Patents

Literature

47results about How to "Bright and full color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

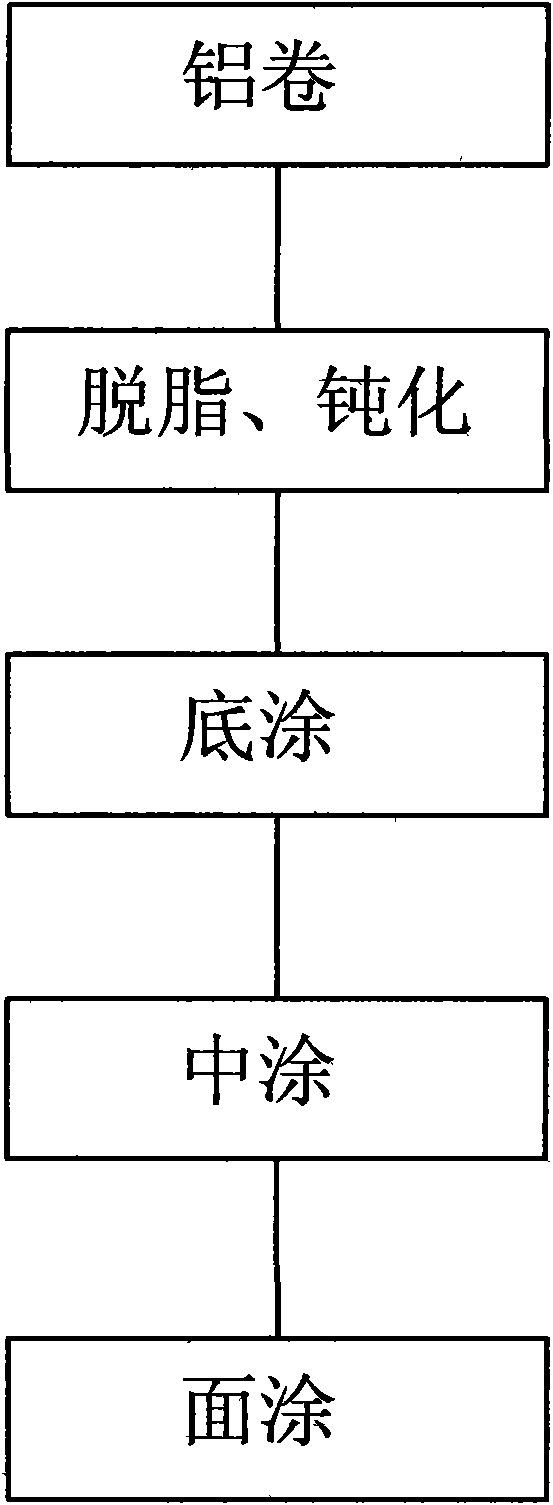

Process for manufacturing discoloration color-coating aluminum plate

ActiveCN101602045ABright and full colorImprove reflective effectPretreated surfacesCoatingsPolyesterFluoropolymer

The invention discloses a process for manufacturing a discoloration color-coating aluminum plate. The process comprises the following steps of: pretreating an aluminum base plate for degreasing and passivation; coating a base coating which is a layer of polyurethane coating on a passivation membrane layer, roasting the base coating in an oven, and forming an organic coating of polyurethane after roasting and membrane forming; coating a middle coating which is a layer of polyester or fluorocarbon coating on the organic coating of polyurethane, roasting the middle coating in the oven, and forming the polyester or fluorocarbon coating after roasting and membrane forming; and coating a surface coating which is a layer of polyester or fluorocarbon varnish mixed with scaly pearly-lustre mica powder on the polyester or fluorocarbon coating, roasting the surface coating in the oven, and forming the discoloration coating after roasting and membrane forming. The color-coating aluminum plate manufactured by the process can show different colors along with changes of a light source and viewing angles of people in the bright light.

Owner:ZHEJIANG WONDERFUL WALL BUILDING MATERIALS

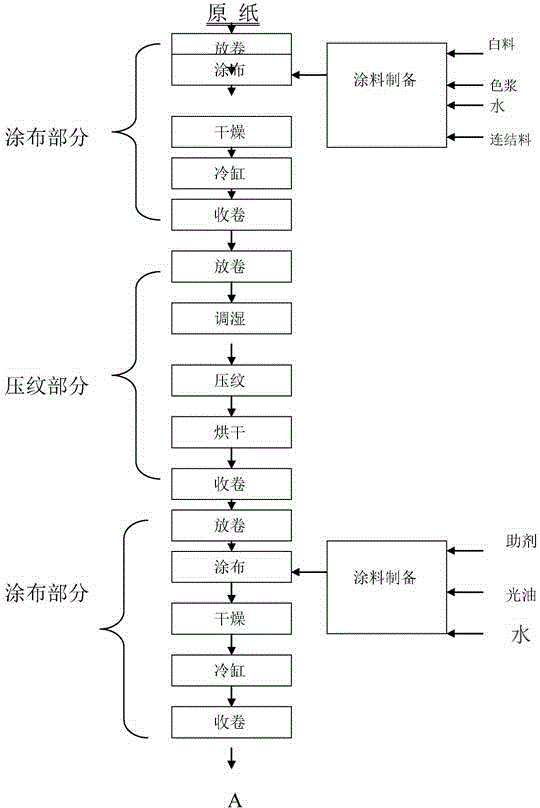

Preparation method of environment-friendly wrapping paper

ActiveCN104674608AImprove water resistanceBright and full colorFlexible coversCoatings with pigmentsSolventPapermaking

The invention relates to the technical field of papermaking and in particular relates to a preparation method of a piece of environment-friendly wrapping paper. Compared with the prior art, the preparation method has the advantages that a new preparation technology and a new preparation formula are adopted, so that water resistance and solvent resistance of the wrapping paper are improved, and the wrapping paper is full and bright in colour; meanwhile, most used materials are easily degradable resin, so that environmental performance of the wrapping paper is also improved.

