Liquid paraffin bath dyeing method of cotton fiber

A technology of liquid paraffin and dyeing method, applied in the field of dyeing and finishing, which can solve the problems of high alkalinity in dyeing wastewater, complicated dyeing process, and large water consumption, and achieve the effects of reducing derivative costs, simple dyeing process, and low consumption of auxiliaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A liquid paraffin bath dyeing method for cotton fibers, comprising the steps of:

[0028] (1) Pretreatment of cotton fibers: take 2g of scoured cotton fibers, smooth and loose them with a brush, put them into deionized water to soak and swell, control the liquid-carrying rate of cotton fibers to 120%, and prepare for dyeing;

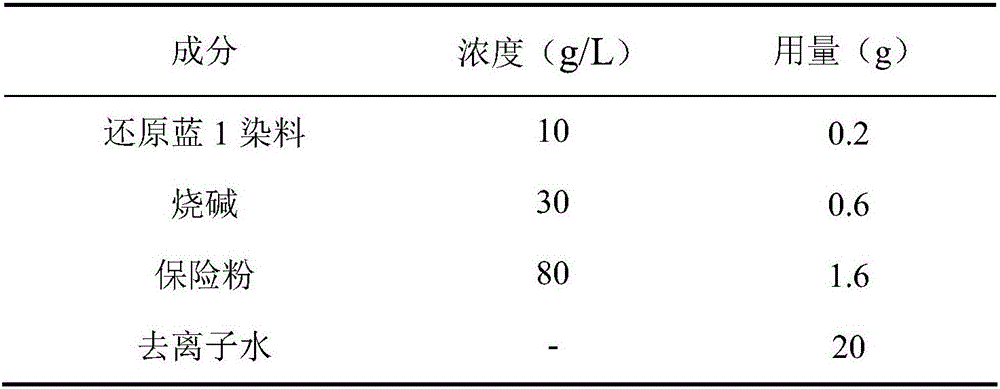

[0029] (2) Preparation of high-concentration vat blue 1 leuco body solution: prepare high-concentration vat blue 1 leuco body solution by using dry vat reduction method, and accurately weigh each drug according to the formula in Table 1. Add 0.6g of caustic soda and 1.6g of sodium hydrosulfite to 20mL of deionized water, stir in a 50°C constant temperature water bath to dissolve to obtain a reducing solution, then add 0.2g of Vat Blue 1 dye to the reducing solution, and seal it with an appropriate amount of liquid paraffin. , and reduced at a constant temperature of 50°C for 20 minutes to prepare a 10 g / L Vat Blue 1 leuco body solution for future ...

Embodiment 2

[0038] The difference from Example 1 is that the preparation conditions of the high-concentration vat blue 1 leucosome in step (2) are different from the dyeing conditions of cotton fibers in step (3). Other conditions are the same as in Example 1.

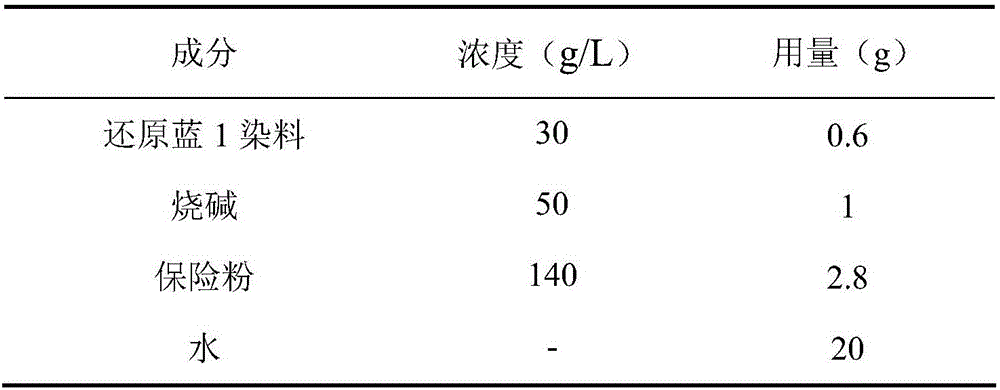

[0039] Step (2) The formula for preparing a high-concentration vat blue 1 leuco body solution is shown in Table 3. The reduction condition is: reduction at 60°C for 10 minutes at a constant temperature.

[0040] Table 3 prepares the formula of high concentration (30g / L) vat blue 1 leuco body solution

[0041]

[0042] In step (3), the dyeing temperature is 80° C., and the dyeing time is 50 min.

Embodiment 3

[0044] The difference from Example 1 is that the dye used is vat violet 2R; step (2) preparation of a high-concentration vat violet 2R leuco solution is shown in Table 4, and the reduction condition is 30 min at a constant temperature of 60°C; The dyeing condition of step (3) cotton fiber is temperature 60 ℃, time 50min. Other conditions are the same as in Example 1.

[0045] Table 4 prepares the formula of high concentration (40g / L) reduced brilliant violet 2R leucosome solution

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com