Patents

Literature

167results about How to "In line with the development direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

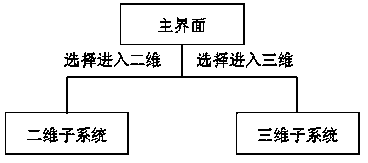

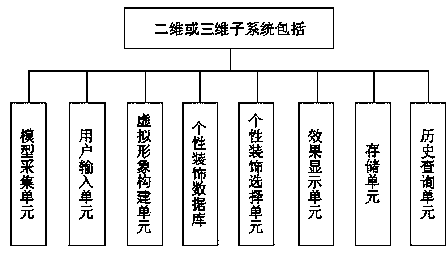

Real person simulation individuality ornament matching system

InactiveCN104376160AIn line with the development directionIn line with interestSpecial data processing applicationsTablet computerUser input

The invention discloses a real person simulation individuality ornament matching system suitable for a PC, a notebook computer, a tablet personal computer, a mobile phone and other platforms. The system is divided into a two-dimensional sub system and a three-dimensional sub system which each comprise a model collecting unit, a user input unit, a virtual image building unit, an individuality ornament database, an individuality ornament selecting unit, an effect displaying unit, a storage unit and a historical inquiring unit. According to the real person simulation individuality ornament matching system, a simulation image can be intelligently spliced according to a head image in a picture and input body parameters, free matching can be carried out by selecting head forms, hair ornaments, facial ornaments, facial makeup, clothes, jewelry, accessories, shoes, socks and other various ornaments, the result is displayed in real time and can be stored, shared and sold, and practicality is high.

Owner:薛景

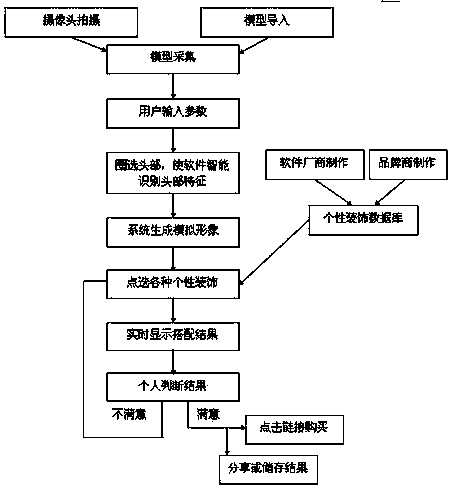

Dyeing process of pure cotton fabric

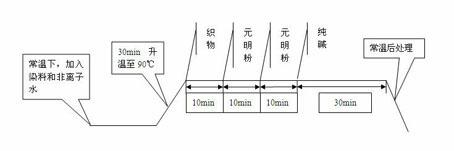

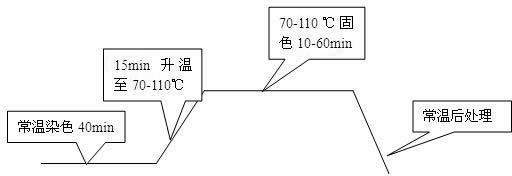

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

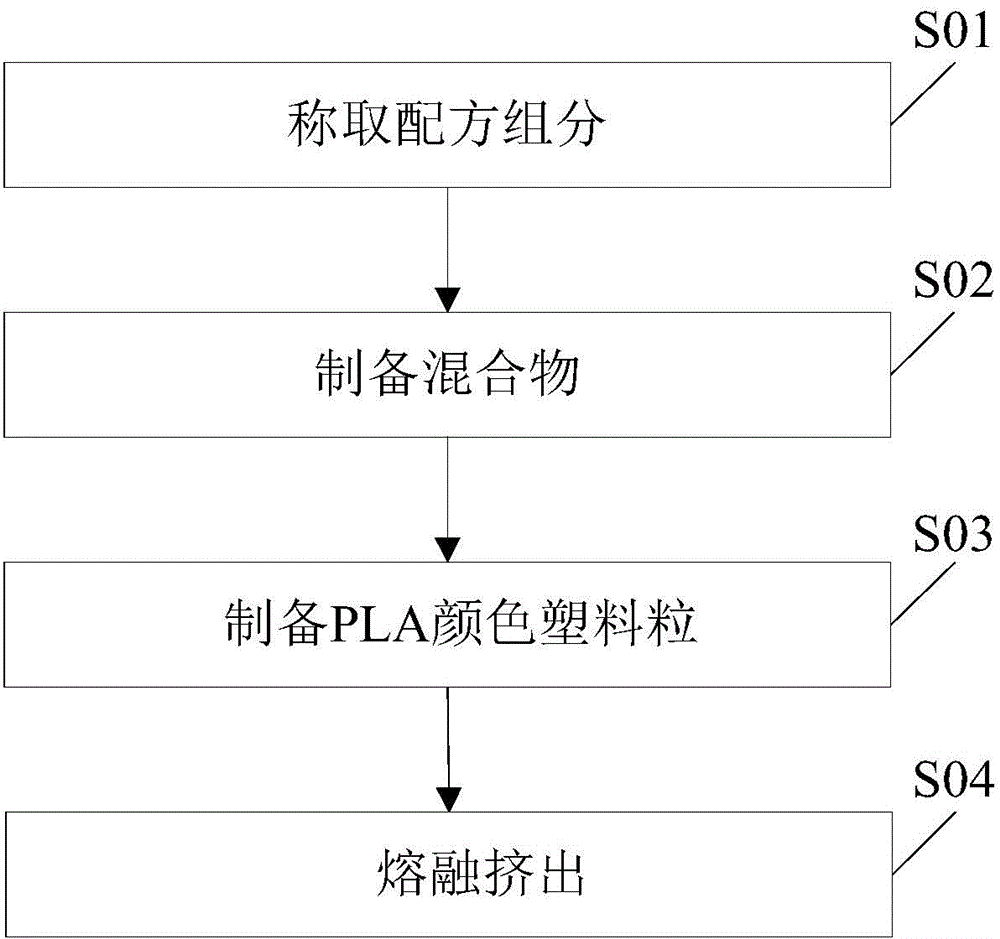

3D printed PLA consumable and preparation method thereof

InactiveCN104672826ABiodegradableQuality improvementAdditive manufacturing apparatusPolymer science3d printer

The invention belongs to the field of 3D printers and provides a 3D printed PLA consumable and a preparation method thereof. The 3D printed PLA consumable is prepared from the following raw materials in percentage by weight: 99.3-99.7% of PLA plastic, 0.1-0.3% of pigments and 0.2-0.4% of auxiliaries. The preparation method comprises the following steps: weighing the components in percentage by weight; uniformly mixing the weighed components to obtain a mixture; adding the obtained mixture into a double screw extruder; coupling and extruding to obtain PLA colored plastic particles; and then adding the PLA colored plastic particles into a 3D twine machine to prepare the 3D printed PLA consumable. According to the 3D printed PLA consumable, a high-quality, environment-friendly and naturally degradable PLA product is manufactured by utilizing PLA plastic on the premise that the environment-friendly degrading advantage of the PLA plastic is not changed, and the preparation method is simple in step, easy to control and low in cost.

Owner:LIFENG NEW MATERIAL TECH SHENZHEN

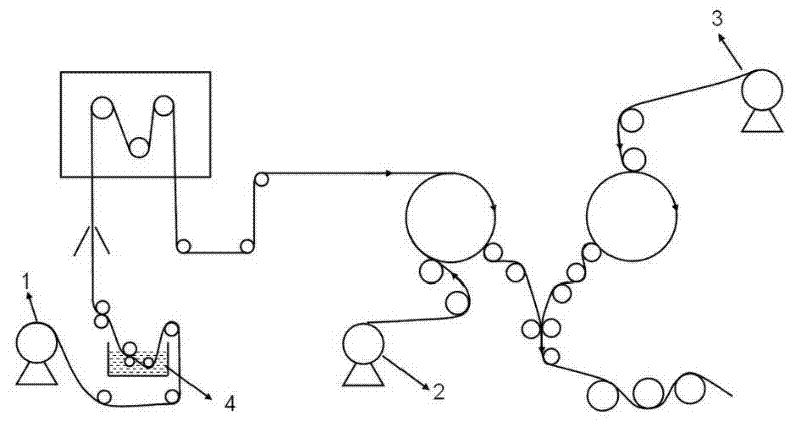

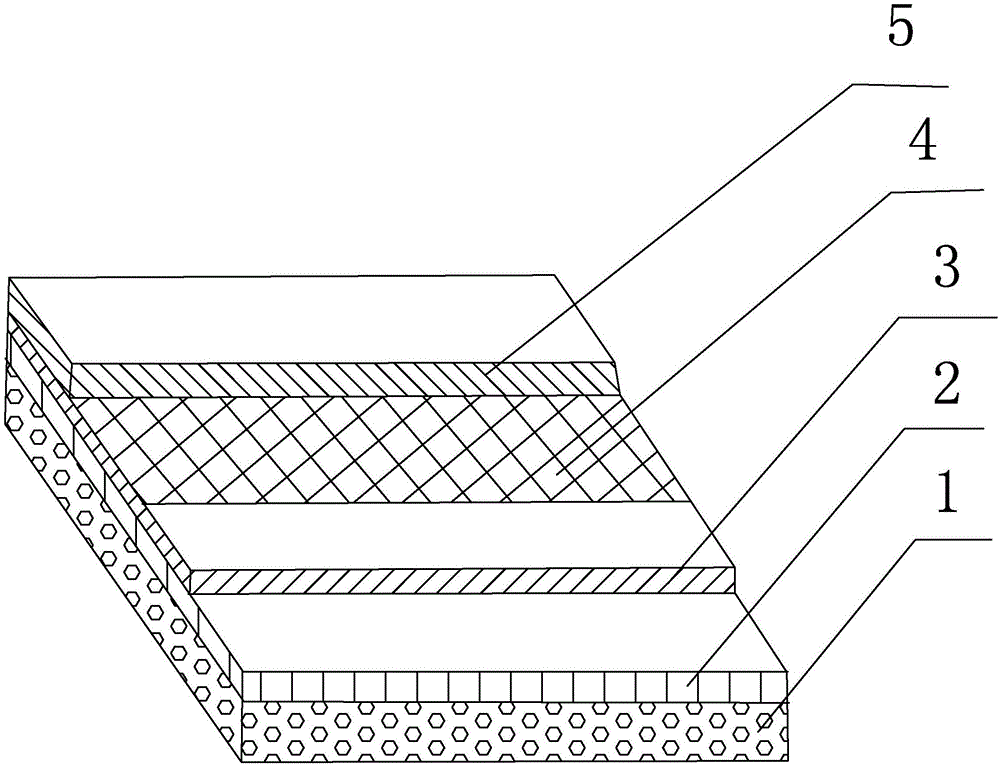

Inkjet printing material for bleeding and eduction resistance and high precision

ActiveCN102501672ANo pollutionStress reliefLamination ancillary operationsDuplicating/marking methodsPolyesterYarn

The invention relates to an inkjet printing material for bleeding and eduction resistance and high precision. The inkjet printing material is prepared by the following method: (1) high-strength, low-shrinkage polyester yarns as material are warped, woven, divided and rolled, so that a base fabric as framework material is produced; (2) the framework material in step 1 is soaked in glue, dried and preshaped, PVC (polyvinyl chloride) films are attached on both surfaces of the framework material by way of hot melting, and after embossing, cooling, shaping and trimming, the inkjet printing material for bleeding and eduction resistance and high precision is prepared. By selecting optimal highly polymerized PVC resin powder, adopting an environment-friendly, high-effective stabilizing system, adding active calcium carbonate and soaking and preshaping the framework material, the invention ensures that the product has the function of bleeding and eduction resistance, i.e., after ink is jetted on the product, the pigment cannot be educed and bled, the phenomena cannot occur at the joints of a large advertisement as well, the inkjet printing material is applicable to high-precision digital inkjet printing, and in addition, the product also has the characteristic of environment-friendliness, and therefore accords with the development direction of advertisement materials.

Owner:浙江明士达股份有限公司

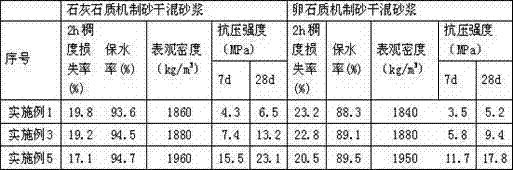

Limestone machine-made sand dry-mixed mortar and preparation method thereof

InactiveCN103922667ASolve the shortage of resourcesAddressing quality degradationCompressive resistanceProcess engineering

The invention relates to a limestone machine-made sand dry-mixed mortar and a preparation method thereof, belonging to the field of building materials. The limestone machine-made sand dry-mixed mortar comprises the following raw materials in parts by weight: 10-25 parts of cement, 5-8 parts of coal ash, 70-85 parts of machine-made sand and 0.06-0.08 part of mortar water-retention plasticizing agents, wherein the machine-made sand is limestone machine-made sand. The limestone machine-made sand dry-mixed mortar disclosed by the invention has the advantages of good cohesiveness, high water-retention rate, high compressive strength, good operability, economy, environmental protection, resource saving and the like, and is a green building material with excellent properties. The preparation method disclosed by the invention is simple and low in cost.

