Method for simultaneously preparing 1,1,1,2,2-pentachloropropane and 2,3,3,3-tetrachloropropene

A technology of tetrachloropropene and pentachloropropane, which is applied in the field of polychlorinated hydrocarbon preparation, can solve the problems of low selectivity of HCC-240ab, unfavorable separation and purification, low utilization rate of raw materials, etc., and achieve good product selectivity and simplified process , highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

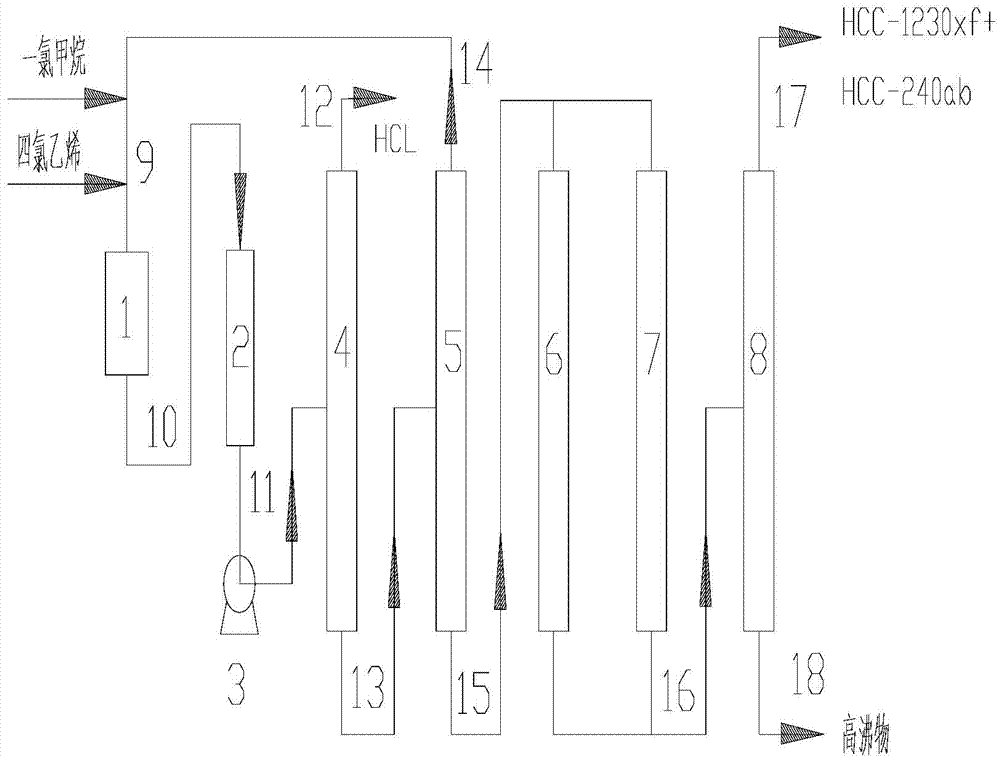

Method used

Image

Examples

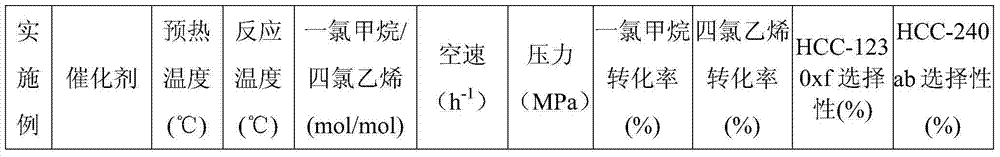

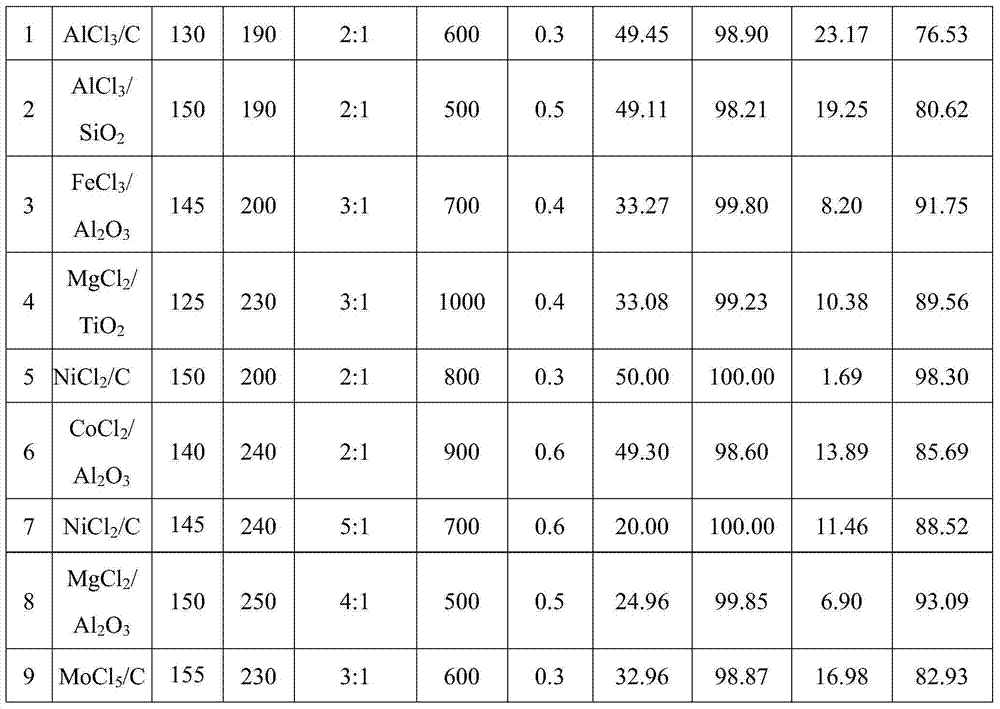

Embodiment 1~9

[0034] 120ml of AlCl 3 The / C catalyst is loaded into reactor 2, the temperature is raised to 300°C, and nitrogen gas is passed through to dry for 6 hours, then the temperature is lowered to 240°C, and chlorine gas diluted with nitrogen gas is passed through, and after activation for 4 hours, the temperature of the reactor is raised to 300°C. Turn off the nitrogen gas for activation, and when there is no more water vapor overflowing from the outlet of the reactor, the activation of the catalyst is completed, and the entire activation process takes 48 hours.

[0035] Adjust the temperature of the reactor to the reaction temperature, mix the monochloromethane and tetrachlorethylene and pass it into the preheater 1, and enter the reactor 2 after preheating to react, and adjust the temperature, pressure, molar ratio and space velocity of the reaction respectively. Reaction, carry out sampling analysis at the outlet of reactor, the product is washed with water and alkali before ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com