Cone yarn dyeing system

A dyeing system and yarn technology, applied in the yarn dyeing and field, can solve the problems of color difference dyeing cost, waste of dye solution, etc., and achieve the effect of saving use, short dyeing time, and avoiding uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

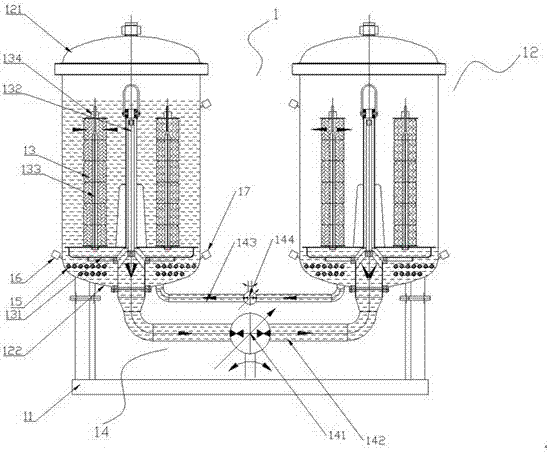

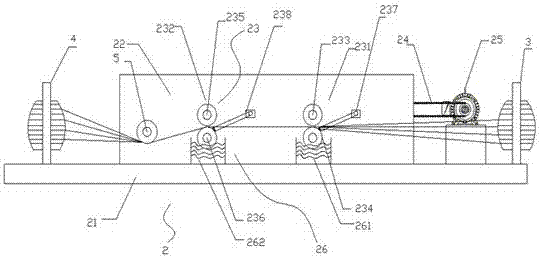

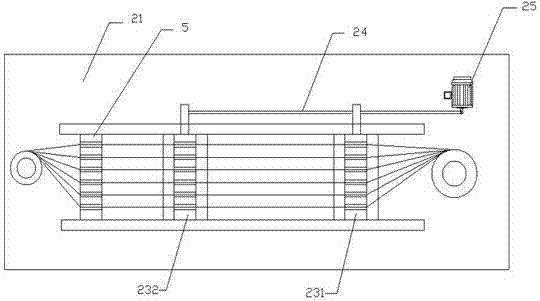

[0032] Such as Figure 1 to Figure 3 A bobbin dyeing system shown includes a high-pressure circulation dyeing mechanism 1 and a normal-pressure brushing mechanism 2;

[0033] The mechanism of the high-pressure circulation exhaust dyeing machine includes a support frame 11, a dyeing vat group 12, a bobbin creel 13, a high-pressure circulation device 14, a heating device and a detection device.

[0034] The dyeing vat group 12 has a pair of dyeing vats and the same height of the pair of dyeing vats is arranged on the support frame 11, the upper end of the dyeing vat group 12 is provided with a cylinder cover 121, and the lower end is welded with a sealing head 122; The ones are connected through the high-pressure circulation device 14; the bobbin creel is arranged in the pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com