Fuel assembly grab using wedge to realize self-locking

A fuel assembly and wedge block technology, which is applied in the directions of reactor fuel elements, manufacturing tools, chucks, etc., can solve the problems of unsatisfactory operation effect, grasping body volume and self-weight, long self-locking stroke, etc., and achieves compact and simple structure. Moreover, the effect of short self-locking stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

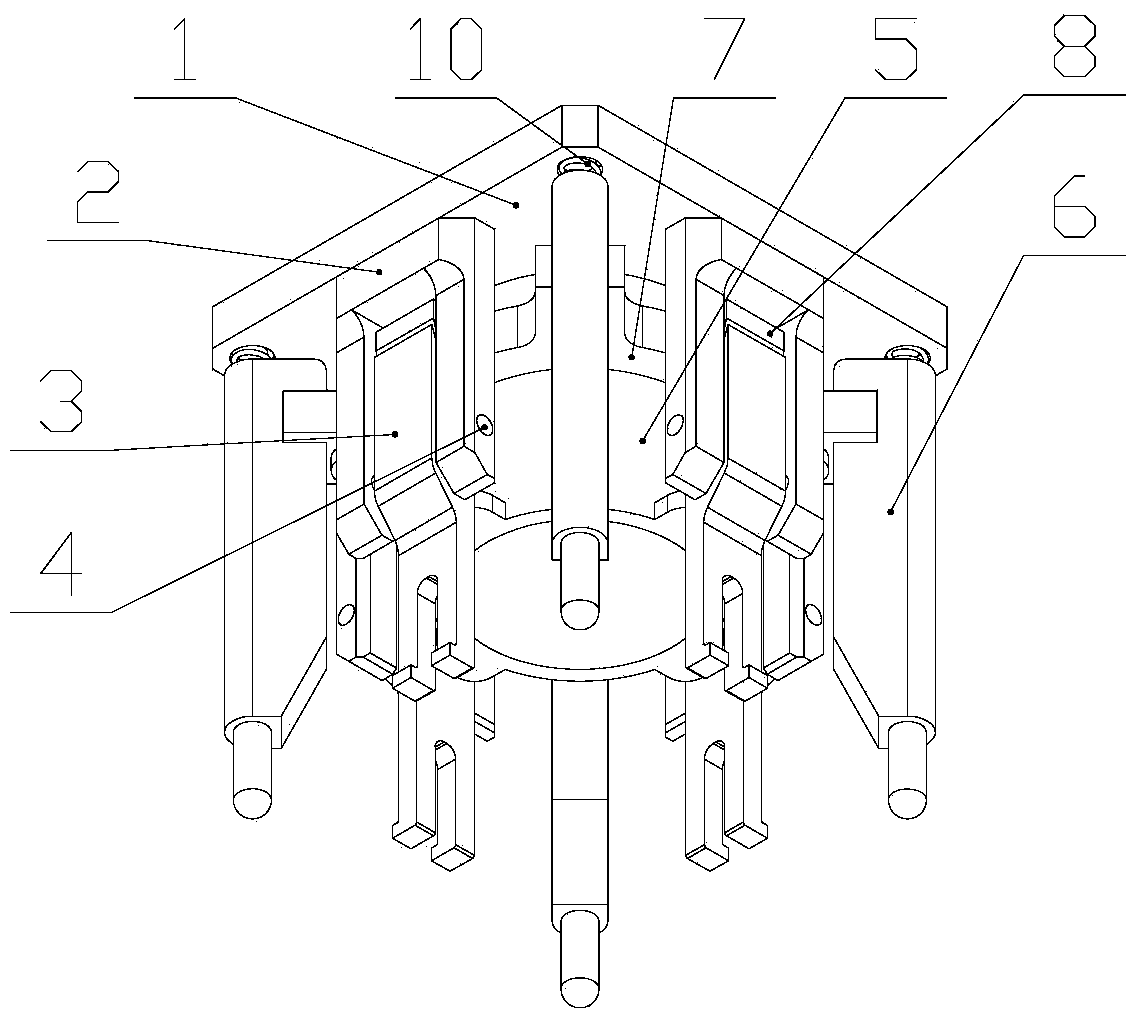

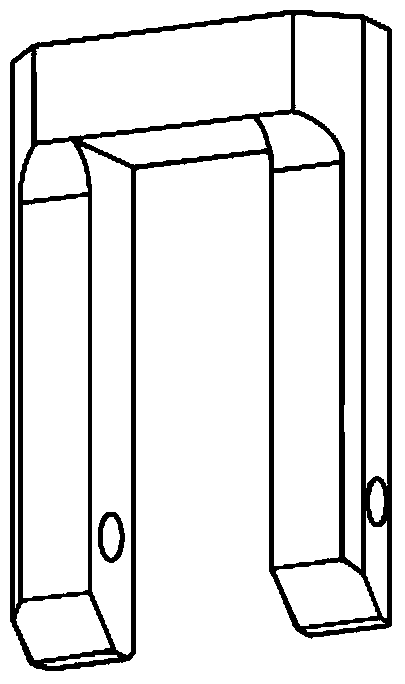

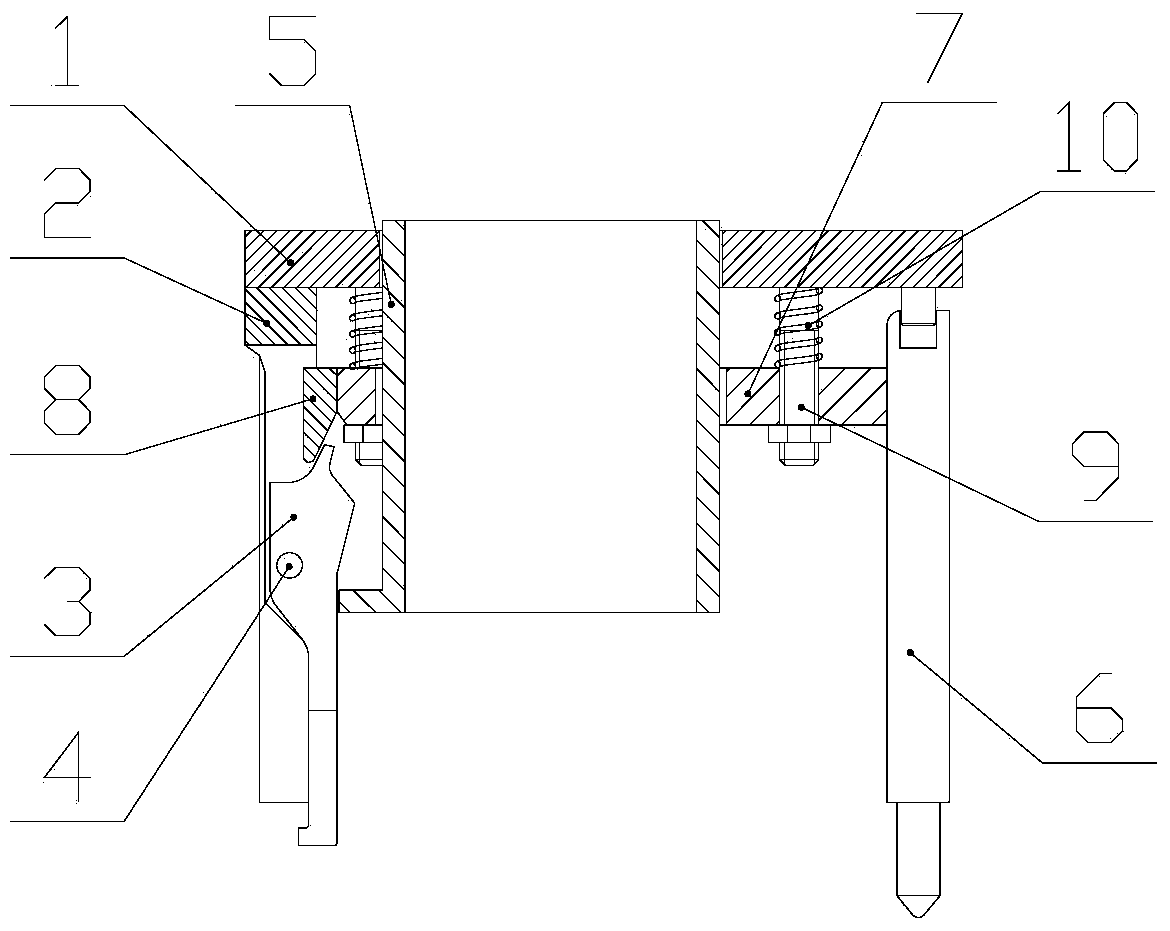

[0019] like figure 1 As shown, the fuel assembly gripper adopting self-locking wedge block is mainly composed of gripper flange 1, gripper support 2, gripper hook 3, pin shaft 4, driving sleeve 5, gripper guide column 6, sliding sleeve 7, Wedge block 8, screw rod and spring 10 form. The gripper flange 1 can be a square plate (not limited to this shape), and the central circular hole is used to pass through the driving sleeve 5 . Through the gripper flange 1, the gripper can be connected to other structures of the loading and unloading machine. Four grapple supports 2 are installed on the four sides of the bottom surface of the grapple flange 1 by screws. The grapple support 2 is a U-shaped block structure, such as figure 2 As shown, the grapple 3 is connected with the grapple support 2 through the pin shaft 4, and can rotate around the pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com