Owner:GUANGXI YUFENG GRP

Ultra-low calorie health-care type soluble drink mate and preparation method thereof

InactiveCN101637293AHydrophilic and lipophilicReduce cholesterolFood preparationNutritive valuesFood additive

The invention relates to an ultra-low calorie health-care type soluble drink mate and a preparation method thereof. The drink mate comprises the following food raw materials and food additives in percentage by weight: soyabean lecithin, sodium casseinate, grape seed extract (containing more than or equal to 30 percent of grape polyphenol and more than or equal to 60 percent of oligomeric proanthocyanidins in percentage by mass), stevioside containing more than or equal to 80 percent of RA, sodium stearoyl lactylate, molecular distilled monoglyceride, sodium citrate, disodium hydrogen phosphate, sodium alginate, carrageenan, edible essence, silicon dioxide, and the like. The preparation method comprises the following steps: blending the materials, dissolving, emulsifying, homogenizing, spray drying, cooling regularly, sieving, metering and packaging. The invention has simple process, stable product quality and high nutritional value. The ultra-low calorie health-care type soluble drinkmate integrates the nutritional values of the soyabean lecithin, the stevioside containing more than or equal to 80 percent of RA, the sodium casseinate and the grape seed extract, has unique taste, smooth and fine mouthfeel and thick fragrance, does not contain trans fatty acid and is a novel ultra-low calorie health-care type soluble drink mate.

Owner:天津美伦医药集团有限公司

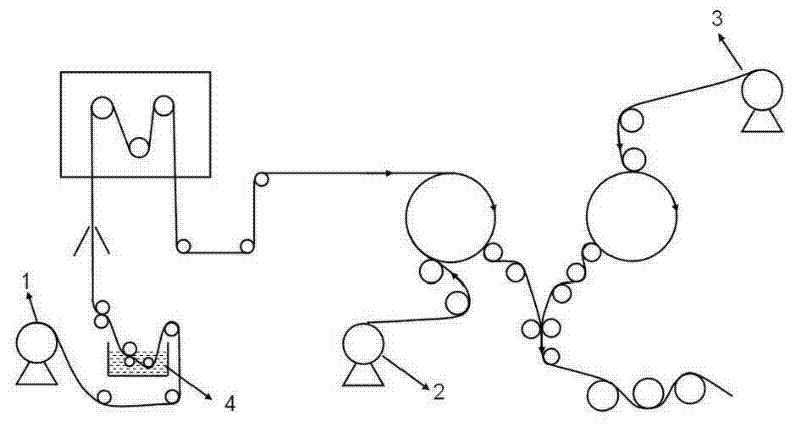

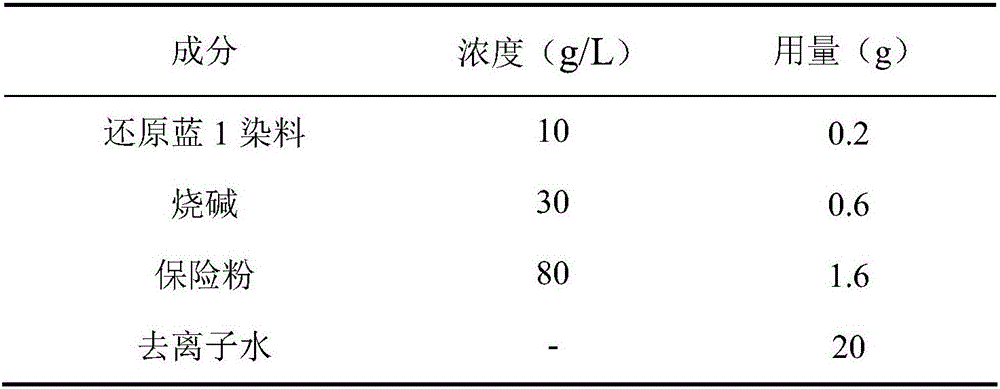

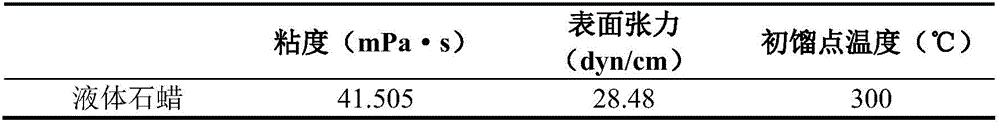

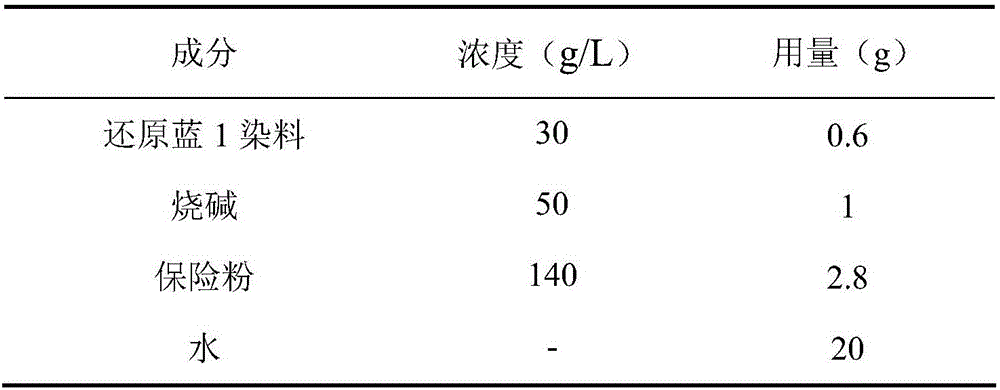

Liquid paraffin bath dyeing method of cotton fiber

The invention discloses a liquid paraffin bath dyeing method of cotton fiber. The method is applied to a liquid paraffin bath for performing reduction dye dyeing on the cotton fiber, due to the fact that liquid paraffin and water are completely immiscible, both the cotton fiber and a reduction dye leuco body have the good compatibility with water, and leuco body droplets dispersing in the liquid paraffin have the intense tendency of being repellent to the liquid paraffin and compatible to the cotton fiber, and the reduction dye leuco body can be spontaneously transferred to the surface of the fiber from the liquid paraffin solution and then dispersed into the fiber. The adopted liquid paraffin is low in cost, safe, environmentally friendly and recyclable. According to the method, the dye-uptake rate of the reduction dye is greatly increased, the leuco body and oxidizing substances are isolated in the dyeing process, oxidation of the leuco body and losses of sodium hydrosulfite are effectively avoided, and the production cost is remarkably reduced. More importantly, the method greatly reduces water for dyeing and wastewater discharge and meets the development requirement for ecological dyeing and finishing.

Owner:ZHEJIANG SCI-TECH UNIV

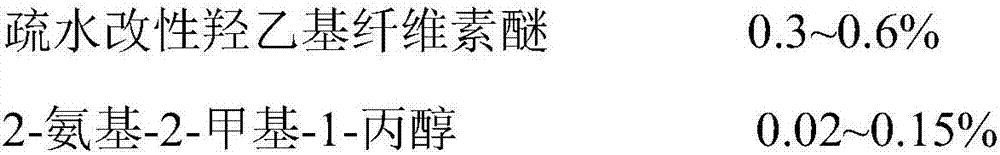

Waterproof heat-insulated granite-speckle-imitated multi-color paint and preparation method thereof

InactiveCN107129735AMeet the progress requirements of energy conservation and environmental protectionGood weather resistanceAntifouling/underwater paintsPaints with biocidesSodium BentoniteSilanes

The invention discloses a waterproof heat-insulated granite-speckle-imitated multi-color paint and a preparation method thereof. The waterproof heat-insulated granite-speckle-imitated multi-color paint comprises a base paint and a continuous phase, wherein the base paint mainly comprises hydrophobic modified hydroxyethyl cellulose ether, 2-amino-2-methyl-1-propanol, propylene glycol, a silicone acrylic emulsion, a silane / siloxane emulsion, a heat reflection high-molecular polymer, a protective colloid solution, hollow glass beads, quartz sand and water; the continuous phase mainly comprises a silicone acrylic emulsion, propylene glycol, a silane / siloxane emulsion, 2-amino-2-methyl-1-propanol and bentonite; the protective colloid solution consists of synthetic flake silicate, a preservative and deionized water; and the protective colloid solution and a colored paint are made into sand in water colored grains, and the colored grains and components of the continuous phase are made into an end paint. The waterproof heat-insulated granite-speckle-imitated multi-color paint is high in weatherability, water resistance and cost performance, is heat-insulated and has high simulation ability, and construction procedures are saved.

Owner:广东东艺宝建材有限公司

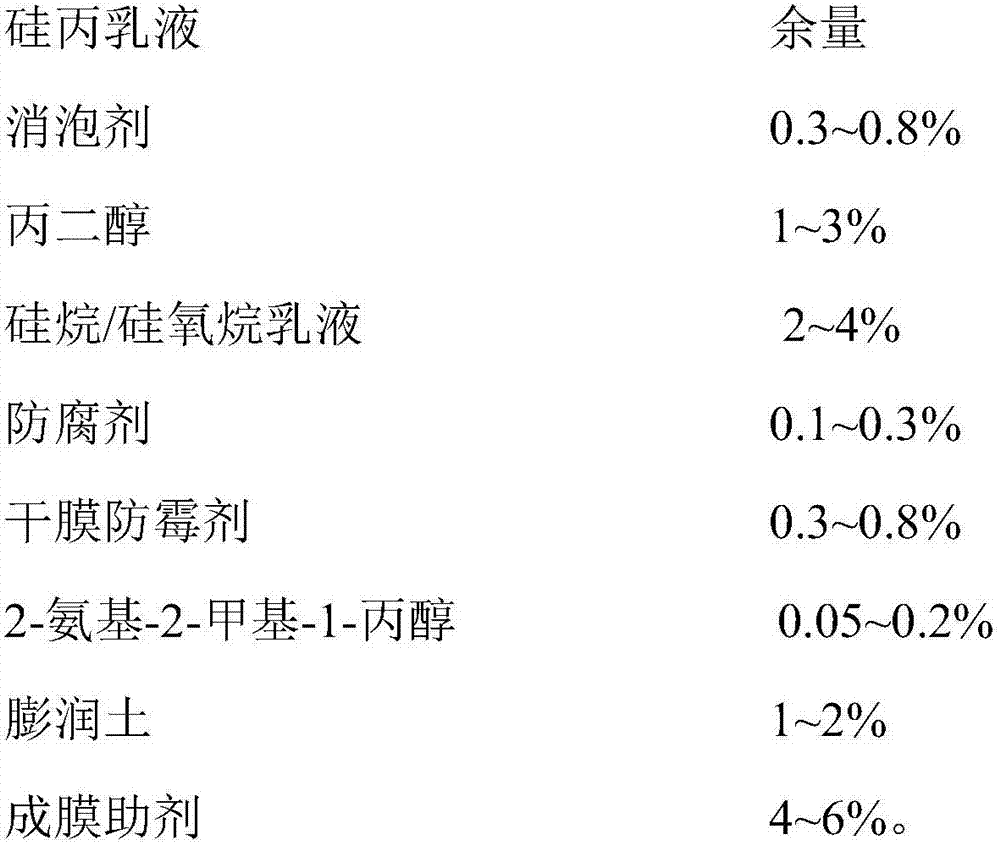

Aqueous inorganic zinc rich paint

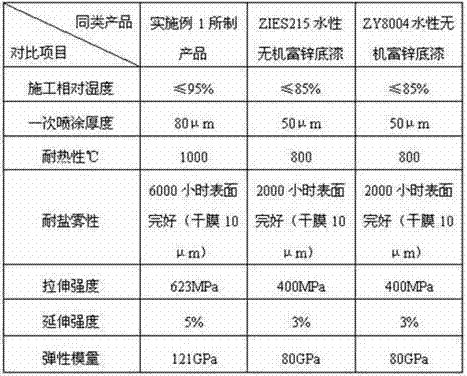

ActiveCN102898913AOvercome the disadvantage of easily forming voids in the paint filmOvercome the disadvantage of easy void formationAnti-corrosive paintsAcrylic resinSilicic acid

The invention provides an aqueous inorganic zinc rich paint, which is prepared by mixing a component A with a component B according to a weight ratio of 4:1, wherein the component A comprises 30-32% of 500-mesh spherical / flaky zinc powder, 30-32% of 800-mesh spherical / flaky zinc powder, 30-32% of 1250-mesh spherical / flaky zinc powder, 6-8% of nanometer cerium dioxide and 2-4% of 800-mesh talcum powder; and the component B comprises 38-50% of potassium silicate, 10-20% of lithium silicate, 8-10% of potassium titanate whiskers, 5-12% of aqueous self-drying organic silicon modified acrylic resin, 0.2-0.5% of defoaming agent, 0.5-1% of wetting agent and 12-20% of water. The aqueous inorganic zinc rich paint provided by the invention has the characteristics of excellent corrosion resistance, physical and mechanical properties, wet resistance, high temperature resistance and strong construction adaptability.

Owner:江苏纽克莱涂料有限公司

SOD radish and production method therefor

InactiveCN1799315AIncreased SOD contentImprove human immunitySeed and root treatmentHorticulture methodsRaphanusFunctional food

The invention relates to a superoxide dismutase radish and the preparing method, seed dressing with SOD special-purpose agent for radish before sowing, managing according to normal planting management condition, spraying with 800-1200 times solution of the SOD special-purpose agent 15 days after the emergence of seedlings, one time for per 15-20 days, and for 4-6 times, then getting the fruit. Employing Yiwei SOD special-purpose agent on radish, and increasing the SOD activity and content in radish through the breeding and shifting of the good endogenetic bacillus in radish. The SOD radish maintains the good property of the regional radish, but the SOD content is obviously increased, which can improve the human immunity and delaying aging, for which the market prospect of the SOD radish is bright , and the radish fits the developing direction of green food and functional food. The radish maintains high SOD activity by employing the special-purpose SOD agent, and also can maintain high SOD activity during additional processing.