Owner:JUNYUAN NEW MATERIAL +1

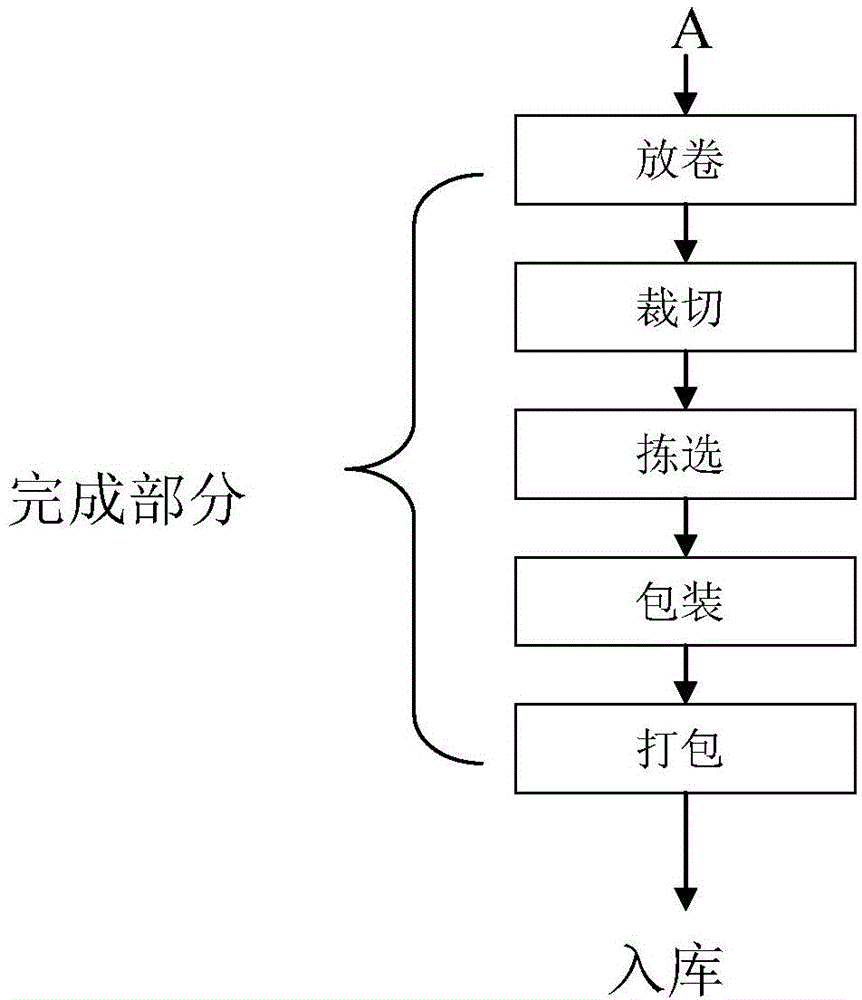

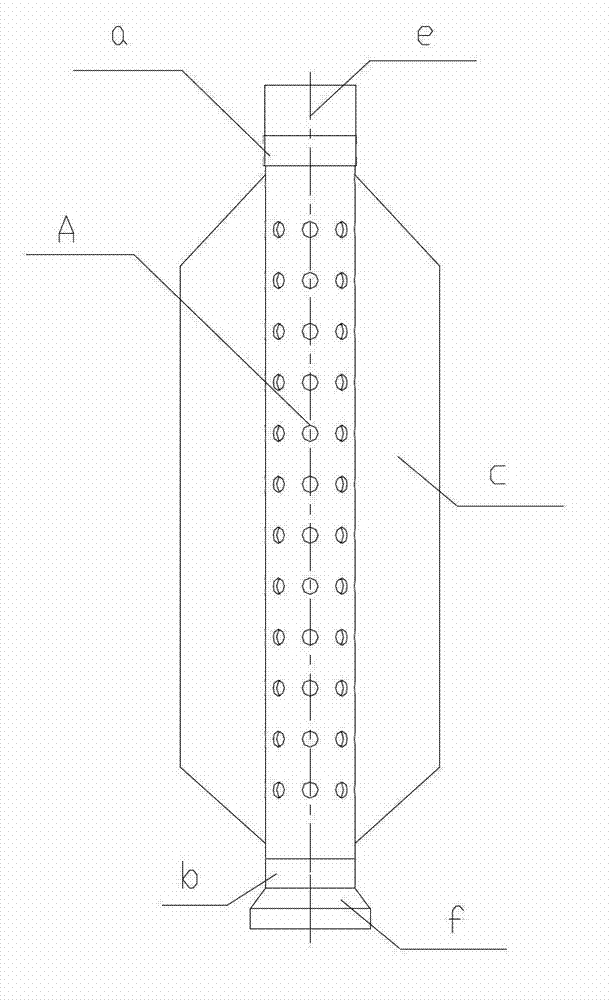

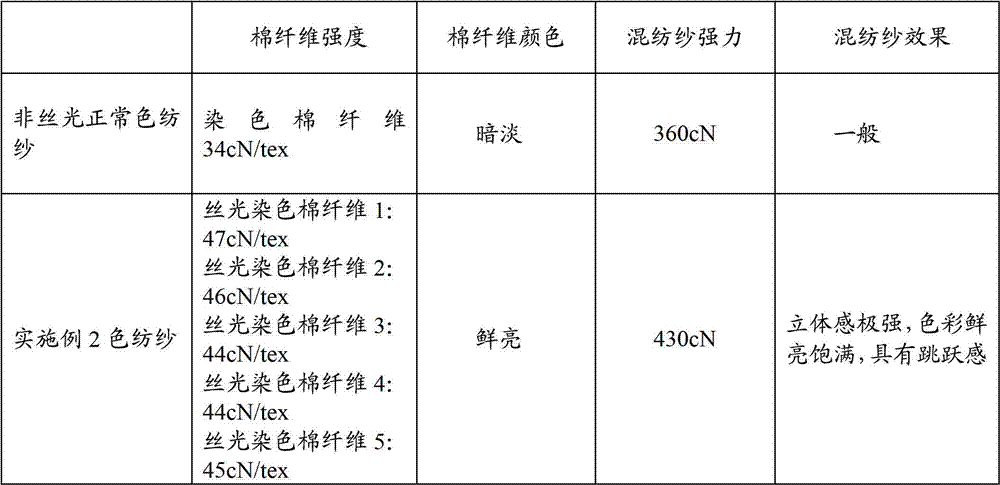

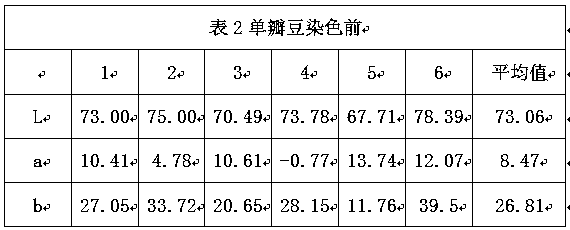

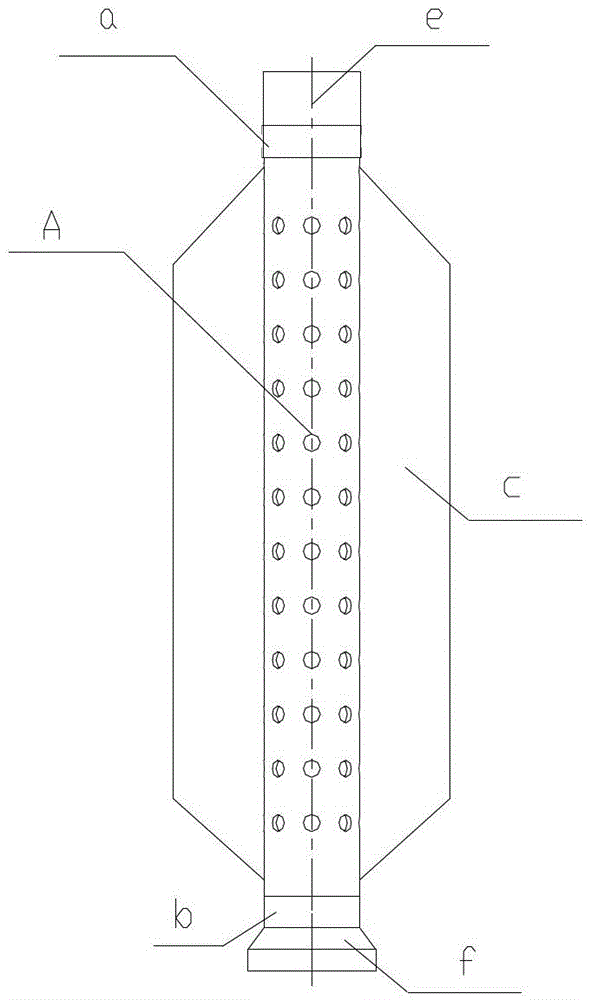

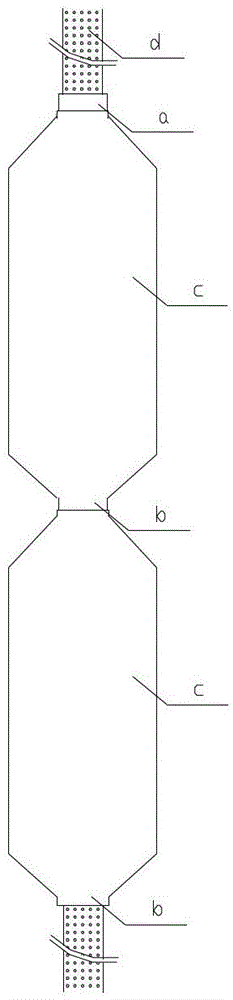

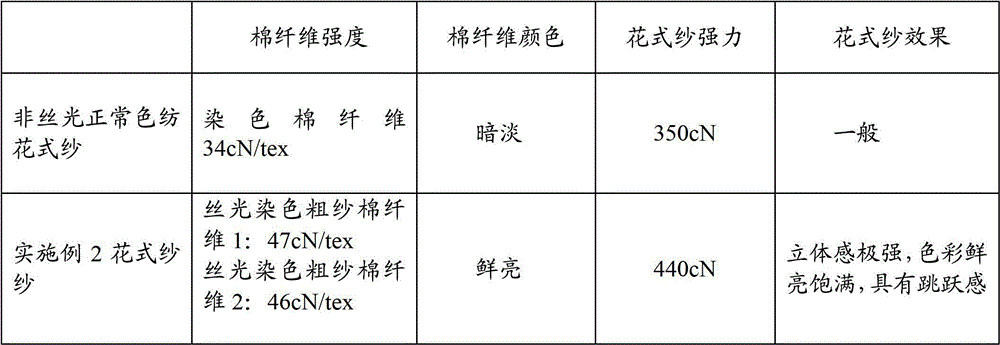

Manufacturing method for colored spun yarn blended with mercerized fiber

ActiveCN102758285AConveniently preparedImprove spinnabilityMercerising of sliversMercerising of tubular fabricsYarnEngineering

The invention discloses a manufacturing method for colored spun yarn blended with mercerized fiber. The manufacturing method comprises the following steps of: preparing rough yarn, mercerizing the rough yarn, dying the rough yarn, drying and loosing the rough yarn, mixing the fiber of the dried rough yarn, carrying out pre-spinning preparation, and spinning. According to the manufacturing method disclosed by the invention, the real mercerized-dyed fiber can be conveniently manufactured by the existing equipment, the fiber intensity of the manufactured mercerized-dyed fiber is greatly enhanced, the manufactured mercerized-dyed fiber is favorable for obviously enhancing the spinnability of the colored spun yarn, the manufactured colored spun yarn is bright and abundant in color, and the stereoscopic impression of the yarn is strong. Meanwhile, the manufacturing method breaks through the limitation that protein fiber which is not alkaline-resisting and the mercerized fiber cannot coexist in the yarn, so that the additional value of cotton fiber is obviously enhanced, and the selection range of customers is enlarged. In addition, the manufacturing method disclosed by the invention is easy to implement, can be implemented with the existing equipment, and provides the possibility and the guarantee for large scale production.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +2

Environment-friendly dyeing technology for cattle hide split leather

ActiveCN106555018AGood flexibilityProvides softnessTanning treatmentPre-tanning chemical treatmentAfter treatmentEngineering

The invention discloses an environment-friendly dyeing technology for cattle hide split leather. The cattle hide split leather is obtained through the technology steps of degreasing and water returning, softening, tanning, dyeing, fixing, after treatment and the like. Clean production is emphasized in the technology process, pollution is little, and very good environment-friendly benefits are achieved; and the cattle hide split leather obtained through production is high in strength, good in hand feeling and full and bright in color.

Owner:福建省永建皮革科技股份有限公司

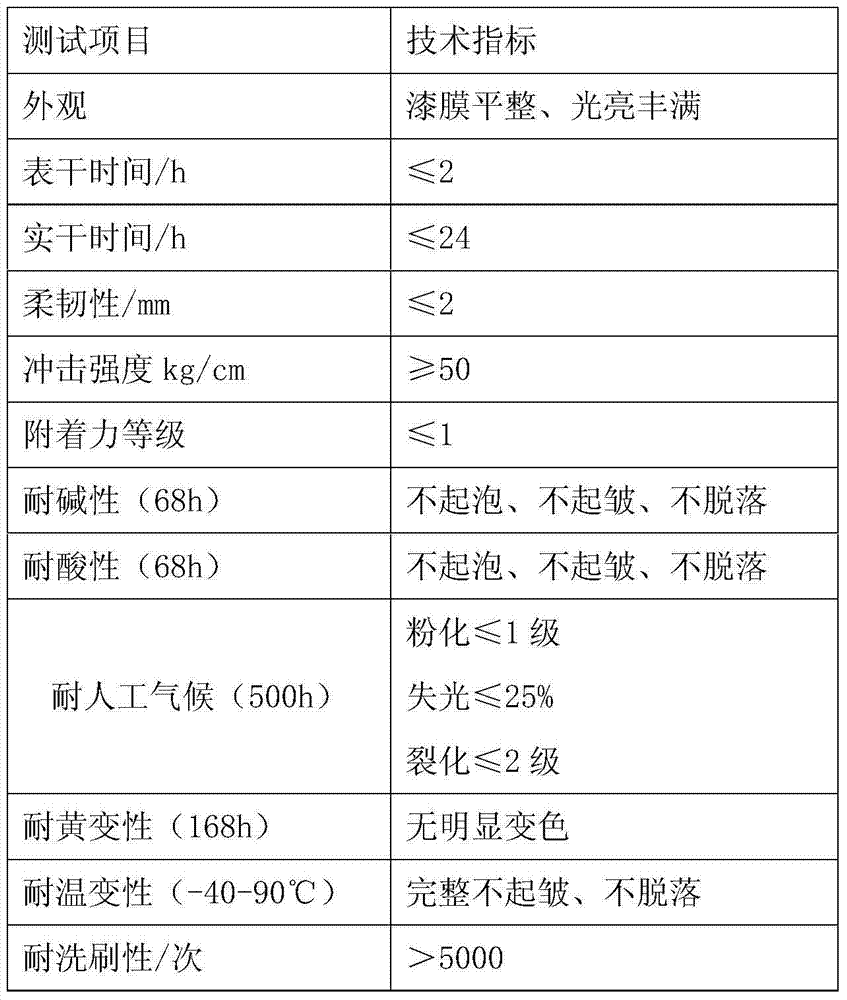

Fluororesin oil paint with weather resistance, temperature resistance and color retention

InactiveCN103694882AStrong adhesionBright and full colorAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinEthylene glycol bis

The invention relates to oil paint and particularly relates to fluororesin oil paint with weather resistance, temperature resistance and color retention. The fluororesin oil paint comprises the following materials in parts by weight: 20-24 parts of fluororesin, 12-15 parts of thermoplastic acrylic resin, 2-3 parts of sodium diacetate, 1-2 parts of ethylene glycol bis-glycidyl ether, 3-4 parts of isocyanuric acid tri-glycidyl ether, 10-12 parts of tripropylene glycol diacryate, 1-2 parts of europium trifluoroacetylacetone, 25-30 parts of urethane acrylate, 2-3 parts of polyacrylamide, 1-2 parts of ferrocene, 2-3 parts of isocyanate, 5-8 parts of epoxidized soybean oil, 1-2 parts of zinc naphthenate, 3-4 parts of diaminodiphenyl-methane, 5-6 parts of additive, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The fluororesin oil paint has the advantages that the adhesive force of a paint film is strong, the color is bright and full, the color retention is lasting and yellowing resistance is achieved, also has the advantages of weather resistance, ageing resistance, temperature change resistance, anti-corrosion and anti-rusting performances and brushing resistance and the like and can be widely applied in protective decoration of articles in various environments.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Process for producing in-glaze color bone china

The invention relates to a process for producing in-glaze color bone china. The surface of a green blank is applied with a layer of mixed glaze material in the general process, the green blank of which the surface is applied with the mixed glaze material is biscuited at a temperature of between 650 and 800 DEG C, then a pattern is drawn on the surface of a biscuit through high-temperature packagepigments, and then the processes such as high-temperature biscuiting and the like are carried out to generate the surface of the biscuit providing more convenience for drawing. The blank body has strong tinting strength and smudging force to achieve the effect of Chinese painting canvas, and tinting and chapped dyeing can be repeatedly carried out on the same position. Bone china finished products produced and processed by the process have the advantages of brilliant and full color, moist pictures, bright glaze surface and light and thin blank body.

