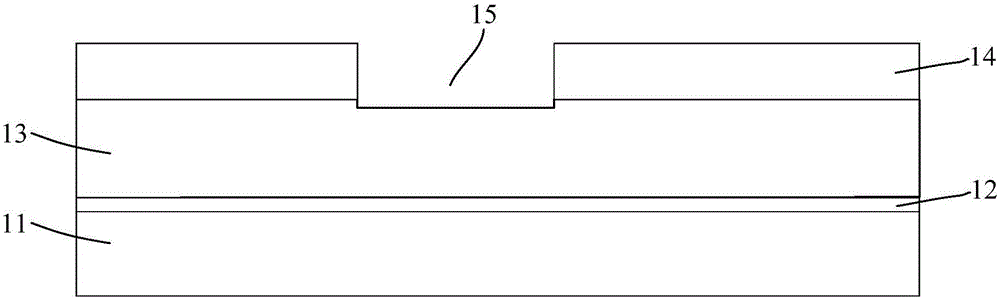

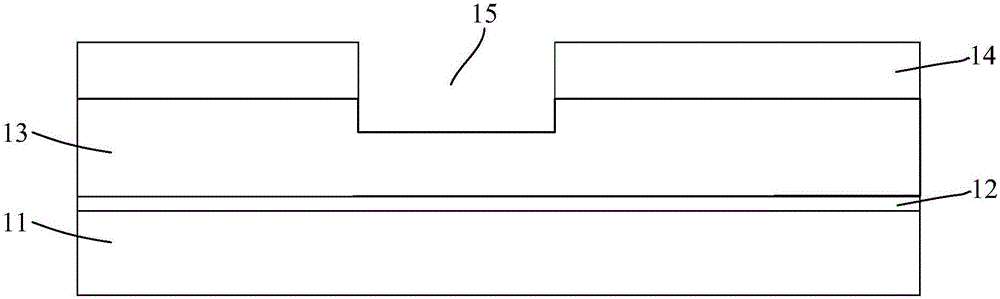

Preparation method for highly-doped phosphorosilicate glass film

InactiveCN102592992AEasy to fillImprove bottom starting positionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEtchingChemical vapor deposition

The invention discloses a preparation method for a highly-doped phosphorosilicate glass film. The preparation method includes the following steps: forming a gate oxide layer, a polycrystalline silicon gate and a side wall on a silicon substrate; injecting a drain source and carrying out rapid thermal annealing; depositing an SACAD PSG (Selected Area Chemical Vapor Deposition Phosphosilicate Glass) film; depositing an HDP PSG (High Density Polyethylene Phosphosilicate Glass) film; and etching a contact hole. According to the preparation method, the phenomenon that the silicon substrate is damaged by over etching of the contact hole can be avoided; and the PSG film prepared by the method has excellent hole-filling performance and a film structure easy to etch. During preparation, firstly, a layer of PSG film is grown by using an SACAD deposition process; and secondly, a highly-doped PSG film is grown by using an HDP CAD deposition process. Due to the utilization of the characteristic that the SACAD PSG film is uniform in the phosphor doping mount, the position of a starting point at the bottom of the HDP PSG film flower-shaped casing is heightened, a process window for selective etching of the contact hole is increased and further the phenomenon that the silicon substrate is damaged caused by the over etching of the contact hole and the performances of the devices are effectively maintained.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

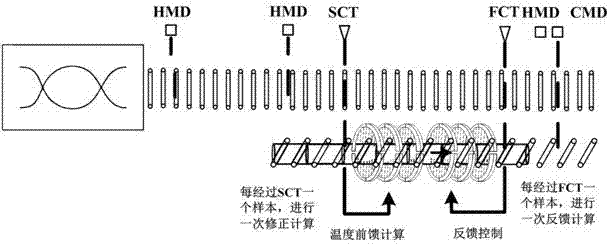

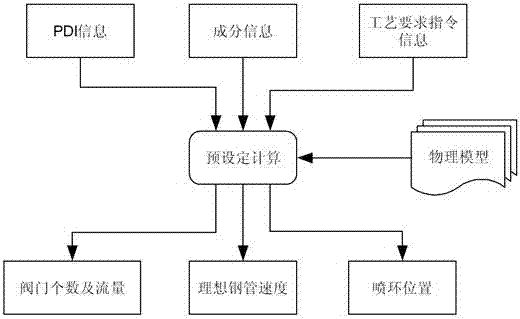

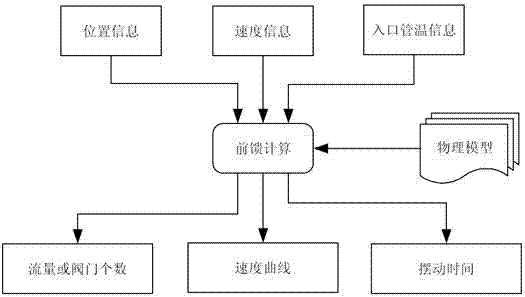

Steel tube online cooling process control system and method

ActiveCN107971345AGood shape and performanceMeet process requirementsTemperature control deviceWork cooling devicesAutomatic controlCooling temperature

The invention relates to online heat treatment technologies for steel tube production, in particular to a steel tube online cooling process control system and method. The steel tube online cooling process control method comprises the steps that the steel tube online cooling process control system receives steel tube original data and cooling target technological data which are sent by an upper computer system; and according to steel tube actually-measured data in the previous working procedure and through operation of a model comprising a presetting calculation module, a feedforward control module and a feedback control calculation module, a steel tube operation speed curve of an online cooling area, spraying ring configuration and the cooling water pressure and flow are set for a steel tube online cooling basic automation system, automatic control over the steel tube online cooling process is achieved, and accordingly precise temperature control over the final cooling temperature of the steel tube product is achieved. The steel tube online cooling process control system and method is used for automatic control over the cooling process of a steel tube online cooling production device, and the steel tube online cooling production device is arranged beside a main conveying roller way line behind a sizing mill parallelly.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Solvent-free unfoamed polyurethane structured adhesive and preparation method thereof

InactiveCN106433546AEasy to operateGood bonding performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventPolyphenyl isocyanate

The invention relates to a solvent-free unfoamed polyurethane structured adhesive which contains a component A and a component B, wherein the mass ratio of the component A to the component B is 4:1; the component A contains the following raw materials in parts by mass: 30-45 parts of polyol, 50-47 parts of packing, 8-6 parts of a water removing agent, 4-2 parts of phthalic acid bi(2-ethylhexyl) ester, 3-0 parts of xylene formaldehyde resin, 4-0 parts of lyophobic gaseous silicon and 1-0 parts of an amino curing agent; and the component B contains the following raw material in part by mass: 100 parts of polymethylene polyphenyl isocyanate. The solvent-free unfoamed polyurethane structured adhesive provided by the invention is small in moisture influence, and is barely affected by ambient humidity, a foaming phenomenon in the gluing curing process can be avoided, and later reliability can be greatly improved.

Owner:YANTAI DARBOND TECH

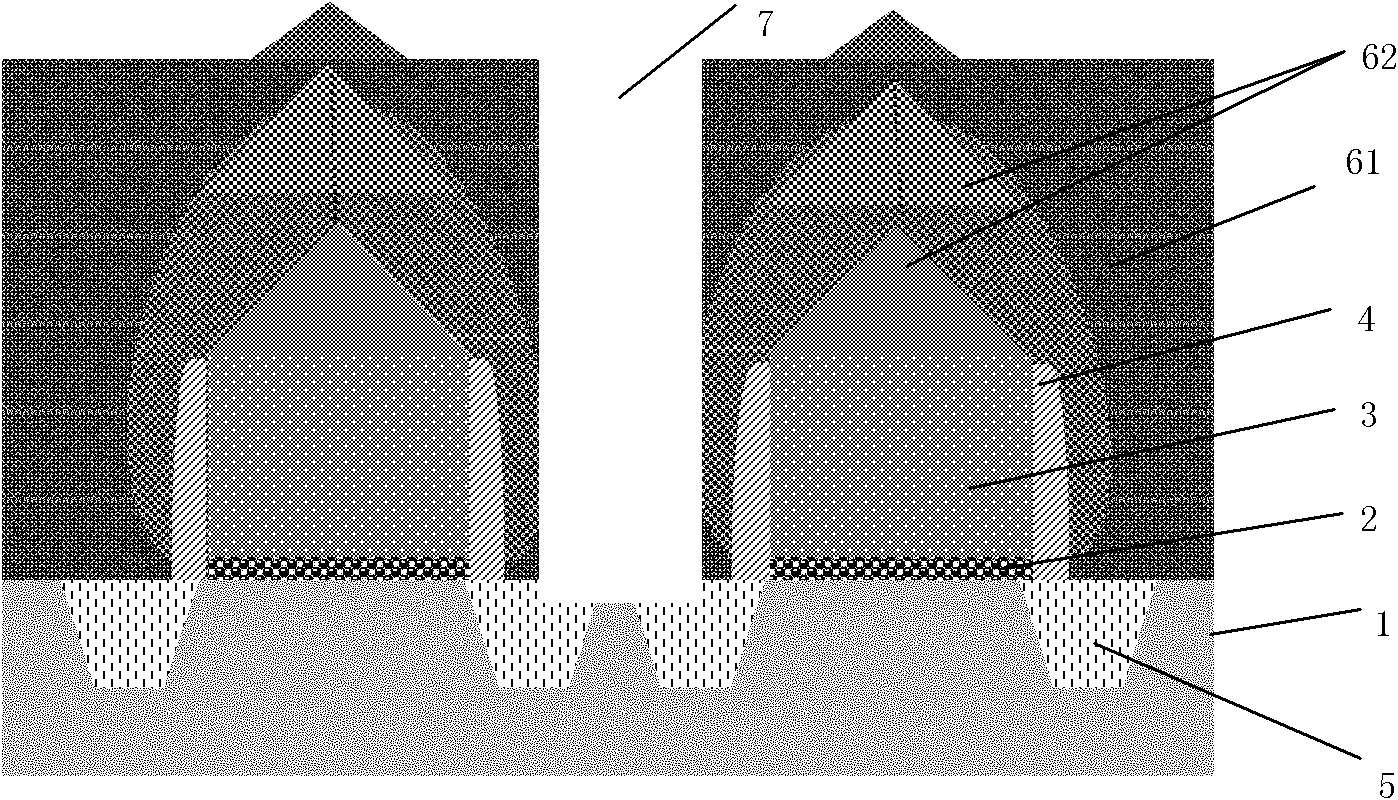

Method for manufacturing flash memories

ActiveCN105679713AMeet process requirementsSmall difference in shapeTransistorSolid-state devicesElectrical and Electronics engineeringFlash memory

A method for manufacturing flash memories comprises the following steps: a graphical hard mask layer forms an opening penetrating a hard mask layer in a thickness direction; a floating gate layer with a first thickness below the opening is etched and removed with a first etching process, wherein etching time of the first etching process is determined based on the initial thickness of the floating gate layer below the opening before the first etching process, so that the thickness of the floating gate layer after the first etching process is completed is a fixed value; after the first etching process, a second etching process is adopted to etch and remove the floating gate layer with a second thickness, part of the floating gate layer below the hard mask layer is also etched and removed, and a floating gate tip region is formed below the hard mask layer, wherein the etching time of the second etching process is fixed. The method improves the morphological stability of formed floating gate tips, so that the yield of manufactured flash memories is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

