Intelligent spraying device for use in streamline production operation

A technology of spraying device and flowing water production, applied in the direction of spraying device, etc., can solve the problems of low production efficiency, high operating cost, and failure to meet the requirements of use, and achieve the effect of high-speed uniform spraying and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

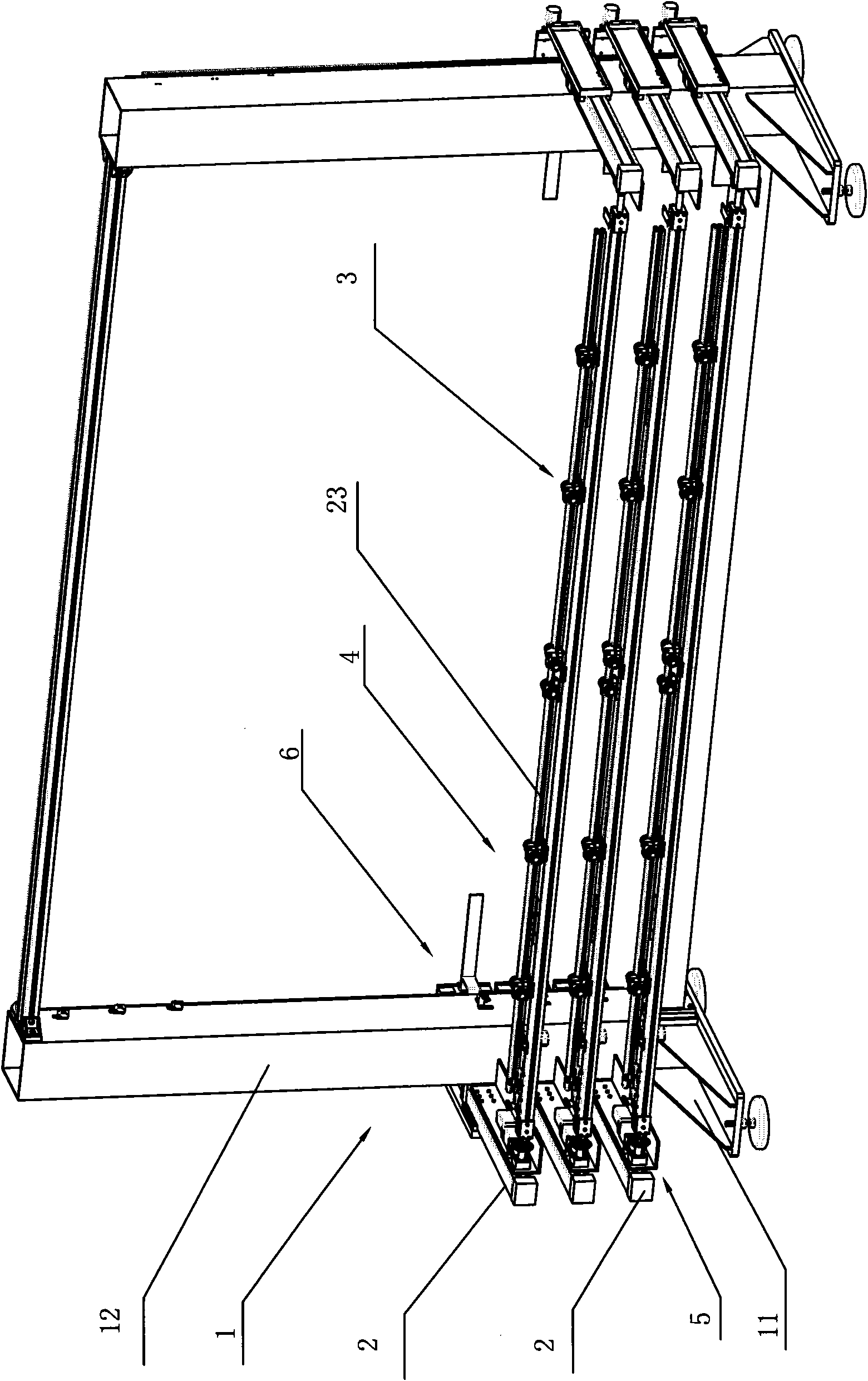

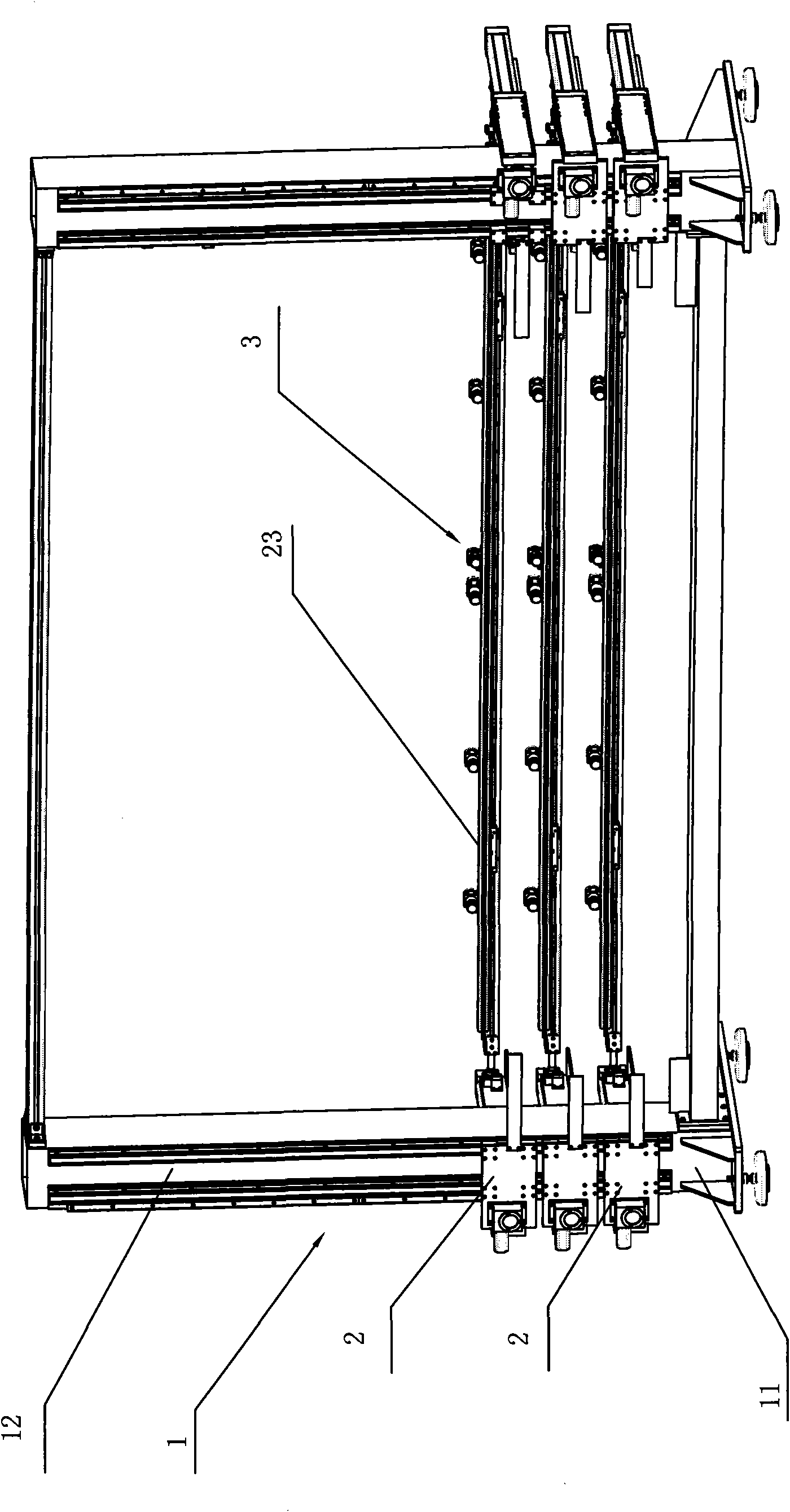

[0022] Embodiment 1: An intelligent spraying device for flow production operations is a three-axis linkage spraying device, including a frame 1 and a control device (not shown), and the frame 1 includes a base 11 and a column 12, and the column 12 is provided with a three-layer working platform 2, and six sets of spray gun assemblies 3 are arranged on the working platform 2. The spray gun assembly 3 is provided with a plane swing mechanism 4 and a pitch swing mechanism 5, and the work platform 2 is provided with a lifting mechanism 6. The swing mechanism 4 and the pitch swing mechanism 5 are electrically connected so that the spray gun assembly 3 performs plane scanning and up and down scanning according to the program set in the control device, and the control device is electrically connected with the lifting mechanism 6 so that the working platform 2 operates according to the program set in the control device. Move up and down.

[0023] Working platform 2 comprises lift seat...

Embodiment 2

[0026] Embodiment 2: Other structures are the same as Embodiment 1, the difference is that: a front and rear moving mechanism 7 is provided between the lifting base 21 and the front and rear moving base 22, and the front and rear moving mechanism 7 includes a mobile motor fixedly arranged on the lifting base 21 71 and the moving lead screw 72 that is fixedly connected with the axle of moving motor 71, the front and rear moving seat 22 is provided with the moving block 25 that is threadedly engaged with moving leading screw 72, and the control device is electrically connected with the moving motor 71, and the movement is controlled by the control device. The speed, direction and running time of the motor 71 enable the spray gun 31 to move forward and backward according to the program set in the control device and control the distance of motion. The device of this embodiment is a four-axis linkage spraying device.