Owner:庄助民 +1

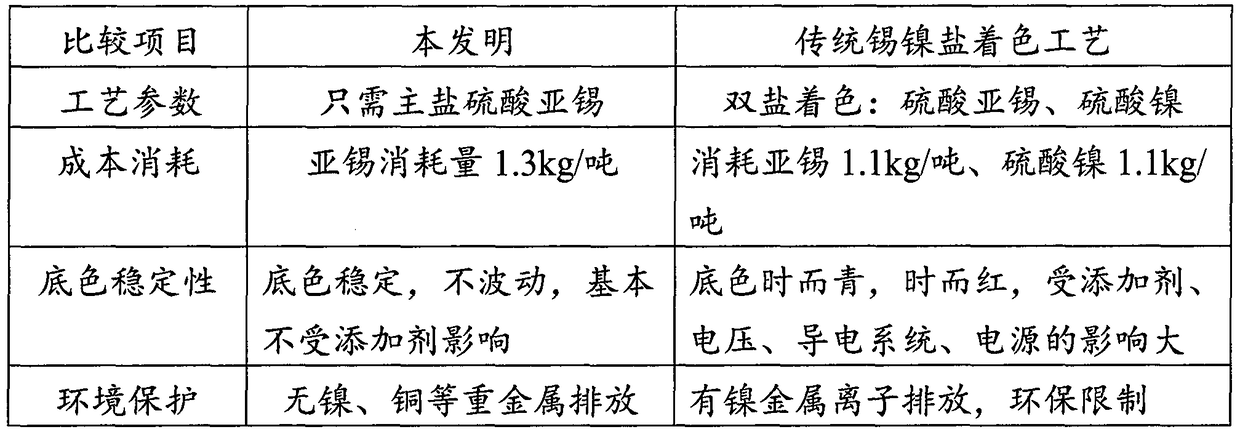

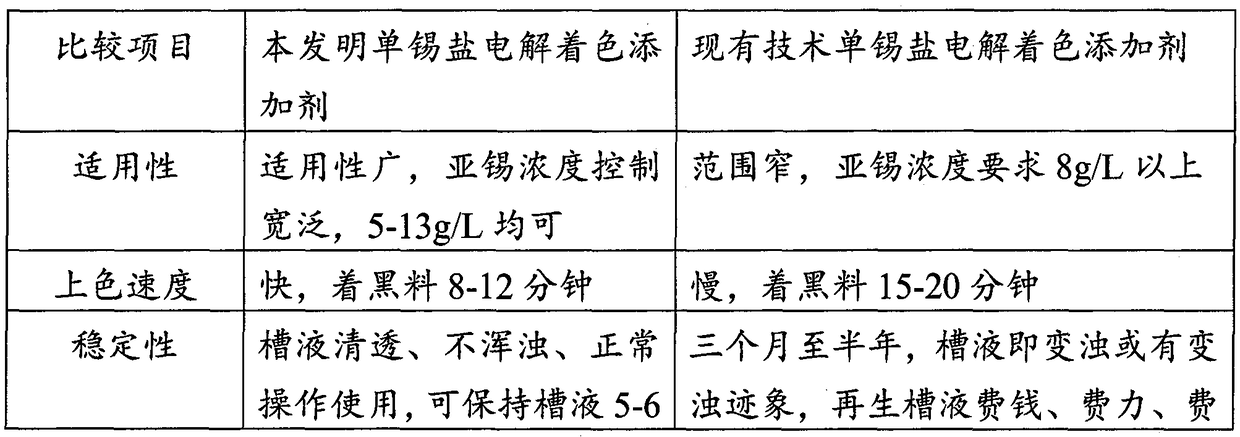

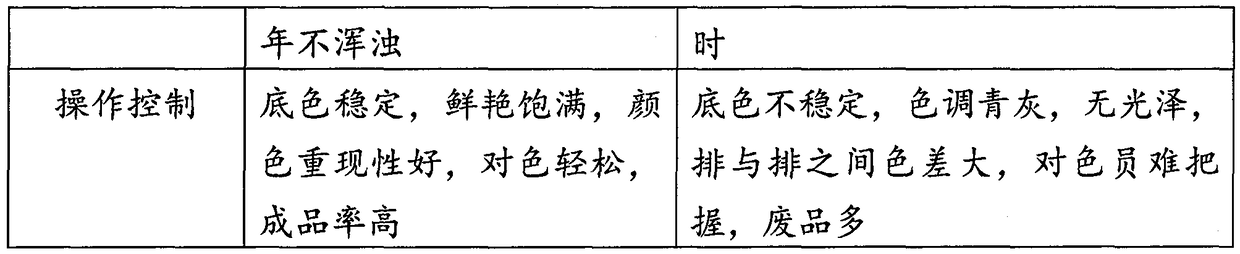

Single tin salt electrolytic coloring additive and application thereof

InactiveCN108342763AAntioxidantProtection stabilitySurface reaction electrolytic coatingZinc phosphateElectrolysis

The invention discloses a single tin salt electrolytic coloring additive. The single tin salt electrolytic coloring additive comprises a complexing agent, a buffer agent, an antioxidant and a surfactant, wherein the antioxidant comprises ferrous sulfate; the single tin salt electrolytic coloring additive also comprises an auxiliary agent containing ferrous sulfate; the auxiliary agent comprises modified amino amide zinc phosphate. The single tin salt electrolytic coloring additive disclosed by the invention has good comprehensive performances, solves the problem that nickel must take part in the reaction in an electrolytic coloring process, and is stable in groove liquid and quick and uniform to color, and the cost can be lowered effectively. Moreover, the single tin salt electrolytic coloring additive is low-carbon, energy-saving and green and environment-friendly, and process and product quality consistent to those of a double salt system can be obtained.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

Yellow cadmium-wrapped pigment, ceramic ink and preparation method thereof

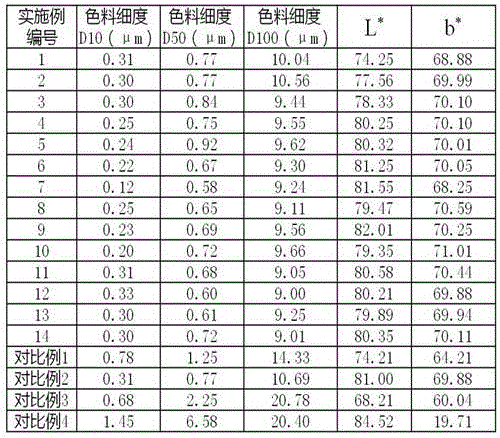

The invention discloses a yellow cadmium-wrapped pigment. The fineness of pigment powder is 0.5 to 3 [mu]m. The invention further provides a method of the yellow cadmium-wrapped pigment. The method comprises the following steps: putting cadmium sulfate, zirconium oxychloride, thiourea, urea, white carbon black, polycarboxylate and polyvinylpyrrolidone which serve as raw materials into water, mixing and stirring till the raw materials are dissolved, putting the solution into a reaction kettle, carrying out reaction under conditions of the temperature of 60 to 200 DEG C and rotating speed of 100 to 300 r / min for 5 to 24 hours, after the reaction is completed, carrying out natural cooling to obtain a pigment precursor, and carrying out washing, sintering and drying to obtain the yellow cadmium-wrapped pigment finished product. The mole ratio of the cadmium sulfate, the zirconium oxychloride, the thiourea, the urea, the white carbon black, the polycarboxylate and the polyvinylpyrrolidone is (6 to 15): (25 to 40): (5 to 35): (60 to 250): (10 to 50): (0.02 to 8.0): (0.01 to 4.0).