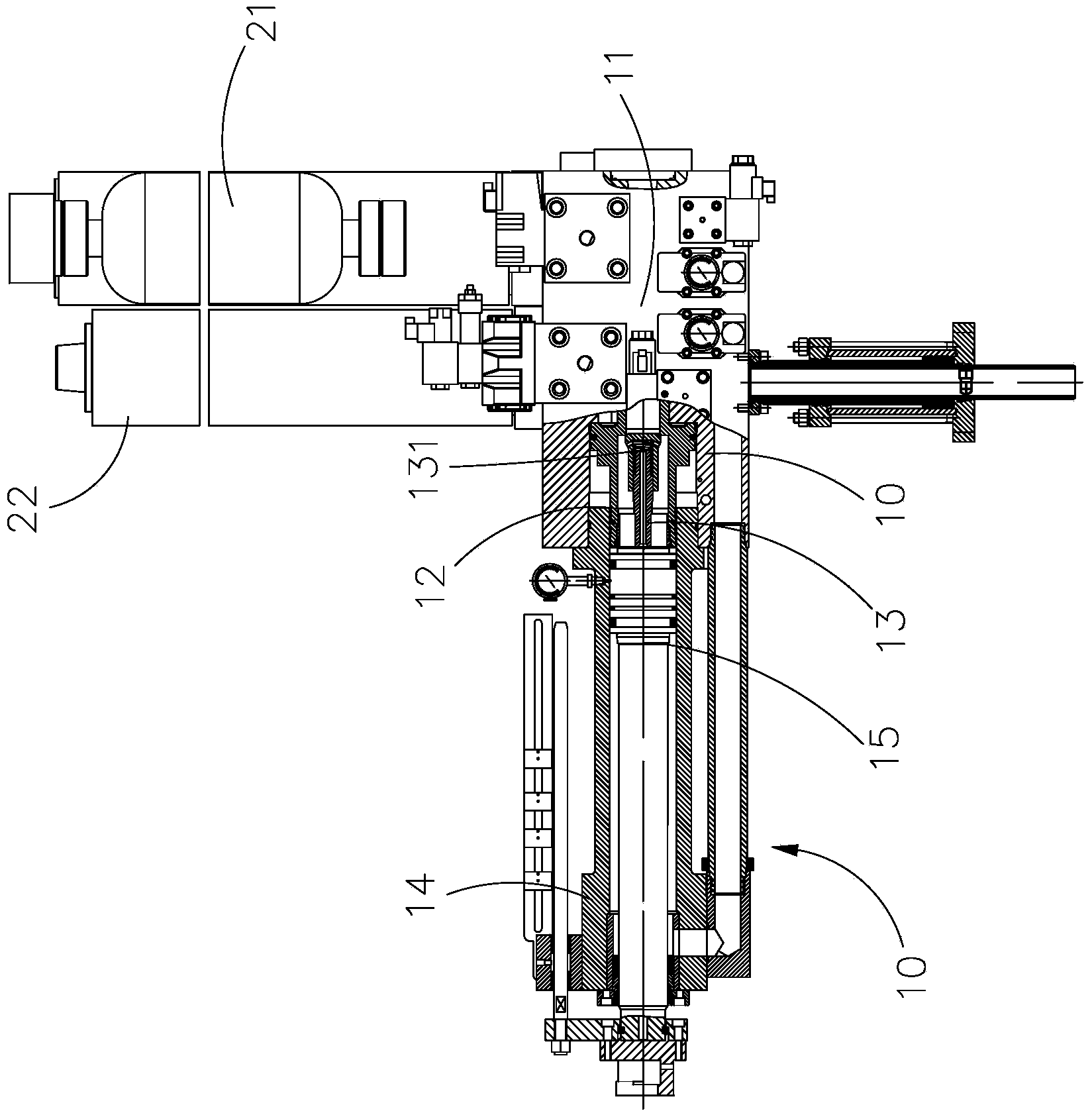

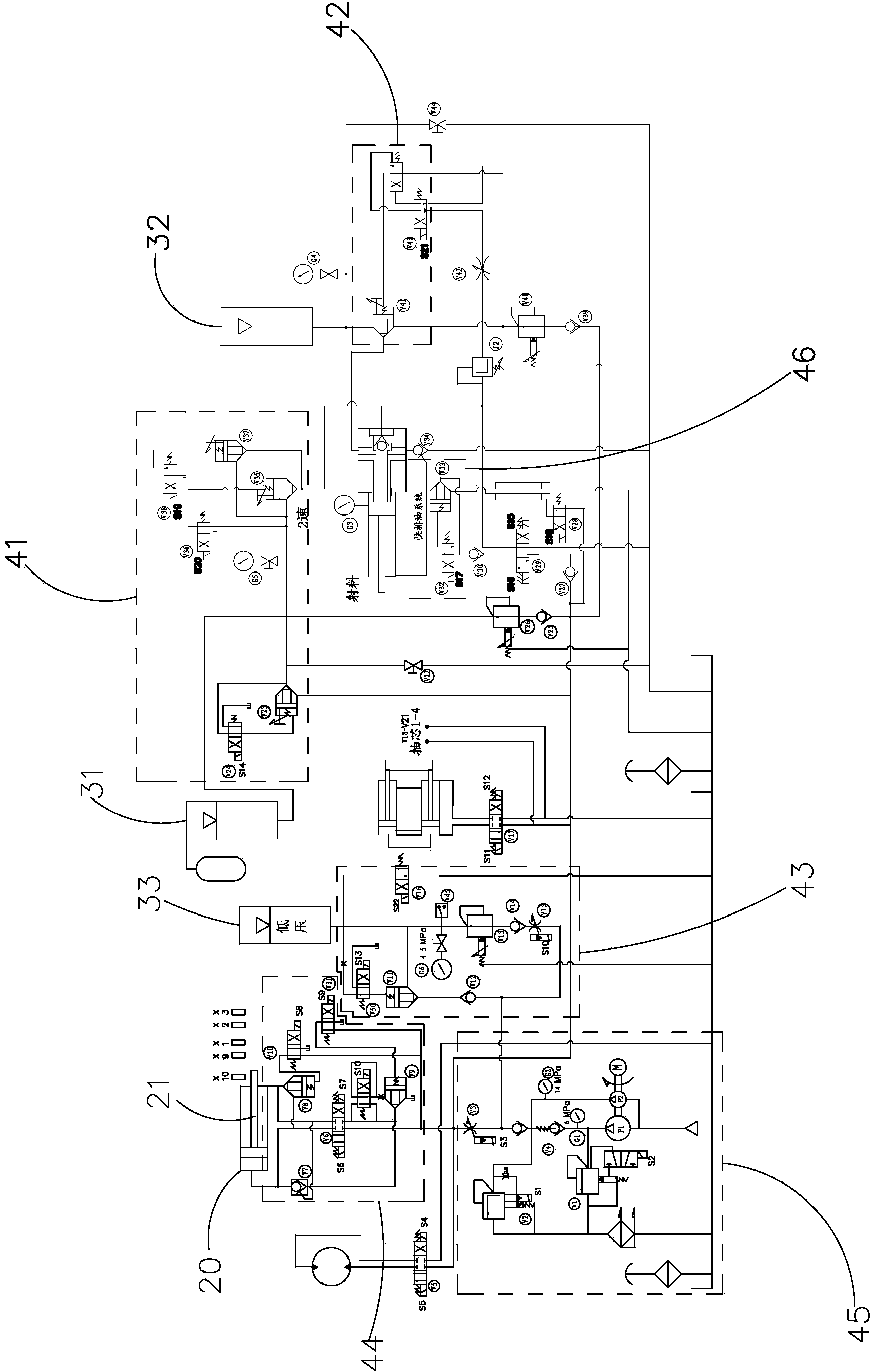

Energy-saving die casting machine

ActiveCN103752792AMeet the needs of maximum oil volumeExtended service lifeControl systemDie casting

An energy-saving die casting machine which comprises a die locking oil cylinder, an injection oil path body, a first oil path system, a second oil path system, a third oil path system, a slow injection system, an injection energy accumulator, a boost energy accumulator and a low-pressure energy accumulator. The first oil path system, the second oil path system and the third oil path system are connected with the injection energy accumulator, the boost energy accumulator and the low-pressure energy accumulator respectively. A die locking body is connected with the first oil path system, the second oil path system and the third oil path system through an oil path control system. The injection oil path body comprises a main oil cylinder; the injection energy accumulator and the boost energy accumulator are arranged on the main oil cylinder, the injection energy accumulator acts on the rear portion in the direction of oil path injection, and the boost energy accumulator acts on the front portion of the direction of oil path injection; an output end of the slow injection system is connected with the oil path control system; in the die assembling process, the low-pressure energy accumulator drives a die locking push rod in the die locking oil cylinder to act, and after die assembly is completed, the slow injection system charges the low-pressure energy accumulator.

Owner:东莞市益格机电有限公司

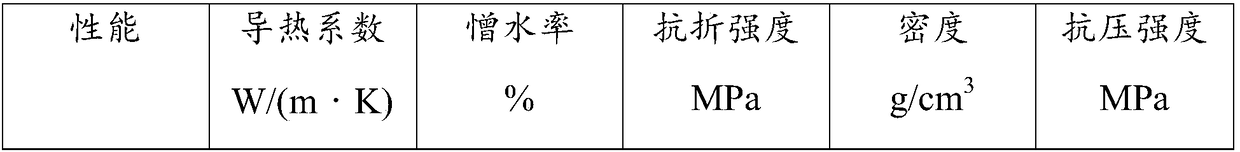

Preparation method of aerogel fiber composite felt, aerogel fiber composite felt and application of aerogel fiber composite felt

PendingCN108179628APrevents cracking and collapsingImprove toughnessVegetal fibresControllabilityFiber

The invention relates to the field of materials, and concretely provides a preparation method of an aerogel fiber composite felt, the aerogel fiber composite felt and an application of the aerogel fiber composite felt. Fibers are added into silica sol, and are uniformly distributed in the silica sol to prepare a mixed solution, the mixed solution forms aerogel in a composite fiber felt, and further ageing modification is performed to prepare the aerogel fiber composite felt. The weight proportion of the fibers is controlled to make the fibers form a three-dimensional network skeleton in the aerogel in order to further achieve the supporting effect, so the stability and the toughness of the composite felt are improved; and the ageing modification further improves the stability and the service life of the composite felt. The preparation method has the advantages of simplicity and controllability in production operation, time saving, and cost reduction. The composite felt prepared in theinvention has a low heat conduction coefficient, doubled flexural resistance and doubled compressive property. The composite belt can be widely applied, and meets demands of different uses and environments.

