Flexible device for multipoint clamping and positioning spatial 3D thin wall part

A multi-point positioning and flexible device technology, applied in positioning devices, workpiece clamping devices, auxiliary devices, etc., can solve problems such as unusable fixtures, high manufacturing costs for special fixtures or molds, and fixtures suitable for a certain type of parts, etc. achieve great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

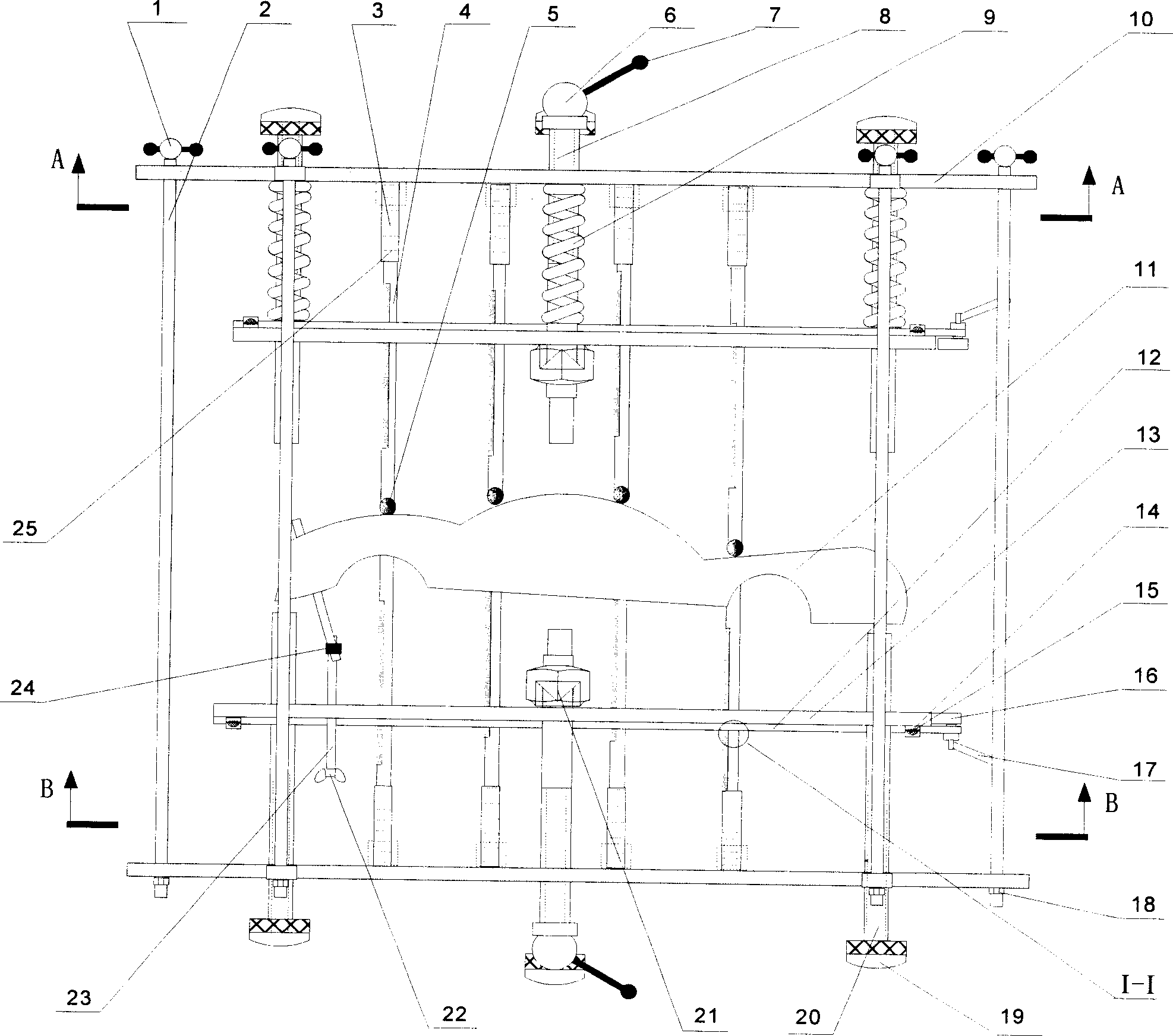

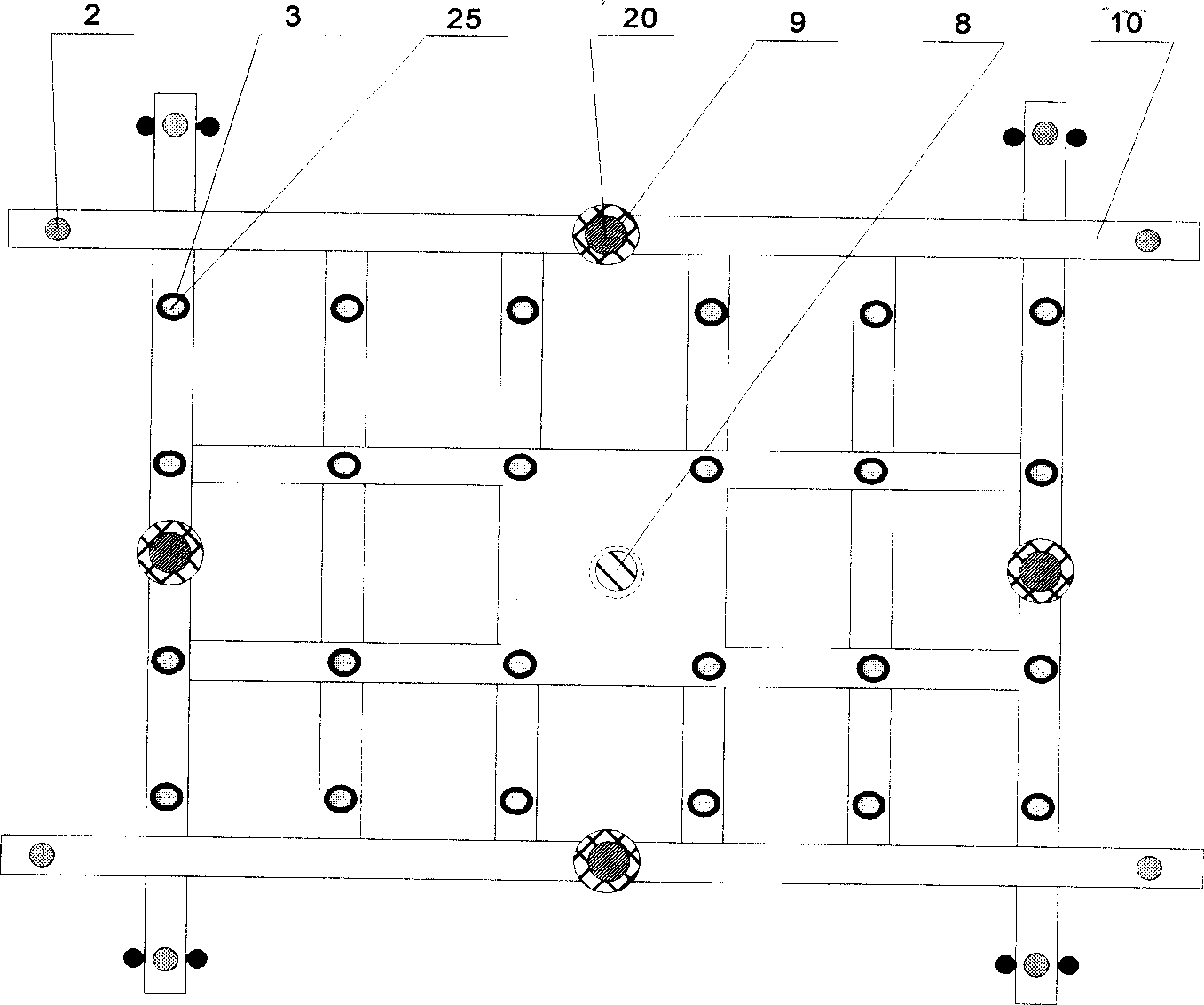