Owner:TIANJIN AGRICULTURE COLLEGE

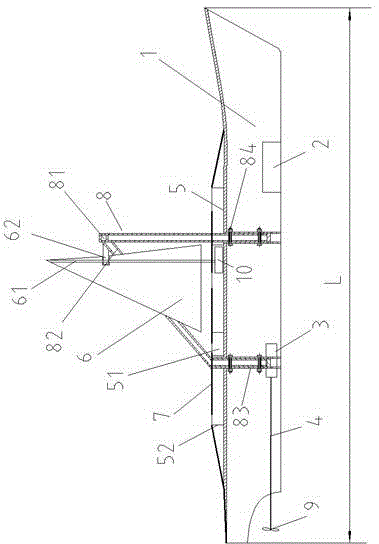

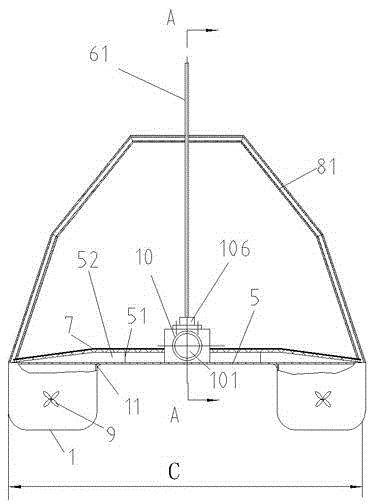

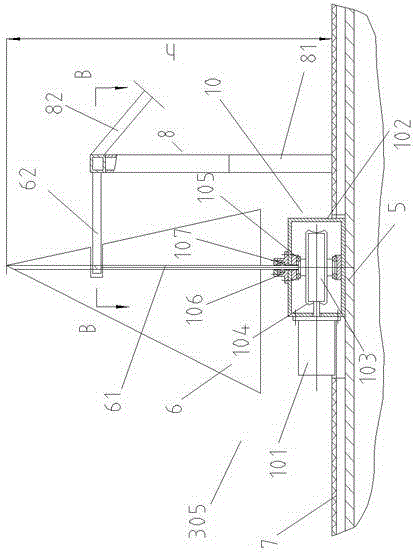

Sail auxiliary propelling catamaran solar ship

InactiveCN104369852ASmall structureHigh strengthPropulsion power plantsVehicular energy storagePropellerElectricity

The invention discloses a sail auxiliary propelling catamaran solar ship. The ship comprises two single-side piece bodies respectively provided with propellers, an accumulator set, an electric main engine, a shaft system, a deck, a sail, a solar panel and a flying bridge frame, wherein the sail is stood on the deck through a sail mast; and the flying bridge frame comprises an arched frame and a pair of inclined support rods. The all-transparent triangular sail is supported at the upper part of the triangular sail mast; the upper part of the triangular sail mast is fixedly connected with the top of the arched frame through a connecting rod; and the lower part of the triangular sail mast is connected with a sail swinging device arranged on the deck. The ship uses a solar catamaran ship as a carrier; and the flying bridge frame overcomes the defect of no superstructure on the deck of a conventional solar catamaran ship. The sail swinging device can be intelligently controlled to form a needed optimal angle between the triangular sail and the wind direction, so that the downwind or headwind driving in the state of no light and no electricity can be realized. The ship is propelled by electric power or the sail, has no pollution and emission, and accords with the development direction of modern green ships.

Owner:JIANGSU UNIV OF SCI & TECH

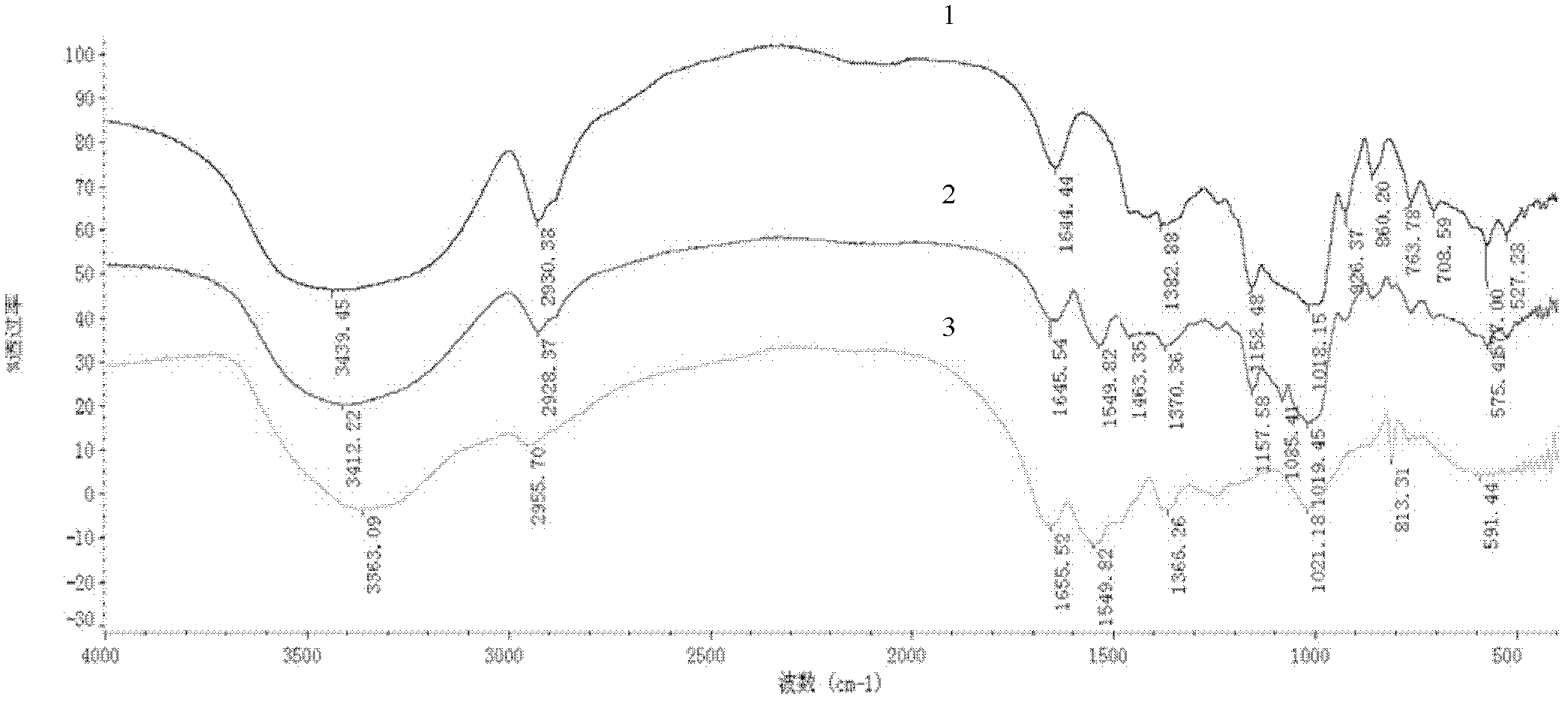

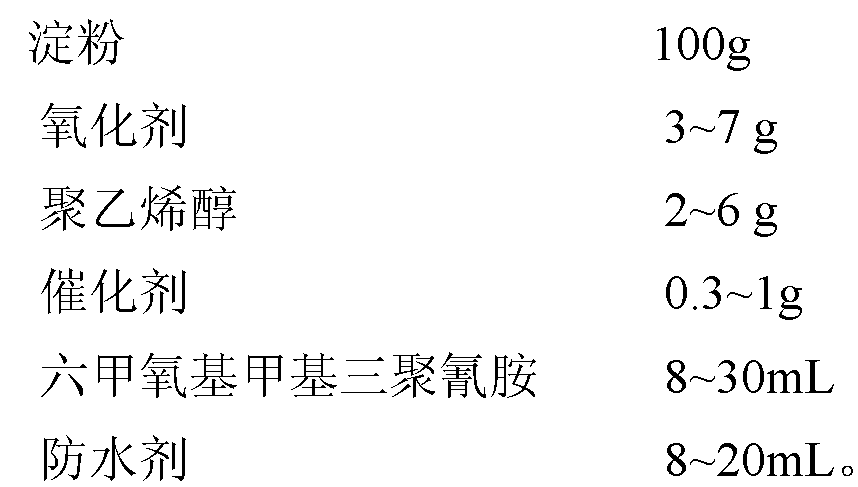

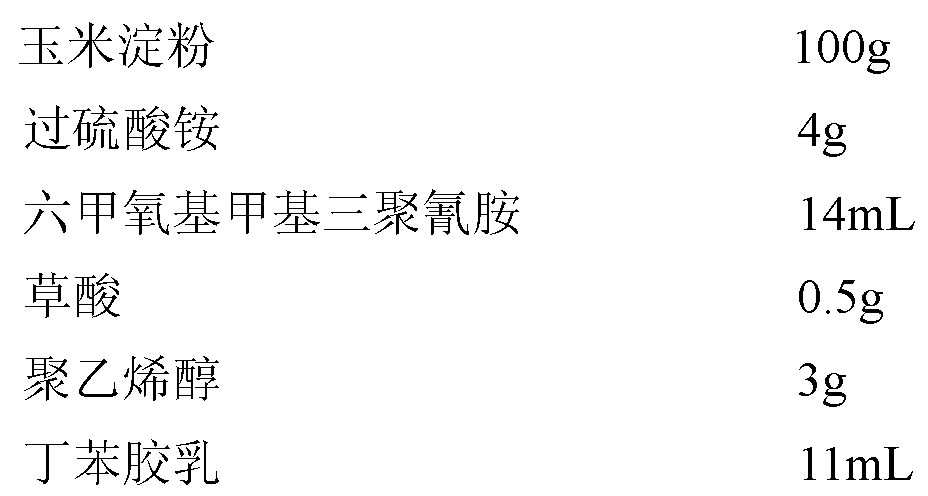

Preparation method of starch adhesive used for artificial board production

ActiveCN102604560AImprove liquidityImprove adhesionStarch derivtive adhesivesMacromolecular adhesive additivesCross-linkHexa(methoxymethyl)melamine

The invention provides a preparation method of a starch adhesive used for artificial board production, belonging to the technical field of preparation of adhesives. The invention provides a method for preparing an environment-friendly starch adhesive used for artificial board production by taking starch as a main raw material. The preparation process of the adhesive provided by the invention comprises the following steps of: carrying out acidolysis oxidation pre-treatment on starch milk, then performing cross-linking reaction on the starch milk with hexamethoxy methyl melamine resin under the action of a catalyst, adding polyvinyl alcohol and then warming and pasting, cooling and then adding an appropriate auxiliary, and finally obtaining environment-friendly non-toxic starch adhesive used for an artificial board. The adhesive prepared by adopting the preparation method provided by the invention has the advantages of high bonding strength, high water resistance, strong flowability and fast drying speed and can be widely applied to production of the artificial board.