Owner:瑞吉斯昇态链(天津)咨询有限公司

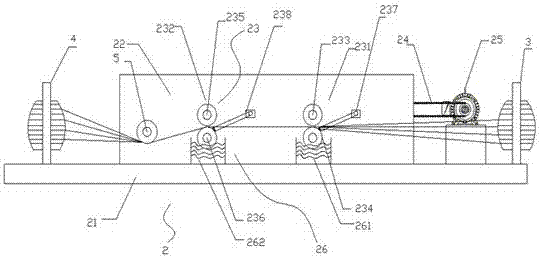

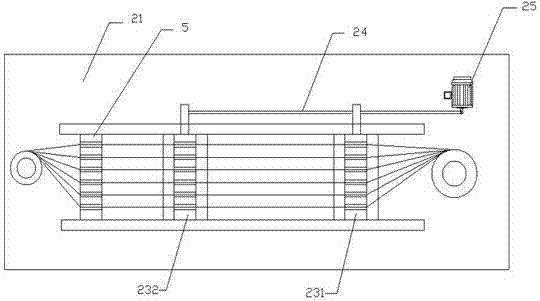

Continuous production-type ultrasonic atomization spraying film-coating equipment

ActiveCN106423649AMeet process requirementsImprove coating efficiencyLiquid surface applicatorsLiquid spraying apparatusEngineeringUltrasonic atomization

The invention discloses continuous production-type ultrasonic atomization spraying film-coating equipment. A heating device is arranged at the middle part of a continuous conveying device, a film-coating device is arranged above the continuous conveying device and faces the heating device, a spraying cavity is arranged in a housing in the film-coating device, a spraying cooling cavity is arranged in the outer wall of the spraying cavity, and the spraying cooling cavity extends to an outlet part from the middle part of the spraying cavity, and communicates with external spraying cooling liquid inlet tube and spraying cooling liquid outlet tube simultaneously; and an ultrasonic atomization assembly, an air blowing nozzle and a gas inlet tube are arranged at an inlet of the spraying cavity, the gas inlet tube blows a carrier gas in the spraying cavity through the air blowing nozzle, the carrier gas carries mist generated by the ultrasonic atomization assembly, and the mist is conveyed to an outlet of the spraying cavity to carry out a high-temperature pyrolysis reaction on the upper surface of a workpiece to be subjected to film-coating, thus film-coating on the upper surface of the workpiece is realized. The continuous production-type ultrasonic atomization spraying film-coating equipment disclosed by the invention is capable of continuously carrying out film-coating on the surface of the workpiece, thus the film-coating efficiency is greatly increased, and the process need of continuous film-coating of some workpieces can be met.

Owner:CHONGQING UNIV OF TECH

Technical configuration method for major-diameter aluminum-alloy round cast ingot heating facility

InactiveCN101817030ASolve the large radial temperature differenceMeet process requirementsExtrusion control devicesNatural gasHeating furnace

The invention relates to a technical configuration method for a major-diameter aluminum-alloy round cast ingot heating facility, which comprises preheating and gradient heating; in the preheating step, aluminum-alloy round cast ingots are conveyed to a natural gas preheating furnace by a chain and chain conveying motor and heated at 300-350 DEG C; and in the gradient heating step, the aluminum-alloy round cast ingots moving out of the natural-gas preheating furnace are adjusted through a rotating plate by 90 degrees, pushed to an ingot conveying dolly and conveyed to an induction heating furnace for gradient heating. The heating coils are divided into different sections; the heating coils in different sections are different in temperature control, and an end temperature compensation coil is additionally arranged outside the heating coil at the discharge end of the induction heating furnace; the temperature of the end temperature compensation coil is 420-500 DEG C; the temperature gradients of in different sections from the heating coils to the temperature compensation coil are controlled to be 60-100 DEG C / m; and the aluminum-alloy round cast ingots processed by gradient heating are conveyed in front of an extruder through an extruder ingot conveying dolly to carry out simulated isothermal extrusion. The invention solves the problem of great radial temperature difference which frequently occurs in major-diameter cast ingot heating.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

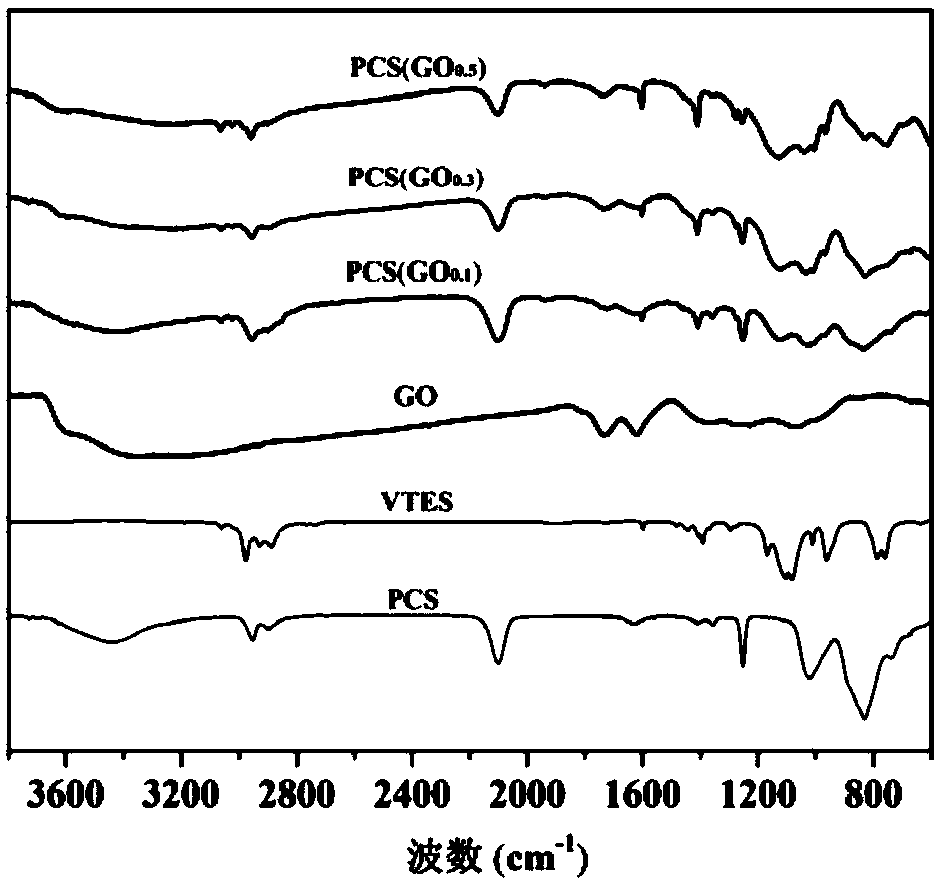

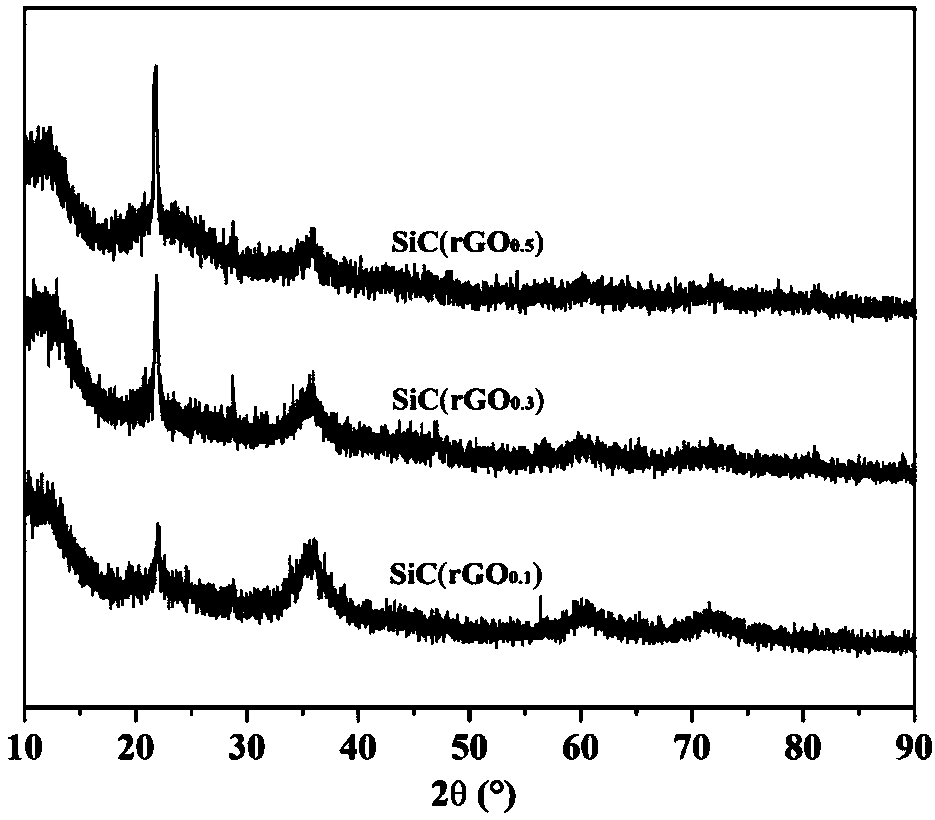

Graphene/silicon carbide nano-composite structure monolithic ceramic and preparation method thereof

The invention provides graphene / silicon carbide nano-composite structure monolithic ceramic and a preparation method thereof, and relates to preparation of a ceramic material. The preparation method comprises the following steps: 1) synthesizing a precursor PCS(GOx); and 2) preparing the graphene / silicon carbide nano-composite structure monolithic ceramic SiC(rGOx). Precursor PCS(GOx) powder is prepared from raw materials comprising GO, VTES and PCS through a chemical modification method, and then the compact graphene / silicon carbide nano-composite structure monolithic ceramic SiC(rGOx) is obtained through the steps of compression molding forming and high-temperature pyrolysis. The VTES has a -Si-O-bond and a -CH=CH2 group, so the GO and the PCS can be compounded to generate a new GO-VTES-PCS macromolecular structure. The GO is compounded to the silicon carbide ceramic, so that the crosslinking area of the precursor can be enlarged obviously, formation of the SiC nano-crystal is inhibited, the sintering temperature is reduced, and the problems that the silicon carbide monolithic ceramic prepared by a precursor method is difficult to form and low in compactness are solved.

