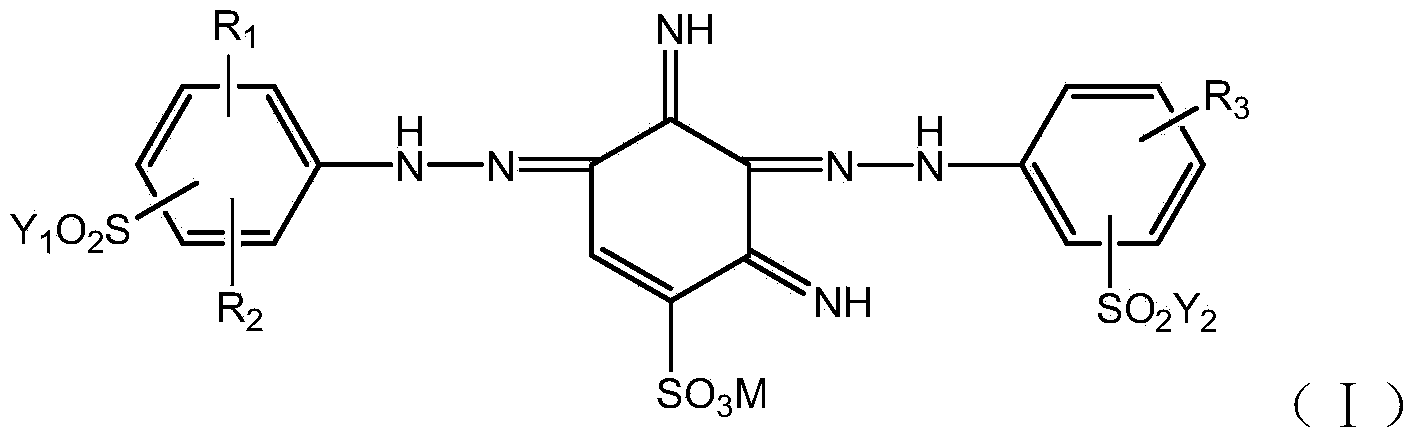

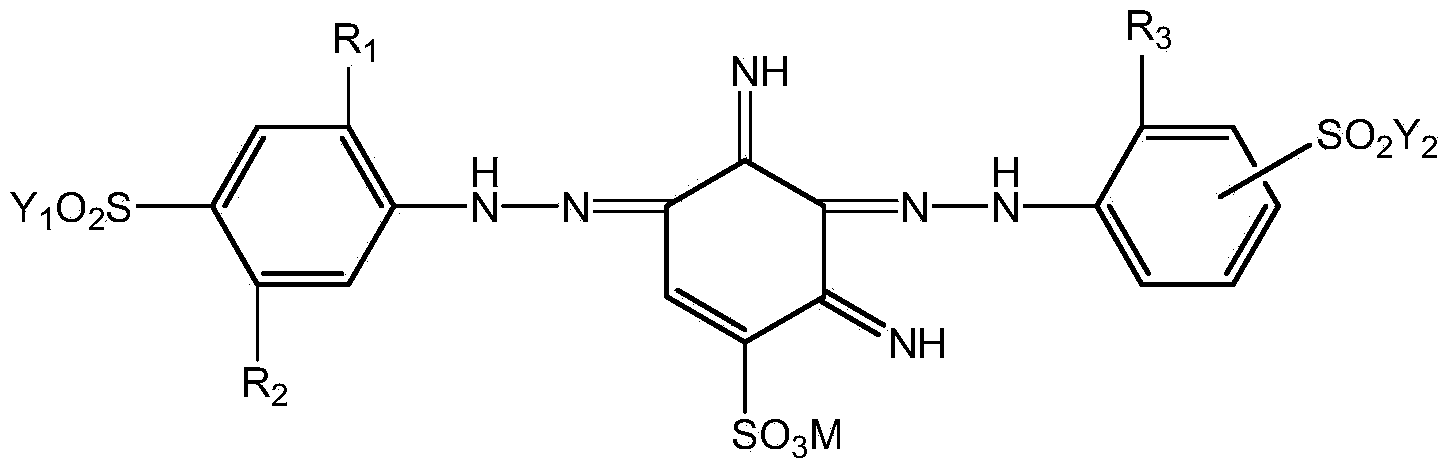

Orange reactive dye compound and application thereof

A compound, orange dye technology, used in reactive dyes, azo dyes, organic dyes, etc., can solve problems such as use safety violations, achieve excellent sweat-light resistance, high dyeing rate and color fixing rate, color and luster Bright and full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