Owner:JIANGNAN UNIV

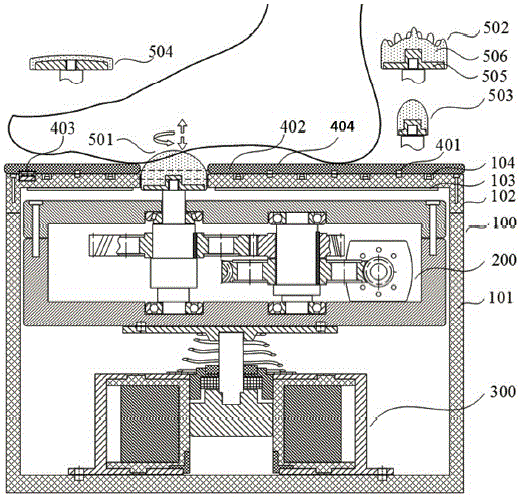

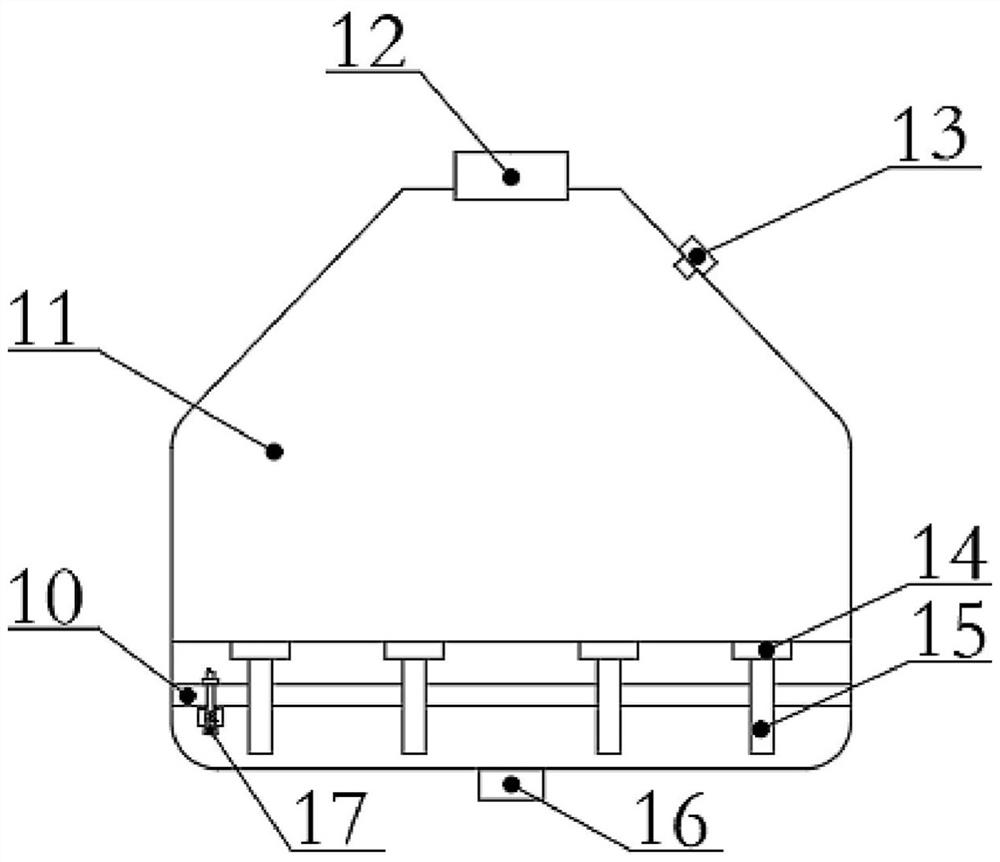

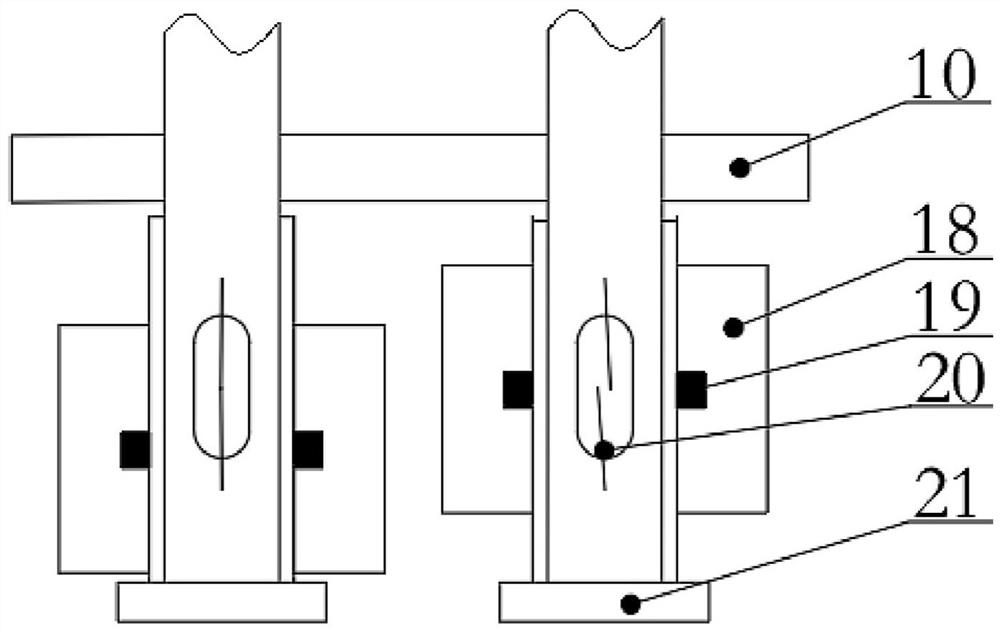

Plantar reflection area treatment instrument with Internet-of-Things function

InactiveCN105878002AReliable curative effectRealize personalized customizationDevices for heating/cooling reflex pointsDevices for locating reflex pointsTreatment effectSide effect

The invention discloses a plantar reflection area treatment instrument with an Internet-of-Things function. The plantar reflection area treatment instrument comprises a case, a reciprocating mechanism, a rotating mechanism, a massaging head, a foot positioning device and a control system, a cavity is arranged in the case, the reciprocating mechanism is arranged in the lower section of the cavity of the case, the rotating mechanism is arranged above the reciprocating mechanism which drives the rotating mechanism to be in up-down reciprocating motion, the massaging head is connected with the reciprocating mechanism and / or the rotating mechanism, the foot positioning device is arranged at the top of the case, a massaging head opening for exposing the massaging head is arranged on the case and / or the foot positioning device, and the control system is electrically connected with the reciprocating and / or the rotating mechanism and / or the foot positioning device. The plantar reflection area treatment instrument has the Internet-of-Things function and can transmit treatment information to a cloud server, personalized customizing of treatment modes can be realized, and health management and health interference are realized. The plantar reflection area treatment instrument can mechanically stimulate planta pedis, can realize photothermal stimulation of planta pedis and is free of trauma, suffering and side effect during treatment, reliable in treatment effect, simple and reasonable in structure and diverse in function.

Owner:SHENZHEN XINJUNHENG TECH DEV CO LTD

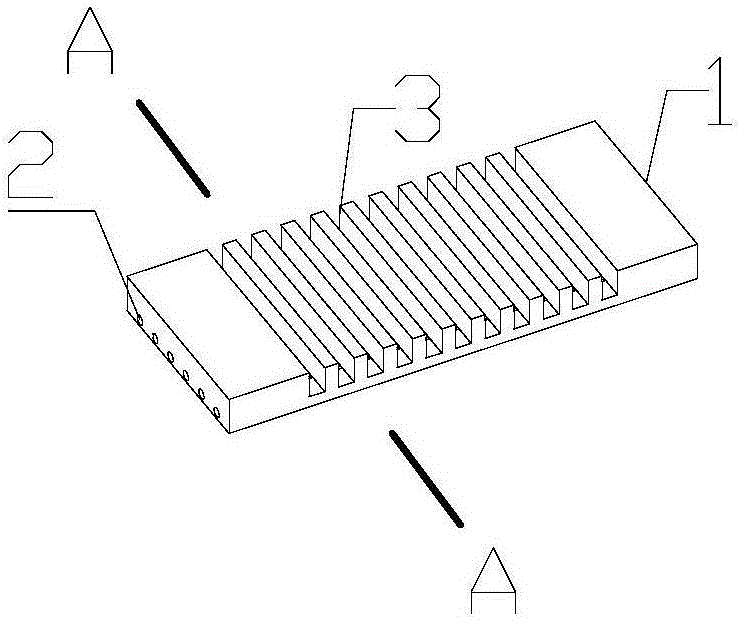

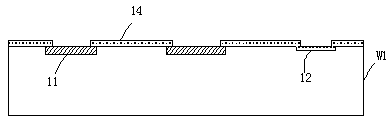

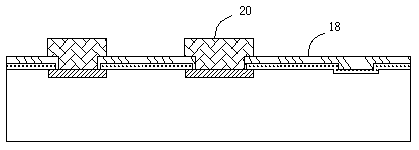

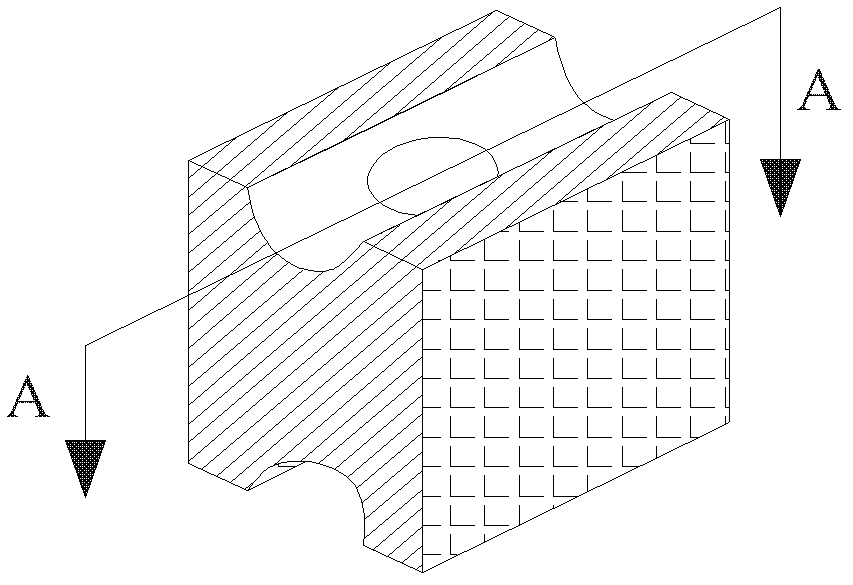

Through bar type concrete composite floor slab structure and manufacturing and assembling method thereof

The invention relates to the field of assembled concrete buildings, in particular to a through bar type concrete composite floor slab structure and a manufacturing and assembling method thereof. The structure comprises prefabricated base plates, longitudinal stressed steel bars, reserved transverse stressed steel bar grooves, hogging moment steel bars, transverse stressed steel bars and the like. Due to the fact that transverse stressed steel bars of the unique prefabricated base plates are continuous, additional connecting measures and additional connecting steel bars are not needed for connection of the prefabricated base plates, construction is simplified, materials are saved, and the integrity of composite slabs is greatly strengthened. The reserved transverse stressed steel bar grooves of the through bar type concrete composite floor slabs reinforce shear resisting and tensile resisting connection of a cast-in-place concrete layer and the prefabricated base plates, and the overall performance of the composite slabs is greatly improved. The transverse stressed steel bars of the through bar type concrete composite floor slab structure are placed in the reserved transverse stressed steel bar grooves formed in the prefabricated base plates, maximum approximating to the prefabricated base plates is achieved, and the anti-bending stress performance of the prefabricated base plates can be same as the performance of cast-in-place slabs.

Owner:SHENYANG SANXIN IND

Production method of transparent leather

ActiveCN111455118AEasy to operateChoose from a wide range of sourcesPre-tanning chemical treatmentSpecial leather manufacturePolymer scienceActive agent

The invention discloses a production method of transparent leather. The production method of the transparent leather disclosed by the invention comprises the following four steps: 1, fully washing deashed and softened pelt with water until a total ash content is less than 0.5%, then taking the pelt out of a drum, carrying out stacking and standing for 30 minutes, and weighing the pelt, wherein theweight of the pelt is used as a reference for materials used in subsequent operation; 2, dissolving a surfactant or a polyfunctional amphiphilic substance such as a fatting agent for leather by usinga proper amount of water, adding the dissolved substance into a rotary drum, and then feeding the leather and carrying out rotating for at least 30 minutes; 3, dissolving or diluting acid or alkali with a proper amount of water, adding the dissolved or diluted acid or alkali into the rotary drum in batches, rotating the rotary drum for at least 10 minutes after each time of addition, continuing to rotate for at least 15 minutes after all the acid or alkali is added, and controlling the pH value of a bath solution to be 3.5-5.5 or 9.5-11.5; and 4, carrying out toggling and drying at a temperature not higher than 35 DEG C to finish the production of the transparent leather. Equipment and materials used in the method are widely used by leather making enterprises, and the types and the usingamounts of the materials and processing technological parameters can be adjusted according to product requirements, so practicability is high. Meanwhile, the pelt does not undergo violent expansion any more in the production process, so the production accident of breakage of the pelt is avoided, operation is easy, and risks are low.