Owner:中科德胜(常州)电子科技有限公司

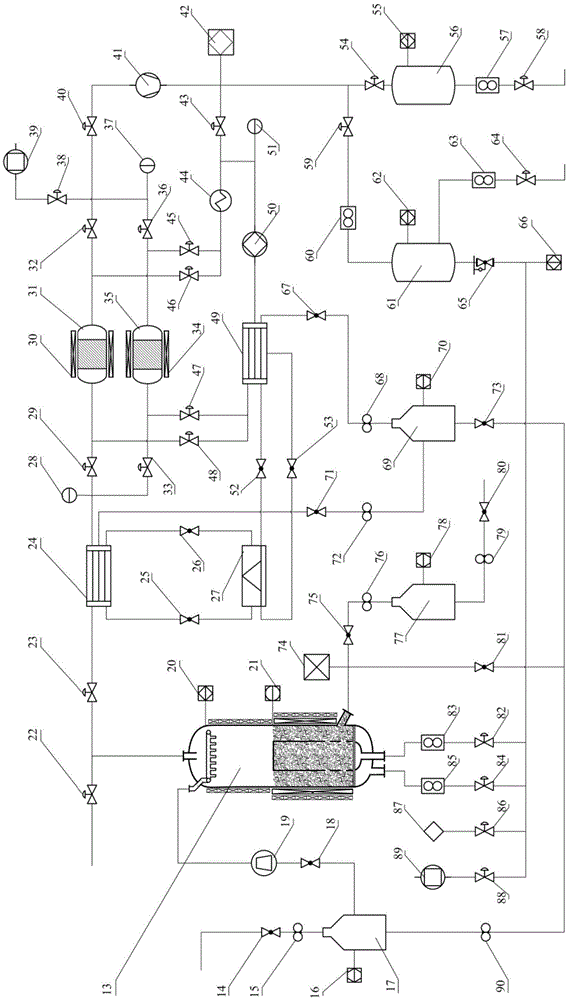

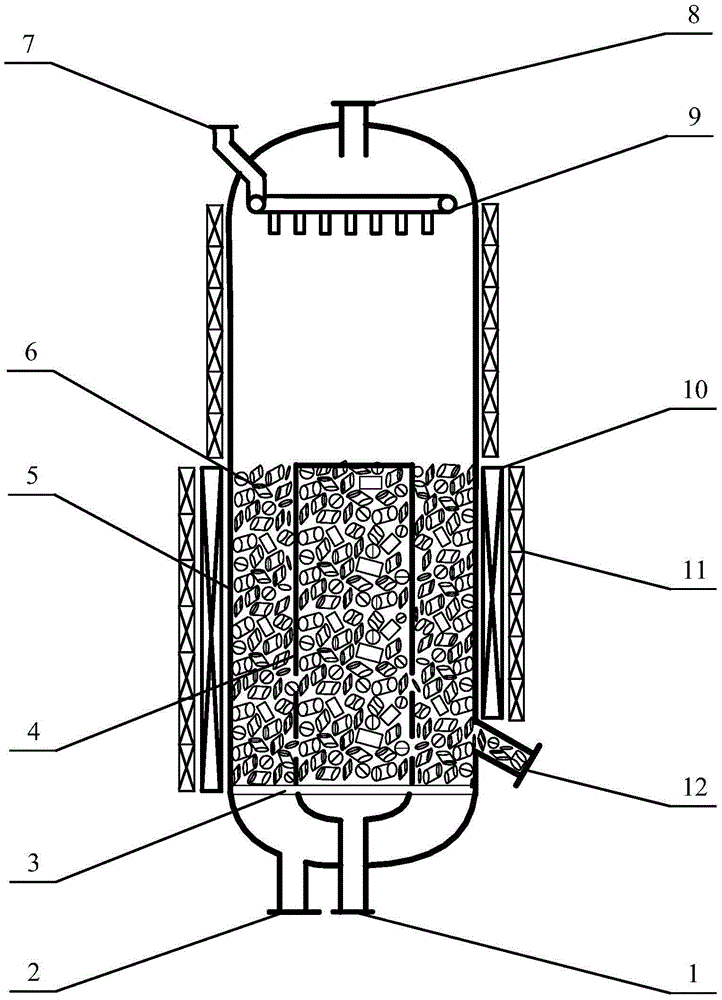

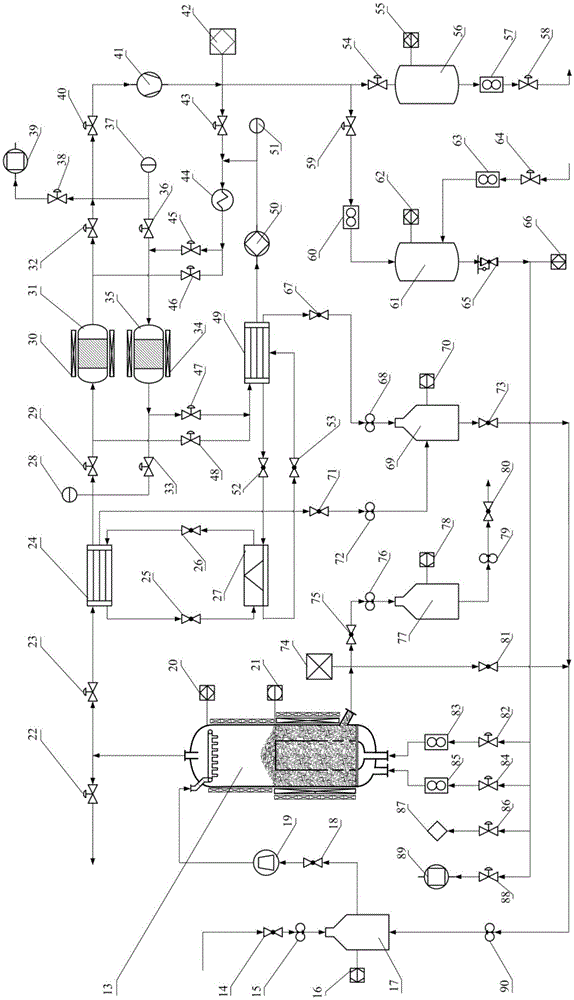

System for realizing detritiation of water and realizing method of system

The invention discloses a system for realizing detritiation of water. The system comprises a catalytic exchange system, a hydrogen supply system, a tritium-containing water supply system, a tritium-containing hydrogen drying and collecting system, a low-tritium-content water collecting system, a condensing system and a detecting control device. The system can meet all the process requirements of detritiation of water, including continuous treatment processes of vacuumizing the system before operation and alternately drying and activating a molecular sieve bed; the system is reasonable in layout, and the tritium-containing water purification efficiency is greatly improved; and meanwhile, tritium-containing hydrogen with high concentration can be obtained. Meanwhile, the system is convenient to operate and low in energy consumption; the interphase contact area of gas and liquid in the catalytic exchange system is large, the mass transfer coefficient is large, and the reaction efficiency is high; and furthermore, fluid can flow in a fixed direction, so as to quantitatively control the water detritiation efficiency. The catalytic exchange device is simple in structure; compared with a conventional water detritiation exchange column, the catalytic exchange device has the advantage that the height is obviously reduced, and investment of equipment and investment of catalysts are greatly reduced.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

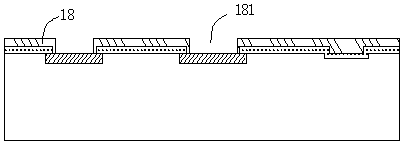

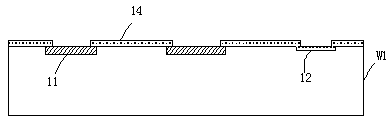

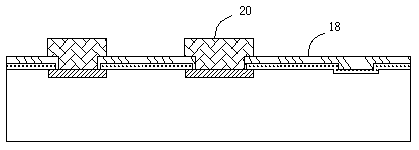

Wafer-level back gold chip packaging structure and packaging method thereof

ActiveCN107910305AIn line with the development directionPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSemiconductor package

The present invention discloses a back gold chip packaging structure and a packaging method thereof, belonging to the technical field of semiconductor packaging. A plurality of chip electrodes and front protective layers are arranged at the front surface of a silicon-based body, each front protective layer is provided with one front protective layer opening to expose chip electrodes again, and metal bump are arranged at the surfaces of the chip electrodes. The back surface of the silicon-based body is provided with a back gold layer, the back gold layer is in bonding connection with the back surface of the silicon-based body through a back gold bonding layer. A plastic packaging layer packages exposed surfaces of the back gold layer and the silicon-based body, and a plastic packaging layeropening is arranged to expose the exposed surface of the back surface of the back gold layer. The wafer-level back gold chip packaging structure and the packaging method thereof are simple in packaging flow, the silicon face processing technology, the back gold technology, the plastic packaging material ablation and the de-bonding technology are completed on a wafer, and therefore, the wafer-level back gold chip packaging structure and the packaging method thereof accord with future development direction of semiconductor manufacturing.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

