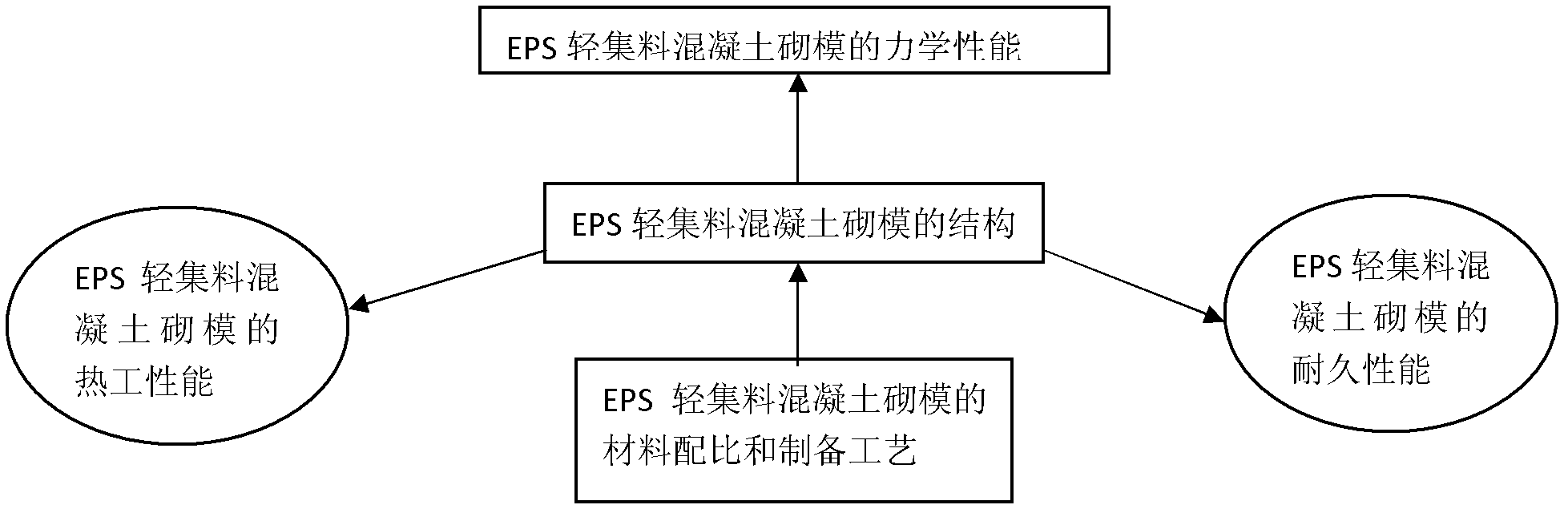

EPS (Expandable Polystyrene) light aggregate concrete thermal insulation hollow block and construction method thereof

A technology of lightweight aggregate concrete and thermal insulation masonry, which is applied in thermal insulation, building components, climate change adaptation and other directions to achieve the effects of saving energy, eliminating environmental pollution and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