Owner:FOSHAN HUAYI CERAMIC COLORS CO LTD

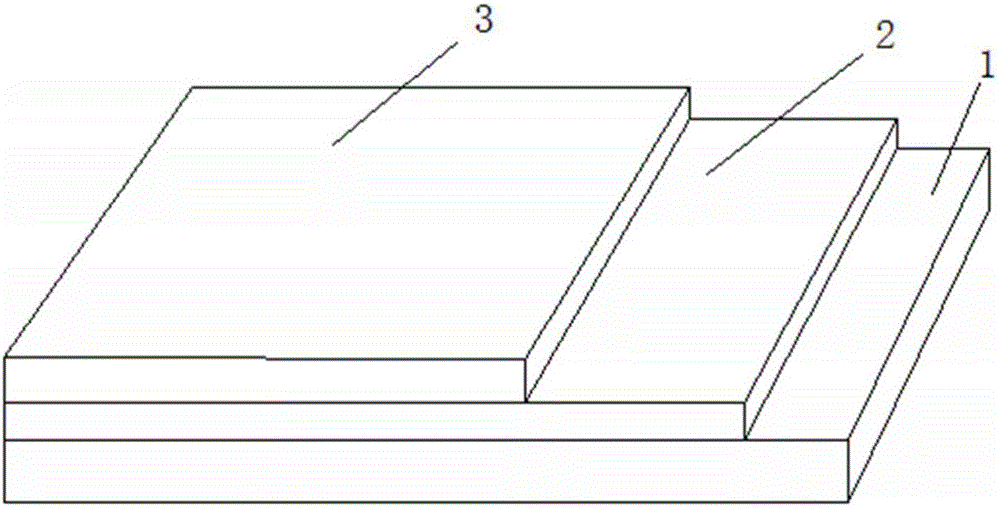

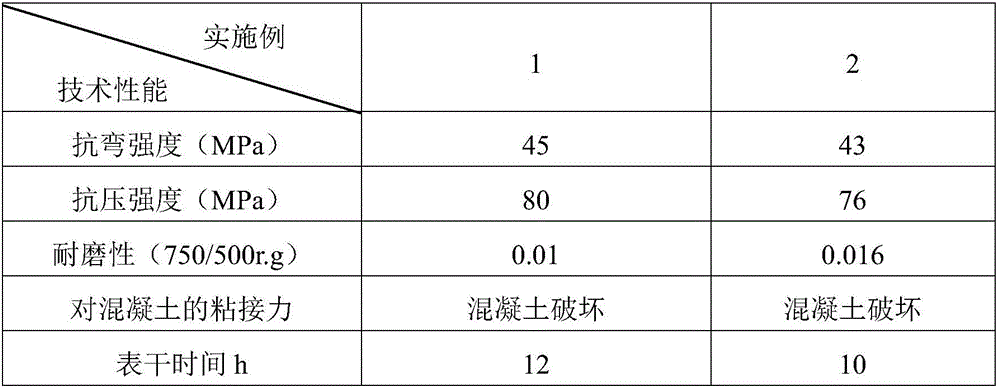

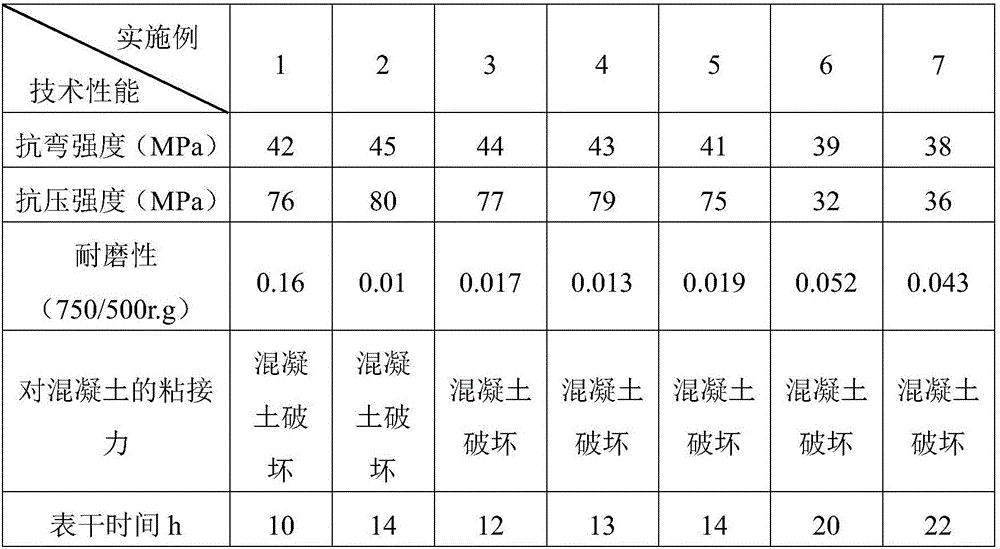

Self-leveling dry powder mortar and preparation method thereof, terrace manufactured from dry powder mortar, and construction method of terrace

The invention discloses self-leveling dry powder mortar and a preparation method thereof, a terrace manufactured from the dry powder mortar, and a construction method of the terrace. The dry powder mortar is prepared from common portland cement, 4-8-mesh mineral substance aggregates, 10-30-mesh quartz sand, 60-140-mesh quartz sand, methycellulose, dispersible emulsion powder, a high-efficiency water reducing agent, an antifoaming agent, rutile type titanium dioxide and high-strength high-mold polyvinylalcohol fibers. The preparation method comprises the following steps of after the three kinds of the mineral substance aggregates are blended, adding the common portland cement, the methycellulose, the dispersible emulsion powder, the high-efficiency water reducing agent, the antifoaming agent, the rutile type titanium dioxide and the high-strength high-mold polyvinylalcohol fibers, and performing blending. The self-leveling dry powder mortar and the preparation method thereof disclosed by the invention have the advantages that the dry powder mortar is high in surface compressive strength, high in density, high in tenacity and high in crack resistance; besides, the self-leveling dry powder mortar is full and bright in color, and has definite decoration properties; and in addition, the preparation technology is simple, complicated synthesis equipment is not needed, the production cost is reduced, and the self-leveling dry powder mortar is environmentally-friendly and pollution-free.

Owner:南京徽腾环保科技有限公司

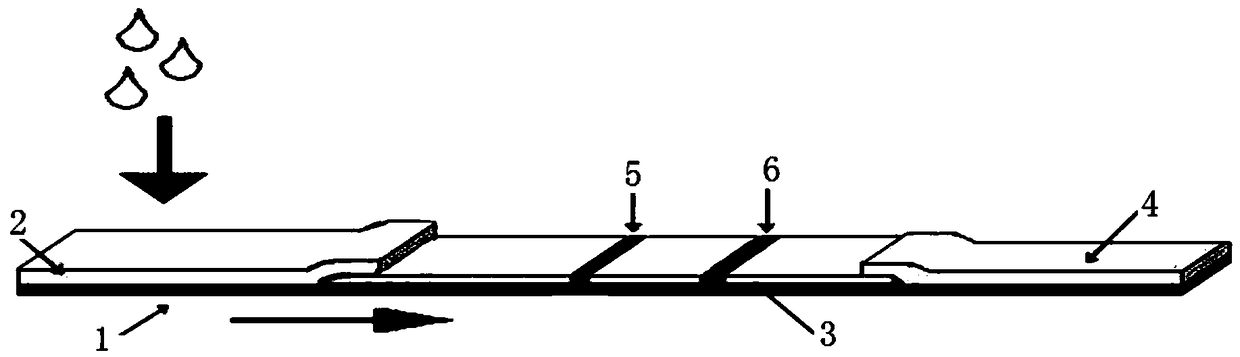

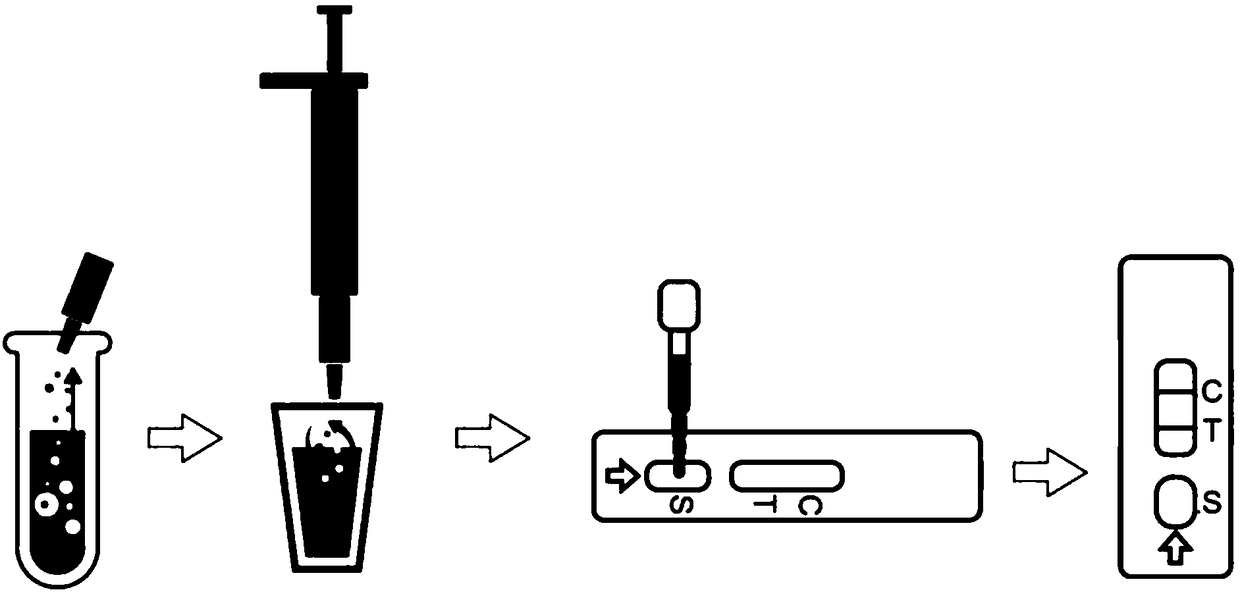

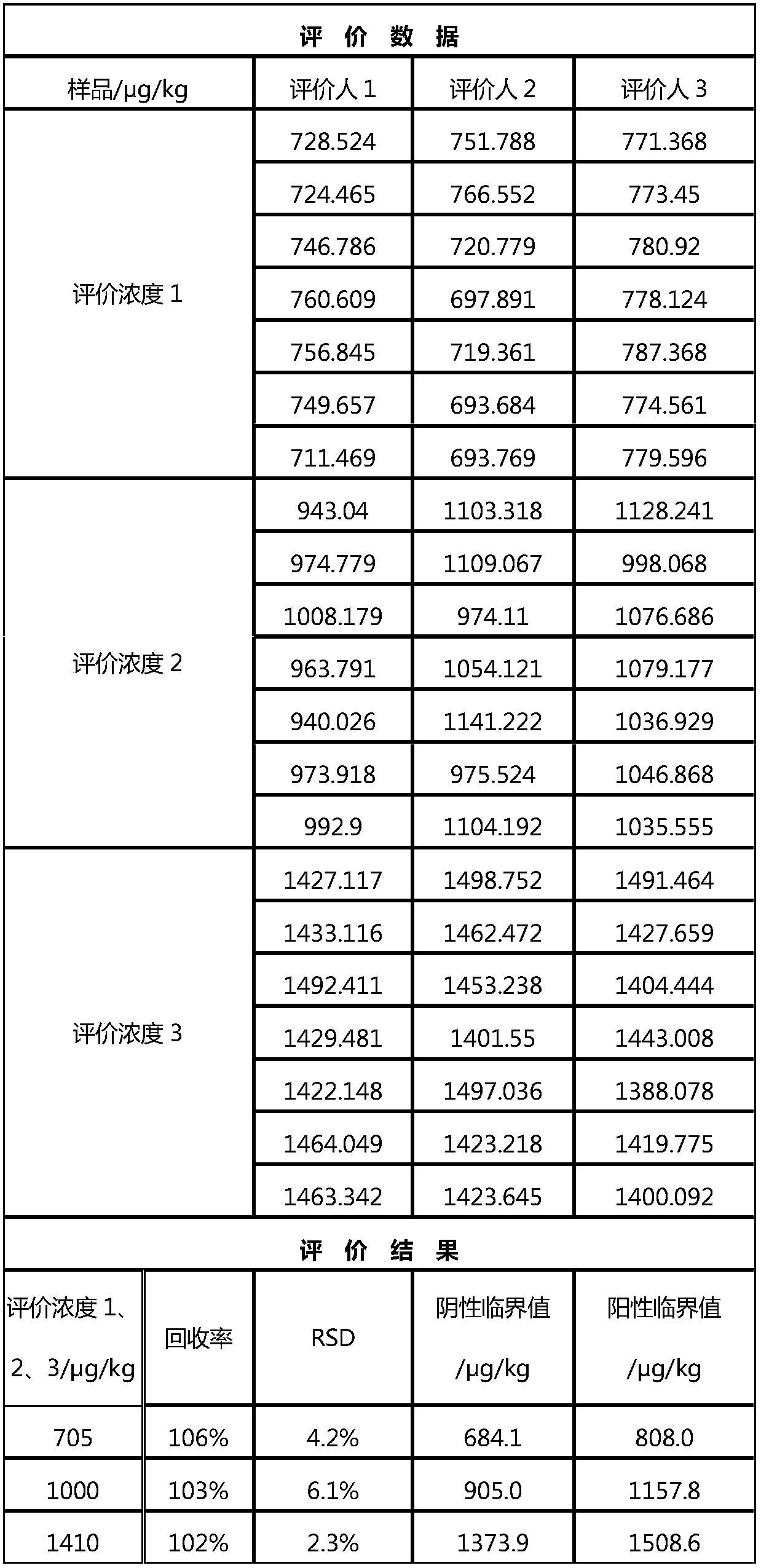

Quantitative rapid deoxynivalenol detection card and detection method thereof

InactiveCN108761075AEasy to makeBright and full colorMaterial analysisBatch productionQuality control

The invention discloses a quantitative rapid deoxynivalenol detection card which comprises a sample pad, a nitrocellulose membrane and an absorbent pad arranged on a bottom plate in sequence, whereina detection line coated with a DON hapten-carrier protein coupling agent and a quality control line coated with a goat anti-rat antibody are arranged on the nitrocellulose membrane; a to-be-detected sample solution is mixed and incubated with latex microspheres coupled with a DON antibody before dropping to the sample pad. The detection method comprises the steps: preheating, adding liquid, incubating, reacting and reading the result. The detection card disclosed by the invention does not need a release pad containing a gold-labelled antibody and is used for detecting the latex microspheres coupled with the DON antibody mixed with the sample solution, the color is bright and easy to determine, and the coupling antibody is in a chemical bond coupling state, has excellent physical adsorptionstability with colloidal gold and is high in detection accuracy and precision degree; the batch-to-batch difference is small, and the cost is low; in addition, the detection method of the detection card disclosed by the invention is simple in operation and suitable for batch production and application.