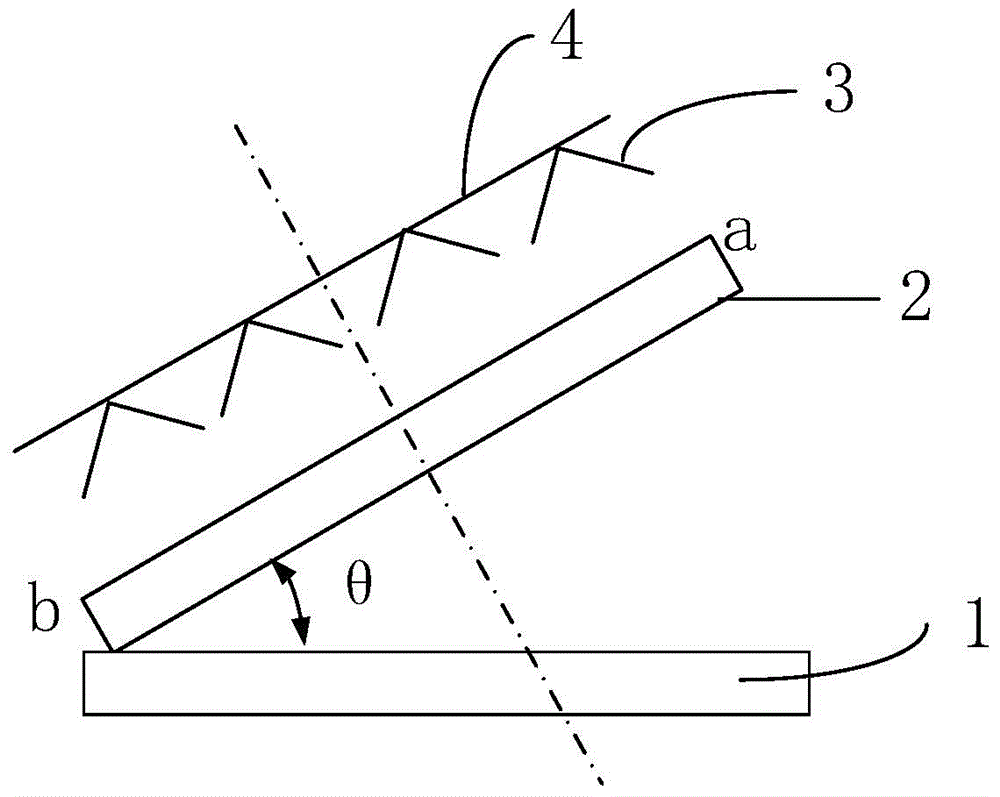

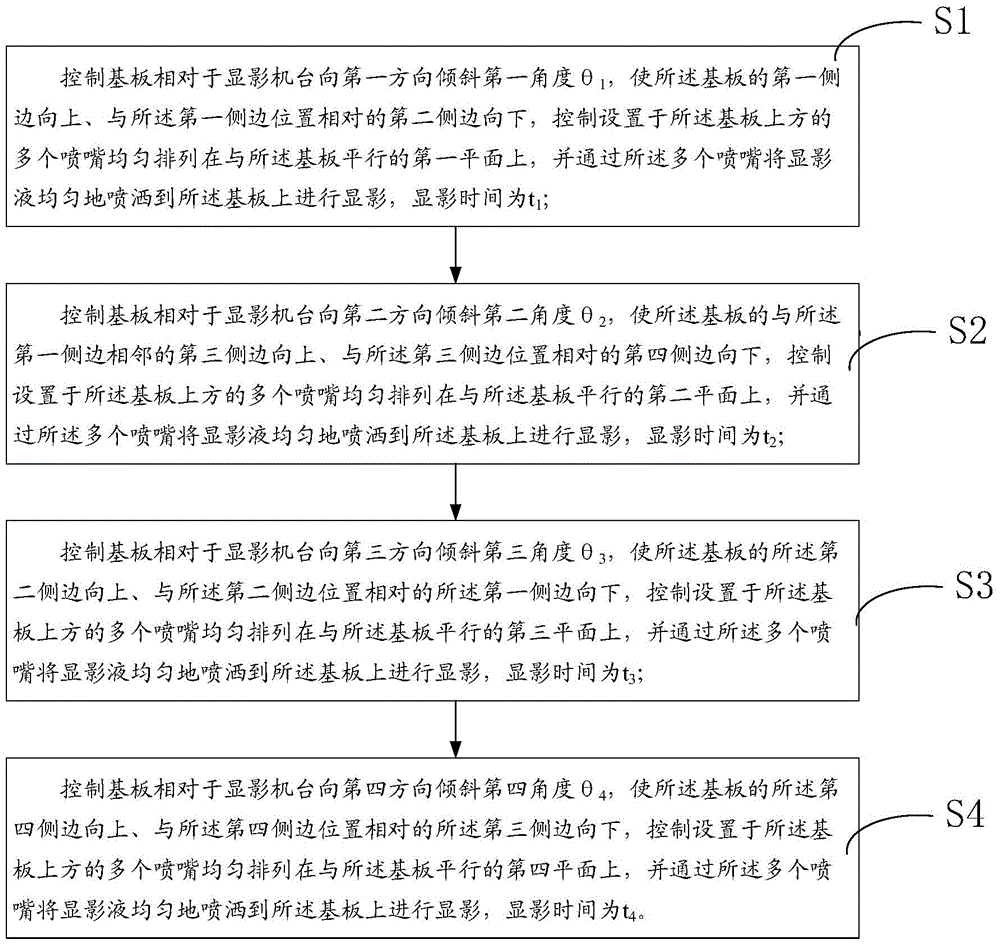

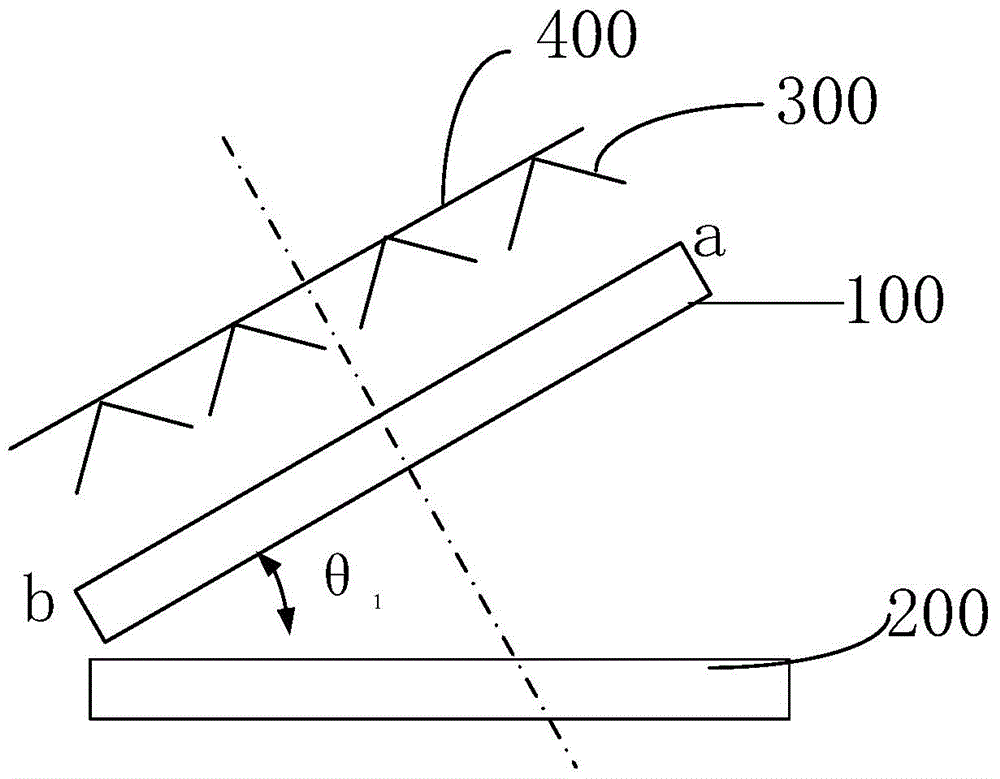

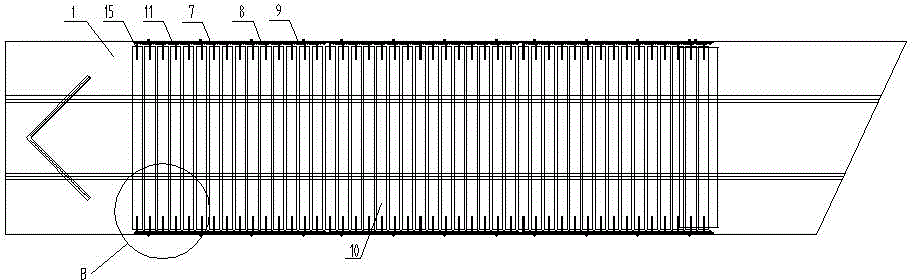

Developing method and developing device

InactiveCN104062857AImprove uniformityRealize all-round oblique developmentPhotosensitive material processingSpray nozzleEngineering

The invention provides a developing method and a developing device. The method comprises the following steps of controlling a base plate to incline for a first angle theta 1 towards a first direction relative to a developing machine table, controlling a plurality of spray nozzles to be on the first plane parallel to the base plate, uniformly spraying developing liquid on the base plate for developing; controlling the base plate to incline for a second angle theta 2 towards a second direction relative to the developing machine table, controlling the plurality of the spray nozzles to be on a second plane parallel to the base plate, and uniformly spraying the developing liquid on the base plate for developing; controlling the base plate to incline for a third angle theta 3 towards a third direction relative to the developing machine table, controlling the plurality of the spray nozzles to be on the third plane parallel to the base plate, uniformly spraying the developing liquid on the base plate for developing; and controlling the base plate to incline for a fourth angle theta 4 towards a fourth direction relative to the developing machine table, controlling the plurality of the spray nozzles to be on a fourth plane parallel to the base plate, and uniformly spraying the developing liquid on the base plate for developing. According to the scheme, the linear width uniformity of a developed photoetching pattern can be improved.

Owner:BOE TECH GRP CO LTD +1

Louver vibration screening device

The invention discloses a louver vibration screening device, and relates to a screening system in a tobacco threshing redrying factory. The louver vibration screening device comprises a vibration groove body. Fixed sliding rails are arranged on the front side and the rear side of the vibration groove body, space adjusting sliding rails are arranged above the fixed sliding rails on the two sides of the vibration groove body respectively, and sliding grooves are formed in the opposite sides of the vibration groove body and the space adjusting sliding rails. W-shaped supporting structures are arranged between the fixed sliding rails on the two sides and the space adjusting sliding rails, and the W-shaped supporting structures are connected with louver blades. Angle adjusting sliding rails are arranged on the vibration groove body and located above the space adjusting sliding rails on the two sides respectively, sliding grooves are formed in the opposite sides of the angle adjusting sliding rails, the two ends of each louver blade are connected with angle adjusting shafts, and the other ends of the angle adjusting shafts are arranged in the sliding grooves of the angle adjusting sliding rails in a sliding mode respectively. According to the louver vibration screening device, the angles and the spaces of louvers can be adjusted according to the technological requirement, so that the optimum screening effect is achieved, threshed oversized leaves are screened out to be subjected to secondary treatment, and therefore the technological requirement can be met.

Owner:JIANGSU HENGSEN TOBACCO MACHINERY +5

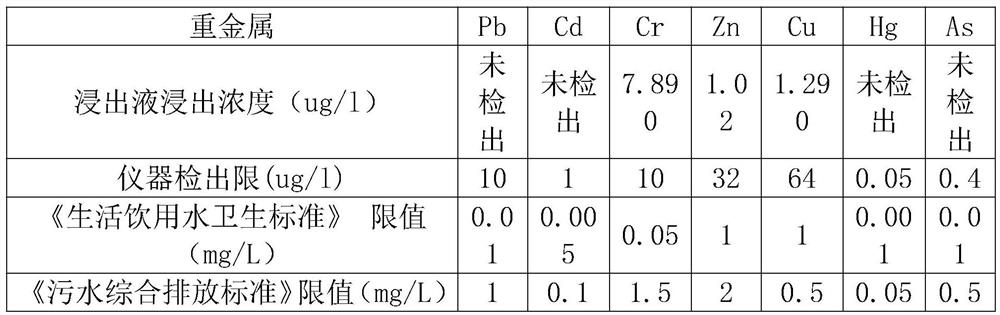

Method for low-temperature pyrolysis and resource utilization of household garbage incineration fly ash

The invention discloses a household garbage incineration fly ash low-temperature pyrolysis and resource utilization method, which comprises the steps: unloading fly ash from a storage tank, feeding into a pyrolysis furnace, and carrying out low-temperature pyrolysis; discharging from the pyrolysis furnace, detecting the total residual amount of dioxins in the fly ash pyrolyzing product, feeding the fly ash pyrolyzing product with the total residual amount exceeding 50 ng-TEQ / kg back to the pyrolyzing furnace, continuously pyrolyzing, and preparing the qualified fly ash pyrolyzing product withthe total residual amount not exceeding 50ng-TEQ / kg into a mine filler, wherein the mine filler is prepared by stirring a cementing agent, aggregate, water and an additive, and the cementing agent isprepared by homogenizing a qualified fly ash pyrolysis product, slag, slag and industrial byproduct gypsum; and sequentially feeding the flue gas generated in the pyrolysis furnace into a secondary combustion chamber, a waste heat recovery system, a deacidification system and a dust removal system, and discharging until atmospheric pollutants in the flue gas meet the national emission standard. According to the method, resource utilization of the fly ash is achieved, the absorption capacity is high, the cost is low, and environmental safety is guaranteed.