Owner:SICHUAN UNIV

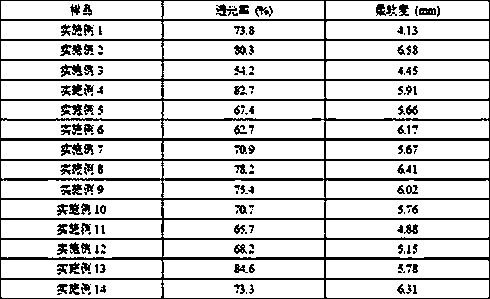

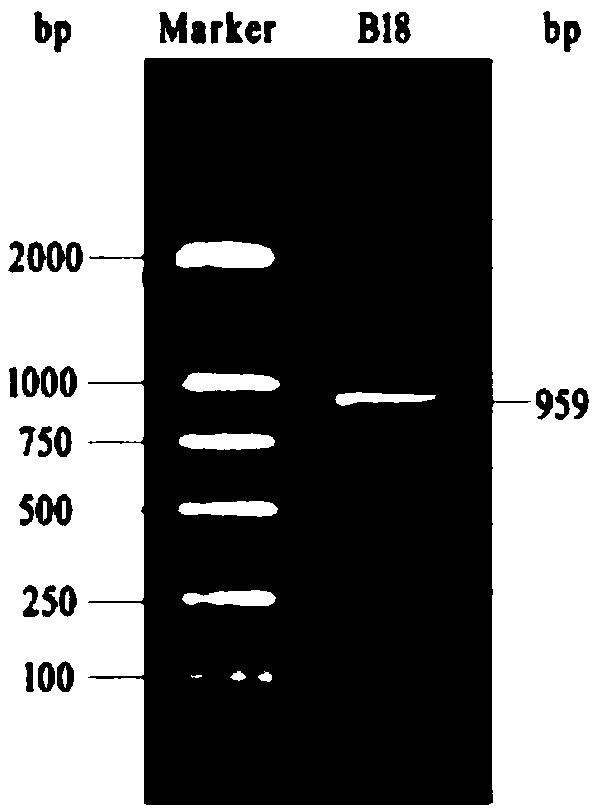

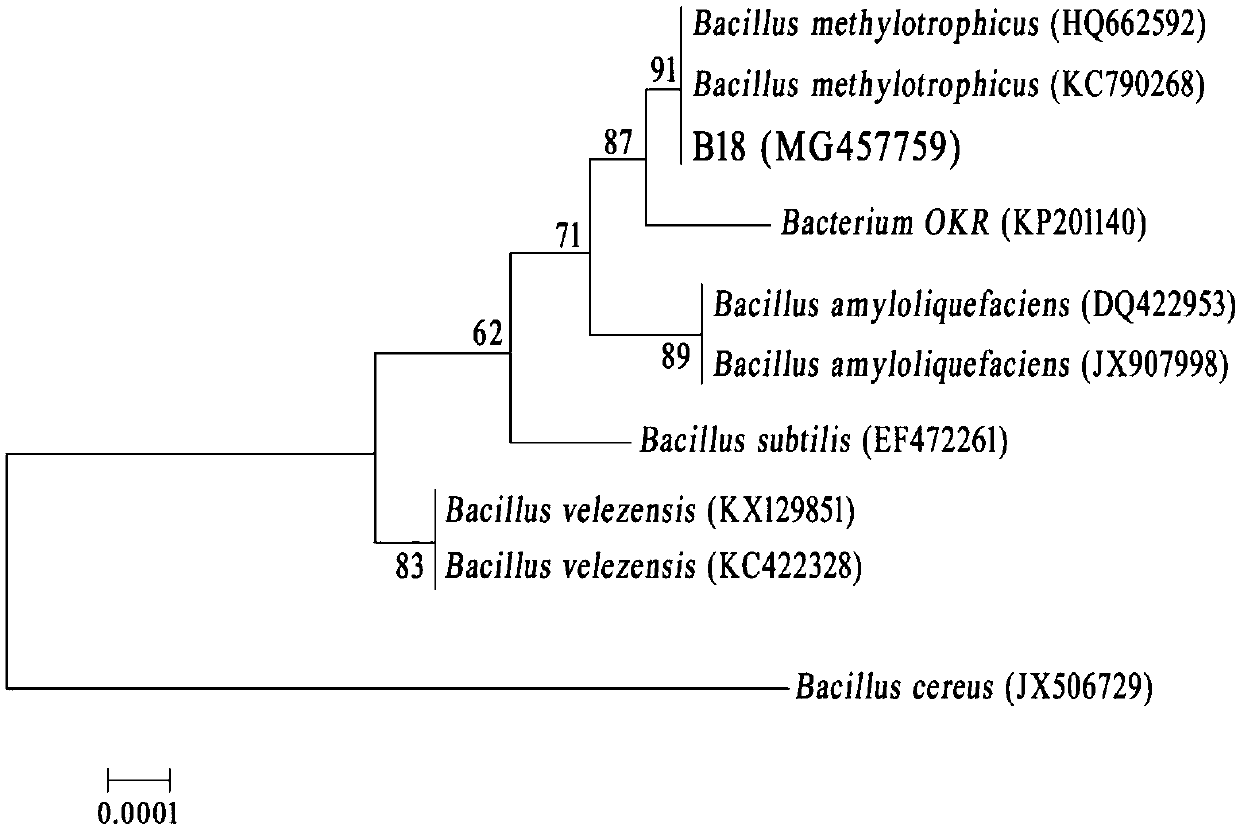

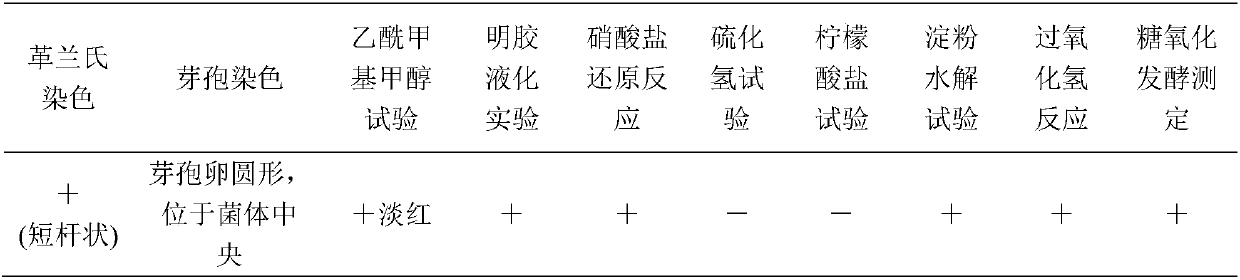

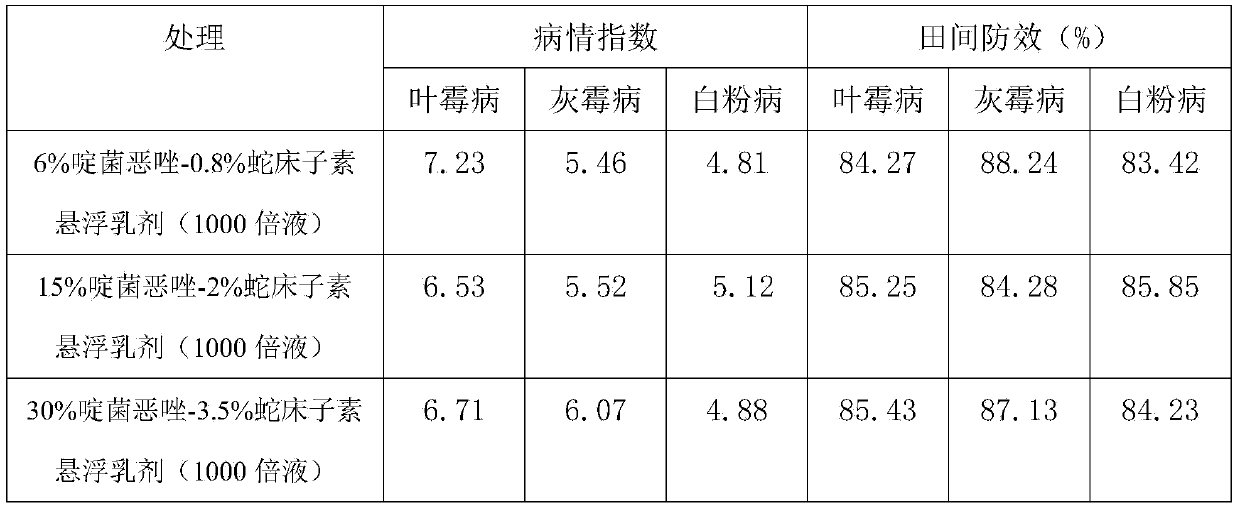

Bacillus methylotrophicus B18 as well as liquid preparation prepared from bacillus methylotrophicus B18 and application of bacillus methylotrophicus B18

The invention discloses bacillus methylotrophicus B18 as well as a liquid preparation prepared from the bacillus methylotrophicus B18 and application of the bacillus methylotrophicus B18. The strain is preserved in China General Microbiological Culture Collection Center (CGMCC) on September 18, 2017 and has a preservation number of CGMCC No. 14641. The liquid preparation is prepared by taking thebacillus methylotrophicus B18 as the strain and carrying out seed cultivation and fermentation cultivation. The biocontrol bacterium-bacillus methylotrophicus B18 strain has double functions of disease prevention and growth promotion, has the characteristics of biological control and bio-fertilizer, and has remarkable effects on the control of damping-off of eucommia ulmoides and the promotion ofgrowth of the eucommia ulmoides; the bacillus methylotrophicus B18 not only can avoid the serious consequences of environmental pollution caused by chemical drugs, but also has the characteristics ofsustainability and low cost.

Owner:SICHUAN AGRI UNIV

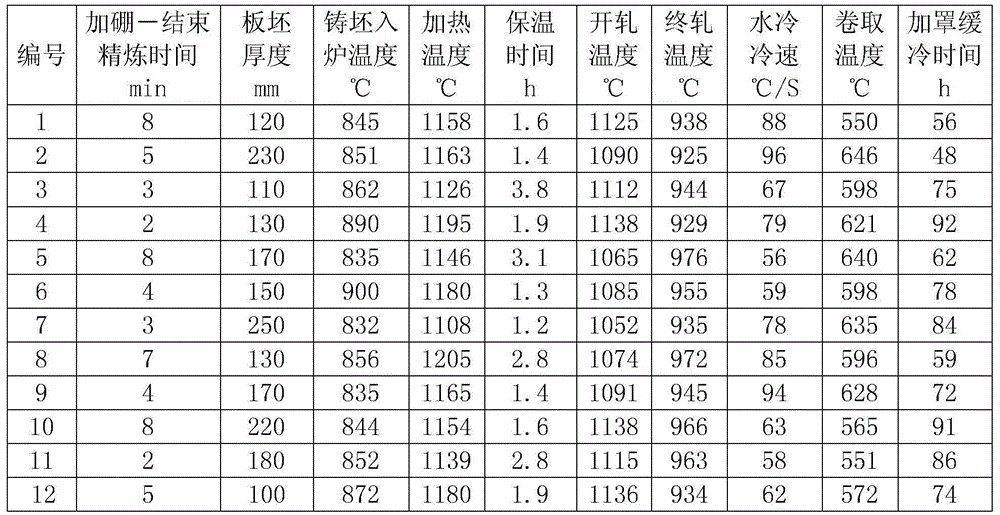

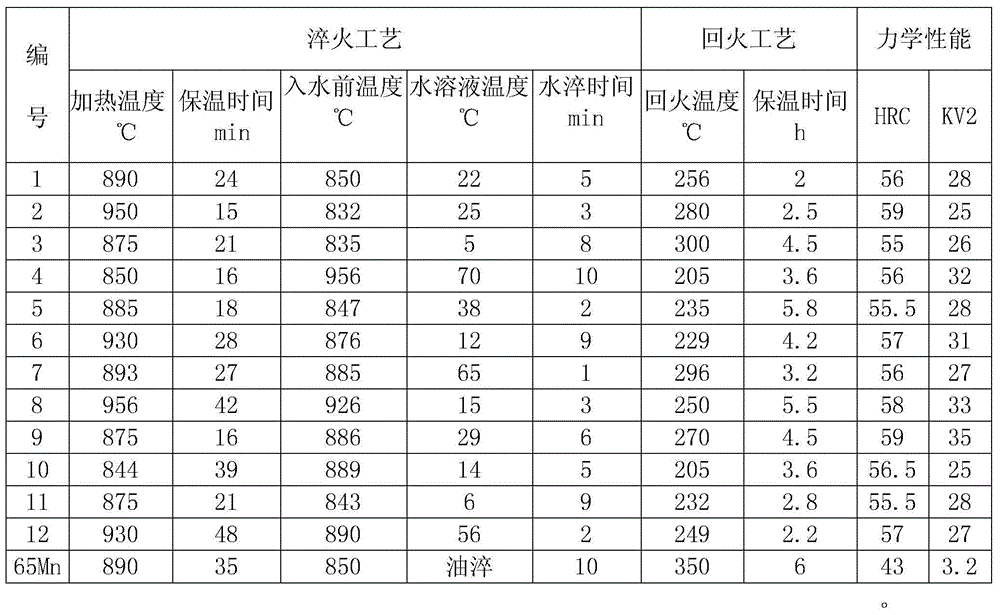

Steel for disk blade, production method and disk blade treatment method

ActiveCN105296866AImprove hardenabilityExtended service lifeTemperature control deviceWork treatment devicesChemical compositionHardness

The invention provides steel for a disk blade, a production method and a disk blade treatment method. The steel includes chemical components of, by weight, 0.25% to 0.35% of C, 0.1% to 0.40% of Si, 1.0% to 1.5% of Mn, not larger than 0.5% of Cr, 0.01% to 0.05% of Al, 0.015% to 0.06% of Ti, 0.001% to 0.006% of B, not larger than 0.0070% N, not larger than 0.020% of P, not larger than 0.015% of S and the balance Fe and impurities, wherein the inequation 4<=(Ti+Al) / N<=20 is satisfied. Continuous casting and rolling is adopted, the cast blank furnace entry temperature is larger than 830 DEG C, the heating temperature ranges from 1100 DEG C to 1200 DEG C, and the temperature is kept for 1 h to 4 h; and the rough rolling and finish rolling temperature ranges from 920 DEG C to 980 DEG C. After finish rolling is finished, the steel is cooled to the temperature ranging from 550 DEG C to 650 DEG C at the cooling speed of 50-100 DEG C / s and then coiled, and the steel is covered with a hood and slowly cooled for over 48 h. The heating temperature of a disk blade blank ranges from 800 DEG C to 1000 DEG C and the temperature is kept for 15 min to 50 min. The pre-quenching temperature is larger than or equal to 830 DEG C, water quenching is performed for 1 min to 10 min, and the water temperature at which the steel is away from water is smaller than or equal to 200 DEG C. The tempering temperature ranges from 200 DEG C to 300 DEG C and the temperature is kept for 2 h to 6 h. The hardness of the disk blade is larger than 55 HRC, the ballistic work is larger than 25 J, abrasive resistance, toughness and plasticity are good, and the service life is longer than that of a 65 Mn steel disk blade.

Owner:ANGANG STEEL CO LTD

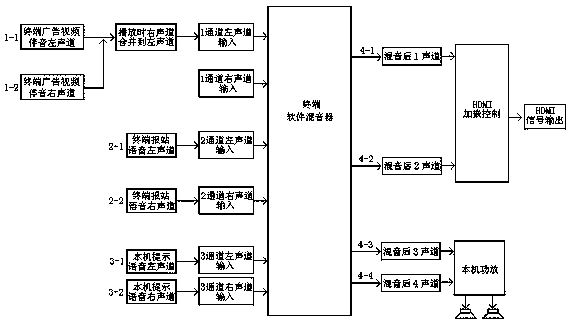

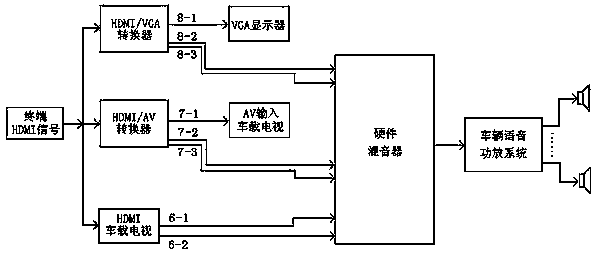

Method for controlling multichannel sound distributing and switching of vehicle-mounted terminal

InactiveCN103686546ASolve the problem of playing different voices at the same time and interacting with each otherIn line with the development directionStereophonic circuit arrangementsHDMISound mixer

The invention discloses a method for controlling multichannel sound distributing and switching of a vehicle-mounted terminal. A software sound mixer comprising a six-path input sound channel and a four-path output sound channel is arranged in the vehicle-mounted terminal; after audio signals of input video accompanying sounds, terminal station reporting sounds and terminal local prompting sounds are mixed through the software sound mixer, the video accompanying sounds and the terminal station reporting sounds are implanted on a left sound channel and a right sound channel of an HDMI signal and played through an audio / video playing device; the terminal local prompting sounds are output to a terminal local power amplifier via another two sound channels, and voice distribution on the vehicle-mounted terminal is achieved; when one video accompanying sound or terminal station reporting sound is played, volume of other audio signals decreases by controlling the software sound mixer and the implantation of and the HDMI or implantation is stopped and recovers the original state after the video accompanying sound or terminal station reporting sound is played, and switching control is achieved. By means of the method, one device can have the function of playing various sounds, and a sound system in the vehicle can be controlled to play various paths of different sounds.