Owner:HEBEI ELISHA BIOTECH CO LTD

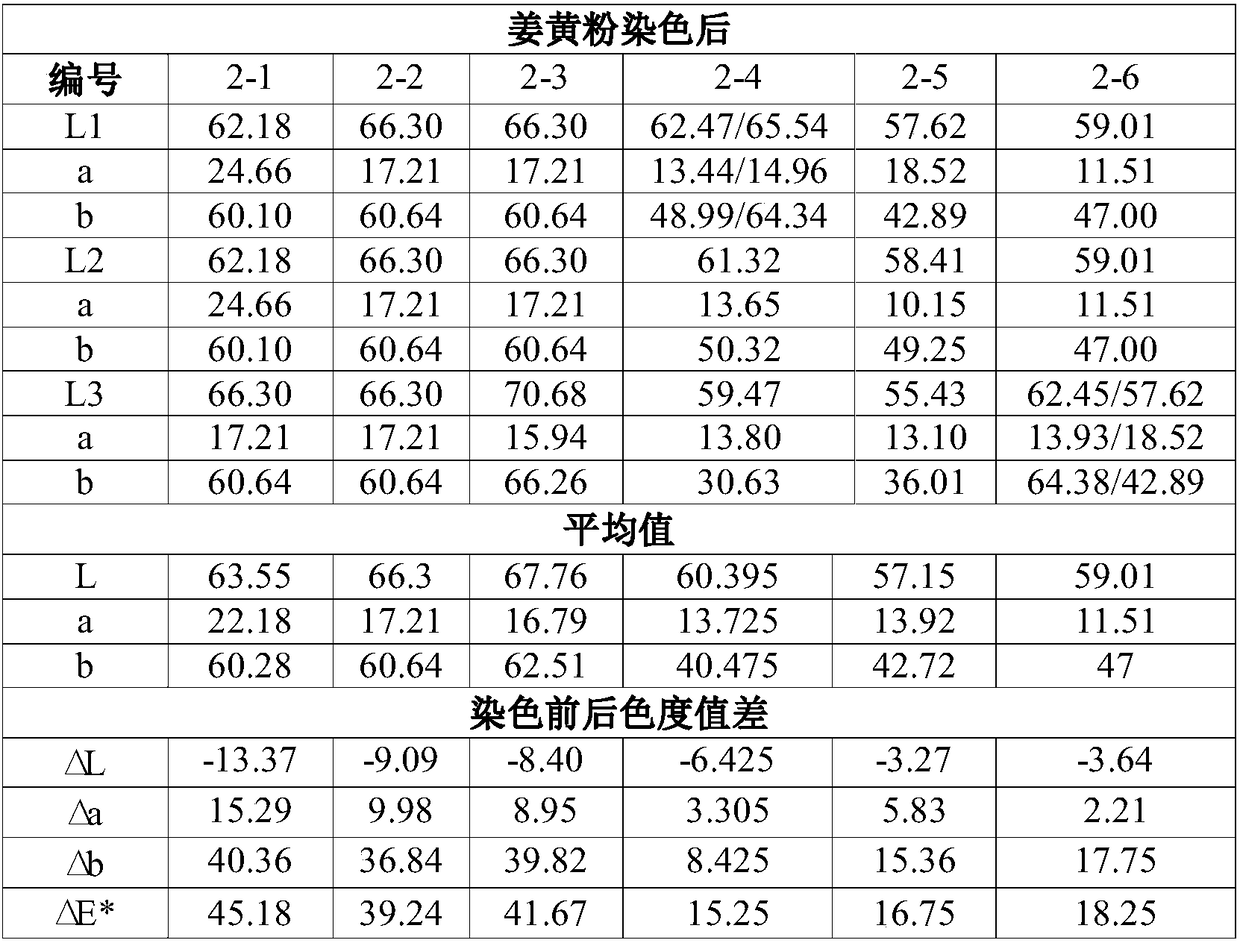

Method for rapidly dyeing wooden veneer by utilizing turmeric powder

InactiveCN108481493ABright and full colorLong lasting colorWood treatment detailsIndian saffronControllability

The invention relates to a method for rapidly dyeing a wooden veneer by utilizing turmeric powder. The method comprises the following steps: firstly, drying the wooden veneer at 45 to 55 DEG C until the weight is constant; then immersing the dried wooden veneer into an ethanol solution; heating and steaming; then fishing out the wooden veneer; after washing the wooden veneer with distilled water,putting the wooden veneer into a drying kiln and drying until the moisture content is 6 to 10 percent; immersing the dried veneer into a turmeric powder extracting solution; after immersing for 2 to 5h, fishing out the veneer; washing and drying. According to the method provided by the invention, a natural dyestuff turmeric is used as a dyeing agent; the natural dyestuff is biodegradable and doesnot contain substances harmful to human bodies; the turmeric also has an antibacterial effect and is healthy and environmentally friendly. The dyeing method provide by the invention has low requirements on equipment, is easy to operate and has strong controllability, so that the dyeing method can be used for large-scale production; the dyed veneer has a bright and full color and a dyeing solutionhas high water fastness and strong dyeing performance; the dyeing method has extremely small damages to wood and no formaldehyde is released; the wooden veneer has a lasting color and antibacterial performance and can be used for preparing wooden tableware and wooden toys for children.

Owner:NANJING FORESTRY UNIV

Decoration wall plate and production process thereof

The invention discloses a decoration wall plate which comprises the following components in parts by mass: 40-50 parts of PVC powder, 20-30 parts of calcium carbonate powder, 30-40 parts of wood flour, 10-20 parts of toner, 15-20 parts of sandalwood powder, 5-10 parts of rose essence, 2-5 parts of a plasticizer, 10-15 parts of a foaming regulator, 2-3 parts of a lubricant, 5-10 parts of a toughening agent, 3-5 parts of a reinforcing agent, 3-8 parts of an antioxidant and 4-6 parts of an anti-aging agent. The decoration wall plate has aromatic odor, is free of toxin or irritation, bright and full in color, hard in texture, not easy to deform, excellent in anti-aging properties and beneficial to market popularization and application.

Owner:嘉兴市三一阳光家居科技股份有限公司

Heat-resistant and flame-retardant anti-ultraviolet aging paint

InactiveCN103694868AFast dryingBright and full colorPolyester coatingsEpoxyDiethylene glycol monobutyl ether

The invention relates to paint, and particularly relates to heat-resistant and flame-retardant anti-ultraviolet aging paint. The paint disclosed by the invention is prepared from the following raw materials in parts by weight: 20-24 parts of long oil alkyd resin, 20-24 parts of amino resin, 3-4 parts of sodium hexametaphosphate, 3-5 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), 1-2 parts of triethanolamine, 3-5 parts of aluminium tripolyphosphate, 3-5 parts of titanium dioxide, 1-2 parts of barium metaborate, 1-2 parts of 2,2-dibromo-3-nitrilopionamide, 2-3 parts of sodium tetraborate, 2-3 parts of sodium thiocyanate, 2-6 parts of hexabromocyclododecane, 3-4 parts of diethylene glycol monobutyl ether, 8-10 parts of propylene glycol methyl ether acetate, 1-2 parts of accelerant Na-22, 12-14 parts of nanosilicon dioxide, 2-3 parts of epoxy flaxseed oil, 3-4 parts of cobalt naphthenate, 1-2 parts of tributyl tin chloride, 5-6 parts of assistant, 10-12 parts of xylene and 10-12 parts of butyl acetate. The paint film of the paint disclosed by the invention is high in drying speed, bright and full in color and luster, lasting in color retaining property, good in thermal denaturation, heat-resistant and flame-retardant, weatherproof and anti-ageing, and ultraviolet irradiation resistant, and can be applied to beautiful protection of articles in various environments.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Weather-resistant and temperature-resistant color-retaining fluororesin paint

InactiveCN103881558AStrong adhesionBright and full colorPolyurea/polyurethane coatingsResistAcrylic resin

The invention relates to paint, in particular to weather-resistant and temperature-resistant color-retaining fluororesin paint. The paint is made from the following raw materials in parts by weight: 20-24 parts of fluororesin, 12-15 parts of thermoplastic acrylic resin, 2-3 parts of sodium diacetate, 1-2 parts of glycol diglycidyl ether, 3-4 parts of triglycidyl isocyanurate, 10-12 parts of tri(propyleneglycol)diacrylate, 1-2 parts of europium trifluoroacetylacetone, 25-30 parts of urethane acrylate, 2-3 parts of polyacrylamide, 1-2 parts of dicyclopentadienyl iron, 2-3 parts of isocyanate, 5-8 parts of epoxidized soybean oil, 1-2 parts of zinc naphthenate, 3-4 parts of diaminodiphenyl-methane, 5-6 parts of aid, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The paint is high in paint film adhesion and bright and full in color, retains color for a long time and resists yellowing, has the advantages of weather resistance, ageing resistance, temperature change resistance, corrosion resistance, rust resistance, erosion resistance and the like, and can be widely applied to protection and decoration of articles in various environments.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

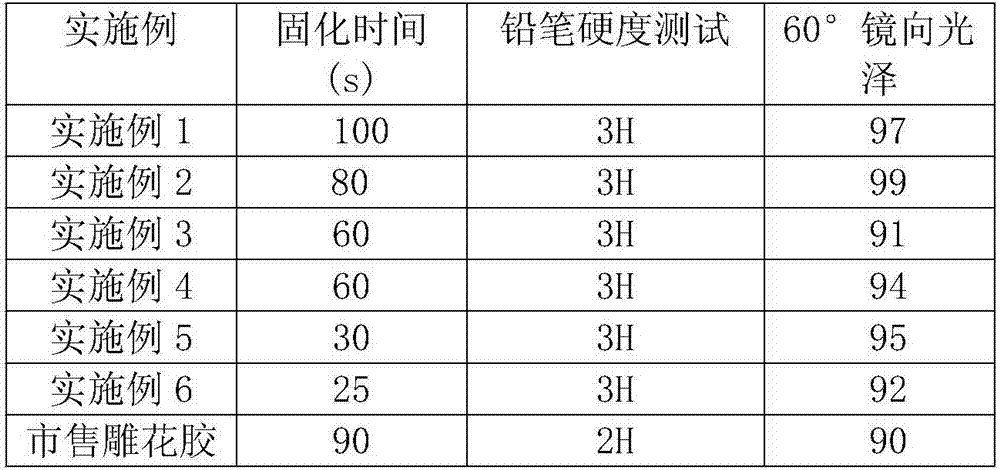

Rapid molding pattern carving glue and preparation method thereof

The present invention discloses a rapid molding pattern carving glue and a preparation method thereof, wherein the rapid molding pattern carving glue comprises an acrylic acid monomer / methacrylic acid monomer, a light starter, polymerized rosin, a filler, and a coloring agent. According to the present invention, after the product performs pattern carving, the molding is rapid, the glue adhesion is good, and a certain hardness and toughness can be provided so as to avoid the damage caused by collision, such that the rapid molding pattern carving glue can be used in the nail beautifying field.