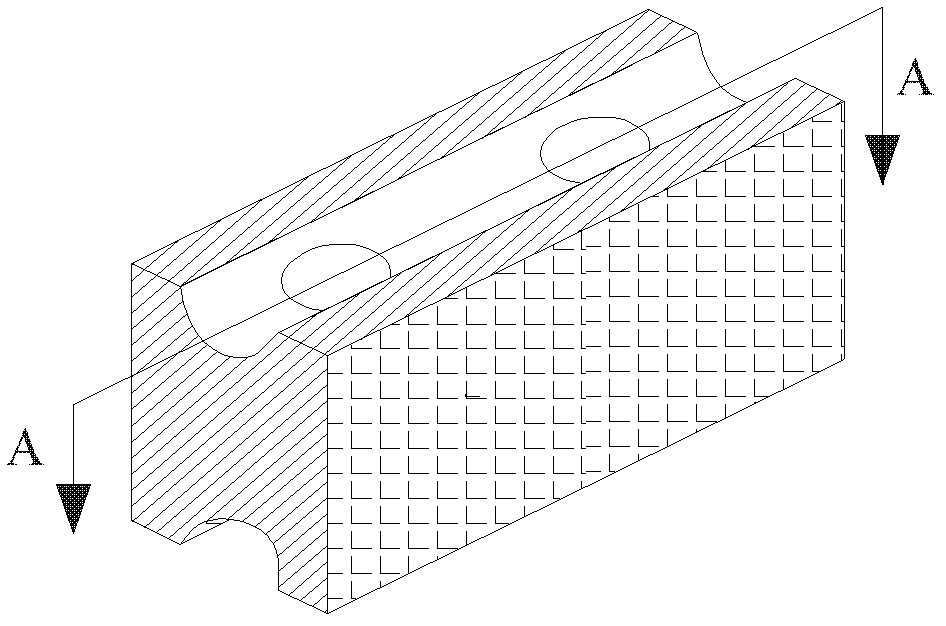

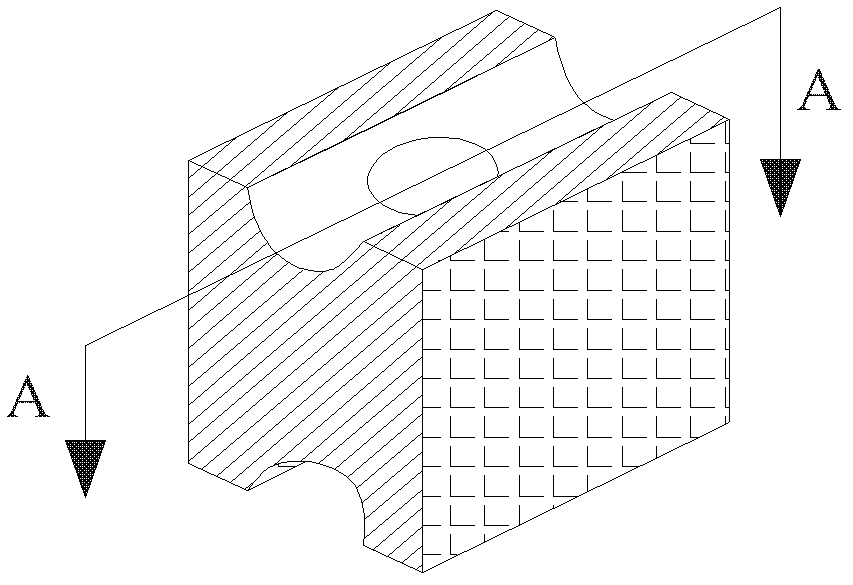

[0058] The preparation process of EPS lightweight aggregate concrete insulation formwork can be divided into three steps: mixing process, forming process and curing process. The mixing process is to first mix cement, fly ash, silica fume, perlite and some water into a low water-cement ratio clean slurry, then mix it with EPS particles, and finally add the remaining water and mix well. Since the density of EPS particles is much smaller than that of cement mortar, serious delamination will occur when the usual vibration molding process is used; resulting in uneven quality of EPS lightweight aggregate concrete, which greatly reduces its performance. In order to overcome this defect, a pressurized vibration molding process with a low water-cement ratio should be used. When vibrating, a flat plate is used to cover the mold, and a slight pressure is applied to make the plate and the mold vibrate at the same time. During the vibration process, the floating EPS particles are limited b...

Embodiment 1

[0066] The EPS light aggregate concrete raw material ratio that is used to prepare embodiment 1 thermal insulation formwork is as shown in table 2:

[0067] Table 2 EPS light aggregate concrete raw material mix ratio (per cubic meter)

[0068]

[0069] The water reducer is UNF-5 type water reducer, the particle size of silica fume is 0.1μm-0.2μm, and the density is 2.0-2.4g / cm 3 , bulk density 200-350kg / m 3 , specific surface area 15000-25000m 2 / kg; the river sand is medium sand, the sand rate is 20-25% by volume, and the bulk density is 1225-1325kg / m 3 , the water absorption rate is 0.95-1.05%; the bulk density of EPS particles is 10-20kg / m 3 ; Perlite is expanded perlite.

[0070] The preparation method of EPS light aggregate concrete formwork is as follows:

[0071] Stir according to the ratio of raw materials listed in Table 2:

[0072] First, mix cement, fly ash, silica fume, perlite, water reducer, river sand and 20%-30% water into a low water-cement ratio clea...

Embodiment 2

[0087] The EPS light aggregate concrete raw material ratio that is used to prepare embodiment 2 thermal insulation formwork is as shown in table 3:

[0088] Table 3 EPS light aggregate concrete raw material mix ratio (per cubic meter)

[0089]

[0090] The water reducer is UNF-5 type water reducer, the particle size of silica fume is 0.1μm-0.2μm, and the density is 2.0-2.4g / cm 3 , bulk density 200-350kg / m 3 , specific surface area 15000-25000m 2 / kg; the river sand is medium sand, the sand rate is 20-25% by volume, and the bulk density is 1225-1325kg / m 3 , the water absorption rate is 0.95-1.05%; the bulk density of EPS particles is 10-20kg / m 3 ; Perlite is expanded perlite.

[0091] The preparation method and construction method of building mold are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com