Method for low-temperature pyrolysis and resource utilization of household garbage incineration fly ash

A technology of domestic waste incineration and low-temperature pyrolysis, which is applied in the field of low-temperature pyrolysis and resource utilization of domestic waste incineration fly ash, can solve the problems of limited absorption capacity, increase, slowness, etc., and achieve the effect of optimizing work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for low-temperature pyrolysis and resource utilization of domestic waste incineration fly ash, comprising the following steps:

[0038] (1) After the fly ash is removed from the storage tank, it is sent to the pyrolysis furnace for low-temperature pyrolysis through a continuous feeding system with a self-sealing mechanism. The temperature of the low-temperature pyrolysis is 500°C and the time is 25 minutes;

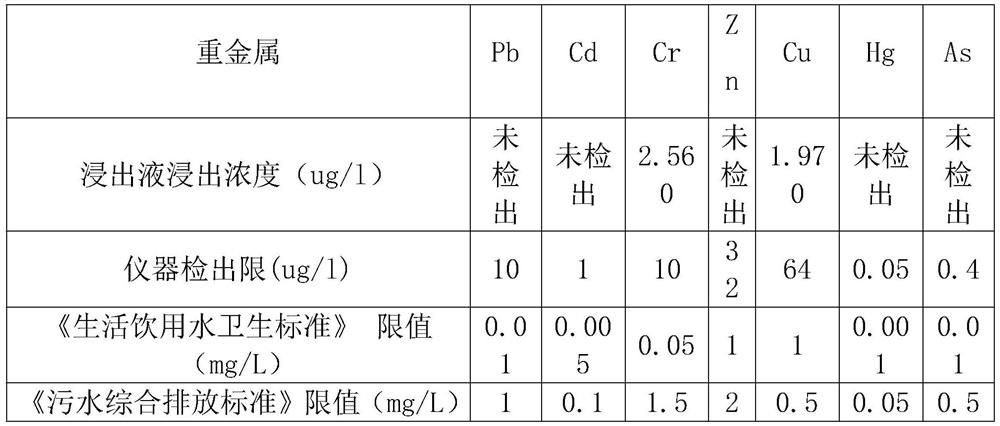

[0039] (2) The fly ash after low-temperature pyrolysis treatment is discharged from the pyrolysis furnace through a discharge system with a self-sealing mechanism, and the total amount of dioxins in the fly ash pyrolysis products is detected to be 65ng-TEQ / kg;

[0040] (3) Send the fly ash pyrolysis product back to the pyrolysis furnace for low-temperature pyrolysis. The temperature of low-temperature pyrolysis is 500°C and the time is 25 minutes. Discharged from the pyrolysis furnace, the total amount of dioxins detected in the fly ash pyrolysis products ...

Embodiment 2

[0049] A method for low-temperature pyrolysis and resource utilization of domestic waste incineration fly ash, comprising the following steps:

[0050] (1) After the fly ash is removed from the storage tank, it is sent to the pyrolysis furnace for low-temperature pyrolysis through a continuous feeding system with a self-sealing mechanism. The temperature of the low-temperature pyrolysis is 500°C and the time is 40 minutes;

[0051] (2) The fly ash after low-temperature pyrolysis treatment is discharged from the pyrolysis furnace through the unloading system with a self-sealing mechanism, and the total amount of dioxins in the fly ash pyrolysis products is detected to be 45ng-TEQ / kg;

[0052] (3) Making qualified fly ash pyrolysis products into mine filling materials;

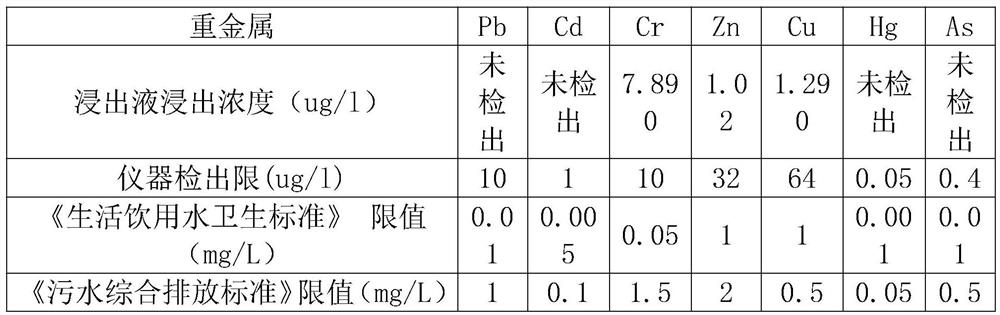

[0053] Weigh 15kg of qualified fly ash pyrolysis product, 50kg of slag, 20kg of slag, 15kg of industrial by-product gypsum, 5kg of red mud, and 5kg of fly ash, and grind the slag, slag, industrial by-product gyp...

Embodiment 3

[0060] A method for low-temperature pyrolysis and resource utilization of domestic waste incineration fly ash, comprising the following steps:

[0061] (1) After the fly ash is removed from the storage tank, it is sent to the pyrolysis furnace for low-temperature pyrolysis through a continuous feeding system with a self-sealing mechanism. The temperature of the low-temperature pyrolysis is 500°C and the time is 60 minutes;

[0062] (2) The fly ash after the low-temperature pyrolysis treatment is discharged from the pyrolysis furnace through the unloading system with a self-sealing mechanism, and the total amount of dioxins in the pyrolysis products of the fly ash is detected to be 42ng-TEQ / kg;

[0063] (3) Making qualified fly ash pyrolysis products into mine filling materials;

[0064] Weigh 20kg of qualified fly ash pyrolysis products, 85kg of slag, 30kg of slag, 20kg of industrial by-product gypsum, 5kg of tailings, and 5kg of ferrochrome slag, grind the slag, slag, industr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com