Owner:大连现代高技术集团有限公司

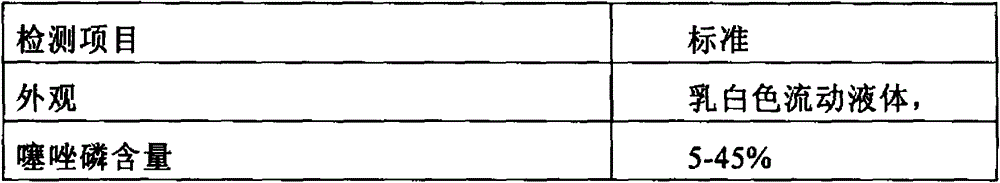

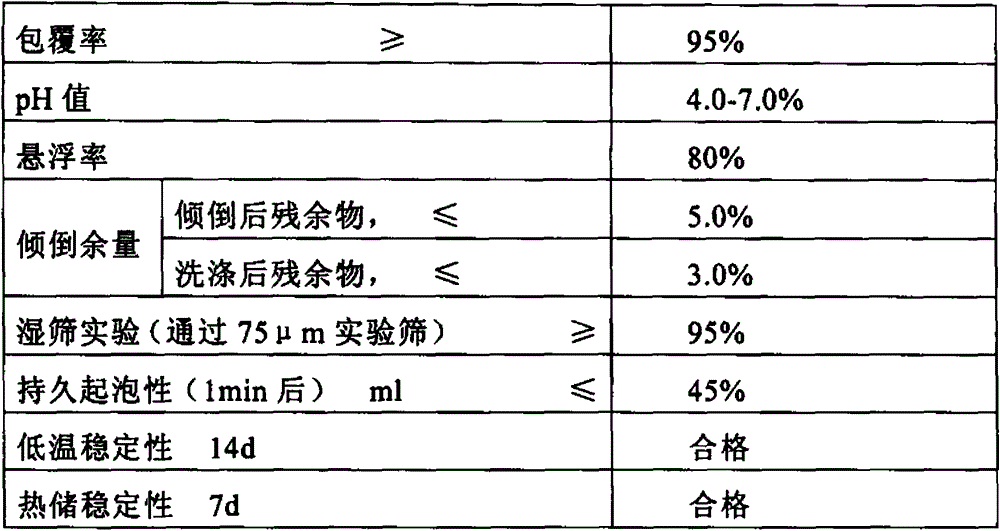

Preparation method of fosthiazate microcapsule suspension

PendingCN104054700AImprove utilization efficiencyControl and extend the release periodBiocideNematocidesDistilled waterOil water emulsion

The invention relates to a preparation method of a fosthiazate microcapsule suspension. The preparation method comprises the following steps: after mixing urea and formaldehyde, adding distilled water to obtain a stable urea-formaldehyde prepolymer water solution; dissolving fosthiazate in an inorganic solvent, adding an emulsifying agent solution, and stirring to form a stable fosthiazate oil-water emulsion; and adding the urea-formaldehyde prepolymer water solution in the fosthiazate oil-water emulsion, stirring to ensure that urea-formaldehyde prepolymer is dissolved in a dispersion medium of the emulsion, slowly regulating a pH for performing a condensation polymerization, then adding a dispersing agent, and stopping the reaction after a warming reaction, regulating a pH value of a reactant, filtering, centrifuging and drying after cooling to prepare the fosthiazate microcapsule suspension. Compared with the prior art, the preparation method adopting a microcapsule technology has the advantages that an active material coats a macromolecule based material so as to be slowly released, thus the dry utilization efficiency is increased and the drug release period is controlled and prolonged, and the advantages of high efficiency, low toxicity, low residue, environment friendliness, and the like are also realized.

Owner:河北三农农用化工有限公司

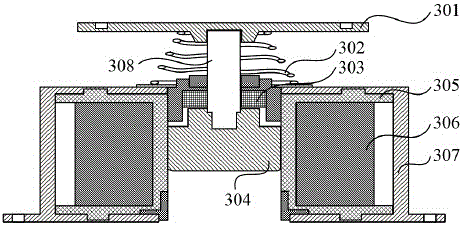

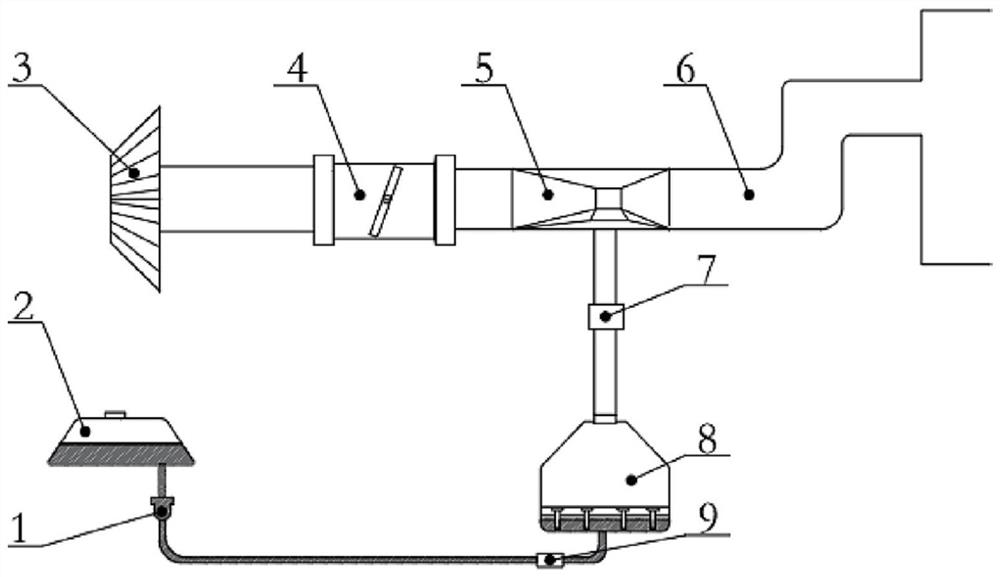

Ultrasonic atomization fuel auxiliary supply system

InactiveCN111828208ASmall change in intake resistanceAchieve premixCombustion-air/fuel-air treatmentMachines/enginesElectronic throttleUltrasonic atomization

The invention discloses an ultrasonic atomization fuel auxiliary supply system. The system is characterized in that an ultrasonic atomization generator is matched with a Venturi mixer for use, so thatpremixed fuel gas with a certain proportion of fresh charge entering an engine is realized, the combustion heat efficiency of the engine is effectively improved, the emission of harmful gas of the engine is reduced. The system mainly aims at a fuel supply system of methanol which is a clean fuel, utilizes the ultrasonic atomization unit to atomize methanol into methanol mist, is matched with thenegative pressure adsorption principle of the Venturi tube, and realizes premixing of air and methanol mist through the adjusting function of an electronic throttle valve on the air inlet flow; and the heat efficiency of the engine is improved in an auxiliary fuel gas supply mode of the premixing part, and emission of the engine is improved.

Owner:唐山阳光动力科技有限公司

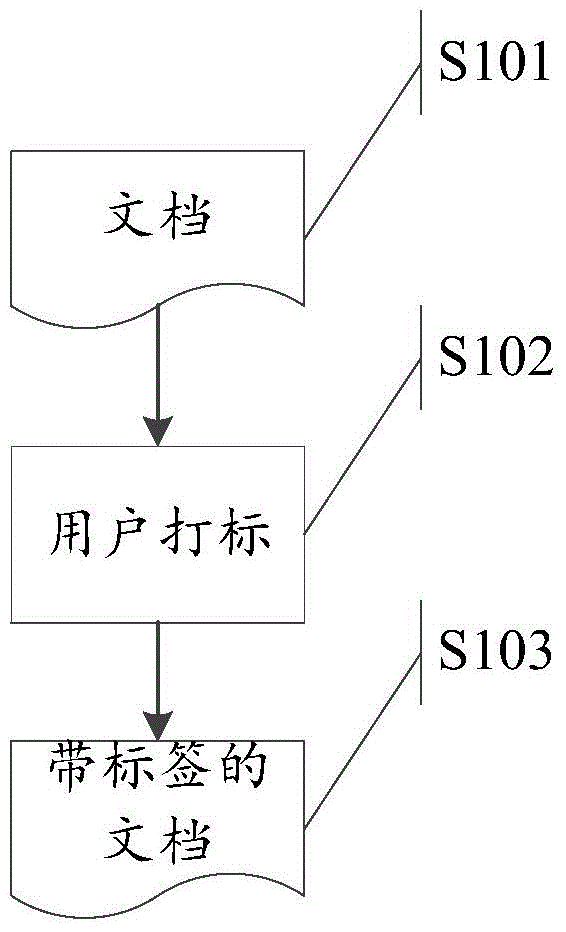

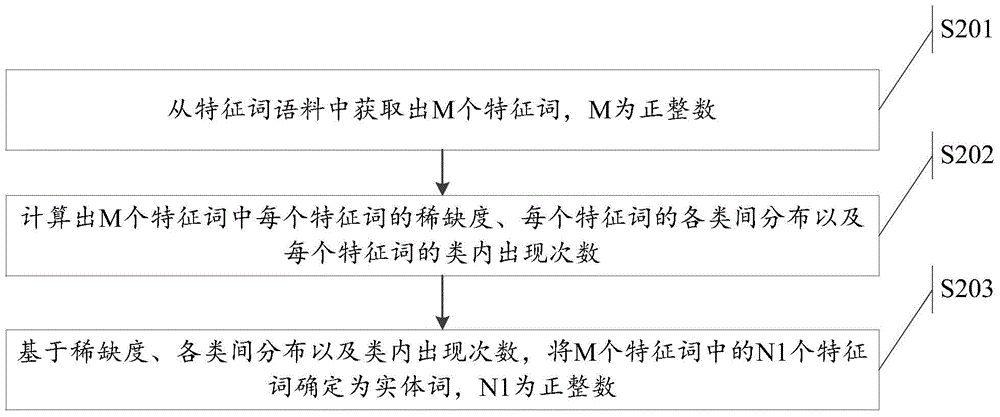

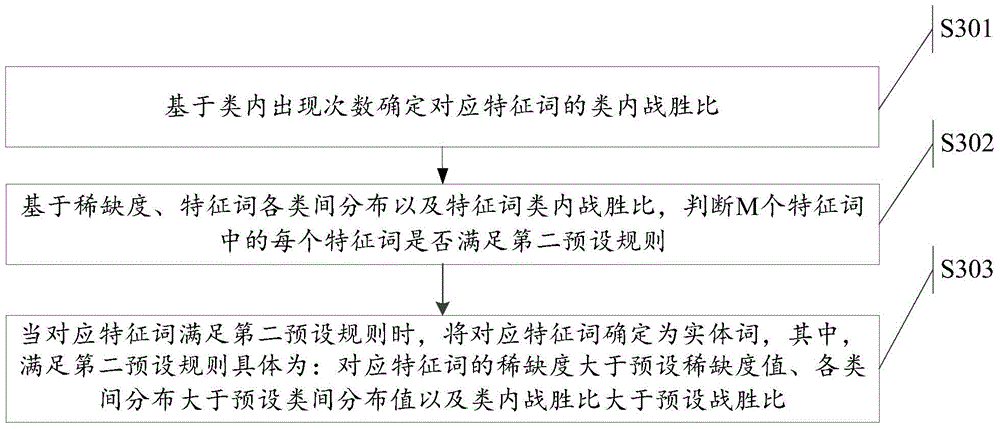

Entity word mining method, information recommendation method and device

ActiveCN106294473AHigh scarcityDetermination of interest characteristicsSpecial data processing applicationsAlgorithmFrequency of occurrence

The invention relates to the field of data mining, and discloses an entity word mining method, an information recommendation method and device in order to solve the technical problem existing in the prior art that user interest characteristics can be obtained only through a manual marking manner. The entity word mining method comprises that a number M of characteristic words are obtained from a characteristic word corpus, and M is a positive integer; the scarcity degree, the between-class distribution and the within-class frequency of occurrence of each characteristic word in the number M of characteristic words are calculated; based on the scarcity degree, the between-class distribution and the within-class frequency of occurrence, a number N1 of characteristic words in the number M of characteristic words are determined to be entity words, and N1 is a positive integer. The user interest characteristics can be determined with no need of the manual marking manner.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

Non-demolition type reforming and refitting construction method

InactiveCN106638209AThe detection and collection items are reasonable and applicableMature technologyIn situ pavingsRoads maintainenceService qualityEngineering

The invention discloses a non-demolition type reforming and refitting construction method. The method particularly comprises the following four steps: (1) acquiring information data of old road traffic conditions; (2) evaluating the diseases and defects of an old road; (3) formulating an operation scheme for reforming and refitting the old road, and performing construction; (4) evaluating and tracking the refitting effect. When the construction method is used for reforming and refitting an urban old and damaged road with a rigid surface layer, the resources of the old road are fully and reasonably utilized, so that excellent service quality performance is obtained; the service life period of the refitted road is long; furthermore, compared with a mode of dismantling the old road and then building a new road, the construction method greatly reduces old structure demolition work load and resource consumption and greatly shortens the construction period; therefore, the construction method corresponds with the development direction of high quality and low consumption, fastness and high efficiency as well as energy conservation and environmental protection, thus being remarkable in promotion and application values.

