Attached lifting scaffold

A lifting and attaching scaffolding technology, which is applied in the field of scaffolding, can solve the problems of being unable to respond to emergencies in time, the degree of tooling of components is not high, and the consumption of on-site turnover materials, etc., to achieve the convenience of load turnover materials, eliminate fire hazards, and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

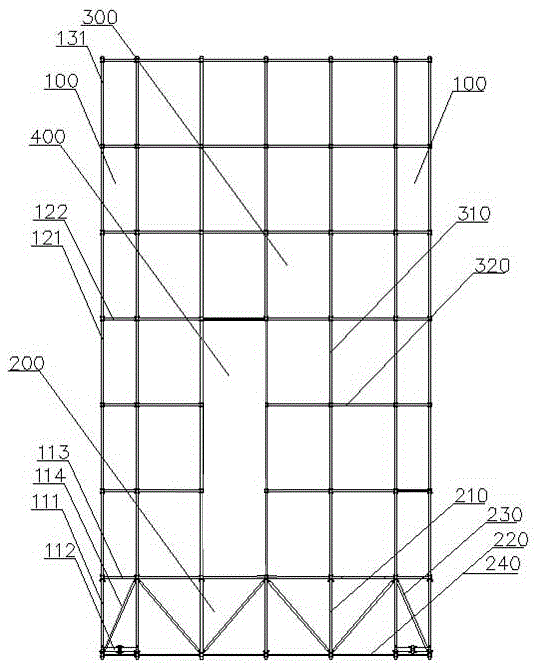

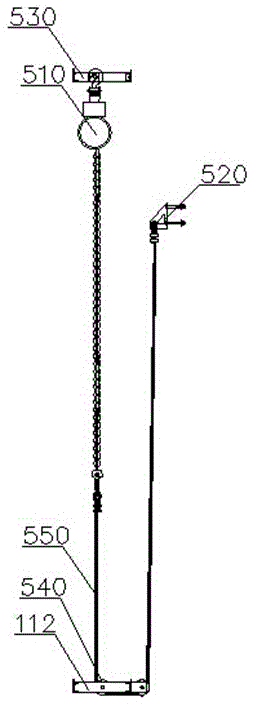

[0045] see Figure 1 to Figure 5 , as shown in the legend, an attached lifting scaffold, including a frame body, a protective safety net, a lifting mechanism, a lifting safety mechanism and a control system.

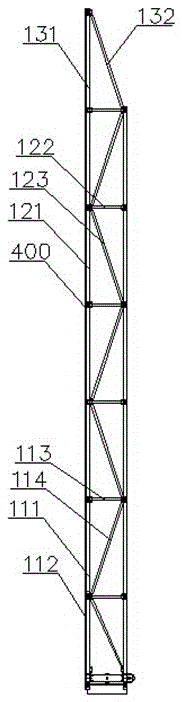

[0046] The frame body is arranged in front of the building wall, and the frame body includes two vertical main frames 100 arranged at intervals along the left and right directions, and a horizontal truss located below and connected between the adjacent vertical main frames 100 200 and a frame frame 300 located above and connected between adjacent vertical main frames 100, the vertical main frame 100 includes a bottom vertical frame 110, a middle vertical frame 120 and an upper protective frame 130, and the bottom vertical frame 110 includes a first pole 111 assembly, a bottom bearing frame 112, a bottom pedal frame 113 assembly and a first diagonal brace 114 assembly, a bottom bearing frame 112, a bottom pedal frame 113 assembly and a first diagonal brace 114 assembly R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com