Owner:北科蕴宏环保科技(北京)有限公司

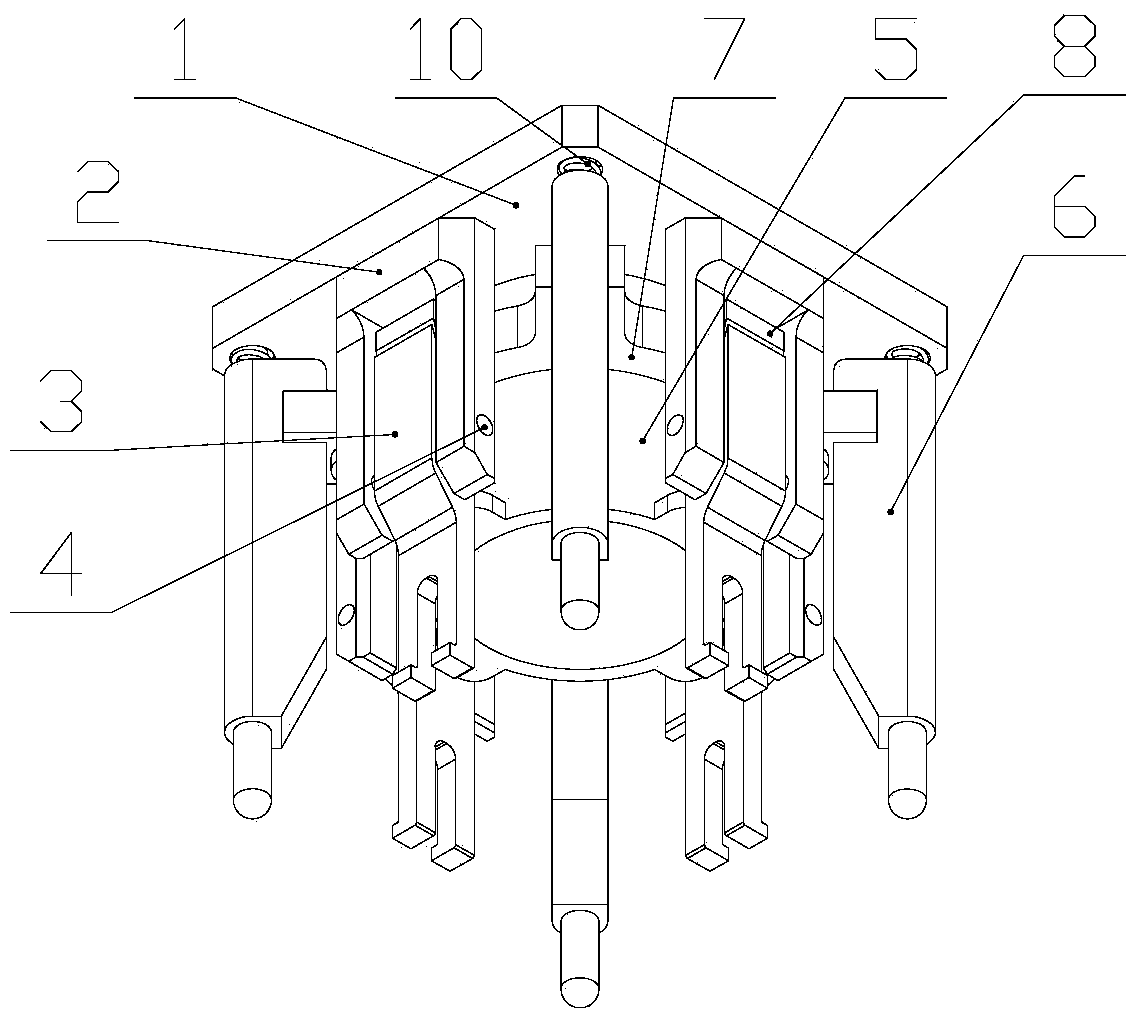

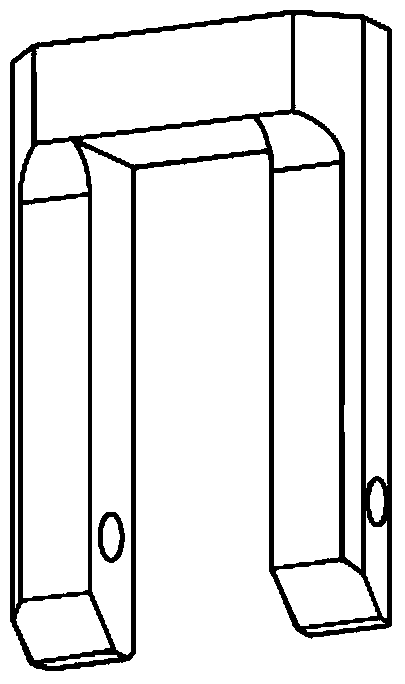

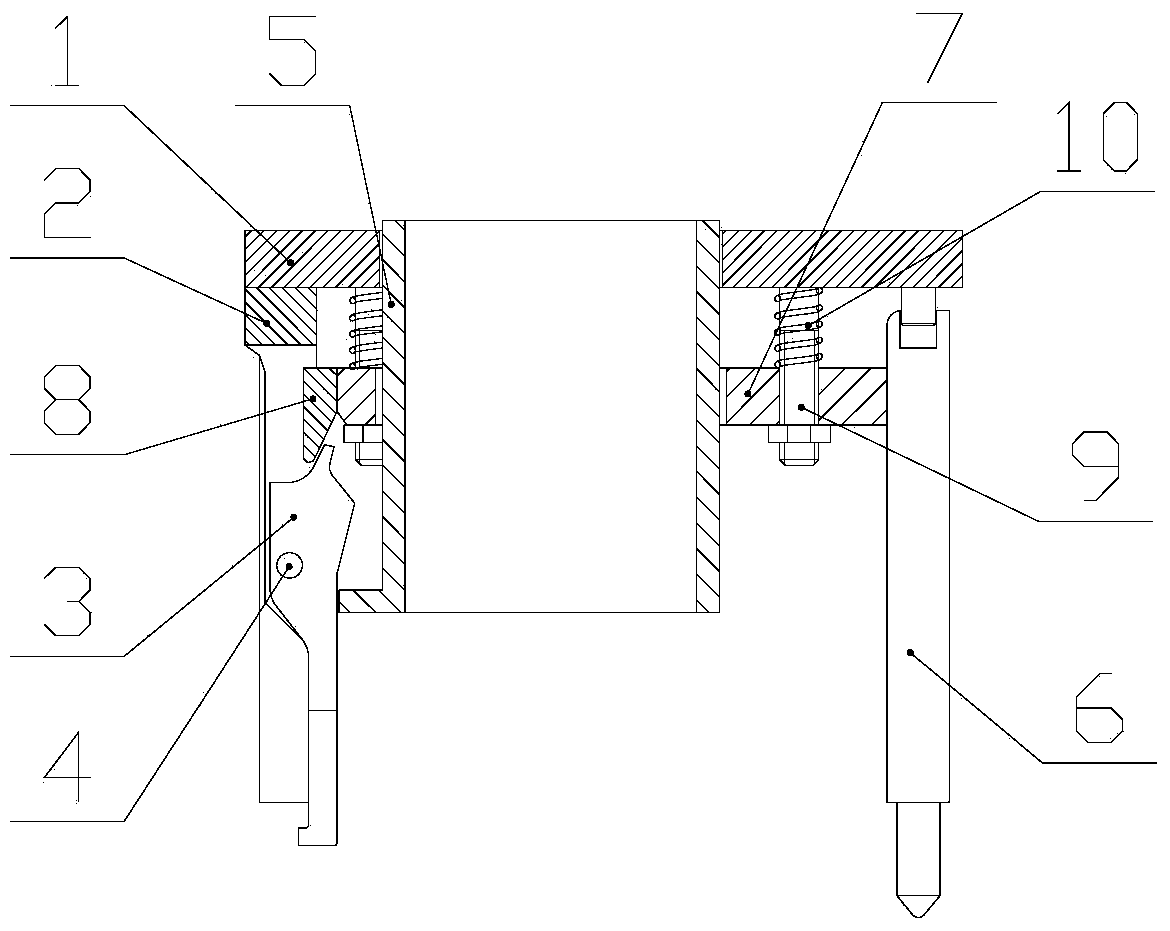

Fuel assembly grab using wedge to realize self-locking

ActiveCN103996420AMeet process requirementsCompact structureNuclear energy generationGripping headsNuclear powerSelf locking

The invention relates to a fuel assembly grab using a wedge to realize self-locking. The grab comprises a grab flange, a grabbing hook bearer, a grabbing hook, a pin shaft, a driving sleeve, a grab guiding column, a sliding sleeve, a wedge, screws and springs. The grabbing hook is installed on the grabbing hook bearer through the pin shaft, the grabbing hook is connected with the driving sleeve, the upper portion of the driving sleeve is connected with the driving mechanism of the grab, and the driving mechanism drives the driving sleeve to lift in order to realize the release and engagement of the grabbing hook; and a compression gap is residual between the top of the grab guiding column and the gap flange, the grab guiding column is connected with the sliding sleeve, the side surface of the sliding sleeve is provided with the wedge, the sliding sleeve is guided by the screws arranged on the bottom surface of the grab flange, the springs cover the screws, and he springs are connected with the sliding sleeve and the grab flange respectively. The grab realizes self-locking depended on the compacting force of the springs and the cooperative contact of the wedge with the grabbing hook, has the advantages of simple and compact structure and safe and reliable operation, and can effectively meet the technological demands of fuel operation of nuclear power plants.

Owner:CHINA NUCLEAR POWER ENG CO LTD

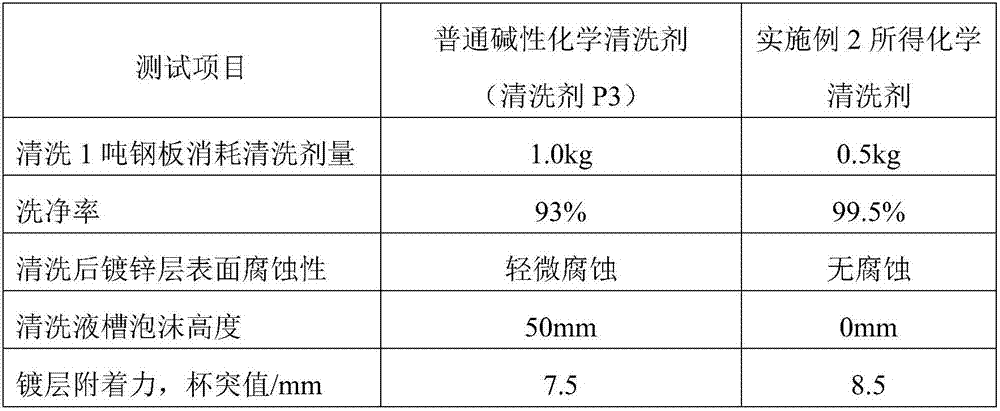

Alkaline chemical cleaning agent for electrogalvanizing pretreatment

The invention provides an alkaline chemical cleaning agent for electrogalvanizing pretreatment. The alkaline chemical cleaning agent for electrogalvanizing pretreatment comprises, by mass, 15%-35% of sodium hydroxide, 25%-55% of sodium carbonate, 5%-30% of trisodium phosphate, 5%-15% of sodium benzoate, 3%-10% of sodium citrate, 5%-15% of polyoxyethylene nonyl phenyl ether surface active agent and 0.5%-2% of polyether type antifoaming agent. The alkaline chemical cleaning agent can effectively restrain generation of foams in the sprinkling process and is rapid in degreasing, high in dirt removing capacity, good in cleaning effect, high in pH value buffering capacity, stable in hard water, long in service life, wide in application temperature range and capable of effectively improving the adhesive force of an electrogalvanizing layer. The alkaline chemical cleaning agent can meet the requirements, for the time and cleaning efficiency of cleaning pretreatment of a galvanizing substrate, of a large-scale electrogalvanizing production technology and has important industrial popularization significance.

