Wool ecological dye paste, preparation method thereof and dyeing method

A wool and ecological technology, applied in the field of dyeing, can solve the problems of long dyeing time, achieve the effects of short dyeing time, avoiding damage to wool quality, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

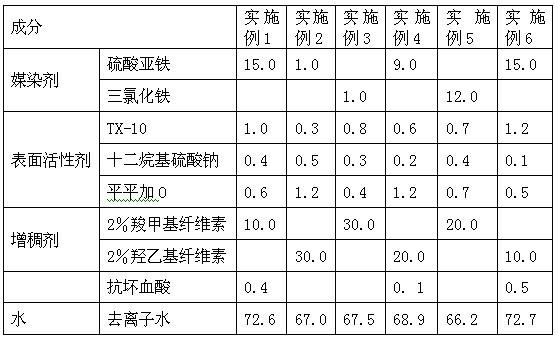

Examples

preparation example Construction

[0026] (1) Preparation method of dyeing paste: Weigh the surfactant in proportion and dissolve it in deionized water, then add the dye, dissolve and mix well, then add a thickener to adjust the viscosity to obtain a viscous paste. Add it to the viscous paste and dissolve it to make a dyeing paste;

[0027] (2) The preparation method of the mordant paste: Weigh the surfactant in proportion and dissolve it in deionized water, add the mordant, add the thickener and ascorbic acid, and mix to prepare the mordant paste.

Embodiment 7

[0028] Embodiment 7: Dyeing wool with any of the aforementioned ecological dyeing creams

[0029] Add 70g of water to the dyeing vat, add 30g of dyeing paste at room temperature, stir evenly, adjust the pH value of the dyeing bath to 9.0 with sodium hydroxide, then add 5g of wool loose fiber, and raise the temperature to 35 at a rate of 1min / °C ℃, keep warm for 35 minutes, then add 30g of mordant paste, stir evenly, keep warm at 35 ℃ for 35 minutes, and wash with water and soap.

Embodiment 8

[0030] Embodiment 8: Dyeing wool with any of the aforementioned ecological dyeing creams

[0031] Add 80g of water into the dyeing vat, add 20g of ecological dye at room temperature, stir evenly, adjust the pH value of the dyeing bath to 8.0 with sodium carbonate, then add 5g of wool loose fiber, and raise the temperature to 40 at a rate of 1min / °C ℃, heat preservation for 40 minutes, then add 20g of mordant paste, stir evenly, heat preservation at 40 ℃ for 40 minutes, after conventional washing and soaping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com