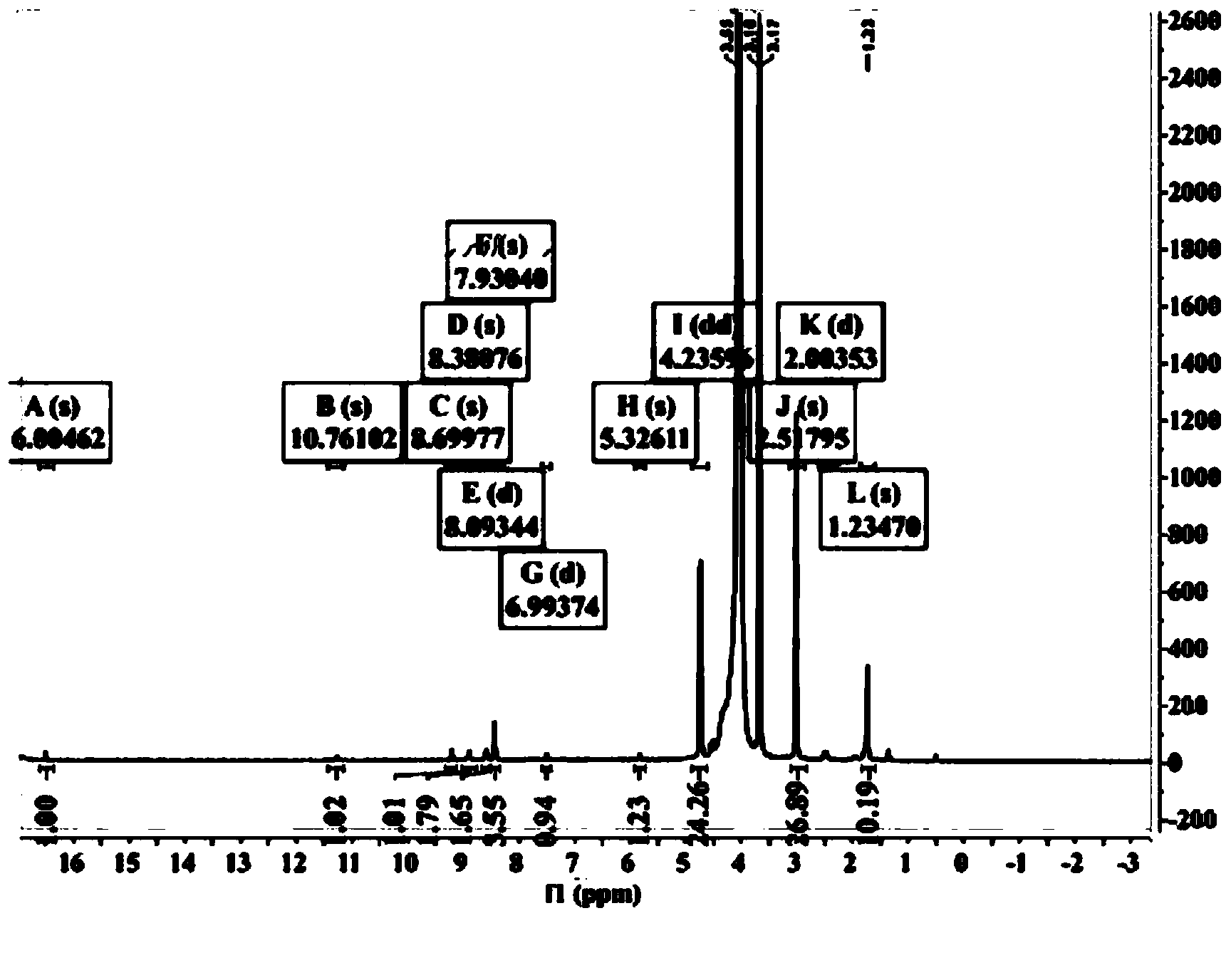

Image

Examples

Embodiment 1

[0036] (1) Diazotization: Add 36.1g of sulfonated para-ester (i.e. 4-β-ethylsulfone sulfate aniline-2-sulfonic acid) to 150mL of water and stir evenly, cool to 0-5°C, add 6.5g of 31% (w / w) hydrochloric acid, beating for 30min, add 24.5g of 30% (w / w) sodium nitrite solution dropwise from the liquid surface at 0~5℃, stir at this temperature for 1 hour, add dropwise and During the reaction process, a slight excess of sodium nitrite is maintained, and excess sodium nitrite is eliminated with sulfamic acid to obtain 4-β-ethylsulfone sulfate aniline-2-sulfonic acid diazonium solution.

[0037] (2) Diazotization: Add 28.1g of p-ester (i.e. p-(β-hydroxyethylsulfone sulfate) aniline) to 150mL of water and stir evenly, then cool to 0-5°C, maintain 0-5°C slowly Slowly add 11.5g of 31% hydrochloric acid and 24.5g of 30% sodium nitrite dropwise, stir at this temperature for 1 hour, use sulfamic acid to eliminate excess sodium nitrite, and obtain the diazonium solution of para-ester.

[00...

Embodiment 2~8

[0046] According to the preparation method described in Example 1 or a similar method, the difference is: the arylamine 1 and arylamine 2 in Table 1 are used to replace the arylamine in step (1) and step (2) respectively to carry out diazo The hydrazone dyes shown in Table 1 can be prepared, and the dyed fabrics appear bright orange.

[0047] Table 1

[0048]

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com