Owner:武汉钢铁有限公司

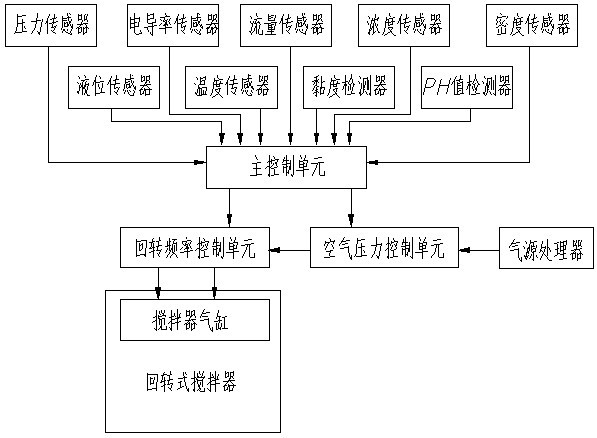

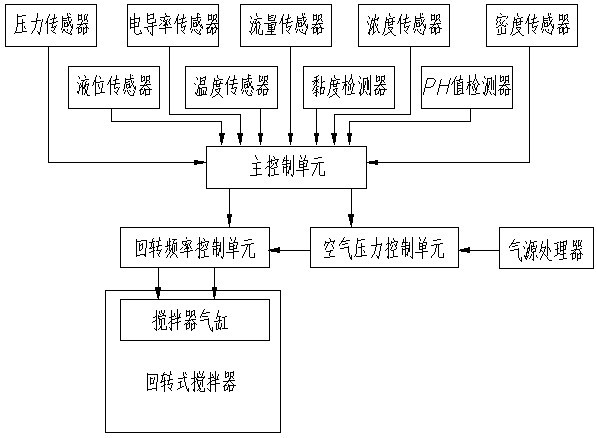

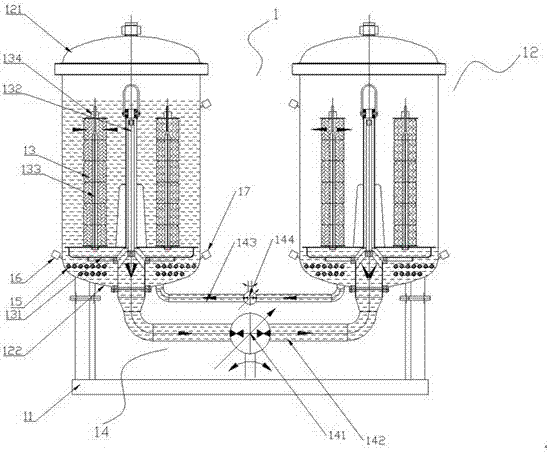

Intelligent pneumatic tumbling agitator

ActiveCN102527282AMeet process requirementsSave energyTransportation and packagingMixer accessoriesControl theoryViscosity

The invention discloses an intelligent pneumatic tumbling agitator which comprises a tumbling agitator, an air source processor, a main control unit, an air pressure control unit and a tumbling frequency control unit, wherein an output of the main control unit is respectively connected with inputs of the air pressure control unit and the tumbling frequency control unit, and the output of the air source processor is sequentially connected with the air pressure control unit, the tumbling frequency control unit and the tumbling agitator. The intelligent pneumatic tumbling agitator provided by the invention can respectively and independently control two key parameters, namely output torque (determined by the air pressure) and tumbling frequency of the agitator, according to external input signals (such as a liquid level signal, a temperature signal, viscosity and a pH value of fluid) and internally preset parameters, thereby achieving the effects of satisfying the process requirement and saving energy.

Owner:刘力

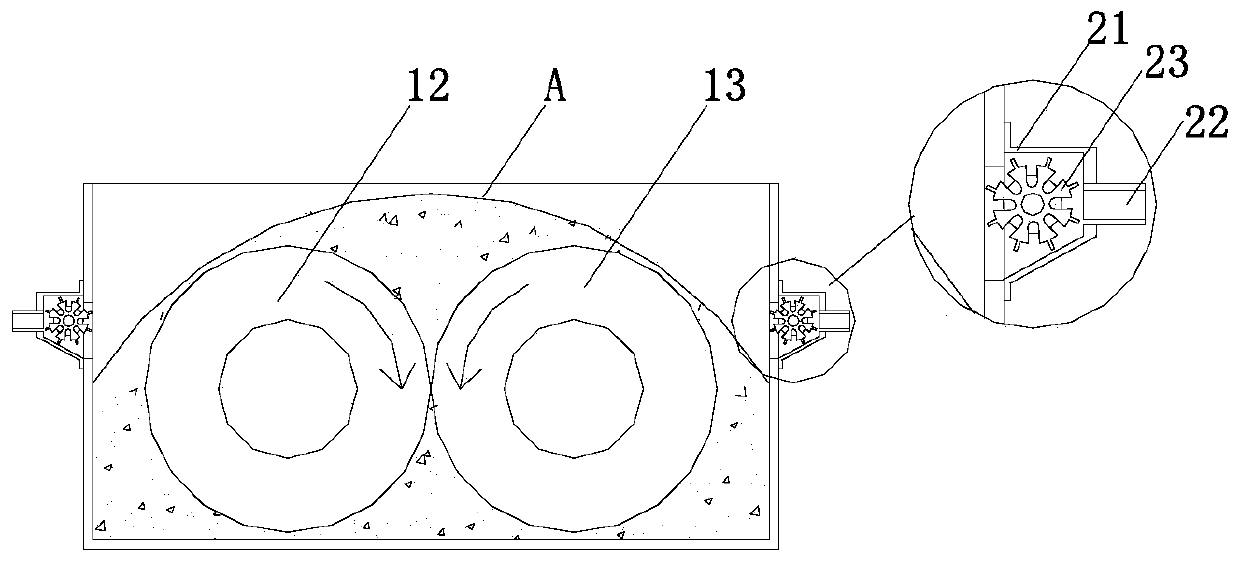

Cone yarn dyeing system

InactiveCN107338595AShort dyeing timeReduce energy consumptionTextile treatment containersTextile treatment machine arrangementsYarnEngineering

The invention relates to a cone yarn dyeing system which is characterized by comprising a high-pressure circular dip dyeing mechanism and a normal-pressure brush dyeing mechanism, wherein the high-pressure circular dip dyeing mechanism is connected in series with the normal-pressure brush dyeing mechanism; the high-pressure circular dip dyeing mechanism performs dip dyeing on cone yarns to achieve primary dyeing; and the cone yarns after the dip dyeing are subjected to brush dyeing by the normal-pressure brush dyeing mechanism to achieve secondary dyeing. According to the system, the traditional single vat dyeing is now changed into double vat yarn dyeing; with the adoption of a bidirectional circulation pump, the front and back dyeing of the yarns in two vats can be achieved; technical requirements are met; a dyeing effect is guaranteed; compared with the traditional dyeing machine, the dyeing system only requires half of a dyeing solution to dye the same quantity of the yarns; the consumption of the dyeing solution is greatly reduced; at the same time, the consumption of heating steam can also be reduced with the reduction of the consumption of the dyeing solution; and the production cost is greatly lowered.

Owner:朱爱民

Martensite stainless steel for manufacture of scalpel blade and manufacturing method of martensite stainless steel

InactiveCN108300945AMeet process requirementsReduce adverse effectsFurnace typesHeat treatment furnacesMetallurgyMartensitic stainless steel

The invention relates to martensite stainless steel for manufacture of a scalpel blade and a manufacturing method of the martensite stainless steel. The martensite stainless steel is prepared from, byweight, 0.65-0.70% of C, smaller than or equal to 0.5% of Si, 0.4-0.7% of Mn, smaller than or equal to 0.03% of P, smaller than or equal to 0.025% of S, smaller than or equal to 0.5% of Ni, 13.0-13.5% of Cr, 0.8-1.2% of Mo, 0.08-0.12% of V and the balance Fe and other inevitable impurities. The hardness reaches HV700 or above after quenching and tempering are completed, meanwhile, the carbon content of the martensite stainless steel is controlled within a reasonable range in order to avoid adverse influences caused by increase of the carbon content in the prior art, and the anti-corrosion effect is good.

Owner:江苏延汉材料科技有限公司

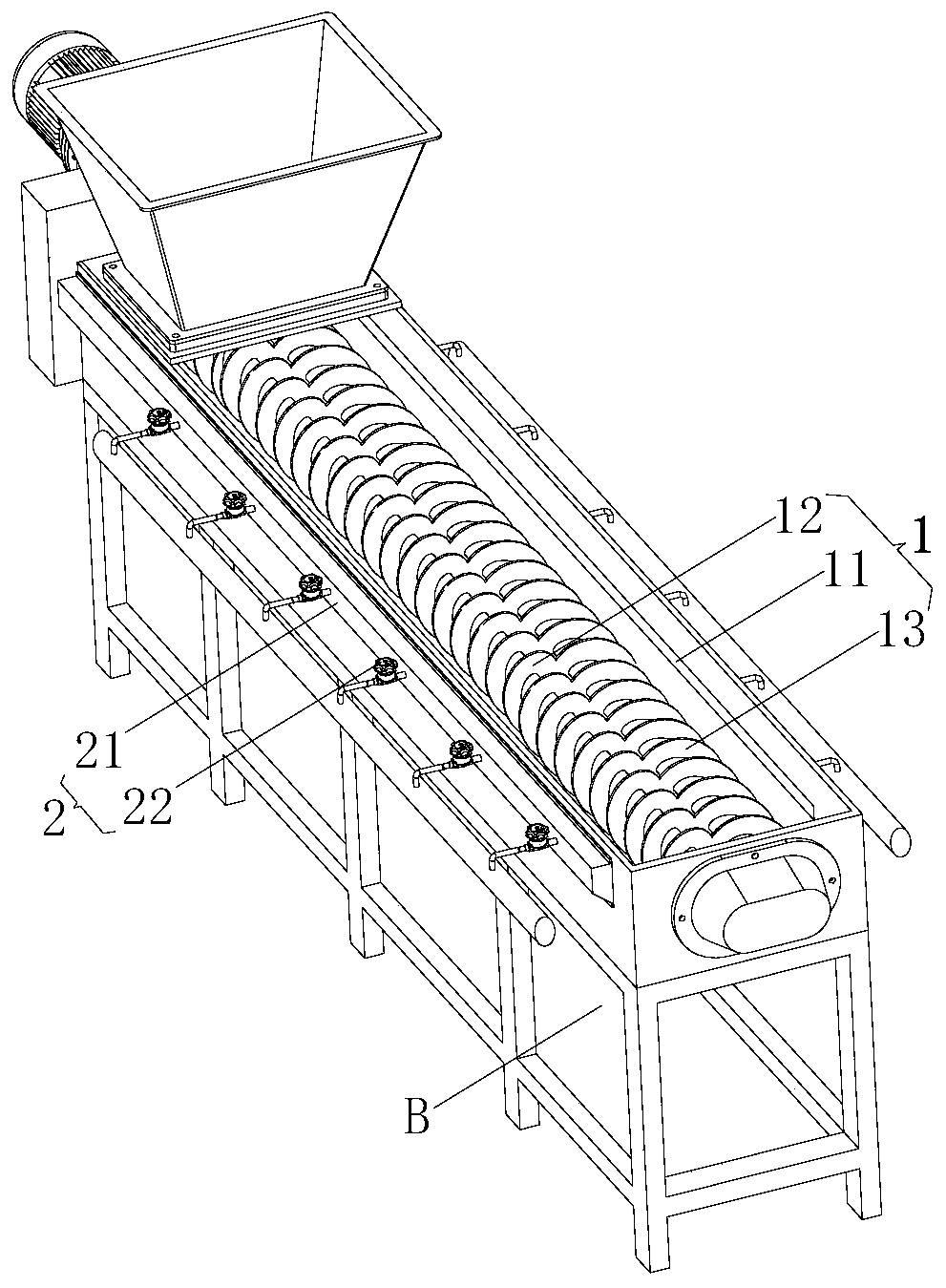

Archaistic black brick production process and equipment

ActiveCN111153680AEvenly distributedImprove uniformityFurnace typesClay mixing apparatusBrickProcess engineering

The invention discloses an archaistic black brick production process. The archaistic black brick production process comprises the procedures of raw material processing, blank making, drying, firing and drying, wherein the raw material processing step comprises raw material preparing and raw material stirring, in the raw material stirring process, steam is introduced while raw materials are stirred, and after the raw material stirring process is completed, the water content of the raw materials is 16%-20%. Meanwhile, the invention further discloses equipment for realizing the process. In the raw material processing process, different from a conventional mode of directly adding water, stirring and mixing, a mode of adding steam while stirring is adopted for humidifying, so that the raw materials are fully mixed, meanwhile, water is more uniformly distributed in the raw materials, and the phenomenon of clumping can be effectively prevented, so that the color uniformity, flatness and mechanical properties of the fired black bricks are improved.

