Preparation method of aerogel fiber composite felt, aerogel fiber composite felt and application of aerogel fiber composite felt

A fiber composite and airgel technology, applied in the field of materials, can solve the problems of no substantial improvement in the toughness of the composite felt, affecting the comprehensive performance of the composite felt, and cracking of the airgel in the composite felt, so as to achieve uniform internal components and long service life Long, prevent cracking and collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] On the one hand, the invention provides a kind of preparation method of airgel fiber composite mat, comprises the following steps:

[0030] (a) Mix the fiber with a length of 1-3 mm and silica sol to obtain a mixed solution, the temperature of the mixed solution is 60-90 ° C, the pH value is 2-4, and the weight ratio of fiber to silica sol is 1: (5- 10);

[0031] (b) adjust the pH value of the mixed solution to 8-9 with a weak base, immerse the fiber mat soaked in alcohol in the mixed solution before forming the airgel, and gelatinize at a temperature of 60-90°C;

[0032] (c) putting the gelled fiber mat into an aging modification solution for aging modification for 12-24 hours at a temperature of 40-60°C; the aging modification solution includes an aqueous solution of trimethylchlorosilane and alcohol;

[0033] (d) drying the fiber mat to obtain an airgel fiber composite mat.

[0034] In this method, short-cut fibers are added to the silica sol, and the fibers form a...

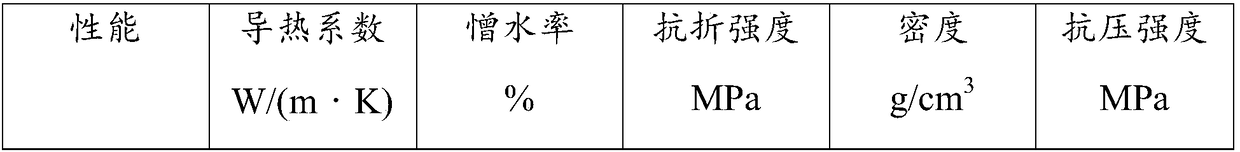

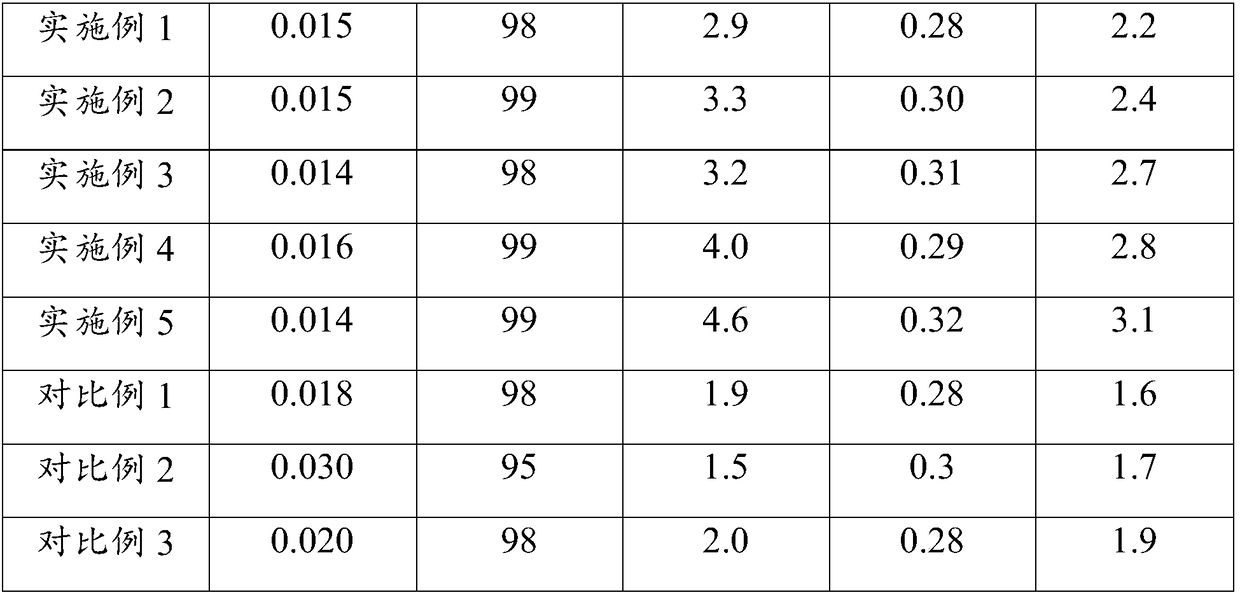

Embodiment 1

[0051] A preparation method of airgel fiber composite felt, comprising the following steps:

[0052] (a) Heating the silica sol to 60°C, mixing the viscose fiber cut to 3 mm with the silica sol solution evenly to prepare a mixed solution, the weight ratio of the fiber to the silica sol is 1:5, and adjusting the pH to 2;

[0053] (b) Adjust the pH of the mixed solution to 8 with a weak base, immerse the composite fiber mat soaked in alcohol (the weight ratio of ceramic fiber and glass fiber is 5:4) in the mixed solution before forming the airgel, and keep the temperature 60°C for gelation;

[0054] (c) put the composite felt into trimethylchlorosilane / alcohol / water solution (1:1:1 by weight ratio) for aging modification for 12 hours at a temperature of 40°C;

[0055] (d) Take out the composite felt and dry it at room temperature for 5 hours to prepare the airgel fiber composite felt.

Embodiment 2

[0057] A preparation method of airgel fiber composite felt, comprising the following steps:

[0058] (a) Heating the silica sol to 90°C, mixing the glass fiber cut to 3 mm with the silica sol solution evenly to prepare a mixed solution, the weight ratio of the fiber to the silica sol is 1:10, and adjusting the pH to 2;

[0059] (b) Adjust the pH of the mixed solution to 9 with a weak base, immerse the composite fiber mat soaked in alcohol (the weight ratio of ceramic fiber and glass fiber is 8:2) in the mixed solution before forming the airgel, and keep the temperature 90°C for gelation;

[0060] (c) put the composite felt in trimethylchlorosilane / alcohol / water solution (weight ratio 1:1:1) for aging modification for 18 hours at a temperature of 45°C;

[0061] (d) Take out the composite felt and dry it at room temperature for 5 hours to prepare the airgel fiber composite felt.

[0062] Compared with Example 1, Example 2 optimizes the composition of the fiber mat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com