Preparation method for highly-doped phosphorosilicate glass film

A high-doping technology of phosphosilicate glass, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of low starting point at the bottom of flower-shaped shell, device damage, low switching point, etc., to achieve Effects of protection from damage, maintenance performance, and uniform phosphorus doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

[0027] The invention provides a method for preparing a highly doped phosphosilicate glass film. The method adopts two different steps of sub-atmospheric pressure chemical vapor deposition (SACVD) and high-density plasma chemical vapor deposition (HDP CVD). Highly doped phosphosilicate glass is grown by the deposition process, and the specific steps are as follows:

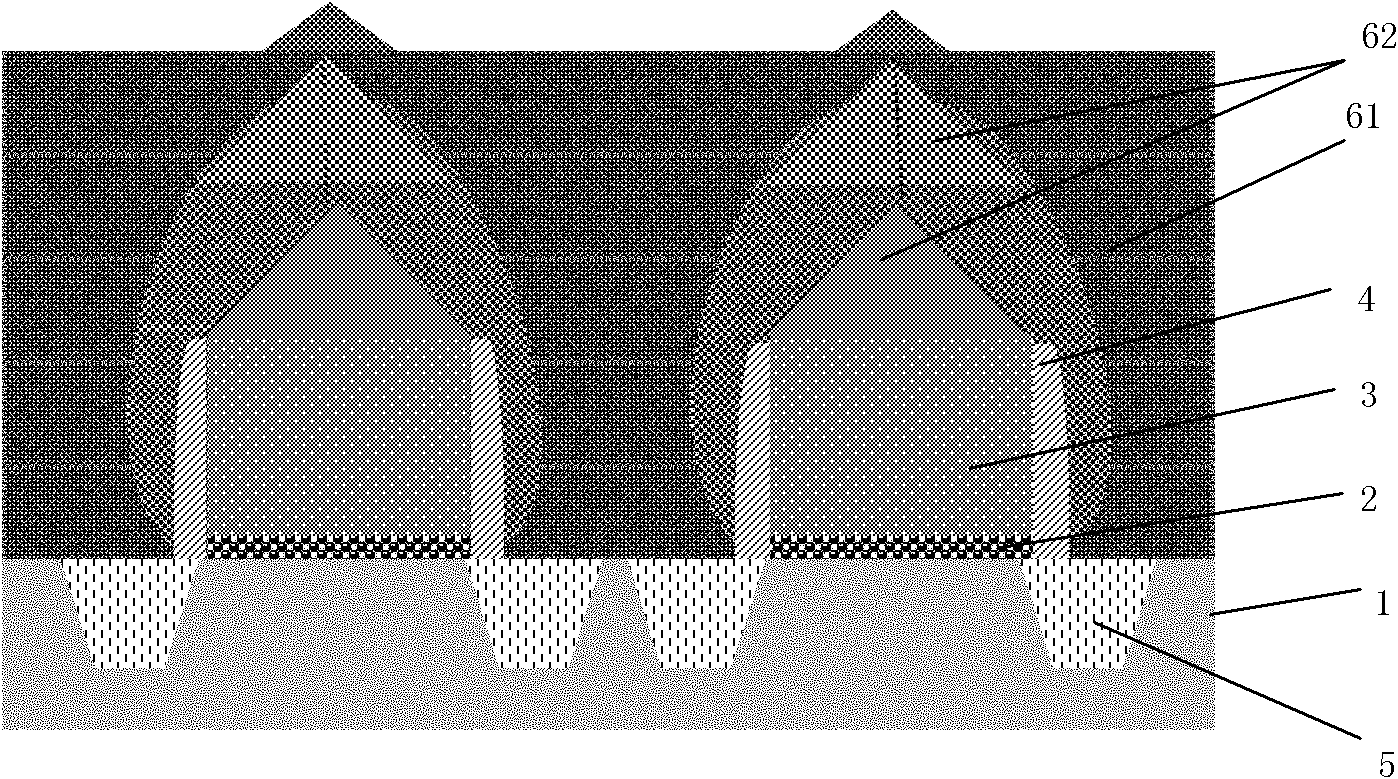

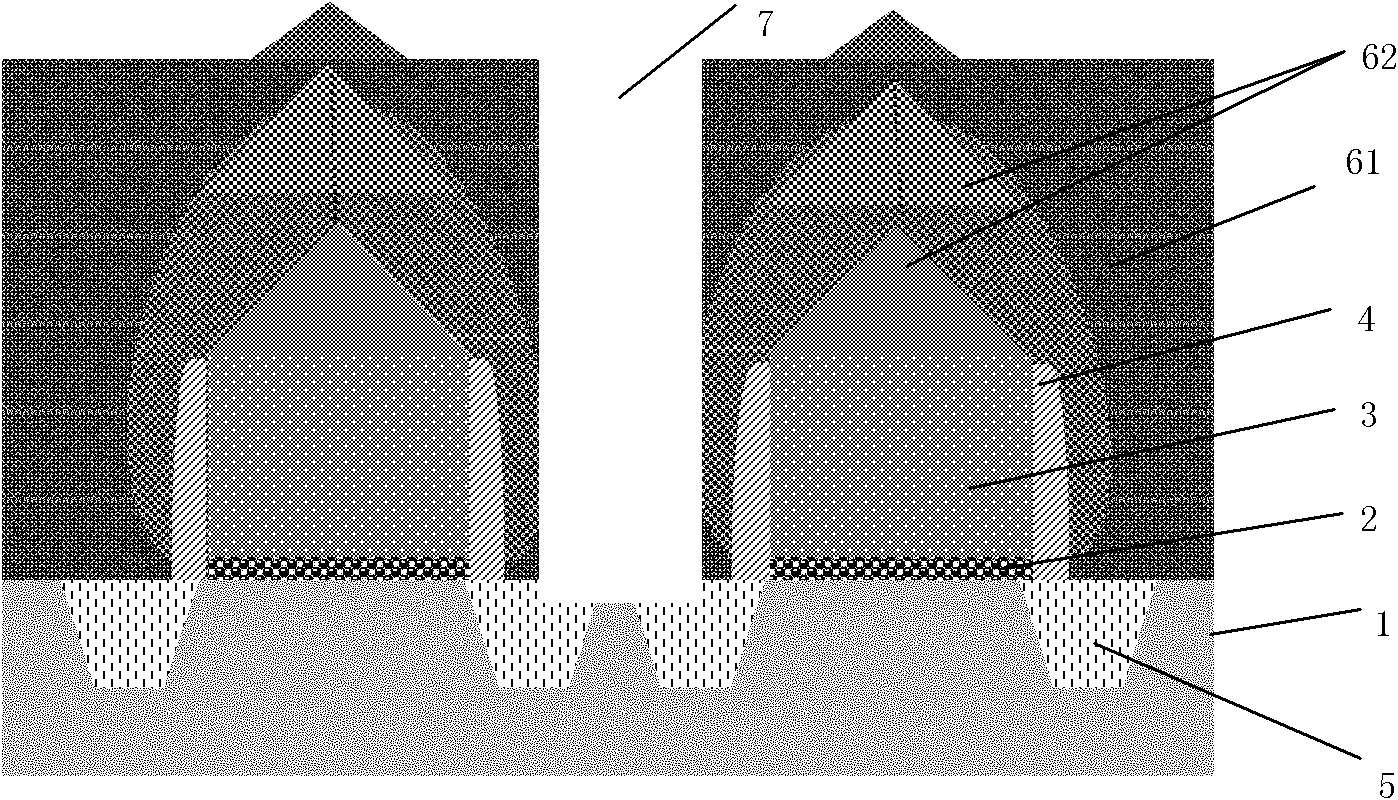

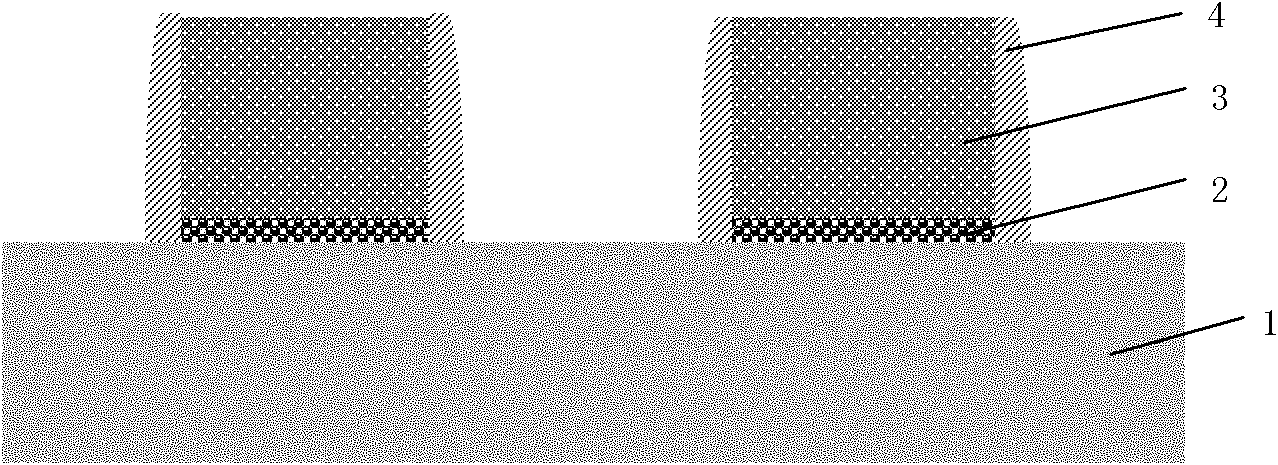

[0028] Step 1, please refer to Figure 3A A gate oxide layer 2 is grown on a silicon substrate 1 by using an existing process, and a polysilicon gate 3 and sidewalls 4 are prepared.

[0029] Step 2, please refer to Figure 3B , on the basis of the first step, performing drain-source implantation and rapid thermal annealing to form source and drain electrodes 5 .

[0030] Step 3, please refer to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com