Owner:郑州外思创造力文化传播有限公司

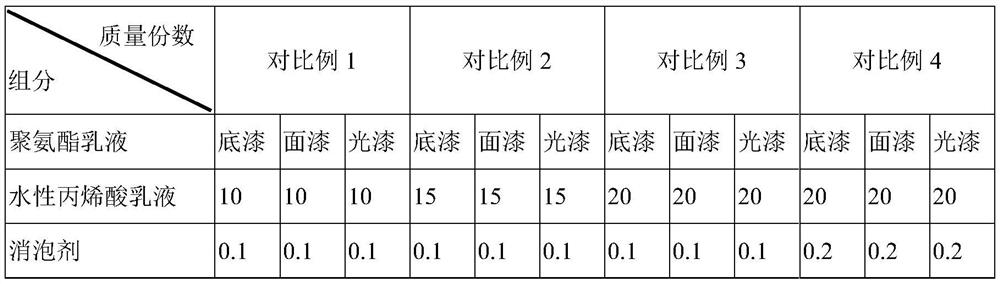

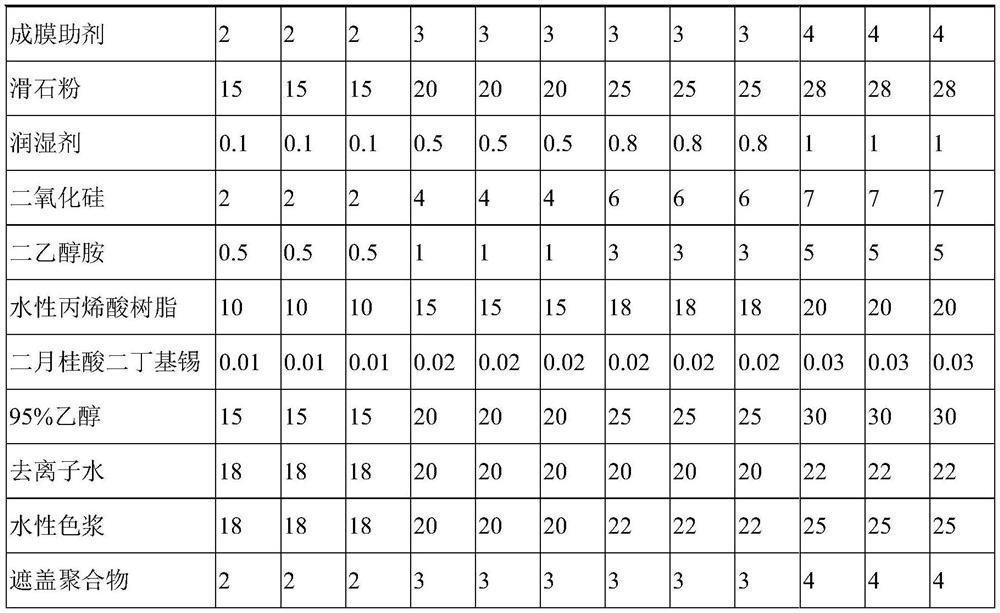

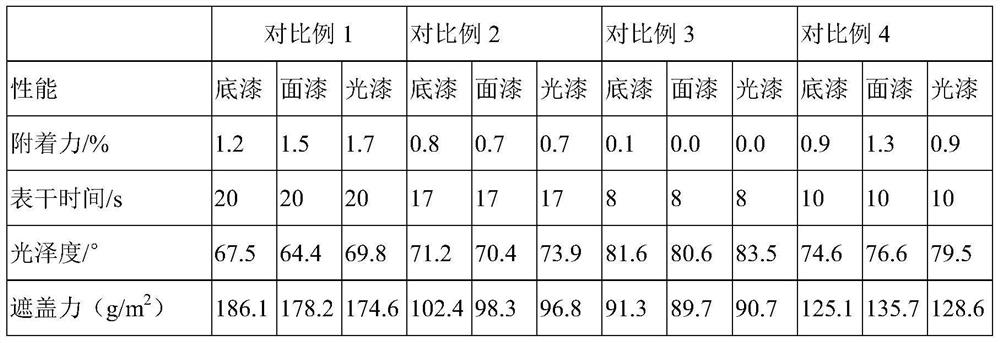

Water-based paint suitable for continuous production of pencils and preparation method thereof

PendingCN112521812AMaintain glossMeet the requirements of quick dryingPolyurea/polyurethane coatingsOrganic chemistryMaterials science

The invention relates to a water-based paint suitable for continuous production of pencils and a preparation method thereof. According to the industrial production requirements of pencils, the basic formula of the water-based paint is improved, water-based resin is selected, water is used as a main solvent, a small amount of an environment-friendly cosolvent is added, no benzene series or ester solvent is contained, and a proper drying aid, coloring aid and brightening aid are selected, so that the quick-drying effects of 10s surface drying and 60s hard drying are achieved, and the requirements of existing pencil continuous production equipment on quick drying of the water-based paint can be completely met. Meanwhile, other adverse factors caused by additives such as a quick-drying aid tothe water-based paint are eliminated, so that the water-based paint formula disclosed by the invention not only realizes 10s surface drying, but also can achieve good adhesive force and glossiness.

Owner:浙江贝斯特软化板有限公司

Temperature-resistant flame-retardant ultraviolet aging-resistant paint

InactiveCN103881546AFast dryingBright and full colorFireproof paintsPolyester coatingsTriethanolamineN-Butyl acetate

The invention relates to a paint and in particular relates to temperature-resistant flame-retardant ultraviolet aging-resistant paint. The paint is prepared from the following raw materials in parts by weight: 20-24 parts of long oil alkyd resin, 20-24 parts of amino resin, 3-4 parts of sodium hexametaphosphate, 3-5 parts of dodecanol, 1-2 parts of triethanolamine, 3-5 parts of aluminum triphosphate, 3-5 parts of titanium dioxide, 1-2 parts of barium metaborate, 1-2 parts of 2,2-dibromo-3-nitrilopionamide, 2-3 parts of sodium tetraborate, 2-3 parts of sodium thiocyanate, 2-6 parts of hexabromocyclododecane, 3-4 parts of diethylene glycol monobutyl ether, 8-10 parts of propylene glycol methyl ether acetate, 1-2 parts of accelerant Na-22, 12-14 parts of nano-silica, 2-3 parts of epoxy linseed oil, 3-4 parts of cobalt naphthenate, 1-2 parts of tributyl tin trichloride, 5-6 parts of aids, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The oil is high in film drying speed, full in color and brightness, long-lasting in color, resistant to temperature modification, fire-resistant, weather-resistant and ageing-resistant and resistant to ultraviolet irradiation, and can be used for protecting attractive appearance of objects in multiple environments.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

UV printable ink

The invention relates to a UV printable ink which can be screen-printed on a nonabsorbing substrate (such as an optical disk), and an image wanted by a customer can be printed by using the ink with a common printer, therefore, the personalized demands are achieved. The ink comprises the following components in percent by weight: 25-30 percent of water-based UV monomer, 2-5 percent of deionized water, 20-28 percent of water-based amino acrylic resin, 3-9 percent of water-based photo initiator, 10-18 percent of filler, 10-20 percent of nano material and 1-2 percent of auxiliary agent. The UV printable ink has the advantages of rapid dryness, little taste, clear printed image, bright and full color and water resistance.

Owner:广州市尤特新材料有限公司

Process for producing in-glaze color bone china

The invention relates to a process for producing in-glaze color bone china. The surface of a green blank is applied with a layer of mixed glaze material in the general process, the green blank of which the surface is applied with the mixed glaze material is biscuited at a temperature of between 650 and 800 DEG C, then a pattern is drawn on the surface of a biscuit through high-temperature packagepigments, and then the processes such as high-temperature biscuiting and the like are carried out to generate the surface of the biscuit providing more convenience for drawing. The blank body has strong tinting strength and smudging force to achieve the effect of Chinese painting canvas, and tinting and chapped dyeing can be repeatedly carried out on the same position. Bone china finished products produced and processed by the process have the advantages of brilliant and full color, moist pictures, bright glaze surface and light and thin blank body.

Owner:庄助民 +1

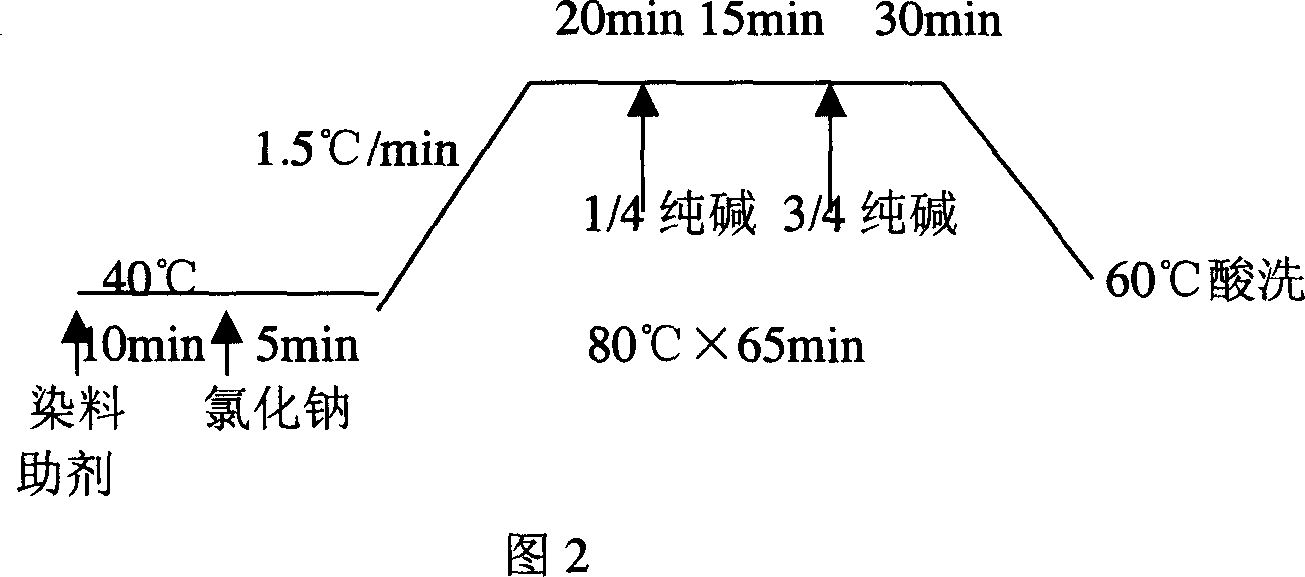

Method for dyeing polyvinyl-alcohol based fabric

InactiveCN101074539ASolve the problem of dyeingUniform dyeingFibre typesBleaching apparatusDyeingPolyvinyl alcohol

This invention discloses one dye method for vinylon fiber-milk products. By adopting bleaching, Cibacron dye and the improvement for the post treatment, this method resolves the problem of dye difficult for vinylon fiber-milk products, it achieve the goals of high dyeing rate, stain uniform, bright full color, color fastness and small damage to the milk fiber.