Owner:石家庄市道桥管理处 +1

Fast effect and slow release combined fertilizer formula special for cotton

InactiveCN1948237ASatisfy the budgetFulfil requirementsFertilising methodsFertilizer mixturesNitrogenPotassium

The present invention relates to a quickly-acting and slowly-released special-purpose formula fertilizer for cotton. Said special-purpose formula fertilizer is made up by mixing quickly-acting complex fertilizer formed from elements of N,P2O5,K2O,B and Zn with coated slowly-released complex fertilizer, in which the total content of nitrogen, phosphorus and potassium is 40%-45%; the weight mixing ratio of N1P2O5,K2O, B and Zn is 1:0.4-0.6:1.0-1.2:0.01-0.02: 0.01-0.02.

Owner:安徽省农业科学院棉花研究所

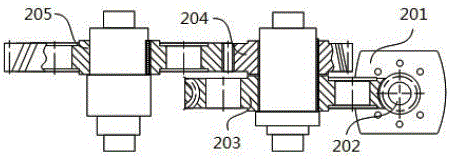

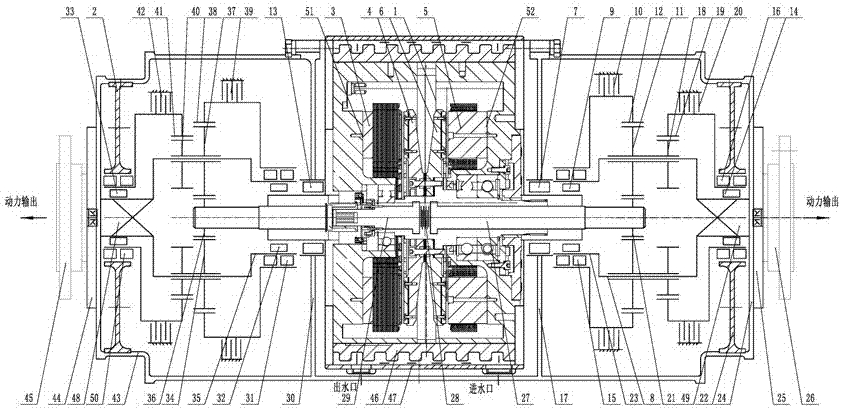

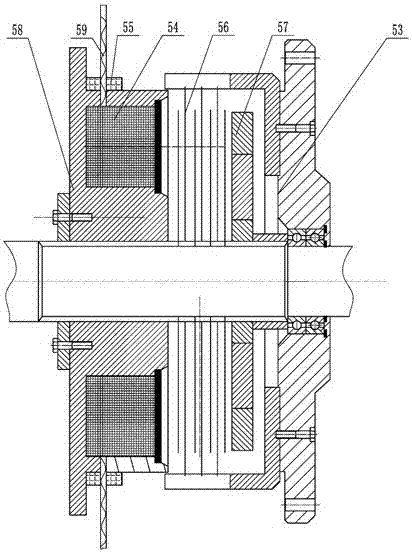

Mining timeliness four-wheel drive automatic speed changing multi-mode power driving system

ActiveCN106985647AImprove energy utilizationEligible for useElectric propulsion mountingControl devicesTime switchingTime switch

The invention belongs to the technical field of design and manufacture of coal mine down hole railless auxiliary transportation equipment, and particularly to a mining timeliness four-wheel drive automatic speed changing multi-mode power driving system. The problem that a mining electric driving vehicle cannot effectively meet the requirement of complicated changing conditions of the coal mine down hole is solved. The power-driven system comprises a water-cooled type middle dual-drive anti-explosion motor, a planetary speed reducing mechanism I, a planetary speed reducing mechanism II, a left output flange and a right output flange, and the dual-drive anti-explosion motor is connected with the planetary speed reducing mechanism I, the planetary speed reducing mechanism II, the left output flange and the right output flange correspondingly through left rotating shafts and right rotating shafts which penetrate through a center. The mining timeliness four-wheel drive automatic speed changing multi-mode power-driven system has obvious advantages that two-motor drive, automatic transmission and driving force switching in the driving system are integrated together, drive mode, driving force switching and automatic speed charging are integrated together, the structure is compact, and making the coal mine vehicle realize the vehicle multiple driving force output and front wheel drive, rear wheel drive and four-wheel drive of the vehicle of the coal mine vehicle can achieve real-time switching to ensure that the motor can work in the efficient range in a long time, the energy use ratio and the applicability of a variety of mine conditions are improved, the drive mode, driving force switching, and automatic speed charging are integrated together, and the driving system is accorded with the using conditions and the development direction of the vehicle of coal mine down hole.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Preparation method of novel health-care white wine

ActiveCN104328012AImprove immunityPlump styleMetabolism disorderDigestive systemSocial benefitsChrysanthemum Flower

The invention discloses a preparation method of novel health-care white wine, belonging to the field of white wine production. The method comprises the following steps: by using Yanghe soft-type white wine as base wine and functional glycogen oligosaccharide as a flavoring agent, preparing wolfberry fruit, ganoderma lucidum, mugwort, licorice, chrysanthemum flower and other medicinal materials into flavoring liquor, and finally, blending the functional soft-type white wine. The final wine body is colorless or light yellow, has delicate mouthfeel, and is soft and thick. When being drunk frequently, the wine has the functions of enhancing the immunity of organisms, resisting oxidation, inhibiting pathogenic bacteria, protecting the liver, lowering the blood fat and the like, and can generate huge economic and social benefits for the Yanghe winery.

Owner:JIANGSU YANGHE BREWERY JOINT STOCK

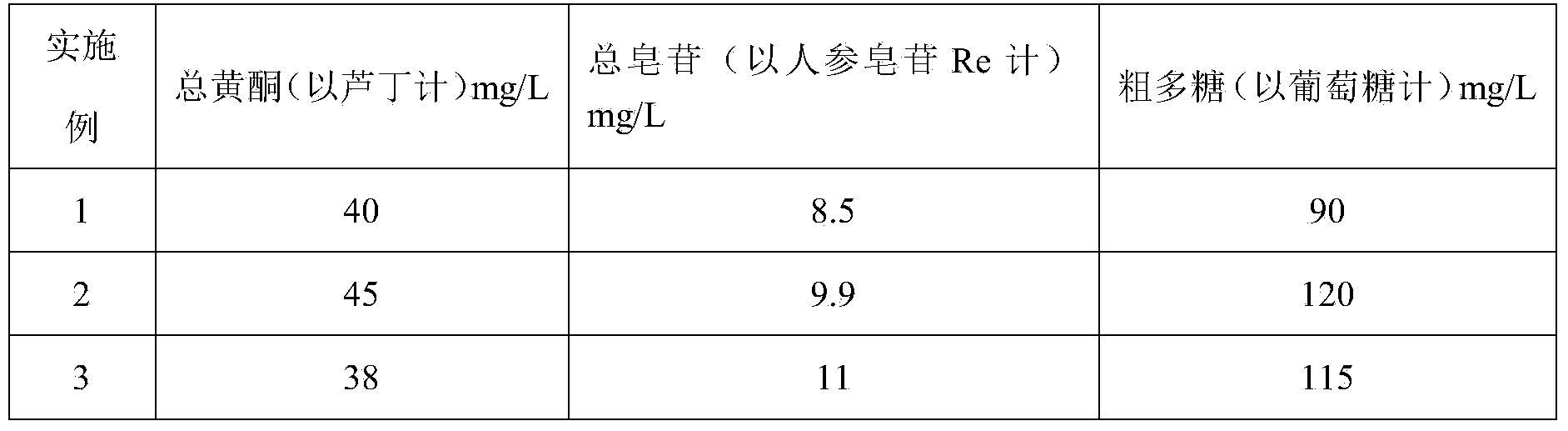

Pyrisoxazole-cnidium lactone suspension emulsion and preparation method thereof

The invention discloses a pyrisoxazole-cnidium lactone suspension emulsion and a preparation method thereof. The suspension emulsion contains the following components in percentage by weight: 1%-40% of pyrisoxazole, 0.05%-5% of cnidium lactone, 1%-50% of a solvent, 1%-40% of an emulsifying agent, 1%-10% of a dispersant, 2%-4% of a botanical fungicide, 0.1%-10% of a thickener, 1%-5% of an anti-freezing agent, 0.1%-1.0% of an anti-foaming agent, 0.1%-1% of a preservative and the balance being water. The compound preparation can effectively prevent and control diseases and pests of crops (for example, the preparation can simultaneously prevent and control a disease, i.e., blight, and pests, i.e., cotton bollworm, of cotton), and is durable in efficacy. The compound preparation can also effectively prevent and control various diseases on crops, for example the preparation can simultaneously prevent and control white rot, gray mold and powdery mildew on grapes as well as gray mold, leaf mold and powdery mildew on tomatoes; the compound preparation has obvious effects of protecting seedlings and increasing production, is simple in production process, and has labor-saving, time-saving and energy-saving effects, obvious economic, ecological and environmental benefits, and wide development prospect.

Owner:QINGDAO AGRI UNIV

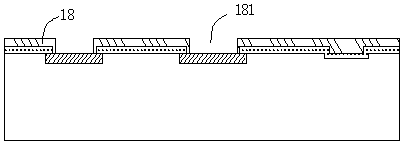

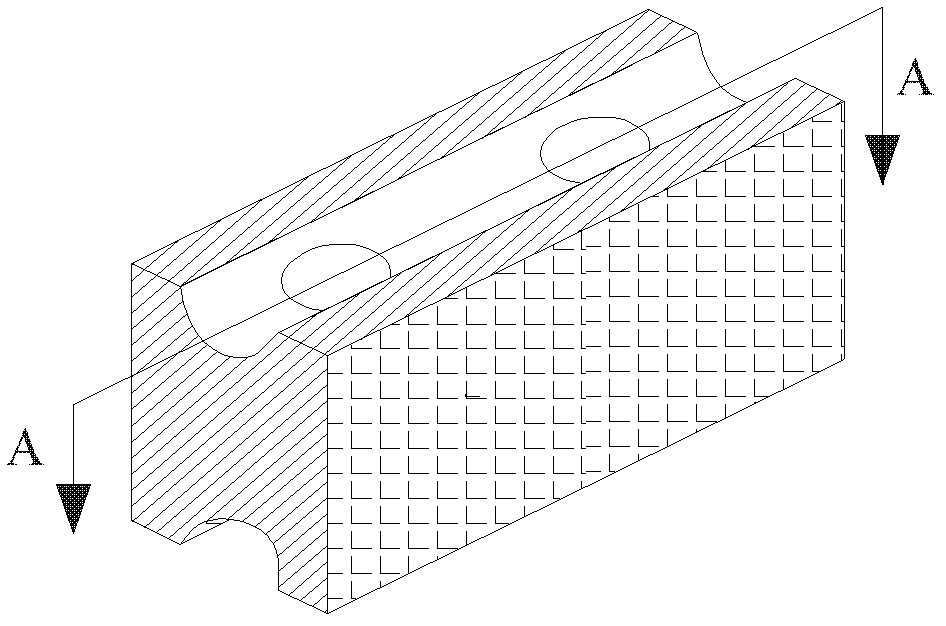

Wafer-level back gold chip packaging structure and packaging method thereof

ActiveCN107910305AIn line with the development directionPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSemiconductor package

The present invention discloses a back gold chip packaging structure and a packaging method thereof, belonging to the technical field of semiconductor packaging. A plurality of chip electrodes and front protective layers are arranged at the front surface of a silicon-based body, each front protective layer is provided with one front protective layer opening to expose chip electrodes again, and metal bump are arranged at the surfaces of the chip electrodes. The back surface of the silicon-based body is provided with a back gold layer, the back gold layer is in bonding connection with the back surface of the silicon-based body through a back gold bonding layer. A plastic packaging layer packages exposed surfaces of the back gold layer and the silicon-based body, and a plastic packaging layeropening is arranged to expose the exposed surface of the back surface of the back gold layer. The wafer-level back gold chip packaging structure and the packaging method thereof are simple in packaging flow, the silicon face processing technology, the back gold technology, the plastic packaging material ablation and the de-bonding technology are completed on a wafer, and therefore, the wafer-level back gold chip packaging structure and the packaging method thereof accord with future development direction of semiconductor manufacturing.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