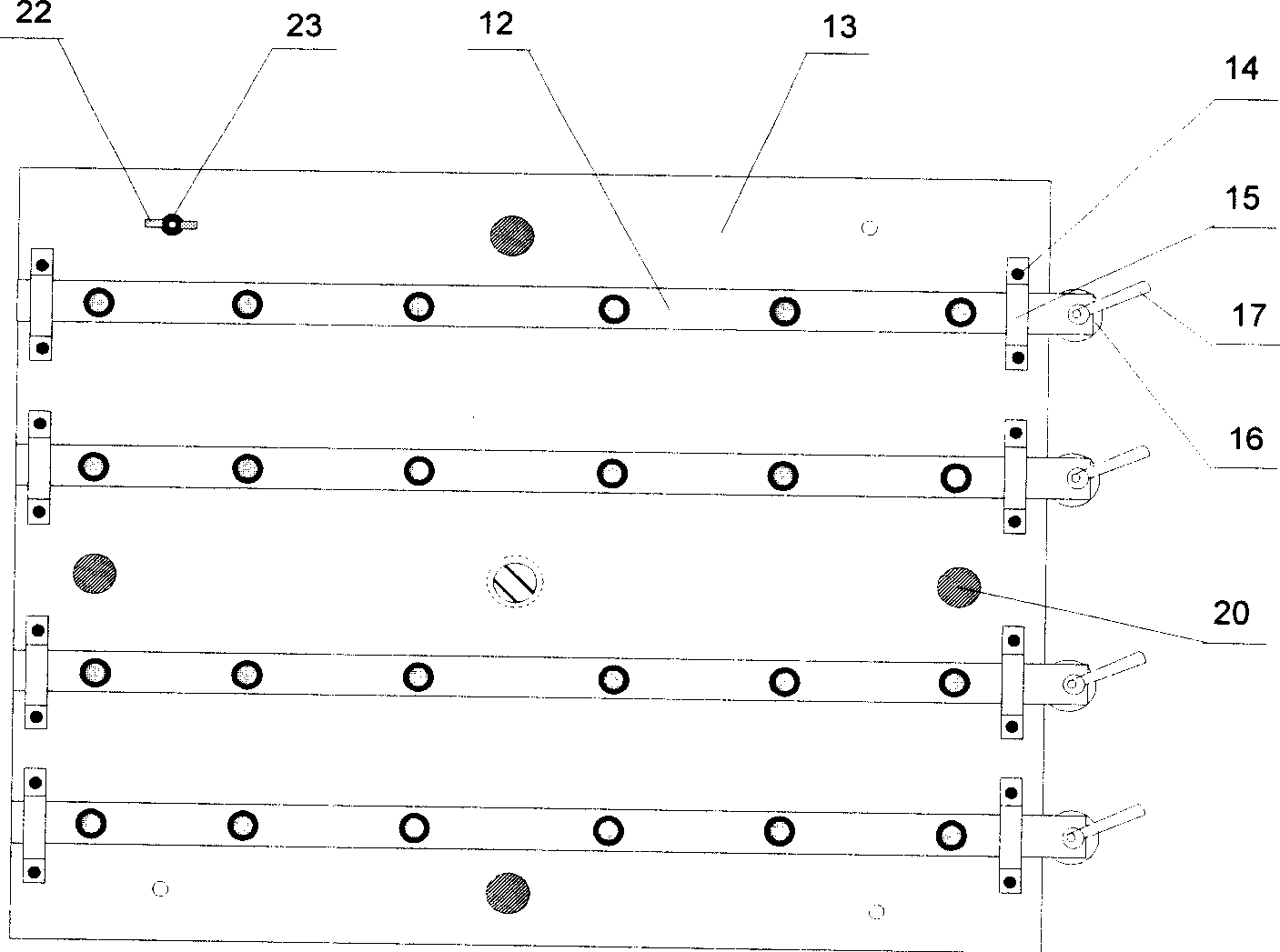

[0026] Such as figure 1 As shown, the present invention is composed of upper and lower sets of clamp bodies arranged symmetrically. The uppermost and lowermost ends are two "well"-shaped frame bodies 10, and there are through holes at the eight end points of the "well" shape, with handles The long-leg screw rod 2 of 1 runs through and connects the upper and lower frame bodies 10, and is fixed with fastening nuts 18. All have threaded mouth in the middle part of four limits of " well " font frame body 10 up and down, the supporting adjustable screw rod 20 of four band size scales is equipped with, and the adjustable screw rod 20 outer ends of supporting have adjustment handle 19. In the upper clamping body, the four supporting adjustable screw rods 20 are respectively covered with springs 9 . Have threaded hole to screw into screw rod 8 respectively at the center of " well " shape frame body 10 , one end of screw rod 8 is connected with ball nut 6 and screw handle 7 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com