Owner:嫩江华强蛋白纤维有限责任公司 +1

Coating technique of imitated scented rosewood

ActiveCN108608541ALow equipment requirementsReduce manufacturing costNatural patternsWood treatment detailsEngineeringRosewood

The invention relates to a coating technique of imitated scented rosewood. The coating technique comprises the following steps: 1) veneer pretreatment; 2) decorative design drawing with potassium permanganate; 3) treatment with sodium hydroxide; 4) dyeing; 5) porefilling and coloring; 6) brushing with primer; 7) clear coating; and 8) wood final treatment. The coating technique has the advantages that 1) monopetalanthus has luster, crisscross lines, fine and uniform structure, intermediate strength, high rotary cutting performance, corrosion resistance and the like, and is easy to process; 2) the color is bright and full, the imitation chroma difference is small, the dyeing is strong, an extremely small color difference exists between the scented rosewood and the dalbergia odorifera, and the destructive effect on wood is extremely small; 3) the device requirement is low, the operation is easy, the controllability is high, the production cost is low, and the imitated scented rosewood canbe used for large-scale industrial production, and has a good actual application prospect; 4) sandalwood is added on the basis of imitating rosewood color to bring smell enjoyment; and 5) healthy andenvironmental-friendly natural dye is selected to meet the current requirement on environmental-friendly and green ecology.

Owner:海太欧林集团华南有限公司

Cashmere fiber dyeing method for improving wash-resistant firmness

InactiveCN107503198AAvoid damageFeel goodUltrasonic/sonic fibre treatmentBiochemical treatment with enzymes/microorganismsPectinaseFiber

The invention belongs to the technical field of cashmere fiber dyeing, and particularly relates to a cashmere fiber dyeing method for improving the wash-resistant firmness. The method comprises the steps of cashmere fiber pretreatment, plasma treatment, soaking and alkaline pectinase solution spray coating after cold storage. Compared with the prior art, the method has the following advantages that the cashmere fiber is pretreated; the softening, bleaching and sterilization effects can be achieved; the subsequent coloring uniformity can be improved; after the drying, plasma treatment is performed, so that the scale form structure on the surface of the cashmere fiber can be changed; the cashmere fiber is enhanced; the distribution is realized in the dyeing process; the ultrasonic treatment is performed, so that the dyeing rate can reaches 97 percent or higher; the color fading cannot easily occur; the dyeing process is simple; the damage to the cashmere fiber is small; after the cold storage treatment, the treatment is performed by the alkaline pectinase, so that hollow groove positions of the cashmere fiber scales can be filled; a reticular crosslinking film structure can be formed, so that the dyed finished product has the vivid and full color and luster; meanwhile, the color fastening effect is further enhanced; the handfeel of the fiber is improved.

Owner:安徽宝源帽业有限公司

Mixing method for screen printing ink

The invention discloses a mixing method for screen printing ink. The mixing method comprises the following steps: analyzing color phases according to an original printing manuscript, determining which types of printing ink can be mixed properly, determining a main color and auxiliary colors, determining a proportion, and reducing the number of types of printing ink of different colors as far as possible; then pre-mixing, spraying mixed printing ink on one side of a piece of paper, scraping the mixed printing ink to ensure that the thickness of the mixed printing ink is as thick as required via another piece of paper, comparing the scrapped printing ink with the original printing manuscript to judge whether the mixed printing ink is proper or not; finally, according to the comparing result, carrying out printing on a sample or continue pre-mixing till the comparing result shows that the mixed printing ink is proper, carrying out printing on the sample, and mixing according to the pre-mixing proportion if the printed sample meets requirements. The mixing method has the advantage that the brightness and the saturation of printing ink mixed according to the mixing method are improved.

Owner:ZHEJIANG DONGHE PRINTING PACKAGING CO LTD

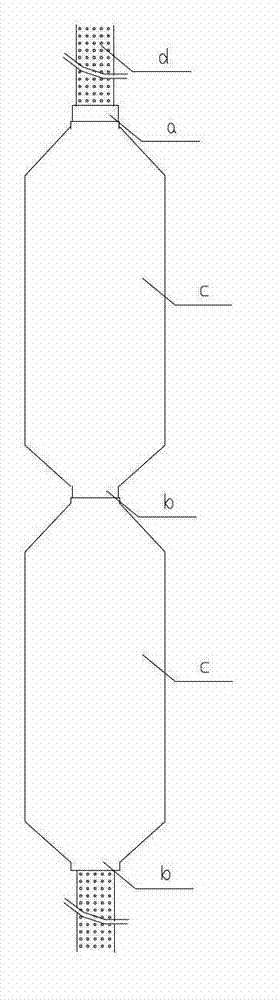

Fancy yarn and method of making the same

ActiveCN102776639BImprove spinnabilityBright and full colorMercerising of yarns/threads/filamentsDyeing processYarnSpinning

The invention discloses fancy yarn and a manufacturing process thereof. The process comprises the steps of preparing rove-mercerizing the rove or mercerizing the rove and dyeing-drying the rove-spinning. According to the process, real mercerized fibers or mercerized dyed fibers can be produced conveniently through existing devices, the fiber strength of produced mercerized fibers or the fiber strength of produced mercerized dyed fibers is greatly improved, the spinnability of the fancy yarn is greatly improved, the produced fancy yarn is bright and full in color and high in dimensionality of the yarn, the problem that protein fiber yarn which is not alkali-resistant and mercerized fibers can not simultaneously exist in the yarn is solved, the additional value of cotton fibers is greatly improved, and the selection range of consumers is enlarged. The process is easy to implement and can be easily achieved through existing devices, and the probability and the guarantee are provided for large-scale production.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +2