Embodiment 3

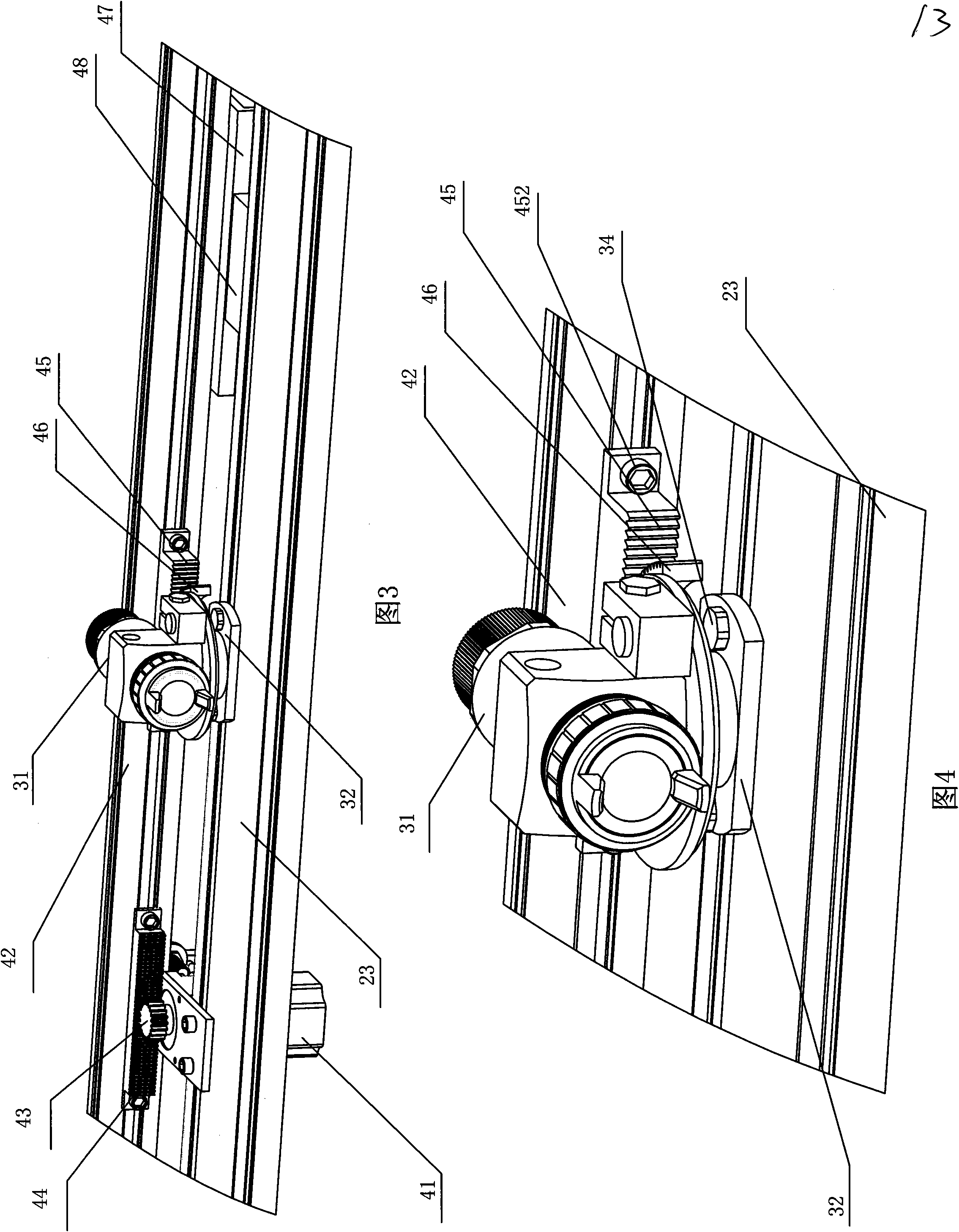

[0027] Embodiment 3: other structures are the same as Embodiment 1 or Embodiment 2, the difference is that: the support bar 23 is provided with a moving groove 26, the spray gun seat 32 is provided with a moving pin 33, and one end of the moving pin 33 is embedded in the moving groove 26, The other end of the moving pin 33 is provided with a positioning lock nut 34, the driving rod 42 is provided with an auxiliary moving groove 421, and the scanning rack 45 is provided with an auxiliary moving pin 451, and one end of the auxiliary moving pin 451 is embedded in the auxiliary moving groove 421 to assist in moving. The other end of the pin 451 is provided with an auxiliary positioning locking nut 452 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com