Forming cylinder system structure in SLM rapid forming equipment

A technology of system structure and molding equipment, which is applied in the field of metal parts processing, can solve problems such as parts defects and insufficient temperature control of the substrate, and achieve the effects of ensuring accuracy, meeting temperature conditions, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

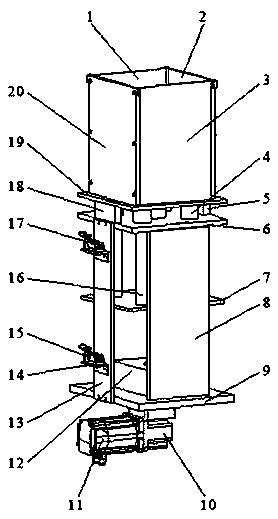

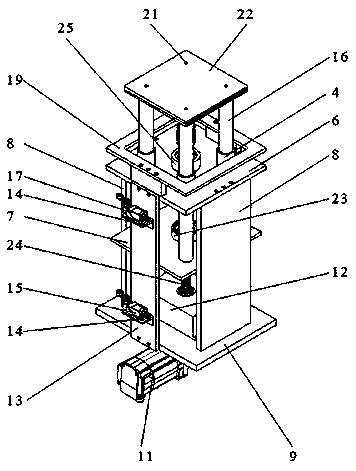

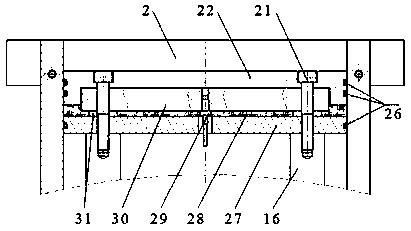

[0031] Such as figure 1 As shown, this embodiment mainly includes: a lifting mechanism, a preheating system structure and a molding cavity structure, wherein:

[0032] The lifting mechanism includes: linear motion bearing 4; rear support plate 5; upper support plate 6; linkage plate 7; side support plate 8; support base plate 9; Position switch fixed plate 13; limit switch support plate 14; lower limit switch 15; guide rod 16; upper limit switch 17; front support plate 18; molding cavity support plate 19; screw 21; base plate 22; linkage plate support Seat 23; leading screw 24; supporting seat 25 on the leading screw; circlip 32; deep groove ball bearing 33; thrust cylindrical roller bearing 34; retaining ring 35, see figure 1 , figure 2 , Figure 5 , Image 6 with Figure 7 .

[0033] Concrete structure: the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com