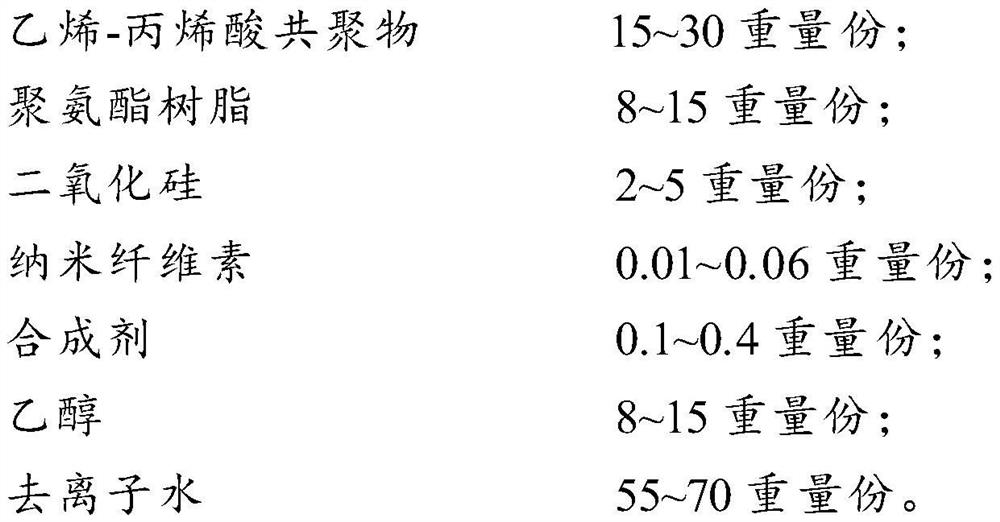

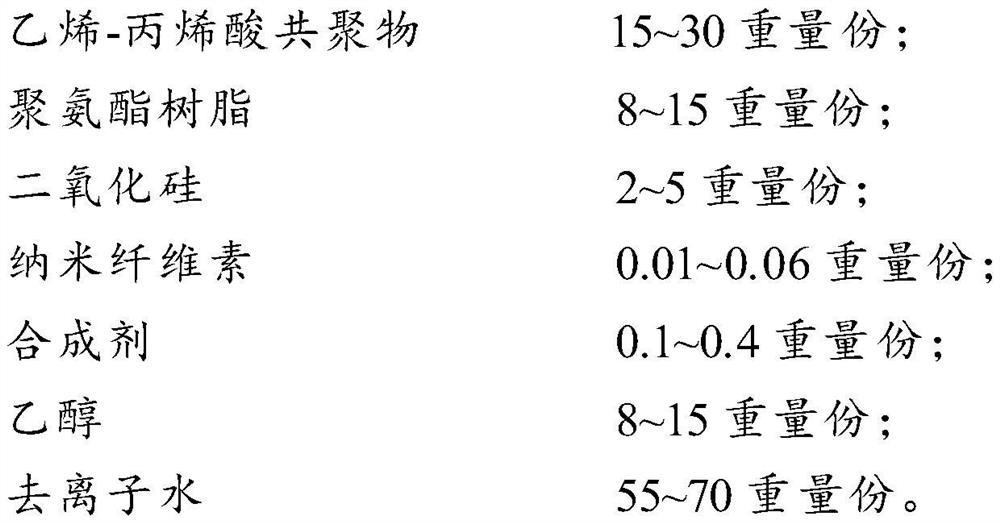

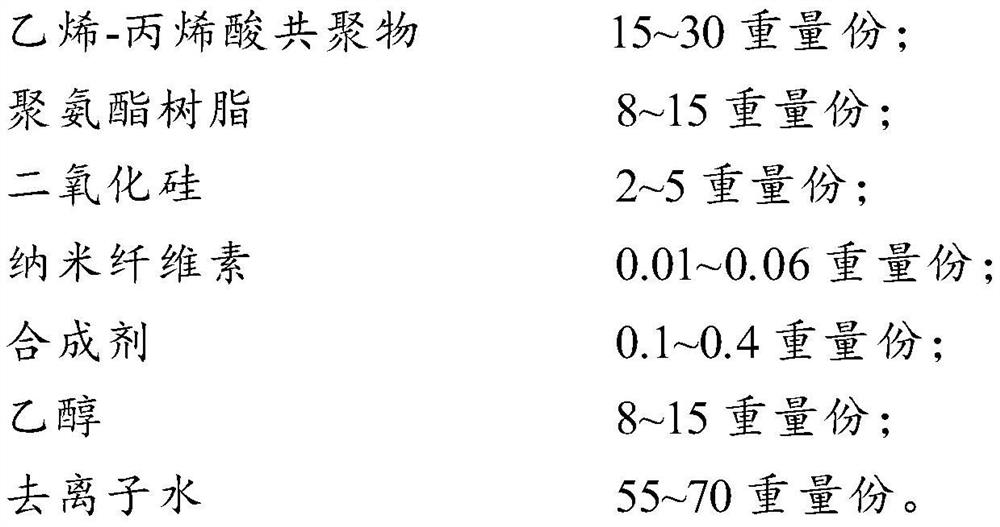

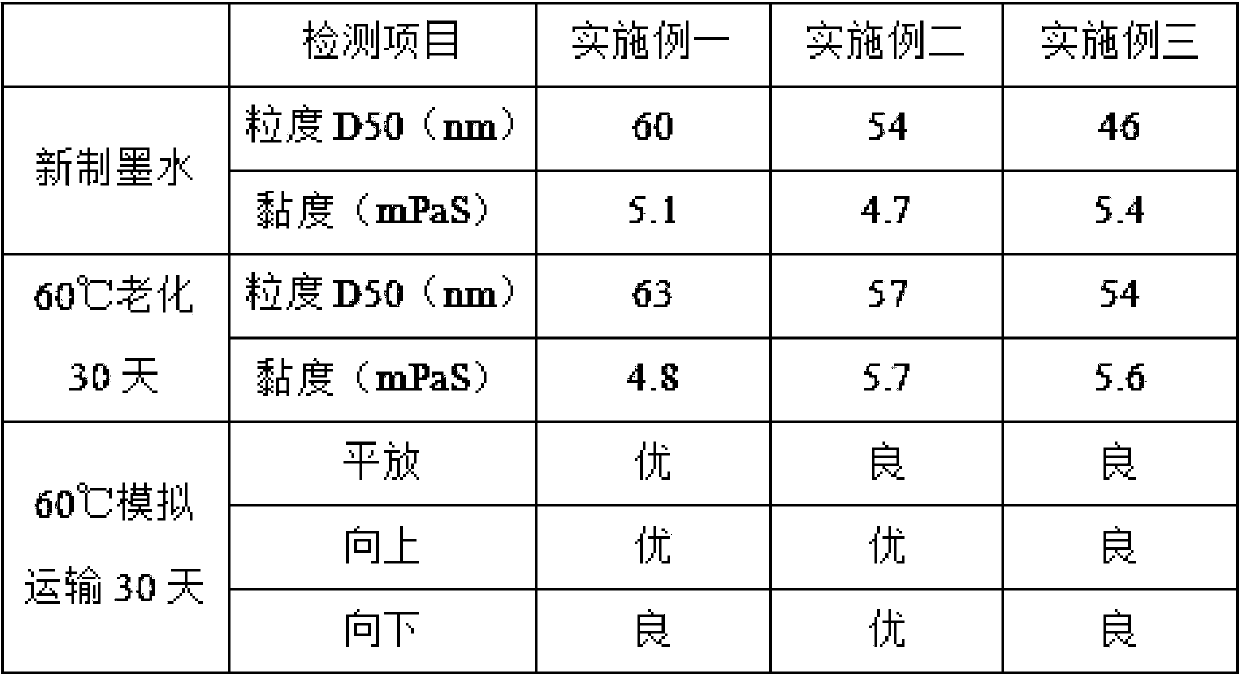

Water-based coating liquid for Dupont paper and preparation method of water-based coating liquid

PendingCN113403881AClosely arrangedFlat surfaceFlexible coversCoatings with pigmentsPolymer scienceSilicon dioxide

The invention provides a water-based coating liquid for Dupont paper. The water-based coating liquid comprises the following raw materials in parts by weight: 15-30 parts of an ethylene-acrylic acid copolymer, 8-15 parts of polyurethane resin, 2-5 parts of silicon dioxide, 0.01-0.06 part of nano-cellulose, 0.1-0.4 part of a synthesis agent, 8-15 parts of ethanol and 55-70 parts of deionized water, summing to 100 parts. The invention also provides a preparation method of the water-base coating liquid for the Dupont paper. The water-based coating liquid provided by the invention is good in water resistance and does not drop ink when being rubbed, the viscosity of the coating liquid is 100-300 Mpa / S, the coating liquid is easy to uniformly coat due to high viscosity, and finally, the effects of good water-resistant effect and good printing adhesive force are achieved.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Water-based nano coating-free yellow pigment ink

InactiveCN110643221AAvoid demandResolve history of dependent importsInksDiethylene glycolAdhesive glue

The invention discloses a water-based nano coating-free yellow pigment ink which is composed of the following components by the weight percentage: 20-30% of yellow nano color paste, 2%-8% of diethylene glycol, 2%-8% of glycerol, 5%-10% of an antioxidant, 8%-12% of a quick drying agent, 10%-14% of glue, 2%-8% of a cross-linking agent, 1%-4% of an adhesion promoter, and the balance being water. Thecolor printed by the pigment ink provided by the invention is bright and full, a coating layer does not need to be added, and the pigment ink is soluble in water. In addition, the color printed by thepigment ink provided by the invention also has metallic luster, and the pigment ink with the metallic luster effect is initiated in the world. According to the invention, the requirements of the market on high-end water-based pigment ink are solved, and imported high-end ink is completely replaced. The problems that when other pigment ink on the market is applied to related picture products, thecolor is dark, and roughness is achieved are effectively solved. The pigment ink can be blended with corresponding concentration, and can be used as writing tool ink. The ink is combined with paper and permeates into a paper core, and the ink can be permanently used indoors without fade.

Owner:丁振柏

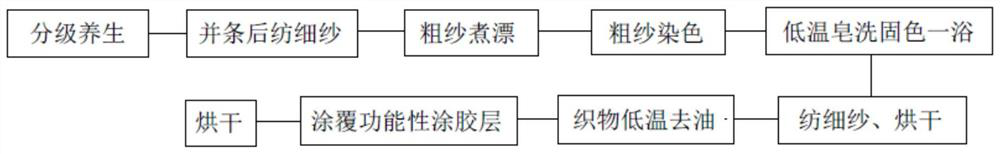

Sports protective fabric based on hemp interval texture structure and production process thereof

ActiveCN111607886AReduce the amount of coatingSoft touchWeft knittingWarp knittingYarnPolymer science

The invention relates to the technical field of textile fabric, in particular to sports protective fabric based on a hemp interval texture structure and a production process thereof. The sports protective fabric based on the hemp interval texture structure comprises substrate fabric. The substrate fabric comprises an upper synthetic fiber layer, a middle fiber layer and a lower fiber layer, the middle fiber layer is composed of two paths of synthetic antibacterial fibers, the lower fiber layer is composed of one path of pure hemp yarn and the other path of a fiber layer, one path of syntheticantibacterial fibers is connected with the upper fiber layer, the other path of synthetic antibacterial fibers is connected with the lower fiber layer, and the upper synthetic fiber layer is coated with a functional glued layer. The production process includes the following steps of (1) graded curing, (2) rough yarn spinning, (3) rough yarn scouring and bleaching, (4) rough yarn dying, (5) low-temperature soaping, fixation and one time bath, (6) fine yarn spinning, (7) low-temperature deoiling of the fabric, (8) coating of the functional glued layer and (9) drying. The sports protective fabricbased on the hemp interval texture structure and the production process thereof combine the characteristics of antisepsis, moisture absorption and ultraviolet resistance of hemp and the fabric interval structure, so that the fabric has good breathability, has soft hand feeling, and doe not deform.

Owner:青岛诺麻织造有限公司

An environmentally friendly dyeing process for cow split leather

ActiveCN106555018BGood flexibilityProvides softnessTanning treatmentPre-tanning chemical treatmentAfter treatmentEngineering

The invention discloses an environment-friendly dyeing technology for cattle hide split leather. The cattle hide split leather is obtained through the technology steps of degreasing and water returning, softening, tanning, dyeing, fixing, after treatment and the like. Clean production is emphasized in the technology process, pollution is little, and very good environment-friendly benefits are achieved; and the cattle hide split leather obtained through production is high in strength, good in hand feeling and full and bright in color.

Owner:福建省永建皮革科技股份有限公司

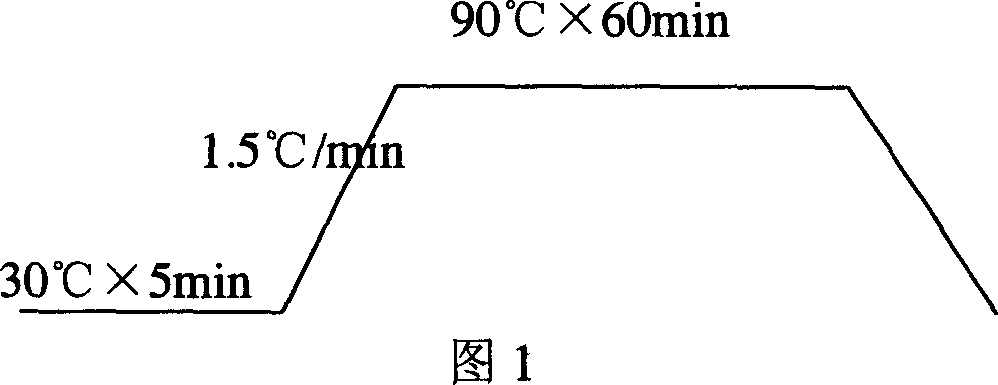

Water-saving and energy-saving scouring and bleaching process based on fibrilia oxygen bleaching auxiliary agent

The invention relates to the technical field of dyeing and finishing processes, in particular to a water-saving and energy-saving scouring and bleaching process based on fibrilia oxygen bleaching auxiliary agent. The method comprises the following steps of (firstly) carrying out acid washing and neutralizing; (secondly) carrying out biochemical modification; (thirdly) carrying out oxygen bleaching: (1) uniformly mixing an oxygen bleaching auxiliary agent, sodium carbonate, a multifunctional pretreatment auxiliary agent and a degumming catalyst in an auxiliary cylinder, pumping the mixture intoa saucepan, and starting heating operation; (2) adding 1 / 2 process amount of caustic soda flakes and hydrogen peroxide with the mass fraction of 27.5% into the saucepan; (3) when the temperature of the saucepan rises to 90 DEG C, adding the rest caustic soda flakes, controlling the bath ratio to be 1: 8, continuously keeping the temperature at 90 DEG C, operating for 60 minutes, and discharging liquid; and (fourthly) washing with water and neutralizing; and (fifthly) passing through a lubricant. According to the scouring and bleaching process, the fibrilia is high in dye-uptake, good in fastness, bright and full in color, relatively high in spinnability and yarn forming rate, softer in hand feeling, water-saving and energy-saving.

Owner:青岛奥洛思新材料有限公司

Quick-freezing method for fresh wolfberry fruits

InactiveCN110326758ABright and full colorReduce churnFood coatingRoasted coffee treatmentLycium barbarum fruitPhytic acid

The invention discloses a quick-freezing method for fresh wolfberry fruits. The quick-freezing method includes the steps that S1, sorting is conducted, specifically, the fresh wolfberry fruits are selected, bad fruits are removed, and then the fruits are cleaned, dirt and impurities on the surfaces of the wolfberry fruits are removed, and the cleaned wolfberry fruits are picked up and drained; andS2, color-protecting is conducted, specifically, phytic acid, citric acid, ascorbic acid and sodium hydrogen sulfite are matched as color-protecting liquid, then the drained wolfberry fruits are putinto a mixture of 0.3% of the phytic acid, 0.8% of the citric acid, 0.4% of the ascorbic acid and 0.15% of the sodium hydrogen sulfite at the mass fraction rate of the concentration to be soaked for 25-40 minutes at the solid-liquid ratio being 1 to 2, and after soaking, the wolfberry fruits are taken out for rinsing. According to the quick-freezing method for the fresh wolfberry fruits, the freshwolfberry fruits are color-protected first and then hardened and saccharified successively, thus finally frozen and dried wolfberry fruits are bright and full in color, the difference from the freshwolfberry fruits in taste is small, thus the wolfberry fruits prepared by the preparation method can fully maintain the original taste and color, and the loss of the wolfberry nutrition is fully lowered in the process.

Owner:宁夏虹桥有机食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com