Owner:南平市建阳区三顺建材有限公司

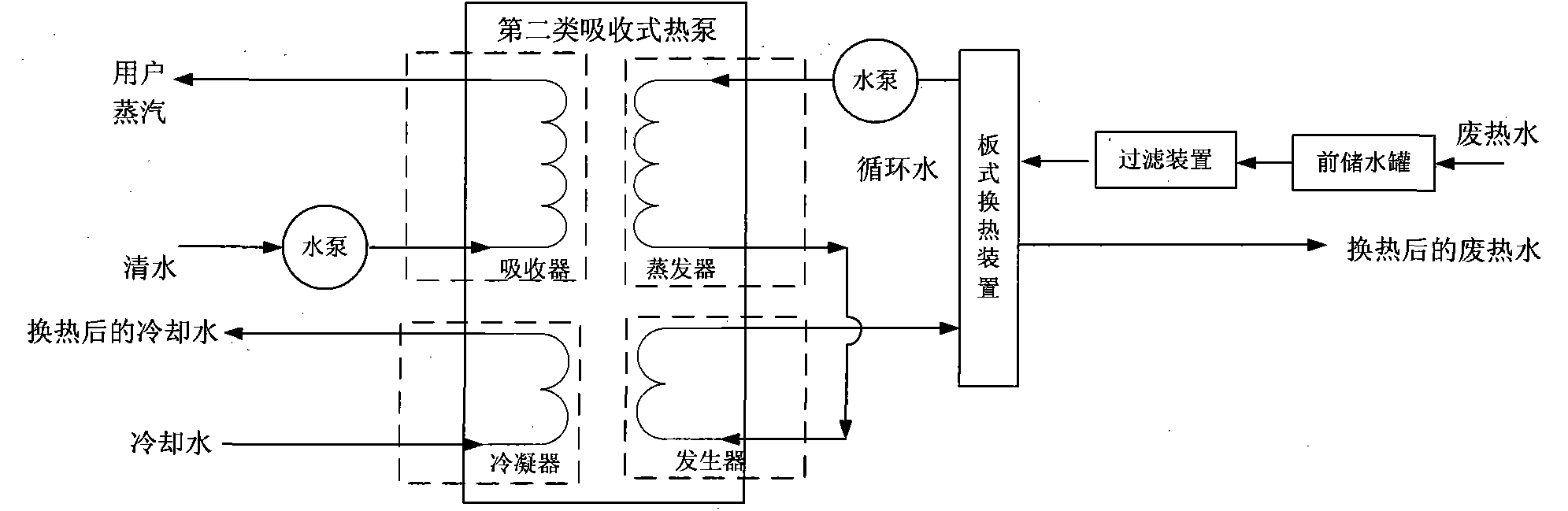

Waste heat recovering system capable of continuously generating steam aiming at impure waste water resources

InactiveCN103727512AEfficient recyclingEfficient productionEnergy efficient heating/coolingEnergy industryWater resourcesAbsorption heat pump

The invention discloses a waste heat recovering system capable of continuously generating steam aiming at impure waste water resources. The system comprises a second-type absorption heat pump, a front water tank, a filtering device, a water pump and a plate type heat exchanging device, wherein cooling water is input into a condenser of the second-type absorption heat pump and is output after heat exchanging, the output end of an evaporator is connected with the input end of a generator, the output end of the generator is connected with the plate type heat exchanging device, tap water is input into the evaporator and forms circulating water through the evaporator, the generator, the water pump and the plate type heat exchanging device, discontinuous waste hot water is changed into continuous waste hot water through the front water tank, input into the plate type heat exchanging device after impurities are filtered out through the filtering device, and then discharged as low-temperature waste hot water through heat exchanging. Low-temperature clear water is input into an absorber after passing through the water pump, and then is output as steam needed by a user. The system has the advantages that the utilization rate of the waste hot water is high, and the steam generating efficiency is high.

Owner:HANGZHOU WORUN ENERGY SAVING TECH

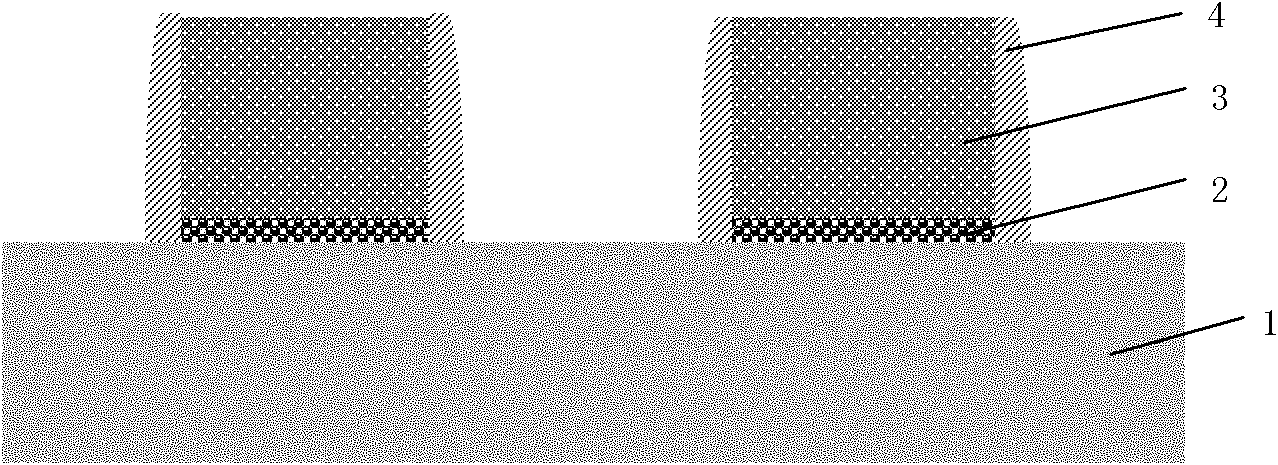

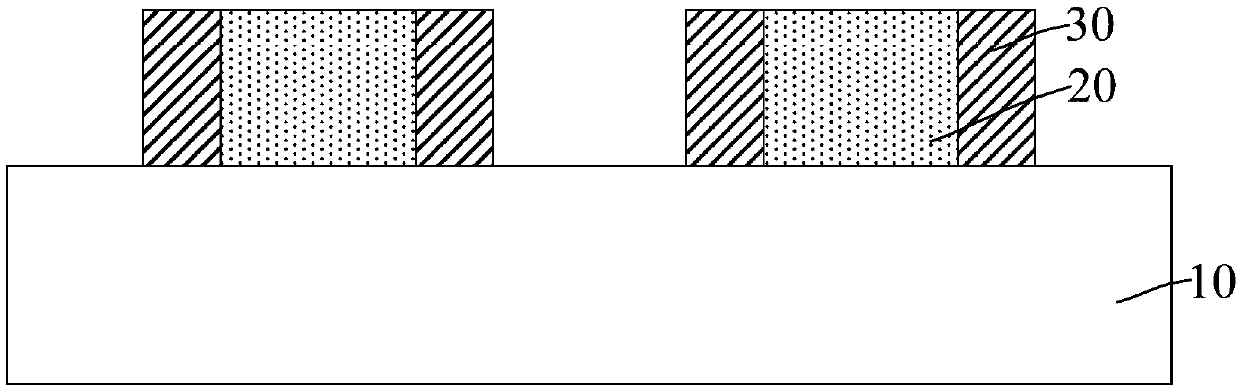

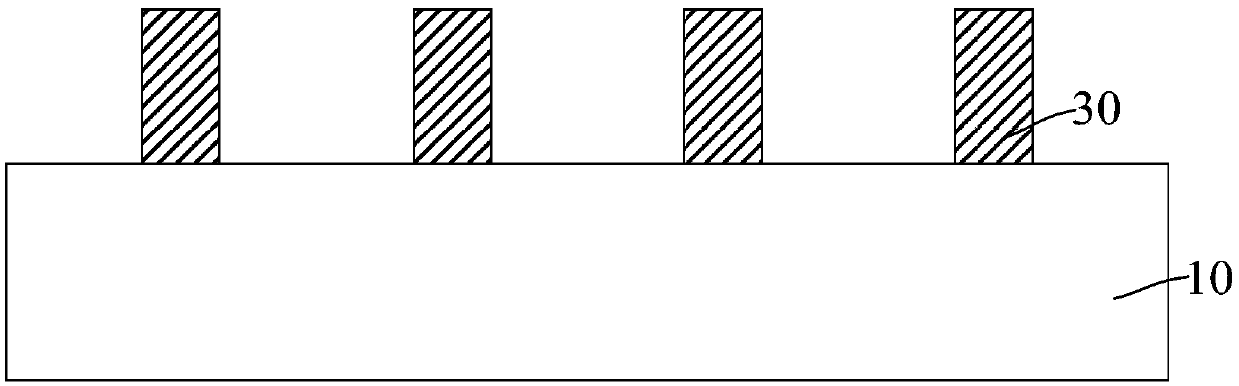

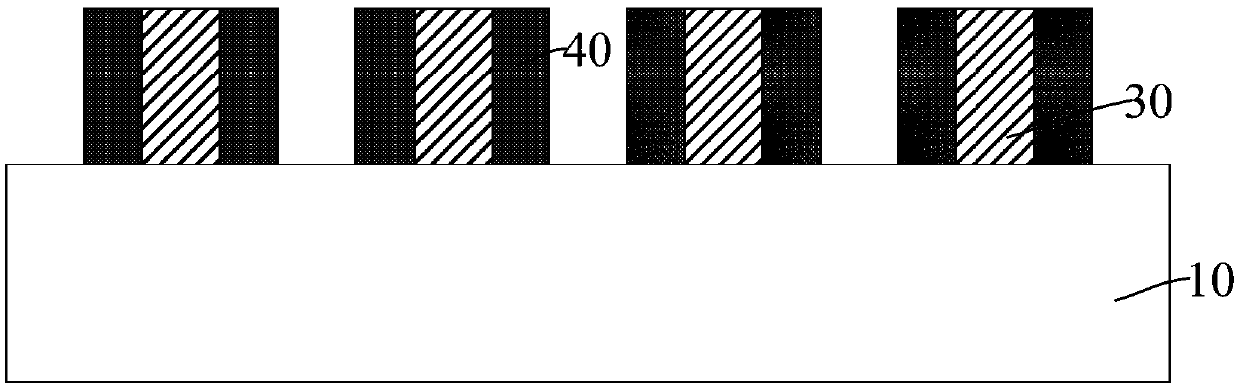

Semiconductor structure and forming method thereof

ActiveCN110739210AReduce processing difficultyGuaranteed shapeSolid-state devicesSemiconductor/solid-state device manufacturingLithography processSemiconductor structure

The invention provides a semiconductor structure and a forming method thereof. The forming method comprises the steps that a substrate is provided; a number of discrete core layers are formed on the substrate; sacrificial side walls are formed on the side walls of the core layers; each sacrificial side wall on one side of a core layer is a first sacrificial side wall, and each sacrificial side wall on the other side of the core layer is a second sacrificial side wall; the first sacrificial side walls and the second sacrificial side walls are spaced apart; a first mask side wall is formed on the side wall of each first sacrificial side wall; the core layers are removed, and openings are formed in the sacrificial side walls; a second mask side wall is formed on the side wall, which is exposed by an opening, of each second sacrificial side wall; the sacrificial side walls are removed; and the first mask side walls and the second mask side walls are used as masks to etch the substrate to form a target pattern. According to the invention, the process difficulty of a photolithography process is reduced; the process operability is improved; the shape and size of a target pattern can meetthe process requirements; and the device performance and the performance uniformity are improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com