Waste heat recovering system capable of continuously generating steam aiming at impure waste water resources

An impurity and waste water technology, applied in the steam generation method using heat carrier, sustainable manufacturing/processing, refrigerators, etc., can solve the problems of impurities, non-continuous waste hot water source, etc. The effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

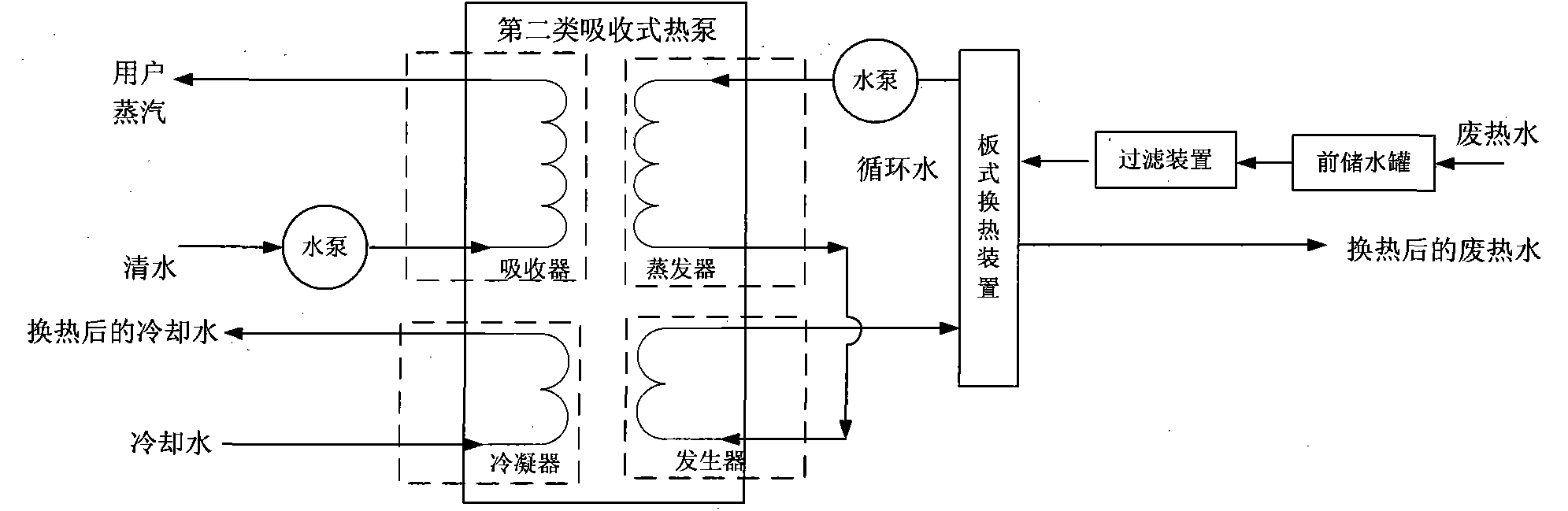

[0007] A waste heat recovery system for continuous production of steam for impurities in waste water sources, such as figure 1 As shown, it includes the second type of absorption heat pump, front water storage tank, filter device, water pump and plate heat exchange device, where the second type of absorption heat pump is divided into generator part, evaporator part, absorber part and condenser part , the input of the condenser part is cooling water, which is output to the cooling tower after heat exchange by the second type of absorption heat pump; the output of the evaporator part is connected with the input of the generator, and the output of the generator is connected with the plate heat exchange device, and the evaporation The input of the device part is tap water, and the tap water passes through the evaporator, generator, water pump and plate heat exchange device of the second type of absorption heat pump to form circulating water. The circulating water absorbs heat from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com