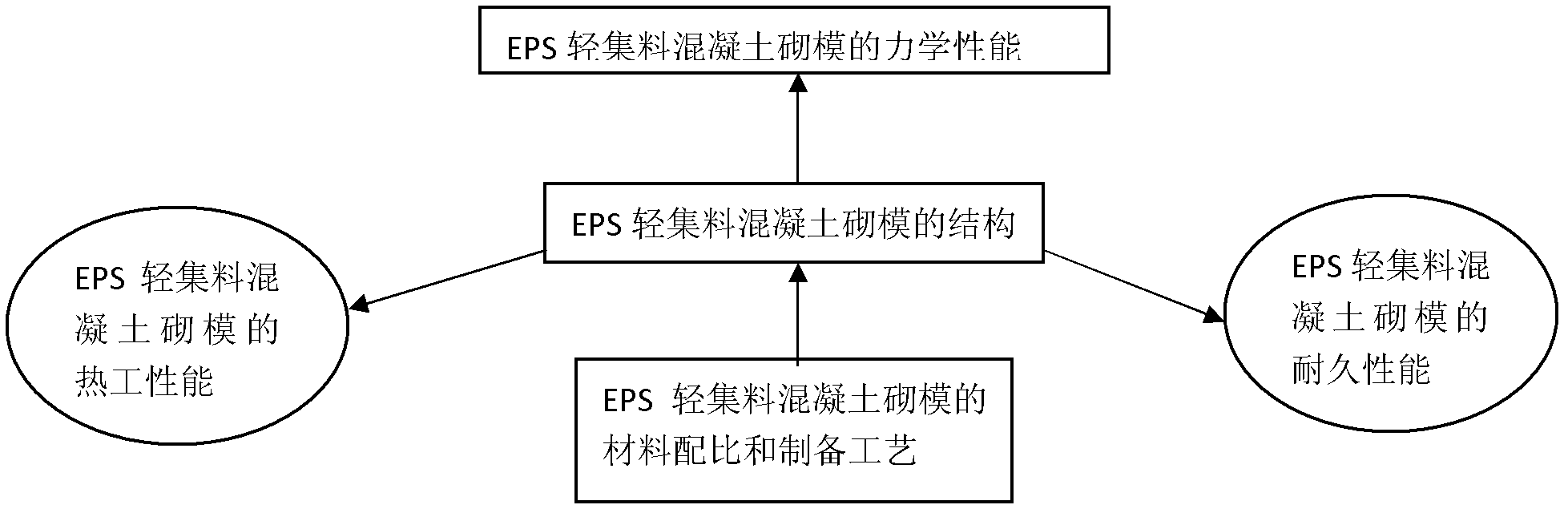

EPS (Expandable Polystyrene) light aggregate concrete thermal insulation hollow block and construction method thereof

InactiveCN102674759ASimple construction methodQuality improvementClimate change adaptationHeat proofingSilica fumeThermal insulation

The invention provides an EPS (Expandable Polystyrene) light aggregate concrete thermal insulation hollow block and a construction method thereof, belonging to the technical of a concrete building material. The hollow block is prepared by using waste EPS (Expandable Polystyrene) particles as aggregates in concrete, the cement as a cementing material and adding pulverized fuel ash, silica fume, polymer emulsion and water. The EPS light aggregate concrete thermal insulation hollow block solves the problems of weight and thermal insulation property when a brick-concrete structure is used as a wall; and due to the recycling of lots of pulverized fuel ash and EPS, the environmental stress is eased, and the EPS light aggregate concrete thermal insulation hollow block has very effect on the elimination of environmental pollution. The hollow block provided by the invention has the characteristics of light weight, excellent thermal insulation property, simple construction method and green environmental protection.

Owner:CHINA ELECTRIC POWER RES INST +1

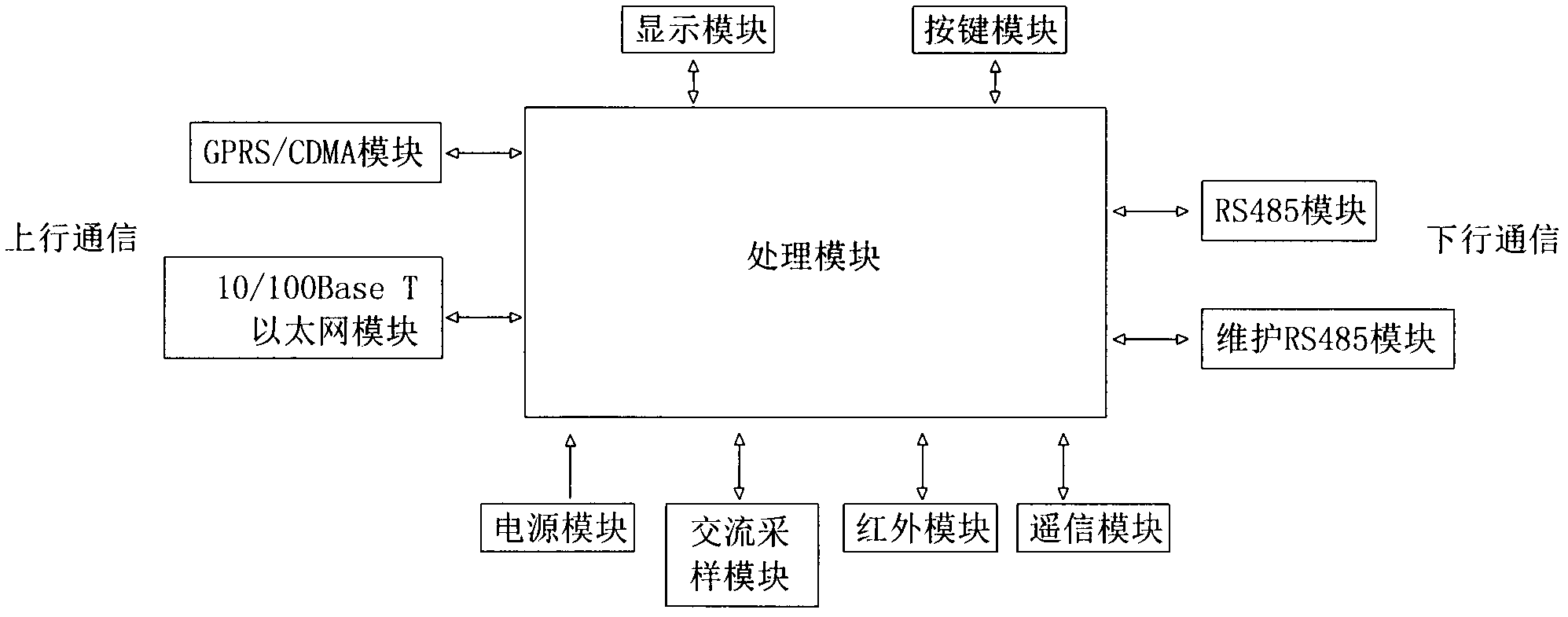

Data concentrator with class-D voltage quality monitoring function

InactiveCN103001321ASolve the layout problemGuaranteed Authenticity and CompletenessCircuit arrangementsEnergy industryEmbedded systemCode division multiple access

The invention discloses a data concentrator with a class-D voltage quality monitoring function. The data concentrator comprises a power module and a processing module, the power module is in electric signal connection with the processing module, an input end of the processing module is connected with a signal output end of a GPRS (general packet radio service) / CDMA (code division multiple access) module or a 0 / 100Base T Ethernet module, signal output or input ends of a display module, a key module, an alternating-current sampling module, an infrared module and a remote signaling module are respectively connected with a signal input or output end of the processing module, and signal output or input ends of an RS485 interface module and a maintenance RS485 interface module are connected with the signal input or output end of the processing module. The data concentrator has functions of an existing data concentrator and a 220V-line voltage monitor monitoring function and achieves class-D voltage monitoring point distribution, so that a great quantity of investment for power supply enterprises to purchase voltage monitors is saved while maintenance and use are facilitated for users.

Owner:NANJING NENGRUI AUTOMATION EQUIP

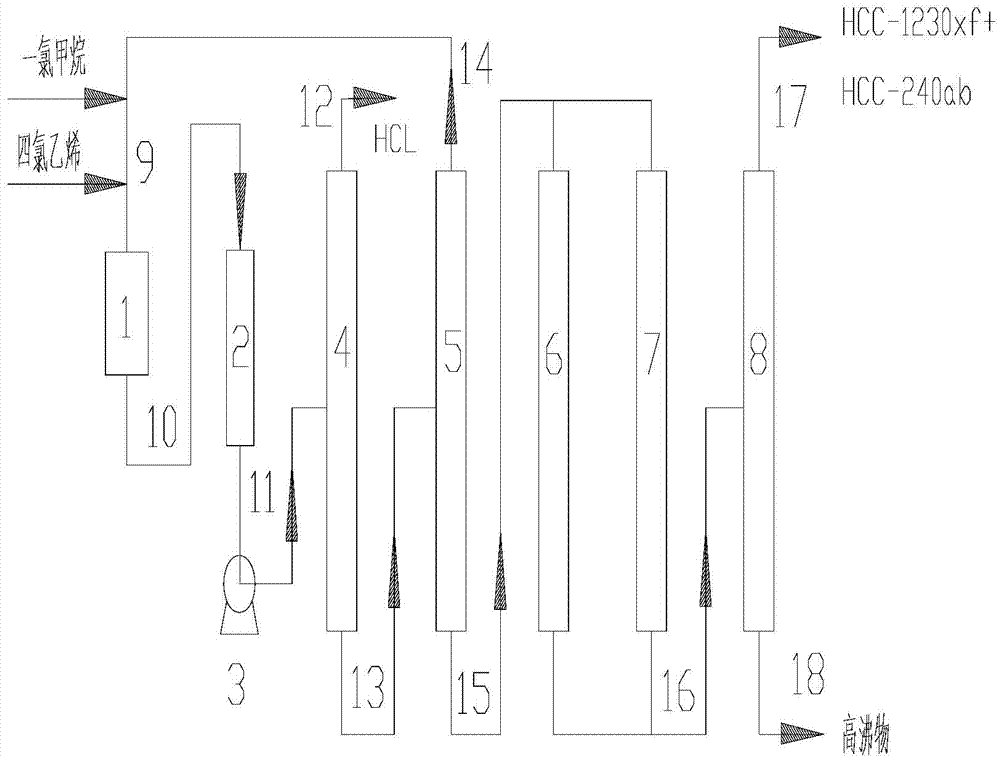

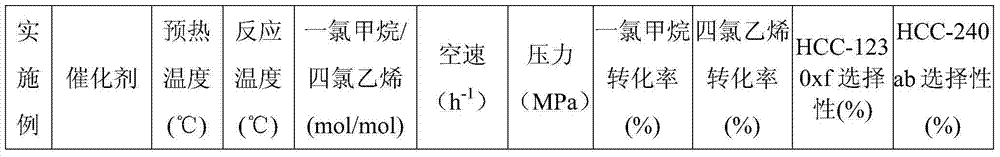

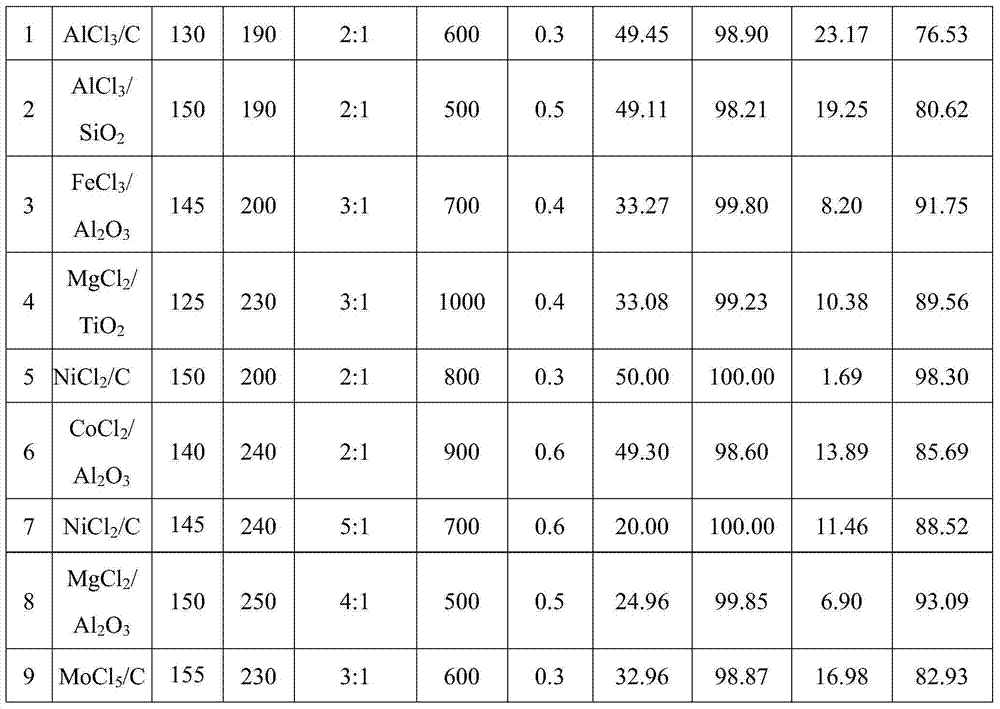

Method for simultaneously preparing 1,1,1,2,2-pentachloropropane and 2,3,3,3-tetrachloropropene

ActiveCN104496746ASimple processLow costPreparation by hydrogen halide split-offTetrachloroethyleneMetal catalyst

The invention discloses a method for simultaneously preparing 1,1,1,2,2-pentachloropropane and 2,3,3,3-tetrachloropropene. The method comprises the following steps: carrying out a one-step reaction between methane chloride and tetrachloroethylene in the presence of a supported metal catalyst, and preparing the 1,1,1,2,2-pentachloropropane and 2,3,3,3-tetrachloropropene. The method disclosed by the invention has the advantages that the raw materials are economical and readily available, the target product is high in selectivity, the process is simple and the equipment investment cost is low.

Owner:ZHEJIANG QUHUA FLUOR CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com